#Global Brake Pads Market Key Players

Text

Motorcycle Brake Pads Market Research and Future Strategy Analysis 2024 - 2031

The global motorcycle brake pads market was valued at approximately $1.62 billion in 2023. It is projected to grow from $1.7 billion in 2024 to $2.5 billion by 2032. This growth represents a compound annual growth rate (CAGR) of about 4.91% during the forecast period from 2024 to 2032. The expanding motorcycle industry and increasing demand for high-performance brake components are key factors driving this market growth.

The motorcycle brake pads market is a vital segment of the automotive industry, driven by increasing motorcycle sales, advancements in braking technology, and rising safety concerns. This article delves into the key aspects of the motorcycle brake pads market, including market dynamics, trends, and forecasts.

Overview of Motorcycle Brake Pads

What are Motorcycle Brake Pads?

Motorcycle brake pads are essential components of the braking system, responsible for creating friction against the brake rotor to slow down or stop the motorcycle. They are made from various materials, including organic, semi-metallic, and sintered metals, each offering distinct performance characteristics.

Types of Brake Pads

Organic Brake Pads: Made from a mixture of materials, including rubber, carbon compounds, and other fibers. They are quieter and provide a good initial bite but may wear faster.

Semi-Metallic Brake Pads: Comprising metal fibers combined with organic materials, these pads offer better heat dissipation and durability, making them suitable for high-performance motorcycles.

Sintered Metal Brake Pads: Made from a blend of metallic particles that are compressed and heated. They provide excellent performance in extreme conditions and have a longer lifespan, making them popular in racing and off-road applications.

Market Dynamics

Drivers of Market Growth

Rising Motorcycle Sales: The global increase in motorcycle ownership, especially in emerging markets, is a primary driver for the brake pads market. Motorcycles are becoming a preferred mode of transportation due to their fuel efficiency and lower maintenance costs.

Advancements in Technology: Innovations in braking systems, such as anti-lock braking systems (ABS) and electronic brake force distribution (EBD), are increasing the demand for high-performance brake pads that can complement these technologies.

Safety Regulations: Stringent regulations concerning vehicle safety are prompting manufacturers to improve brake performance, thereby increasing the demand for high-quality brake pads.

Challenges in the Market

Raw Material Costs: Fluctuations in the prices of raw materials used in manufacturing brake pads, such as metals and composites, can affect profit margins for manufacturers.

Competition from Aftermarket Products: The availability of low-cost aftermarket brake pads presents a challenge to original equipment manufacturers (OEMs), leading to price competition and potential quality concerns.

Regional Analysis

North America

The North American motorcycle brake pads market is characterized by a strong demand for high-performance products, driven by a significant number of motorcycle enthusiasts and competitive motorsport activities. The presence of established OEMs and aftermarket suppliers further supports market growth.

Europe

Europe is witnessing a growing trend towards eco-friendly and high-performance motorcycle components. The increasing adoption of electric motorcycles is also influencing the brake pads market, with manufacturers focusing on sustainable materials.

Asia-Pacific

The Asia-Pacific region dominates the global motorcycle market due to the high number of motorcycle sales in countries like India and China. The rising disposable income and urbanization are fueling demand for motorcycles and, consequently, brake pads.

Competitive Landscape

Key Players

The motorcycle brake pads market comprises several key players, including:

Brembo S.p.A.

EBC Brakes

Galfer

Ferodo

SBS Friction

These companies focus on innovation, product quality, and strategic partnerships to strengthen their market position.

Recent Developments

Product Launches: Companies are continually developing new brake pad formulations to enhance performance and reduce environmental impact.

Collaborations: Partnerships between manufacturers and motorcycle OEMs are becoming more common to ensure compatibility and optimize performance.

Future Outlook

The motorcycle brake pads market is expected to witness steady growth in the coming years. With advancements in technology and increasing awareness about safety, manufacturers are likely to focus on developing innovative and high-quality products. The shift towards electric motorcycles will also create new opportunities for brake pad manufacturers.

Conclusion

In conclusion, the motorcycle brake pads market is poised for growth, driven by increasing motorcycle sales, technological advancements, and stringent safety regulations. While challenges such as raw material costs and competition from the aftermarket exist, the overall outlook remains positive as manufacturers continue to innovate and cater to evolving consumer demands.

0 notes

Text

What is Brake Lining? Understanding its Importance in Vehicle Safety

Brake lining is an essential component of the braking system in any vehicle. It plays a critical role in ensuring smooth and safe stopping, making it crucial for overall vehicle safety. In this blog, we will explore what brake lining is, its importance, and why selecting the right brake lining manufacturers and brake lining suppliers is key to maintaining vehicle performance.

What is Brake Lining?

Brake lining is a material attached to the surface of the brake shoe or pad. It creates the necessary friction when pressed against the brake drum or disc, allowing vehicles to decelerate or come to a complete stop. Typically, brake linings are made from various materials such as organic, semi-metallic, or ceramic composites, each designed for specific performance needs.

Types of Brake Linings

There are different types of brake linings based on the vehicle and braking system used. For example, brake lining shoe refers to the linings used in drum brakes. Drum brakes are common in both passenger vehicles and larger commercial vehicles. Similarly, commercial vehicle brake lining is designed for heavier loads, offering better heat resistance and durability under extreme braking conditions.

Importance of Brake Lining in Vehicle Safety

The primary function of brake lining is to create friction that slows down or stops the vehicle. Over time, these linings wear out, and if not replaced, can lead to unsafe driving conditions, such as reduced braking efficiency, longer stopping distances, or complete brake failure. Regular inspection and replacement of worn-out linings are essential to prevent accidents and ensure road safety.

Brake Lining Manufacturers: Ensuring Quality and Safety

The quality of the brake lining depends heavily on the manufacturer. Reputable brake lining manufacturers ensure that their products meet high safety and performance standards. Using low-quality brake linings can result in quicker wear, more frequent replacements, and unsafe driving conditions. Therefore, it’s crucial to purchase brake linings from trusted brake lining suppliers.

In countries like India, brake lining manufacturers from India have earned a reputation for producing high-quality and cost-effective products. Companies like BBL Brakes are known for their innovative manufacturing processes and commitment to safety, making them a reliable choice for automotive manufacturers and service providers.

India’s Role in the Global Brake Lining Market

India is a major player in the global brake lining industry, with many companies recognized as top brake lining exporters in India. These manufacturers offer high-quality products at competitive prices, contributing to the global supply chain for both passenger and commercial vehicles. For businesses looking to source reliable brake lining suppliers, Indian companies offer a blend of affordability, quality, and timely delivery.

Choosing the Right Brake Lining Supplier

Selecting the right brake lining supplier can make a significant difference in vehicle safety and maintenance costs. A good supplier should offer durable, high-performance products that comply with international safety standards. Additionally, partnering with a supplier who has a strong track record, like the leading brake lining manufacturers from India, ensures long-term reliability.

