#Galvanized Threaded Rod 3/4

Explore tagged Tumblr posts

Text

Behind the Scenes with Bolt Manufacturers: How Your Everyday Fasteners Are Made

Bolts are an essential component in almost every industry you can think of, from construction and automotive to electronics and furniture. But have you ever wondered how these everyday fasteners are made? Understanding the intricate process of bolt manufacturing not only gives us an appreciation for these small but mighty tools but also highlights the craftsmanship and technology involved in their production. In this article, we'll take a deep dive into the world of bolt manufacturing, exploring the materials, processes, and quality control measures that ensure each bolt performs its crucial role effectively.

1. Raw Materials: The Foundation of Quality Bolts

The quality of a bolt begins with the raw materials used in its production. Steel is the most common material for bolts due to its strength, durability, and cost-effectiveness. Depending on the application, bolts may be made from different types of steel, including carbon steel, alloy steel, stainless steel, and even superalloys for high-stress environments. The choice of material impacts the bolt’s strength, corrosion resistance, and ability to withstand extreme conditions.

Carbon Steel: Used for standard bolts, suitable for general applications.

Alloy Steel: Contains additional elements like chromium and molybdenum for enhanced strength and wear resistance.

Stainless Steel: Offers excellent corrosion resistance, ideal for environments exposed to moisture or chemicals.

Superalloys: Designed for extreme conditions, such as high temperatures or high stress.

2. The Bolt Manufacturing Process: From Wire Rod to Finished Product

The journey of a bolt begins with a simple wire rod. This rod undergoes several stages to transform into the final product:

2.1. Wire Drawing

The manufacturing process starts with wire drawing, where a large steel rod is drawn through a series of dies to reduce its diameter. This process also enhances the material's strength by aligning the molecular structure of the steel.

2.2. Cold Heading

Next comes cold heading, a process that shapes the bolt’s head without heating the material. The wire is cut to the required length and then formed into the desired shape using a series of dies and punches. Cold heading is preferred because it maintains the steel's integrity and strength while being cost-effective.

2.3. Thread Rolling

Once the bolt head is formed, the thread rolling process begins. This step involves rolling the blank bolt between two dies to create threads. Unlike cutting, thread rolling displaces the material, which results in stronger threads due to the grain flow of the steel.

3. Heat Treatment: Strengthening the Bolts

After forming, bolts often undergo heat treatment to enhance their mechanical properties. Heat treatment processes such as quenching and tempering adjust the bolt's hardness and strength, making them suitable for different applications. This step is crucial for bolts that need to withstand high stress or extreme environmental conditions.

4. Surface Coating: Enhancing Corrosion Resistance

To ensure bolts last longer and perform well, especially in harsh environments, manufacturers apply surface coatings. Coatings like zinc plating, galvanization, or specialty coatings provide corrosion resistance and reduce wear. The choice of coating depends on the intended use of the bolt and the environmental conditions it will face.

5. Quality Control: Ensuring Every Bolt Meets Standards

Quality control is a critical part of the bolt manufacturing process. Manufacturers use various tests to ensure each bolt meets the required specifications and standards:

Dimensional Checks: Ensuring the bolt's dimensions are within specified tolerances.

Tensile Testing: Measuring the bolt's strength under tension to ensure it can handle the required load.

Hardness Testing: Checking the material's hardness to confirm it has been properly heat-treated.

Corrosion Testing: Evaluating the bolt’s resistance to corrosion in simulated environmental conditions.

6. The Role of Technology in Modern Bolt Manufacturing

Modern bolt manufacturing has evolved significantly with the advent of new technologies. Computer Numerical Control (CNC) machines and automation have revolutionized the industry, allowing for more precise manufacturing and reduced human error. These advancements have also enabled manufacturers to produce bolts at a faster rate while maintaining high-quality standards.

7. Environmental Considerations in Bolt Manufacturing

As with many manufacturing industries, bolt manufacturers are increasingly focused on sustainability. Efforts to reduce waste, recycle materials, and improve energy efficiency are becoming standard practice. Some manufacturers are also exploring eco-friendly coatings and alternative materials that reduce environmental impact without compromising on performance.

Being A Superior High-Quality Bolt Manufacturer In India

Bhansali Fasteners is one of the biggest bolt manufacturers in India. For fluid transmission in a range of industries, including construction, food, chemicals, oil & gas, and pharmaceuticals, bolts are a great option. They also offer low maintenance costs and benefits for sustainability. They provide security and reliability.

We provide low-cost, high-quality bolts to support efficient and successful work. Our bolts comply with several standards, including ASTM, ASME, ANSI, UNS, and DIN. Our inventory, which comprises different sizes, thicknesses, bars, and grades, satisfies a wide range of needs. In addition, we are a major screw manufacturer in India.

