#Global Electronics Conformal Coating Market

Explore tagged Tumblr posts

Text

Electronics Conformal Coating Market to Hit $1277.80 Million by 2032

What's Trending in Electronics Conformal Coating Market?

- Keep Yourself Up-To-Date With The Latest Market Trends.

The global Electronics Conformal Coating Market was valued at USD 890.32 Million in 2024 and it is estimated to garner USD 1277.80 Million by 2032 with a registered CAGR of 4.62% during the forecast period 2024 to 2032.

Firstly, the Market report for Electronics Conformal Coating Market describes the current state of the companies and recommends where it is likely to go next. The report shows the production, revenue, price, market share, and growth rate of each type, mainly divided into Product Types and Product Applications etc.

Additionally, this market report focuses on offering key business measures such as real market moves, market size, qualities, and freedoms, as well as forecast opportunities. This Electronics Conformal Coating Market report also offers distinctive insights into wealthy regions such as Europe, North America, the Middle East, Africa, and Latin America.

Get a Sample Copy of the Electronics Conformal Coating Market Report at: https://www.vantagemarketresearch.com/electronics-conformal-coating-market-1272/request-sample

Top Competitors:

Illinois Tool Work (US), Henkel (Germany), Dow (US), H.B. Fuller (US), Shin-Etsu Chemical (Japan), Electrolube (UK), Dymax Corporation (US), Chase Corporation (US), Specialty Coating System (US), and MG Chemical (Canada).

This market report has all the information you need to start or grow your business in the industry. It also includes market drivers, restraints, competitiveness, and geographic estimates, as well as a price and emerging market structure. It is a complete description of a company's business model, benchmarks, consumer preferences, value proposition, and net profit. This comprehensive Electronics Conformal Coating Market study also sheds light on key techniques that help companies truly assess their customers' buying behavior.

It represents global economic trends between 2024 and 2032. With the help of this market research, top companies can easily make smarter financial decisions. This market analysis is an excellent technique to help companies implement new products. It also includes critical data on major industry topics, including market expansions and evolving market conditions.

This well-researched Electronics Conformal Coating Market report describes the negative impact COVID-19 is having on various companies and offers companies recommendations on how to recover from the damage suffered by the outbreak as well as the nationwide quarantine. The plan analyzes the company's expectations and priorities, as well as the delivery of all crucial data.

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/electronics-conformal-coating-market-1272/0

This report analyzes key market segments by type, application, and geography. The geographic analysis section covers key regions such as Europe, North America, the Middle East, Africa, and the Asia-Pacific region.

This Electronics Conformal Coating Market report not only provides valuable data but outlines key goals, pricing strategies, and approaches to help market participants' recommendations in this report will make accelerating economic growth easy. It offers some specific tips and business-related data to help new competitors in the market grow their businesses and diversify their product lines. Companies in the industry should choose tactics that include new product launches, mergers, and partnerships to survive in the competitive marketplace and strengthen their position.

Regional Analysis

-North America [United States, Canada, Mexico]

-South America [Brazil, Argentina, Columbia, Chile, Peru]

-Europe [Germany, UK, France, Italy, Russia, Spain, Netherlands, Turkey, Switzerland]

-Middle East & Africa [GCC, North Africa, South Africa]

-Asia-Pacific [China, Southeast Asia, India, Japan, Korea, Western Asia]

The quantitative information in this Electronics Conformal Coating Market analysis helps predict future sales and market penetration. This type of information is based on statistics. The qualitative information provided here will greatly help the key players understand the buyer's opinion of your brand. Improving business goals becomes easy with the information provided in this report.

The industries can draw some conclusions about their original goals. In business. This Electronics Conformal Coating Market research helps you make assumptions about your competition, customers, and the market in order to make informed business decisions. Additionally, it forecasts the competition in the market for the estimated period of 2024-2032. Effective decision-making in companies leads to business growth and is made possible by this precise market study.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/electronics-conformal-coating-market-1272

Some of the Key Questions Answered in this Report:

Which are the five top players of the Electronics Conformal Coating Market?

How will the Electronics Conformal Coating Market change in the upcoming years?

Which product and application will take a share of the Electronics Conformal Coating Market?

What will be the CAGR and size of the Electronics Conformal Coating Market throughout the forecast period?

What are the drivers and restraints of the Electronics Conformal Coating Market?

Which regional market will show the highest growth?

What is the current industry size, what will the market size be in 2030 and what will the growth rate be?

Who are the major competitors and what is their strategy?

What are the challenges to grow in the industry?

What are the market opportunities and challenges faced by the key vendors?

What are the barriers to entry for new players in the Electronics Conformal Coating industry?

Check Out More Reports

Global Agricultural Robot Market: Report Forecast by 2032

Global Air Quality Control Systems Market: Report Forecast by 2032

Global Organic Foods Market: Report Forecast by 2032

Global Map-Controlled Automotive Thermostat Market: Report Forecast by 2032

Global India Textile Market: Report Forecast by 2032

#Electronics Conformal Coating Market#Electronics Conformal Coating Market 2024#Global Electronics Conformal Coating Market#Electronics Conformal Coating Market outlook#Electronics Conformal Coating Market Trend#Electronics Conformal Coating Market Size & Share#Electronics Conformal Coating Market Forecast#Electronics Conformal Coating Market Demand#Electronics Conformal Coating Market sales & price

0 notes

Text

Sirens Market Research by Key players, Type and Application, Future Growth Forecast 2022 to 2032

In 2022, the global sirens market is expected to be worth US$ 170.1 million. The siren market is expected to reach US$ 244.0 million by 2032, growing at a 3.7% CAGR.

The use of sirens is expected to increase, whether for announcements or on emergency vehicles such as ambulances, police cars, and fire trucks. A siren is a loud warning system that alerts people to potentially dangerous situations as they happen.

Rapidly increasing threats and accidents have resulted in more casualties and missed business opportunities in developing economies. Demand for sirens is expected to rise during the forecast period as more people use security solutions.

As a result of rising threats and accidents in developing economies, the number of victims and lost business opportunities has rapidly increased. Adopting security solutions, such as sirens, is an effective way to deal with these challenges. Long-range sirens are used in mining and industrial applications, whereas motorised sirens are used in home security. Hand-operated sirens are used when there is no power or when a backup is required.

Some additional features of sirens include a solar panel upgrade system to keep the batteries charged and a number of digital communication methods, including Ethernet, satellite, IP, fiber optic and others. Sirens have conformal coatings on their electronics, which help protect them against harsh environments. Some of the systems are made in such a way that they can be expanded or scaled depending on future capabilities.

Omni-directional sirens can be used in areas of high noise levels and those with large population densities as they provide a greater area of coverage. Sirens have external controls with triggers, which can be customized according to needs. The lightening types of sirens include bulb revolving, LED flashing and xenon lamp strobe. The loud speakers in sirens are adopted from latest piezoelectric ceramic technology.

