#Fuel Oil Filter Element

Explore tagged Tumblr posts

Text

The Importance of Choosing the Right Lube Oil Filter Element - Filterselementsstrainers

The Guardians of Engine Cleanliness: A Look at Lube Oil Filter Elements

Filterselementsstrainers are the unsung heroes Lube Oil Filters Elements of the automotive world. These small, unassuming components play a vital role in keeping engines clean and running smoothly. By filtering out contaminants like dirt, debris, and metal shavings, they prevent premature wear and tear, extending the life of your engine and saving you money on repairs.

The Different Types of Lube Oil Filter Elements

There are two main types of lube oil filter elements: full-flow and bypass. Full-flow elements filter all of the oil circulating through the engine, while bypass elements only filter a portion of the oil. Bypass elements are typically used in conjunction with full-flow elements to provide дополнительная защита.

The filter media is typically made from paper, cellulose, or synthetic materials. As oil flows through the element, the contaminants are trapped in the media, while the clean oil flows on to the engine.

Bypass elements are typically smaller and simpler than full-flow elements. They состоят из a spring-loaded valve that opens when the oil pressure reaches a certain level. When the valve opens, a portion of the unfiltered oil bypasses the filter element and flows directly to the engine. This helps to protect the engine from damage in the event that the filter element becomes clogged.

Choosing the Right Lube Oil Filter Element

You can choose will depend on a number of factors, including the make and model of your engine, your driving conditions, and your budget. It is important to consult your owner's manual or a qualified mechanic to determine the correct filter element for your vehicle.

Once you have selected the right element, it is important to change it regularly. The frequency with which you need to change your filter element will depend on your driving habits and the рекомендации from your vehicle's manufacturer. Typically, it is a good idea to change your filter element every time you change your oil.

Related Products

In addition to lube oil filter elements, we also offer a wide range of related products, including:

Oil filters

Air filters

Fuel filters

Cabin air filters

We hope this blog post has given you a better understanding of the importance of lube oil filter elements. If you have any questions, please feel free to contact us.

In addition to the tips mentioned above, here are a few other things to keep in mind when choosing and using lube oil filter elements:

Look for a filter element that is specifically designed for your make and model of vehicle.

Install the filter element correctly, following the manufacturer's instructions.

Dispose of used filter elements properly. Do not recycle them with your household trash.

Phone:

+91-9328433915

Email:

Address:

Wing A, Fourth Floor FOF 10 & 11, Signet Plaza, Kunal Char Rasta, Samta Gotri Road, Gotri, Vadodara - 390 021, Gujarat, INDIA

#Air Filter Elements#Basket Strainer#Compressed Air Filter Cartridges#Compressed Air Line Filter#Compressor Air Filter Element#Filter Elements#Fuel Oil Filter Element#Industrial Duplex Filter

