#Global Chemical Storage Tank Market 2018

Explore tagged Tumblr posts

Text

Collapsible Fuel Tanks, Global Market Size Forecast, Top 10 Players Rank and Market Share

Collapsible Fuel Tanks Market Summary

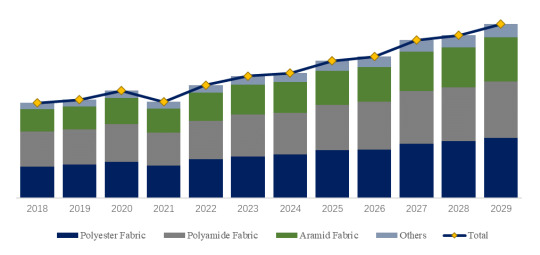

According to the new market research report “Global Collapsible Fuel Tanks Market Report 2023-2029”, published by QYResearch, the global Collapsible Fuel Tanks market size is projected to reach USD 813.2 million by 2029, at a CAGR of 6.1% during the forecast period.

Figure. Global Collapsible Fuel Tanks Market Size (US$ Million), 2018-2029

Based on or includes research from QYResearch: Global Collapsible Fuel Tanks Market Report 2023-2029.

Market Drivers:

Increasing remote military training, weapon testing, surveillance, and defense activities are to augment the sales of collapsible fuel tanks in the market.

Collapsible fuel tanks are gaining huge popularity across the various industries such as oil & gas, mining, agriculture, and industries among others, owing to their favorable attributes such as easy install, bulk storage, high durability, resistance to temperature fluctuation & moisture, others.

In addition to this, collapsible fuel tanks are also finding numerous applications for disaster relief fuel supply purposes, owing to their high portability and ease of installation for fuel storage purposes. Hence, increasing floods, landslides, forest fires, earthquakes, and others worldwide is expected to create lucrative opportunities for growth in the global market.

Restraint:

Inability to install on irregular surfaces, high risk of puncture, and safety issues associated with the collapsible fuel tanks are the factor hampering the growth in the global market.

Growing concerns about environmental issues have led to stricter material requirements for these temporary storage tanks.

Opportunity:

Increasing demand for temporary storage solutions across rising on-shore mining and oil & gas exploration activities across the world is projected to accelerate the sales of collapsible fuel tanks in the global market.

The Russian-Ukrainian war and the game between China and the United States have increased instability in some regions, and frequent military activities will drive market demand in the short term.

Increasing floods, landslides, forest fires, earthquakes, and others worldwide is expected to create lucrative opportunities for growth in the global market.

Figure. Collapsible Fuel Tanks, Global Market Size, The Top 10 Players Hold 70% of Overall Market

Based on or includes research from QYResearch: Global Collapsible Fuel Tanks Market Report 2023-2029.

This report profiles key players of Collapsible Fuel Tanks such as Continental, MPC Containment, Safran.

In 2022, the global top five Collapsible Fuel Tanks players account for 52% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Collapsible Fuel Tanks.

Figure. Collapsible Fuel Tanks, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Collapsible Fuel Tanks Market Report 2023-2029.

In terms of product type, Polyester Fabric is the largest segment, hold a share of 34%.

Figure. Collapsible Fuel Tanks, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Collapsible Fuel Tanks Market Report 2023-2029.

In terms of product application, Commercial is the largest application, hold a share of 55.7%.

Figure. Collapsible Fuel Tanks, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Collapsible Fuel Tanks Market Report 2023-2029.

About The Authors

Wangzhuang - Lead Author

Email: [email protected]

John is a technology & market senior analyst specializing in semiconductor devices, materials, and equipment. Wang has 3 years’ experience in semiconductor and focuses on Chemicals, consumer goods, food and beverages, machinery and equipment, software and business services, etc. He is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Vapour Recovery Units Market Set to Reach US$ 2,105.5 Million by 2033, According to Future Market Insights, Inc. The market for vapour recovery units is anticipated to reach US$ 1,256.2 Million in 2023. It is anticipated to be worth more than US$ 2,105.5 Million by 2033. The market is estimated to expand at a modest CAGR of 5.3% between 2023 and 2033. Controlling volatile organic compounds (VOCs) and other dangerous vapour released during various industrial operations is made possible by vapour recovery machines. These procedures consist of manufacturing chemicals, operating storage tanks, and producing oil and gas, among others. Governments all across the world are putting strict regulations into place to cut these emissions and improve sustainability. The increasing implementation of strict government norms is likely to bolster market growth during the forecast period. Furthermore, VOC and other hazardous emissions pose severe health problems. To mitigate these health and safety risks, the implementation of VRUs can substantially aid companies across various industries. Unlock growth potential with industry expertise. Request your market sample report now: https://www.futuremarketinsights.com/reports/sample/rep-gb-993 The surging awareness of sustainability and environmental issues is creating new opportunities for products that can minimize emissions. Companies offering VRUs can gain a competitive edge due to the growing demand. The increasing Corporate Social Responsibility (CSR) activities by companies are likely to aid market expansion. Reduction of the environmental footprint can help businesses uptick their brand recognition and cater to a large consumer base. The market’s growth is also being boosted by the expanding use of vapor recovery units in the oil and gas sector. The need for vapour recovery units is astronomically increasing as many crude oil storage tanks are being built around the world. End users are using vapour recovery equipment frequently to limit the emission of light hydrocarbon and other volatile chemicals. During the forecast period, it is anticipated that the upcoming oilfield and oil storage opportunities might offer growth prospects for manufacturers of vapour recovery units. Key Takeaways From the Market Report: In 2018, the global vapour recovery units market size stood at US$ 955.5 Million. The global market accounted for US$ 1,196.4 Million in 2022. The market developed at a modest CAGR of 4.6% from 2017 to 2022. The condensation segment by technology captured 46.0% market share in 2022. The oil & gas compressors segment captured 39.6% market shares in 2022. India’s vapour recovery units market occupied 6.5% of the global market share in 2022. The United States captured 17.6% market share in 2022.

0 notes

Text

Shale Gas Processing Equipment set for Significant Growth

The global shale gas processing equipment market size was valued at $4.5 billion in 2018, and is projected to reach $13.5 billion by 2026, growing at a CAGR of 14.8% from 2019 to 2026.

The major key players operating in the global shale gas processing equipment industry include Schlumberger Ltd, Sivalls, Inc, Van Air Systems, Croft Production Systems, Inc., Koch Industries, Inc., Pall Corporation, PEMCO, Burckhardt Compression AG, Gas Processing Equipment, and ATB Riva Calzoni S.p.A.

Get a PDF brochure for Industrial Insights and Business Intelligence:

Shale gas equipment are used to eliminate components such as N2, H2S, heavy hydrocarbons, CO2, and water from the raw shale gas and oil before it is sent for transportation. This method includes various processes such as distillation, filtration, cracking, reheating, pyrolysis, and chemical treatment.

As per the U.S. energy information administration, the global shale gas industry surpassed more than $200 billion revenue in 2018 and as per their estimates it is anticipated to generate more than $390 billion revenue by 2025. Shale gas and oil infrastructure and markets for their related products, more specifically, processing equipment, altogether are heading toward their growth expansion phase as whole.

Due to abundant shale gas reserves, its infrastructure expected to grow significantly over the next decade. Hence, processing equipment is expected to have a promising future over the years to come

The U.S. reported shale gas production of over 37 billion cubic feet following Mexico and China at over 5 and 2.1 billion cubic feet respectively in 2015. As per the estimates of U.S. Energy Information Administration, the U.S. anticipated to produce over 80 billion cubic feet of shale gas by offering a scope to huge technological investment along with processing equipment manufacturing.