Get a Sample Copy of this Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-4274

Other sirens are hydraulic or air driven and mostly find applications in plants and factories. Lithium batteries have replaced alkaline batteries in sirens now, since lithium batteries need not be replaced for several years. Modern sirens use latest technologies and find applications in civil defense, emergency vehicles, security systems and others. Typically, sirens are made of stainless steel, aluminum or UV stabilized polycarbonate to avoid corrosion and are equipped with protection cages. An LED flashing siren has a light source with a semi-permanent lifespan and it is used in places where bulb replacement is a problem.

Region-wise Outlook

In the global sirens market, the dominant share is held by the U.S., India, China, Japan, Australia, Germany, Singapore and the UAE. This can be attributed to the demand for security solutions in developed as well as developing economies.

The regional analysis includes:

North America (U.S., Canada)

Latin America (Mexico. Brazil)

Western Europe (Germany, Italy, France, U.K, Spain)

Eastern Europe (Poland, Russia)

Asia-Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

The Middle East and Africa (GCC Countries, S. Africa, Northern Africa)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Market Participants

Some of the key market participants identified in the global siren market are Acoustic Technology Inc., Sentry Siren Inc., MA Safety Signal Co. Ltd, Whelen Engineering Co. Inc., Federal Signal Corporation, B & M Siren Manufacturing Co., Projects Unlimited Inc., Phoenix Contact, Mallory Sonalert Products and Qlight USA Inc.

Rising population and rapid urbanization have led to an increase in demand for security solutions. The need for implementation of security has paved way for the use of electronic equipment on a large scale globally, which in turn has created opportunities for the global sirens market. As these products are durable with a high voltage capacity and easy to install, they find high selling propositions. Characteristics and properties of electronic and pneumatic equipment play a vital role in security solutions, thereby driving the global sirens market with a rise in diverse end-user applications, such as industrial warning systems, community warning systems, campus alert systems and military mass warning systems.

Report Highlights:

Detailed overview of parent market

Changing market dynamics in the industry

In-depth Polishing / Lapping Film market segmentation

Historical, current and projected market size in terms of volume and value

Recent industry trends and developments

Competitive landscape

Strategies of key players and products offered

Potential and niche segments, geographical regions exhibiting promising growth

A neutral perspective on market performance

Must-have information for market players to sustain and enhance their market footprint.

Browse Detailed Summary of Research Report with TOC @ https://www.futuremarketinsights.com/reports/sirens-market

Key Segments

Product Type:

Electronic

Electro-mechanical

Rotating

Single/dual toned

Omnidirectional

By Application:

Civil defense

Industrial signaling

Emergency vehicles

Home/vehicle safety

Security/warning systems

Military use

Others

By Installation Type:

Wall mounting

Self-standing

Water proof connector

By Regions:

North America

Europe

Asia Pacific

Latin America

MEA

2 notes

·

View notes

Text

Conductive Polymer Coating Market Demand: Fueling Innovations Across Industries

The demand for conductive polymer coatings has been steadily increasing across various industries, driven by their unique properties and versatile applications. Conductive polymers, which combine the flexibility of plastics with the electrical conductivity of metals, offer a range of benefits, including lightweight, cost-effectiveness, and environmental sustainability. These characteristics make them highly sought after in sectors such as electronics, automotive, aerospace, and energy storage. This article explores the key drivers of demand for conductive polymer coatings and how they are shaping the market.

1. Growth of the Electronics Industry

The electronics industry remains the largest consumer of conductive polymer coatings. The increasing demand for smaller, more efficient, and highly functional electronic devices, including smartphones, tablets, and wearable gadgets, is one of the key factors fueling the market's growth. Conductive polymers are used in the production of printed circuit boards (PCBs), displays, sensors, and batteries, where they provide electrical conductivity while protecting sensitive components from corrosion and environmental damage. As the need for more compact and durable electronic devices grows, the demand for conductive polymer coatings is expected to increase accordingly.

In addition, the rise of flexible electronics and smart devices has spurred further demand for conductive coatings that can conform to irregular surfaces without compromising performance. This trend, driven by innovations in the Internet of Things (IoT) and wearable technology, continues to expand the application range for conductive polymer coatings in electronics.

2. Surge in Electric Vehicle (EV) Production

The global shift towards sustainable and energy-efficient transportation is one of the most significant factors boosting the demand for conductive polymer coatings. As the automotive industry transitions toward electric vehicles (EVs), there is a growing need for high-performance coatings in critical components such as batteries, fuel cells, sensors, and motors. Conductive polymer coatings offer excellent protection against corrosion and moisture, which is particularly important for the long-term durability and efficiency of EV parts.

Additionally, these coatings play a vital role in improving the electromagnetic shielding of electronic systems in EVs, which helps reduce electromagnetic interference (EMI) and ensures the smooth functioning of critical systems. As EV production accelerates globally, particularly with the rising consumer preference for environmentally friendly vehicles, the demand for conductive polymer coatings in the automotive sector is expected to grow rapidly.

3. Advancements in Renewable Energy Technologies

The demand for conductive polymer coatings is also being driven by the growing adoption of renewable energy technologies. Solar energy, wind energy, and energy storage solutions require materials that can withstand harsh environmental conditions while offering high conductivity. Conductive polymer coatings are increasingly being used in solar panels, batteries, and energy storage devices to enhance their efficiency and durability.

As governments and organizations worldwide focus on reducing carbon footprints and promoting clean energy solutions, the renewable energy sector is expected to continue expanding, leading to higher demand for conductive polymer coatings in energy-related applications.

4. Aerospace and Defense Applications

In the aerospace sector, conductive polymer coatings are widely used for their ability to provide electromagnetic interference (EMI) shielding and protection against environmental factors like moisture and extreme temperatures. These coatings are crucial in protecting sensitive aerospace electronic components and systems from electromagnetic radiation, which can cause malfunctions. The growing need for advanced, lightweight materials in aircraft, spacecraft, and military applications is driving demand for conductive polymer coatings in the aerospace and defense industries.

5. Environmental and Cost Advantages

Another factor contributing to the rising demand for conductive polymer coatings is their environmental sustainability and cost-effectiveness. Conductive polymers are more environmentally friendly compared to traditional metal coatings, as they are less energy-intensive to produce and are often biodegradable. The increasing emphasis on reducing volatile organic compounds (VOCs) and other harmful emissions in industrial processes is pushing manufacturers to adopt eco-friendly alternatives like conductive polymer coatings.

Moreover, conductive polymer coatings offer a lower cost alternative to metals like silver or copper, making them a more affordable choice for manufacturers looking to reduce production costs while maintaining performance.

Challenges and Market Outlook

While the demand for conductive polymer coatings is on the rise, challenges such as the cost of raw materials and long-term stability remain. The incorporation of expensive materials like carbon nanotubes or graphene can increase production costs, potentially limiting their widespread adoption. Additionally, the long-term durability of these coatings, particularly in extreme environmental conditions, needs further improvement.

However, with continuous advancements in nanotechnology and material science, these challenges are being addressed. As a result, the conductive polymer coating market is expected to see continued growth across industries like electronics, automotive, aerospace, and renewable energy.