0 notes

Text

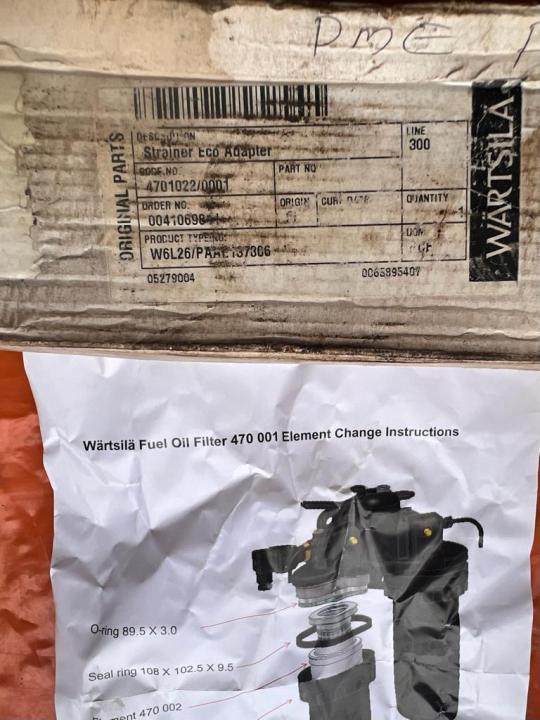

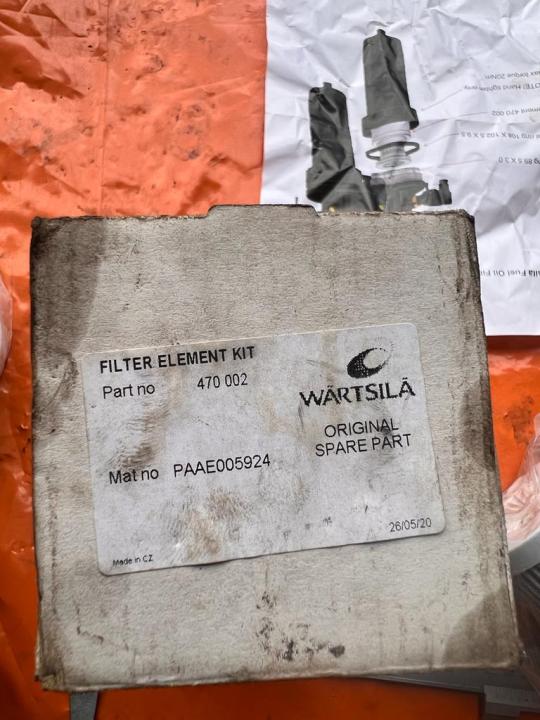

470002 wartsila W6L26 strainer eco Adapter 4701022 / 0001 filter element Part no 470 002 for wartsila Fuel Oil Filter 470 001, -838991Q, -938978Q, We have for sale as below: For wartsila W6L26 Name: Filter element P/N: 470 002 Qty 5pcs

Also, we have as below: 838991Q Qty:3pieces L420MM 938978Q :2pieces L109MM We do export all types of marine filters worldwide. Best regards, Shakeel Sheikh IDEAL DIESEL MARINE E-MAIL: [email protected]

#470002-wartsila-W6L26-strainer-eco-Adapter-4701022 / 0001-filter-element-Part no-470 002-for-wartsila-Fuel-Oil-Filter-470 001-838991Q-938978#wartsila W6L26 strainer eco Adapter 4701022 / 0001 filter element Part no 470 002#wartsila Fuel Oil Filter 470 001#W6L26 strainer eco Adapter 4701022#470002 wartsila W6L26#parker 838991Q#-938978Q#parker 838978q#wartsila W26 FILTER ELEMENT#wartsila W6L26#Name: Filter element#P/N: 470 002#WARTSILA 4700002#470002 WARTSILA#WARTSILA W26 FILTER

0 notes

Text

a theory of love

pairing- Professor!Kim Seungmin x Fashion Assistant!Reader summary- A fashion assistant and a literal genius find themselves on a date in an upscale restaurant, navigating their differences with humor and warmth. As insecurities creep in, they realize that intelligence comes in many forms—and maybe, just maybe, love doesn’t need a formula to work. genre- Fluff, Romance, Light Humor word count- 1.1k warnings- Mild language, mention of alcohol, light self-doubt/insecurity a/n- ahh i finally did it!!! the arvin and haley from modern family inspired seungmin x reader fic!! hope you like it! 😊💖

The restaurant was dimly lit, the kind of place that whispered elegance in hushed candlelight and overpriced wine. A soft murmur of conversation hummed around you, punctuated by the occasional clink of glasses. The air smelled of aged oak and truffle oil, a distinct reminder that this was not your usual kind of place. It wasn’t exactly your scene—though, in fairness, you weren’t sure what your scene was anymore. Lately, your life had felt like a chaotic series of events stitched together with double-knotted (😉) hope and caffeine-fueled survival.

Your date, on the other hand, looked like he belonged here.

Kim Seungmin. A literal genius.

Not just the “oh, he’s really smart” kind of genius, but the “has-won-awards-and-actually-discovered-elements” kind of genius. The kind who spoke in equations and theories and had NASA plaques somewhere in his office. The kind who was universally impressive in every way.

And then there was you.

A fashion assistant who had once used a shoelace to hold up a broken bag strap because you "didn’t have time for physics." A college dropout who navigated the world through instinct, aesthetic, and sheer determination rather than formulas and theorems. You weren’t unintelligent—you knew that much. But there was a difference between knowing how to style an outfit that could make a magazine cover and understanding the atomic structure of the universe. And unfortunately, you were firmly in the former category.

You watched Seungmin as he spoke, his voice smooth and measured, as if he were carefully picking the most precise words. His sleeves were rolled to his elbows in that effortlessly cool way, and his fingers tapped lightly against the table as he explained something—something about molecular structures or spectroscopic methods. The words filtered through your brain like static, half-comprehended and quickly dissolving into the ether of your mental fatigue.

“So, while that theory had been debated for years, our research team was finally able to prove it using a new form of spectroscopy. It was—”

“Totally! Wow,” you cut in, nodding rapidly. “That is so… spectroscopic.”

