#Global Threaded Fastener

Text

Fasteners Manufacturers in India: A Growing Industry Powering Global Markets

Jinnox Bolt is one of the leading Fasteners Manufacturers in India. We supply fasteners made of different materials, including Stainless steel, Carbon steel, High tensile, Inconel, Monel, and Hastelloy. We are a top Fasteners Suppliers in India We also provide customized solutions to clients by delivering top-notch quality and other types of fasteners with specified qualities.

India’s fasteners manufacturing industry is one of the key sectors driving the nation's industrial growth. From automotive to construction, and from aerospace to infrastructure development, fasteners play a crucial role across a wide range of industries. The rise of Indian fasteners manufacturers over the years has been nothing short of remarkable, and today the country stands as a significant player in the global fasteners market.

Overview of the Fasteners Industry in India

Fasteners are components used to mechanically join two or more objects together. They include a variety of items like nuts, bolts, washers, rivets, screws, and specialized parts. In India, the fasteners industry can be broadly divided into two categories: industrial fasteners and automotive fasteners. The latter accounts for a significant share, driven by the growing demand from the automotive sector.

The Indian fasteners industry is currently valued at approximately $4 billion, and this figure is expected to grow significantly in the coming years. The reasons behind this growth are manifold – increasing infrastructure projects, growing domestic automotive production, and a surge in demand from overseas markets. Additionally, government initiatives like "Make in India" have further bolstered manufacturing capabilities, encouraging both domestic and foreign investments in this sector.

Major Hubs for Fasteners Manufacturing in India

India's Fastener Manufacturers are concentrated in a few key regions that have evolved into industrial hubs over the years. These include:

Ludhiana, Punjab: Known as the “fasteners capital” of India, Ludhiana houses a large number of small and medium enterprises (SMEs) involved in manufacturing fasteners. This region accounts for a significant share of the fasteners production in the country, especially for the automotive and bicycle industries.

Pune, Maharashtra: Pune is an important industrial hub, especially for automotive fasteners. The presence of major automobile companies in and around Pune has attracted many fasteners manufacturers to set up production facilities here.

Gurgaon, Haryana: Another key center for automotive fasteners, Gurgaon’s proximity to the National Capital Region (NCR) makes it an attractive location for fasteners manufacturers catering to the automotive and construction sectors.

Rajkot, Gujarat: Rajkot is emerging as a growing hub for fasteners, with manufacturers here focusing on producing precision fasteners that cater to both domestic and international markets.

Fasteners Products We Manufactured

Bolt Manufacturers in India

Nut Manufacturer in India

Washers Manufacturer in India

Threaded Rod Manufacturers in India

Screw Manufacturer in India

Coated Fasteners Manufacturer in India

Key Factors Driving the Growth of Fasteners Manufacturing in India

Several factors have contributed to the rapid growth of the Fastener Manufacturers in India:

Increased Demand from the Automotive Sector: India is one of the largest automobile manufacturers in the world. The demand for automotive fasteners has skyrocketed, especially with the rapid adoption of electric vehicles (EVs). Fasteners play a crucial role in EV assembly, and Indian manufacturers have stepped up to meet this demand.

Infrastructure Development: Massive infrastructure projects across the country, including highways, bridges, and metro systems, have significantly increased the demand for industrial fasteners. Fasteners are essential components in construction, and the ongoing urbanization and industrialization efforts in India are fueling this demand further.

Government Support and Initiatives: The Indian government’s focus on boosting manufacturing under the “Make in India” initiative has provided a boost to the fasteners sector. Policies promoting ease of doing business, tax benefits, and incentives for manufacturers have helped attract both domestic and foreign investment.

Export Growth: India has emerged as a key exporter of fasteners to markets in Europe, North America, and the Middle East. Indian manufacturers are recognized for producing high-quality fasteners at competitive prices, which has helped expand their footprint in global markets. Countries like the United States, Germany, and the UAE are some of the major importers of Indian fasteners.

Future Outlook

The future of Fasteners Suppliers in India looks promising. With continued investment in infrastructure, a robust automotive industry, and growing demand for exports, the industry is poised for sustained growth. Technological advancements and the adoption of Industry 4.0 practices will likely play a pivotal role in shaping the future of fasteners manufacturing in India.

In conclusion, the Fasteners Suppliers sector in India is not only an integral part of the country’s industrial ecosystem but also a growing player on the global stage. By addressing key challenges and capitalizing on emerging opportunities, Indian fasteners manufacturers are set to continue their growth trajectory in the years to come.

0 notes

Text

Leading Brass Inserts Exporter with Extensive Experience in Precision Manufacturing

Brass inserts are vital components in many industries, offering secure fastening solutions and enhancing the overall performance of machinery, electronic devices, and automotive systems. As a leader in the manufacturing and exporting of these components, Oracle International stands out as a reliable brass inserts exporter, supplying high-quality products to meet the demands of clients worldwide. Our focus on precision, durability, and customer satisfaction ensures that we continue to be the trusted partner for businesses seeking dependable brass inserts for their applications.

The Role of Brass Inserts in Modern Industries

Brass inserts play a significant role in multiple industries, providing durable, corrosion-resistant, and reliable fastening solutions in materials such as plastics, wood, and metal. Brass is an ideal material for these inserts because of its excellent mechanical properties, including:

Corrosion Resistance: Brass resists rust and corrosion, making it suitable for use in environments where moisture and harsh chemicals are common.

High Strength: Brass inserts are strong and durable, capable of withstanding significant mechanical stress without deforming or losing their grip.

Dimensional Accuracy: Due to its machinability, brass allows for precise production, ensuring that the inserts are manufactured to exact specifications.

Industries such as automotive, electronics, and industrial machinery rely heavily on brass inserts to maintain the integrity of their systems. Whether it's securing components in a vehicle, providing a reliable thread in a plastic casing, or ensuring the longevity of industrial machines, brass inserts offer unmatched performance.

Oracle International: A Leading Brass Inserts Exporter

At Oracle International, we have honed our expertise as a brass inserts exporter by maintaining a rigorous focus on quality and precision. Our brass inserts are known for their long-lasting performance, superior strength, and dimensional accuracy, which are critical in high-performance industries. With advanced manufacturing capabilities, we produce brass inserts that meet international standards, ensuring compatibility and reliability across global markets.

As an exporter, we understand the importance of complying with international standards. Our products meet global benchmarks like ISO, ASTM, and DIN, which reflect the high quality and precision of each insert we deliver. By adhering to these standards, Oracle International guarantees that our brass inserts can be seamlessly integrated into any system or application, regardless of location.

Precision Manufacturing for High-Performance Applications

The industries that rely on brass inserts require components that perform flawlessly under varying conditions. To meet these expectations, Oracle International utilizes cutting-edge manufacturing techniques that ensure each brass insert is produced with the utmost precision. Our processes involve:

CNC Machining: We use CNC machining to achieve exact tolerances, ensuring that each insert fits perfectly in its intended application. This level of precision is critical in industries like electronics and automotive, where even a slight deviation can lead to performance issues.

High-Quality Materials: We use the finest grades of brass, ensuring that each insert offers exceptional strength and corrosion resistance. This is particularly important in industrial machinery and automotive applications, where durability is essential.

Custom Solutions: At Oracle International, we understand that different industries have unique needs. That’s why we offer custom brass inserts, allowing clients to specify the dimensions, thread types, and other characteristics that best suit their applications. Customization ensures that our inserts deliver the optimal fit and performance for any given project.

International Standards for Durability and Precision

Being a brass inserts exporter means delivering products that meet the highest international standards. Oracle International is committed to maintaining these standards through stringent quality control processes. Our brass inserts are designed to excel in demanding environments, providing both durability and precision.

