#Global ESD Foam

Explore tagged Tumblr posts

Text

Conductive Foam Market Expanding Applications Across Multiple Industries

The conductive foam market has seen remarkable growth due to the increasing demand for ESD (Electrostatic Discharge) protection in various sectors, especially in electronics, automotive, telecommunications, and healthcare industries. Conductive foam, a material with both insulating and conductive properties, is primarily used to safeguard sensitive electronic components from electrostatic damage, offering superior cushioning and conductivity. With technological advancements and expanding end-user applications, the demand for conductive foam is expected to continue to rise, making it a critical component in several industries.

1. Understanding Conductive Foam

Conductive foam is made from a polymer matrix that is infused with conductive materials such as carbon, graphite, or metals. This unique material combines the characteristics of both foam (for cushioning and protection) and conductivity (to dissipate electrostatic charge). The primary function of conductive foam is to protect electrostatic discharge-sensitive devices such as semiconductors, circuit boards, and display screens from damage during manufacturing, storage, and transport.

There are two primary types of conductive foams: electrically conductive foam and static dissipative foam. The former is primarily used in industries where high conductivity is necessary, while the latter is designed to reduce and control static electricity, offering a lower level of conductivity suitable for more sensitive electronic components.

2. Key Drivers of Demand

Several key factors are driving the demand for conductive foam across multiple industries:

Rising Electronics Production: The global electronics market has been expanding rapidly, with consumer electronics, including smartphones, laptops, tablets, and wearables, leading the growth. These products are increasingly incorporating miniaturized components that are highly sensitive to electrostatic discharge, driving the need for protective materials like conductive foam. With a steady rise in the number of electronic devices being manufactured, the demand for conductive foam remains strong.

Growing Semiconductor Industry: Semiconductors are fundamental components of modern electronics. As the semiconductor industry grows, with innovations in processing power, memory, and connectivity, the demand for effective ESD protection is becoming more crucial. Conductive foam is increasingly used in semiconductor packaging and during transportation to prevent electrostatic discharge that could potentially damage or destroy microchips.

Automotive Electronics: Modern vehicles are equipped with a variety of electronic systems, from infotainment units to advanced driver assistance systems (ADAS) and electric vehicle (EV) technologies. As automotive electronics continue to advance, the need for protective solutions like conductive foam has increased. This is especially true in the case of electric vehicles, where battery management systems, electric circuits, and sensors must be protected from ESD during production and assembly.

Telecommunications and 5G Technology: The global rollout of 5G networks and increasing demand for telecom equipment has created new opportunities for conductive foam. Telecom equipment, including base stations, routers, and other communication devices, often contains highly sensitive electronic components that require protection from electrostatic discharge. With the rapid expansion of 5G infrastructure, the demand for conductive foam for packaging, transport, and protection applications is also increasing.

Healthcare Devices: The healthcare industry, especially in the field of medical devices and diagnostics, relies heavily on electronic systems that need to function without disruption. Conductive foam is used to protect electronic components in medical devices, such as MRI machines, ultrasound equipment, and patient monitoring systems. As the medical industry continues to innovate and incorporate advanced technologies, the need for conductive foam solutions is expected to grow.

3. Emerging Applications and Demand Growth

While traditional uses of conductive foam in ESD protection continue to dominate the market, new applications are emerging that further bolster demand. The integration of conductive foam with 3D printing is one such example. 3D printed electronics and conductive inks are growing rapidly, and conductive foam plays an important role in the production, packaging, and protection of these components during and after manufacturing.

Additionally, the sustainability trend is pushing the demand for more eco-friendly conductive foams. Manufacturers are working towards developing conductive foams made from biodegradable or recyclable materials to meet the growing demand for green products across industries.

4. Regional Demand for Conductive Foam

North America: North America is one of the largest markets for conductive foam, primarily driven by the strong electronics, automotive, and telecommunications industries in the United States and Canada. The region has a well-established semiconductor manufacturing industry, which is a major contributor to the demand for conductive foam. Additionally, advancements in automotive electronics and electric vehicles continue to drive market growth in North America.

Asia-Pacific: The Asia-Pacific region is experiencing the highest growth in the conductive foam market. Countries like China, Japan, South Korea, and India are major players in the electronics and semiconductor industries, making the region a dominant market for conductive foam. China, in particular, is both a large producer and consumer of electronics, making it a key market for ESD protection solutions like conductive foam. Moreover, the rise of electric vehicles and the push for 5G infrastructure in Asia-Pacific is further contributing to the demand.

Europe: Europe has seen steady growth in the conductive foam market, particularly driven by the automotive and telecommunications sectors. Countries like Germany and the United Kingdom, with strong automotive manufacturing industries, are significant consumers of conductive foam for use in vehicle electronics. Furthermore, Europe’s emphasis on sustainable development and green technologies is pushing manufacturers to focus on producing eco-friendly conductive foam.

5. Challenges in the Conductive Foam Market

Despite the positive growth trends, the conductive foam market faces several challenges:

High Production Costs: The production of high-quality conductive foam materials can be expensive, especially when using advanced conductive materials or striving for eco-friendly alternatives. The cost factor can make it difficult for manufacturers, especially in price-sensitive industries, to adopt conductive foam on a wide scale.

Competition from Alternative Materials: Conductive films, bags, and mats are gaining traction as alternative ESD protection solutions. These materials often offer cost advantages over conductive foam and can be more versatile, especially for packaging and transportation.

Material Innovations and Sustainability: As sustainability becomes a major focus across industries, there is an increasing push for more eco-friendly conductive foam solutions. Developing recyclable or biodegradable conductive foam without compromising its performance remains a challenge for manufacturers.

6. Market Outlook

The future of the conductive foam market looks promising, with strong growth expected due to the increasing demand from the electronics, automotive, telecommunications, and healthcare sectors. Innovations in material science, such as the development of eco-friendly conductive foam, as well as the increasing adoption of conductive foam in new applications, will likely drive further demand. Additionally, the ongoing growth of industries like electric vehicles, semiconductors, and telecommunications infrastructure presents lucrative opportunities for market expansion.

Conclusion

In conclusion, the demand for conductive foam is expected to continue expanding across various industries, driven by the need for effective ESD protection and the growing reliance on electronics and advanced technologies. As manufacturers address challenges such as cost and sustainability, conductive foam is poised to remain a crucial component in ensuring the protection and functionality of sensitive electronic components.

0 notes

Text

Electrostatic Discharge Packaging Market: Trends, Growth Drivers, and Future Outlook

Electrostatic Discharge (ESD) packaging is essential for safeguarding electronic components from the detrimental effects of static electricity during storage and transportation. As the electronics industry continues to expand, the demand for effective ESD packaging solutions has surged, prompting significant growth and innovation within this market.

Market Overview

The global ESD packaging market has demonstrated robust growth in recent years. In 2023, the market was valued at approximately USD 0.50 billion and is projected to reach USD 0.92 billion by 2030, exhibiting a compound annual growth rate (CAGR) of 8.00% during the forecast period.

Get Sample PDF

Key Growth Drivers

Expansion of the Electronics Industry: The proliferation of electronic devices, including smartphones, computers, and wearable technology, has heightened the need for reliable ESD packaging to protect sensitive components.

Stringent Regulatory Standards: Governments and industry bodies have implemented strict regulations to ensure the safe handling and transportation of electronic components, necessitating the use of ESD-safe packaging materials.

Technological Advancements: Continuous innovation in packaging materials and technologies has led to the development of more effective and cost-efficient ESD protection solutions.

Market Segmentation

The ESD packaging market can be segmented based on product type, material type, end-use industry, and region.

By Product Type:

Bags and Pouches: These accounted for a dominant market share of around 40% in 2022, owing to their versatility and widespread use in protecting various electronic components.