Seungmin blinked at you, his lips twitching like he was holding back a laugh. “Spectroscopy,” he corrected gently.

“Right, totally what I said,” you mumbled, taking a sip of your drink, the wine burning a little as it slid down your throat.

He tilted his head, watching you with quiet amusement. “You don’t have to pretend to understand, you know.”

You set your glass down, eyes narrowing. “I’m not pretending.”

He raised an eyebrow.

“…Okay, maybe a little,” you admitted. “But in my defense, you just said, like, eight words that I didn’t even know existed.”

Seungmin chuckled, shaking his head. “I’ll simplify it. Basically, we proved something that people thought was impossible. It changes how we understand certain atomic structures.”

You pursed your lips. “Okay, but like… does that mean I get a flying car soon?”

He let out a sharp laugh, eyes crinkling at the corners in a way that sent an unexpected thrill through you. “Not quite, but I appreciate your enthusiasm.”

You grinned, relieved to have made him laugh. Because the thing about dating a genius—something you hadn’t fully considered before tonight—was that it came with an invisible weight. Not on his end. On yours.

You liked Seungmin. A lot. He was kind and thoughtful, and despite his intimidating intelligence, he never made you feel small. But sometimes, you felt like a different species entirely, like he was speaking in a language you’d never be fluent in.

“Hey, for the record,” he said, voice softer now, “I like that you don’t think like I do. It’s refreshing.”

You scoffed. “Refreshing? I feel like a kindergartener trying to read Shakespeare.”

Seungmin rested his chin on his hand, considering you. “You do things I could never do,” he said. “You see the world in a way I don’t. That’s impressive.”

You bit your lip, warmth creeping up your neck. “Yeah, well… I guess I do put together some pretty great outfits.”

“That you do.” His gaze flickered over your outfit appreciatively. “In fact, I’m still trying to understand how you matched those patterns and made it work.”

You wiggled your eyebrows. “It’s called talent, Professor.”

He chuckled, then took another sip of his drink before setting it down. “So, tell me about work. What’s the latest in the fashion world?”

You brightened at the topic shift. “Oh! So, my boss, right? She’s launching this new campaign, and—”

Before you could finish, your phone buzzed. You glanced down and sighed. Your boss.

“Crap,” you muttered. “I have to take this.”

Seungmin gestured for you to go ahead. “Of course.”

You answered, pressing the phone to your ear as you leaned slightly away. “Hello?”

“Where are you?” your boss demanded. “I need you to approve these fabric samples, like, yesterday.”

“I’m… uh, kind of in the middle of something?” you whispered.

“Is this about that date?” she scoffed. “Listen, unless he’s a billionaire who’s funding our next line, I need you to focus.”

You pinched the bridge of your nose. “Can this wait, like, an hour?”

She sighed dramatically. “Fine. But if we end up with the wrong shade of beige, it’s on you.”

You hung up and turned back to Seungmin, giving him an apologetic smile. “Sorry about that.”

“All good.” He smirked. “Sounds like high-stakes beige selection.”

“You have no idea.”

There was a beat of silence, then he leaned forward slightly. “You’re really passionate about what you do, huh?”

You shrugged. “Yeah. I mean, it’s fashion, not, like, world-changing science or anything, but I love it.”

Seungmin studied you for a moment before replying. “You don’t have to change the world for your work to matter.”

Something about the way he said it made your heart skip.

You exhaled, leaning your elbows on the table. “You’re kind of perfect, you know that?”

His eyebrows shot up. “Oh?”

You gestured vaguely at him. “You’re a genius, you’re kind, and you say things like that? It’s unfair.”

Seungmin laughed, shaking his head. “Trust me, I have my flaws.”

“Name one.”

He pretended to think. “I sometimes get so lost in research that I forget to eat.”

“Okay, that’s just a humblebrag.”

“Fine.” He sighed dramatically. “I’m terrible at assembling IKEA furniture.”

You gasped. “Oh my god. A weakness.”

“Yes.” He nodded solemnly. “It’s my greatest struggle.”

You laughed, and Seungmin smiled at you—really smiled, the kind that made your stomach flip.

For all your differences, for all the ways you felt like you didn’t belong in his world, here he was, looking at you like you were just as fascinating as he was.

Maybe you didn’t need to understand spectroscopy. Maybe he didn’t need to know the intricacies of fabric selection. Maybe—just maybe—there was a theory of love that worked beyond equations and logic.

And maybe, you thought as Seungmin reached across the table to take your hand, you had just proven it.