Equipment used in the shale gas processing are known as shale gas processing equipment. Popularly known equipment used in the shale gas processing include compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Apart from these, the others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. These equipment are used in the midstream phase of the oil & gas industry, wherein, gas/shale gas is processed, refined, and treated before it is transported for commercial usage.

Abundance shale gas reserves in some of the geographies across the globe and its commercial exploitation is the major factor and it has an immense impact on the global market growth. In response to the increasing natural gas prices, oil & gas industry seeks an alternative

to natural gas resources at economic terms. Shale gas is nothing but a natural gas trapped within a shale formation whose reserves are spread almost all across the globe.

Enquiry Before Buying: https://www.alliedmarketresearch.com/purchase-enquiry/1007

Heat exchanger is important equipment used in the overall gas processing plants. Technological evolution of heat exchangers is further contributing in the global shale gas processing equipment market growth. On the other hand, environmental hazards associated with hydraulic fracturing is the major restraining factor hampering the growth of the global shale gas processing equipment market. Nevertheless, growing initiatives from government from various geographies is anticipated to offer new growth opportunities over the forecast period.

The global shale gas processing equipment market is segmented on the basis of component and country. On the basis of component, the global market is studied across compressors & pumps, electrical machinery, heat exchangers, internal combustion engines, measuring & controlling devices, and others. Others segment includes separators & filters, hydrator/glycol dehydrator, injection systems, and storage tanks. Compressor and pumps is the largest segment among all and its growing demand is significantly expanding the global shale gas processing equipment market size.

Based on country, the global shale gas processing equipment market is studied across the U.S., Canada, China, Algeria, Mexico, Argentina, and others. The U.S. is the largest country level market among others due to abundant shale gas reserves and technically sound nature of the country, and investment in the shale gas exploration. Increased penetration of small-scale and mid-scale processing equipment manufacturers over large scale equipment manufacturers in the U.S. is one of the recent shale gas processing equipment market trend observed in recent years.

Browse complete industry report : https://www.alliedmarketresearch.com/shale-gas-processing-equipment-market

The U.S. is the largest country level market among others. The U.S. is the first country that has undertaken successful commercial scale production of shale gas and is offering scope to gas processing equipment. Therefore, the U.S. has the dominant share in the global shale gas market and is expected to be the largest one during the forecast period.

Based on component, Compressors and pumps segment accounted for the largest market share in 2018 and is expected to be the largest segment by the end of the forecast period. Demand for compressors is mainly seen in the U.S. as it is the largest market for shale gas processing equipment. Gas processing capacity have expanded in most of plants located in the U.S. as a result of increasing shale gas production. Hence, demand for compressors is rising in the U.S.

About Us

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of "Market Research Reports" and "Business Intelligence Solutions." AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain. Pawan Kumar, the CEO of Allied Market Research, is leading the organization toward providing high-quality data and insights. We are in professional corporate relations with various companies and this helps us in digging out market data that helps us generate accurate research data tables and confirms utmost accuracy in our market forecasting. Each and every data presented in the reports published by us is extracted through primary interviews with top officials from leading companies of domain concerned. Our secondary data procurement methodology includes deep online and offline research and discussion with knowledgeable professionals and analysts in the industry.

Contact:

David Correa

5933 NE Win Sivers Drive

205, Portland, OR 97220

United States

USA/Canada (Toll Free):

+1-800-792-5285, +1-503-894-6022

UK: +44-845-528-1300

Hong Kong 852 - 301 - 84916

India (Pune): +91-20-66346060

Fax: +1(855)550-5975

Web: www.alliedmarketresearch.com

Allied Market Research Blog:

Follow Us on Facebook | LinkedIn | YouTube

0 notes

Text

Research Deliver Insight into Global Chemical Storage Tank Market 2018

This report studies the global Chemical Storage Tank market status and forecast, categorizes the global Chemical Storage Tank market size (value & volume) by manufacturers, type, application, and region. This report focuses on the top manufacturers in North America, Europe, Japan, China, and other regions (India, Southeast Asia, Central & South America, and Middle East & Africa).

The global Chemical Storage Tank market is valued at million US$ in 2017 and will reach million US$ by the end of 2025, growing at a CAGR of during 2018-2025.

Request Sample Report at https://www.wiseguyreports.com/sample-request/2750890-global-chemical-storage-tank-market-research-report-2018

The major manufacturers covered in this report

CST

ZCL Composites

Snyder Industrial Tanks

BELCO

Poly Processing

Containment Solutions

Synalloy(Palmer)

Highland Tank

L.F. Manufacturing

Red Ewald

TF Warren(Tarsco)

Holvrieka

Enduro

Polymaster

Assmann

Tuffa

Xinlong

Geographically, this report studies the top producers and consumers, focuses on product capacity, production, value, consumption, market share and growth opportunity in these key regions, covering

North America

Europe

China

Japan

Southeast Asia

India

We can also provide the customized separate regional or country-level reports, for the following regions:

North America

United States

Canada

Mexico

Asia-Pacific

China

India

Japan

South Korea

Australia

Indonesia

Singapore

Rest of Asia-Pacific

Europe

Germany

France

UK

Italy

Spain

Russia

Rest of Europe

Central & South America

Brazil

Argentina

Rest of South America

Middle East & Africa

Saudi Arabia

Turkey

Rest of Middle East & Africa

On the basis of product, this report displays the production, revenue, price, market share and growth rate of each type, primarily split into

Stainless Steel Tanks

Fiberglass (FRP) Tanks

Polyethylene Tanks

Other

On the basis of the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate for each application, including

Ordinary Chemical

Fuel and Oil

Wastewater

View Detailed Report at https://www.wiseguyreports.com/reports/2750890-global-chemical-storage-tank-market-research-report-2018

The study objectives of this report are:

To analyze and study the global Chemical Storage Tank capacity, production, value, consumption, status (2013-2017) and forecast (2018-2025);

Focuses on the key Chemical Storage Tank manufacturers, to study the capacity, production, value, market share and development plans in future.

Focuses on the global key manufacturers, to define, describe and analyze the market competition landscape, SWOT analysis.

To define, describe and forecast the market by type, application and region.

To analyze the global and key regions market potential and advantage, opportunity and challenge, restraints and risks.

To identify significant trends and factors driving or inhibiting the market growth.

To analyze the opportunities in the market for stakeholders by identifying the high growth segments.

To strategically analyze each submarket with respect to individual growth trend and their contribution to the market

To analyze competitive developments such as expansions, agreements, new product launches, and acquisitions in the market

To strategically profile the key players and comprehensively analyze their growth strategies.

In this study, the years considered to estimate the market size of Chemical Storage Tank are as follows:

History Year: 2013-2017

Base Year: 2017

Estimated Year: 2018

Forecast Year 2018 to 2025

For the data information by region, company, type and application, 2017 is considered as the base year. Whenever data information was unavailable for the base year, the prior year has been considered.