Conclusion

The conductive polymer coating market is experiencing significant demand growth due to its wide-ranging applications and technological advantages. The electronics industry's evolution, the rise of electric vehicles, and advancements in renewable energy technologies are key drivers of this growth. With ongoing innovations and a focus on sustainability, conductive polymer coatings are set to play a critical role in the development of high-performance, cost-effective, and environmentally friendly solutions across various sectors.

0 notes

Text

Adhesive Tape Films Market Size, Share, Forecast Report by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Adhesive Tape Films Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Adhesive Tape Films Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Adhesive Tape Films Market?

The global adhesive tape films market was valued at US$ 14.7 Billion in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 21.1 Bn in 2032.

What are Adhesive Tape Films?

Adhesive tape films are multifunctional materials widely utilized across various industries, from manufacturing to everyday consumer products. These films comprise a thin layer of adhesive-coated material that adheres securely to numerous surfaces while remaining flexible and durable. Typically crafted from polymers such as polyethylene, polypropylene, or polyester, adhesive tape films can be tailored to possess specific characteristics, including moisture resistance, UV stability, and heat resistance, making them ideal for applications like packaging, insulation, electrical work, and automotive uses. Their easy application and ability to conform to irregular shapes make them crucial in both professional and DIY projects, enhancing efficiency and reliability across multiple sectors.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2466

What are the growth prospects and trends in the Adhesive Tape Films industry?

The adhesive tape films market growth is driven by various factors and trends. The adhesive tape films market is experiencing substantial growth, driven by rising demand for versatile bonding solutions across diverse industries such as automotive, electronics, packaging, and construction. These films provide unique features, including moisture resistance, heat resistance, and electrical insulation, making them suitable for various applications. The surge in e-commerce and the need for effective packaging solutions further stimulate market expansion, as businesses seek reliable products to ensure safe delivery. Moreover, advancements in manufacturing technologies and the introduction of innovative adhesive formulations are enhancing product performance and broadening their applications. With a growing emphasis on sustainability, the market is also shifting toward eco-friendly and recyclable adhesive tape films, aligning with global initiatives to reduce environmental impact. Overall, the adhesive tape films market is well-positioned for continued growth, driven by changing consumer preferences and technological innovations. Hence, all these factors contribute to adhesive tape films market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Transparent

Colored

By Backing Material Type

Polyethylene (PE) Films

Polypropylene (PP) Films

Polyvinyl Chloride (PVC) Films

Polyester (PET) Films

Others

By Adhesive Type

Rubber-Based Adhesives

Acrylic Adhesives

Silicone Adhesives

Others

By End Use

Packaging

Automotive

Electronics

Construction

Healthcare

Paper & Printing

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Taghleef Industries

Nitto Denko Corporation

PAC Adhesive Products (Suzhou) Co., Ltd.

Berry Global Inc.

YANGFENG TAPE AND ADHESIVE PRODUCTS, LTD.

LINTEC Corporation

Shurtape Technologies, LLC

FROMM Holding GmbH Co. KG

USG Corporation

Henkel AG Co. KGaA

Tes tape group

Avery Dennison Corporation

View Full Report: https://www.reportsandinsights.com/report/Adhesive Tape Films-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Innovations Shaping the Future of the Electronic Adhesives Market

The electronic adhesives market plays a critical role in the assembly and production of electronic devices, ensuring reliable performance and durability. Electronic adhesives are specially formulated to meet the rigorous demands of modern electronics, where miniaturization, heat resistance, and high conductivity are essential. These adhesives are used for bonding electronic components, sealing, encapsulating, and conformal coating applications. With the continued expansion of industries such as consumer electronics, automotive, telecommunications, and healthcare, the demand for electronic adhesives is on the rise.

The global electronic adhesives industry, valued at US$ 5.3 billion in 2022, is projected to grow at a CAGR of 6.7% from 2023 to 2031, reaching an estimated US$ 5.6 billion by the end of 2031. This growth is attributed to the increasing use of electronic devices, the rise of electric vehicles (EVs), and the growing popularity of smart devices and IoT (Internet of Things) applications.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/electronic-adhesives-market.html

Market Segmentation

By Type of Adhesive

Epoxy Adhesives: Widely used for their excellent bonding strength, heat resistance, and durability.

Silicone Adhesives: Preferred for flexibility, moisture resistance, and high thermal stability.

Acrylic Adhesives: Known for fast curing and strong bonds, commonly used in high-performance applications.

Polyurethane Adhesives: Provide good mechanical properties and adhesion to various substrates.

By Formulation Type

Liquid Adhesives

Paste Adhesives

Film Adhesives

By Application

Surface Mount Devices (SMDs)

Conformal Coatings

Potting and Encapsulation

Wire Tacking and Bonding

By Industry Vertical

Consumer Electronics: Phones, laptops, and wearable devices.

Automotive: Electric vehicles, battery management systems, sensors.

Healthcare: Medical devices such as pacemakers and hearing aids.

Telecommunication: Communication devices, data centers, and fiber optic assemblies.

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: A mature market for electronic adhesives, driven by advancements in the automotive and healthcare sectors. The region benefits from a high concentration of technology firms and investments in research and development (R&D).

Europe: The growth in electric vehicle (EV) adoption, coupled with stringent environmental regulations, is promoting the use of eco-friendly adhesives. Germany, France, and the UK are key contributors to the market.

Asia-Pacific: The largest and fastest-growing region, driven by the booming electronics manufacturing industry in countries like China, Japan, South Korea, and India. The region's strong presence in consumer electronics and automotive manufacturing is a key driver.

Latin America and Middle East & Africa: Emerging regions with increasing investments in technology, healthcare infrastructure, and automotive industries are contributing to gradual market growth.

Market Drivers and Challenges

Market Drivers:

Increasing Adoption of Electric Vehicles (EVs): The surge in electric vehicle production is a major driver for the demand for high-performance adhesives, especially those that can withstand thermal cycling, moisture, and vibration.

Growing Demand for Miniaturized Devices: The trend toward miniaturization in electronic devices demands more precise and durable adhesives for surface-mount components and intricate assemblies.

Rising Use of Consumer Electronics: The increasing penetration of smartphones, wearables, and other consumer electronics across the globe boosts demand for adhesives in circuit assemblies.

Challenges:

High Cost of Advanced Adhesives: The high cost associated with the development and application of advanced adhesives poses a challenge, especially for small and medium-sized manufacturers.

Stringent Environmental Regulations: Compliance with environmental and safety standards, especially regarding volatile organic compounds (VOCs) in adhesives, creates additional pressure on manufacturers.

Market Trends

Sustainability and Eco-Friendly Adhesives: There is a growing emphasis on developing environmentally friendly electronic adhesives with low VOC emissions to comply with stringent environmental regulations.

Adoption of 5G Technology: The global rollout of 5G technology is driving the demand for advanced adhesives in the telecommunication sector, particularly for bonding and sealing 5G infrastructure components.

Flexible and Wearable Electronics: The rise of flexible electronics and wearable devices is spurring innovation in adhesive formulations that offer flexibility, durability, and compatibility with various substrates.