©sunshineangel0 𖹭 if you liked this work, please consider reblogging, commenting or liking! xoxo franzi 💋

skz general tags: @velvetmoonlght @scarlet789

(if you want to be added to my taglist, please comment under the post.)

#skz scenarios#skz au#skz imagines#skz x reader#stray kids scenarios#kim seungmim#skz seungmin#seungmin#seungmin x reader#seungmin fake texts#kim seungmin#stray kids fake texts#seungmin fluff#skz fluff#seungmin scenarios#seungmin x you#stray kids imagines#kim seungmin x reader#kim seungmin imagines#kim seungmin x y/n#franzi writes ✰

98 notes

·

View notes

Text

Dungeon Meshi Miscellaneous Monster Tales 4

This volume's MMTs is catching up on what happened last volume.

Giant Frogs

I'm so glad this one exists because it proves I was right about the frog skins. It's not the skin that's immune to tentacle stings, it's the mucous layer over the skin.

There could be a potential market for Chilchuck if he wants to go from toad oil salesman to frog slime salesman though. He'd need to harvest some of that slime to have it studied. Then he could sell a mass-produced oil similar to sunscreen. Maybe he could try selling full-body suits that adventurers can wear and coat the slime onto so they don't ruin their clothes and Chilchuck could offer a service where he coats the suits themselves.

Those frog gloves are probably unconfortable since they only have four digits while every human has five.

That 1,000 gold price Chilchuck was considering is actually really cheap based on the exchange rate I suggested in MMT1. It would end up being roughly $50 USD. It's less than the walking mushroom guidebook.

Tentacles

Additional information in this segment reinforces that these are meant to be monstrous anemones. They're filter feeders that eat airborne spirits. So then why did that one tentacle grab Kiki and Laios? Maybe they're opportunistic generalists.

It's not the tentacle's fault that architecture designed to be easily gripped by human fingers is also ideal for tentacles to grip.

I love when the joke is that no one finds the dirty joke funny.

Mermaids

Most of the comments I want to make about mermaids is tied to the fishmen section so I'll save that there.

The entire joke is a callback to the mandrake harvesting method back in chapter 4, including replacing the dog ghost with a Chilchuck ghost.

I don't imagine most dwarfs would be likely to encounter mermaids. Senshi's probably talking about the whole "Canary in a cola mine" thing.

Fishmen

Love how the fishman introduction is a parody of the mermaid introduction all the way to how the last line is "drag them into the ocean".

It feels like the author wants to make it clear that Laios was right and there's no moral dilemma with eating fishmen (aside from personal beliefs and feelings). It does point out fishmen and mermaids have some physical similarities, but they're entirely coincidental. Fishmen develop and mature the same way most fish would.

Mermaids and other demihumans probably share a mammalian ancestor with humans and they all coincidentally developed common body frames, but the biological relation would probably be roughly on the same level as a human compared to a kangaroo.

Mermaids would probably feel insulted if you told them they and fishmen are the same taxonomic species.

Also, hard confirm: Mermaids have fingernails.

Undines

Mostly just talk about mana and spirits. Chapter 20 already mentioned that Undines are water spirits. I'm curious what other elemental spirits look like.

Is this panel saying there is mana in the panel and word bubble borders?

More confusion about the "human" definition. So is human a catch-all term for all the standard D&D races? And did the orc chieftain say "elves and humans" because he wanted to single out elves especially?

And it turns out Namari was suffering the equivalent of water intoxication after going through that teleporter.

Wargs

We've never interacted with a warg. This is the first time we've actually been shown a proper warg. The burned corpses from chapter 23 had all their fur burned off.

There were three corpses in chapter 23 and two skeletons in the dragon's fuel sac, so there were at least five wargs in the pack in the orc village.

Laios said one of the only differences between him and orcs is the number of fingers and toes.

I had to look through so many panels to confirm this statement. Orcs and humans have the same number of fingers per hand, but orcs have four toes per foot.

It really shows what Laios pays attention to if he doesn't notice all the obvious differences between himself and an orc like body hair, teeth, jawline, etc. but he is aware that orcs have fewer toes.

Red Dragons

Have I mentioned that I like how the story will delve into the real-world logistics that would have to go into being an adventurer? This story isn't using video game logic. You don't kill a monster and then have dragon fangs and dragon claws in your infinite inventory.

Since dragons are so large, it would actually take a large team to transport the body after slaying it. So the gross profit of dragon slaying is high, but the net gain is actually not much compared to the overall work needed.

Maybe that skin Senshi was using as a cooking sheet might net the party a nice profit... if Senshi lets them have it.