ISO Standards Compliance: The International Organization for Standardization (ISO) sets benchmarks for quality and reliability across industries. By adhering to these standards, Oracle International ensures that our brass inserts are recognized for their durability and precision worldwide.

Dimensional Accuracy: Precision is key in manufacturing brass inserts, especially when they are used in complex machinery or electronics. We use state-of-the-art technology to ensure that each insert is machined with the utmost accuracy, providing a seamless fit in various applications.

Performance Testing: Oracle International subjects its brass inserts to rigorous testing, ensuring they can withstand the mechanical stress and environmental conditions they will encounter in real-world applications. Our inserts are designed to retain their strength and integrity even in the most challenging environments.

Industries That Rely on Brass Inserts

The versatility of brass inserts means that they are indispensable in several industries. Oracle International serves clients across various sectors, each with its own unique set of requirements. Some of the primary industries we cater to include:

Automotive: Brass inserts are used in various automotive applications, from dashboards to engine components. The strength and corrosion resistance of brass ensure that these inserts can withstand the harsh conditions found in automotive environments, including exposure to heat, chemicals, and moisture.

Electronics: In the electronics industry, brass inserts provide reliable threading and fastening in plastic and metal components. Their precision ensures that delicate electronic devices function smoothly and reliably.

Industrial Machinery: In heavy-duty machinery, brass inserts are essential for providing secure fastening in high-stress applications. Oracle International's brass inserts are built to handle the rigors of industrial environments, where durability and precision are paramount.

Custom Brass Inserts for Unique Applications

Oracle International understands that no two projects are alike. That’s why we offer custom brass inserts to meet the specific needs of our clients. Whether you require a unique size, threading configuration, or material composition, we work closely with you to design and manufacture inserts that meet your exact specifications.

Customization is especially important in industries where the slightest variation can affect performance. For example, in the automotive sector, precision is essential to ensure that components fit together perfectly, preventing malfunctions or inefficiencies. Similarly, in electronics, the need for precise threading and secure fastening is critical to maintaining the performance of devices.

Our custom brass inserts are designed with the same attention to detail and quality that defines our standard products. Whether it’s a specialized design for a unique application or a high-volume production run for a common use case, Oracle International delivers reliable and durable solutions tailored to your needs.

Oracle International's Commitment to Quality

At Oracle International, we take pride in the quality of our brass inserts. Our commitment to customer satisfaction is reflected in every stage of our production process, from initial design to final inspection. We ensure that our brass inserts not only meet but exceed the expectations of our clients.

Quality Control: Each brass insert is subjected to rigorous quality control checks throughout the manufacturing process. This includes material testing, dimensional checks, and performance evaluations, ensuring that our products meet the highest standards for durability and precision.

Advanced Technology: We use the latest technology to manufacture our brass inserts, allowing us to produce components with tight tolerances and exceptional precision. Our facilities are equipped with cutting-edge machinery, enabling us to deliver products that meet the exacting demands of modern industries.

Customer Support: Oracle International is dedicated to providing exceptional customer service. Our team works closely with clients to understand their needs and provide the best solutions for their applications. We offer technical support and guidance throughout the process, ensuring that our customers receive the highest level of service and satisfaction.

Why Choose Oracle International?

As a brass inserts exporter with a proven track record, Oracle International is your trusted partner for high-quality brass inserts. Here are a few reasons why businesses around the world choose us:

Global Standards Compliance: Our brass inserts meet international standards for quality and performance, ensuring they can be used in any market or industry.

Advanced Manufacturing: We employ cutting-edge techniques and technology to deliver brass inserts with exceptional precision and durability.

Custom Solutions: We offer custom brass inserts designed to meet the unique needs of each client, providing tailored solutions for any application.

Unwavering Quality Control: Our rigorous quality control processes ensure that every brass insert we produce meets the highest standards for performance and reliability.

Conclusion

Oracle International continues to lead the way as a trusted brass inserts exporter, delivering products that meet international standards for durability, precision, and performance. Whether you need standard or custom brass inserts, we provide solutions that enhance the efficiency and reliability of your operations. From automotive and electronics to industrial machinery, Oracle International's brass inserts offer the strength, accuracy, and long-lasting performance that industries worldwide rely on.

1 note

·

View note

Text

Monel K500 Washers Manufacturers

Monel K500 is a nickel-copper alloy that stands out for its exceptional corrosion resistance, high strength, and durability, even in harsh environments. These characteristics make it an essential material for various industries, particularly in the manufacturing of washers. Monel K500 washers are widely used in marine, chemical, oil and gas, and aerospace industries, where they play a critical role in ensuring the reliability and longevity of assemblies.

The Importance of Quality Monel K500 Washers

Washers are small, flat rings that are used to distribute the load of a threaded fastener, such as a screw or nut. In many applications, the choice of material for washers can have a significant impact on the performance and safety of the entire assembly. Monel K500 washers are particularly valued for their ability to resist corrosion, even in saltwater or acidic environments, which makes them ideal for use in marine and chemical processing applications.

Moreover, the alloy’s high tensile strength and hardness ensure that Monel K500 washers maintain their integrity under extreme conditions, such as high pressure or temperature. This reliability is crucial in industries like oil and gas, where the failure of a single component can lead to catastrophic results.

The Role of Exporters in the Global Supply Chain

Exporters of Monel K500 washers play a vital role in the global supply chain, ensuring that these critical components are available to industries around the world. The demand for Monel K500 washers is global, with significant markets in North America, Europe, Asia, and the Middle East. Exporters must navigate complex logistics, international trade regulations, and varying quality standards to deliver products that meet the exacting specifications of their clients.

Chhajed Steel Limited is one of the renowned makers and suppliers of Monel K500 Washers, which are precipitation cementing washers manufactured from copper nickel composite with development of titanium and aluminum. With the parts of aluminum and titanium, Monel K500 Flat Washers offers the wonderful insurance from utilization of Alloy 400; with raised quality, hardness, breaking down security and oxidation shortcoming assurance. We make a wide scope of Monel K500 Machined Washers in all shapes and sizes. We moreover give passivation, quality covering in Monel K500 Punched Washers also dealing with as per client's need. All our delivered Monel K500 Round Washers are according to national and furthermore overall models. Monel K500 Square Washers are into two halves string and full string length with arranged movement, material in stock.

MONEL ALLOY K500 WASHERS SPECIFICATION

Material

Specification

Standards

Size

Length

Monel Alloy K500

IS

BS

ASTM

ASTM B865-04

3 mm

to

200 mm

M02 to M33

MONEL ALLOY K500 WASHERS GRADE DESIGNATION

Alloy

Common Name

Related Specification

British

European

ASTM

UNS

Alloy K500

Monel K500 ®

BS 3076 NA18

4.4375

B865-04

N05500

Conclusion

Monel K500 washers are indispensable in various high-performance applications, and choosing the right exporter is crucial to ensuring that these components meet the stringent demands of your industry. By focusing on quality, experience, supply chain capabilities, and customer support, you can find a reliable partner to supply you with Monel K500 washers that deliver optimal performance and durability in your specific applications.

For More Information:

Visit Our Website -https://www.chhajedfastners.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

From Factories to Frontlines: Exploring India's Premier Bolt Manufacturers

Introduction

The overlooked leaders of industrial applications are bolts, holding together everything from massive structures to tiny gadgets. In India, the bolt manufacturing industry has grown significantly, providing high-quality products for both domestic and international markets. This article delves into the intricacies of bolt manufacturing in India, highlighting its history, types, materials, top manufacturers, and future prospects.