Future Outlook

The electronic adhesives market is poised for significant growth over the next decade. The rapid advancements in 5G technology, IoT, and EVs are expected to create new opportunities. Manufacturers are likely to focus on innovation in adhesive formulations to meet the evolving requirements of the electronics industry, such as higher heat resistance, lower weight, and eco-friendly solutions. With increasing R&D efforts, the development of next-generation adhesives will enhance product performance and efficiency.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=54981<ype=S

Key Market Study Points

Rising Demand for High-Performance Adhesives: The growing adoption of electronic adhesives in high-performance applications, particularly in automotive and telecommunications, is expected to drive market growth.

Technological Innovation: Continuous advancements in adhesive technologies, such as UV-curing adhesives and conductive adhesives, will create opportunities for market expansion.

Supply Chain Optimization: Manufacturers are focusing on optimizing their supply chains to meet the rising demand for electronic adhesives, especially in emerging markets.

Competitive Landscape

The electronic adhesives market is highly competitive, with key players focusing on innovation, product development, and strategic partnerships. Leading companies include:

Henkel AG & Co. KGaA

3M Company

H.B. Fuller Company

Dow Inc.

BASF SE

Sika AG

Master Bond Inc.

These companies are investing in R&D and expanding their product portfolios to cater to the growing demand for specialized adhesives in various sectors.

Recent Developments

Henkel introduced a new range of thermally conductive adhesives designed specifically for electric vehicle battery systems, aimed at improving thermal management and reducing battery pack weight.

3M announced advancements in UV-curing adhesives to accelerate production processes in the electronics assembly industry.

Dow has expanded its portfolio with new silicone-based adhesives optimized for use in flexible and foldable electronics.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Anthracene Market — Forecast(2024–2030)

Anthracene Market size is forecast to reach US$440.3 million by 2030, after growing at a CAGR of 4.1% during 2024–2030. Anthracene is a three-fused benzene ring solid polycyclic aromatic hydrocarbon (PAH) with the formula C14H10 and is often found in coal tar. Anthracene is extensively utilized in the manufacture of red dye alizarin, insecticides, anti-cancer agents, wood preservatives, organic light-emitting diodes, and more. The rapid growth in the number of cancer patients has increased the demand for anti-cancer agents. With cancer incidence on the rise, there is a consequential surge in the demand for anti-cancer agents, and anthracene plays a pivotal role in this context. Anthracene derivatives are integral components of various pharmaceuticals and therapeutic agents designed to combat cancer. As research and development in oncology intensify, anthracene’s significance as a key building block in anti-cancer drug formulations is amplifying.

The market’s trajectory is intricately linked to advancements in cancer treatment, making anthracene a critical element in the pharmaceutical industry’s ongoing efforts to address the global cancer burden thereby, fueling the anthracene market growth. Another factor assisting the growth of the global anthracene market is the increasing production of coal tar. The anthracene market is benefiting from the escalating production of coal tar, a key source of anthracene. Increased coal tar output meets the rising demand for anthracene, particularly in the pharmaceutical and chemical sectors. Furthermore, the flourishing textile industry is also expected to drive the anthracene market substantially during the forecast period.

Request Sample

Anthracene Market COVID-19 Impact

The COVID-19 outbreak had a significant effect on the agriculture, electronics, textile, and furniture industry. Due to this the demand for anthracene significantly reduced, which affected the overall market growth. According to the Vietnam Textile and Apparel Association (VITAS). Aside from restrictions, the textile industry faced plenty of issues, including production bottlenecks, fluctuating raw material prices, transportation issues, a scarcity of skilled workers, the sale of textile products, and reduced export/import orders. The COVID-19 pandemic caused significant disruptions in the textile industry, including production, exports, and logistics management. The first disruption occurred in production during the first quarter (Q1) of 2020 when China went into lockdown, causing shortages of materials. The second disruption in exports started in Q2 2020 when COVID-19 spread to the export destinations. As a result, these back-to-back disruptions badly affected the textile industry globally, resulting in a downdrift in anthracene market revenue.

Report Coverage

The report: “Anthracene Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the anthracene market.

By Application: Wood Preservatives, Pesticides (Insecticides, Herbicides, and Fungicides), Plasticizers, Drugs (Anti-Cancer Agent, Anti-Psoriatic Agent, and Others), Dyes & Coatings (Conformal Coating, Red Dye Alizarin, and Others), Electronics (Organic Light-Emitting Diodes, Transistors, Photovoltaic, and Others), scintillators, and Others.

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying

Key Takeaways

● Asia-Pacific dominates the Anthracene market, owing to the expanding pharmaceutical, textile, and electronics industries in the region. Increasing per capita income coupled with the increasing population is the major factor that is driving the pharmaceutical, textile, and electronics industries in the region.

● Anthracene is expected to grow into a major market owing to its utility in identifying situations such as radiation leaks. Following the radiation leak in Japan, there has been an increase in demand for proper radiation leak-checking equipment at nuclear reactor sites all over the world. This is expected to boost the market for anthracene, which is used in scintillators as a luminescent material.

For More Details on This Report — Request for Sample

Anthracene Market Segment Analysis — By Application

The dyes & coatings segment held the largest share in the anthracene market in 2023 and is forecasted to grow at a CAGR of 3.8% during 2024–2030, owing to the increasing demand for anthracene to manufacture conformal coating and red dye alizarin. Anthracene is colorless in nature but exhibits a blue fluorescence under ultraviolet light. Thus, it is used in the production of red dye alizarin and coatings. Anthracene is commonly used as a UV tracer in conformal coatings applied to printed circuit boards. The anthracene tracer permits UV inspection of the conformal coating. It’s one of the most important feedstocks for anthraquinone production. Vat dyes are a class of water-insoluble dyes that can be easily reduced to a water-soluble, usually colorless leuco form that readily impregnates fibers and textiles. Anthraquinone is a common and important raw material in the production of vat dyes. Their main characteristics are brightness and fastness. And such extensive application of anthracene in the dyes & coatings industry is estimated to fuel the anthracene market growth during the forecast period.

Buy Now

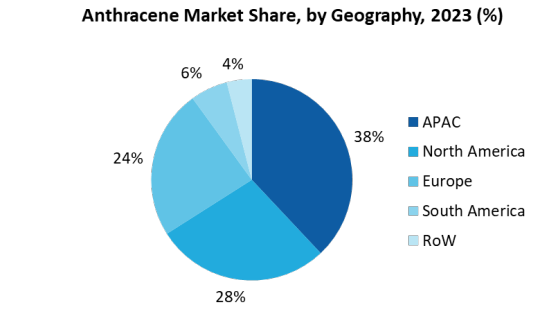

Anthracene Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the anthracene market in 2023 up to 34% and is estimated to grow at a CAGR of 4.6% during 2024–2030, owing to the flourishing textile and printed circuit board industry in the region, which is accelerating the demand for anthracene in the region. India’s textile and apparel market was valued at US$108.5 billion in 2015 and is projected to rise to US$226 billion by 2023, with a compound annual growth rate of 8.7% between 2009 and 2023. The Government of India is strongly encouraging the manufacturing and usage of Printed circuit boards in the country. It has launched many initiatives such as ‘Make in India’, ‘Digital India’, and more. By easing the tax regime and lowering bureaucratic barriers, the government hopes to encourage manufacturers to set up more local plants in the country. This is expected to bring in a significant positive impact on the overall printed circuit board demand. Thus, the increasing demand for textiles and printed circuit boards in the region is set to drive the anthracene industry in Asia-Pacific during the forecast period.