When Laios compared the amount of information on dragons to the amount on walking mushrooms, I think he was implying that studying walking mushrooms is the actual pinnacle of monster research. Recall that Laios owns a book dedicated specifically to walking mushrooms.

Marcille and Chilchuck are always shocked at Laios's obsession with monsters, but Laios implies his antics are nothing compared to what dragon fans are like.

back

13 notes

·

View notes

Link

0 notes

Link

1 note

·

View note

Text

Nissan Parts Exporter from India – Trusted Worldwide by Smart Parts Exports

When it comes to global automobile brands, Nissan is on one's feet as a symbol of revolution, durability, along with production. With a strong presence in worldwide markets across Asia, Africa, the Middle East, and Latin America, the request for Nissan genuine parts continues to rise steadily. To meet this demand, Smart Parts Exports has made an appearance as a well founded through well planned Nissan Parts Exporter from India, trusted by purchasers in all inspection the globe for supplying high-quality elements at fierce prices.

Why Nissan Genuine Parts Matter

Nissan vehicles are known for their engineering accuracy as well as long-lasting performance. However, even the best vehicles require regular continuation together with infrequent repairs. receipts on Nissan genuine parts is the best way to keep the performance, safety, and fuel order of your Nissan car or SUV.

Original parts are designed to match the exact statement of each model, offering a perfect fit and long-term reliability. At Smart Parts Exports, we take pride in being a trusted Nissan genuine parts exporter, ensuring our consumers receive only authentic OEM elements—no counterfeits, no compromises.

Who We Are – Smart Parts Exports

Smart Parts Exports is India’s leading automobile parts exporter, serving customers in over 80 countries. From two-wheelers to commercial vehicles and passenger cars, we deal in a vast range of brands—including Nissan.

As a reputable Nissan OEM parts exporter, we offer a wide selection of elements inclusive of engine parts, brake systems, suspension kits, electrical systems, filters, body parts, and more. Whether you're a distributor, workshop owner, fleet operator, or car parts retailer, you can count on us for reliable service along with excellent service.

Why Choose Smart Parts Exports for Nissan Parts?

100% Genuine OEM Nissan Parts We are committed to convey only genuine parts sourced directly from authorized suppliers. When you single out us as your Nissan parts exporter, you're guaranteed factory-tested, original articles components that make definite maximum vehicle life and performance.

Extensive Product Range Whether you're looking for a spark plug for a Nissan Sunny, an air filter for a Nissan Micra, or a brake pad kit for the X-Trail, we’ve got it all. Our arrangement encircles each and every single article from small fast-moving effects to blended parishioners, making us a one-stop solution for Nissan spare parts needs.

Affordable Pricing As a leading Nissan parts exporter from India, we keep up strong supplier relations that allow us to offer the most aggressive prices in the market. This ensures a higher quality perimeter for your business and affordability for your customers.

Global Shipping and Logistics We ship Nissan parts to countries across the globe, including regions in Africa, South America, Southeast Asia, along with the Middle East. We handle the entire export process—right from packaging to customs documentation—ensuring a smooth and hassle-free experience.

Experienced Export Team With years of experience in the auto parts export industry, our team understands worldwide regulations, market demands, and dictate customer supposition. We are of use to with part identification, order processing, and after-sales support to build long-term business relationships.

Nissan Parts Export Services We Offer

As a specialized Nissan OEM parts exporter, we cater to a wide range of Nissan vehicles, including:

Nissan Micra

Nissan Sunny

Nissan Terrano

Nissan Kicks

Nissan X-Trail

Nissan Patrol

Nissan Navara

Nissan Sentra and more

We also export parts for discontinued or older models, based on availability. If you're looking for rare or hard-to-find components, our sourcing team can track them down for you efficiently.

Some of the Popular Nissan Spare Parts We Export

Engine oil filters, fuel filters, and air filters

Timing belts, serpentine belts, and pulleys

Brake pads, brake shoes, rotors, and calipers

Electrical parts like alternators, starters, and sensors

Body panels, headlights, bumpers, and mirrors

Suspension and steering components

Radiators, condensers, and AC parts

Every part we supply is backed by a quality assurance check to ensure it meets Nissan’s OEM standards.

Nissan Parts Export – Trusted Globally

Smart Parts Exports is more than just a supplier—we are your trusted global partner in the auto spare parts trade. Our clients span across continents, jointly in the company of many of them have been working with us for years. Their loyalty is a testament to our loyalty to quality, reliability, as well as lucidity.

As your Nissan parts exporter from India, we aim to be an appendage of your business—supplying the right parts at the right time so you can serve your customer better

.