History of Bolt Manufacturing in India

The journey of bolt manufacturing in India began in the early 20th century with small-scale operations. Over the decades, the industry evolved, driven by increasing industrialization and technological advancements. Today, India is a prominent player in the global bolt manufacturing sector.

Types of Bolts Manufactured in India

Indian manufacturers produce a wide range of bolts to meet diverse industrial needs. Here are some of the key types:

Hex Bolts: Known for their hexagonal heads, these bolts are commonly used in construction and machinery.

Carriage Bolts: Featuring a rounded head and square neck, these bolts are used in wood and metal applications.

Anchor Bolts: Essential for securing structures to concrete, these bolts are crucial in construction.

Eye Bolts: With a looped end, these bolts are used for lifting and securing cables.

Other Specialized Bolts: Customized bolts for specific applications in various industries.

Key Materials Used in Bolt Manufacturing

The choice of material is crucial for bolt performance. Indian manufacturers use a variety of materials:

Stainless Steel: Known for its corrosion resistance and strength.

Carbon Steel: Commonly used due to its affordability and versatility.

Alloy Steel: Offers enhanced mechanical properties for high-stress applications.

Non-Ferrous Metals: Used for specialized bolts requiring unique properties.

Manufacturing Process of Bolts

Bolt manufacturing is a meticulous process involving several stages:

Raw Material Selection: High-quality materials are chosen based on the bolt's intended use.

Forging and Shaping: The material is heated and forged into the desired shape.

Heat Treatment: Bolts undergo heat treatment to enhance strength and durability.

Threading: Threads are cut or rolled onto the bolt shaft.

Finishing: The bolts are coated or plated for protection against corrosion.

Quality Standards and Certifications

Ensuring quality is paramount in bolt manufacturing. Indian manufacturers adhere to various standards:

ISO Certifications: International standards ensuring consistent quality.

ISI Mark: Indian standard mark for product quality.

International Quality Standards: Compliance with global benchmarks.

Superior High-Quality Bolt Manufacturer In India

One of the largest bolt manufacturer in India is Bhansali Fasteners. Bolts are an excellent choice for fluid transfer in a variety of sectors, including construction, culinary, chemical, oil and gas, and pharmaceuticals. They also provide sustainability advantages and cheap maintenance. They offer dependability and security.

We provide low-cost, high-quality bolts that promote efficient and successful work. Our bolts meet numerous standards, including ASTM, ASME, ANSI, UNS, and DIN. Our collection, which includes various sizes, thicknesses, bars, and grades, meets a wide variety of demands. In addition, we are one of leading screw manufacturer in India.

Bhansali Fasteners is one of the leading Bolt Manufacturers in India. Bolts are polished to the specifications provided by the customer, including wall thickness and size. For more demanding applications, heat treatment is also available. At the lowest possible price, we manufacture, provide, and stock a wide variety of bolts in all sizes. Check the bolt weight chart as well.

We are also a Bolt Manufacturers in UAE, Bolt Manufacturer in Bangladesh.

The bolt manufacturing industry in India is a dynamic and growing sector, contributing significantly to various industrial applications. With advancements in technology, government support, and a focus on quality and sustainability, Indian bolt manufacturers are well-positioned for future success.

For More Detail

Website: bhansalibolt.com

Product: SS Bolt Manufacturer

Other Product: Fasteners Manufacturers In Saudi Arabia.

#Bolt Manufacturers In India#Bolt Manufacturers#SS Bolt Manufacturer#Bolt Suppliers#Fasteners Manufacturers In Saudi Arabia

0 notes

Text

Bolts Market Poised to Witness High Growth Due to Rising Construction Industry

The bolts market has been gaining significant traction over the years, owing to their widespread application in construction, machinery, automotive, and other industrial sectors. Bolts are essentially threaded fasteners that join or fix two or more pieces together by means of their own threads fitting exactly into mating threads. They provide mechanical advantage and act as inexpensive and durable connectors for applications involving stresses from various kinds of loading. Some key advantages of bolts include ease of installation, high strength, reliability, and longevity. With rapid infrastructure development and rising construction spending globally, the demand for bolts from the construction industry has been increasing substantially.

The global bolts market is estimated to be valued at US$ 9.56 billion in 2024 and is expected to exhibit a CAGR of 18% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the bolts market are 3M, Reckitt Benckiser Group PLC, Procter & Gamble, Cantel Medical Corporation, The Clorox Company, Ecolab, SC Johnson Professional, Whiteley Corporation, and Steris PLC. These companies collectively account for a significant share of the market.

The Bolts Market Growth is expected to witness lucrative opportunities owing to rising investments in public infrastructure projects across developing nations. Furthermore, ongoing industrialization and growth of manufacturing industries will further propel the demand.

Globally, the Asia Pacific region dominates the bolts market and is expected to maintain its leading position throughout the forecast period. This can be attributed to rapid urbanization, growing construction activities, and expansion of manufacturing industries in China, India, and other Southeast Asian countries. North America and Europe are other major markets for bolts.

Market Drivers

The primary driver aiding the growth of the bolts market is the strong performance of the global construction industry. Rapid infrastructure development projects around the world, especially in developing regions, are significantly driving the consumption of bolts. According to estimates, the global construction industry is expected to grow at over 4% annually until 2031. This rising construction spending will continue to generate high demand for bolts for various building structure assemblies and machinery installation. The booming manufacturing industry and increasing automotive production will further augment the market for bolts during the forecast period.

PEST Analysis

Political: The bolts market is regulated by govermamt standards and norms regarding materials, sizes of bolts to ensure safety. Recently some regulations were modified regarding use of certain metal alloys.

Economic: The steady growth of automotive and construction industries fosters demand for bolts. However, rising raw material prices may impact bolts manufacturers.

Social: People are more aware now about quality and durability of products. They prefer branded bolts for peace of mind.

Technological: Companies are using advanced methods like 3D printing, robotics for bolts production to improve quality and yield. Some are developing bolts with sensors for IoT-enabled machinery.

North America accounts for around 35% of the global bolts market value owing to large scale infrastructure projects and strong automotive industry in the US and Canada. Western Europe is the second largest regional market led by Germany, France and UK.

Asia Pacific region is witnessing the fastest growth in bolts market value during the forecast period. This is attributed to rapid urbanization and industrialization activities in China and India. Both countries are major automotive and construction hubs globally. Additionally, governments of various Asian countries are investing heavily in development of road, rail and building infrastructure which spur the demand for construction fasteners including nuts, bolts and screws.

Get more insights on Bolts Market

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Bolts Market#Bolts#Fasteners#Hardware#Mechanical components#Construction#Metalworking#Engineering#Industrial supplies#Threaded fasteners#Nuts and bolts

0 notes

Text

Global Top 9 Companies Accounted for 60% of total Flow Drilling Screw (FDS) and Driving Machine market (QYResearch, 2021)

Flow drill screw driving (FDS) is a one–sided thermomechanical assembly process based on heat generation by frictional force and plastic deformation. A special screw, known as hole forming and self-tapping screw, is used in this process as both fastener and tool. Moreover, rotational and translation movements are applied to the screw to create special friction conditions with the workpiece. Furthermore, unlike traditional drilling and thread milling processes, there is no chip or waste of material in FDS and the machining operations are realized through plastic deformation. The report study flow drilling screw (FDS) and the driving machine.

