#GrainBoundaries

Explore tagged Tumblr posts

Video

Crystal Defects in Alloy Steels

1. Types of Crystal Defects: Point Defects: These include vacancies (missing atoms), interstitials (extra atoms positioned in between the regular lattice points), and substitutional defects (atoms replaced by different atoms). Line Defects: Dislocations are the primary type of line defect and include edge dislocations (where an extra half-plane of atoms is inserted) and screw dislocations (where the lattice planes are twisted). Planar Defects: These include grain boundaries, twin boundaries, and stacking faults, which occur when the regular stacking sequence of atomic planes is disrupted. Volume Defects: These involve larger imperfections like voids, precipitates, and inclusions that can affect the material properties.

2. Formation of Defects: Solidification Process: During the cooling and solidification of alloy steels, crystal defects naturally form due to uneven cooling rates and the incorporation of alloying elements. Mechanical Deformation: When alloy steels are deformed, dislocations move through the material, creating or interacting with existing defects. Thermal Treatments: Heat treatments like annealing can reduce certain defects like dislocations but may also cause others, like precipitates, to form.

3. Impact on Material Properties: Strength and Hardness: Dislocations and other defects can significantly increase the strength of alloy steels by impeding the movement of dislocations (a process known as work hardening). Ductility: While defects can enhance strength, they can also reduce ductility, making the material more brittle. Corrosion Resistance: Certain defects, especially those at grain boundaries or involving alloying elements, can decrease corrosion resistance by creating localized areas where corrosion can initiate. Fatigue Life: Defects such as inclusions or precipitates can act as stress concentrators, leading to crack initiation and reducing the fatigue life of the material.

4. Controlling Defects: Alloying: The choice of alloying elements can influence the type and amount of defects. For example, adding elements like carbon can strengthen steel by creating carbides but also increase brittleness. Processing Techniques: Techniques like controlled rolling, annealing, and quenching can be used to control the size and distribution of defects, optimizing the steel's properties for specific applications. Microstructural Engineering: By carefully controlling the cooling rates and subsequent heat treatments, it is possible to engineer the microstructure of alloy steels to achieve a desired balance between strength, ductility, and toughness.

More Info: physicistparticle.com

contact us: [email protected]

0 notes

Text

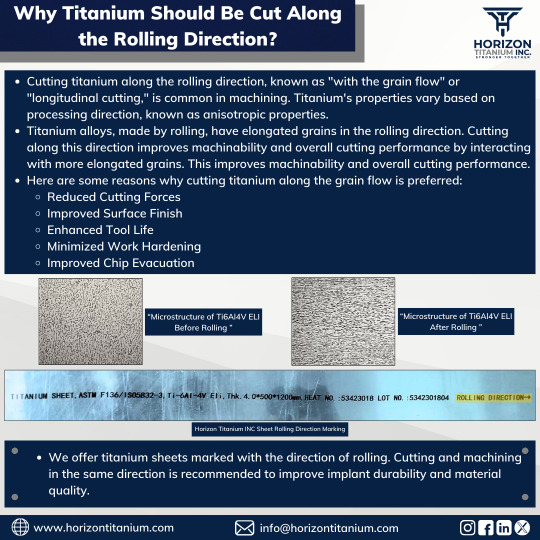

Interested in titanium? For details and to purchase superior titanium materials, email us at [email protected]

#KnowYourTitanium#Titanium#Rolling#Forging#Crystaline#GrainFlow#GrainBoundaries#RollingDirection#ElongatedGrains#LongitudinalDirection#AnisotropicProperties#CuttingEffect#MachiningEffect#WorkHardening#HorizonTitanium#StrongerTogether

0 notes

Text

Atomic-scale origin of the low grain-boundary resistance in perovskite solid electrolyte Li0.375Sr0.4375Ta0.75Zr0.25O3

Experimental methods LSTZ0.75 ceramics synthesis LSTZ0.75 were synthesized via conventional solid state reaction method. Stoichiometric amounts of Li2CO3 (99.99%, Sigma-Aldrich), SrCO3 (99.9%, ALB Materials Inc.), ZrO2 (99.9%, MSE Supplies), and Ta2O5 (99.9%, ALB Materials Inc.) were ground and mixed with ethanol for 18 h by high energy vertical planetary ball mill (MSE Supplies) with yttria…

View On WordPress

#Atomicscale#electrolyte#grainboundary#Li0.375Sr0.4375Ta0.75Zr0.25O3#Origin#perovskite#resistance#Solid