How to Get Started with Smart Parts Exports

Getting started is simple. Share your Nissan parts requirement with us via email or WhatsApp. Our team will instantly revert with availability, pricing, and shipping options. Whether you're placing a one-time order or want to put in place a recurring supply partnership, we’re here to put it together easily.

You can also provide us with the OEM part number, VIN (Vehicle Identification Number), or just the model as well as year of the car—and we’ll help you find the exact match.

Final Words

With Nissan's growing popularity in international markets, having a reliable and professional export partner is key to staying ahead. Smart Parts Exports is proud to be a trusted Nissan parts exporter, delivering excellence from India to the world.

If you’re looking for a dependable Nissan parts exporter from India, look no further. Join the network of satisfied clients who trust Smart Parts Exports for all their Nissan spare parts needs.

0 notes

Text

The Benefits of Professional Kia Car Servicing: Ensuring Safety and Reliability

Owning a Kia vehicle comes with the promise of performance, style, and reliability. However, like any modern car, keeping it running smoothly requires regular maintenance and servicing. For Kia owners in North Wales, particularly those living near the beautiful coastal town of Llandudno, professional Kia car servicing in Llandudno is essential to ensure the longevity and performance of their vehicle.

Whether you drive a sporty Ceed, a versatile Sportage, or an eco-friendly Niro, understanding the importance of professional servicing can save you time, money, and potential hassle down the line. In this blog, we’ll explore the benefits of routine Kia servicing, what it typically includes, and why choosing expert services in Llandudno is a smart move for every local Kia owner.

Why Kia Car Servicing Matters

Vehicles are complex machines that rely on numerous components working in harmony. Over time, these components experience wear and tear due to regular use. If not addressed, even minor issues can evolve into significant problems. Regular servicing helps to:

Detect issues early

Improve vehicle performance

Maintain fuel efficiency

Extend the lifespan of the vehicle

Uphold the vehicle’s resale value

Ensure passenger safety

By investing in Kia car servicing in Llandudno, you are ensuring that your vehicle stays roadworthy and efficient all year round.

What’s Included in a Professional Kia Service?

A comprehensive Kia service typically includes a variety of checks and replacements to keep your vehicle in top condition. Here are some of the common elements:

1. Engine Oil and Filter Change

Engine oil serves to lubricate the moving components of your engine, minimizing friction and helping to avoid overheating. However, as time passes, the oil can become tainted with dirt and other particles. Replacing it regularly is key to maintaining engine health.

2. Brake System Inspection

The braking system is among the most vital safety components of your vehicle. A professional inspection checks the brake pads, discs, and fluid levels to ensure everything is functioning correctly.

3. Tyre Check and Rotation

Tyres are inspected for wear and tear, tread depth, and pressure levels. Rotating them helps ensure even wear, extending their lifespan.

4. Battery Health Check

A failing battery can leave you stranded. During a service, your battery’s charge and overall condition will be assessed to prevent unexpected breakdowns.

5. Suspension and Steering Inspection

This ensures your Kia handles smoothly and safely, especially on uneven roads or during cornering.

6. Fluid Level Checks

Coolant, brake fluid, transmission fluid, and windshield washer fluid are all essential for different vehicle functions. All are checked and topped up or replaced as needed.

7. Air Filter and Cabin Filter Replacement

Filters trap contaminants that can affect engine performance and cabin air quality. They are inspected and replaced when necessary.

Benefits of Kia Car Servicing in Llandudno

1. Local Expertise

Technicians who specialise in Kia car servicing in Llandudno understand the specific needs and performance characteristics of Kia vehicles. Their familiarity with the brand ensures precise diagnostics and efficient service.

2. Tailored to Local Driving Conditions

Llandudno, with its scenic coastlines and nearby hilly terrains, can put unique demands on your vehicle. Local service providers can tailor maintenance schedules and services based on common driving patterns and conditions in the region.

3. Time and Convenience

Choosing a local Kia service in Llandudno means you don’t have to travel far to keep your vehicle in top shape. It saves time, and many local service centres offer flexible booking options to fit your schedule.

4. Compliance with Warranty Requirements

If your Kia is still under warranty, sticking to a regular service schedule is often a requirement to keep the warranty valid. Opting for Kia car servicing in Llandudno ensures that all services are carried out to the manufacturer's recommended standards.

5. Enhanced Safety

Servicing checks for worn-out components that could compromise safety, such as brakes or tyres. This is especially important for families and those who frequently travel longer distances.

How Often Should You Service Your Kia?