According to the new market research report “Global Flow Drilling Screw (FDS) and Driving Machine Market Report 2023-2029”, published by QYResearch, the global Flow Drilling Screw (FDS) and Driving Machine market size is projected to reach USD 0.09 billion by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Flow Drilling Screw (FDS) and Driving Machine Market Size (US$ Million), 2018-2029

Figure. Global Flow Drilling Screw (FDS) and Driving Machine Top 9 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flow Drilling Screw (FDS) and Driving Machine include EJOT Holding, Arnold Umformtechnik, Weber, Atlas Copco, Deprag, etc. In 2021, the global top four players had a share approximately 60.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

1 note

·

View note

Text

Best Manufacturer & Exporter of Self Tapping Screws in India: Dasset Engineering

Self-tapping screws are essential components in various industries, known for their ability to create their own threads as they are driven into materials. In India, one company stands out for its excellence in manufacturing and exporting these vital fasteners—Dasset Engineering. Renowned for its commitment to quality, innovation, and customer satisfaction, Dasset Engineering has established itself as a leader in the self-tapping screw industry.

Why Self-Tapping Screws?

Before delving into Dasset Engineering’s contributions, it is crucial to understand why self-tapping screws are so valuable. Unlike traditional screws that require pre-drilled holes, self-tapping screws can create threads as they are driven into materials. This feature makes them incredibly versatile and efficient, reducing the need for additional tools and saving time during assembly. They are widely used in automotive, construction, electronics, and woodworking industries due to their convenience and reliability.

Dasset Engineering: A Legacy of Excellence

Dasset Engineering has built a strong reputation over the years as a top manufacturer and exporter of self-tapping screws. Their success can be attributed to several key factors:

Quality Assurance

Quality is the cornerstone of Dasset Engineering’s operations. The company employs stringent quality control measures at every stage of production, from raw material selection to the final inspection. Their self-tapping screws are made from high-grade materials, ensuring durability, strength, and corrosion resistance. This commitment to quality ensures that their products meet and exceed industry standards, providing customers with reliable and long-lasting solutions.

Advanced Manufacturing Facilities

Dasset Engineering boasts state-of-the-art manufacturing facilities equipped with the latest machinery and technology. These advanced facilities enable the company to produce a wide range of self-tapping screws in various sizes, designs, and specifications. Their manufacturing process is streamlined and efficient, allowing for high-volume production without compromising on quality.

Innovative Designs

Innovation is at the heart of Dasset Engineering’s product development strategy. The company continually invests in research and development to create innovative screw designs that cater to the evolving needs of different industries. Their self-tapping screws are designed for optimal performance, with features such as sharp cutting edges, precise threading, and superior holding power. This dedication to innovation ensures that Dasset Engineering remains at the forefront of the industry.

Customization Options

Understanding that different projects have unique requirements, Dasset Engineering offers customization options for their self-tapping screws. Customers can specify dimensions, materials, coatings, and other parameters to meet their specific needs. This flexibility makes Dasset Engineering a preferred choice for businesses looking for tailored solutions.

Global Reach

As a leading exporter, Dasset Engineering has a strong presence in international markets. Their self-tapping screws are in high demand worldwide, thanks to their reputation for quality and reliability. The company has a robust logistics network that ensures timely delivery to customers across the globe, making them a trusted partner for businesses in various industries.

Customer-Centric Approach

Dasset Engineering’s success is also driven by its customer-centric approach. The company prioritizes customer satisfaction by offering excellent after-sales support, technical assistance, and responsive service. Their team of experts is always ready to assist customers with their queries and provide guidance on the best solutions for their projects.

Conclusion

Dasset Engineering stands out as the best manufacturer and exporter of self-tapping screws in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their advanced manufacturing facilities, innovative designs, and customer-centric approach make them a trusted partner for businesses across various industries. Whether you are in the automotive, construction, electronics, or woodworking sector, Dasset Engineering offers reliable and high-performance self-tapping screws that meet your needs and exceed your expectations.

#PET bottle recycling process explained#Plastic bottle lifecycle analysis#Importance of PET bottle recycling#Steps in PET bottle recycling#Environmental impact of PET recycling#Sustainable PET bottle management#PET bottle disposal and recycling#Recycling journey of plastic bottles#PET bottle recycling technology#Benefits of PET bottle recycling#Circular economy and PET recycling#Innovations in PET bottle recycling#PET recycling best practices#PET bottle recycling facilities#Role of Lyka Global Plast in PET recycling#Impact of PET recycling on the environment#Challenges in PET bottle recycling#Consumer awareness of PET recycling#Future of PET bottle recycling#PET recycling trends and insights#PET bottle recycling process steps#Sustainable solutions for plastic bottle disposal#PET bottle recycling initiatives worldwide#Environmental benefits of PET bottle recycling#PET bottle recycling impact on climate change#Effective PET bottle waste management strategies#PET bottle recycling rates and statistics#Innovations in PET bottle recycling technology#Circular economy principles in PET recycling#Best practices for PET bottle collection and sorting

0 notes

Text

The Global Luggage Market: Key Players and Emerging Trends

The luggage market has undergone significant transformation over the past decade. With increasing globalization and the rise of travel culture, the demand for innovative and durable luggage solutions has never been higher. In this page, we'll explore the key players in the global luggage market and the emerging trends shaping the industry's future.

## Key Players in the Luggage Market

Several companies have established themselves as leaders in the global luggage market. These key players are known for their innovation, quality, and ability to adapt to changing consumer preferences.

### 1. Samsonite

Samsonite is a household name in the luggage industry. Founded in 1910, the company has built a reputation for producing durable and stylish luggage. Samsonite offers a wide range of products, from carry-ons to large suitcases, and has embraced smart luggage technology to stay ahead of the competition.

### 2. Tumi

Tumi is synonymous with luxury and premium quality. The brand is popular among business travelers and professionals who value durability and sophisticated design. Tumi's products often feature advanced materials and smart functionalities, such as GPS tracking and USB ports.

### 3. American Tourister

As a subsidiary of Samsonite, American Tourister caters to budget-conscious travelers without compromising on quality. The brand offers vibrant and fun designs, making it a popular choice for families and young travelers.

### 4. Rimowa

Rimowa, a German luggage manufacturer, is renowned for its aluminum and polycarbonate suitcases. Known for their sleek design and robust construction, Rimowa products are favored by travelers who seek both style and functionality.

### 5. Delsey

Delsey, a French luggage brand, combines elegance with practicality. The brand is known for its innovative features, such as the Overweight Indicator and Zip SECURITECH® zippers, which provide enhanced security for travelers.

## Emerging Trends in the Luggage Market

The luggage industry is evolving rapidly, driven by technological advancements and changing consumer needs. Here are some of the most significant trends shaping the future of luggage:

### 1. Smart Luggage

Smart luggage is one of the most exciting trends in the industry. These high-tech bags come equipped with features like GPS tracking, built-in scales, and USB charging ports. Brands like Samsonite and Tumi are leading the way in integrating technology into their products, offering travelers added convenience and peace of mind.

### 2. Sustainable Materials

As environmental concerns grow, consumers are increasingly seeking eco-friendly luggage options. Brands are responding by using sustainable materials like recycled plastics and organic fabrics. This shift not only appeals to environmentally conscious travelers but also sets the stage for a more sustainable future in the luggage industry.

Manufacturers and Traders of Luggage materials:

a.Niwar Corner: Running for the past more than 42 years, Is the leading Manufacturer, Trader, and Importer of all types of Luggage and Bag material/accessories (e.g., Zipper, Zip Puller/Slider, Non-Woven Fabric, Fabric, Net, USB cables(for smart luggage and Bag), Stitching material for luggage like Thread and Yarn, Plastic and Metal fittings (buckles, Hooks, Kunda, Runner, Locks, etc), and, Velcro, etc. The company has thousands of satisfied customers all over India. With highly dedicated management team, high-tech machines, reliable workforce allow Niwar Corner to expand its business outside India too.

b.YKK: This is a Japanese group of manufacturing companies. They are the world's largest zipper manufacturer, also producing other fastening products, architectural products, plastic hardware, and industrial machinery. They have worked with the world’s leading luggage companies.