Key Stakeholders

Chemical Storage Tank Manufacturers

Chemical Storage Tank Distributors/Traders/Wholesalers

Chemical Storage Tank Subcomponent Manufacturers

Industry Association

Downstream Vendors

Table of Contents

1 Chemical Storage Tank Market Overview

2 Global Chemical Storage Tank Market Competition by Manufacturers

3 Global Chemical Storage Tank Capacity, Production, Revenue (Value) by Region (2013-2018)

4 Global Chemical Storage Tank Supply (Production), Consumption, Export, Import by Region (2013-2018)

5 Global Chemical Storage Tank Production, Revenue (Value), Price Trend by Type

6 Global Chemical Storage Tank Market Analysis by Application

7 Global Chemical Storage Tank Manufacturers Profiles/Analysis

8 Chemical Storage Tank Manufacturing Cost Analysis

9 Industrial Chain, Sourcing Strategy and Downstream Buyers

10 Marketing Strategy Analysis, Distributors/Traders

11 Market Effect Factors Analysis

12 Global Chemical Storage Tank Market Forecast (2018-2025)

13 Research Findings and Conclusion

14 Appendix

About Us:

Wise Guy Reports is part of the Wise Guy Research Consultants Pvt. Ltd. and offers premium progressive statistical surveying, market research reports, analysis & forecast data for industries and governments around the globe.

Contact Us:

NORAH TRENT

Ph: +1-646-845-9349 (US)

Ph: +44 208 133 9349 (UK)

#Global Chemical Storage Tank Market#Global Chemical Storage Tank Market 2018#Global Chemical Storage Tank Market Growth

0 notes

Text

How To Manage The Production In Your Bottled Water Plant

Bottled water is a global commodity and is a profitable business if well – managed. Water is like the air we breathe in. Since the outbreak of the COVID-19 virus, bottled water demand has increased sharply. Consumers spent the year working and studying from home to try and limit its spread. The U.S. market is the largest bottled water consumer market. Americans drank over 14 billion gallons of bottled water in 2019, according to IBWA, 2020. In 2018, the industry generated a total amount of 18.36 billion dollars. According to Statista (2020), the market should grow by 8.0% from 2021 to 2025. Furthermore, the Bottled Water segment will show a revenue growth of 12.4% by 2022. More individuals and companies have shown interest in this profitable business venture. This is due to the If you intend venturing into the bottled water business. I've discussed in detail all it entails to produce bottled water. 01. Running a Bottled Water Production Plant In simple terms, the production of bottled water involves two major processes. The Purification and packaging of water for consumption. The basic process of producing bottled water is usually the same for all plants. But there are different type of products and applications. All you need to do is to adapt your equipment to fit your specific requirements. I have explained the steps involved in the production of bottled water below. Water Sourcing The source of water plays a key role in bottled water production. Both the quantity and quality of water one wants to produce, as well as profitability. You must ensure that you have an excellent water source on quality and quantity. I recommend a local well or municipal water supply. You must carry out all the required tests to aid decision-making. You must also ensure that you carry out routine checks on the water source to track anomalies. Water Treatment Water is a very delicate product, and contamination is a possible occurrence. Chemical pollution, as well as microbiological contaminants, affect water quality. The process of production is quite simple. Yet, you must take necessary precautions to avoid pollutants. You will face some challenges as a producer. Some of them are due to Pathogenic organisms and protozoa contamination. These pollutants could taint water quality. They also reduce the shelf life of bottled water. These pollutants could also be a pathogenic threat to customers. Strict production control is critical. This is to avoid contamination from pathogenic bacteria or protozoa. Quality control is a vital part of bottled water production. Producers must ensure that they produce only water of recommended quality. The water treatment section of the plant is very essential, and you must treat it as such. There are different processes involved in water treatment, including Activated Carbon Filtration. This is the removal of Chlorine and Trihalomethanes through a daily-monitored filtration process. Demineralization is then done to remove unwanted minerals in the water, a process called Reverse Osmosis. Water is then transferred to the Storage tank for further processing. You must ensure that the air in the tank is void of microorganisms. This helps to ensure that the water stored is not polluted. You then add minerals to the water according to consumers' taste. The final process of treatment is micro-filtration and ultra-violet filtration. Packaging Packaging involves filling treated waters into plastic or bottles. You must maintain the quality of your water. You must ensure that your packaging materials are not contaminated. The water used to wash and rinse these bottles must be clean before filling. Your filling room must be hygienic to ensure bottling in a controlled environment. You can carry out quality assurance of product via human inspection. 02. Cost of Operating a Bottled Water Plant Starting a bottled water production plant is a capital-intensive process. The bulk of the expenses is on getting a facility to locate your plant. The cost of acquiring the various machines required is also capital-intensive. The operating cost is lower than the start-up capital. These are the expenses incurred daily in the operation of a business. Labor Labor is a significant operating cost in any business. A bottled water production plant employs an average of 24 employees. These workers include Plant operator, machine operator, Watchman, Mechanic, Electrician, Quality Technician, etc. The average wage in bottled water production is $17.33 per hour (Payscale, 2020). See https://www.payscale.com/research/US/Industry=Bottled_Water_Manufacturing/Hourly_Rate for full details. For a 16-hour production cycle per day, $277.28. You can have your working period for 6 days. So, the total wage demand per week will be $1,363.68. The monthly wage demand will range from $5,454.72 to $6,818.4 for a 5-week month Power The manufacturing sector of the United States of America is energy-consuming. The sector used 32% of the total energy consumption in 2019. In 2019, the average power cost for industrial consumers was $0.0683 per kilowatt-hour of electricity. (Sönnichsen, 2020). Manufacturing facilities use and average of 95.1 kilowatt-hours (kWh) of electricity per day. For a production day, the total cost of electricity is $6.495. For a production day, the total cost of electricity is $ 6.495. The total monthly electricity cost will be $ 155.88 for a 6-working day bottling plant. You can make efforts to cut your electricity cost. To reduce cost, always switch off electrical appliances that are not in use. You must instruct your workers to switch off lights after the close of work. Rent for Facility You will spend a bulk of the start-up capital on acquiring a facility. Most plant owners rent this facility or get them through leasing. The average rent paid for warehouses for manufacturing in 2019 was $ 6.36 per square foot of the warehouse. For a 5000 sq. ft. warehouse, the average cost of rent is $31,800 monthly. Packaging Packaging goes a long way in a bottled water production business. Apart from water quality, the packaging is also capital-intensive. After the machinery's initial investment, the Cost Per Unit could range from $ 0.15 to $ 0.65. You must choose a bottle design that meets your business goals. You must also consider the raw materials which account for 70% of the bottle cost. Other factors are the power required and the amount of high-pressure air you need to blow the container. See https://inter-techltd.com/how-much-does-it-cost-to-produce-plastic-bottles/ to learn how to cut bottle production costs. Maintenance Effective maintenance and operation will ensure the sustainability of the business. You must ensure that you carry our routine maintenance activity on your plant. I'll recommend a quarterly check to ensure the longevity of the different machines. The average maintenance cost of a plant is between 2-3% of the total value of the machines in the plant. Under poor operations, maintenance costs over 5% of the asset replacement value yearly. 03. References https://www.payscale.com/research/US/Industry=Bottled_Water_Manufacturing/Hourly_Rate Please click below to watch the production process of bottled water production. https://www.youtube.com/watch?v=HlaloqvTOT8&list=PL2Jxij6gf8xTby1W0HOr7vWd-3_quZrc6&index=1 Read the full article

0 notes

Text

Flow Battery Market 2022 Statistics, Analysis & Forecast to 2030

Market Analysis

The global flow battery market size will grow at a whopping 30.68% CAGR between 2018- 2023, states the recent Market Research Future’s flow battery market forecast. A flow battery, simply put, is a form of a rechargeable battery or electrochemical cell. This is an electrical storage device that is connected between a conventional battery and a fuel cell. It offers two chemical components that are easily dissolved in liquids and contain two electrolyte solutions in two tanks that are connected with two independent loops.