Anthracene Market Drivers

Increasing Prevalence of Cancer Patients

The anthracene-9,10-dione (anthraquinone) derivatives are a particularly valuable class in the development of anticancer drugs. Since the discovery of these chemotypes, medicinal chemists have been drawn to anthracycline antibiotics because of their outstanding antitumor potency. Doxorubicin, mitoxantrone, and more recently epirubicin, idarubicin, and valrubicin are anthraquinone-based drugs that have been successfully used in the treatment of hematological and solid tumors. World Health Organization (WHO) says cancer is one of the leading causes of death worldwide. According to World Health Organisation 2023, An estimated 10 million people died from cancer worldwide, and there were 20 million new instances of the disease. Over the next 20 years, there will be a 60% rise in the cancer burden, placing additional strain on communities, individuals, and health systems. In low- and middle-income nations, the biggest increases in the global burden of cancer cases are expected to occur, with an estimated 30 million more cases worldwide by 2040. Due to this increase in the number of cancer patients the demand for anti-cancer agents will significantly increase, owing to which the Anthracene market will exhibit rapid growth over the forecast period.

Soaring Demand from the Agriculture Industry

Anthracene is extensively used in the agriculture sector as herbicides, insecticides, and fungicides. The world population is gradually increasing. With the population steadily growing, enough crops must be produced each year to provide food to people. And pesticides such as herbicides, insecticides, and fungicides play an important role in providing crops with the nutrients they need to grow and enhance crop yield. Thus, to improve the crop yield within the same area of arable lands and provide crops proper nutrients, pesticides are being extensively utilized during crop production. According to European Commission in March 2023, Italian rice is mostly grown in northern regions of Lombardy. Italy is the world’s only grower of types such as Arborio and Carnaroli that are most suitable for the popular Italian dish risotto. With the increasing crop production, there is an increasing demand for pesticides, which is driving the anthracene market in the agriculture sector.

Anthracene Market Challenges

Various Hazards Associated with Anthracene

If inhaled through contaminated air, anthracene has harmful effects on the body. The Occupational Safety and Health Administration’s (OSHA) Hazardous Substance List includes anthracene. When someone inhales it, their lungs are first and foremost damaged. If a person works at a hazardous waste site where polycyclic aromatic hydrocarbons (PAH) are disposed of, there is a high risk of inhaling anthracene and polycyclic aromatic hydrocarbons (PAH). Similarly, it can enter one’s body through foods and beverages. When a person’s skin comes into contact with creosote, roofing tar, heavy oils, or coal tar, as well as contaminated soil containing PAHs, there is a risk of exposure. Once inside the human body, the polycyclic aromatic hydrocarbon (PAH) can spread and target fat tissues. The kidneys, liver, and fat tissues in the human body may be affected. When people are exposed to it, it can harm their health by irritating their eyes, skin, and respiratory tract. When exposed to the environment, it can also cause fire and explosion. Thus, these hazards associated with anthracene are anticipated to hamper the anthracene market.

Anthracene Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Anthracene market. Anthracene market top companies include:

1. Fisher Scientific

2. Tokyo Chemical Industry Co., Ltd.

3. CHEMOS GmbH & Co. KG

4. Santa Cruz Biotechnology, Inc.

5. Haihang Industry Co., Ltd.

6. Wego Chemical Group

7. Glentham Life Sciences

8. Spectrum Chemical

9. Merck KGaA

10. Henan Daken Chemical Co., Ltd.

0 notes

Text

Global Air Knife Coater Market Assessment and Future Developments Analysis 2024 - 2031

The global air knife coater market is evolving rapidly, driven by advancements in coating technologies and increasing demand for precision coating in various industries. This article explores the key trends, applications, regional dynamics, and future outlook of the air knife coater market.

Key Trends in the Air Knife Coater Market

The global air knife coater market is poised for significant growth, driven by the demand for high-quality coatings and technological advancements. While challenges such as high initial investments and competition from alternative technologies exist

Growing Demand for High-Quality Coatings

The demand for high-quality coatings that enhance product performance and aesthetics is on the rise. Industries such as packaging, automotive, and electronics are increasingly adopting air knife coating technologies to achieve uniform coating applications with minimal material waste.

Technological Innovations

Recent innovations in air knife coater technology have significantly improved efficiency and effectiveness. New designs, such as adjustable air knives and automated systems, allow for better control of coating thickness and consistency, thereby enhancing product quality.

Focus on Sustainability

As industries strive to reduce their environmental impact, the air knife coater market is witnessing a shift towards sustainable coating solutions. Air knife coaters minimize material waste and VOC emissions, making them an attractive option for manufacturers seeking eco-friendly alternatives.

Applications of Air Knife Coaters

Packaging Industry

Air knife coaters are widely used in the packaging industry for applying coatings, adhesives, and inks. Their ability to deliver a precise and uniform coating makes them ideal for various packaging materials, including plastics, paper, and metal.

Automotive Industry

In the automotive sector, air knife coaters are employed for applying protective coatings and paints on vehicle components. These coaters ensure a smooth finish and uniform application, enhancing both the durability and aesthetic appeal of automotive parts.

Electronics Manufacturing

The electronics industry relies on air knife coaters for applying conformal coatings to circuit boards and other electronic components. These coatings protect sensitive parts from moisture, dust, and corrosion, ensuring long-term reliability and performance.

Regional Analysis

North America

North America is a significant player in the global air knife coater market, driven by advancements in manufacturing technologies and a strong focus on innovation. The region’s robust automotive and electronics sectors further bolster the demand for efficient coating solutions.

Europe

Europe is witnessing substantial growth in the air knife coater market, largely due to stringent environmental regulations and a focus on sustainable manufacturing practices. Countries such as Germany and the UK are leading the way in adopting advanced coating technologies across various industries.

Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in the air knife coater market, fueled by expanding manufacturing capabilities and increasing investments in technology. Countries like China, Japan, and India are at the forefront, driven by the booming automotive and electronics industries.

Challenges Facing the Market

High Initial Investment

One of the primary challenges facing the air knife coater market is the high initial investment required for advanced coating systems. Smaller manufacturers may find it difficult to justify these costs, which could hinder widespread adoption.

Competition from Alternative Coating Technologies

The air knife coater market faces competition from alternative coating technologies such as roller coaters and spray coaters. Manufacturers must continuously innovate to differentiate their products and demonstrate the advantages of air knife coating systems.

Future Outlook

The future of the global air knife coater market appears promising, driven by ongoing technological advancements and increasing applications across various sectors.

