#GRP water

Explore tagged Tumblr posts

Text

What are the Key Benefits of Using a GRP Water Tanks

The Blog In a time when water scarcity is a growing concern, GRP Water Tanks provide an efficient solution for both domestic and commercial uses. Their key benefits include corrosion resistance, ensuring safe water storage for consumption, fire protection, rainwater harvesting, and emergency water supply. Lightweight yet durable, GRP tanks are also easy to install and ideal for various industrial applications. Their versatility makes them a reliable choice for storing large water volumes, ensuring a consistent and sustainable supply.

For more details, visit HP Engineers.

0 notes

Text

Optimized Water Storage for Hospitals: The Role of GRP Panel Tanks

Introduction to Water Storage in Healthcare

Water is a cornerstone of hospital operations, playing an essential role in every aspect of patient care, facility sanitation, and equipment sterilization. Hospitals require a constant, uncontaminated water supply to support activities that directly impact patient health, from surgical procedures and hand hygiene to the cleaning of linens and preparation of meals. In emergency situations, a reliable water storage system is not just a convenience but a necessity, helping facilities maintain their standards of care even in the face of supply interruptions.

The demand for safe, effective water storage in healthcare facilities has driven the adoption of advanced materials and storage technologies. GRP (Glass Reinforced Plastic) panel tanks have become the preferred solution, combining durability, hygiene, and adaptability to meet the strict requirements of the healthcare environment. Unlike traditional storage materials, GRP tanks resist corrosion, microbial growth, and other contaminants that could compromise water quality, providing hospitals with an efficient and sustainable option.

Additionally, GRP panel tanks offer modular construction, allowing hospitals to customize their water storage solutions to fit any space constraints and capacity needs. This flexibility makes them suitable for various healthcare facilities, from compact clinics to expansive hospital campuses, ensuring that each can maintain an uninterrupted, sanitary water supply tailored to its specific demands.

Understanding GRP Panel Tanks

GRP (Glass Reinforced Plastic) panel tanks are constructed from a composite material combining glass fibers with plastic resin, resulting in a tank that’s both strong and resistant to corrosion. This construction offers several benefits: the glass fibers provide excellent tensile strength, while the plastic resin ensures the tank is lightweight, non-corrosive, and safe for water storage.

A key feature of GRP panel tanks is their modular design. The tanks are assembled from individual panels, making it easy to configure them for specific dimensions and capacities. This flexibility allows GRP tanks to be installed in diverse locations within a facility, such as rooftops, basements, or tight spaces where traditional tanks might not fit.

Due to their exceptional durability, high hygiene standards, and adaptability, GRP panel tanks are well-suited to demanding environments like healthcare facilities. They support the need for clean, reliable water storage and withstand the challenges of continuous use and exposure to environmental elements, making them a practical and effective choice for hospitals and other medical institutions.

Key Benefits of GRP Tanks in Hospital Settings

Hygienic Standards: GRP (Glass Reinforced Plastic) tanks are designed with hygiene as a top priority, an essential feature in any healthcare environment. The smooth, non-porous internal surfaces of GRP tanks significantly reduce the potential for bacterial growth and biofilm accumulation, helping to maintain clean, safe water storage. Unlike traditional metal tanks, which are susceptible to rust and contamination over time, GRP is chemically inert and does not leach harmful substances into the water. This makes GRP tanks an ideal choice for hospitals, where maintaining stringent water quality standards is vital for patient safety, equipment sterilization, and daily sanitation practices.

Long-Term Durability: GRP tanks offer exceptional durability, resisting both physical wear and environmental stressors. Their corrosion-resistant construction enables them to withstand humid environments and exposure to water without degrading, unlike metal tanks that are prone to rust. GRP's resilience to extreme temperatures means these tanks remain structurally sound even in harsh weather conditions or high-heat environments, minimizing the risk of leaks, cracks, or other damage. This durability translates to fewer repairs, lower maintenance costs, and an extended service life, making GRP tanks a cost-effective, reliable solution for hospital water storage over the long term.

Flexible Design for Varied Applications: GRP panel tanks are modular, allowing them to be customized and assembled to fit the specific requirements of a hospital's water storage needs. The modular nature of GRP tanks means they can be configured in various sizes and shapes, adapting to limited or unconventional spaces such as basements, rooftops, or mechanical rooms. This adaptability also extends to capacity, accommodating both small and large water volumes for different hospital applications. GRP tanks can store potable water for drinking and general use, as well as specialized water for sanitation, cleaning, and other critical hospital operations. This flexibility ensures that GRP tanks are versatile enough to meet the unique water needs of each healthcare facility, optimizing space and functionality without compromising on safety or hygiene.

By meeting the demands of healthcare environments, GRP tanks provide hospitals with a reliable, safe, and efficient water storage solution, supporting critical infrastructure while enhancing operational resilience and water quality.

Comparing GRP Tanks with Other Materials: A Comprehensive Overview

Glass Reinforced Plastic (GRP) tanks stand out among other water storage materials due to their unique combination of strength, durability, and low maintenance requirements. When compared with metal, concrete, and polyethylene tanks, GRP tanks offer advantages in hygiene, resilience, and ease of installation, making them especially valuable in critical settings such as hospitals, industrial facilities, and remote installations.