Conclusion

Brake linings are critical to vehicle safety, and regular maintenance is key to avoiding costly repairs and ensuring driver safety. Whether for personal or commercial vehicle brake lining, it is essential to invest in high-quality products from reputable brake lining manufacturers and brake lining suppliers. With India’s strong presence as a brake lining exporter in India, businesses can find reliable, affordable, and high-performing brake linings to suit their needs.

#Brake Lining#Brake Lining Manufacturers#Brake Lining Supplier#Brake Lining Exporter in India#Brake Lining Shoe#Brake Lining Manufacturers From India#Commercial Vehicle Brake Lining

0 notes

Text

Dynamics of Brakes Market: Global Trends and Opportunities

With the rise of electric and autonomous vehicles, the innovations in the Brakes Market are not just keeping pace but setting new benchmarks in the development of the automobile industry in general towards smarter, safer and more efficient braking systems.

Take the Tesla Model 3’s regenerative braking system, for a prime example—this technology not only recaptures kinetic energy but also boosts range by converting up to 70% of the braking energy into power. Bosch’s iBooster which integrates electronic stability control with brake actuation is another game-changer, allowing for faster response times—just 150 milliseconds—and increased safety in vehicles equipped with Advanced Driver Assistance Systems (ADAS). Meanwhile, Brembo’s Sensify braking system leverages the power of AI to offer millisecond-level precision, enhancing both performance and safety. The market is also shifting toward low-copper and ceramic brake pads which reduce particulate emissions by up to 90% and improve durability.

Brakes Market Supply Chain in 2024

The brakes market supply chain in 2024 is a complex but globally interconnected system that involves several key stages, from raw material sourcing to manufacturing, distribution and final assembly. Raw materials such as steel, aluminium and composites are sourced from various suppliers which often require precision engineering to meet strict quality standards. These materials are then processed into components like brake discs, pads and callipers, often in specialized manufacturing facilities. Tier-1 suppliers such as Bosch and Brembo play a crucial role in producing and supplying these components to automotive manufacturers. Their supply chain also includes logistics and distribution networks that ensure timely delivery to automakers and aftermarket retailers. The integration of advanced technologies, such as AI-driven inventory management and real-time tracking is increasingly important in optimizing the supply chain, minimizing delays and reducing costs. However, the industry faces challenges such as fluctuating raw material prices and the need for sustainable practices which are driving innovations in supply chain efficiency and resilience.

Key Challenges in the Global Brakes Market

Supply Chain Disruptions have been amplified by ongoing geopolitical tensions and the aftermath of the COVID-19 pandemic continues to cause material shortages and drive up costs, straining manufacturers.

Raw Material Volatility remains a critical concern, with fluctuating prices of essential components like steel, aluminium and rare earth elements introducing additional layers of risk and uncertainty, particularly for advanced braking systems.

Rigorous Environmental Regulations are further pressuring manufacturers to innovate, necessitating the development of low-emission, noise-reducing brake technologies. These regulations demand substantial investment in research and development, making compliance a costly endeavour.

The Shift to Electric Vehicles (EVs) presents another complex challenge, as traditional brake systems must be re-engineered to work alongside regenerative braking technologies thereby reducing demand for conventional components and forcing companies to rethink product portfolios.

Intense Competition has been reshaping the market landscape, with established renowned players and emerging startups pushing the boundaries of innovation. However, this fierce rivalry is now compressing profit margins, making it harder for companies to make sustainable long-term growth future plans.

Requirement for Skilled Labor is becoming increasingly critical, especially in regions facing labour shortages. The complexity of modern braking systems requires highly trained workers for both manufacturing and maintenance creating bottlenecks that could slow down the brake production.

Best-Selling and Most Popular Brakes in the Global Brakes Market

Brembo Brakes

EBC Brakes

Wagner Brakes

Raybestos Brakes

Bosch Brakes

Akebono Brakes

Brakes Market by Type

Disc Brakes: Use callipers to squeeze pads against a rotating disc for strong and reliable stopping power.

Drum Brakes: Press brake shoes outward against a drum to create friction and slow the vehicle.

Anti-lock Braking System (ABS): Prevents wheel lockup during hard braking to maintain steering control.

Regenerative Brakes: Converts braking energy into electricity, recharging the battery in EVs and hybrids.

Hydraulic Brakes: Uses brake fluid pressure to apply brakes which provides smooth and effective braking.

Electronic Braking System (EBS): Replaces hydraulic control with electronic signals for quicker and more precise braking.

Parking Brakes: Keeps the vehicle stationary when it is parked which is often operated mechanically or electronically.

Drum-in-Hat Brakes: Combines disc brakes with a small drum for the parking brake function into an all-in-one unit.

Carbon-Ceramic Brakes: High-performance brakes that resist heat and wear are ideal for sports and luxury cars.

Air Brakes: Uses compressed air to apply brakes which are commonly found in heavy trucks and buses for powerful braking.

Browse more relevant reports :

Light Duty Vehicle Market and Motorcycle Market

Learn about - Automotive Fastener Market Research

Road Bikes Market and Micro EVs Market

Car Brake Pads Market Research and Overview

Read more about - The Aerospace Cold Forgings Market

Automotive Sun Visors Market Research 2023-2030

Automotive Air Conditioning Market Overview 2024-2031

Market Research by Report Prime.

#BrakesMarket #BrakesMarketResearch #BrakesMarketSegmentation #BrakesMarketOverview #BrakeMarket #BrakesMarketSize

0 notes

Text

Aceforge Pvt Ltd: Premier Automobile Spare Parts Manufacturer

Aceforge Pvt Ltd: Premier Automobile Spare Parts Manufacturer

In the rapidly evolving automotive industry, Aceforge Pvt Ltd stands out as a leading manufacturer of high-quality automobile spare parts. With a strong emphasis on innovation, precision, and reliability, Aceforge has established itself as a trusted partner for vehicle manufacturers and aftermarket service providers. This article delves into what makes Aceforge a standout player in the automobile spare parts manufacturing sector.

Unwavering Commitment to Quality

At the core of Aceforge’s operations is an unwavering commitment to quality. The company employs state-of-the-art manufacturing technologies and rigorous quality control processes to ensure that every spare part produced meets the highest industry standards. From the selection of raw materials to the final inspection, Aceforge’s quality assurance protocols are designed to deliver products that offer durability, performance, and safety.

Extensive Product Range

Aceforge boasts an extensive range of automobile spare parts catering to various vehicle models and makes. Their product portfolio includes:

Engine Parts: High-performance pistons, cylinder heads, and camshafts designed to enhance engine efficiency and longevity.

Transmission Components: Robust gears, shafts, and clutches that ensure smooth power transfer and reliable performance.

Brake Systems: Precision-engineered brake pads, discs, and calipers that provide superior stopping power and safety.

Suspension Parts: Durable shock absorbers, struts, and control arms that improve vehicle handling and ride comfort.

Electrical Components: Advanced alternators, starters, and wiring harnesses essential for modern vehicle electrical systems.

Cutting-Edge Manufacturing Capabilities

Aceforge’s manufacturing facilities are equipped with the latest technology and machinery, enabling the production of high-precision spare parts. Key capabilities include:

CNC Machining: Advanced CNC machines ensure precision and consistency in the production of intricate parts.