One of the top bolt manufacturers in India is Bhansali Fasteners. Bolts are polished in accordance with the customer's specifications, which include wall thickness and size. Heat treatment is an additional option for applications with higher demands. We produce, provide, and store a large range of bolts in various sizes at the best possible price. Additionally, look at the bolt weight chart.

We are also a Bolt Manufacturers in UAE, Bolt Manufacturer in Bangladesh.

For More Detail

Website: bhansalibolt.com

Product: SS Bolt Manufacturer

Other Product: Fasteners Manufacturers In Saudi Arabia.

#Bolt Manufacturers In India#Bolt Manufacturers#SS Bolt Manufacturer#Bolt Suppliers#Fasteners Manufacturers In Saudi Arabia

0 notes

Text

Helical Bracket

Bracket Material: ASTM A36, Made of three different thickness of plates.

Cap Plate: ASTM A572 Grade 50

Bracket Hardware: (2)-3/4”X16”Long Grade B7 All thread Rod with Nuts

All welding to be in accordance with AWS D1.1

Brackets and Caps are all available as either plain steel or Hot-dipped galvanized in accordance with ASTM A123

Bracket Hardware is provided as Electro-zinc plated in accordance with ASTM B633

0 notes

Text

Anchor Rod

Anchor Rod

Name: Anchors Rods, Threaded, Forged-Eye Anchor rods, also refer to anchor bolts, concrete embeds or foundation bolts, are embedded in concrete foundations to support structural steel columns, light poles, traffic signals, highway signstructures, industrial equipment and many other constructions.

Used for guying utility poles

For use with expanding and cross-plate anchors

Contoured to prevent damage to strand

Each rod is threaded 3-1/2" minimum length

Minimum tensile strength is 16000 lbs

All the rods are assembled with a heavy square nut

Anchor Rods conform to IEEE Standard C135.2 (1999) and Bell Specification CAO 7082

Hot dip galvanized to meet ASTM Specification A123, Class B1 and C

Specifications TypeSINGLE STRAND ANCHOR RODDOUBLE STRAND ANCHOR RODTRIPLE STRAND ANCHOR RODRod Dia (inch) x Length (ft)5/8 X 55/8 X 63/4 X 85/8 X 65/8 X 73/4 X 95/8 X 75/8 X 81 X 85/8 X 83/4 X 61 X 105/8 X 103/4 X 8- - 3/4 X 9- - 1 X 8- - 1 X 10-

Notes:OEM service is available, different materials and specifications can be customized according to your demands.

0 notes

Text

Helical Bracket

Bracket Material: ASTM A36, Made of three different thickness of plates.

Cap Plate: ASTM A572 Grade 50

Bracket Hardware: (2)-3/4”X16”Long Grade B7 All thread Rod with Nuts

All welding to be in accordance with AWS D1.1

Brackets and Caps are all available as either plain steel or Hot-dipped galvanized in accordance with ASTM A123

Bracket Hardware is provided as Electro-zinc plated in accordance with ASTM B633

0 notes

Text

Ananka

Q1) Are there hex bolts with specialized coatings for enhanced durability?

Ans) Certainly, hex bolts are available with specialized coatings intended to augment their durability and corrosion resistance across various environments. These coatings provide an extra layer of defense against factors such as moisture, chemicals, and other corrosive agents. Several common specialized coatings for hex bolts include:

1. Zinc Coating (Galvanized): Zinc coating, often referred to as galvanization, is a prevalent method for boosting the corrosion resistance of hex bolts. Galvanized hex bolts are enveloped in a layer of zinc that serves as a sacrificial barrier against corrosion. This coating is especially effective in environments prone to moisture and atmospheric exposure.

2. Cadmium Plating: Cadmium plating is an alternative choice for augmenting corrosion resistance. Hex bolts with cadmium coatings provide robust protection in environments with high corrosion rates, such as marine applications. However, cadmium is a toxic material, and its usage is restricted in some regions due to environmental concerns.

3. Xylan Coating: Xylan, a fluoropolymer-based coating, delivers exceptional corrosion resistance alongside non-stick properties. Hex bolts coated with Xylan are frequently employed in situations requiring resistance to chemicals, heat, and harsh surroundings.

4. Dacromet Coating: Dacromet is an inorganic, water-based coating that offers notable corrosion resistance and strong adhesion. It excels at safeguarding against salt spray and other corrosive substances.

5. Phosphate Coating: Phosphate coatings create a layer of phosphate crystals on the hex bolt's surface. These coatings heighten both lubrication and corrosion resistance, making them apt for applications involving sliding or moving components.