Various factors are propelling the global flow battery market share. According to the recent MRFR report, such factors include the growing demand for energy storage applications, long life span, instant recharge capability, easy replaceability of electrolytes, high construction price of flow batteries, growth in telecommunication tower installations, growing demand from the utility sector, rising investments in Flow Battery, and inherent perks of a flow battery.

Get Free Sample PDF @ https://www.marketresearchfuture.com/sample_request/6620

On the contrary, the need for large tanks of electrolytes, low energy density, high initial investment, and the impact of the COVID-19 outbreak may limit the global flow battery market growth over the forecast period.

Market Segmentation

The MRFR report highlights an inclusive segmental analysis of the global flow battery market based on application, storage type, material type, and product type.

By product type, the global flow battery market is segmented into hybrid and redox. Of these, the redox segment will lead the market over the forecast period for its flexibility and reliability in energy storage applications in power stations and grid operations.

By material type, the global flow battery market is segmented into zinc bromine and vanadium. Of these, zinc bromine will dominate the market over the forecast period.

By storage type, the global flow battery market is segmented into compact and large scale. Of these, the large scale segment will have a major share in the market over the forecast period.

By application, the global flow battery market is segmented into commercial, industrial, defense, utilities, and other segments. Of these, the commercial segment will have the lions share in the market over the forecast period.

Regional Analysis

By region, the global flow battery market covers the growth opportunities and recent trends across Europe, North America, the Asia Pacific (APAC), & the Middle East and Africa (MEA). Of these, North America will spearhead the market over the forecast period. Customers striving to reduce energy costs, the introduction of several residential storage solutions, increasing deployment of energy storage in residential and commercial properties in their building plans, and high investments in technology due to rising energy costs are adding to the global flow battery market growth in the region.

The global flow battery market in the APAC region is predicted to have healthy growth over the forecast period. Emerging countries China, Japan, and India modifying their energy policies constantly to ensure that a good amount of energy comes from renewable sources of energy like wind and solar, growing interest in renewable sources of energy in light of the deteriorating environmental health, growing investments in the development of flow battery, and financial backing from the government are adding to the global flow battery market growth in the region.

The global flow battery market in Europe is predicted to have sound growth over the forecast period, and in the MEA is predicted to have admirable growth over the forecast period.

Key Players

Eminent players profiled in the global flow battery market report include Elestor (Europe), Schmid (Germany), EnSync Energy Systems (US), ViZn Energy Systems. (US), Sumitomo Electric Industries, Ltd (Japan), redT energy plc. (UK), Primus Power (US), Redflow Limited (Australia), Gildemeister Energy Solutions (Austria), and ESS Inc. (US).

Browse Complete Report @ https://www.marketresearchfuture.com/reports/flow-battery-market-6620

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Edibles.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone:

+1 628 258 0071(US)

+44 2035 002 764(UK)

Email: [email protected]

0 notes

Text

High-performance Anti-corrosion Coatings Market to Develop Rapidly by 2027

Global High-performance anti-corrosion coatings Market: Highlights

The global high-performance anti-corrosion coatings market is projected to grow at a CAGR of more than 5.0% between 2019 and 2027. The market is driven by growth of the global oil & gas industry.

Key Developments in Global High-performance anti-corrosion coatings Market

In December 2019, RPM International Inc. announced that its Mantrose-Haeuser Co., Inc. business has acquired Profile Food Ingredients, LLC, a manufacturer of dry stabilizer and emulsifier blends for the food industry.

In October 2019, AkzoNobel launched range of high performance primers for corrosion protection. It covers a full array of substrates, surfaces and environments – from cable cars and chemical plants to window frames and wind turbines.

The number of oil & gas drilling and exploration activities has increased in the last few years. The Gulf of Mexico, Southeast Asia, and North Sea are currently rich in oil & gas resources and they have a large number of oil rigs. These activities are expected to increase expenditure on maintenance and repair in the near future. Thus, currently, there exists a requirement for protective coatings that are capable of increasing the shelf life and durability of equipment under varying temperatures and climatic conditions.

High-performance anti-corrosion coatings protect metal surfaces of various components used in the oil & gas industry. These coatings offer an influential barrier against corrosion, especially when components or parts such as storage vessels, offshore drilling equipment, and other machinery come in contact with chemicals and moisture.

Stages such as manufacture, extraction, storage, and distribution of oil & gas are key sources of corrosion. Storage tanks, transmission pipelines, oil rigs, steel structures, and other oil vessels are subjected to moisture, salt, fog, and corrosive environment.

Asia Pacific dominates the global market, due to growth of pharmaceutical and health care industries in the region. Rapid infrastructure development in major countries of Asia Pacific such as China, India, Indonesia, Vietnam, Singapore, and Malaysia is expected to boost the consumption of high-performance anti-corrosion coatings in the region between 2018 and 2026. High-performance anti-corrosion coatings are extensively consumed in the construction industry.

Request PDF Brochure –

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=8587

Global High-performance anti-corrosion coatings Market: Segmental Trends

Based on product, the global high-performance anti-corrosion coatings market has been segmented into epoxy, urethane, acrylic, and others. Epoxy coatings protect substrates from the deterioration caused by corrosive surroundings. These coatings have excellent adhesion and flexibility. Therefore, these are highly preferred in various end-user industries.

Rising demand for acrylic coatings is expected to fuel the high-performance anti-corrosion coatings market between 2019 and 2027. These coatings offer superior structural and mechanical characteristics than other anti-corrosion coatings such as alkyd and vinyl coatings. Acrylic coatings have high color retention rate and they are chemically inert. Additionally, they are eco-friendly.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=8587

High-performance anti-corrosion coatings are widely used in the oil & gas industry. In terms of demand, the oil & gas segment is expected to present growth opportunities to the high-performance anti-corrosion coatings market from 2019 to 2027. Rise in maintenance and repair activities in the global oil & gas industry, especially for oil drilling equipment, offshore installation machinery, process vessels, and transmission pipelines, is likely to be a major driver of the market in the near future.

The power generation segment is estimated to present lucrative opportunities to the high-performance anti-corrosion coatings market between 2019 and 2027. High-performance anti-corrosion coatings are required for coating applications in insulated wires, electricity-generating components, turbine blades, and hydraulic systems used in nuclear, geothermal, and solar power sectors.

Global High-performance anti-corrosion coatings Market: Regional Highlights

Some of the key uses of high-performance anti-corrosion coatings include their application on steel, metal, and concrete substrates used in extraction, utilities, manufacturing, and transport infrastructure. Development of the transport infrastructure in Asia Pacific is anticipated to be the key driving factor for the market during forecast period.

Rising usage of metal and steel in the construction of bridges, roadways, highways, waterways, airports, and railways is likely to offer immense growth opportunities to the high-performance anti-corrosion coatings market in the next few years.

Buy Our Premium Research Report@

https://www.transparencymarketresearch.com/checkout.php?rep_id=8587<ype=S

In August 2018, RPM International Inc. announced that its Rust-Oleum Group would be acquiring the Mean Green branded line of specialty cleaning products

In March 2018, RPM International Inc. announced that its Rust-Oleum Group had acquired Miracle Sealants Company

In November 2017, Nippon Paint Co., Ltd. engaged in a discussion with Axalta regarding a potential acquisition of Axalta

In October 2017, 3M announced that it has completed the acquisition of Scott Safety, a premier manufacturer of innovative products, such as self-contained breathing apparatus (SCBA) systems, gas and flame detection instruments, and other safety devices, that complement the former’s personal safety portfolio

In May 2017, AkzoNobel opened new performance coatings facility in Chonburi, Thailand.