Forging and Casting: Utilizing modern forging and casting techniques to create strong and durable components.

Heat Treatment: Enhancing the mechanical properties of parts to ensure optimal performance and durability.

Quality Assurance: Comprehensive testing and inspection procedures that guarantee every part meets or exceeds industry standards.

Innovation and R&D

Innovation is a driving force at Aceforge. This focus on innovation enables Aceforge to continuously improve its products and processes, offering spare parts that are not only reliable but also incorporate the latest technological advancements.

Customer-Centric Approach

Aceforge prides itself on its customer-centric approach. Whether it’s an OEM (Original Equipment Manufacturer) looking for specific components or an aftermarket service provider needing reliable spare parts, Aceforge delivers tailored solutions that meet and exceed customer expectations.

Sustainability Practices

In line with global efforts to promote sustainability, Aceforge implements eco-friendly manufacturing practices. The company focuses on energy-efficient production processes, waste reduction, and responsible resource management. By prioritizing sustainability, Aceforge aims to minimize its environmental impact while maintaining high operational efficiency.

Global Reach and Strategic Partnerships

Aceforge’s reputation for quality and reliability has earned it a strong presence in both domestic and international markets. The company has established strategic partnerships with leading automotive manufacturers and aftermarket service providers around the world. These partnerships are a testament to Aceforge’s ability to deliver high-quality spare parts that meet diverse market demands.

Vision for the Future

As the automotive industry continues to evolve, Aceforge Pvt Ltd is committed to remaining at the forefront of innovation and excellence. By embracing new technologies and expanding its product offerings, Aceforge is well-positioned to meet the future needs of the automotive sector. The company’s vision includes a continued focus on quality, sustainability, and customer satisfaction, ensuring its status as a leading manufacturer of automobile spare parts.

In conclusion, Aceforge Pvt Ltd exemplifies excellence in the automobile spare parts manufacturing industry. With a comprehensive product range, advanced manufacturing capabilities, and a strong commitment to quality and innovation, Aceforge is a trusted partner for automotive manufacturers and service providers worldwide.

0 notes

Text

Braking New Ground: Exploring Trends, Drivers, and Future Growth in the Global Automotive Brake Pad Market

Automotive Brake Pad Market was valued at US$ 9.35 billion in 2023 and is projected to reach US$ 14.94 billion by 2031, growing at a CAGR of 6.12% from 2024 to 2031.

This comprehensive research study on the global Automotive Brake Pad market gives detailed insights into the sector, offering a detailed analysis of market trends, prominent drivers, and future growth prospects. In order to make wise business decisions, it gives readers an extensive understanding of the market environment. Furthermore, the report covers several aspects, such as estimated market sizing, strategies employed by leading companies, restraining factors, and challenges faced by market participants.

Exploring Market Value: Secure Your Sample Copy of the Automotive Brake Pad Market Report Now and Drive Informed Business Decisions:

Market Forecast and Trends

The report's precise market forecasts and identification of emerging trends will allow readers to foresee the industry’s future and outline their tactics for the following years accordingly. Understanding market trends can help in gaining a competitive edge and staying ahead in a fast-paced business environment.

Regional and Segment Analysis

The study on the global Automotive Brake Pad market will aid industry participants find high-growth regions and profitable market segments through region-specific and segment-by-segment analysis. This information helps in implementing better marketing strategies and product lineups to meet the preferences and needs of various target audiences. The major regions covered in this comprehensive analysis include North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Investment and Expansion Opportunities

The research report supports strategic decision-making by revealing prospective areas for investment and business growth in the global Automotive Brake Pad market. This report is a great tool for finding markets that are foreseen to grow substantially for aiding readers who want to expand into new and untapped markets or launch new products.

Competitive Analysis

The research report comprises an in-depth competitive analysis, which profiles major market competitors and evaluates their tactics, weaknesses, and market shares. These key players employ top business strategies, such as partnerships, alliances, mergers, acquisitions, product innovations, and product development, to establish a competitive advantage. Industry participants may use this information to measure their business against rivals and develop winning strategies for distinguishing themselves in the market.

Why Buy This Report?

Obtain an in-depth understanding of market trends and growth catalysts.

Utilize precise market forecasts for informed decision-making.

Outperform competitors through extensive competitive analysis.

Identify and leverage profitable regional and segment prospects.

Strategically plan investments and expansions in the global Automotive Brake Pad market

The key players in the Automotive Brake Pad Market are:

Robert Bosch GmbH

Continental AG

Akebono Brake Industry Co., Ltd.

Tenneco Inc.

Brembo S.p.A.

Nisshinbo Holdings Inc.

Delphi Technologies

TBC Corporation

MIBA AG

Aisin Seiki Co., Ltd.

The global Automotive Brake Pad Market is segmented as:

By Vehicle Type

Passenger Cars

Light Commercial Vehicles

Heavy Trucks

Buses and Coaches

Others

By Material

Non-metallic

Semi-metallic

Fully Metallic

Ceramic

By Sales Channel

Aftermarket

OEMs

By Region

North America

U.S.

Canada

Mexico

Europe

France

U.K.

Spain

Germany

Italy

Russia

Rest of Europe

Asia-Pacific

China

Japan

India

South Korea

Rest of Asia-Pacific

Middle East & Africa

GCC

North Africa

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America.

0 notes

Text

Friction Materials Market Size, Trends And Industry Outlook 2031

The “Friction Materials Market Share, Size, and Trends | 2031” is market research by The Insight Partners. The Friction Materials market has perceived tides of change in the recent past. This study offers precise projections after detailed scrutiny of a range of factors impacting the business. Considering the present market scenario, this report brings forward correct predictions on revenue, market size, and CAGR of the Friction Materials market. The novel market research which is based on a fact-based foundation is now accessible for purchase. This report can make a variance in wide decision-making and drive business forward in the right direction.

Business is no longer a game of instincts when it comes to capitalizing on new production lines. In a highly competitive Friction Materials market, companies may face several challenges. Having trusted market research is always endorsed for both veteran and new entrants. Friction Materials Market report prSize, Trends And Industry Outlook 2030esents a thorough analysis of local, regional, and global market scenarios through the following details.

Report Attributes

Details

Segmental Coverage

By Product

Pads

Linings

Discs

Blocks

Business Type

OE and Aftersales

Application

Brakes

Clutches

Geography

North America

Europe

Asia Pacific

and South and Central America

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Aisin Seik

Akebono Brake Industry Co., Ltd.

Carlisle Brake and Friction

Federal-Mogul Corporation,

Fras-le S A

Honeywell Corporation

MIBA AG

Nisshinbo Brake Inc.

Valeo Friction Materials India Private Limited

Other key companies

Competitive Landscape

Knowing the state of rivals is a strategically right move to outperform them. This report is the right place to explore key strategies, developments, and recent launches by key Friction Materials market players. This report emphasizes an analysis of business strategies and expected growth opportunities for brands.