Trays and Containers: Utilized for the safe storage and transport of larger or more delicate components.

Foams: Employed to cushion and protect components from physical shocks in addition to ESD.

By Material Type:

Conductive Plastics: Held a significant market value of USD 0.6 billion in 2022, favored for their ability to dissipate static charges effectively.

Metals: Used in applications requiring robust protection and grounding.

Static Dissipative Plastics: Preferred for their balance between conductivity and insulation.

By End-Use Industry:

Electronics and Semiconductors: Dominated the market in 2022, reflecting the sector's extensive need for ESD protection.

Automotive: With the integration of advanced electronics in vehicles, the automotive industry has become a significant consumer of ESD packaging.

Aerospace and Defense: Requires stringent ESD protection for sensitive equipment and components.

Regional Analysis

North America: A leading market due to the presence of major electronics manufacturers and a strong emphasis on regulatory compliance.

Asia-Pacific: Anticipated to experience substantial growth, driven by the rapid expansion of electronics manufacturing hubs in countries like China, Japan, and South Korea.

Europe: Maintains a significant market share, supported by a robust automotive industry and increasing adoption of advanced electronic systems.

Competitive Landscape

The ESD packaging market is characterized by the presence of several key players striving to enhance their market position through product innovation, mergers, and acquisitions. Notable companies include:

Teknis: Specializes in providing a comprehensive range of ESD packaging solutions tailored to various industry needs.

Summit Packaging Solutions: Focuses on innovative packaging designs that offer superior ESD protection.

Desco Industries: Offers a wide array of ESD control products, including packaging materials designed to safeguard sensitive electronics.

Challenges and Opportunities

While the ESD packaging market presents significant growth opportunities, it also faces challenges such as:

Environmental Concerns: The use of non-biodegradable materials in ESD packaging has raised environmental issues, prompting a shift towards sustainable and eco-friendly alternatives.

Cost Constraints: High-performance ESD packaging materials can be expensive, posing a challenge for cost-sensitive markets.

Addressing these challenges through the development of sustainable materials and cost-effective solutions is essential for market players to maintain a competitive edge.

Future Outlook

The ESD packaging market is poised for continued growth, driven by the escalating demand for electronic devices and the increasing complexity of electronic components requiring advanced protection. Embracing sustainable practices and investing in research and development to innovate cost-effective solutions will be pivotal for companies aiming to capitalize on emerging opportunities in this dynamic market.

Conclusion

In conclusion, the Electrostatic Discharge Packaging market is set to experience significant growth, propelled by advancements in the electronics industry and heightened awareness of the importance of ESD protection. By understanding market dynamics, embracing innovation, and addressing environmental concerns, stakeholders can effectively navigate the challenges and opportunities within this evolving landscape.

0 notes

Text

Electrostatic Discharge Packaging Market: Protecting Sensitive Electronics

In today’s high-tech world, where electronics drive the economy, Electrostatic Discharge (ESD) packaging has become an essential element in ensuring the reliability and safety of electronic components. ESD occurs when there is a sudden flow of electricity between two objects with different electric potentials, often leading to damage in sensitive electronic products. The Electrostatic Discharge Packaging Market has emerged as a vital industry to protect components from these electrical surges. ESD packaging materials, such as bags, containers, and tapes, are specifically designed to mitigate this risk, keeping sensitive devices safe during storage, transportation, and handling.

Market Overview and Growth Drivers

The growth of the Electrostatic Discharge Packaging Market is closely linked to the expansion of the electronics industry, which includes the production of semiconductors, circuit boards, and consumer electronics. The growing adoption of electronic devices across various industries, such as automotive, telecommunications, healthcare, and aerospace, has resulted in a heightened demand for ESD protective materials. This trend is driving the market, as manufacturers increasingly rely on ESD packaging solutions to protect their products from potential damage during the production and logistics process.

The rapid rise in demand for consumer electronics such as smartphones, laptops, and wearables, along with advancements in the semiconductor industry, is a key driver behind the growth of the market. The global semiconductor shortage in recent years has highlighted the importance of safeguarding delicate microchips and components from electrostatic discharge, further propelling the demand for effective ESD packaging solutions.

Types of ESD Packaging Materials

The market is segmented based on the types of ESD packaging materials used. These materials vary in terms of their protective capabilities and applications. The primary types of ESD packaging include:

ESD Bags: These are the most commonly used form of ESD protection. Available in conductive and static shielding versions, they are used for packaging components like semiconductors and circuit boards.

ESD Containers: These hard containers are used for bulk handling of electronic components and provide additional protection against physical damage while ensuring ESD safety.

ESD Foam: This material is used for cushioning sensitive components, offering both physical protection and ESD protection during transit.

ESD Tapes and Labels: These are used for labeling and sealing ESD-safe packages, offering easy identification and further ensuring compliance with safety standards.

Key Trends in the ESD Packaging Market

Increasing Adoption of Smart Electronics: As industries evolve, the demand for smart devices, such as IoT devices, wearables, and automotive electronics, is increasing. These devices contain delicate electronic components that are highly susceptible to ESD, thus increasing the demand for high-quality ESD packaging solutions.

Sustainability Efforts: As businesses and consumers alike move toward more sustainable practices, the demand for eco-friendly ESD packaging materials is growing. Companies are developing biodegradable and recyclable alternatives to traditional packaging materials, addressing environmental concerns while maintaining the required protective features.

Automation and Robotics in Packaging: With the rise of automated manufacturing and logistics systems, packaging solutions that integrate seamlessly into these automated workflows are becoming more common. ESD packaging solutions are now being designed to be compatible with robotic handling systems, improving efficiency and reducing human error in handling sensitive components.

Regional Insights

North America and Europe are leading the global Electrostatic Discharge Packaging Market due to their well-established electronics industries, particularly in the semiconductor and consumer electronics sectors. The Asia Pacific region is expected to experience the highest growth, driven by the growing electronics manufacturing sector in countries such as China, Japan, and South Korea. The increasing adoption of ESD packaging solutions in emerging economies like India and Brazil is also contributing to the market’s growth.

Challenges in the ESD Packaging Market

Despite the growing demand, there are some challenges facing the Electrostatic Discharge Packaging Market. One of the primary challenges is the high cost associated with advanced ESD packaging solutions. Moreover, the complexity of maintaining and ensuring consistent quality control in ESD protection across multiple sectors remains a challenge for manufacturers.

Conclusion

The Electrostatic Discharge Packaging Market is poised for substantial growth as the demand for electronics continues to rise globally. Manufacturers are increasingly turning to advanced ESD packaging solutions to safeguard sensitive electronic components and improve product reliability. As technological advancements continue and consumer demand for smart devices escalates, the market for ESD packaging will remain critical to the success of the electronics industry.

0 notes

Text

Unshakeable Growth: Why the Foam Packaging Market is Here to Stay

The Foam Packaging Market report is the most important research for who looks for all information about the market. The report covers all information about the global and regional markets, including historical and future trends for market dominance, size, trades, supply, competitors, and prices, as well as key vendor information across the globe. Forecast market information, SWOT analysis, Foam Packaging market scenario, and feasibility study are important aspects in this report.

Get a sample copy of this report: https://wemarketresearch.com/sample-request/foam-packaging-market/1315

Companies Covered: Foam Packaging Market:

JSP Corporation

UFP Technologies Inc.

Synbra Holding bv

UFP Technologies

Armacell LLC

Tosoh Corporation

ACH Foam Technologies

FoamCraft Packaging Inc

Hanwha Corporation

Plastifoam Company

Marko Foam Products Inc.

TotalEnergies

NCFI Polyurethanes

Huebach Corporation

Wasatch Container

Dongshing Industry Inc.

Zotefoams Plc.