Global High-performance anti-corrosion coatings Market: Competition Landscape

The global high-performance anti-corrosion coatings market witnesses high degree of competition among market players. The market is highly concentrated, as well-established players constitute a significant market share. High level of competition among established players is expected during the forecast period, due to their integrated value chains.

Some of the key players operating in the global high-performance anti-corrosion coatings market include Akzo Nobel N.V., PPG Industries Inc., Jotun A/S, Hempel A/S, Nippon Paint Holdings Co., Ltd., and 3M.

More Trending Report by Transparency Market Research –

Metal and Ceramic Injection Molding Market – Global metal and ceramic injection molding market is broadly affected by several factors, including increase in demand for metal and ceramic injection molded components and parts in various end-use industries

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey Transparency Market Research, 90 State Street, Suite 700, Albany, NY 12207 Tel: +1-518-618-1030 USA – Canada Toll Free: 866-552-3453 Email: [email protected] Website: https://www.transparencymarketresearch.com

0 notes

Text

Methylene Diphenyl Di-Isocyanate (MDI) Market Market Future Outlook – Methylene Diphenyl Di-Isocyanate (MDI) Market Market To Gain Massive Growth : BASF SE, Huntsman International LLC, Covestro AG, Wanhua Chemical Group Co

Methylene Diphenyl Di-Isocyanate (MDI) is an aromatic diisocyanate formed by positioning isocyanate in its fourth position called 4,4���-Methylene Diphenyl Di-Isocyanate. The structure is most often used in the high volume chemical production of polyurethane foams. It is also used in non-foam applications, including paints and coating, elastomers, and adhesives and sealants, and other related products. Methylene Diphenyl Di-Isocyanate (MDI) is the least hazardous, delivers low vapor pressure, and hence decreases hazards during handling as compared to other major isocyanates involving Toluene Diisocyanate (TDI) and Hexamethylene Diisocyanate (HDI). Additionally, insulation rendered with Methylene Diphenyl Di-Isocyanate (MDI), combined with consumers' needs to conserve energy by reducing the cost of heating and cooling appliances in daily life which incorporates refrigerators and heaters. Other additional industries that cover MDI applications are footwear, leisure, and sports, where this structure is used to provide flexible foams.

Grab a sample PDF here https://straitsresearch.com/report/methylene-diphenyl-di-isocyanate-mdi-market/request-sample

Key Drivers

Growth and evolution of end-use industries

Growth in the manufacturing of polyurethane products, where MDI is a raw material

Key Restraints

Rising environmental concerns and availability of environmental-friendly substitutes

Fluctuation in raw material prices

Key Opportunities

Phosgene-free MDI or non-toxic phosgene production process acts as the opportunity of the global market. As phosgene free MDI helps towards countering the government standards related to health issue and further enhances the market share in future

Intended Audience

MDI Manufacturers and Other Stakeholders

Major End-Users of MDI

Organizations, Forums, and Alliances Related to MDI

Government Bodies Such as Regulating Authorities and Policy Makers

Market Research and Consulting Firms

Rigid Foam & Construction Industry to Account for Prominent Market Shares by Application & End-Use Industry, Respectively

MDI is used in rigid foam, flexible foam, coatings, elastomers, adhesives, and sealants on account of its flexibility and significant environmental benefits, including reduced project weight and increased energy efficiency. The usage of rigid PU foam in insulated panels, roof and wall insulation, and gap fillers will increase its accessibility in the global market. Rigid foam accounts for a strong share in construction applications, where it is used to cover irregular shapes and seal gaps.

Predominantly, MDI’s array of forms are used in construction, furniture, electronics, automotive, and other end-use industries. The construction end-use industry is pegged to increase on account of upcoming infrastructure projects in emerging economies, including storage tanks, roadways, warehouses, and other buildings with added rising in market share. Favorable government norms and policies pertaining to construction and building further augment market growth. According to the report of National Statistics of the U.K. Government in 2018, the construction industry grew 6.2% in the Great Britain in 2017, of which new firm construction is about 3.4%.

China & India Will Drive Growth of Asia-Pacific’s MDI Market

The methylene diphenyl di-isocyanate market in Asia-Pacific is projected to increase by more than 6% on account of the rising demand in emerging countries such as China and India. Presently, the growth of end-use industries such as electronics, construction, and automotive are imparting to the growth of the regional MDI market. China’s MDI market is estimated to grow on account of low-cost transportation, less stringent government norms, and the availability of low-cost raw material, labor, and land. According to China’s central government, the automobile industry output will reach 30 million units by 2020 and 35 million units by 2025 on account of the fact that polyurethanes are widely used in the manufacturing of cars due to the benefits regarding energy conservation, comfort, and protection.

Europe – The Largest Value Shareholder Globally

Europe holds the largest market share globally, with leading players such as BASF SE and Covestro AG driving growth. With increasing prices of isocyanates and usage of polyurethanes, the regional methylene diphenyl di-isocyanate market is growing by more than 5.5 % across global market share. Strong demand, R&D activities, and efforts towards the development of eco-friendly MDI are expected to create opportunities for market expansion in the years to come.

Key Players

The market is competitive in nature, and a small number of market players hold prominent market shares. Some of the most noteworthy market participants are BASF SE, Huntsman International LLC, Covestro AG, Wanhua Chemical Group Co., Ltd., The Dow Chemical Company, Bayer Material Science, Tosoh Corporation, Chemtura Corp, and Mitsui Chemicals, Inc. In light of the rising demand from end-use industries, companies are aiming to establish new partnerships or relationships with other players to meet customer requirements.

Company and Industry News

In April 2019, BASF SE invested USD 87 million on the second phase of its methylene diphenyl diisocyanate (MDI) unit at the Verbund plant in Geismar; with this investment, the company hopes to increase its share in the North America market

In February 2019, Huntsman released its yearly report, in which the company mentioned a 16% increase in revenue in 2018; furthermore, on account of the low price of MDI in 2018, the company faced revenue loss in the chemical section

In October 2018, Conestro AG invested USD 1.6 billion in its new MDI plant in Baytown, Texas, which is expected to start in 2024 with a production capacity of 0.5 meter tons/year; with this new production facility, the company increased its market share in Europe

Methylene Diphenyl Di-isocyanate (MDI) Market Segmentation

By Application

Rigid foam

Flexible foam

Coating

Elastomer

Adhesive

Sealant

Others

By End-User Industry

Construction

Furniture and interiors

Electronics and appliances

Automotive

Footwear

Others

By Region

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Russia

Poland

Rest of Europe

Asia-Pacific

Japan

India

China

South Korea

Australia

Vietnam

Indonesia

Malaysia

Singapore

Rest of Asia-Pacific

Latin America

Brazil

Argentina

Colombia

Rest of Latin America

Middle East

Saudi Arabia

Oman

Qatar

Bahrain

UAE

Rest of ME

Africa

Nigeria

Tanzania

South Africa

Ghana

Rest of Africa

#MethyleneDiphenylDiIsocyanate(MDI)Market#MethyleneDiphenylDiIsocyanate(MDI)Marketreport#MethyleneDiphenylDiIsocyanate(MDI)Marketresearch#MethyleneDiphenylDiIsocyanate(MDI)Marketreports#MethyleneDiphenylDiIsocyanate(MDI)Marketreserachreports#MethyleneDiphenylDiIsocyanate(MDI)Marketshare#MethyleneDiphenylDiIsocyanate(MDI)Marketsize#MethyleneDiphenylDiIsocyanate(MDI)Marketgrowth#MethyleneDiphenylDiIsocyanate(MDI)Markettrends#MethyleneDiphenylDiIsocyanate(MDI)Marketinsight#MethyleneDiphenylDiIsocyanate(MDI)Marketrevenue#MethyleneDiphenylDiIsocyanate(MDI)Marketanlaysis#MethyleneDiphenylDiIsocyanate(MDI)Marketapplications#MethyleneDiphenylDiIsocyanate(MDI)Marketregions

0 notes

Text

Water Filters Market Size, Trends, Revenue Share Analysis, Forecast, 2020–2026

The global water filters market is forecast to reach USD 18.50 Billion by 2026, according to a new report by Reports and Data. The market is rising rapidly in the global market due to the high demand for water filters owing to the extreme increase of waste disposal into rivers and regulations with safe drinking water by different regulatory bodies globally. Many households have started adopting the technology in developed and developing countries because of its affordable pricing.