1. Metal Tanks vs. GRP Tanks: Metal tanks, commonly made from steel or other alloys, are known for their strength but are also highly susceptible to rust and corrosion, especially in humid or saline environments. Over time, corrosion can lead to water contamination and structural deterioration, requiring regular maintenance or replacement. GRP tanks, on the other hand, are fully resistant to corrosion due to their non-metallic composition. The glass fibers and plastic resin used in GRP construction do not react with water or air, providing a long-lasting solution with minimal risk of contamination. This feature is particularly important in settings where water purity is essential, such as healthcare and food processing.

2. Concrete Tanks vs. GRP Tanks: Concrete tanks are often chosen for their durability and capacity to store large volumes of water. However, they are prone to cracking over time due to ground movement, freeze-thaw cycles, or other environmental factors, which can compromise water quality and require costly repairs. Additionally, the rough surface of concrete can harbor bacteria, making it harder to maintain hygienic conditions. GRP tanks avoid these issues with their smooth, non-porous internal surfaces, which discourage bacterial growth and make cleaning easier. The modular construction of GRP tanks also enables rapid assembly on-site, providing a flexible solution without the need for heavy machinery or complex foundation work often associated with concrete tanks.

3. Polyethylene Tanks vs. GRP Tanks: Polyethylene tanks are lightweight and cost-effective, often used in smaller, low-demand settings. While they are resistant to rust, polyethylene can degrade over time when exposed to UV light or extreme temperatures, leading to structural weaknesses and potential leakage. GRP tanks are also lightweight but far more durable, with superior resistance to environmental stressors. GRP's UV stability and thermal resilience make it an ideal choice for both indoor and outdoor installations, ensuring long-term reliability even in extreme climates.

4. Installation and Maintenance Efficiency: One of the defining advantages of GRP tanks over other materials is their lightweight, modular design, which allows for easy transportation and quick on-site assembly. Unlike concrete tanks, which require heavy lifting equipment, or metal tanks that need specialized coatings and protective measures against corrosion, GRP tanks offer a straightforward installation process with minimal maintenance needs. The modular panel system also allows for customizable sizes and configurations, accommodating various space constraints or specific volume requirements without compromising quality.

In summary, GRP tanks combine the best attributes of other materials—such as the strength of metal, the durability of concrete, and the convenience of polyethylene—while eliminating their respective drawbacks. This makes GRP an ideal choice for modern water storage applications that demand reliability, hygiene, and adaptability across a wide range of environments and industries.

Selecting the Right GRP Tank for Hospital Applications: Essential Considerations

When it comes to water storage in hospitals, selecting the right GRP (Glass Reinforced Plastic) tank is crucial for maintaining reliable access to clean water, essential for patient care, equipment sterilization, and sanitation. Here are some key factors to consider:

Capacity Requirements: Hospitals have high water demands, so it’s vital to choose a GRP tank with the right storage capacity to ensure uninterrupted access. Tank sizes should align with the hospital's daily consumption and any emergency reserve needs. GRP tanks are available in a wide range of sizes and can be configured modularly to fit specific space constraints, allowing hospitals to meet both their immediate and future water demands.

Compliance with Health and Safety Standards: Hospitals must comply with strict hygiene and safety regulations to protect patient health. GRP tanks meet international standards for potable water storage, offering smooth, non-porous interiors that resist bacterial growth and prevent contamination. Selecting a tank from a certified manufacturer ensures compliance with health and safety standards and provides reassurance that the tank will contribute to a clean water supply in medical settings.

Installation and Space Considerations: The layout of a hospital may require custom solutions to accommodate water storage needs. GRP tanks offer flexibility through their modular panel design, which allows for on-site assembly in hard-to-reach locations, such as rooftops, basements, or narrow spaces. This adaptability ensures that tanks can be installed with minimal disruption to hospital operations.

Cost-Efficiency and Maintenance Benefits: Hospitals require cost-effective solutions that also minimize maintenance burdens. GRP tanks are durable, corrosion-resistant, and have low upkeep requirements, leading to significant savings over time. The tanks’ chemical stability means they don’t require regular treatments to prevent corrosion, unlike metal tanks, making them an economical long-term investment for healthcare facilities.

In summary, GRP tanks provide hospitals with a dependable, efficient, and compliant solution for water storage, aligning with the high standards and operational demands of healthcare facilities. With their modular design, hygiene assurance, and durability, GRP tanks are an excellent choice for hospitals prioritizing safety, reliability, and cost-efficiency in water storage.

Why Choose Solico Tanks?

Solico Tanks has earned the trust of healthcare facilities around the globe by delivering GRP (Glass Reinforced Plastic) panel tanks that meet the high standards required for hospital environments. With a commitment to quality and innovation, Solico’s tanks are designed to prioritize hygiene, resilience, and flexibility—key factors for effective hospital water storage.

Certified to rigorous standards like NSF 61 and WRAS, Solico Tanks’ GRP solutions ensure safe, potable water storage that meets international health and safety requirements. Solico’s fully customizable tanks are built to adapt to any space or layout, whether for potable water, equipment sterilization, or sanitation needs. With over 50 years of expertise, Solico combines reliable manufacturing with tailored support to ensure hospitals receive not only high-performance tanks but also long-term, low-maintenance solutions essential for the healthcare sector. Contact Solico Tanks for all your water storage solution!