Innovations in Coating Materials

Future developments in coating materials will likely enhance the performance of air knife coaters. The emergence of advanced polymers and eco-friendly coatings will open new avenues for application, catering to the growing demand for sustainable solutions.

Expansion of Automation

The integration of automation in air knife coating systems is expected to grow, improving efficiency and reducing labor costs. Automated air knife coaters can offer greater precision and consistency, making them an attractive option for manufacturers.

Conclusion

The global air knife coater market is poised for significant growth, driven by the demand for high-quality coatings and technological advancements. While challenges such as high initial investments and competition from alternative technologies exist, the overall outlook remains positive. As industries continue to seek sustainable and efficient coating solutions, air knife coaters will play a crucial role in shaping the future of manufacturing processes across various sectors.

#Global Air Knife Coater Market Size#Global Air Knife Coater Market Trend#Global Air Knife Coater Market Growth

0 notes

Text

Electronic Protection Device Coatings Market Growing Technology Opportunities and Future Business Trends to 2032

Allied Market Research, titled, “Electronic Protection Device Coatings Market," The electronic protection device coatings market size was valued at $1.1 billion in 2022, and is estimated to reach $1.9 billion by 2032, growing at a CAGR of 5.6% from 2023 to 2032.

Electronic protection device coatings refer to specialized coatings or films applied to electronic devices or components to offer protection against various environmental and operational factors. These coatings are designed to enhance the durability, reliability, and performance of electronic devices by safeguarding them from moisture, dust, chemicals, heat, electrical interference, and different potential hazards. These coatings are thin and transparent films that conform to the structure of the device. They protect against moisture, dust, chemicals, and corrosion. Conformal coatings are commonly used in printed circuit boards (PCBs), connectors, and other electronic components.

The rising demand for electronic devices such as smartphones, tablets, laptops, and wearable devices has significantly boosted the electronic protection device coatings market growth. These coatings are used to protect electronic components from environmental factors like moisture, dust, chemicals, and corrosion, thereby extending the lifespan and reliability of the devices. Moisture and dirt can cause short circuits and different electrical malfunctions, whilst chemicals and corrosion can degrade the performance and lifespan of electronic components. By applying protective coatings, producers can enhance the durability and reliability of their devices, ensuring that they continue to function optimally even in challenging environments. The increasing demand for electronic devices, along with the need for better device durability and reliability, has been a key driver of the electronic protection device coatings market.

The electronic protection device coatings market lacks standardized testing methods and performance criteria. The absence of widely accepted standards can create uncertainty and make it difficult for customers to evaluate and compare different coating options. This can slow down the adoption of coatings and hinder electronic protection device coatings market growth. Without standardized testing methods and performance criteria, it becomes difficult to assess and compare the effectiveness of different coatings. Customers may lack confidence in the claims made by coating manufacturers, leading to hesitation in adopting new products. The absence of standardized quality control measures may result in variations in coating performance across different manufacturers. Customers may find it challenging to determine the reliability and consistency of coatings, making it harder for them to make informed decisions.

Owing to the increasing reliance on electronic devices in various sectors such as consumer electronics, automotive, aerospace, and healthcare, there is a rising demand for effective protection of these devices. Electronic protection device coatings play a vital role in safeguarding electronic components from environmental factors such as moisture, chemicals, UV radiation, and mechanical stress. The consumer electronics sector, including smartphones, tablets, laptops, and gaming consoles, continues to experience robust growth. These devices are exposed to various external factors that can potentially damage their electronic components. Electronic protection device coatings offer enhanced protection against moisture, dust, scratches, and other environmental factors, thereby extending the lifespan and reliability of these devices. The expanding market for electronic devices presents a significant opportunity for the growth of the electronic protection device coatings market.

The global electronic protection device coatings market share is segmented based on chemistry, application, and region. By chemistry, it is classified into parylene, urethane, acrylic, silicone, and epoxy. By application, it is classified into aerospace & defense, automotive, power & renewable energy, consumer electronics, industrial, medical, and others. By region, the electronic protection device coatings market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The key players profiled in the electronic protection device coatings market analysis report include 3M, Henkel Corporation, P2i Ltd., ENDURA, Specialty Coating Systems Inc., Electronic Coating Technologies, MATERIAL SCIENCES CORPORATION, Aculon, ABB, Electrolube.

The report offers a comprehensive analysis of the global electronic protection device coatings market trends by thoroughly studying different aspects of the market including major segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working towards the growth of the electronic protection device coatingsmarket. The report also sheds light on the present scenario and upcoming trends & developments that are contributing to the growth of the electronic protection device coatings market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the electronic protection device coatings market.

Impact of COVID-19 on the Global Electronic Protection Device Coatings Industry

The pandemic disrupted global supply chains, including the availability of raw materials and transportation. This led to delays in production and potentially impacted the availability of electronic protection device coatings.

The economic slowdown caused by the pandemic affected various industries, including consumer electronics, automotive, and aerospace, which are major consumers of electronic protection device coatings. Reduced consumer spending and business investments in these sectors resulted in lower demand for coatings.

With the increased adoption of remote work and online learning, there has been a surge in the demand for electronic devices such as laptops, tablets, and smartphones. This increase in demand for electronic devices led to rise in the need for electronic protection coatings to safeguard these devices from environmental factors.

Key Findings of the Study

Based on chemistry, the acrylic sub-segment emerged as the global leader in 2022 and is expected to grow with the highest CAGR during the forecast period.

Based on application, the automotive sub-segment emerged as the global leader in 2022 and is predicted to have the fastest growth rate.

Based on region, the Asia-Pacific electronic protection device coatings market registered the highest market share in 2022 and is projected to show the fastest growth during the forecast period.

0 notes

Text

Conformal Coatings Equipment Market Size, Analyzing Forecasted Outlook and Growth for 2024-2030

Our Conformal Coatings Equipment Market report is a comprehensive study of the current state of the industry. It provides a thorough overview of the market landscape, covering factors such as market size, competitive landscape, key market trends, and opportunities for future growth. It also pinpoints the key players in the market, their strategies, and offerings.

The report offers an in-depth look into the current and future trends in Conformal Coatings Equipment, making it an invaluable resource for businesses involved in the sector. This data will help companies make informed decisions on research and development, product design, and marketing strategies. It also provides insights into Conformal Coatings Equipment’ cost structure, raw material sources, and production processes. Additionally, it offers an understanding of the regulations and policies that are likely to shape the future of the industry. In essence, our report can help you stay ahead of the curve and better capitalize on industry trends.

The research report encompasses the prevailing trends embraced by major manufacturers in the Conformal Coatings Equipment Market, such as the adoption of innovative technologies, government investments in research and development, and a growing emphasis on sustainability. Moreover, our research team has furnished essential data to illuminate the manufacturer's role within the regional and global markets. The research study includes profiles of leading companies operating in the Conformal Coatings Equipment Market: The report is structured into chapters, with an introductory executive summary providing historical and estimated global market figures. This section also highlights the segments and reasons behind their progression or decline during the forecast period. Our insightful Conformal Coatings Equipment Market report incorporates Porter's five forces analysis and SWOT analysis to decipher the factors influencing consumer and supplier behavior.