The Municipal segment had the highest market share of 22.5% in the year 2018 as municipal corporations mostly conduct great safeguarding for their water supplies to ensure the safe drinking and other safe usage of water for the habitants of major cities and urban outskirts. They incorporate a different type of filtration and follow the highest level of safety treatments for their supplied water.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/313

Asia Pacific region is forecasted to generate the highest revenue of USD 7.36 Billion in the year 2026, owing to its extensive market penetration coupled with the rising population mostly in China, India, and Philippines.

Key participants include Mann-Hummel, Veolia, Suez Water Technologies & Solutions, Kent RO Systems Ltd., Pentair Plc, Mitsubishi Rayon Cleansui Co., EcoWater Systems LLC., Ion Exchange, EvoQua Water Technologies, Eaton Corporation.

To know more about the report @ https://www.reportsanddata.com/report-detail/water-filters-market

For the purpose of this report, Reports and Data have segmented the global water filters market on the basis of the type of filters, Application, end-use verticals, and region:

Type of Filters Outlook (Revenue, USD Billion; 2016-2026)

Single & Dual Media Filter

Multi-Media Filtration

Activated Carbon Filtration

Ultra Filtration

Strainer Cartridge

Others

Type of Plastic Outlook (Revenue, USD Billion; 2016-2026)

Storage Based

Non-storage Based

End-Use Verticals Outlook (Revenue, USD Billion; 2016-2026)

Municipal

Household

Commercial

Industrial

Chemicals & Pharmaceuticals

Hospitals & Clinics

Sewage Recycle

Others

Regional Outlook (Revenue, USD Billion; 2016-2026)

North America

Europe

Asia Pacific

MEA

Latin America

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/313

Further key findings from the report suggest

Industries such as bottled drinking water, drinks, foods, and beverages have to manufacture the products following the highest level of quality standards in order to ensure safety for their consumers and achieve higher brand trust also. Industry segment is rising with a CAGR of 7.1% during the forecast period and will deliver a revenue of USD 3.68 Billion.

Household usage has been proliferated significant times in recent years due to the rise in the awareness for safe drinking water coupled with a reduction in overall pricing of the water filters. The segment is calculated to grow with a CAGR of 7.6% throughout the forecast period.

Ultra Filtration (UF) is the type of membrane-based filtration in which hydrostatic pressure forces is embodied to a liquid against a semipermeable membrane. The semipermeable thin layered membrane then separates the impurities when a driving force is applied across the membrane. This sub-segment is forecasted to gain a market share of 9.0% by 2026 by the type of filters segment.

By the application type, the market has two sub-segments. One of them is storage based water filters. Storage based designs are mostly used in household purposes as it comes with a built-in storage tank which contains the filtered water for convenient instant usage. This segment is growing with a CAGR of 7.7% in the forecast period.

APAC owing to its massive population and record water-based diseases because of extreme waste disposal in rivers mostly in India, Bangladesh and Afghanistan is expected to grow with the highest CAGR of 8.2% throughout the forecast.

North America is accounted to gain 29.1% of market possession by 2026 with a CAGR of 7.4% in the forecast period.

Europe is forecasted to witness significant growth in the overall market, with 14.2% of market possession by 2026 and CAGR of 3.8% during the forecast period.

Key Features of the Water Filters Market Report:

· Detailed assessment and exhaustive understanding of the Water Filters Market

· Significant insights into manufacturing processes, major barriers, and risks

· 8-year forecast estimation to offer information about the market size and market share on the global and regional levels

· Evaluation of the key drivers, restraints, growth opportunities, threats, limitations, barriers, and other key elements

· Identification of growth prospects and potential for the Water Filters industry

· Comprehensive analysis of the key market players and their strategies

Request a customization of the report @ https://www.reportsanddata.com/request-customization-form/313

Thank you for reading our report. Customization of this report is available. Please get in touch with us for further inquiry.

Explore Reports and Data’s Prime Analysis of the global Consumer Electronics:

Security Inspection Market @ https://www.reportsanddata.com/report-detail/security-inspection-market

Wheelchair Market @ https://www.reportsanddata.com/report-detail/wheelchair-market

Chromebooks Market @ https://www.reportsanddata.com/report-detail/chromebooks-market

Bluetooth Speakers Market @ https://www.reportsanddata.com/report-detail/bluetooth-speakers-market

Electronic Table Games Market @ https://www.reportsanddata.com/report-detail/electronic-table-games-market

About Reports and Data

Reports and Data is a market research and consulting company that provides syndicated research reports, customized research reports, and consulting services. Our solutions purely focus on your purpose to locate, target and analyze consumer behavior shifts across demographics, across industries and help client’s make a smarter business decision. We offer market intelligence studies ensuring relevant and fact-based research across multiple industries including Healthcare, Technology, Chemicals, Power and Energy. We consistently update our research offerings to ensure our clients are aware about the latest trends existent in the market. Reports and Data has a strong base of experienced analysts from varied areas of expertise.

#Water Filters Market#Water Filters Market trends#Water Filters Market Size#Water Filters Market Growth

0 notes

Text

Cryogenic Insulation Market Is Set To Become A Market Of $2.9 Billion Value Till 2025

The global cryogenic insulation market size is expected to reach USD 2.9 billion by 2025, expanding at a CAGR of 6.5%, according to a new report by Grand View Research, Inc. Rising preference for low temperature insulation from various application industries including energy and power and metallurgy is likely to propel the market growth.

The growth of aerospace and space exploration industries across the economies is anticipated to fuel the demand for cryogenic insulation systems. In addition, rising demand for LNG as an environment friendly alternative to the conventional energy resources has resulted in high demand for cryogenic engines, pipes, valves, and storage tanks.

Increasing R&D spending by the major players is expected to have positive impact on product enhancement and differentiation strategies. In addition, the participants are focusing on developing novel materials for higher efficiency and lower operational costs. Also, the players are pooling their technology and resources together in order to serve the rising demand.

North America and Europe are anticipated to dominate the market on account of the rising offshore gas production in order to cater the rising demand from various application industries. In addition, the rising LNG/LPG transportation across the regions is further likely to propel the market growth.

To request a sample copy or view summary of this report, click the link below: www.grandviewresearch.com/industry-analysis/cryogenic-insulation-market

Further key findings from the report suggest:

PUR and PIR accounted for the largest market share of 42.9% in terms of revenue in 2018, owing to its wide range of applications in gas liquefaction and regasification industry

LPG/LNG transport and storage industry dominated the market in 2018 and is estimated to reach USD 1.5 billion by 2025, due to rising demand for LNG or LPG from various sectors including automotive and power generation

North America is anticipated to emerge as one of the prominent regions for the industry over the forecast period and is projected to account for USD 699.9 million by 2025 on account of the rising offshore oil production in countries such as the U.S.