6. Teflon Coating (PTFE): Teflon, or PTFE (polytetrafluoroethylene), coatings bring forth superb non-stick attributes and resistance to chemicals and elevated temperatures. Hex bolts coated with PTFE are often chosen for scenarios where achieving adequate lubrication proves challenging.

7. Epoxy Coating: Epoxy coatings furnish robust defense against corrosion and environmental variables. They are commonly found in industrial and marine applications that demand substantial durability.

8. Nickel Coating: Nickel coatings contribute to both corrosion resistance and aesthetic appeal. They are frequently employed in decorative and marine settings.

9. Stainless Steel: While not conventionally deemed a coating, employing stainless steel hex bolts ensures inherent corrosion resistance. Stainless steel contains chromium, which generates a protective oxide layer halting rust and corrosion.

When opting for specialized coated hex bolts, it's pivotal to assess the specific environmental circumstances and requisites of your particular application. Different coatings provide varying degrees of safeguarding and performance, making the selection of the appropriate coating pivotal in ensuring that hex bolts maintain enhanced longevity within their designated environment.

Elevator Bolt Manufacturers in Mumbai

Q2) How do you choose between standard hex nuts and flange nuts?

Ans) The decision between standard hex nuts and flange nuts hinges on the distinct needs of your application and the advantages each type offers. Here are key considerations to factor in when making your selection:

Standard Hex Nuts:

1. Versatile Application: Standard hex nuts, also known as hexagon nuts or regular nuts, are versatile and commonly used across various contexts. They enjoy wide availability.

2. Simplicity: Standard hex nuts are straightforward to work with, designed to match standard hex bolts and threaded rods.

3. Cost-Effectiveness: Generally, standard hex nuts are more budget-friendly compared to specialized alternatives like flange nuts.

4. Space Constraints: Standard hex nuts feature a lower profile than flange nuts, which proves advantageous in situations with confined space or limited clearance.

5. Load Distribution: Although not as comprehensive as flange nuts, standard hex nuts still distribute loads across the threaded connection.

Flange Nuts:

1. Integrated Washer: Flange nuts possess an integrated washer-like flange at their base. This flange spreads the load over a larger surface area, mitigating the risk of the nut digging into softer materials and ensuring a more secure linkage.

2. Resistance to Vibration: The flange of a flange nut effectively counters loosening due to vibrations, rendering them apt for scenarios where movement or vibration is a concern.

3. Sealing Properties: Flange nuts can offer a certain degree of sealing between the nut and the connected surface, forestalling the entry of moisture or debris into the threaded connection.

4. Temperature Adaptability: Flange nuts exhibit enhanced resistance to temperature-related expansion and contraction, making them fitting for applications subjected to temperature fluctuations.

5. Reduced Surface Impact: The expanded flange bestows more uniform pressure dispersion, curbing the possibility of surface impairment to the fastened material.

6. Elevated Strength: In certain instances, flange nuts can yield higher strength on account of the enlarged bearing surface.

Factors for Consideration:

1. Application Prerequisites: Evaluate your application's distinct demands. Should you require augmented load dispersion, vibration resistance, or sealing, flange nuts might be the more appropriate choice.

2. Spatial Limitations: In cases of confined space, standard hex nuts could be more favorable due to their lesser profile.

3. Budget Considerations: Given that flange nuts are generally pricier than standard hex nuts, financial considerations may factor into your choice.

4. Material Compatibility: Ensure that the selected nut type aligns with the material you're fastening and the kind of bolt or threaded rod being utilized.

Ultimately, your selection between standard hex nuts and flange nuts hinges on the balancing of cost, functionality, and the distinct requisites of your application. It's advisable to seek insights from engineering professionals or fastening system experts to make an educated decision grounded in your unique circumstances.

Hex Nut Suppliers

Q3) What are the implications of using oversized or undersized plain washers?

Ans) Using oversized or undersized plain washers can have various implications on the effectiveness and safety of the fastening system. Here's how both scenarios can impact the application:

Oversized Plain Washers:

1. Load Distribution: Oversized washers can provide better load distribution across the connected surfaces. This can help reduce the pressure on the material being fastened and prevent surface damage or deformation.

2. Stability: The larger diameter of oversized washers can improve the stability of the connection by increasing the bearing surface area.

3. Vibration Damping: Larger washers might offer better vibration damping properties, which can be beneficial in applications where vibration is a concern.

4. Clearance Issues: However, using oversized washers can lead to clearance issues in tight spaces or applications with limited room for the washer to fit.

5. Aesthetics: Oversized washers might not have a neat appearance and could affect the overall aesthetics of the assembly.