0 notes

Text

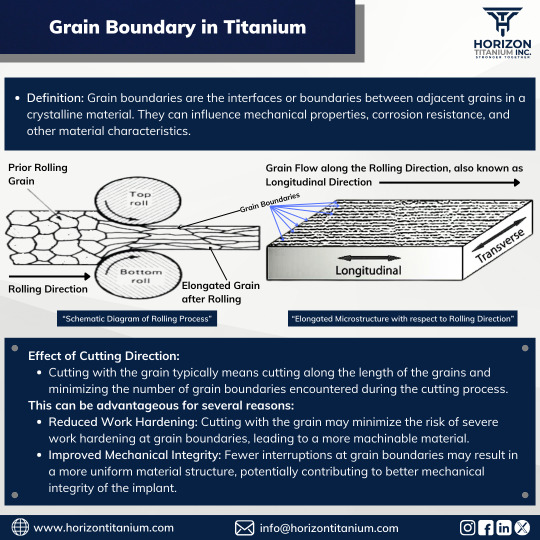

If you're interested in learning more about titanium or wish to buy premium titanium materials, feel free to contact us at [email protected]

#KnowYourTitanium#Titanium#Rolling#Forging#Crystaline#GrainFlow#GrainBoundaries#RollingDirection#ElongatedGrains#LongitudinalDirection#CuttingEffect#MachiningEffect#HorizonTitanium#StrongerTogether

0 notes

Text

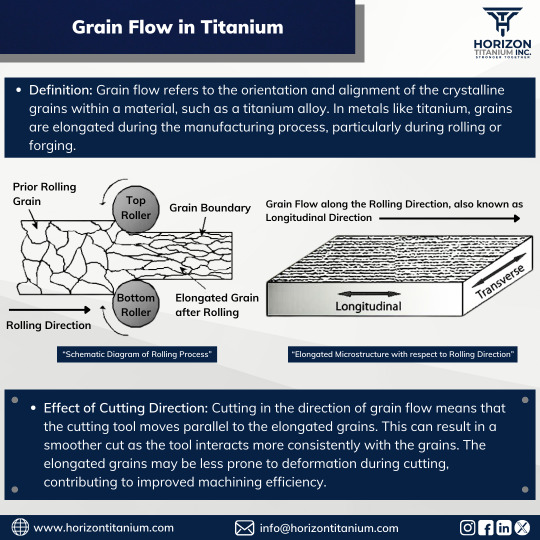

For more information about titanium and to purchase top-quality titanium materials, please reach out to us at [email protected]

#KnowYourTitanium#Titanium#Rolling#Forging#Crystaline#GrainFlow#GrainBoundaries#RollingDirection#ElongatedGrains#LongitudinalDirection#CuttingEffect#MachiningEffect#HorizonTitanium#StrongerTogether

0 notes

Photo

The ISO 5832-2 specification qualifies Unalloyed Titanium Grades for medical applications.

These specification grades are used in medical implant manufacturing because they have stringent microstructure requirements such as uniform alpha phase distribution, grain size, and no foreign phases (Alpha case), which can improve Unalloyed Titanium properties.

Because there are fewer grain boundaries with coarser grain sizes, the mobility of dislocations is not as restricted. As a result, the strength of Titanium implants with the coarser grain is less. With fine grain size, there are a large number of grain boundaries that obstruct dislocation migration as we apply stresses to Titanium. As a result, it improves the strength of a Titanium implant.

If the grain size of Titanium materials is not uniform, there will be different properties at different locations, which is inappropriate for the long life of Titanium implants. If the grain size of Titanium implants is uniform throughout the Titanium implant, it can have homogenous properties, and an implant can last longer in the human body.

That's why ISO 5832-2 states that the grain size of Titanium material used for medical applications should be uniform and with a grain size 5 or finer.

To explain the alpha case, we will make a separate post as it is a common requirement for all medical Titanium grades.

For any information regarding Titanium metallurgy, you can write us at [email protected]

#KnowYourTitanium#ISO#Titanium#CPTitanium#AlphaCase#Metallurgy#Grains#GrainBoundaries#Dislocations#GrainSize#Strength#Quality#Microstructure#TitaniumSheets#TitaniumImplants#MedicalImplants#OrthopaedicImplants#OrthopedicIntruments#Orthopedic#MedicalDevices#StrongerToghether#HorizonTitanium

0 notes