The recommended service interval for most Kia vehicles is every 10,000 to 12,000 miles or once every 12 months—whichever comes first. However, this can vary based on your specific model, driving habits, and road conditions. If you're unsure, a local Kia service expert in Llandudno can help you determine the best servicing schedule for your vehicle.

Warning Signs Your Kia May Need Servicing

While scheduled servicing is vital, your vehicle might also give signs it needs attention sooner:

Warning lights on the dashboard

Unusual engine noises

Poor fuel efficiency

Difficulty starting

Vibrations or pulling when braking

If you notice any of these, it’s best to book Kia car servicing in Llandudno promptly.

Conclusion

Your Kia is more than just a way to get from A to B—it’s an investment in comfort, safety, and reliability. Regular professional servicing is key to protecting that investment. With expert Kia car servicing in Llandudno, you can rest assured your vehicle is in safe hands, ready to tackle both everyday errands and scenic drives along the North Wales coast.

Don’t wait until a warning light appears—stay ahead with scheduled servicing and enjoy peace of mind on every journey.

If you're looking to keep your Kia running smoothly, find your nearest professional Kia servicing specialist in Llandudno today and give your vehicle the care it deserves.

#Honda Car Dealers in Llandudno#Kia Car Dealers Llandudno#Kia Car Dealership Llandudno#Honda Car Dealership Llandudno#Honda Car Servicing in Llandudno#Kia Car Servicing Llandudno#Leading Used Car Dealership Llandudno#Approved Used Cars Llandudno#Approved Used Car Dealership llandudno#Used Cars Llandudno#Smart Repair Services Llandudno#car maintenance#car service

0 notes

Text

How Used Heavy Equipment Ages Differently Based on Terrain

The Science of Wear and Tear

Heavy equipment needs to handle tough conditions yet its survival depends mainly on operating environment factors. Irregular surfaces of rocks and mud make difficult operating conditions that cause faster damage to machines. Buyers and contractors need to understand terrain effects on equipment parts to pick used heavy equipment wisely. Mechanical stress and environmental elements along with how operators use equipment determine the speed at which machines age which affects their usefulness and maintenance requirements.

The Impact of Rocky and Hard Terrain

Rocks and mountains push the undercarriage system beyond its limits in both quarry and mountain areas. Metal parts in the system fail sooner by developing cracks when heavy rocks keep hitting the same spots. Operating over uneven ground worsens damage to joint parts, bearings, and hydraulic links which raises the risk of mechanical breakdown and fluid leakage. Dirt and debris from off-road areas enter into vehicle cooling systems and filters plus engine areas which makes them work poorly and creates a danger of engine overheating. Equipment from used sources that worked in demanding conditions tends to show stress on its frame and needs a complete inspection before being acquired.

How Soft and Muddy Terrain Affects Equipment Lifespan

When machinery operates on soft muddy surfaces such as construction sites with loose soil and wet clay it endures high pressure. Operating machines becomes challenging when they lose traction which makes operators push their engines harder and causes both fuel waste and damage to mechanical parts. Water enters metal parts which leads them to develop rust and become gradually weaker. Continuous exposure to wet muddy undercarriage surfaces speeds up wear damage to hydraulic parts and other critical elements. Inspection of used heavy equipment from muddy areas must identify corrosion damage plus signs of excessive hydraulics wear and engine problems caused by pushover work.

Sand and Desert Conditions

The desert terrain poses special damage effects on heavy equipment. Sand causes faster damage to mechanical parts such as gears and hydraulic cylinders than any other surface type. Dust particles build up in air filters leading to engine problems and overheating unless air filter maintenance is done regularly. Heat extremes hurt equipment life by changing hydraulic fluid thickness and raising the chance of overheating. The heat speeds up rubber part failure in tire seals so it must be checked often. Buyers considering used heavy equipment from desert areas need to focus on inspecting wear on visible moving parts and the cooling system performance.

Cold and Icy Terrain

Heavy machinery operators in cold construction zones must deal with specific operational issues. When temperatures drop metal parts shrink creating a risk of cracks that form when the parts face load. Cold temperatures make hydraulic fluids and engine oils harden which puts more stress on pumps and cylinders as they work less efficiently. Snow and ice make it harder to stop and slide more often which puts extra strain on braking parts and undercarriage parts. Running engines for long periods without use becomes necessary for system warmth which wastes fuel and damages the engine over time. Cold environment equipment needs inspections for metal damages plus testing of fluid systems and traction parts wear.