Undersized Plain Washers:

1. Load Distribution: Undersized washers might not distribute the load evenly across the connected surfaces, leading to localized pressure points that can cause surface damage or material deformation.

2. Reduced Stability: Smaller washers have a smaller bearing surface area, which can reduce the stability of the connection and potentially lead to bolt or nut loosening.

3. Vibration Issues: Undersized washers may not provide effective vibration damping, increasing the risk of fastener loosening due to vibrations.

4. Compromised Sealing: In applications where sealing is important, using undersized washers might compromise the effectiveness of the seal between the fastener and the connected surface.

5. Potential for Nut/Bolt Failure: In extreme cases, the use of significantly undersized washers might increase the risk of nut or bolt failure due to inadequate load distribution.

Choosing the Right Size:

1. It's essential to choose plain washers of an appropriate size that match the diameter of the bolt or screw being used. The washer's outer diameter should not exceed the diameter of the connected material.

2. Consider the specific requirements of the application, load, vibrations, and any space limitations when selecting the washer size.

3. Follow manufacturer guidelines and industry standards to ensure proper washer size selection.

In summary, the implications of using oversized or undersized plain washers can affect load distribution, stability, vibration resistance, clearance, aesthetics, and even the overall integrity of the fastening system. It's crucial to carefully select the appropriate washer size based on the application's needs and follow best practices to ensure a secure and effective connection.

Carbon Steel Fasteners

Q4) How do you choose between standard stud bolts and fully threaded studs?

Ans) Choosing between standard stud bolts and fully threaded studs depends on the specific application, requirements, and structural considerations. Here are some factors to consider when making this decision:

Standard Stud Bolts:

1. Load Distribution: Standard stud bolts typically have a threaded portion at both ends and an unthreaded portion (the shank) in the middle. This unthreaded portion can provide improved load distribution and reduce stress concentrations in the connected components.

2. Assembly Ease: The unthreaded shank of standard stud bolts allows for easier assembly and disassembly. Nuts can be threaded onto the stud more easily without encountering resistance from threads on the entire length.

3. Thread Engagement: Standard stud bolts provide better thread engagement within the nut due to the unthreaded shank. This can enhance the overall stability and reliability of the connection.

4. Torque Transmission: The unthreaded shank of standard stud bolts allows for efficient torque transmission during tightening, reducing the risk of overloading or damaging the components being connected.

5. Application Flexibility: Standard stud bolts are versatile and suitable for various applications where load distribution, ease of assembly, and torque transmission are critical.

Fully Threaded Studs:

1. Threaded Engagement: Fully threaded studs have threads along their entire length, providing more threads to engage with nuts or threaded holes. This can offer increased resistance against loosening in dynamic or vibrating environments.

2. Length Adjustment: Fully threaded studs allow for precise length adjustment by threading the nut along the entire length. This can be beneficial when the connected components need to be precisely positioned.

3. Space Constraints: In applications with limited space, fully threaded studs can be advantageous as they eliminate the need for a nut on one end, potentially saving space.

4. Shear Strength: In applications requiring shear strength, fully threaded studs may have a more uniform cross-sectional area along their length, potentially providing higher shear resistance compared to standard studs.

5.Specific Design Requirements: Some applications may require fully threaded studs due to design constraints or specific assembly requirements.

Choosing Between Them:

1. Load Distribution and Stability: If load distribution and stability are critical, standard stud bolts with unthreaded shanks are often preferred.

2. Vibration and Dynamic Loads: For applications with significant vibration or dynamic loads, fully threaded studs might offer better resistance against loosening.

3. Ease of Assembly: Standard stud bolts can offer easier assembly and disassembly due to the unthreaded shank.

4. Precise Positioning: If precise positioning is required, fully threaded studs allow for more precise length adjustment.

5. Application Constraints: Consider space constraints, shear strength requirements, and other specific application factors when making the choice.

Ultimately, the decision depends on the specific needs of your application. Assess the load distribution, assembly requirements, space constraints, and other relevant factors to determine whether standard stud bolts or fully threaded studs are the better fit for your particular situation.

Inconel Bolts Price

0 notes

Text

Features and Applications of Ground Rod Clamps in The Electrical Industry

A ground rod clamp is an underground electrical fitting that creates a connection between the ground cable and the bearing section of the ground rod in the best way. The rod ensures the grounding cable has been properly installed in the ground. The clamp plays a significant role in completing the connection and making sure that everything is completely secure in the first place.

A ground rod is constructed with good-quality and heavy-duty steel to ensure the finished product can adequately withstand the problems of nature while exposed to ground conditions. There are different diameters for the ground rod clamps. The right size choice will depend on the diameter you have for the ground rod and the grounding conductor.