#water tank#grp water tanks#frp water tanks#manufacturer#grp tanks#business#construction#water storage solution

0 notes

Text

GRP panel tank suppliers in dubai

GRP (Glass Reinforced Plastic) panel tanks are highly durable, corrosion-resistant water storage solutions widely used in Dubai due to their longevity and weather resistance. These modular tanks are customizable to various sizes and capacities, making them suitable for residential, commercial, and industrial applications. Leading GRP panel tank suppliers in Dubai typically offer:

Modular GRP Panel Tanks: Made with high-strength panels for easy on-site assembly, allowing flexibility in tank dimensions.

GRP Panel Type Water Tanks: Known for their durability, lightweight design, and resistance to extreme temperatures, ideal for outdoor use.

Customized GRP Solutions: Suppliers provide tailored sizes and configurations to meet specific water storage needs, including sectional, insulated, and non-insulated options.

If you need recommendations or further details about grp panel water tank suppliers, let me know!

0 notes

Text

Advanced GRP Panel Technology for Water Tanks

Glass Reinforced Plastic (GRP) panels have become an integral part of modern water tank construction, offering high structural integrity, excellent durability, and enhanced insulation properties. This article delves into the advanced features of GRP panels, including their physical properties, stress resistance, and thermal insulation capabilities, making them the ideal choice for water tanks used in industrial and residential applications.

Key Physical Properties of GRP Panels

One of the most defining features of GRP panels is their superior physical properties, which make them highly resistant to stress, deformation, and environmental factors. Below are some critical parameters that set GRP panels apart from other materials used in water tanks:

Specific Gravity (23°C/23°C): 1.806, a lightweight yet robust structure ensuring ease of installation and transportation.

Water Absorption: 0.02%, maintaining structural integrity even after prolonged moisture exposure.

Tensile Strength: 115 MPa, offering high resistance to breaking under tension.

Flexural Strength: 213 MPa, allowing the panel to resist bending without cracking.

Thermal Conductivity: 0.115 W/(m·K), ensuring excellent heat insulation properties.

Test ItemUnitSampleResultTest MethodSpecific Gravity (23°C/23°C)--1.806ASTM D792-13(Test Method A)Water Absorption%-0.02ASTM D570-98(2010)e1 (24 h Immersion)Tensile StrengthMPa-115ASTM D638-14(*)Tensile Elastic ModulusGPa-17.5ASTM D638-14(*)Flexural StrengthMPa-23.3ASTM D790-17(Procedure A)Flexural Elastic ModulusGPa-15.9ASTM D790-17(Procedure A)Shear StrengthMPa-114ASTM D732-17Izod Impact StrengthJ/m-923ASTM D256-10e1 (Test Method A)Compressive StrengthMPa-234ASTM D695-15(**)Thermal Conductivity (Mean Temperature 20°C)W/(m.k)-0.115KS L 9016: 2010 (By means of the Heat Flow Meter Apparatus)Thermal Conductivity (Mean Temperature 20°C)W/(m.k)-0.024KS L 9016: 2010 (By means of the Heat Flow Meter Apparatus)Barcol Hardness--53ASTM D2583-13aGlass content%-over 42.9%ASTM D2584-11

These properties are tested and validated according to international standards, ensuring the quality and longevity of GRP water tanks.

Stress Analysis of GRP Panels

GRP Water Tank panels are designed to withstand stress and deformation, making them highly durable. Their special shape and high-pressure, high-temperature oil-hydraulic manufacturing process give them superior strength compared to traditional circular tank designs. These panels maintain high water pressure without dimensional deviations, even when exposed to extreme temperature variations.

Excellent Heat Insulation Capabilities

GRP panels are known for their superior heat insulation, which is critical in maintaining water temperature inside tanks. The advanced design of the joint parts and corner sections of the panel ensures minimum heat transfer, offering thermal stability and energy efficiency.

The following elements play a key role in their thermal insulation:

Corner Support Frame: Prevents cold air leakage, ensuring the internal temperature remains constant.

Heat Insulation Cover: Provides a barrier to external temperature changes.

Special Sealing Tape: Prevents air leakage and ensures a secure seal.

Flange Bar and Foam Material: Contribute to enhanced insulation by providing an airtight seal.

Composition of the Insulation Panel

The insulation panel of a GRP water tank consists of eco-friendly polyurethane materials that prevent freezing and condensation. Inside the panel, non-woven fabric ensures adhesion and shape stability. Additionally, the 4-layer structure ensures optimal thermal performance, with panel thicknesses ranging from 40 to 50 mm for enhanced insulating capabilities.

Conclusion

GRP panels offer exceptional durability, stress resistance, and heat insulation, making them an ideal solution for water tanks. Whether for industrial or residential applications, these panels deliver long-term performance, reduced maintenance costs, and effective temperature management. With these advanced materials and manufacturing techniques, GRP water tanks are set to become the future standard for reliable water storage solutions.