Borealis Arkema

Kaneka Corporation

Recticel

Sealed Air Corporation

BASF SE

Synthos SA

Growth Factors:

Since polyethylene foam has excellent protecting and vibration resistant qualities, it is a plastic engineering material that is frequently used to package fragile items. The global packaging foam market is driven by rising production, increased globalization efforts, and new business prospects. Polypropylene foam is becoming more and more important because of the transportation industry's growing need for lightweight products.

Throughout the projection period, the growing eCommerce industry will fuel the need for packaging foam, resulting in an increase in shipments abroad. Foam packaging is getting more and more needed since numerous industries counting electronics, consumer goods, and pharmaceuticals—are using more efficient packaging.

These companies have the potential to drive market growth through various strategies. They can focus on offering innovative and high-performance products, taking advantage of advancements in technology. Additionally, expanding their distribution channels to target new customers would be beneficial. Strategic partnerships and collaborations can also be pursued to strengthen market presence and enhance competitiveness.

Global Foam Packaging Market Segmentation:

By Product Type

Flexible Foam

Rigid Foam

By Material Type

Polystyrene

Polyethylene

Polyurethane

polypropylene

Poly Vinyl Chloride

By Application

Inserts

Corner and edge protectors

Anti-Static ESD Foam

Liners

By End-User

Medical and Pharmaceutical

Food and Beverages

Aerospace and Defence

Automotive

Electrical and Electronics

Personal Care

Consumer Packaging

Others

Foam Packaging Market Regional Insights:

The report provides a comprehensive examination of the factors driving growth, constraints, future prospects, and competitive landscape across all regions. The market is segmented by region into North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. Additionally, the report identifies the top countries in each region and provides market forecasts for each one.

Key objectives of this research are:

To explore Global Foam Packaging Market size by respective indicators.

To scrutinize the sum and estimation of the Global Foam Packaging Market, Based on key aspects.

To offer an account of the competitive landscape and investigate their development plans.

To examine the Global Foam Packaging Market for growth possibilities, and strategic growth.

To review the Global Foam Packaging Market size (volume and worth) from the organization, key market regions, items and applications, and statistical data.

To generate competitive learnings and factors analysis, SWOT examination, and business improvement plans for the future.

To scrutinize the range of available and novel organic business growth strategies.

Directly Purchase a Copy of this Foam Packaging Market research report at: https://wemarketresearch.com/purchase/foam-packaging-market/1315?license=single

The research includes historical data from 2018 to 2023 and forecasts until 2033, making the report valuable to industry executives, marketing, sales and product managers, consultants, analysts, and stakeholders in clearly presented tables Together, we are looking for documents that are easily accessible graph.

Finally, the Foam Packaging Market report is the believable source for gaining the Market research that will exponentially accelerate your business. The report provides locales, economic conditions, item values, benefits, limits, creations, supplies, requests, market development rates, numbers, etc. Foam Packaging industry report additionally presents a new task SWOT exam, speculation attainability investigation, and venture return investigation.

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Our strategic market analysis and capability to comprehend deep cultural, conceptual and social aspects of various tangled markets has helped us make a mark for ourselves in the industry. WE MARKET RESEARCH is a frontrunner in helping numerous companies; both regional and international to successfully achieve their business goals based on our in-depth market analysis. Moreover, we are also capable of devising market strategies that ensure guaranteed customer bases for our clients.

Contact Us:

Mr. Robbin Joseph

Corporate Sales, USA

We Market Research

USA: +1-724-618-3925

Websites: https://wemarketresearch.com/

Email: [email protected]

#packagingideas#packagingoftheworld#marketingconteudo#marketingsuccess#Created by Inflact Hashtags Generator#Foam Packaging Market

0 notes

Text

Expanded Polystyrene Market is Expected to Grow at CAGR of 3.5% during the forecast period 2032

The expanded polystyrene (EPS) market has witnessed significant growth and evolution in recent years, driven by various factors shaping the global landscape. EPS, a versatile and lightweight thermoplastic material, finds extensive applications across diverse industries, including packaging, construction, automotive, and electronics. Its unique properties, such as excellent insulation, shock absorption, buoyancy, and affordability, have contributed to its widespread adoption worldwide.

One of the primary drivers of the EPS market is the increasing demand for sustainable and energy-efficient packaging solutions. With growing environmental concerns and stringent regulations aimed at reducing carbon footprint and promoting recyclability, EPS emerges as an attractive choice for packaging materials due to its recyclability, lightweight nature, and ability to protect goods during transit. As e-commerce continues to thrive and consumer preferences shift towards eco-friendly packaging options, the demand for EPS packaging solutions is expected to surge.

Read Full Report: https://www.chemanalyst.com/industry-report/expanded-polystyrene-market-2967

In the construction sector, EPS plays a crucial role in insulation applications, contributing to energy efficiency and thermal comfort in buildings. With the emphasis on green building practices and energy conservation, EPS insulation materials offer an effective solution for reducing heat loss, minimizing energy consumption, and enhancing indoor comfort. As governments worldwide introduce initiatives to promote sustainable construction practices and improve building energy performance, the demand for EPS insulation products is projected to grow substantially.

Moreover, the automotive industry represents another significant market for EPS, driven by the increasing demand for lightweight materials to enhance fuel efficiency and reduce vehicle emissions. EPS is widely used in automotive applications such as interior components, cushioning materials, and protective packaging due to its lightweight, shock-absorbing, and acoustic insulation properties. With the automotive sector undergoing a rapid transition towards electric and autonomous vehicles, the demand for EPS-based solutions is expected to further escalate.

Furthermore, the electronics industry presents lucrative opportunities for the EPS market, particularly in the manufacturing of electronic packaging materials and components. EPS foam packaging offers superior protection against electrostatic discharge (ESD), moisture, and mechanical damage, ensuring the safe transport and storage of sensitive electronic devices and components. As the electronics sector continues to innovate and introduce new products, the demand for EPS packaging solutions is anticipated to remain robust.

Despite the promising outlook, the EPS market faces challenges and uncertainties, including fluctuating raw material prices, regulatory constraints, and growing concerns about plastic waste and environmental pollution. However, industry stakeholders are actively addressing these challenges through initiatives focused on recycling, circular economy principles, and the development of bio-based alternatives to traditional EPS materials. By embracing sustainability and innovation, the EPS market can adapt to changing market dynamics and capitalize on emerging opportunities in a rapidly evolving global landscape.

In conclusion, the expanded polystyrene market is poised for continued growth and innovation, driven by its versatile applications across multiple industries and its inherent properties that align with evolving consumer preferences and regulatory requirements. By leveraging its strengths in sustainability, efficiency, and performance, the EPS market can navigate towards a more resilient and sustainable future, ensuring its relevance and competitiveness in the global marketplace.

About Us:

ChemAnalyst is an online platform offering a comprehensive range of market analysis and pricing services, as well as up-to-date news and deals from the chemical and petrochemical industry, globally.

Being awarded ‘The Product Innovator of the Year, 2023’, ChemAnalyst is an indispensable tool for navigating the risks of today's ever-changing chemicals market.

The platform helps companies strategize and formulate their chemical procurement by tracking real time prices of more than 400 chemicals in more than 25 countries.

ChemAnalyst also provides market analysis for more than 1000 chemical commodities covering multifaceted parameters including Production, Demand, Supply, Plant Operating Rate, Imports, Exports, and much more. The users will not only be able to analyse historical data but will also get to inspect detailed forecasts for upto 10 years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

Contact US:

420 Lexington Avenue, Suite 300

New York, NY

United States, 10170

Emai-id: [email protected]

Mobile no: +1- 3322586602

#expandedpolystyrene#expandedpolystyreneprices#expandedpolystyrenemarket#expandedpolystyrenemarketsize#expandedpolystyrenemarketforecast#expandedpolystyrenemarkettrends

1 note

·

View note

Text

0 notes

Text

Electrostatic Discharge Technologies Market Size Expected To Acquire USD 6355.36 million By 2030 At CAGR of 7.8%

The latest market report published by Credence Research, Inc. “Global Electrostatic Discharge Technologies Market: Growth, Future Prospects, and Competitive Analysis, 2016 – 2030. The global electrostatic discharge technologies market has witnessed rapid growth in recent years and is expected to grow at a CAGR of 7.8% between 2023 and 2030. The market was valued at USD 3484.9 million in 2022 and is expected to reach USD 6355.36 million in 2030.