Design of a Ground Rod Clamp

The design of the ground rod clamps is done in such a way that it ensures a proper connection that is both stable and strong. The grounding cable and ground rod are securely connected with this component's ahelp. It can achieve this goal without actually interfering with the functionality and capabilities of the grounding cable in the first place.

The apt design of the ground rod clamp ensures a stable and robust connection with the ground rod and the ground cable. It achieves this goal without interfering with the functionality of the grounding cable.

The ground rod clamp consists of a hex bolt and a proper frame. The bolt must pass through the hole to ensure that the clamping process is successful.

Features of A Ground Rod Clamp

The ground rod clamp is robust and durable.

It is made using some heavy-duty metal to ensure that the component can survive all sorts of destructive forces.

The clamp is also properly galvanized; hence, it can resist all the chemical damage caused, such as rust, corrosion, and much more.

This component is also able to withstand additional pressure and torque

Threaded and is accompanied by a hexagonal head bolt

Able to withstand extra torque and pressure

The ground rod clamps are available in diffident diameters such as 3/8″, 1/2″, 5/8″, and 3/4″

Working Mechanism of the Ground Rod Clamp

The entire process of the working mechanism of the ground rod clamp is straightforward. Once the ground rod and the ground cable get adequately positioned next to one another, the hex bolt will be rotated until the connection that is formed between the rod and the cable becomes unbreakable. Despite playing an essential role in the clamping process, a ground rod clamp doesn't interfere with the working mechanism of the cable or the rod.

Application of A Ground Rod Clamp

A ground rod clamp is one of the most common components seen in domestic and commercial electrical installations. It is mostly used in grounding with rods and cables to ensure that ground rods and cables are properly joined to create a lasting connection.

0 notes

Photo

Galvanized Threaded Rod grade 8.8 Din 975 rods

click here to see more of this product

#Galvanized Threaded Rod#Threaded Rod grade 8.8#Din 975 rods#Galvanized Threaded Rod home depot#Galvanized Threaded Rod near me#Galvanized Threaded Rod 3/4#Galvanized Threaded Rod 3/8#M30 Threaded Rod grade 8.8#M36 Threaded Rod grade 8.8#M16 Threaded Rod grade 8.8#M12 Threaded Rod grade 8.8#M24 Threaded Rod grade 8.8#Threaded rods din 975#Thread rods din975#Din975 threaded rods

1 note

·

View note

Text

The skin can absorb in-depth moisturizers

The skin can absorb in-depth moisturizers (which are designed to work at the dermis layer of skin) and surface-level moisturizers galvanized threaded rod (which work on the epidermis layer)

but only if certain ingredients are used. First, you need to understand the skin structure. What gives skin a toned, uplifted, youthful appearance thats free of age lines and wrinkles?Collagen is about 90% of connective tissue so its pretty much the foundation of our skin and responsible for holding our face together. The depletion of our collagen stores is one of the primary reasons we appear to age. You could compare it to a beautiful building with an eroding foundation - over time, the façade will crumble beyond recognition.

When collagen fibers are nourished and hydrated by collagen fibrils, skin is healthy and youthful looking. But as we age, the body stops producing the collagen fibrils. Elastin is only 2-4% of connective tissue, but its crucial to skins youthful appearance. Like an elastic band, elastin fibrils bind the collagen fibrils together. So it not only supports collagen hydration, it also gives skin the elasticity and resilience that makes skin smooth and supple. With age, elastin fibers thicken and lose elasticity. Proteoglycans act as molecular messengers. Their job is to 1) detect deficiencies of collagen and elastin fibrils and 2) calibrate fibroblasts (the cells responsible for collagen and elastin production) to 3) jump-start fibroblasts natural production of collagen and elastin. Cytokins are the messages that Proteoglycans, the molecular messengers, carry. In effect, theyre the molecular information delivered to fibroblasts to synchronize activities - they tell fibroblasts to start producing more collagen and elastin or if a new cell is needed. Skins intercellular matrix is the skins first line of defense against aging.

The Natural Moisturizing Factor (NMF) is one of the primary elements in keeping the epidermis (outer layer of skin) healthy. Its a layer of natural, water-soluble compounds that lock-in moisture and protect skin. It helps protect skin from such harmful age-aggressors as the sun, pollution, chemicals, etc., but it breaks down quickly. When the NMF content of skin is reduced, skin becomes rough, flakes, develops fine lines and becomes dry.

1 note

·

View note

Text

Copper Bonded Copperweld Ground/EarthRod

What is the copper-bonded copperweld steel ground rod?