0 notes

Text

Top Swimming Pool Companies in Qatar: Creating Luxurious Oases

Swimming pool companies in Qatar are transforming outdoor spaces into luxurious oases, offering custom-designed pools that blend functionality with aesthetics. These companies specialize in creating stunning pools for residential, commercial, and recreational purposes, utilizing cutting-edge technology and high-quality materials. From initial design and construction to maintenance and renovation, they provide comprehensive services to ensure every pool meets the highest standards. Whether you desire a serene backyard retreat or a lavish poolside entertainment area, Qatar's leading swimming pool companies bring your vision to life. Their expertise and dedication to excellence make them the go-to choice for creating beautiful, durable, and enjoyable swimming pools.

#grp tank supplier in qatar#grp water tank suppliers in qatar#grp ladder supplier in qatar#grp gratings and ladders suppliers in qatar#frp companies in qatar#frp gratings and ladders in qatar#waterproofing suppliers in qatar#waterproofing companies in qatar#roofcurbs suppliers in qatar#roofcurbs companies in qatar#swimming pool companies in qatar#Grp enclosures in qatar#Kiosks in qatar#Fiberglass products in qatar#GRP products in qatar

0 notes

Text

Unveiling the Advantages of Hot Press GRP Panel Tanks for Potable Water Storage

Introduction

Choosing the right material for potable water storage involves evaluating various factors, such as hygiene, durability, environmental impact, and customization. Among the options available, hot press GRP (Glass Reinforced Plastic) panel tanks excel due to their superior attributes. Here’s a closer look at why hot press GRP tanks surpass other materials in providing safe and effective water storage solutions.

Optimal Hygiene and Chemical Purity

Conventional GRP Tanks: Standard GRP tanks, composed of fiberglass and resin, can retain volatile chemicals that might leach into the water if the resin is not fully cured. This poses risks to water quality and safety.

Concrete Tanks: Concrete’s porous nature can lead to the leaching of minerals such as lime, which can alter the water’s taste and quality. Regular maintenance is necessary to avoid contamination from cracks and leaks.

Steel Tanks: Steel tanks often need protective coatings to prevent rust and corrosion, which can deteriorate over time and potentially introduce harmful chemicals into the water. They also have a higher rust risk if the coating is damaged.

In contrast, hot press GRP tanks are manufactured at high temperatures, which evaporates any residual chemicals from the material, resulting in a stable and inert composite. This ensures that no harmful substances leach into the water, thereby maintaining its purity.

Exceptional Durability and Longevity

Conventional GRP Tanks: Although reasonably strong, standard GRP tanks can suffer from inconsistent strength and surface finish, leading to potential damage and deterioration over time, especially in harsh conditions.

Concrete Tanks: While concrete tanks are durable, they are prone to cracking and erosion and require regular inspections and maintenance to maintain their integrity.

Steel Tanks: Steel tanks are vulnerable to corrosion, particularly in humid or saline environments, and require ongoing maintenance and protective coatings to prevent rust.

Hot press GRP tanks, made from Sheet Molding Compound (SMC) and subjected to high pressure, feature a dense and uniform structure that offers superior resistance to physical damage, environmental stress, and chemical corrosion. This ensures a longer-lasting and more reliable storage solution.

Environmental Benefits and Efficiency

Conventional GRP Tanks: While an improvement over some alternatives, standard GRP tanks still involve resins that may have environmental impacts during production.

Concrete Tanks: Concrete production is highly energy-intensive and contributes significantly to CO2 emissions. Additionally, concrete tanks are heavy and resource-demanding in terms of transport and installation.

Steel Tanks: Steel production is resource-heavy and involves mining and processing that contribute to environmental degradation. Steel tanks also have a larger carbon footprint due to their weight and the need for protective coatings.

Hot press GRP tanks are manufactured with minimal environmental impact. The high-temperature process eliminates excess chemicals, and their lightweight nature reduces transportation emissions. Their durability also means fewer replacements and less overall waste.

Flexibility and Customization

Conventional GRP Tanks: While versatile, standard GRP tanks may lack the precise customization and finish that hot press tanks offer.

Concrete Tanks: Customizing concrete tanks can be challenging, often requiring significant on-site adjustments, and they are cumbersome to transport and install.

Steel Tanks: While customizable, steel tanks often need additional coatings and treatments, and their heavy weight can complicate installation.

Hot press GRP tanks offer outstanding flexibility in terms of size, shape, and features. The precision of the hot pressing process allows for exact specifications and customization, making them suitable for a wide range of applications.

In summary, hot press GRP panel water tanks provide unparalleled benefits over other materials for potable water storage. Their superior hygiene, durability, environmental efficiency, and customization options make them the optimal choice for safe and effective water storage.

#tanks#business#water tank#water industry#grp water tanks#architecture#water treatment#watertreatment#construction#water storage tanks#civil engineering#mechanical engineering#mep design

1 note

·

View note

Text

Why GRP is a Green Choice for the UAE?

GRP or Glass Reinforced Plastics is a technological innovation that has outsmarted conventional fabrication materials, especially in the field of water storage systems. It is a blend of plastic resins and glass fibers where the latter is enclosed in a mesh of plastic resins. Thus it perfectly blends the strength of glass fibers along with the versatility of plastic. Moreover, the lightweight, durable, and anti-corrosive nature of this material makes it the favorite of any GRP water tank supplier in UAE.