Electrostatic Discharge (ESD) Technologies:

Electrostatic discharge (ESD) refers to the sudden flow of electricity between two objects with differing electrical potentials. This phenomenon can occur due to various reasons, including friction, contact, or separation of materials, and it can potentially damage electronic components and devices. To mitigate the risks associated with ESD, a variety of technologies and products have been developed to prevent or redirect the discharge of static electricity.

Market Overview:

The ESD technologies market encompasses a range of products and solutions designed to prevent or control electrostatic discharges in various industries. This market is driven by the increasing complexity and sensitivity of electronic components used in various applications, such as consumer electronics, automotive, aerospace, medical devices, and manufacturing.

Here are some factors that were contributing to the growth of the ESD Technologies market:

Increasing Use of Electronics: The proliferation of electronic devices in various industries, including consumer electronics, automotive, aerospace, and healthcare, has led to a growing demand for ESD protection solutions. As electronic components become smaller and more sensitive, the risk of ESD damage also increases, driving the need for advanced ESD technologies.

Rising Awareness of ESD Hazards: Awareness of the damage caused by electrostatic discharge to electronic components and products has been increasing. This has led to greater adoption of ESD prevention measures and technologies in manufacturing and handling processes.

Stringent Industry Standards and Regulations: Various industries have established standards and regulations for ESD protection to ensure the reliability and longevity of electronic products. Compliance with these standards has become a significant driver for ESD technology adoption.

Some of the major players in the market and their market share are as follows:

Mettler-Toledo International Inc, Desco Industries Inc, SCHURTER AG, Trek Inc, Terra Universal Inc, ESD Systems, Transforming Technologies LLC, 3M Company, Advantek Inc

Browse 240 pages report Electrostatic Discharge Technologies Market ESD Protection Devices (ESD Diodes, ESD Transistors, ESD Suppressors, ESD Filters) ESD Packaging Materials (ESD Bags and Pouches, ESD Trays and Containers, ESD Foam and Cushioning Materials, ESD Films and Sheets) Growth, Future Prospects & Competitive Analysis, 2016 – 2030 - https://www.credenceresearch.com/report/electrostatic-discharge-technologies-market

Here are some key offerings in the ESD technologies market:

1. ESD Protection Devices:

Transient Voltage Suppressor (TVS) Diodes: TVS diodes are commonly used to shunt transient voltage spikes, including ESD events, away from sensitive electronic components. They provide a low-resistance path for high-voltage surges, protecting components.

ESD Protection ICs: These integrated circuits provide comprehensive protection by combining various ESD protection features, such as TVS diodes, clamping diodes, and current limiting.

2. ESD Packaging and Materials:

Anti-Static Bags: These bags are designed to prevent the buildup of static charges on sensitive electronic components during storage and transportation.

Conductive Foam: Foam inserts and liners made from conductive materials provide cushioning and protection while dissipating static charges.

ESD-Safe Containers: Containers made from conductive materials help prevent electrostatic discharge from damaging components inside.

3. ESD Test and Measurement Equipment:

ESD Simulators: These devices generate controlled ESD events to test the resilience of electronic devices and components under simulated conditions.

ESD Testers: Instruments designed to measure the ability of materials, devices, and systems to withstand ESD events and comply with industry standards.

4. ESD Workstation Equipment:

ESD-Safe Wrist Straps: Worn by personnel to ensure that they remain at the same potential as sensitive electronic components, preventing potential ESD discharges.

ESD Mats and Flooring: Conductive mats and flooring materials help dissipate static charges to the ground, ensuring that personnel and workstations remain ESD-safe.

The Electrostatic Discharge Technologies Market can be segmented based on various factors:

By Type

ESD Protection Devices

ESD Diodes

ESD Transistors

ESD Suppressors

ESD Filters

By Industry Vertical

Electronics and Semiconductors

Automotive

Aerospace and Defense

Healthcare and Medical Devices

Telecommunications

Energy and Utilities

Manufacturing and Industrial

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Electrostatic Discharge Technologies Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Electrostatic Discharge Technologies Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major players analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/electrostatic-discharge-technologies-market

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/application-specific-integrated-circuits-asics-market

Browse Our Blog: https://www.linkedin.com/pulse/electrostatic-discharge-technologies-market-size-expected-shukla

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

The Global Electrostatic Discharge (ESD) Foam Packaging Market Forecast 2030: AMR

0 notes

Text

Conductive Foam Market: Forecasting Growth and Trends

The conductive foam market, a specialized segment within the materials industry, plays a pivotal role in the protection of electronic components and devices from electrostatic discharge (ESD). As industries continue to rely on increasingly sensitive and sophisticated electronics, the demand for conductive foam is expected to see significant growth in the coming years. This article explores the forecast for the conductive foam market, examining key trends, growth drivers, and challenges.

Key Trends Influencing the Conductive Foam Market

Increased Electronics Manufacturing: The rapid growth of consumer electronics, automotive electronics, and industrial automation is a key factor driving the demand for conductive foam. As electronic devices continue to evolve, the need for effective ESD protection systems becomes more critical. Conductive foam, which provides shielding against electrostatic discharge, is an essential component for preserving the integrity and functionality of sensitive electronic equipment.

Rise in Demand for ESD Protection: Electrostatic discharge is a leading cause of failure in modern electronics. As a result, industries like electronics manufacturing, automotive, aerospace, and medical equipment are focusing on ESD protection measures. Conductive foam, used in packaging, enclosures, and shipping materials, plays a vital role in minimizing the risks associated with electrostatic discharge, fostering growth in the market.

Technological Advancements: Continuous innovations in conductive foam materials are enhancing their efficiency and functionality. Manufacturers are developing foam materials with improved conductivity, durability, and flexibility. Additionally, the development of foam products that meet higher performance standards and more stringent regulatory requirements is expected to drive market growth.

Increased Adoption in Automotive and Aerospace Sectors: With the ongoing rise in electric vehicles (EVs) and the push for advanced autonomous driving systems, the automotive sector is anticipated to be a major contributor to the conductive foam market. The aerospace sector also demands high-quality ESD protection materials due to the sensitive nature of components used in aircraft. The adoption of conductive foam in these sectors is expected to boost demand.

Market Growth Drivers

Expanding Consumer Electronics Industry: Consumer electronics, including smartphones, tablets, laptops, and wearable devices, continue to proliferate globally. As electronic components become smaller and more complex, the necessity for ESD protection becomes more pronounced. Conductive foam is integral in safeguarding devices during manufacturing, packaging, and transportation, further expanding the market.

Automotive Industry Expansion: The shift toward electric vehicles, along with the increasing use of advanced electronics in vehicles, is expected to accelerate the demand for conductive foam. Electric vehicles require specialized parts that are sensitive to electrostatic discharge, further increasing the importance of ESD protection.

Emerging Markets: The growth of the conductive foam market is also fueled by increasing industrial activities in emerging economies, especially in Asia-Pacific and Latin America. With expanding electronics manufacturing industries in countries like China, India, and South Korea, the demand for conductive foam is set to increase.

Sustainability and Eco-friendly Trends: In response to growing environmental concerns, the market is witnessing a rise in the development of eco-friendly conductive foam products. Manufacturers are focusing on creating sustainable and recyclable alternatives, which is anticipated to drive the adoption of conductive foam in industries that prioritize sustainability.