Cryogenic insulation market in China is projected to exhibit a CAGR of 6.5% from 2019 to 2025 on account of the rapid industrialization and rising disposable income

Market participants across the globe have increased their R&D spending in order to develop high performance insulation for various applications.

Grand View Research has segmented the global cryogenic insulation market on the basis of product, application, and region:

Cryogenic Insulation Product Outlook (Revenue, USD Billion, 2014 - 2025)

PUR and PIR

Cellular Glass

Polystyrene

Fiberglass

Perlite

Others

Cryogenic Insulation Application Outlook (Revenue, USD Million, 2014 - 2025)

LPG/LNG Transport & Storage

Energy and Power

Metallurgical

Others

Cryogenic Insulation Regional Outlook (Revenue, USD Million, 2014 - 2025)

North America

Europe

Asia Pacific

Middle East & Africa

Central & South America

U.S.

Canada

Mexico

Germany

The Netherlands

Russia

Turkey

Spain

France

China

India

South Korea

Australia

Iran

Qatar

Argentina

Brazil

About Grand View Research

Grand View Research, Inc. is a U.S. based market research and consulting company, registered in the State of California and headquartered in San Francisco. The company provides syndicated research reports, customized research reports, and consulting services. To help clients make informed business decisions, we offer market intelligence studies ensuring relevant and fact-based research across a range of industries, from technology to chemicals, materials and healthcare.

0 notes

Text

Glass Flake Market - Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth And Forecast 2021 - 2027

On the basis of the resin type, the global glass flake coatings market is segmented into the epoxy, polyester, vinyl ester, and others. The polyester is sub-segmented to isophthalic polyester and bisphenol polyester. The epoxy is sub-segmented to pure epoxy and hybrid epoxy. The hybrid epoxy glass flake coatings are further segmented to polyamine cured epoxy and polyamide cured epoxy. The vinyl ester is sub-segmented into standard vinyl ester and brominated vinyl ester. Epoxy resin accounted for the major share of the global glass flake coatings market in 2017 owing to its superior properties such as excellent corrosion, abrasion, and impact resistance as well as strong wettability & moisture retention property.

On the basis of the substrate type, the global glass flake coatings market is segmented into steel and concrete. The steel substrate consumed glass flake coatings on a large scale under substrate type category due to increased use of steel in shipbuilding, offshore & onshore platforms, chemical storage tanks, pipelines in 2017 and is expected to continue the dominance during the forecast period.

On the basis of the application method, the Glass Flake Market is segmented into brush/roller, conventional spray, and airless spray. Airless spray accounted the major share of the global glass flake coatings market owing to the precision centric and large-scale application in marine, oil & gas, chemical and constructions industries.

On the basis of the end-use industries, the global glass flake coatings market is segmented into oil & gas, marine, chemical, construction, and others. The oil & gas industry is sub-segmented into offshore and onshore. The marine and oil & gas industries are collectively expected to become major consumers of the global glass flake coatings market owing to its wide application in oil & gas tanks and pipelines, offshore & onshore infrastructure and shipbuilding during the forecast period.

Access Report @

https://www.marketresearchfuture.com/reports/glass-flake-coatings-market-6159

Regional Analysis

The global glass flake coatings market is segmented into five regions namely Asia Pacific, North America, Europe, Latin America, and the Middle East and Africa. Asia Pacific is expected to dominate the global glass flake coatings market during the forecast period. North America and Europe are followed Asia Pacific in terms of market size in 2017 and are expected to show steady demand during the forecast period. The Middle East & Africa and Latin America are likely to show rising demand for glass flakes coatings during the forecast period, 2018–2023.

Competitive Analysis

Some of the prominent players operating in the global glass flake coatings market are Akzo Nobel N.V. (Netherlands), Nippon Sheet Glass Co., Ltd. (Japan), PPG Industries, Inc. (U.S.), Jotun (Norway), Hempel A/S (Denmark), CHEMIPROTECT ENGINEERS (India), The Sherwin-Williams Company (U.S.), KCC CORPORATION. (South Korea), Corrosioneering Group (UK), Winn & Coales (Denso) Limited (England), BASF SE (Germany), Clean Coats. (India), Berger Paints India Limited (India), Shalimar Paints Limited (India), and Samhwar Paints Industrial Co. Ltd (South Korea).

Get A Sample Report of @

https://www.marketresearchfuture.com/sample_request/6159

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future

Phone: +16468459312

Email: [email protected]

Read More Related Article:

https://www.marketresearchfuture.com/reports/electrochromic-glass-market-5530

https://www.marketresearchfuture.com/reports/acrylonitrile-butadiene-styrene-market-5566

https://www.marketresearchfuture.com/reports/thermal-spray-market-5561

0 notes

Text

Ammonia Market Trends and Demand Analysis to 2028 | Future Scope, Price Structure, Industry Share and Forecast to 2028 by Fortune Business Insights™

The global ammonia market size is projected to reach USD 110.93 billion by 2028, exhibiting a CAGR of 6.4% during the forecast period. Fortune Business Insights™ highlights this information in its report, titled “Ammonia Market, 2021-2028”, which also provides that this market’s value stood at USD 67.01 billion in 2020 and is expected to touch USD 71.98 billion in 2021.

The COVID-19 pandemic outbreak has caused the market growth to stumble and decline by 4.8% in 2020 owing to the obstructions created by lockdowns and social distancing measures for the fertilizer industry. These obstructions are mainly in the form of supply chain upheavals leading to production delays and a sudden contraction in the availability of agricultural inputs.

Cummins Partners with KBR to Develop Integrated Green Ammonia

In May 2021, technology leader Cummins and KBR inked a Memorandum of Understanding (MoU) to join forces to develop holistic and integrated solutions and techniques to produce NH3 from renewable energy sources. The partnership would be characterized by Cummins’s expertise in proton exchange membrane electrolysis to generate hydrogen and KBR’s competencies in NH3 technologies. Together, thus, the two companies aim at speeding up de-carbonization in various industries and accelerate the development of green ammonia, which holds enormous potential in aiding the growth of sustainable agriculture. Moreover, the combined financial strength of the two entities will be an added advantage for this joint venture.

Emergence of NH3 as an Energy Storage Solution to Catalyse the Market

The most challenging task facing the energy industry today is the issue of energy storage. While lithium has proven to be adequate in storing excess energy, especially from renewables, more efficient solutions and technologies are being demanded due to the soaring consumption of electricity worldwide. In response, leading technology companies have been engaged in the development of next-generation solutions based on the potential of ammonia. For example, in June 2018, Siemens unveiled its Green Ammonia Energy Storage Demonstrator in the UK. The technology uses renewable energy to produce NH3 from hydrogen and nitrogen from the air and the NH3 thus derived is stored in a tank and reconverted to electricity as and when required. The potential of this chemical in storing energy has also encouraged researchers to devise innovative ways to produce the compound. In May 2020, for instance, researchers at the Massachusetts Institute of Technology (MIT) formulated a technique under which hydrogen and nitrogen can be synthesized using an electric current to generate a lithium catalyst, where the two elements will create ammonia.