Key Coverings:

Current and Future Market Estimates- Friction Materials Market Share, CAGR, and Forecast | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation Contributing Market Growth

Need a Customized Market Research Report?

You can always share any specific requirements that you have, and our team will adjust the scope of research offerings as per your needs.

The following are some customizations our clients frequently ask for:

The Friction Materials market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

Key Questions Addressed in the Friction Materials Market Research Include:

What are present Friction Materials market values, and what can be expected in the upcoming decade?

What are the key segments in the Friction Materials market?

What is the regional distribution of the Friction Materials market report?

What are the key players and their recent strategies?

What are the key factors driving Friction Materials market growth?

What are regulatory concerns and requirements businesses have to compel?

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

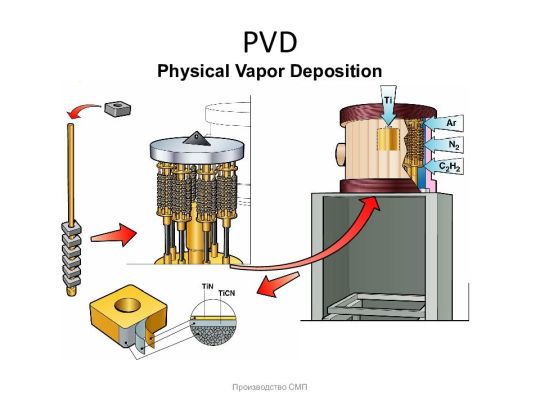

In-depth Analysis of Key Players Shaping the Physical Vapor Deposition Market

The Physical Vapor Deposition Market is estimated for 2023 for the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

Market Overview:

Physical vapor deposition (PVD) is a process used to deposit thin films on substrates by condensation of a vaporized form of the desired material. It finds applications in microelectronics, data storage, cutting tools, and decorative coatings.

Market Dynamics:

The growth of the physical vapor deposition market is driven by increased adoption in microelectronics and data storage industries. Physical vapor deposition processes such as sputtering and evaporation are widely used in the manufacturing of semiconductors and data storage devices. As the demand for electronic components grow, the need for PVD techniques for thin film applications also increases. Further, the increasing demand for wear and corrosion resistant coatings from automotive and industrial machinery sectors is expected to fuel the market growth during the forecast period.

Increasing Demand for Low-Friction and Wear-Resistant Coatings is Driving the Physical Vapor Deposition Market

The demand for low-friction and wear-resistant coatings has been growing significantly across various industries such as automotive, aerospace, cutting tools, and medical devices. Physical vapor deposition is an effective and commonly used technique for depositing hard coatings like titanium nitride and chromium nitride that improve surface properties and durability. The increasing usage of PVD coatings on components subjected to severe friction, wear and corrosion is propelling the physical vapor deposition market growth. For instance, PVD coatings are widely used on engine components, brake pads and rotors in automobiles to enhance fuel efficiency and performance. They are also used on drill bits, cutting tools and inserts in manufacturing industries to increase tool life. With technological advancements and requirement for high-quality surface finishes, the need for functional PVD coatings is expected to continue rising thereby driving market expansion over the coming years.

Growing Requirement for Decorative Coatings Stimulates Demand

The demand for decorative and aesthetic coatings has increased substantially across various sectors including consumer electronics, architectural and solar glass. Physical vapor deposition enables depositing thin films, with excellent uniformity and adhesion, that impart color, luster and anti-reflective properties to surfaces. Metals like gold, silver, platinum and alloys are commonly deposited using PVD techniques for visually appealing finishes. The growing production of smartphones with decorative bezels and televisions and laptops with anti-glare and scratch-resistant coatings has fueled the market growth. Moreover, the thriving solar and architectural glass industry is utilizing PVD coatings for achieving tinting, low-emissivity and self-cleaning effects. The rising consumer inclination towards aesthetics and appearance is driving increasing preference for decorative PVD coatings hence boosting the market.

Fluctuating Raw Material Prices Pose a Challenge

The physical vapor deposition market experiences price fluctuations due to shifting costs of raw materials used including metals and gases. The prices of precious metals like gold, silver and platinum that are commonly used for decorative and electrical coatings are highly unstable and vary as per global market conditions and supply-demand variations. Similarly, reactive gases used in PVD processes including argon, nitrogen and oxygen exhibit price volatility depending upon availability and supplier contracts. Major market players have limited control over raw material costs due to supplier dependence. Therefore, frequent changes in prices of these crucial inputs pose major challenges related to budgeting, profit margins and project costs for equipment manufacturers, service providers as well as end-use industries. Unpredictable raw material prices can restrain market growth to some extent until better inventory management and long-term supplier contracts are implemented.

Opportunity for High-Volume Production of Smart Wearables

The emerging concept of smart wearables presents significant opportunities for the physical vapor deposition market. Technologies like smart watches, fitness bands and AR/VR headsets are gaining widespread popularity and demand. For optimal performance and durability, these devices require PVD coatings on components contacting human skin. Coatings such as silver, indium tin oxide and fluorinated diamond-like carbon are functional as well as provide corrosion resistance under harsh conditions of perspiration, skin oils and cleaning agents. As new smart wearable products are rapidly introduced and consumer electronics giants expand production, high-volume PVD coating of components offers valuable opportunities for equipment manufacturers and service providers. Moreover, the integration of decorative and anti-reflective coatings will further stimulate market growth by improving product design aesthetics, visual experience and marketability of wearable devices. This presents lucrative scope for PVD market players in collaborating with major consumer electronics OEMs.

Technology Innovations Catalyze Market Evolution

The physical vapor deposition market is continuously evolving due to ongoing technology innovations that enhance coating quality and throughput. Advancements like multi-target cathodic arc deposition enable depositing multifunctional and nanostructured coatings. Meanwhile, industrial-scale pulsed laser deposition systems facilitate mass production of complex thin films. Vendors are also developing modular PVD deposition heads capable of multi-wafer handling for improving productivity. Technologies such as electron beam PVD offer cost-effectiveness for nano-engineered coatings even on temperature-sensitive substrates.

#Physical Vapor Deposition Market#Physical Vapor Deposition Market Trends#Physical Vapor Deposition Market Growth

0 notes

Text

Revolutionizing the Automotive Aftermarket: Navigating Challenges and Opportunities in Auto Parts

Originally Published on: SpendEdge |Auto Parts Market -“Brilliance” in the Automotive Aftermarket

The current state of the global auto parts aftermarket is witnessing a significant overhaul, primarily propelled by key factors such as the rapid adoption of electrification, the surge in shared mobility services, and the pervasive influence of digitization. These transformative trends hold promising prospects for steering the automotive industry toward greater sustainability. However, amidst these positive changes, there are challenges emerging for traditional auto parts manufacturers that demand a strategic response.

Electrification Dynamics:

The shift toward electrification in the automotive sector, while contributing to reduced greenhouse gas emissions, introduces a paradigm shift. With electric vehicles (EVs) relying on electric motors instead of conventional engines, the demand for traditional internal-combustion engine components, such as starters and alternators, is expected to decline. Furthermore, the longevity of key components like brake pads is significantly extended in EVs, affecting the demand for replacements in comparison to traditional fossil fuel vehicles. This underscores the need for auto parts manufacturers to recalibrate their product offerings and explore new avenues within the evolving market landscape.