Regional Outlook

The global conductive foam market is expected to see substantial growth across all regions. North America, led by the U.S., is one of the dominant markets, owing to the high demand for electronic products and innovations in the automotive and aerospace sectors. Europe is also poised to see growth driven by the increasing adoption of advanced ESD protection systems in industrial applications.

The Asia-Pacific region, particularly China, India, and Japan, is anticipated to experience the highest growth rate. The expansion of electronics manufacturing and automotive industries in this region, coupled with the increasing demand for ESD-sensitive components, will propel the demand for conductive foam in the coming years.

Challenges in the Conductive Foam Market

Despite the positive growth forecast, the conductive foam market faces several challenges. The high cost of advanced conductive foam materials may hinder adoption in price-sensitive industries, particularly in emerging markets. Additionally, the development of alternative materials that offer similar protective qualities, such as conductive coatings or films, may pose competition to traditional conductive foams.

Conclusion

The conductive foam market is poised for significant growth, driven by increasing demand across electronics, automotive, aerospace, and emerging markets. As industries prioritize electrostatic discharge protection for sensitive components, conductive foam will continue to be a critical component in safeguarding product quality. Advancements in materials, regional growth, and emerging applications will further fuel the market’s expansion, making it a promising sector for investment and innovation in the coming years.

Get Free Sample and ToC : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NDc2&RD=Conductive-Foam-Market-Report

0 notes

Link

This report focuses on the global ESD Foam Packaging status, future forecast, growth opportunity, key market and key players. The study objectives are to present the ESD Foam Packaging development in United States, Europe and China.

0 notes

Text

Electrostatic discharge foams materials are made of plastic which helps in reducing the static electricity and protects electro-sensitive devices or products that contain inflammable gases or liquids.

ESD foams are manufactured using the antistatic agents which aids them in generating the static charges. ESD foams majorly help in not generating the static electricity that can be caused due to the friction between the electrical components while in motion. North America region market accounted for $119.8 million in 2020 and is predicted to grow with a CAGR of 9.0% in the forecast period.

#Electrostatic Discharge (ESD) Foams Market Analysis#Electrostatic Discharge (ESD) Foams Market Demand#Electrostatic Discharge (ESD) Foams Market Outlook#Electrostatic Discharge (ESD) Foams Market Forecast#Electrostatic Discharge (ESD) Foams Market Size

0 notes

Text

Electrostatic Discharge Packaging Market Driven by Growing Demand for Consumer Electronics, Communication Equipment

Global Electrostatic Discharge Packaging Market - Overview

The global Electrostatic Discharge Packaging Market is expected to exhibit a strong 8.2% CAGR over the forecast period from 2022 to 2030, according to the latest research report from Market Research Future (MRFR). The report studies the global electrostatic discharge packaging market in detail to find out more about the market’s leading drivers and restraints, key segments, and dominant players.

The global electrostatic discharge packaging market is mainly driven by the growing global demand for the manufacturing and transportation of electronic components. The growing manufacturing of computers, smartphones, and other networking infrastructure is likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the demand for electrical and electronic components is likely to grow over the forecast period and beyond with the rising reliance on digital communication media. Electrostatic discharge packaging protects the product from the effects of electrostatic discharge, which can hamper a product even before it is sold and considerably reduce its operational lifetime. Obtain Brochure For Latest Technology Advancements @ https://www.marketresearchfuture.com/sample_request/3211

Global Electrostatic Discharge Packaging Market – Prominent Players The notable players profiled in the global Electrostatic Discharge Packaging Market report include Summit Packaging Solutions (U.S.),GWP Group Limited (U.K.),Desco Industries Inc. (U.S.),Teknis Limited (U.K.),Protektive Pak (U.S.),Tandem Equipment Sales, Inc. (U.S.),Static (U.S.),Elcom UK Ltd (U.K.)

Electrostatic Discharge Packaging Market Dynamics

The Electrostatic discharge packaging is also called as antistatic packaging. Static can be caused by various factors such as including other devices, friction or even the weather. Electrostatic discharge packaging is vital for the safe transportation and storage of most electronic products. Also, the operational requirement among original equipment manufacturers to isolate ESD sensitive items, components and devices during manufacturing, assembling and shipping has led to such specific packaging need catered by packaging manufacturers. The growing demand for smartphones and other consumer electronics is likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the growing demand for consumer electronics is likely to result in an increasing demand for the transportation of the same from the manufacturing sites to the assembly units. The growing demand for communication network infrastructure is also likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the operations of the industrial sector as well as other, service-oriented sectors such as BFSI, healthcare, and government, are likely to rely increasingly on digital, 21st-century communication methods in the coming years. Access Complete Report @ https://www.marketresearchfuture.com/reports/electrostatic-discharge-packaging-market-3211 Electrostatic Discharge Packaging Market - Segments:

The global electrostatic discharge packaging market share is segmented on the basis of product, end use, and region.

By product, the global electrostatic discharge packaging market is segmented into bags, trays, boxes and containers, ESD foams, and others.

By end use, the global electrostatic discharge packaging market is segmented into communication network infrastructure, consumer electronics, computer peripherals, automotive, and others. Buy Now @ https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=3211 Electrostatic Discharge Packaging Market - Regional Analysis:

The global electrostatic discharge packaging market is segmented by region into North America, Europe, Asia Pacific, and rest of the world.

Asia Pacific is likely to dominate the global electrostatic discharge packaging market over the forecast period due to the growing electronics manufacturing industry in the region. Companies such as Samsung, LG, and Huawei are leading manufacturers of consumer electronics, the demand for which is being driven rapidly in Asia Pacific due to the growing disposable income of the consumers in Asia Pacific. The growing production of communication equipment in countries such as China, Taiwan, and Japan is likely to be a key driver for the global electrostatic discharge packaging market over the forecast period. Companies such as Samsung and Huawei have emerged as global leaders in the manufacturing of communication equipment in recent years, leading to a steady growth in the demand from the electrostatic discharge packaging market in Asia Pacific over the forecast period. The growing initiation of safety regulations in the packaging and transportation industry in the region is also likely to drive the demand from the electrostatic discharge packaging market in the region.

Following Asia Pacific, Europe is likely to hold a considerable share in the global electrostatic discharge packaging market over the forecast period due to the growing demand for safety in product consumption and usage. The steady advancement of the packaging industry in Europe has led to the legislation of several supportive regulations mandating the use of electrostatic discharge protection in electronics transportation and storage. This is likely to drive the electrostatic discharge packaging market in Europe over the forecast period.

North America is also likely to emerge as a key player in the global electrostatic discharge packaging market over the forecast period due to the growing demand for consumer as well as communication electronics in the region. The U.S. is likely to remain one of the leading regional markets for electrostatic discharge packaging over the forecast period.

Scope of the Report This study provides an overview of the global electrostatic discharge packaging market, tracking two market segments across four geographic regions. The report studies key players, providing a five-year annual trend analysis that highlights market size, volume and share for Asia-Pacific, North America, Europe and Rest of the World (ROW). The report also provides a forecast, focusing on the market opportunities for the next five years for each region. The scope of the study segments the global electrostatic discharge packaging market by its product, end-users and region. Read more reports at: https://www.marketresearchfuture.com/categories/chemicals-market-report Read more details at: https://www.marketresearchfuture.com/infographics Read more details at: https://www.marketresearchfuture.com/videos About Market Research Future:- At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services. MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions. Contact Us: Wantstats Research and Media Private Limited 99 Hudson Street,5Th Floor New York, New York 10013 United States of America Maharashtra, India

0 notes

Text

REASONS TO CHOOSE MESSUNG WORKPLACE SOLUTIONS

"In my electronics lab, flexibility and modularity are essential, as are spare parts and service support."