Sustainable Material Sourcing

Energy Efficiency in Manufacturing

Longevity and Durability

Recyclability and Waste Reduction

Reduced Carbon Footprint

In case you are looking for a GRP water tank supplier in UAE this is where your search ends. Polycom Plastic Industries with over 18 years of experience in delivering water storage solutions has in its store a range of GRP supplies that make your water storage requirements green and efficient.

0 notes

Text

Discover high-quality commercial pumping stations compliant with BS EN standards. Benefit from free UK Mainland shipping, expert commissioning, and 24/7 support. With 50 years' experience, our GRP pumping stations cater to various diameters and site needs, ensuring efficient waste management for your projects.

#Commercial pumping stations#GRP pumping stations#stormwater management#sewage disposal#effluent management#vertical chambers#horizontal chambers#water management solutions

0 notes

Text

GRP Water Tank Repair Service By Seaglobaluae.

Seaglobaluae provides Grp Water Tank Repair Services in Abu Dhabi. The service that we provide includes evaluation, cleaning, and precise reparation using quality materials. We seal cracks, leaks, and structural problems, thereby making your tank efficient. By extensive testing and our maintenance recommendations, we will make reliable repairs. Trust us with your GRP water tank repair for a professional and quality service.

Website URL: https://seaglobaluae.com/grp-water-repair.html

0 notes

Text

The high-quality chemical storage with GRP Chemical Tanks supplier in UAE is Capital Fiber Glass Tank Industry LLC. Designed for the challenging UAE climate, these tanks are built tough, resisting corrosion and ensuring durability. Capital Fiber Glass Tank Industry LLC is skilled at customizing these tanks to suit different industrial requirements, such as storing petrochemicals and facilitating water treatment. Offering reliability and cost-effectiveness, their GRP chemical tanks are the go-to choice for businesses aiming for secure and efficient chemical storage solutions in the UAE.

#GRP Panel Tanks Distributor in UAE#GRP lining in UAE#GRP Panel Water Tanks in UAE#GRP Vertical Water Tank In UAE#Car Parking Shade in UAE

1 note

·

View note

Text

Successful Implementations of GRP Panel Water Tanks

Real-world examples of successful implementations can provide valuable insights into the effectiveness and benefits of Glass Reinforced Plastic (GRP) panel water tanks. In this blog post, we'll explore case studies highlighting diverse applications of GRP tanks across different industries.

1. Industrial Water Storage in Manufacturing Facility

Challenge:

An industrial manufacturing facility required a reliable and corrosion-resistant water storage solution for its production processes.

Solution:

GRP panel water tanks were chosen for their corrosion resistance, durability, and flexibility in customization. The modular design allowed the tanks to be tailored to fit the available space within the facility.

Outcome:

The GRP tanks provided a long-lasting and low-maintenance water storage solution. The corrosion-resistant properties ensured the purity of water used in manufacturing processes, contributing to the efficiency and reliability of production operations.

2. Agricultural Irrigation Project

Challenge:

A large agricultural project needed an efficient water storage system for irrigation purposes.

Solution:

GRP panel water tanks were selected due to their lightweight nature, making them easy to transport to remote agricultural locations. The tanks were customized to accommodate varying water requirements for different crops.

Outcome:

The GRP tanks facilitated efficient irrigation, contributing to increased crop yield. The lightweight panels and easy assembly process reduced installation time, allowing for swift deployment in the agricultural fields.

3. Municipal Water Supply Upgrade

Challenge:

A municipality faced the need to upgrade its water storage infrastructure to meet growing population demands.

Solution:

GRP panel water tanks were chosen for their versatility and customization options. The tanks were designed to fit within the existing water supply infrastructure, providing additional storage capacity.

Outcome:

The municipality successfully increased its water storage capacity without the need for extensive construction. The GRP tanks integrated seamlessly into the existing system, ensuring a reliable and sustainable water supply for the growing population.

4. Emergency Relief in Disaster-Stricken Area

Challenge:

A disaster-stricken area required an urgent and portable water storage solution for emergency relief efforts.

Solution:

Rapid deployment of GRP panel water tank provided a quick and reliable solution. The lightweight panels facilitated easy transportation to the disaster site.

Outcome:

The GRP tanks provided a temporary but effective water storage solution in emergency situations. Their quick assembly and disassembly allowed for swift response and assistance to affected communities.

5. Residential Water Storage Solution

Challenge:

Homeowners sought a durable and space-efficient water storage solution for residential use.

Solution:

GRP panel water tanks were installed due to their customization options and compact design. The tanks were tailored to fit available spaces in residential areas.

Outcome:

Homeowners benefited from a reliable and low-maintenance water storage system. The tanks' durability and resistance to corrosion ensured a long lifespan, providing a sustainable solution for residential water needs.

These case studies demonstrate the versatility and effectiveness of GRP panel water tanks in addressing diverse challenges across different sectors. Whether for industrial, agricultural, municipal, emergency relief, or residential applications, GRP tanks have proven to be a reliable and sustainable choice. The comparative analysis in the final segment of this blog series will summarize the key advantages of GRP panel water tanks compared to tanks made from other materials. Stay tuned for an insightful overview of the distinctive features that set GRP tanks apart in the realm of water storage solutions. For more info contact GRP Panel Water Tank or call us at +971 4 2522966.