Product Name: Copper coated copperweld steel ground rod

Production process: electroplating / continuous electroforming

Raw materials: Cold draw high quality mild steel

Product type: one pointed, one flat, two threads (requires with a striker, connector, drill)

Thread production process: mainly consists of two processes: turning before electroplating and rolling after electroplating

Tensile strength: 450-600MPA

Copper layer thickness: more than 0.254mm

Super copper thickness: 0.33-1mm

Why choose our Copper-bonded steel ground rod?

1. Factory history 30 years

2. Export history 10years

3. Quality control

4. Technical skill(copper thickness 0.5mm/0.8mm/1mm)

5. OEM service

6. Free sample

Copper-bonded copperweld steel ground rod advantags:

1. Higher tensile strength than pure copper ground rod, can be as high as 600MPA and above

2. Superior corrosion resistance: underground service life of up to 30-50 years

3. Compared with pure copper ground rod, it has excellent electrical conductivity of copper and saves cost.

4. Compared with traditional galvanized ground rods, the conductivity is higher and the corrosion resistance is stronger.

5. The connection to the grounding grid can be made by exothermic welding, integrated and molded, and the grounding resistance is small, making it a permanent maintenance-free grounding device.

Production reference standard: US UL467, national grid production enterprise standard QDW466-2010, etc.

Copper-bonded copperweld steel ground rod application range:

Lightning protection grounding projects in petrochemical plants, oil storage, power plants, substations, communication base stations, airports, network equipment rooms, etc.

Remarks: Copper-bonded copperweld steel copperweld ground rod steel material and copper plating thickness can be customized according to requirements, the company provides OEM service.

If you want buy earth rod, please contact us.

2 notes

·

View notes

Text

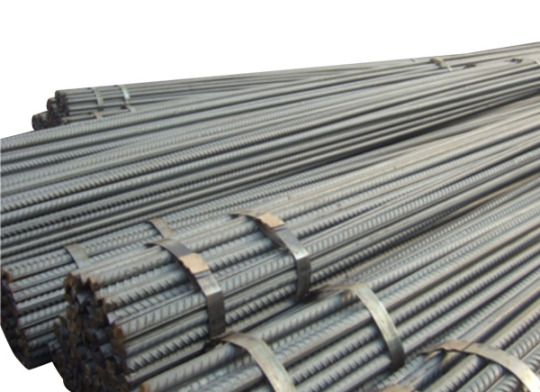

Rebar

Steel Searcher Rebar is a common name for hot-rolled ribbed steel bars. The grade of ordinary hot-rolled steel bar consists of HRB and the minimum yield point of the grade. H, R, and B are the first letters of the three words, Hotrolled, Ribbed, and Bars, respectively.

Specification of Rebar

Product Name

Construction steel rebar, bridge concrete Iron Rod

Grade

HRB400 HRB500 ASTM GR40 GR60

Size

6MM~40MM

Length

Length: Single random length/Double random length

5m-14m,5.8m,6m,10m-12m,12m or as customer's actual reques

Packing

Bundle, or with all kinds of colors PVC or as your requirements

Pipe Ends

Plain end/Beveled, protected by plastic caps on both ends, cut quare, grooved, threaded and coupling, etc.

Surface Treatment

1. Galvanized

2. PVC, Black and color painting

3. Transparent oil, anti-rust oil

4. According to clients requirement

Origin

Tianjin China

Certificates

API ISO9001-2008, SGS.BV

Delivery Time

Usually within 10-45 days after receipt of advance payment

Features of Rebar

What are the advantages of rebar:

High hardness and good durability.

It can improve the wear resistance of screw connections to a large extent, and can effectively avoid damage to connecting threads.

Good shock resistance and firmness.

Even when it is subjected to strong vibration, its screws will not loosen, which is better than the usual locking device.

0 notes

Text

Quick and Easy Wire Mesh Cable Tray Installation: A Complete Guide

When it comes to organizing and managing cables in industrial, commercial, or IT environments, wire mesh cable trays have become the go-to solution. Their lightweight, flexible design and easy installation process make them a favourite for projects where speed and efficiency are crucial. If you're ready to install wire mesh cable trays but aren't sure where to start, this guide will walk you through the process, offering helpful tips and best practices to ensure a successful installation.

Wire Mesh Cable Tray

Why Choose Wire Mesh Cable Trays?

Before diving into the installation steps, let’s briefly look at why wire mesh cable trays are so popular:

Flexibility: Wire mesh trays can be easily cut and shaped to fit around obstacles or tight spaces.

Ventilation: The open design allows for better airflow, which helps prevent overheating of cables.

Durability: Made from corrosion-resistant materials, wire mesh trays are ideal for harsh environments.

Ease of Maintenance: Their open structure provides easy access for future cable adjustments or repairs.