"My industry unit needs ESD protection that doesn't wear out in a few years."

"Our calibration centre requires customised workbenches and storage systems."

"We want the world-class specs of international ESD furniture without the international prices."

For all these requirements and wish lists, Messung Workplace Technology has the solution.

Messung Workplace Technology is one of India’s leading ESD products manufacturers. It is a business unit of the diversified Messung Group. Messung is well-known as the pioneer of the first indigenous PLC in India, and a leading name in industrial automation for four decades.

Messung’s indepth knowledge of the Electronics and industrial sectors has enabled it to provide best-in-class workplace solutions that fulfil the most demanding criteria.

MESSUNG SOLUTIONS FOR ESD AND GENERAL WORKPLACES

Under its 'Navonmesh - Make in India initiative', Messung offers the AFM-PLUS range of indigenously designed and manufactured ESD workplace products that incorporate the latest Volume ESD technology, so you get durable, long-lasting ESD protection as per IEC 61340-5-1.

Messung has its own design and manufacturing facilities with the latest international machines for aluminum and wood cutting, testing facilities, etc. Messung offers a complete range of ESD products for the automotive manufacturing and other industries. Messung can provide customised solutions for industrial worktables, ESD workstations, ESD tables, ESD trolleys, ESD storage racks,drawer cabinets and cupboards.

Messung is also the trusted ESD chairs manufacturer in Bangalore manufacturing a range of ESD task chairs & stools in standard and high versions, in accordance with the European EN 61340-5-1 standards for conductivity. Messung’s ESD chairs with armrests and stools are built of robust metal frames with non-conductive materials, static-free fabric and static free casters/glides, to deliver reliable ESD protection and long service life. The ergonomic workstation chairs come in three options: Thermoplastic PU Integral Foam, Synthetic Leather and Fabric.

All the products in the AFM-PLUS range are also available in non-ESD version for general applications.

WHY CHOOSE MESSUNG WORKPLACE SOLUTIONS

There are many valid reasons to opt for Messung’s workplace furniture:

Flexible and modular: Messung's furniture is modular so it offers a high degree of flexibility. It is lightweight, easy to assemble and re-locate. You can personalise your space, move the furniture around and make alterations as per changing needs and users.

Customisation: Messung has its own design studio, and sprawling ISO 9000 TUV certified manufacturing facility in Pune with all the requisite machines, materials and staff needed for efficient production. This means products can be tailored for specific customer requirements. That too, with fast turnaround times.

Quality: Whether it is long-lasting volume ESD for ESD-safe furniture or the metal frames, casters, shelves, lights, wood and other components that make up the product, Messung delivers quality as per latest international standards. Inhouse QA, QC and ESD testing facility testing facilities ensure no product leaves their facility unless certified fit.

Spares: Messung has built up a ready inventory of all the parts and components that go into the making of each product. So, customers are assured spare parts availability, should the need arise.

Service: Messung is a group with a strong commitment to service. They stand firmly by every product and solution they deliver, and provide unconditional support long-term.

Economy: Messung’s workplace solutions are more economical than international brands, without compromising on global quality standards. Messung’s offerings deliver world-class looks and specifications but at a cost-effective price. That’s because Messung’s AFM-PLUS range is manufactured indigenously as per the latest standards, under its 'Navonmesh - Make in India initiative'.

CONCLUSION

Whether it is global IEC and ANSI-certified ESD standards or ruggedness for heavy-duty industrial use; customised designs or reliable service support; ergonomic design for enhanced comfort and productivity or cost-effective prices - Messung's workplace solutions score on every point, every time.

Messung’s painstaking attention to detail complemented by meticulous manufacturing and inhouse testing, ensure their products add real value to the industrial workplaces, making the work environment safe, ergonomic and comfortable.

Please contact Messung Workplace Technology with your requirements today.

#ESD products manufacturers.#IEC 61340-5-1.#industrial worktables#ESD workstations#ESD tables#ESD storage racks#ESD chairs manufacturer in Bangalore#ESD chairs with armrests#workstation chairs

0 notes

Text

Electrostatic Discharge Packaging Market Research Methodology, Structure, Forecast to 2027

Market Overview

The global Electrostatic Discharge Packaging Market is expected to exhibit a strong 8.2% CAGR over the forecast period from 2017 to 2023, according to the latest research report from Market Research Future (MRFR). The report studies the global electrostatic discharge packaging market in detail to find out more about the market’s leading drivers and restraints, key segments, and dominant players.

The global electrostatic discharge packaging market is mainly driven by the growing global demand for the manufacturing and transportation of electronic components. The growing manufacturing of computers, smartphones, and other networking infrastructure is likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the demand for electrical and electronic components is likely to grow over the forecast period and beyond with the rising reliance on digital communication media. Electrostatic discharge packaging protects the product from the effects of electrostatic discharge, which can hamper a product even before it is sold and considerably reduce its operational lifetime.

The growing demand for smartphones and other consumer electronics is likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the growing demand for consumer electronics is likely to result in an increasing demand for the transportation of the same from the manufacturing sites to the assembly units. The growing demand for communication network infrastructure is also likely to be a major driver for the global electrostatic discharge packaging market over the forecast period, as the operations of the industrial sector as well as other, service-oriented sectors such as BFSI, healthcare, and government, are likely to rely increasingly on digital, 21st-century communication methods in the coming years.

Get Free Sample PDF@ https://www.marketresearchfuture.com/sample_request/3211

Competitive Analysis:

Leading players in the global electrostatic discharge packaging market include Desco Industries Inc., GWP Group Limited, Protektive Pak, Elcom UK Ltd., Statico, Stephen Gould Corp., Summit Packaging Solutions, Tandem Equipment Sales Inc., and Teknis Limited.

Segmentation:

The global electrostatic discharge packaging market is segmented on the basis of product, end use, and region.

By product, the global electrostatic discharge packaging market is segmented into bags, trays, boxes and containers, ESD foams, and others.

By end use, the global electrostatic discharge packaging market is segmented into communication network infrastructure, consumer electronics, computer peripherals, automotive, and others.

Regional Analysis:

The global electrostatic discharge packaging market is segmented by region into North America, Europe, Asia Pacific, and rest of the world.

Asia Pacific is likely to dominate the global electrostatic discharge packaging market over the forecast period due to the growing electronics manufacturing industry in the region. Companies such as Samsung, LG, and Huawei are leading manufacturers of consumer electronics, the demand for which is being driven rapidly in Asia Pacific due to the growing disposable income of the consumers in Asia Pacific. The growing production of communication equipment in countries such as China, Taiwan, and Japan is likely to be a key driver for the global electrostatic discharge packaging market over the forecast period. Companies such as Samsung and Huawei have emerged as global leaders in the manufacturing of communication equipment in recent years, leading to a steady growth in the demand from the electrostatic discharge packaging market in Asia Pacific over the forecast period. The growing initiation of safety regulations in the packaging and transportation industry in the region is also likely to drive the demand from the electrostatic discharge packaging market in the region.

Following Asia Pacific, Europe is likely to hold a considerable share in the global electrostatic discharge packaging market over the forecast period due to the growing demand for safety in product consumption and usage. The steady advancement of the packaging industry in Europe has led to the legislation of several supportive regulations mandating the use of electrostatic discharge protection in electronics transportation and storage. This is likely to drive the electrostatic discharge packaging market in Europe over the forecast period.

North America is also likely to emerge as a key player in the global electrostatic discharge packaging market over the forecast period due to the growing demand for consumer as well as communication electronics in the region. The U.S. is likely to remain one of the leading regional markets for electrostatic discharge packaging over the forecast period.