Fertilizer Segment to Spearhead the Market, states Fortune Business Insights

On the basis of application, the market is segmented into fertilizers, textiles, refrigeration, pharmaceuticals, household & industrial cleaning, and others. While the textile segment held a share of 10.93% in the US market in 2020, the fertilizer segment is anticipated to dominate the market as ammonia is the fundamental compound in the production of ammonium nitrate fertilizers. Moreover, NH3 is also vital in the manufacturing of urea, which is an essential element in coating seeds.

Based on geography, the market is segregated into North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Heightening Demand for Food to Drive the Market in Asia Pacific

Asia Pacific is expected to dictate the ammonia market share during the forecast period on account of the exponential demand for food and food security in the region’s developing economies. Furthermore, China has emerged as the largest producer and consumer of fertilizers in the world due to the lack of availability of fertile soils in the country. The Asia Pacific market size stood at USD 27.41 billion in 2020.

The increase in agricultural lands in the US will be a prominent growth factor for the market in North America, where the production and deployment of NH3 are considerably high.

In Latin America, on the other hand, sufficient access to natural gas and improving farming infrastructure will create ample business opportunities in the region.

Introduction of Digital Tools by Key Players to Feed Market Growth

Key players in this market, in a bid to expand their footprint, are introducing digital technologies to take NH3 production and supply to the next level. The idea behind the launch of such advanced tools is to enhance value chains and augment the production and distribution competencies of players of all sizes. In addition, these technologies are also enabling leading companies to further entrench their market position and broaden their sales horizons.

Browse In-depth Summary of This Research Insight@ https://www.fortunebusinessinsights.com/industry-reports/ammonia-market-101716

Industry Development

August 2020: Haldor Topsoe and BASF teamed up to integrate BASF’s OASE connect simulation platform with TopSEOs’s flagship connected service solution for NH3 producers, Clearview Ammonia. Using the combined capabilities of these tools, NH3 producers can optimize operations at plants and gain real-time insights into production processes.

List of Key Players Profiled in this Market Report

China National Petroleum Corporation (Beijing, China)

Koch Fertilizer, LLC (Kansas, the U.S.)

Qatar Petroleum (Doha, Qatar)

Nutrient Ltd. (Saskatoon, Canada)

BASF SE (Ludwigshafen, Germany)

Rashtriya Chemicals and Fertilizers Limited (RCFL) (Mumbai, India)

Praxair Technology, Inc. (Connecticut, the U.S.)

EuroChem Group (Zug, Switzerland)

SABIC (Riyadh, Saudi Arabia)

CF Industries Holdings, Inc. (Illinois, the U.S.)

Yara International ASA (Oslo, Norway)

0 notes

Text

Asia pacific to be the key regions for high-performance anti-corrosion coatings market: TRANSPARENCY MARKET RESEARCH

Global High-performance anti-corrosion coatings Market: Highlights

The global high-performance anti-corrosion coatings market is projected to grow at a CAGR of more than 5.0% between 2019 and 2027. The market is driven by growth of the global oil & gas industry. Asia Pacific accounts for a major share of the global market, due to growth of construction, marine, and oil & gas industries in the region.

The number of oil & gas drilling and exploration activities has increased in the last few years. The Gulf of Mexico, Southeast Asia, and North Sea are currently rich in oil & gas resources and they have a large number of oil rigs. These activities are expected to increase expenditure on maintenance and repair in the near future. Thus, currently, there exists a requirement for protective coatings that are capable of increasing the shelf life and durability of equipment under varying temperatures and climatic conditions.

High-performance anti-corrosion coatings protect metal surfaces of various components used in the oil & gas industry. These coatings offer an influential barrier against corrosion, especially when components or parts such as storage vessels, offshore drilling equipment, and other machinery come in contact with chemicals and moisture.

Stages such as manufacture, extraction, storage, and distribution of oil & gas are key sources of corrosion. Storage tanks, transmission pipelines, oil rigs, steel structures, and other oil vessels are subjected to moisture, salt, fog, and corrosive environment.

Request for sample-

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=8587

Global High-performance anti-corrosion coatings Market: Segmental Trends

Based on product, the global high-performance anti-corrosion coatings market has been segmented into epoxy, urethane, acrylic, and others. Epoxy coatings protect substrates from the deterioration caused by corrosive surroundings. These coatings have excellent adhesion and flexibility. Therefore, these are highly preferred in various end-user industries.

Rising demand for acrylic coatings is expected to fuel the high-performance anti-corrosion coatings market between 2019 and 2027. These coatings offer superior structural and mechanical characteristics than other anti-corrosion coatings such as alkyd and vinyl coatings. Acrylic coatings have high color retention rate and they are chemically inert. Additionally, they are eco-friendly.

High-performance anti-corrosion coatings are widely used in the oil & gas industry. In terms of demand, the oil & gas segment is expected to present growth opportunities to the high-performance anti-corrosion coatings market from 2019 to 2027. Rise in maintenance and repair activities in the global oil & gas industry, especially for oil drilling equipment, offshore installation machinery, process vessels, and transmission pipelines, is likely to be a major driver of the market in the near future.

The power generation segment is estimated to present lucrative opportunities to the high-performance anti-corrosion coatings market between 2019 and 2027. High-performance anti-corrosion coatings are required for coating applications in insulated wires, electricity-generating components, turbine blades, and hydraulic systems used in nuclear, geothermal, and solar power sectors.

Request for covid19 impact analysis –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=8587

Global High-performance anti-corrosion coatings Market: Regional Highlights

Asia Pacific dominates the global market, due to growth of pharmaceutical and health care industries in the region. Rapid infrastructure development in major countries of Asia Pacific such as China, India, Indonesia, Vietnam, Singapore, and Malaysia is expected to boost the consumption of high-performance anti-corrosion coatings in the region between 2018 and 2026. High-performance anti-corrosion coatings are extensively consumed in the construction industry.

Some of the key uses of high-performance anti-corrosion coatings include their application on steel, metal, and concrete substrates used in extraction, utilities, manufacturing, and transport infrastructure. Development of the transport infrastructure in Asia Pacific is anticipated to be the key driving factor for the market during forecast period.

Rising usage of metal and steel in the construction of bridges, roadways, highways, waterways, airports, and railways is likely to offer immense growth opportunities to the high-performance anti-corrosion coatings market in the next few years.

Buy now-

https://www.transparencymarketresearch.com/checkout.php?rep_id=8587<ype=S

Key Developments in Global High-performance anti-corrosion coatings Market

In December 2019, RPM International Inc. announced that its Mantrose-Haeuser Co., Inc. business has acquired Profile Food Ingredients, LLC, a manufacturer of dry stabilizer and emulsifier blends for the food industry.

In October 2019, AkzoNobel launched range of high performance primers for corrosion protection. It covers a full array of substrates, surfaces and environments – from cable cars and chemical plants to window frames and wind turbines.

In August 2018, RPM International Inc. announced that its Rust-Oleum Group would be acquiring the Mean Green branded line of specialty cleaning products

In March 2018, RPM International Inc. announced that its Rust-Oleum Group had acquired Miracle Sealants Company

In November 2017, Nippon Paint Co., Ltd. engaged in a discussion with Axalta regarding a potential acquisition of Axalta

In October 2017, 3M announced that it has completed the acquisition of Scott Safety, a premier manufacturer of innovative products, such as self-contained breathing apparatus (SCBA) systems, gas and flame detection instruments, and other safety devices, that complement the former’s personal safety portfolio

In May 2017, AkzoNobel opened new performance coatings facility in Chonburi, Thailand.

Global High-performance anti-corrosion coatings Market: Competition Landscape