0 notes

Text

What is SMC Water Panel Tank?

Unlike traditional days, storing water has become advanced and new technology has emerged to make the water storing process easier and safe. One such invention in water tanks are SMC (Sheet Molding Compound) panel tanks, also known as GRP water tanks. SMC water tank manufacturers have designed it in a way that it can be used in both residential and industrial applications without any issue. These tanks are manufactured with durable SMC panels which makes it highly resistant to rust and corrosion, temperature extremes, and other environmental challenges. In this blog, we will study in detail on what actually is a SMC water tank, along with its features, applications, and usage across multiple industries.

#SMC Panel tank#GRP Panel tank#GRP Water Tank Manufacturer#SMC Water Tank Manufacturer#GRP Tank Installation Services

0 notes

Text

Revolutionizing Water Storage: GRP Panel Tanks for the Modern World

Introduction: Transforming Water Management for a Sustainable Future

As the global population grows and environmental challenges intensify, the demand for efficient and sustainable water storage solutions has become urgent. Traditional methods like metal and concrete tanks are increasingly struggling to keep pace with modern water management needs. These older systems often suffer from durability issues and high maintenance costs, especially under extreme weather conditions and changing climate patterns. To address these limitations, a new generation of water storage systems has emerged, with Glass Reinforced Plastic (GRP) panel tanks leading the way.

GRP panel tanks are setting a new standard for water storage, offering unmatched strength, adaptability, and sustainability. Their corrosion-resistant construction and modular design make them highly durable and versatile for various applications, from residential water systems to industrial-scale operations. GRP tanks not only meet the modern demands for durability but also offer significant environmental benefits through their recyclable materials and energy-efficient production processes.

Unparalleled Durability for Diverse Conditions

GRP (Glass Reinforced Plastic) panel tanks are designed with exceptional strength and durability, making them capable of withstanding the most challenging environmental conditions. Their high strength-to-weight ratio allows these tanks to endure extreme weather, such as severe heat, cold, storms, and heavy winds, while still being relatively lightweight and easy to handle. This combination of strength and portability makes GRP tanks highly versatile, suitable for installation in various settings without the complications associated with heavier materials like metal or concrete.

Compared to traditional tanks, GRP tanks are superior in terms of long-term durability and lower maintenance needs. Metal tanks are prone to rust, and concrete tanks can crack over time, but GRP tanks resist these issues due to their advanced construction. This means they not only last longer but also require less frequent repairs or replacements. The extended lifespan of GRP tanks translates to reduced environmental waste and significant cost savings on repairs and maintenance.

Whether used in residential homes, commercial buildings, or large-scale industrial operations, GRP tanks provide a reliable, long-lasting solution for water storage. Their robust design ensures that they maintain their integrity over time, making them a cost-effective choice for sustainable water management in a wide range of environments.

Superior Corrosion Resistance for Clean Water Storage

GRP (Glass Reinforced Plastic) panel tanks offer a significant advantage with their exceptional resistance to corrosion, a problem commonly seen in metal tanks. This corrosion resistance is crucial for maintaining the purity and safety of stored water, as it prevents contaminants and pollutants from affecting water quality. For residential users, this ensures a steady supply of clean, safe drinking water, while in industrial settings, where water purity is often critical to operations, GRP tanks provide reliable storage.

In addition to protecting water quality, the corrosion-resistant nature of GRP tanks minimizes the need for frequent maintenance or costly repairs. This makes them a more cost-effective and reliable long-term solution. Especially in environments with high moisture levels or exposure to aggressive chemicals, GRP tanks excel, providing a durable, low-maintenance option for preserving the cleanliness and integrity of water supplies.

Efficient Installation and Customization

GRP (Glass Reinforced Plastic) panel tanks stand out for their ease of installation, thanks to a modular design that simplifies the process. The lightweight panels are easy to transport and assemble on-site, significantly reducing both time and labor costs. This design offers flexible configurations, enabling the tanks to be tailored to any space or capacity requirement. Whether for a small residential water system or a large industrial water storage project, GRP tanks can be adapted to fit specific needs, making installation efficient and straightforward.

The customization options of GRP tanks make them suitable for a wide range of applications. From rainwater harvesting systems in homes to large-scale water management in commercial properties like factories and hotels, these tanks can be sized and configured to meet diverse demands. Their combination of efficient installation and adaptability ensures that GRP panel tanks provide a flexible, reliable solution for various water storage needs.

Versatile Applications for a Range of Environments

GRP panel tanks offer exceptional versatility, making them an ideal choice for a wide range of water storage needs, from small residential setups to large industrial operations. Homeowners can utilize these tanks for efficient rainwater harvesting, providing a sustainable and eco-friendly water source. In commercial settings, GRP tanks are often relied upon for daily operations, offering reliable, high-capacity storage. Whether it’s for regular use or emergency backup, these tanks maintain stable water supplies, even in harsh environmental conditions, thanks to their durability and resistance to extreme weather.