Browse Full Report Details @

https://www.marketresearchfuture.com/reports/electrostatic-discharge-packaging-market-3211

0 notes

Text

Global Electrostatic Discharge (ESD) Packaging Market Snapshot and Industry Analysis Forecast 2021-2027

The latest survey on Electrostatic Discharge (ESD) Packaging Market Industry managed various organizations of the industry from different geographies or regions. The Report study consists of qualitative and quantitative information highlighting key market developments challenges that industry and competition are facing along with gap analysis, new opportunities available and trend also include COVID-19 impact Analysis in Electrostatic Discharge (ESD) Packaging Market and impact various factors resulting in boosting Electrostatic Discharge (ESD) Packaging Market at global as well as regional level. There are huge competitions take place worldwide and must require the study of MARKET ANALYSIS such as Top Competitors /Top Players are: Smurfit Kappa, DS Smith, Sealed Air, Pregis, Achilles, Desco, Storopack, NEFAB, Teknis, Elcom, Summit Container, Kiva Container, Protective Packaging, GWP, Pure-Stat, International Plastics, AUER Packaging, Dou Yee Enterprises, Botron.

Our Research Analyst Analyses Research Methodology overview including Primary Research, Secondary Research, Company Share Analysis, Model ( including Demographic data, Macro-economic indicators, and Industry indicators: Expenditure, infrastructure, sector growth, and facilities ), Research Limitations and Revenue Based Modeling. Company share analysis is used to derive the size of the global market. As well as a study of revenues of companies for the last three to five years also provides the base for forecasting the market size (2021- 2027 ) and its growth rate. Porter’s Five Forces Analysis, impact analysis of covid-19 and SWOT Analysis are also mentioned to understand the factors impacting consumer and supplier behaviour. This Electrostatic Discharge (ESD) Packaging Market Report covers global, regional, and country-level market size, market shares, market growth rate analysis (include Reseaon of highest and lowest peak Market analysis), product launches, recent trend, the impact of covid19 on worldwide or regional Electrostatic Discharge (ESD) Packaging Market. This report includes the estimation of Electrostatic Discharge (ESD) Packaging market size for value (million USD) and volume (K Units)

Download FREE PDF Sample Copy of Electrostatic Discharge (ESD) Packaging Market @ https://www.syndicatemarketresearch.com/sample/electrostatic-discharge-esd-packaging-market

We are here to implement a Free PDF Sample Report copy as per your Research Requirement, also including impact analysis of COVID-19 on Electrostatic Discharge (ESD) Packaging Market Size

Don’t miss out on business opportunities in Electrostatic Discharge (ESD) Packaging Market. Speak to our analyst and gain crucial industry insights that will help your business growth while filling Free PDF Sample Reports

Advantage of requesting FREE Sample PDF Report Before purchase

A brief introduction to the research report and Overview of the market

Syndicate Market Research methodology

Graphical introduction of global as well as the regional analysis

Selected illustrations of market insights and trends.

Know top key players in the market with their revenue analysis

Example pages from the report

Key Highlights of the TOC provided by Syndicate Market Research:

Electrostatic Discharge (ESD) Packaging Market Executive summary: This section emphasizes the key studies, market growth rate, competitive landscape, market drivers, trends, and issues in addition to the macroscopic indicators.

Electrostatic Discharge (ESD) Packaging Market Study Coverage: It includes key market segments, key manufacturers covered, the scope of products offered in the years considered, global Electrostatic Discharge (ESD) Packaging Market and study objectives. Additionally, it touches the segmentation study provided in the report on the basis of the type of product and applications.

Electrostatic Discharge (ESD) Packaging Market Production by Region: The report delivers data related to import and export, revenue, production, and key players of all regional markets studied are covered in this section.

Electrostatic Discharge (ESD) Packaging Market Profile of Manufacturers: Analysis of each market player profiled is detailed in this section. This segment also provides SWOT analysis, products, production, value, capacity, and other vital factors of the individual player.

Major Product Type of Electrostatic Discharge (ESD) Packaging Covered in Market Research report: Bags, Trays, Clamshell, Shrink Films, Boxes and Containers, Tapes and Labels, Foams, Totes/IBC, Racks

Application Segments Covered in Market Research Report: Electrical and Electronics, Automobile, Defense and Military, Manufacturing, Aerospace, Healthcare

Global Electrostatic Discharge (ESD) Packaging Industry Market: By Region

North America

U.S.Canada

Rest of North America

Europe

UK

Germany

France

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

Southeast Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

The Middle East and Africa

GCC Countries

South Africa

Rest of Middle East & Africa

Competitive Market Share

In terms of Electrostatic Discharge (ESD) Packaging market, Smurfit Kappa, DS Smith, Sealed Air, Pregis, Achilles, Desco, Storopack, NEFAB, Teknis, Elcom, Summit Container, Kiva Container, Protective Packaging, GWP, Pure-Stat, International Plastics, AUER Packaging, Dou Yee Enterprises, Botron are the top players operating in the global market. These behemoths have implemented key business strategies such as product innovation, strategic partnerships & collaborations, new product launches, new service launches, joint ventures, and contracts to reinforce their market position along with gaining a huge chunk of the market share.

In addition, the report also covers key strategic developments of the market including acquisitions & mergers, new type launch, agreements, partnerships, collaborations & joint ventures, research & development, regional expansion of major participants involved in the Electrostatic Discharge (ESD) Packaging market on a global and regional basis.

Table of Content include Electrostatic Discharge (ESD) Packaging Market Worldwide are:

1 Study Coverage 1.1 Electrostatic Discharge (ESD) Packaging Product 1.2 Key Market Segments in This Study 1.3 Key Manufacturers Covered 1.4 Market by Type 1.4.1 Global Market Size Growth Rate by Type (Bags, Trays, Clamshell, Shrink Films, Boxes and Containers, Tapes and Labels, Foams, Totes/IBC, Racks) 1.5 Market by Application 1.5.1 Global Market Size Growth Rate by Application (Electrical and Electronics, Automobile, Defense and Military, Manufacturing, Aerospace, Healthcare) 1.6 Study Objectives 1.7 Years Considered

2 Executive Summary —contd—

3 Electrostatic Discharge (ESD) Packaging Market Size by Manufacturers 3.1 Production by Manufacturers 3.1.1 Production by Manufacturers 3.1.2 Production Market Share by Manufacturers 3.2 Revenue by Manufacturers 3.2.1 Revenue by Manufacturers (2013-2018) 3.2.2 Revenue Share by Manufacturers (2013-2018) 3.3 Price by Manufacturers 3.4 Mergers & Acquisitions, Expansion Plans

4 Electrostatic Discharge (ESD) Packaging Production by Regions —–contd—

5 Electrostatic Discharge (ESD) Packaging Consumption by Regions 5.1 Global Electrostatic Discharge (ESD) Packaging Consumption by Regions 5.1.1 Global Electrostatic Discharge (ESD) Packaging Consumption by Regions 5.1.2 Global Electrostatic Discharge (ESD) Packaging Consumption Market Share by Regions 5.2 North America 5.2.1 North America Electrostatic Discharge (ESD) Packaging Consumption by Application 5.2.2 North America Electrostatic Discharge (ESD) Packaging Consumption by Countries 5.2.3 United States 5.2.4 Canada 5.2.5 Mexico 5.3 Europe 5.3.1 Europe Electrostatic Discharge (ESD) Packaging Consumption by Application 5.3.2 Europe Electrostatic Discharge (ESD) Packaging Consumption by Countries 5.3.3 Germany 5.3.4 France 5.3.5 UK 5.3.6 Italy 5.3.7 Russia 5.4 Asia Pacific 5.4.1 Asia Pacific Electrostatic Discharge (ESD) Packaging Consumption by Application 5.4.2 Asia Pacific Electrostatic Discharge (ESD) Packaging Consumption by Countries 5.4.3 China 5.4.4 Japan 5.4.5 South Korea 5.4.6 India 5.4.7 Australia 5.4.8 Indonesia 5.4.9 Thailand 5.4.10 Malaysia 5.4.11 Philippines 5.4.12 Vietnam 5.5 Central & South America 5.5.1 Central & South America Electrostatic Discharge (ESD) Packaging Consumption by Application 5.5.2 Central & South America Electrostatic Discharge (ESD) Packaging Consumption by Country 5.5.3 Brazil 5.6 Middle East and Africa 5.6.1 Middle East and Africa Electrostatic Discharge (ESD) Packaging Consumption by Application 5.6.2 Middle East and Africa Electrostatic Discharge (ESD) Packaging Consumption by Countries 5.6.3 GCC Countries 5.6.4 Egypt 5.6.5 South Africa