SS Wire Mesh Cable Tray

Tools and Materials You'll Need:

To get started, make sure you have the following tools and materials:

Wire mesh cable trays (stainless steel or galvanized)

Cable tray supports (brackets, hangers, or wall mounts)

Screws, nuts, and bolts

Cutting tools (wire cutters, hacksaw)

Measuring tape

Level

Drill

Safety gear (gloves, goggles)

Wire Cable Tray

Step-by-Step Installation Process:

1. Plan Your Layout

Before installing, it’s essential to plan the cable tray route. Identify the path for your cables, considering obstacles like walls, beams, or other equipment. Ensure that the tray’s width and height can accommodate your cable bundle, with some room for future expansion.

Pro Tip: Mark the installation route on the wall or ceiling using a measuring tape and chalk. This will help guide you during installation and ensure a straight, even run.

2. Install Tray Supports

Wire mesh cable trays need sturdy support. Depending on your setup, you can use ceiling brackets, wall mounts, or hanging supports. The supports should be placed every 4 to 6 feet (1.2 to 1.8 meters), depending on the load weight.

Ceiling Support: Attach ceiling brackets with threaded rods for suspended trays.

Wall Mounts: For wall installations, secure L-shaped brackets to the wall, ensuring they are level.

Floor Mounts: If installing on the floor, use riser supports to keep the tray elevated.

Pro Tip: Use a level to ensure that the supports are evenly aligned for a straight and professional look.

SS Wire Mesh Cable Tray Manufacturer

3. Cut and Prepare the Tray

Wire mesh trays are flexible and can be cut to fit your specific requirements. Use wire cutters or a hacksaw to cut the tray to the appropriate length, ensuring smooth edges to prevent cable damage.

Pro Tip: Wear protective gloves and goggles when cutting the tray to avoid injury from sharp edges or debris.

4. Position and Secure the Tray

Once the supports are in place and the tray is cut to size, position the wire mesh tray on the brackets or hangers. Secure the tray using screws, nuts, or bolts, making sure it is tightly fastened.

For long runs, join the trays using tray connectors to ensure a continuous cable path. These connectors help maintain the tray’s structural integrity and keep the cables secure.

Pro Tip: Check the stability of the trays after securing them by gently pushing or pulling on them to ensure they won’t shift or sag.

5. Organize and Lay the Cables

With the tray installed, it’s time to organize and lay your cables. Group cables based on their type (power, data, etc.) to avoid interference and maintain a clean, professional look.

Pro Tip: Use cable ties or Velcro straps to bundle cables neatly along the tray. This will make future maintenance easier and keep the setup organized.

Wire Cable Tray

6. Final Inspection and Adjustments

After the installation, perform a final inspection to ensure that all the trays are securely fastened and the cables are properly organized. Check for any sharp edges or protrusions that might damage the cables and make necessary adjustments.

Pro Tip: Make sure there’s enough slack in the cables to prevent tension, which could lead to damage over time.

Maintenance Tips for Wire Mesh Cable Trays:

Wire mesh cable trays require minimal maintenance, but regular checks can ensure their longevity:

Periodic Inspections: Regularly inspect the trays for signs of corrosion, especially in environments with high humidity or chemical exposure.

Cable Organization: Check that cables are securely fastened and haven't shifted out of place. Replace any damaged cable ties or straps.

Cleanliness: Keep the tray and surrounding area clean to prevent dust build-up, which could affect cable performance over time.

Wire Mesh Cable Tray Manufacturer

Conclusion

Installing wire mesh cable trays is a straightforward process that requires basic tools and a bit of planning. Their ease of installation, flexibility, and long-term durability make them an ideal solution for a wide range of cable management needs. By following these steps and tips, you’ll ensure a smooth installation that results in a clean, organized, and efficient cable system.

Whether you’re working on an industrial project, data center, or office building, wire mesh cable trays offer the quick and easy installation you need to keep your cables organized and protected.

#stainless steel wire mesh cable tray#wire cable trays#wire mesh cable tray#wire mesh cable tray manufacturer

0 notes

Text

What Are Rod Clevises?

Basically, a clevis is an assembly that is used to attach two components together. They are commonly used in applications that require the assembly to withstand tension loads. They can be used to connect two cylinders, a sailboat's rigging, or in a variety of other applications. A clevis is typically a U-shaped piece with two holes at each end. The clevis is then secured with a pin, which holds it in place.

Rod clevises are a type of clevis that is used in a variety of applications. They are threaded on one end. They can also be coated or galvanized. They are usually cast or machined, but can also be made from stainless steel. They are also used in a variety of industries, including agriculture, aviation, and the automobile industry.