### 3. Lightweight and Durable Designs

Travelers are always looking for ways to reduce the weight of their luggage without sacrificing durability. Advances in materials science have led to the development of lightweight yet robust materials, such as polycarbonate and carbon fiber, which are now commonly used in high-quality luggage.

### 4. Customization

Personalization is becoming a key trend in the luggage market. Consumers want luggage that reflects their personality, and brand name and meets their every single need. A lot of Brands are offering customization(Niwar Corner) options, such as monogramming and interchangeable components, to cater to this demand.

### 5. Multi-Functionality

Modern travelers often seek luggage that can serve multiple purposes. Convertible luggage that can be transformed from a suitcase to a backpack, or bags with modular compartments that can be reconfigured based on the trip's requirements, are becoming increasingly popular.

## Conclusion

The global luggage market is dynamic and ever-evolving, with key players continuously innovating to meet the demands of modern and classic travelers. From high-tech smart luggage to sustainable materials, the trends shaping the industry are all geared towards enhancing the travel experience. As these trends continue to develop, every traveler( can look forward to even more convenient, stylish, reliable, compact, and functional luggage options in the future.

Whether you're a frequent flyer or an occasional vacationer, staying informed about the latest developments in the luggage market can help you make smarter choices for your travel needs. So, next time you shop for luggage, consider these key players and emerging trends to find the perfect travel companion.

0 notes

Text

Anand Steel: What Are the Benefits of Using Nuts?

Nuts are critical components in the global of hardware and creation. They are available in numerous sizes and styles and are used at the side of bolts and screws to lock materials together securely. In this blog, we are able to delve into the benefits of using nuts, the different sorts to be had, and how they make a contribution to the stableness and durability of numerous systems. We can also touch on associated hardware collectively with washers, socket screws, self-tapping screws, and threaded rods, to offer a whole knowledge of their significance.

1. Strength and Stability

Secure Fastening

Nuts are designed to offer a secure fastening when used with bolts and screws. This mixture creates a sturdy and sturdy connection that could resist widespread strain and pressure. The use of nuts ensures that the set up substances live intact and aligned, it truly is critical for structural integrity.

Load Distribution

When used with washers, nuts assist distribute the burden flippantly throughout the floor of the cloth. Washers act as a buffer among the nut and the material, stopping damage and ensuring that the pressure is calmly spread. This load distribution is critical in preventing material fatigue and failure, specially in high-stress programs.

2. Versatility and Adaptability

Various Applications

Nuts are utilized in a large kind of packages, from easy household upkeep to complex business gadgets. Their versatility makes them a necessary issue in plenty of industries, which includes manufacturing, car, aerospace, and production.

Compatibility with Different Fasteners

Nuts are like minded with various fasteners, together with bolts, screws, and threaded rods. This compatibility lets in for bendy and adaptable fastening answers, accommodating specific sizes and varieties of hardware. For example, a socket screw, that is a sort of screw with a hexagonal socket in its head, may be paired with a nut to create a strong connection in limited spaces.

3. Ease of Use and Installation

Simple to Install

Nuts are pretty simple to install and do not require specialized devices. A simple wrench or socket set is commonly sufficient to tighten or loosen them. This ease of setup makes nuts a realistic desire for each expert and DIY programs.

Reusable

Unlike a few fasteners that could best be used as soon as, nuts can often be reused more than one times. This reusability makes them a fee-powerful alternative for various projects, as they'll be removed and reapplied without dropping their effectiveness.

4. Durability and Longevity

Material Choices

Nuts are available in numerous substances, including chrome steel, brass, aluminum, and nylon. Stainless metal nuts, for example, are fantastically immune to corrosion and rust, making them ideal for outdoor and marine packages. This durability ensures that the fixed structures stay steady and intact for extended periods.

Corrosion Resistance

Many nuts are designed to withstand corrosion, which is in particular vital in harsh environments. Using nuts made from corrosion-resistant materials ensures that the fasteners do not degrade over time, retaining the integrity of the relationship.

5. Specific Types of Nuts and Their Benefits

Hex Nuts

Hex nuts are the most common shape of nut and are characterised with the resource in their hexagonal form. They are utilized in a big range of applications and offer excellent grip and torque.

Lock Nuts

Lock nuts are designed to resist loosening because of vibration or torque. They are typically applied in device and vehicle programs in which keeping a steady connection is crucial.

Wing Nuts

Wing nuts have sticking out "wings" that allow for smooth hand-tightening. They are regularly utilized in applications where the nut needs to be often adjusted or eliminated, together with in furnishings meeting.

Flange Nuts

Flange nuts have an included washing machine that enables distributing the load and gives a greater strong fastening. They are normally utilized in vehicle and structural applications.

6. The Role of Anand Steel in Providing Quality Hardware Solutions

Anand Steel, a firm of excellent hardware, offers an in-depth kind of nuts, washers, socket screws, self-tapping screws, and threaded rods. Their dedication to high-quality and client delight ensures that you get dependable and strong fasteners to your duties. By deciding on Anand Steel, you can be confident that your fastening goals can be met with precision and excellence.

7. Complementary Fasteners: Washers, Screws, and Rods

Washers

Washers are used along facet nuts and bolts to distribute the load and save you damage to the cloth. They are to be had severa types, including flat washers, spring washers, and lock washers, every serving a specific reason.

Socket Screws

Socket screws, additionally called Allen screws, have a hexagonal socket in the head that permits for a stable and unique fastening. They are normally utilized in programs wherein a flush end is needed.

Self-Tapping Screws

Self-tapping screws are designed to create their personal threads as they'll be driven into the cloth. They are perfect to be used in materials like steel and plastic, in which pre-drilling is not viable or sensible.

Threaded Rods

Threaded rods are lengthy rods with non-stop threading alongside their duration. They are applied in applications wherein a long, stable connection is wanted, collectively within production and device.

8. Conclusion

Nuts play a crucial function in providing stable, sturdy, and sturdy connections in numerous packages. Their versatility, ease of use, and compatibility with other fasteners motive them to an important trouble within the hardware industry. By experiencing the benefits and styles of nuts, as well as their complementary fasteners, you could make informed picks for your initiatives.

Anand Steel gives a large style of excellent nuts and special hardware solutions, ensuring that your fastening dreams are met with reliability and precision. Whether you are an expert contractor or a DIY enthusiast, Anand Steel's products will assist you obtain solid and long-lasting consequences.

0 notes

Text

Exploring the Fascinating World of Qatar's Premier Bolt Producers

Jinnox Bolt is a leading Bolt Manufacturer in Qatar, known for its quality, innovation, and customer instruction. We have been in the industry for decades now and have stamped a niche among customers for being a reliable high-strength precision bolt producer for various applications across different industries. We are approved bolt suppliers to many prestigious construction companies, automotive, aerospace, and other industrial sectors.

The Precision and Craftsmanship of Qatari Bolts

Stringent Quality Control

At the heart of Qatar's bolt manufacturing prowess lies a relentless pursuit of quality. Each stage of the production process is meticulously monitored, from raw material selection to final inspection. Sophisticated testing equipment and rigorous quality control measures ensure that every bolt that leaves the factory meets the highest international standards, earning the trust of discerning customers worldwide.

Specialized Bolt Varieties

Qatar's bolt producers have diversified their offerings to cater to the unique needs of various industries. From high-tensile strength bolts for heavy-duty applications to corrosion-resistant fasteners for marine environments, these manufacturers have developed a comprehensive range of specialized products. Their ability to tailor solutions to specific requirements has solidified their position as trusted partners in diverse sectors.