Impact of Shared Mobility:

The exponential growth of shared mobility, characterized by fleet operators providing rentable vehicles, brings about both economic advantages and challenges for the automotive aftermarket. While shared mobility is forecasted to become a trillion-dollar industry by the end of the decade, it introduces complexities for auto parts manufacturers. The electrification trend within shared mobility fleets, coupled with advancements in autonomous driving capabilities, alters the demand dynamics for specific auto components. Fewer individual vehicles in operation, replaced by shared modes of transport, imply reduced wear and tear on certain auto parts. This necessitates a proactive approach by auto parts manufacturers to align their production and distribution strategies with the evolving needs of shared mobility services.

Digitization's Influence:

The pervasive digitization of the automotive value chain, extending into the aftermarket and service segments, intensifies competition and exerts pricing pressures. While established players like eBay Motors dominate the digital distribution of aftermarket auto parts, niche players are gradually refining their cost structures and enhancing customer experiences. The emergence of specialized players, especially in the automotive IoT (Internet of Things) sector, poses a challenge to industry incumbents. This digital disruption compels auto parts manufacturers to embrace innovative technologies, streamline operations, and enhance their digital presence to remain competitive.

In navigating this transformative landscape, auto parts manufacturers face a dual challenge and opportunity—to adapt to changing market dynamics and leverage emerging trends for sustained growth. Successful navigation requires a strategic reevaluation of product portfolios, manufacturing processes, and distribution channels to align with the demands of an evolving automotive aftermarket. The ability to turn these challenges into opportunities will define the brilliance of auto parts manufacturers in this era of industry transformation.

Contact us.

0 notes

Text

Global Phenolic Resins Market Is Estimated To Witness High Growth Owing To Increasing Demand for Fire-Resistant Materials and Growing Automotive Industry Trend

The global Phenolic Resins Market is estimated to be valued at USD 14,605.0 million in 2021 and is expected to exhibit a CAGR of 4.84% over the forecast period of 2022-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Phenolic resins are synthetic polymers derived from the reaction between phenol and formaldehyde. They are widely used in various industries for their excellent chemical and thermal resistance properties. Phenolic resins find applications in a wide range of products including coatings, adhesives, laminates, molding compounds, and insulation materials.

B) Market Dynamics:

The growth of the Phenolic Resins Market can be attributed to two major drivers. Firstly, the increasing demand for fire-resistant materials across various industries is driving the market growth. Phenolic resins possess excellent fire-resistant properties, making them ideal for applications in construction, automotive, and electrical industries. With the growing focus on safety regulations and the need for fire-resistant materials, the demand for phenolic resins is expected to surge.

Secondly, the booming automotive industry is another factor driving the market growth. Phenolic resins are extensively used in automotive components such as brake pads, gaskets, and clutch plates. The increasing production of vehicles worldwide, coupled with the stringent emission standards and safety regulations, is expected to fuel the demand for phenolic resins in the automotive sector.

C) Market Key Trends:

One key trend observed in the Phenolic Resins Market is the growing preference for water-based phenolic resins. These resins offer environmental benefits such as low volatile organic compound (VOC) emissions and reduced toxicity. Water-based phenolic resins are being increasingly adopted in the manufacturing of coatings, adhesives, and laminates, driven by the growing focus on sustainability and stringent regulations on VOC emissions.

D) SWOT Analysis:

Strengths:

1. High fire-resistant properties

2. Wide range of applications

Weaknesses:

1. Long curing time for certain applications

2. Relatively high cost compared to other resins

Opportunities:

1. Growing demand for composites in various industries

2. Increasing adoption of phenolic resins in the aerospace industry

Threats:

1. Availability of alternative resins in the market

2. Fluctuating raw material prices

E) Key Takeaways:

In terms of market size, the global phenolic resins for market is expected to witness high growth, exhibiting a CAGR of 4.84% over the forecast period. This growth can be attributed to the increasing demand for fire-resistant materials and the booming automotive industry.

In terms of regional analysis, Asia Pacific is expected to be the fastest-growing and dominating region in the phenolic resins for market. The region is witnessing rapid industrialization and urbanization, leading to increased construction activities and automotive production. Moreover, favorable government policies and investments in infrastructure development are further driving the market in this region.

Key players operating in the global phenolic resins for market are TBASF SE, Chang Chun Plastics Co. Ltd., Georgia Pacific Chemicals LLC, Kolon Industries Inc., Prefere Resins, Mitsui Chemicals Inc., Sumitomo Bakelite Co., Ltd, Hitachi Chemical Co. Ltd., SI Group, Inc., and Momentive Specialty Chemicals, Inc. These players focus on product development, collaborations, and mergers and acquisitions to strengthen their market position.

The Phenolic Resins Market is witnessing significant growth due to the increasing demand for fire-resistant materials and the flourishing automotive industry. The adoption of water-based phenolic resins and the growth opportunities in the composites and aerospace industries further contribute to the market's growth. Asia Pacific is expected to dominate the market, driven by rapid industrialization and infrastructure development. The key players in the market continue to invest in research and development to maintain their competitive edge.

0 notes

Text

The Future of Brakes Parts Manufacturing From India: Predictions and Trends

The brakes parts manufacturing industry in India is undergoing a significant transformation, driven by advancements in technology, quality standards, and global market strategies. This blog explores the key trends and future directions of the industry, focusing on the role of Brake Pads, the emergence of the Best Brake Pad Manufacturer, and the broader landscape of Brakes Parts Manufacturers From India.

Innovations Driving the Industry

Indian Brakes Parts Manufacturers From India are at the forefront of integrating innovative technologies into their manufacturing processes. These advancements are not only enhancing product quality but also streamlining production efficiency. Modern manufacturing techniques, such as automation and smart technology, are becoming increasingly prevalent. For instance, the use of advanced materials and computer-aided design (CAD) systems has enabled manufacturers to produce high-quality Brake Pads with greater precision.

Emphasis on Quality and Standards

As the demand for Brake Pads continues to rise globally, there is a growing emphasis on maintaining rigorous quality standards. The Best Brake Pad Manufacturer in India is known for adhering to international quality norms, ensuring that their products meet both domestic and international safety regulations. These manufacturers implement stringent quality control measures throughout the production process, from raw material selection to final product testing, to deliver reliable and durable brake components.

The Rise of Sustainable Practices

Sustainability is becoming a key focus for many Brakes Parts Manufacturers From India. Companies are increasingly adopting eco-friendly practices to reduce their environmental footprint. This includes the use of recyclable materials, energy-efficient production methods, and waste reduction strategies. By prioritizing sustainability, Indian manufacturers are not only contributing to environmental conservation but also appealing to eco-conscious consumers and partners in the global market.