A clevis's thread is usually right-hand thread, but can also be left-hand thread if it is used in conjunction with a turnbuckle. The clevis's thread direction is dependent on the type of rod it is used on. It is also important to consider the rod's thickness when choosing a clevis. For instance, a rod with a diameter of 3/8" can be threaded on the left side of the rod clevises clevis, whereas a rod with a diameter of 4" can be threaded on the right side of the clevis.

Clevises are manufactured to meet specific load requirements and dimensional specifications. They are used in a variety of fastening applications, including sailboat rigging, trailers, and aircraft. They are also used to connect structural members subjected to tension loads. Depending on the application, clevises can be used with a variety of mounting hardware, including eye brackets, autoswitch bands, and brackets. A clevis is typically used in conjunction with a turnbuckle, which dissects the assembly to allow for limited motion along the clevis pin's axis. A clevis bracket is another type of mounting hardware, which has a rectangular base with holes. These clevis brackets are made of solid metal and are generally used to mount rods on flat surfaces.

Clevises are available in a variety of sizes, including plain finished steel, hot-dip galvanized medium carbon steel, and stainless steel. They are also available in a variety of types, including cross-link clevises, plow clevises, and a clevis with two cotters on each end. The size of the clevis, or the "D" dimension, determines the capacity of the assembly. A clevis can also be used to attach a tie rod assembly to a gusset plate, as a bolt-on tie rod, or as part of a clevis fastener assembly. It is important to match the size of the clevis with the size of the gusset plate, the number of clevises to be used, and the finish to be used on the hardware.

Clevises are typically manufactured to meet state and federal safety standards, including ASTM A473 and the American Institute of Steel Construction's Manual of Steel Construction. Cleveland City Forge clevises are manufactured according to these standards and meet funding requirements.

0 notes

Text

Threaded Rod

Material: Carbon steel or stainless steel.

Size: 3/8-16x120", 1/2-13x120", 5/8-11x120", 3/4-10x120" or other sizes on request.

Finish: Natural finish, Electro galvanized, Hot dip galvanized.

Ideal for steel, wood and concrete applications where threaded rod needs to be installed.

All kinds of threaded rods are available according to customers' demand.

0 notes

Text

Helical Brackets

Bracket Material: ASTM A36, Made of three different thickness of plates.

Cap Plate: ASTM A572 Grade 50.

Bracket Hardware: (2)-3/4”X16”Long Grade B7 All thread Rod with Nuts.

All welding to be in accordance with AWS D1.1.

Brackets and Caps are all available as either plain steel or Hot-dipped galvanized in accordance with ASTM A153.

Bracket Hardware is provided as Electro-zinc plated in accordance with ASTM B633.

0 notes

Text

Pile Caps

Top Plate Conforms to ASTM A936 for Hot Rolled Carbon Steel,

Corrison Protection Conforms to ASTM A153 Standard,

Specification for Hot-dipped Zinc Coating,

Pipe Weld 90 Degrees to Plate,

Pipe material to be C1020.

Type 1 : 8"x8"x1/2" Steel Plate,

2 3/8"OD x1/8" wall x5" Length.

Type 2 : 200x200x8mm Base Plate,

102 OD x4x100mm short pipe,

80x39x5mm Tringle Supporter.

Type 3: φ240mm x10mmSteel Plate,

109mmOD x9.5mm wall x220mm Length.

Type 4: φ240mm x 10mm round plate,

100mm x 100mm x 10mm wall x200mm length square tube,

120mm x 120mm x 10mm thickness square plate,

φ109mm x 9.5mmwall x 220mm length,

Surface: Hot-dipped galvanized, plain or others.

Type 5: 200mm x 200mm x 8mm or 10mm, 12mm top steel plate,

Grade 4.8 Thread Rod,

60mm-140mm outer diameter round pipe,

Surface: Hot-Dip Galvanized/Powder coated or Zinc-plated.

Notes:OEM service is available, different materials and specifications can be customized according to your demands.

0 notes

Text

Cushioned Pipe Clamp, Pipe Size 1/2 In

Cushioned Pipe Clamp, Pipe Size 1/2 In

Price: (as of – Details) ‘Pipe Clamp, Cushioned, Pipe Size (In.) 1/2, Tube Size (In.) 3/4, Rod Size 3/8 In., Max. Load (Lb.) 180, Material of Construction Electro-Galvanized Steel, EPDM-SBR Rubber, Thread Size (In.) 3/8, Bolt Size (In.) 3/8-16, Metal Detectable Yes, With EPDM Cushion; Recommended For Suspension Of Stationary Non-Insulated Pipe Lines, Includes Welded 3/8 In. Cap Nut, Standards…

View On WordPress

0 notes