Customization and Flexibility

In an ever-evolving global market, the ability to adapt and customize is crucial. Bolt Manufacturers in Qatar have embraced this challenge, offering bespoke solutions to clients. Whether it's modifying thread patterns, altering material compositions, or developing custom-designed fasteners, these companies demonstrate a remarkable level of flexibility to meet the unique demands of their customers.

The Impact of Qatari Bolts on Global Industries

Infrastructure Development

The construction and infrastructure sectors have been major beneficiaries of Qatar's bolt manufacturing prowess. The country's fasteners have been instrumental in the development of iconic landmarks, highways, and industrial complexes across the Middle East and beyond. Their durability, reliability, and adherence to safety standards have made Qatari-made bolts an indispensable component in ambitious building projects worldwide.

Renewable Energy Revolution

As the world shifts towards a more sustainable future, the demand for renewable energy technologies has surged. Bolt Suppliers in Qatar have seamlessly integrated their products into this burgeoning industry, supplying high-performance fasteners for wind turbines, solar panels, and other green energy infrastructure. Their commitment to innovation and environmental responsibility has made them key partners in the global renewable energy revolution.

Aerospace and Automotive Advancements

From the precision-engineered components of aircraft to the intricate assemblies of automobiles, Qatari bolts have left an indelible mark on these dynamic industries. Their unwavering quality, adherence to rigorous safety standards, and ability to adapt to specialized requirements have made them indispensable for manufacturers seeking reliable fastening solutions. As these industries continue to push the boundaries of innovation, Qatar's bolt producers remain at the forefront, driving progress and shaping the future.

Countries where we supply bolts

Bolt Manufacturers in UAE

Bolt Manufacturers in UK

Bolt Manufacturers in Australia

Bolt Manufacturers in South Africa

Bolt Manufacturers in USA

Bolt Manufacturers in Kenya

Bolt Manufacturers in Qatar

Bolt Manufacturers in India

Conclusion

Qatar's bolt manufacturing industry has emerged as a true powerhouse, transforming the country into a global centre of fastener excellence. Through their unwavering commitment to quality, innovation, and customer-centric approaches, these Qatari companies have not only carved out a niche in the global market but have also become indispensable partners in the development of the world's most ambitious projects. As we witness the continued growth and evolution of this unsung industry, it becomes clear that Qatar's bolt producers are poised to remain at the forefront of this dynamic and ever-evolving landscape.

For more details;

Product: Bolt Manufacturers

Website: jinnoxbolt.com

0 notes

Text

Precision Fastening Solutions: Leading Suppliers of Nickel Alloy 201 Bolts in India

In the realm of industrial infrastructure where reliability and durability are paramount, the choice of fastening solutions plays a crucial role. Nickel Alloy 201 bolts stand out as exemplary components, known for their exceptional corrosion resistance and mechanical properties. When sourcing these critical elements, turning to trusted suppliers in India ensures not just quality but also reliability and efficiency. In this article, we'll explore the significance of Nickel Alloy 201 bolts, the expertise of leading suppliers in India, and why they're the preferred choice for industries worldwide.

Understanding the Significance of Nickel Alloy 201 Bolts

Nickel Alloy 201 is a commercially pure wrought nickel alloy known for its outstanding resistance to corrosion, particularly in reducing environments. Nickel Alloy 201 bolts, precision-engineered from this alloy, offer exceptional mechanical strength, thermal stability, and resistance to various corrosive media. These bolts serve as indispensable components in industrial applications where reliability and longevity are paramount, including chemical processing, marine engineering, and aerospace industries.

The Expertise of Nickel Alloy 201 Bolt Suppliers in India

Leading suppliers of Nickel Alloy 201 bolts in India are distinguished by their commitment to excellence, precision engineering, and adherence to international quality standards. Here's why they excel in the global market:

Comprehensive Product Range: Renowned suppliers offer a comprehensive range of Nickel Alloy 201 bolts in various sizes, lengths, and configurations to meet diverse industrial requirements. Whether it's standard bolts, hex bolts, or custom-designed fasteners, they cater to the specific needs of customers with precision-engineered solutions.

Quality Assurance: Suppliers prioritize quality assurance at every stage of the supply chain. They source high-quality raw materials, conduct rigorous quality checks and inspections, and adhere to international quality standards such as ASTM and ASME to ensure the integrity and performance of Nickel Alloy 201 bolts.

Customization Capabilities: Recognizing the unique needs of customers, suppliers offer customization options for Nickel Alloy 201 bolts to meet specific requirements. Whether it's different sizes, thread pitches, or surface finishes, they collaborate closely with customers to deliver tailored solutions that optimize performance and reliability.

Technical Support: Suppliers provide comprehensive technical support to assist customers in selecting the right Nickel Alloy 201 bolts for their applications. They offer expertise, guidance, and recommendations based on the specific requirements and operating conditions, ensuring optimal performance and reliability.

Timely Delivery: Suppliers understand the importance of timely delivery to meet project deadlines and operational requirements. They maintain efficient logistics networks and partnerships with shipping carriers to ensure prompt delivery of Nickel Alloy 201 bolts to customers, minimizing downtime and disruptions in operations.

Why Choose Leading Suppliers in India for Nickel Alloy 201 Bolts

Customers worldwide prefer leading suppliers in India for Nickel Alloy 201 bolts due to the following reasons:

Quality and Reliability: Suppliers are known for their commitment to quality, reliability, and customer satisfaction. They consistently deliver high-quality Nickel Alloy 201 bolts that meet or exceed international standards, ensuring long-term performance and reliability in industrial applications.

Competitive Pricing: Suppliers offer competitive pricing without compromising on quality. Their cost-effective solutions make Nickel Alloy 201 bolts accessible to a wide range of industries, enabling customers to optimize their operational costs without sacrificing performance.

Customization and Flexibility: Suppliers offer customization options to meet specific customer requirements. They collaborate closely with customers to understand their needs and deliver tailored solutions that optimize performance and efficiency.

Technical Expertise: Suppliers possess in-depth technical knowledge and expertise in Nickel Alloy 201 bolts. They provide valuable insights, recommendations, and support to assist customers in selecting the right fastening solutions for their applications, ensuring optimal performance and reliability.

Conclusion

In the competitive landscape of industrial procurement, leading suppliers of Nickel Alloy 201 bolts in India stand out for their expertise, precision engineering, and commitment to quality. By choosing trusted suppliers, customers worldwide can access high-quality Nickel Alloy 201 bolts that meet their specific requirements and performance standards.

For more details

Email: [email protected]

Contact: 8779038854

If any enquiries please contact us our support team will connect you as soon as possible.

#Nickel 201 Washers Manufacturers#Nickel 201 Washers Suppliers#Nickel 201 Washers Stockists#Nickel 201 Washers Exporters#Nickel 201 Washers Manufacturers In India#Nickel 201 Washers Suppliers In India#Nickel 201 Washers Stockists In India#Nickel 201 Washers Exporters In India

0 notes

Text

What Is the Function of a pipe clamp ? And Types of it - Arcellor Controls

The elaborate global of business piping structures is predicated on a network of unseen heroes – pipe clamps. These apparently simple additives play an important position in making sure the secure, steady, and efficient operation of those systems Arcellor Controls, a leading issuer of industrial automation solutions arcellor controls ON Arcellor Controls is familiar with the significance of superb pipe clamps. In this blog, we'll delve into the characteristics of pipe clamps, explore numerous sorts, and speak about their applications.