Segmenting the Conformal Coatings Equipment Market by application, type, service, technology, and region, each chapter offers an in-depth exploration of market nuances. This segment-based analysis provides readers with a closer look at market opportunities and threats while considering the political dynamics that may impact the market. Additionally, the report scrutinizes evolving regulatory scenarios to make precise investment projections, assesses the risks for new entrants, and gauges the intensity of competitive rivalry.

Conformal Coatings Equipment Market by Type: Automatic、Semi-automatic Conformal Coatings Equipment Market by Application: Automotive Board (ECU)、Power Conditioner Control Board、Home Appliances、Industrial、Electronic Board for Ships/Aviation/MIL Standards Key Profits for Industry Members and Stakeholders:

The report includes a plethora of information such as market dynamics scenario and opportunities during the forecast period.

Which regulatory trends at corporate-level, business-level, and functional-level strategies.

Which are the End-User technologies being used to capture new revenue streams in the near future.

The competitive landscape comprises share of key players, new developments, and strategies in the last three years.

One can increase a thorough grasp of market dynamics by looking at prices as well as the actions of producers and users.

Comprehensive companies offering products, relevant financial information, recent developments, SWOT analysis, and strategies by these players.

The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Conformal Coatings Equipment product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Conformal Coatings Equipment, with price, sales, revenue and global market share of Conformal Coatings Equipment from 2019 to 2024. Chapter 3, the Conformal Coatings Equipment competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Conformal Coatings Equipment breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Conformal Coatings Equipment market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Conformal Coatings Equipment. Chapter 14 and 15, to describe Conformal Coatings Equipment sales channel, distributors, customers, research findings and conclusion. Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Global Conformal Coating Market Forecast to 2028: Key Trends in Acrylic, Silicone, and Epoxy Coatings

The Conformal coatings market size is estimated to be USD 1.4 billion in 2023, and it is projected to reach USD 1.8 billion by 2028 at a CAGR of 5.3%. Conformal coatings refer to thin layers of protective material that are applied to electronic components and circuit boards. The primary purpose of these coatings is to shield these components from a range of environmental factors, including…

0 notes

Text

Conformal Coatings Market Research Report 2024: In-depth Industry Analysis and Business Key Insights

The Conformal Coatings Market is Valued at USD 1.61 billion by 2024 and projected to reach USD 2.43 billion by 2032, growing at a CAGR of 4.7% During the Forecast period of 2024–2032.

Introduction: Conformal coatings are protective chemical barriers applied to electronic circuits and components to safeguard them against environmental factors such as moisture, dust, chemicals, and temperature extremes. These coatings ensure the longevity and reliability of electronic devices, making them indispensable in industries ranging from automotive and aerospace to consumer electronics and medical devices.

Download a Free Sample Copy of the Report: https://www.marketdigits.com/request/sample/3735

Major Vendors: ↬ Henkel AG & Co. KGaA, ↬ Chase Corporation, ↬ H.B. Fuller Company, ↬ Dymax Corporation, ↬ Shin-Etsu Chemical Co., Ltd., ↬ Illinois Tool Works, Inc. (ITW), ↬ MG Chemicals, ↬ Kisco Conformal Coatings, ↬ Electrolube (HK Wentworth Ltd), ↬ ACL Staticide, Inc., ↬ Europlasma NV, ↬ Cytec Industries Inc. (Solvay SA), ↬ Gen3 Systems Limited, PVA, ↬ ALTANA, ↬ SCH Technologies, ↬ Para Tech Coating, Inc., ↬ Dow Corning ↬ and Others.

Why Should Access to This Report? ➽ In-depth Market Analysis: Detailed insights into market size, growth drivers, challenges, and opportunities. ➽ Strategic Insights: Guidance on market trends, technological advancements, and regulatory frameworks. ➽ Competitive Landscape: Profiling of key players and analysis of their strategies. ➽ Future Forecasts: Market projections and trend analysis to help plan long-term strategies.

Inquire Before Buying at - https://www.marketdigits.com/request/enquiry-before-buying/3735

Recent Developments: ✦ In June 2023, A distribution agreement was established between Henkel and Labori International. As per the agreement's terms, Henkel will retain responsibility for overseeing the brand's business operations during a transitional phase. ✦ In July 2023, Chase Corporation confirmed its engagement in a definitive agreement for acquisition by an affiliate of KKR, a prominent global investment firm.

Research Methodology: ➢ Primary Research: Involves interviews with industry experts, key opinion leaders, and stakeholders. ➢ Secondary Research: Includes an extensive review of industry reports, company publications, and relevant documents. ➢ Data Analysis: Utilizes advanced analytical tools to interpret data and derive actionable insights. ➢ Validation: Cross-verification of data through multiple sources to ensure accuracy and reliability.

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/3735

Conclusion: The Conformal Coatings Market is poised for significant growth, driven by increasing demand for electronic devices and advancements in coating technologies. This report provides essential insights and strategic recommendations to help stakeholders navigate the market landscape and make informed decisions. Accessing this report will equip you with the knowledge needed to leverage market opportunities and achieve sustainable growth.

0 notes

Text

Sustainable Practices in Coating Operations - A Comprehensive Overview

As the global landscape increasingly shifts toward sustainability, industries across the board are reevaluating their processes to meet environmentally-friendly standards. In the domain of electronics manufacturing, coating operations are pivotal for product longevity and functionality. Particularly, the utilization of various sophisticated machines such as conformal coating PCB coating machine spray coating machines, and SMT conformal coating machines is essential. This article delves into how adopting sustainable practices in these operations not only benefits the environment but also enhances efficiency and compliance with international regulations.

Embracing Eco-Friendly Technologies

The introduction of the conformal coating machine marked a significant advancement in electronic production. This machine meticulously applies a protective chemical coating to printed circuit boards (PCBs), safeguarding them against moisture, dust, and thermal variations. Enhancing this process, the selective conformal coating machine allows for precise application on specified areas, significantly reducing waste and volatile organic compound (VOC) emissions.

Further refining coating precision, PCB glue coating machines and PCB conformal coating machines cater specifically to intricate designs and high-density component populations. They ensure optimal coverage without excess, adhering strictly to the required areas, thus minimizing material usage and spillage.

Integrated Automation in Coating Lines

The development of automated conformal coating lines epitomizes efficiency in modern production setups. By integrating systems such as the Coating spraying gluing machine for PCB LED, manufacturers can achieve a uniform high-quality coat across large volumes of boards while dramatically cutting down on manual labor and associated errors. The reduced need for touch-ups and rework conserves resources and leads to a substantial decline in raw material consumption.

For surface-mount technology (SMT), specific machines like the SMT coating machine and SMT conformal coating machine have been tailored to address the unique needs of SMT components and assemblies. These specialized devices ensure that environmentally sensitive applications can be completed with precision, adhering to stringent environmental standards.