In industrial environments, GRP panel tanks truly shine by handling large volumes of water needed for essential processes like manufacturing, cooling, and more. Their robust construction ensures that they withstand the demanding requirements of industrial operations, while their corrosion-resistant properties eliminate the concerns associated with traditional metal tanks. The low maintenance needs and long-lasting performance of GRP tanks make them a cost-effective, dependable solution for businesses looking to optimize their water storage capabilities and achieve long-term savings.

Emergency Preparedness and Water Security

In the realm of emergency preparedness, GRP panel tanks stand out as a crucial resource for maintaining water security when conventional systems are compromised. Their robust construction and substantial storage capacity make them exceptionally reliable in the face of natural disasters such as floods, earthquakes, or prolonged supply disruptions. GRP tanks are designed for rapid deployment, allowing for swift setup and immediate access to water in critical situations. Their resilience to extreme conditions, including harsh weather and physical impacts, ensures they remain functional when traditional storage solutions might fail.

Integrating GRP panel tanks into disaster preparedness plans significantly boosts a community's or organization's ability to manage emergencies effectively. Their consistent performance and durability under duress make them indispensable for maintaining a secure and clean water supply during crises. By including GRP tanks in emergency strategies, cities and organizations can ensure that they are well-equipped to handle water shortages, reinforcing their overall resilience and readiness for unforeseen challenges.

A Long-Term, Eco-Friendly Investment

GRP panel tanks are designed to offer exceptional long-term value, making them a smart investment for water storage needs. Their impressive durability ensures a lifespan of up to 40 years, far exceeding that of many traditional alternatives. This extended service life means fewer replacements and repairs, translating to significant cost savings over time. By reducing the frequency of replacements, GRP tanks not only cut down on expenses but also lessen the environmental impact associated with the manufacturing, disposal, and transportation of replacement tanks.

Moreover, GRP tanks contribute to environmental sustainability through their use of recyclable materials. The production process for GRP panels is designed to be energy-efficient, and the materials themselves can be recycled at the end of their life cycle. This aligns with contemporary sustainability objectives by reducing waste and minimizing resource consumption. By choosing GRP panel tanks, you are investing in a solution that merges high performance with eco-friendly practices, offering both economic and environmental benefits while supporting a more sustainable future.

Conclusion: The Future of Water Storage

GRP panel tanks are at the forefront of transforming water storage solutions, offering an innovative combination of durability, adaptability, and environmental sustainability. Designed to meet a wide range of needs—from residential rainwater harvesting to large-scale industrial applications—these tanks address the complexities of modern water management with ease. Their robust construction ensures long-term performance, while their eco-friendly features align with contemporary sustainability objectives.

Opting for GRP panel tanks represents a commitment to both efficiency and environmental stewardship. By integrating these advanced tanks into your water storage systems, you are investing in a future-proof solution that provides reliable service and supports your sustainability goals. Their extended lifespan, minimal maintenance requirements, and recyclable materials make them a smart choice for anyone seeking a balance of performance, cost-effectiveness, and ecological responsibility. Contact Solico Tanks for all your water storage tanks!

#manufacturer#business#water tank#frp water tanks#grp water tanks#construction#grp tanks#architecture#water storage solution#home & lifestyle#plumbing#potable water storage tanks#GRP panel type water tanks

0 notes

Text

Understanding GRP Tank Material: Benefits, Applications, and Manufacturing Process

Glass Reinforced Plastic (GRP), also known as fiberglass, is a composite material made from a polymer matrix reinforced with fibers of glass. Over the years, GRP has become the material of choice for manufacturing storage tanks, particularly in industries where durability, corrosion resistance, and lightweight properties are paramount. This article will delve into the specifics of GRP tank material, exploring its benefits, applications, and the process of manufacturing GRP tanks, all while ensuring a high degree of SEO relevance.

What is GRP Tank Material?

Benefits of GRP Tank Material

Corrosion Resistance: One of the most significant advantages of GRP tank material is its exceptional resistance to corrosion. Unlike steel tanks, which are prone to rust and require regular maintenance, GRP tanks are resistant to most chemicals and environmental conditions. This makes them ideal for storing corrosive liquids or being used in harsh environments.

Lightweight: GRP tanks are significantly lighter than their steel or concrete counterparts, which simplifies transportation and installation. The reduced weight also leads to cost savings in terms of handling and support structures.

High Strength-to-Weight Ratio: Despite its lightweight nature, GRP tank material is incredibly strong. This high strength-to-weight ratio means that GRP tanks can withstand high pressures and external loads without compromising their structural integrity.

Long Lifespan: GRP tanks are known for their durability and longevity. They do not degrade over time, and their resistance to UV radiation, chemical attack, and environmental stressors ensures a long service life with minimal maintenance.

Versatility in Design: The manufacturing process of GRP allows for flexibility in design, enabling the production of tanks in various shapes and sizes. This versatility makes GRP tanks suitable for a wide range of applications, from small residential water storage to large industrial chemical tanks.