Global Market Expansion

Indian Brake Pads Manufacturer are expanding their reach beyond domestic markets to cater to international demand. This expansion is driven by the increasing need for high-quality braking components in various automotive sectors worldwide. To meet global standards, Indian manufacturers are continuously upgrading their technologies and adhering to international certifications. This global perspective helps them compete effectively in the international arena and establish themselves as key players in the global brakes parts industry.

Challenges and Opportunities

While the future looks promising, the industry faces several challenges. These include fluctuating raw material costs, regulatory compliance, and the need for constant technological upgrades. However, these challenges also present opportunities for growth and innovation. By addressing these issues proactively, Indian Brakes Parts Manufacturers From India can capitalize on emerging trends and continue to thrive in the competitive global market.

Conclusion

The future of brakes parts manufacturing in India is bright, with a strong focus on innovation, quality, and sustainability. As the demand for high-performance Brake Pads grows, the Best Brake Pad Manufacturer and other industry players are well-positioned to lead the way. With ongoing advancements and a commitment to excellence, Indian manufacturers are set to make significant strides in the global brakes parts market, shaping the industry's future for years to come.

#Brake Pads#Best Brake Pad Manufacturer#Brakes Parts Manufacturers From India#Brake Pads Manufacturer

0 notes

Text

India Phenolic Resin Market Size, Share, Growth & Forecast by FY2030 | ChemAnalyst

According to ChemAnalyst report, “India Phenolic Resin Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-User Industries, Sales Channel, Regional Demand, Company Share, Foreign Trade, FY2015-FY2030”, The India Phenolic Resin Market is likely to grow at a CAGR of 5.12% during the forecasted period by FY2030. The end-use industries like Automobile, Building and Construction, Electrical & Electronics, and Furniture industry are anticipated to multiply the demand for Phenolic Resin in India in the forthcoming years.

Phenolic resins are high-temperature polymers produced when an aldehyde-containing molecule interacts with a carbon-based alcohol. It is used in a wide array of industries including furniture, electrical, aerospace, and rubber industries. Phenolic Resin offers superior quality heat resistance and high friction resistance, thus making it suitable for use in brake linings and disc brake pads. Owing to its application as an adhesive, it is being used prominently used in the construction industry. Also, Phenolic Resin finds application in the electrical industry as well which includes the manufacturing of household electrical switches owing to its high heat-resistant property, making it another factor responsible for uplifting the demand for the product.

Read Full Report Here: https://www.chemanalyst.com/industry-report/india-phenolic-resin-comprehensive-techno-commercial-market-31

The India Phenolic Resin market is primarily driven by the automotive industry. With the growing deman for light-weight vehicles in order to reduce the crabon emissions by vehicles is antciapted to drive upo the demand for Phenolic Resins in the forecat period. Additionally, its use in coatings, moulding compounds, and laminating contributes to fuel the product's rising demand. The need for items for interior like furniture is anticipated to rise in the coming years, which will most likely drive up the demand for laminates and lead to a significant increase in the use of phenolic resin.

The India Phenolic Resin Market is segmented based on end-use, sales channel, and region. Based on end-use, the India Phenolic Resin market is segregated into Automobile, Building and Construction, Electrical & Electronics, Furniture, and Others. Among these, the Automobile industry is dominating the segment of Phenolic Resin. This segment held roughly 34% of the Phenolic Resin market in FY2023. In the automobile industry, Phenolic Resin finds application as a reinforcing agent in tires, sound insulation felts, and clutch and friction facing. The Indian automobile industry has seen a massive quantitative jump in the past years and is anticipated to boom the demand for Phenolic Resin in the country.

Geographically, India Phenolic Resin Market is segregated into North, South, East, and West. In the historic period of FY2015-FY2023, West India has been dominating the market followed by South India. Western states like Gujarat and Maharashtra, have been the key consumers of Phenolic Resin due to the abundance of numerous plasticizers and other end-use industries allocated in these locations.

Request Sample Form: India Phenolic Resin Market

“India Phenolic Resin Market Analysis: Industry Market Size, Plant Capacity, Production, Operating Efficiency, Demand & Supply, End-User Industries, Sales Channel, Regional Demand, Company Share, Foreign Trade, FY2015-FY2030” Significant players in the India Phenolic Resin market are Revex Group, Kanoria Chembond Private Limited, KayDee Corporation, Forace Polymers Pvt. Ltd., and Others. Some of the major global players operating in the Phenolic Resins market are DIC Corporation, Kolon Industries, Inc., Sumitomo Bakelite Co., Ltd., Hexcel Corporation, Hexion, and Others.

“The constant rising demand of Phenolic Resin to manufacture automotive components such as clutch facings and brakes owing to their properties like superior heat resistance and flame-rsesiatnce is anticipated to drive the India Phenolic Resin market in the forecast period until FY2030. Furthermore, the usage of phenolic resin to produce moulding and castings for furniture and electronic items such as ovens and knobs also contributes significantly to the India Phenolic Resin market. “Said Mr. Karan Chechi, Research Director with TechSci Research, a research-based management consulting firm promoting ChemAnalyst worldwide.

About Us:

ChemAnalyst is a subsidiary of Techsci Research, which was established in 2008, and has been providing exceptional management consulting to its clients across the globe for over a decade now. For the past four years, ChemAnalyst has been a prominent provider of Chemical commodity prices in more than 15 countries. We are a team of more than 100 Chemical Analysts who are committed to provide in-depth market insights and real-time price movement for 300+ chemical and petrochemical products. ChemAnalyst has reverberated as a preferred pricing supplier among Procurement managers and Strategy professionals worldwide. On our platform, we provide an algorithm-based subscription where users can track and compare years of historical data and prices based on grades and incoterms (CIF, CFR, FOB, & EX-Works) in just one go.

The ChemAnalyst team also assists clients with Market Analysis for over 1200 chemicals including assessing demand & supply gaps, locating verified suppliers, choosing whether to trade or manufacture, developing Procurement Strategies, monitoring imports and exports of Chemicals, and much more. The users will not only be able to analyze historical data for past years but will also get to inspect detailed forecasts for the upcoming years. With access to local field teams, the company provides high-quality, reliable market analysis data for more than 40 countries.

ChemAnalyst is your one-stop solution for all data-related needs. We at ChemAnalyst are dedicated to accommodate all of our world-class clients with their data and insights needs via our comprehensive online platform.

Contact Us:

ChemAnalyst

B-44 Sector-57 Noida,

National Capital Region

Tel: 0120-4523990

Mob: +91-8882805349

Email: [email protected]

Website: https://www.chemanalyst.com/

0 notes

Text

Iron Powder Market Research by Key players, Type and Application, Future Growth to 2032

The global iron powder market stood at US$ 6.18 Billion in the year 2022 and is expected to reach US$ 10.26 Billion by the year 2032 at a CAGR of 5.2% between 2022 and 2032.

Iron powder’s particle size does vary from 20 to 200 micrometers. The powder is available at the commercial level in 3 kinds – atomized powder, reduced iron powder, and electrolyte iron powder. Electrolyte iron powder holds the largest market share due to stability, purity, and monetary advantage. It’s actually at par with traditional iron salts as well as chelates used for the fortification of food and water.