Reducing Environmental Footprint

Adopting machines like the PCB spray coating machine also plays a crucial role in reducing the ecological footprint of manufacturing operations. By implementing targeted spraying technologies, these machines lower overspray and solvent use, leading directly to fewer emissions. This not only helps companies comply with stricter environmental regulations but also fosters goodwill among environmentally conscious consumers.

Moreover, advanced filtration systems can be integrated into these machines to capture contaminants before they enter the atmosphere, adding an additional layer of environmental protection. Enhanced maintenance protocols contribute further by extending machine life spans and optimizing their performance, thereby reducing waste and the need for frequent replacements.

The pivot toward sustainable practices in coating operations is not merely a response to regulatory demands but a strategic move towards greater economic efficiency and market positioning. As technology continues to evolve, the potential for fully sustainable coating operations becomes increasingly tangible. With continued innovation and commitment, the coatings industry can expect to see significant advancements in both environmental stewardship and operational prowess.

By aligning with green initiatives through sophisticated machinery and processes, companies not only contribute to the health of our planet but also position themselves as leaders in a competitive industry where sustainability has become a benchmark of success and integrity.

1 note

·

View note

Text

Fasteners Manufacturer in Nigeria - Sachiya Steel International

Nigeria’s dynamic industrial landscape demands high-quality fasteners across various fields such as construction, automotive, and infrastructure development. Fasteners play a crucial role in mechanically joining or attaching two objects together. Different types of fasteners such as bolts, screws, nuts, washers, and rivets are specifically tailored for specific uses, ensuring reliability and durability in various applications.

Sachiya Steel International Private Limited: Leaders in Fastener Manufacturing

Sachiya Steel International Private Limited, based in India, has emerged as one of the premier producers and exporters of fasteners worldwide. Through a commitment to quality, innovation, and customer satisfaction, Sachiya serves global markets, including Nigeria, with products that adhere to international standards and exceed customer expectations.

Types of Fasteners Manufactured by Sachiya Steel International Private Limited

Bolts:

Hex Bolts

Carriage Bolts

Eye Bolts

U-Bolts

Screws:

Machine Screws

Wood Screws

Self-tapping Screws

Nuts:

Hex Nuts

Lock Nuts

Wing Nuts

Washers:

Flat Washers

Spring Washers

Belleville Washers

Rivets:

Solid Rivets

Blind Rivets

Materials Used

Sachiya Steel International Private Limited utilizes a variety of materials in manufacturing fasteners, carefully selected based on their properties and applications:

Stainless Steel: Known for its corrosion resistance and durability, making it suitable for marine and industrial use.

Carbon Steel: Offers higher strength and hardness, ideal for structural applications and machinery purposes.

Alloy Steel: Provides superior mechanical properties such as tensile strength and toughness, suitable for critical applications.

Brass: Features excellent electrical conductivity and aesthetic appeal, often used in electrical or decorative applications.

Aluminum: Lightweight with superior corrosion resistance, perfect for aerospace and automotive applications.

Chemical and Mechanical Properties

For each material utilized by Sachiya Steel International Private Limited, stringent quality checks are conducted to ensure compliance with international standards. Some key properties include:

Raw Material Procurement: Sourcing high-quality raw materials from trusted suppliers worldwide.

Production: Utilizing state-of-the-art machinery and techniques for cutting, forming, and shaping fasteners to precise specifications.

Heat Treatment: Applying controlled heat treatment processes such as annealing, tempering, or quenching to enhance material properties like hardness and toughness.

Surface Treatment: Applying coatings or platings such as zinc plating, galvanizing, or nickel coating to improve corrosion resistance and aesthetic appeal.

Fasteners manufactured by Sachiya Steel International Private Limited find extensive applications across various industries:

Construction: Used in structural steel assemblies, bridges, and infrastructure projects.

Automotive: Essential for vehicle manufacturing, assembly, and aftermarket services.

Oil and Gas: Utilized in offshore platforms, pipelines, and refineries for reliability and safety.

Electronics: Critical for consumer electronics, telecommunications, and IT hardware.

Aerospace: Essential for aircraft assembly and maintenance, adhering to stringent safety and performance standards.

As Nigeria continues to expand its industrial capabilities, the need for reliable and high-performance fasteners grows. Sachiya Steel International Private Limited stands ready to meet this demand by manufacturing fasteners that conform to international standards, providing robust solutions across a range of applications within Nigeria’s industries.

Sachiya Steel International Private Limited provides world-class fastener solutions distinguished by quality, reliability, and technical expertise. For more information about their products and services, please visit their website or contact their sales team today.

Read More: Fasteners Manufacturer in Nigeria

0 notes

Text

Conformal Coatings Market for PCBs to Reach USD 5.3 billion, Growing 5.5% CAGR

The global conformal coatings market for PCBs is estimated to flourish at a CAGR of 5.5% from 2023 to 2031. Transparency Market Research projects that the overall sales revenue conformal coatings market for PCBs is estimated to reach US$ 5.3 billion by the end of 2031.

The increasing adoption of PCBs in medical devices necessitates conformal coatings that meet stringent regulatory requirements for biocompatibility, sterilization, and long-term reliability in harsh medical environments. The proliferation of renewable energy technologies such as solar panels and wind turbines requires PCBs with durable conformal coatings to withstand outdoor exposure to UV radiation, moisture, and temperature fluctuations.

The expansion of telecommunications infrastructure, including 5G networks and satellite communication systems, drives demand for high-performance PCBs with conformal coatings optimized for reliability and longevity in demanding outdoor environments. The growing interest in space exploration and satellite technology necessitates PCBs equipped with conformal coatings capable of withstanding extreme temperature variations, vacuum conditions, and radiation exposure in space environments.

Download Sample Copy of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=44288

Market Segmentation

By Service Type: Segmented into coating application services, consulting, and customization services catering to diverse industry needs.

By Sourcing Type: Includes acrylics, silicones, urethanes, perylene, and other material variants, reflecting different performance characteristics and application requirements.

By Application: Covers PCB protection, automotive electronics, aerospace components, industrial equipment, medical devices, and consumer electronics.

By Industry Vertical: Encompasses electronics manufacturing, automotive, aerospace & defense, healthcare, industrial machinery, and telecommunications.

By Region: Analysis based on geographical regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, considering regional demand dynamics and regulatory frameworks.

Regional Analysis

North America: Technological advancements in electronics, automotive innovations, and aerospace developments drive significant demand for conformal coatings in the region.

Europe: Strict regulatory standards for electronic devices and automotive components boost adoption of high-performance conformal coatings.

Asia Pacific: Dominant region in electronics manufacturing, automotive production, and consumer electronics, fueling market growth for conformal coatings.

Latin America, Middle East & Africa: Emerging markets witnessing increased industrialization and infrastructure development contribute to market opportunities for conformal coatings.

Market Drivers and Challenges

Drivers:

Electronic Device Miniaturization: Shrinking electronic components require advanced protection against environmental factors, driving demand for conformal coatings.

Automotive and Aerospace Innovations: Complex electronic systems in vehicles and aircraft demand reliable protection solutions, boosting coating market growth.