6 Market Size by Type —–contd—

7 Market Size by Application 7.1 Overview 7.2 Global Breakdown Dada by Application 7.2.1 Global Consumption by Application 7.2.2 Global Consumption Market Share by Application (2013-2018)

8 Manufacturers Profiles —–contd—

9 Production Forecasts —–contd—

10 Consumption Forecast —–contd—

11 Value Chain and Sales Channels Analysis 11.1 Value Chain Analysis 11.2 Sales Channels Analysis 11.2.1 Electrostatic Discharge (ESD) Packaging Sales Channels 11.2.2 Distributors 11.3 Customers

12 Market Opportunities & Challenges, Risks and Influences Factors Analysis 12.1 Market Opportunities and Drivers 12.2 Market Challenges 12.3 Market Risks/Restraints 12.4 Key World Economic Indicators

13 Key Findings in the Global Electrostatic Discharge (ESD) Packaging Study

14 Appendix 14.1 Research Methodology 14.1.1 Methodology/Research Approach 14.1.1.1 Research Programs/Design 14.1.1.2 Market Size Estimation 14.1.1.3 Market Breakdown and Data Triangulation 14.1.2 Data Source 14.1.2.1 Secondary Sources 14.1.2.2 Primary Sources 14.2 Author Details 14.3 Disclaimer

Read Our Other Exclusive Blogs:–

https://www.openpr.com/news/2237973/global-recruitment-and-staffing-market-five-forces-analysis

https://melvinasmarketblogs.blogspot.com/2020/11/global-openstack-market-may-see-big.html

About Syndicate Market Research:

At Syndicate Market Research, we provide reports about a range of industries such as healthcare & pharma, automotive, IT, insurance, security, packaging, electronics & semiconductors, medical devices, food & beverage, software & services, manufacturing & construction, defence aerospace, agriculture, consumer goods & retailing, and so on. Every aspect of the market is covered in the report along with its regional data. Syndicate Market Research committed to the requirements of our clients, offering tailored solutions best suitable for strategy development and execution to get substantial results. Above this, we will be available for our clients 24×7.

Contact US:

Syndicate Market Research 244 Fifth Avenue, Suite N202 New York, 10001, United States Website: https://www.syndicatemarketresearch.com/ Blog: Syndicate Market Research Blog

from NeighborWebSJ https://ift.tt/3cX5IPx via IFTTT

from WordPress https://ift.tt/3gFKjfU via IFTTT

0 notes

Text

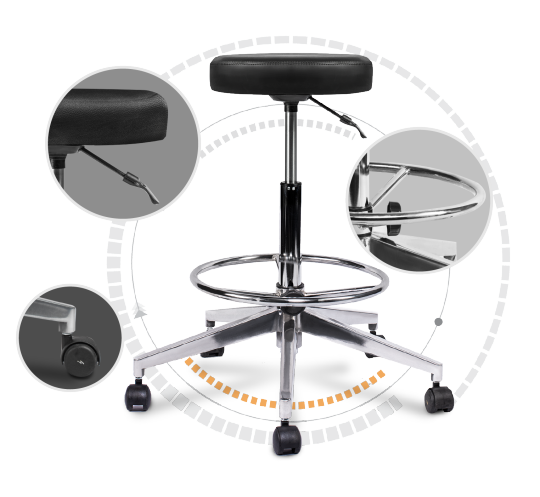

HIGH QUALITY ESD - HIGH CHAIRS & HIGH STOOLS FROM MESSUNG

Ours is an increasingly technological age requiring more and more sophisticated electronic components. From our laptops& TVs to washing machines to cars, electronics run our lives. In such a world, Electrostatic Discharge (ESD) poses a serious problem for industry.

Static discharge can damage electronic components in electronics manufacturing. ESD can attract contaminants in clean environments or cause products to stick together. The cost of ESD-damage can range from a few rupees for a simple diode to several thousand for more complex components. The time and cost of repairs or replacements can be huge; the damage to the company's reputation can be incalculable.

ESD-SAFE HIGH CHAIRS & STOOLS

ESD high chairs and high stools are the modern solution. They have become essential parts of the industry, for workers who deal with delicate electronic circuitry or work areas that require minimized environmental pollutants such as a cleanroom environment.

They are commonly used in the semiconductor, bioscience, pharmaceutical, computer, and medical equipment industries.

Workers in such workplaces also need the same comfort, adjustability and ergonomic support that workers in non-ESD areas require. Seating ergonomics enables long hours of work, promotes productivity and protects wellbeing.

Messung offers a range of ergonomic ESD workstation chairs and stools, in both standard and high versions.

ABOUT MESSUNG ESD CHAIRS & STOOLS

Messung’s ESD chairs and stools are specifically designed for use in electrical and electronics industry. They are proven to minimise environmental pollutants in cleanroom applications too.

Some of the tasks associated with ESD areas call for elevated seating positions or require workers to stand for long periods or to alternate between standing up and sitting down. As a result, their bodies are often subjected to a great deal of physical stress. Messung’s high chairs and stools with footrests support the human body and relieve physical stress. Also called task chairs, they have pneumatic seats that adjust to an optimal working height.

In accordance with the European EN 61340-5-1 standards for conductivity, Messung’s ESD chairs and stools are built of robust metal frames with non-conductive materials, static-free fabric and static free casters/glides, to deliver reliable ESD protection and long service life.

They also ensure ergonomic seating and support for worker productivity and comfort. The adjustable conductive backrests (for chairs) and smooth gas lift height adjustment make Messung ESD task chairs and ESD-safeindustrial metal stools a must-have for industry.

FEATURES OF MESSUNG ESD HIGH STOOLS

Messung’s work stools are designed to withstand tough environments, including heavy industry. Thermoplastic PU can withstand oils, sparks, and blows. The synthetic leather and fabric model are soft but at the same time resistant to disinfectants and cleaning agents.

- Height adjustment between 580-840 mm

- 75mm thick seat of 350 diameter

- Up to 120 kg weight carrying capacity

- Chrome-plated safety gas spring

- Aluminum die-cast five-star base

- Foot ring of 457 mm diameter

- 700 mm diameter base for stability

- Conductive casters/glides

- Class-4 cleanliness

- ESD range: 106 - 107ohms

- As per IEC 61340-5-1 standard

- Available in 3 versions: Thermoplastic PU Integral Foam, Synthetic Leather and Fabric

FEATURES OF MESSUNG ESD HIGH CHAIRS

Messung’s high chairs are suitable for industrial work that involves a lot of standing. They offer a non-slip seat,smooth height adjustment for the seat and the footrest ring that can help lower the pressure on your feet by up to 60%. The polyurethane surface is durable and easy to clean.

- Height adjustment between 580-840 mm

- Seat tilt of 7 degrees, and backrest tilt of 35 degrees with forward tilt of 15 degrees and backward tilt of 20 degrees

- Up to 120 kg weight carrying capacity

- Chrome-plated safety gas spring

- Aluminium die-cast five-star base

- Foot ring of 457 mm diameter