The other applications include soft magnets and welding in electromagnetics, wherein both – DC and ac are addressed. The iron powder does play an important role with respect to recycling of the industrial chemicals. As such, it is used in pharmaceutical and steel plants. Intake of iron is prescribed for those who are anemic. Regular intake of iron also helps in boosting immunity.

Particle metallurgy alone accounts for the majority of revenue, especially in the automobile sector. Iron powder finds its way as a filler in friction materials-oriented applications like automotive OEMs and aftermarket brake pads with clutches. They are used in the production of sintered parts; which cater to engines and transmissions.

Download PDF Sample Copy of Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-9599

Competitive Analysis

Mimete S.r.l. (based out of Biassono, Monza, Italy), in November 2020, did release two iron base powders – Duplex MARS F51 and Super-Duplex F53. These powders would be addressing demands from power generation, oil & gas, and aerospace verticals about additive manufacturing. Manufacturers like Mercedes-Benz, Porsche, and Volkswagen do produce components and parts by making use of additive manufacturing technology. These measures are expected to keep the hopes high for the iron powder market in the forecast period.

Sumitomo Electric Industries Ltd., in October 2020, did develop a power magnetic core to cater to axial gap motors. This core gets derived from die-pressing soft-magnetic iron powder into a 3D shape.

KEY SEGMENTS

End Use:

Aerospace & defence

Automotive

Oil & Gas

Medical

Others

Type:

Unalloyed

Alloyed

Insulated Iron powder

Manufacturing Process:

Physical

Chemical

Mechanical

Atomization

Electro deposition

Reduction

Decomposition

Pulverization

What does the Report scale through?

The research study is based on end-use (aerospace & defense, automotive, oil & gas, medical, and others), by type (unalloyed, alloyed, and insulated iron powder), by manufacturing process (physical (atomization and electrodeposition), chemical (reduction and decomposition), and mechanical (pulverization)).

With rising demand for automobiles, the global iron powder market is expected to grow on an accelerated note going forward.

0 notes

Text

Latest Research Report on Brake Fluid Market by Application, Industry Share, End User, Opportunity Analysis 2030

The brake fluid market refers to the global industry that produces and distributes fluids used in automotive braking systems. Brake fluids are used to transfer force from the brake pedal to the brake components, such as calipers and wheel cylinders, which apply pressure to the brake pads or shoes to stop the vehicle.

For Sample Report Click Here:-https://www.globmarketreports.com/request-sample/248716

The global brake fluid market is driven by the growing demand for passenger cars and commercial vehicles, especially in emerging economies. The increasing focus on safety features in automobiles, including advanced braking systems, is also driving the market growth.

The market is segmented based on type, application, and region. The most common types of brake fluids are glycol-based and silicone-based fluids, with glycol-based fluids being the most widely used. The main applications of brake fluids are in passenger cars, commercial vehicles, and motorcycles.

Geographically, the brake fluid market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East and Africa. Asia-Pacific is the largest market for brake fluid due to the growing automotive industry and increasing disposable incomes in the region.

The key players in the brake fluid market include Exxon Mobil, Royal Dutch Shell, Chevron, Total, and BASF SE, among others. These companies are constantly investing in research and development to improve the performance and efficiency of their products, as well as expand their market reach.

0 notes

Text

Braking New Ground: Exploring Trends, Drivers, and Future Growth in the Global Automotive Brake Pad Market

Automotive Brake Pad Market was valued at US$ 9.35 billion in 2023 and is projected to reach US$ 14.94 billion by 2031, growing at a CAGR of 6.12% from 2024 to 2031.

This comprehensive research study on the global Automotive Brake Pad market gives detailed insights into the sector, offering a detailed analysis of market trends, prominent drivers, and future growth prospects. In order to make wise business decisions, it gives readers an extensive understanding of the market environment. Furthermore, the report covers several aspects, such as estimated market sizing, strategies employed by leading companies, restraining factors, and challenges faced by market participants.

Exploring Market Value: Secure Your Sample Copy of the Automotive Brake Pad Market Report Now and Drive Informed Business Decisions:

https://www.kingsresearch.com/request-sample/automotive-brake-pad-market-520

Market Forecast and Trends

The report's precise market forecasts and identification of emerging trends will allow readers to foresee the industry’s future and outline their tactics for the following years accordingly. Understanding market trends can help in gaining a competitive edge and staying ahead in a fast-paced business environment.

Regional and Segment Analysis

The study on the global Automotive Brake Pad market will aid industry participants find high-growth regions and profitable market segments through region-specific and segment-by-segment analysis. This information helps in implementing better marketing strategies and product lineups to meet the preferences and needs of various target audiences. The major regions covered in this comprehensive analysis include North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Investment and Expansion Opportunities

The research report supports strategic decision-making by revealing prospective areas for investment and business growth in the global Automotive Brake Pad market. This report is a great tool for finding markets that are foreseen to grow substantially for aiding readers who want to expand into new and untapped markets or launch new products.

Competitive Analysis The research report comprises an in-depth competitive analysis, which profiles major market competitors and evaluates their tactics, weaknesses, and market shares. These key players employ top business strategies, such as partnerships, alliances, mergers, acquisitions, product innovations, and product development, to establish a competitive advantage. Industry participants may use this information to measure their business against rivals and develop winning strategies for distinguishing themselves in the market.

0 notes

Text

Automotive Brake Friction Products Market Future Scenario, Key Insights, Top Companies 2032

The global automotive brake friction products market is expected to create lucrative growth opportunities with an opulent CAGR of 4.8% during the forecast period from 2022 to 2032. The market was valued at around US$ 10.4 Bn in 2021 and is likely to reach a valuation of US$ 17.2 Bn by 2032.

Automotive brake friction products are the components that generate friction to stop or slow down a vehicle. These products are installed on the brake system's calipers and pads and create friction when they come in contact with the brake rotors or drums.

There are different types of brake friction products, including:

Semi-metallic brake pads - these are the most common type of brake pads and are made of a mixture of metals, including copper, iron, and steel. They are durable, have good heat dissipation properties, and offer good stopping power.

Ceramic brake pads - these pads are made of ceramic fibers and filler materials. They produce less dust than other types of brake pads and offer better braking performance at high temperatures. They are also quieter than other types of brake pads.

Key Takeaways

The replacement rate of brake friction products within vehicles is projected to be hampered by increasing the life of automotive brake friction products and sophisticated brake technology. Manufacturers of brake friction products now utilise more durable materials due to government restrictions that are stringent and the requirement to function in all types of environments.

It is projected that rapid advancements in brake friction products will lower the need for brake friction products by lowering the number of replacements in cars. Additionally, OEMs place a high priority on brake friction solutions with regulated friction, low wear, and noise-dampening properties.

The increased demand for automobile parts on a global scale has attracted counterfeiters. Brake pads, brake linings, and other associated vehicle components are now more prevalent counterfeits that can't be distinguished from the real thing. OEM-produced brake friction products are pricey yet of high quality.

In India, counterfeit items are to blame for about 20% of traffic accidents. FICCI reported that fake vehicle components caused the Indian government to lose US$ 282,912 as a result. Several agencies have taken efforts to stop the illegal trade of car parts.