The Function of Pipe Clamps

Pipe clamps, additionally known as pipe becoming clamps or clamp pipe fittings, are mechanical gadgets designed to soundly maintain and guide pipes inside a system. They prevent undesirable movement, vibration, or misalignment, safeguarding in opposition to capacity leaks, harm to pipes, and even system failure. Pipe fitting clamps work with the aid of gripping the pipe with a saddle or band and securing it to a wall, ceiling, or other helping shape the use of bolts or other fasteners.

Types of Pipe Clamps: Catering to Diverse Needs

A huge variety of pipe clamps exist, catering to particular pipe sizes, materials, and applications.

Here are some not unusual kinds:

U-Clamp: A versatile and fee-effective alternative, presenting a U-fashioned frame that encircles the pipe and tightens with a bolt. U-clamps are suitable for various pipe sizes and substances, making them a famous preference for general-reason packages.

Saddle Clamp: This clamp capabilities a half-spherical frame that fits across the pipe and secures it to the mounting floor. Saddle clamps offer right guidance and are frequently used for large diameter pipes or situations requiring high load bearing ability.

Clevis Clamp: Ideal for putting pipes from ceilings or overhead structures, a clevis clamp features a U-formed frame with a threaded rod and a clevis on the lowest for attaching to a hanger or bracket.

Band Clamp: A flexible choice including a metallic band that wraps across the pipe and tightens with a screw mechanism. Band clamps are suitable for packages requiring frequent changes or wherein particular positioning is wanted.

pipe clamp fittings: Made from a light-weight and corrosion-resistant plastic material, PVC pipe clamps are specifically designed for securing PVC pipes in low-pressure packages like irrigation systems or drainage lines.

Specifications and Standards for Pipe Clamps

The selection of appropriate pipe clamps requires considering specifications and requirements:

Pipe Size: Clamps need to be compatible with the particular diameter of the pipe they're intended to aid.

Material: Pipe clamp fabric choice depends on elements just like the pipe cloth, working environment, and load necessities. Stainless steel is a common desire for its sturdiness and corrosion resistance, at the same time as nylon or PVC clamps are suitable for low-strain applications.

Load Rating: Clamps are rated for the maximum load they are able to correctly assist. Choosing a clamp with a good enough load score is critical for making sure device integrity.

Standards: Reputable manufacturers adhere to industry requirements like ASTM International (ASTM) or American Society of Mechanical Engineers (ASME) for cloth residences and overall performance requirements.

Applications of Pipe Clamps: Spanning Various Industries

pipe clamp pvc discover software in a wide range of industries:

Plumbing Systems: Securing pipes in residential and industrial buildings for water supply, drainage, and waste disposal.

HVAC Systems: Supporting pipes sporting hot or bloodless water, refrigerant lines, and ductwork in heating, ventilation, and aircon structures.

Industrial Piping: Providing aid for pipes carrying fluids, gasses, or chemical compounds in diverse commercial methods.

Fire Sprinkler Systems: Securing pipes inside hearth sprinkler networks to make certain proper functionality and safety.

Electrical Conduit Systems: Supporting electric conduit and cable trays for safe and prepared wiring.

Conclusion

Pipe clamps, though reputedly easy, play a crucial function in making sure the smooth and safe operation of business piping systems. Understanding the different types, specs, and programs of pipe clamps empowers you to make knowledgeable decisions for your particular needs. When it comes to outstanding pipe clamps and different industrial automation answers, Arcellor Controls is your dependent on companions. We offer a comprehensive variety of clamps to fulfill your task necessities and make sure of the most advantageous performance of your piping structures.

#pipe clamp types#pipe fitting clamp#pipe clamp fittings#clamp pipe fittings#pvc pipe clamp#pipe clamp pvc

0 notes

Text

Bolt It Right: Innovative U-Bolts for Every Project

When it comes to fastening and securing components across various industries, from automotive to construction, U-Bolts are an indispensable ally. These versatile tools, shaped like the letter U with screw threads on both ends, are used to support pipework, secure tubing, and hold together machinery. This blog post explores the various kinds of U-Bolts, their applications, and why sourcing from reputable U-bolt exporters India can make a significant difference in your projects.

Introduction to U-Bolts

In the vast landscape of industrial fasteners, U-Bolts stand out as pivotal components utilized extensively across various sectors, including construction, automotive, and marine industries. These U-shaped bolts are distinctive for their ability to securely clamp down pipes, conduits, and other cylindrical bodies to surfaces, ensuring stability and structural integrity. The versatility of U-Bolts lies in their simple yet effective design, which comprises a curved body with threaded arms on both ends that can be fastened with nuts.

Central to the effectiveness of U-Bolts is the precision in their manufacturing. Material selection, dimensional accuracy, and threading are critical factors that determine the durability and suitability of U-Bolts for specific environments. This is where U-bolt exporters India have carved a niche. Known for their commitment to quality and innovation, Indian exporters have mastered the art of producing high-grade U-Bolts that meet rigorous international standards. They offer a range of materials, from carbon steel to stainless steel, each tailored to resist the environmental challenges of the applications they serve.

The capability of Indian manufacturers to provide customized solutions sets them apart. Whether the requirement is for standard piping support in commercial buildings or specialized applications in corrosive marine environments, U-bolt exporters India can deliver products designed to meet exact specifications. Their role extends beyond mere suppliers to collaborative partners who contribute to the engineering and design process, ensuring that the U-Bolts not only fit the technical requirements but also contribute to the overall efficiency and safety of projects.

As global industries continue to expand and evolve, the demand for reliable and adaptable fastening solutions like U-Bolts also grows. In this context, U-bolt exporters India are not just fulfilling a need in the market; they are actively enhancing how industries secure and stabilize their most critical structures. Choosing the right U-Bolt, and more importantly, the right exporter, can make a substantial difference in the success of any project.

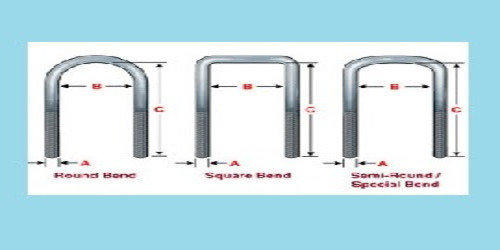

Types of U-Bolts and Their Applications

U-Bolts are diverse in their designs and applications, meeting the specific needs of various industries with precision. Each type of U-Bolt serves a unique purpose, and U-bolt exporters India have honed their manufacturing processes to cater to these varied requirements with expertise. The most common types include:

Standard U-Bolts

Standard U-Bolts serve as the cornerstone of secure fastening across a myriad of industries. Their straightforward design, comprising a U-shaped body with threaded arms, makes them versatile and reliable for a wide range of applications. Typically used to secure pipes, conduits, and machinery to surfaces, standard U-Bolts provide stability and support in construction, automotive, and plumbing projects. Available in various materials such as carbon steel and stainless steel, these U-Bolts offer durability and corrosion resistance, ensuring long-lasting performance even in demanding environments. With their ubiquity and effectiveness, standard U-Bolts continue to be a trusted choice for fastening needs in diverse industrial settings.

Long Tangent U-Bolts

Long Tangent U-Bolts are engineered to provide extended reach and increased clearance for specific fastening requirements. With longer legs compared to standard U-Bolts, they offer versatility in applications where additional space is necessary, such as when mounting objects with insulation or requiring a larger grip. These U-Bolts ensure a secure and stable connection between pipes, conduits, or other cylindrical objects and their support structures. Their design facilitates proper alignment and minimizes the risk of slippage or shifting, making them ideal for use in construction, electrical installations, and automotive systems. Available in various materials and sizes, Long Tangent U-Bolts offer tailored solutions to meet the unique needs of different projects, ensuring optimal performance and reliability.