Applications of GRP Tank Material

Water Storage Tanks: GRP is widely used in the production of water storage tanks, particularly in areas where clean, uncontaminated water storage is critical. The non-reactive nature of GRP ensures that the stored water remains pure, free from contamination. Whether it's a GRP SQUARE SHAPE TANK or a FIBERGLASS TANK, GRP ensures long-term, reliable storage.

Chemical Storage Tanks: The corrosion-resistant properties of GRP make it ideal for storing various chemicals, including acids, alkalis, and other corrosive substances. GRP tanks are often used in chemical processing plants, where they provide safe and reliable storage solutions.

Wastewater Treatment Tanks: GRP is also employed in the construction of tanks used in wastewater treatment plants. The material's resistance to biological degradation and chemical attack makes it perfect for handling the harsh conditions typically found in wastewater processing.

Food and Beverage Industry: GRP tanks are used in the food and beverage industry for storing ingredients and finished products. The material's non-toxic nature and ease of cleaning make it suitable for contact with food substances.

The Manufacturing Process of GRP Tanks

Design and Mold Preparation: The first step in manufacturing a GRP tank is the design phase. This involves creating a mold based on the desired dimensions and specifications of the tank. The mold is typically made from wood, metal, or even existing GRP structures.

Layering and Reinforcement: Once the mold is prepared, layers of glass fiber matting are laid over it. Each layer is coated with a resin that bonds the fibers together, creating a strong, unified structure. The number of layers applied depends on the required strength and thickness of the tank walls.

Curing: After the layers are applied, the tank is left to cure. Curing can be done at room temperature, or the tank can be placed in an oven to accelerate the process. The curing process solidifies the resin and glass fibers, creating a rigid and durable tank.

Demolding and Finishing: Once cured, the tank is removed from the mold and inspected for defects. Any necessary finishing touches, such as trimming or sanding, are applied to ensure the tank meets the required specifications.

Quality Testing: The final step involves rigorous testing of the tank to ensure it meets industry standards. Tests may include pressure testing, leak testing, and inspections for structural integrity.

Conclusion

GRP tank material represents a significant advancement in storage solutions across various industries. Its combination of corrosion resistance, lightweight properties, and durability makes it an ideal choice for applications ranging from water storage to chemical processing. By understanding the benefits, applications, and manufacturing process of GRP tanks, industries can make informed decisions that enhance their operational efficiency and longevity. Whether you're in the market for a new storage solution or simply looking to learn more about composite materials, GRP offers a reliable, long-lasting option that is sure to meet your needs.

0 notes

Text

Fiberglass GRP linings are reinforced plastic glass fibres produced by saturating glass fibre mat in unsaturated polyester resin. GRP linings are applied to protect different types of surfaces like steel,wood, concrete fiberglass etc. Apart from the above mentioned benefits GRP lining acts as a strong protective layer for the surface you want to protect. Fiberglass GRP lining creates a smooth homogenous layer that acts as a strong protective layer on the surface.

#grp lining#grp lining material#grp lining works#grp lining for water tank#grp lining services#grp lining abu dhabi#grp waterproofing#fiberglass lining#grp lining suppliers in uae#grp lamination#grp lamination in abu dhabi

0 notes

Text

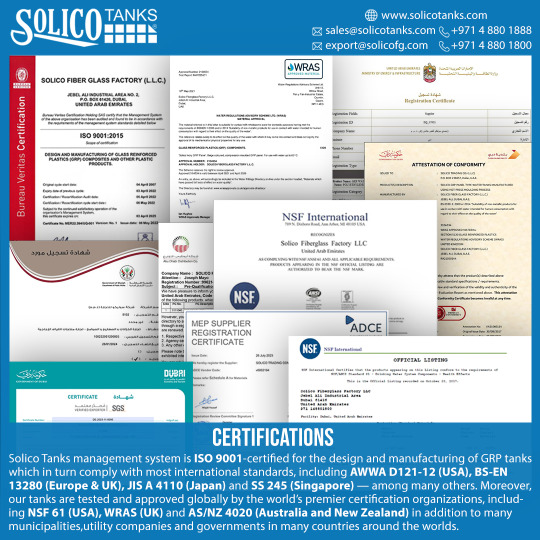

Solico Tanks: Internationally Certified Excellence

Solico Tanks boasts an impressive array of international certifications, showcasing our unwavering dedication to excellence in quality, safety, and reliability across our products and operations.

Management System: • ISO 9001: Design and manufacturing of GRP tanks

Product Compliance: • USA: AWWA D121-12 • Europe & UK: BS-EN 13280 • Japan: JIS A 4110 • Singapore: SS 245

Global Testing & Approval: • USA: NSF 61 • UK: WRAS • Australia and New Zealand: AS/NZ 4020

Additional Approvals: • Numerous municipalities • Utility companies • Government bodies worldwide

Why Our Certifications Matter:

Demonstrate commitment to quality, safety, and reliability

Showcase global recognition and trust

Reflect our dedication to transparency and accountability

Ensure consistent delivery of superior products

At Solico Tanks, we don't just meet standards - we exceed them. Our extensive list of international certifications is our promise to you: uncompromising quality, every time.

#business#water tank#grp water tanks#construction#water industry#watertreatment#water storage tanks#architecture#water treatment#tanks#GRP sectional water tank#long lasting water tank#Most durable water tank

1 note

·

View note