The car industry, the trade platform, and the U.K. government collaborated to establish a consumer education campaign to combat fake brake friction goods. Online retailers like Amazon and eBay have also expressed their opinions on purchasing aftermarket cars. The listing of brake pads and related components on Alibaba's marketplace was prohibited.

During the historic period from 2017 to 2021, the metallic disc material is projected to increase at a pace of about 3.2%, and is expected to see a 4.5% CAGR during the forecast period. Due to its ability to resist heat, metallic materials are used more frequently in brake friction products. They are the perfect material for stopping against large machinery since they do not compress like ceramic material does.

Brake shoes are expected to experience the fastest growth in the aftermarket with regard to product type. From 2017 to 2021, brake shoes accounted for a 3.2% CAGR. Because they are located in the back of the automobile, brake shoes have a longer lifespan than brake pads because they have more room to produce the friction needed to stop the car. They also don't need as much power to stop the car as brake pads do. Brake shoes are expected to expand at a 4.5% annual rate between 2022 and 2032.

For more information:

https://www.futuremarketinsights.com/reports/automotive-brake-friction-products-market

Competitive Landscape

Key players in the global automotive brake friction products market are massively aiming at expanding their manufacturing facilities, investing in research and development along with innovating new products.

The key companies operating in the automotive brake friction products market include:

ABS Friction, Bendix Spicer, Robert Bosch, Nisshinbho Holdings Inc., Brembo S.p.A, Tenneco Inc., Federal-Mogul, Delhphi, Akebono Brake Industries, Miba AG, Aisin Seiki Co., Ltd., Macas Automotive, Masu brakes Pvt Ltd, Sundaram Brake Linings Ltd, Standard Friction Components Ltd, Japan Brake Industrial Co., Ltd, and Toughla Brake Linings.

More Insights into the Automotive Brake Friction Products Market

China is predicted to account for over 30% of the global automotive brake friction products market. China is expected to create an absolute dollar opportunity by accounting for a total market share of around US$ 361.2 Mn by 2032. With the rise in ABS and EBD brake technologies, the demand for brake friction products is increasing continuously. The market in China is anticipated to reach a market size of US$ 1.2 Bn by 2032.

Japan accounted for around 24% of the global market share in automotive brake friction products in 2021. The absolute dollar opportunity growth in Japan is projected at US$ 219.1 Mn during the forecast period. Japan continues to extend its offering in the Middle East and Asia for Industrial and Automotive OE in the aftermarket. Japan’s anticipated market size in the automotive brake friction product market is expected to reach US$ 924.7 Mn during the forecast period.

Key Segments Covered in Automotive Brake Friction Products Industry Survey

Automotive Brake Friction Products by Disc Materials:

Metallic

Ceramic

Composites

Automotive Brake Friction Products by Product Type:

Brake Shoes

Break Pad

Brake liner

Disc Brake

Drum Brake

Automotive Brake Friction Products by Vehicle Type:

Passenger Vehicles

Commercial Vehicles

0 notes

Text

Automotive Parts Aftermarket Key Opportunity, Analysis, Growth, Trends 2032

The report published on Automotive Parts Aftermarket is a comprehensive analysis that includes the key parameters and indicators critical in understanding the market. The data from the years 2022 to 2030 has been used to present the market status and size. The study also covers the overall market valuation along with the CAGR for the forecast period. The introductory chapter presents an overview of Automotive Parts Aftermarket Market along with the product definition and market scope. The report also analyzes consumer trends regarding the products along with the industry development trends.

Market Dynamics

Automotive Parts Aftermarket growth in the current scenario as well as in the coming years and the factors affecting it has been discussed in detail. The interplay of demand and supply forces in this market along with the external factors have been studied. The effect on the market in terms of growth has been studied to aid the market forecast. The pricing policies used in various regions of Automotive Parts Aftermarket Market and the effect they have on the consumption behavior have been studied.

Demand for automotive parts in the aftermarket is being aided by increased maintenance and repair activities carried out by vehicle owners because stock vehicle parts suffer wear and tear over a period of time. Air filters, fuel filters, and spark plugs, as well as brake pads, are more likely to be replaced at regular intervals.

Governments all over the world have enacted strict car emission standards that require product manufacturers to provide ecologically sustainable and high-performing parts for both, local and international markets, which is expected to drive demand of automotive parts. The automobile parts industry has seen significant expansion in recent years, with rising economies such as China, India, and Brazil expected to drive worldwide market growth.

Market players are rapidly innovating and bring in new, advanced parts into the aftermarket:

In June 2021, Michelin introduced new winter tires for trucks, named “Michelin X Multi Grip”. These tires deliver better performance and ensure maximum safety in extreme weather conditions such as snow- and slush-covered roads as well as wet roads.

In Feb 2021, Gabriel India Limited developed the first adjustable electronic hydraulic shock absorber for a leading SUV vehicle in the aftermarket sector.

Key Takeaways from Market Study

At a CAGR of 6.7%, electrical parts is projected to be the fastest-growing product segment through 2031.

Tires are expected to have the highest share in the product segment, with nearly 42% market share by 2031.

By vehicle, passenger cars are projected to be the segment leader with a market share of more than 64%.

By Region, Europe is projected to have the highest share in the global market accounting to more than 34%. Germany is expected to hold nearly 29% of the European market share by 2031.

The market in the Middle East & Africa region is projected to expand at the fastest CAGR of 6.2%

The U.S. is projected to register the highest absolute $ opportunity of more than US$ 44 Bn from 2021 to 2031.

By sales channel, authorized dealers are anticipated to lead with more than 45% share of the market.

Market Landscape Identified to Be Fairly Competitive

On a regional, national, and global basis, the worldwide Automotive Parts Aftermarket By Products is highly competitive and fragmented.

Some of the key players included in the report are Robert Bosch GmbH, ZF Friedrichshafen AG, Hella KGaA Hueck & Co., NGK Spark Plug, Exide Technologies, Gabriel India Limited, Hitachi Astemo, Ltd., KYB Corporation, Tenneco, Inc., Denso Corporation, Magna International, Continental AG, Valeo SA, Bridgestone, Michelin, Goodyear, Pirelli, Mahle GmbH, BorgWarner, OSRAM Licht AG, Knorr-Bremse, and Aisin Corporation.

Buy Full Report Now and Get Up to 20% Discount @ https://www.persistencemarketresearch.com/market-research/automotive-parts-aftermarket.asp

Key Questions Answered in This Report.

How much is the global automotive parts aftermarket valued at currently?

What is main factor driving demand for automotive parts in the aftermarket?

At what CAGR did demand for automotive parts in the aftermarket increase over the past 5 years?

What will be the demand outlook for automotive parts through 2031?

What are the key trends being witnessed in this marketplace?

What is the market share of the top 5 manufacturers of automotive parts in the aftermarket?

At what rate is the market in Germany registering growth in Europe?

Which are the top 5 countries driving most demand for automotive parts in the aftermarket?

0 notes