Square U-Bolts

Square U-bolts are specially designed to provide stability and strength when fastening square-shaped objects or structures. Their unique square shape ensures a secure grip and prevents rotation, making them ideal for applications where a stable connection is paramount, such as in framing and construction projects. Square U-bolts are commonly used to secure posts, beams, and other square components in place, ensuring structural integrity and preventing movement or displacement. Available in a variety of sizes and materials including stainless steel and galvanized steel, these U-Bolts offer durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With their reliability and versatility, Square U-Bolts are indispensable components in ensuring the stability and safety of various structural installations.

Custom U-Bolts

Custom U-Bolts offer a versatile and flexible approach to fastening solutions, catering to the specific requirements of diverse applications. Unlike standard U-Bolts, which have predefined sizes and configurations, custom U-Bolts can be precisely engineered to meet unique specifications. This includes customization of dimensions, materials, thread sizes, and even specialized coatings or finishes. Whether it's accommodating non-standard pipe diameters, unusual mounting surfaces, or challenging environmental conditions, custom U-Bolts provide a tailored solution for every situation. U-bolt exporters India specialize in producing custom U-Bolts with precision and expertise, ensuring that each fastening component perfectly aligns with the needs of the project. By opting for custom U-Bolts, businesses can achieve optimal performance, reliability, and efficiency in their fastening applications, ultimately contributing to the success of their projects.

Choosing the Right U-Bolts for Your Project

Selecting the appropriate U-Bolts is crucial for ensuring the structural integrity and longevity of your project. With a myriad of options available, partnering with reputable U-bolt exporters India and Square Head Bolts Suppliers can streamline the decision-making process while guaranteeing quality and reliability.

First and foremost, consider the environmental factors your project will encounter. U-bolt exporters India offer a range of materials, including stainless steel and galvanized steel, each tailored to withstand specific conditions such as corrosion from exposure to moisture or chemicals.

Next, evaluate the load requirements of your application. U-bolt exporters India can provide guidance on selecting the right size and strength of U-Bolts to support the intended weight without compromising safety.

Additionally, factor in any special considerations such as temperature variations, vibration levels, or potential for expansion and contraction. Indian exporters can customize U-Bolts to accommodate these unique needs, ensuring a precise fit and optimal performance.

Lastly, assess your budget and timeline constraints. U-bolt exporters India are known for their competitive pricing and efficient manufacturing processes, making them an ideal choice for projects with cost and time sensitivities.

By collaborating with U-bolt exporters India, you can confidently choose the right U-Bolts for your project, knowing they are backed by industry expertise and stringent quality standards.

U-Bolt Coatings and Finishes

U-bolt exporters India offer a variety of coatings and finishes to enhance the performance and durability of their products. From galvanized coatings for corrosion resistance in outdoor environments to fluoropolymer finishes for extreme conditions, Indian exporters ensure that their U-Bolts are equipped to withstand the challenges of any application. These coatings not only protect against rust and corrosion but also provide a polished appearance, making them suitable for both functional and aesthetic purposes. With a range of options available, U-bolt exporters India ensure that your fastening solutions are tailored to meet your specific requirements.

U-bolt exporters India

When sourcing U-Bolts, particularly for large projects or specialized requirements, it is crucial to partner with experienced and reliable exporters. U-bolt exporters India are renowned for their high-quality manufacturing standards and cost-effectiveness. They offer a wide range of U-Bolts, including custom options, and can provide valuable guidance on the best choices for specific applications.

Installation Tips for U-Bolts

Proper installation of U-Bolts is crucial for ensuring their effectiveness and longevity. U-bolt exporters India recommend several tips for optimal installation. Firstly, ensure that the U-Bolts are tightened evenly to prevent uneven stress distribution. Secondly, use appropriate torque values to avoid over-tightening, which can lead to deformation or damage. Additionally, regularly inspect the U-Bolts for signs of wear or corrosion, and replace them as needed to maintain structural integrity. By following these installation tips, provided by experienced U-bolt exporters India, you can maximize the performance and lifespan of your U-bolt assemblies.

Read Also: U BOLTS MANUFACTURER: HIGH-PERFORMANCE FASTENING SOLUTIONS

U-Bolt Maintenance

Maintaining U-Bolts is essential for ensuring their continued performance and safety. U-bolt exporters India advise regular inspections to check for signs of wear, corrosion, or loosening. Tighten any loose U-Bolts to prevent potential hazards and ensure a secure connection. Additionally, consider applying lubricants to threaded areas to prevent rust and make future adjustments easier. If corrosion is present, U-bolt exporters India recommend cleaning the affected areas and applying protective coatings to prevent further deterioration. By incorporating these maintenance practices, you can extend the lifespan of your U-Bolts and maintain the integrity of your structures.

Why Choose U-bolt Exporters India

Choosing U-bolt exporters India offers a multitude of advantages for businesses worldwide. Indian exporters are renowned for their commitment to quality, offering U-Bolts that adhere to stringent international standards at competitive prices. With a robust manufacturing infrastructure and skilled workforce, U-bolt exporters India can fulfill large volume orders with efficiency and precision, ensuring timely delivery for projects of any scale. Moreover, Indian exporters prioritize customization, allowing customers to tailor U-Bolts to their specific requirements. By partnering with U-bolt exporters India, businesses can access high-quality products, cost-effective solutions, and reliable service, ultimately enhancing project outcomes.

Conclusion

U-Bolts are fundamental in numerous industrial applications, offering versatility, reliability, and strength. Understanding the various types of U-Bolts, their applications, and proper maintenance can significantly enhance project outcomes. For businesses looking to secure high-quality U-Bolts, partnering with reputable U-bolt exporters India can provide an edge in product quality and cost-effectiveness. Whether your project is local or international, ensuring you choose the right U-Bolt and supplier is key to securing your structures safely and efficiently. You can bolt it right for every project with the right bolts and the right partner.

Read Also: U Bolt Dynamics: Crafting Precision Fasteners for Every Need

0 notes

Text

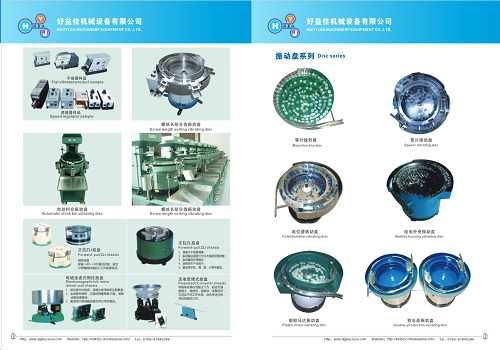

Stay Ahead of the Competition: Top Nut Bolt Manufacturing Machine Suppliers of 2024

In the ever-evolving manufacturing sphere, the product of nuts and bolts remains a foundational aspect across colorful assiduity. With demands for perfection, effectiveness, and customization reaching new heights, choosing the right manufacturing ministry supplier becomes consummate for businesses seeking to maintain a competitive edge. Enter Dongguan, a commanding name in 2024, offering slice-edge results acclimated to the demands of ultramodern product lines.

Dongguan Pioneering Innovation in Nut Bolt Manufacturing Machinery

With a heritage of invention and a commitment to excellence, Dongguan has long been synonymous with quality in the manufacturing sector. using state-of-the-art technology and an unvarying pursuit of perfection, Dongguan has solidified its position as a global leader in furnishing advanced ministry for nut and bolt products.

Key Features and Advantages

1. Precision Engineering

Dongguan's nut bolt manufacturing machines are finagled with perfection at their core. By exercising advanced CNC technology and automated processes, these machines ensure unexampled delicacy and viscosity in every product manufactured.