Swamps and Wetlands

When operating equipment in wet swampy areas it faces serious damage from rust because of excessive moisture exposure. Water contact damages steel components including frames buckets and undercarriages because it makes them weaker. Organic residue that builds up in cooling systems and hydraulic lines stops proper flow which reduces performance and makes the engine too hot. Water that enters electrical systems creates short circuits and damages sensor performance. Examine hydraulic hoses and electrical components after buying used heavy equipment that worked in water since these elements could need replacement when found damaged.

Urban and Paved Surfaces: Wear Patterns in City Projects

Despite being less demanding than off-road terrains urban construction sites require special tire treatment. Repeated work on paved roads creates extra tire and track friction which wears them down faster. The frequent stopping and starting work at city construction jobs puts heavy pressure on engines and transmission systems which causes them to wear out sooner. The metal parts in machinery suffer faster corrosion when they take in pollutants along with road salts and industrial chemicals. When buying used heavy equipment from urban areas customers should check the transmission fluid quality as well as brake parts and tire or track health to assess the machine's potential lifespan.

Preventative Maintenance Strategies for Different Terrain Types

Heavy equipment needs proper maintenance based on where it operates to reach its full lifespan. Equipment that works on rocky surfaces needs regular examination of its base parts and shock absorption system tests. Muddy terrain needs frequent equipment cleaning to stop moving parts from gathering debris and desert operations need air filter changes plus checking the cooling system. To avoid hydraulic system issues in cool weather use winter-grade fluids while adding engine oil protection and swamp components can last longer with rust-prevention coating. Using predictive maintenance tools helps fleet managers detect equipment wear trends so they can solve problems before they become serious issues.

0 notes

Text

7 Essential Tips for Caring for Your Old Tractor

Owning an old tractor can be a rewarding experience. These machines are designed to last, but just like any piece of machinery, they require regular care and maintenance to keep running smoothly. If you’ve inherited or purchased a classic tractor, you want to ensure it operates for years to come. Below are seven essential tips for caring for your old tractor, so you can preserve its performance and longevity.

1. Regularly Check and Change the Oil

Oil is the lifeblood of any engine, and an old tractor is no exception. Over time, the oil breaks down and becomes less effective, leading to increased wear and tear. Make it a habit to check the oil regularly. Look for any signs of contamination or thinning and change it according to the manufacturer’s recommendations. For older tractors, it might be wise to change the oil more frequently, especially if it’s been sitting idle for long periods.

Tip: Always use high-quality oil suitable for your tractor’s engine to ensure maximum performance.

2. Inspect and Replace the Air Filter

Air filters prevent dust, dirt, and debris from entering the engine, which could cause significant damage over time. On older tractors, air filters can get clogged more easily due to years of use. Regularly inspect the air filter and clean or replace it if necessary. A clogged air filter will cause the engine to run inefficiently, reducing fuel efficiency and overall power.

Tip: Clean or replace your air filter every 100 to 200 hours of use, depending on your environment.

3. Monitor the Battery Condition

The battery is crucial for starting your tractor, but over time, it can lose its charge or become corroded. Regularly inspect the battery for signs of wear or corrosion on the terminals. Clean the battery terminals with a mixture of baking soda and water to remove corrosion and ensure a solid connection.

Tip: If your tractor is going to sit unused for an extended period, consider removing the battery and storing it in a cool, dry place. You can also invest in a battery tender to keep it charged when not in use.

4. Grease the Moving Parts

Old tractors often have a lot of moving parts, such as the wheels, joints, and linkages. These components need regular lubrication to reduce friction and prevent premature wear. Check your tractor’s grease points and apply grease as recommended by the manufacturer. This is especially important if the tractor has been exposed to harsh weather conditions like rain, snow, or high humidity.

Tip: Use the right type of grease and follow the manufacturer’s maintenance schedule to ensure proper lubrication.

5. Check the Fuel System

Fuel lines and filters can deteriorate over time, causing fuel leaks or clogging. It’s essential to regularly inspect your tractor’s fuel system. Look for cracked or worn fuel lines, and replace them as needed. If the tractor has a carburetor, make sure it’s clean and free of debris to maintain smooth engine performance.

Tip: Use fresh fuel in your tractor, as old fuel can gum up the carburetor and fuel lines. If you’re storing the tractor for a while, consider adding a fuel stabilizer to prevent fuel degradation.

6. Keep the Cooling System in Check

Overheating can be a common issue for older tractors. To avoid this, regularly check the coolant levels and inspect the radiator for leaks or clogs. If you notice the tractor is running hot or the coolant levels are low, it’s time for a thorough check of the cooling system. Over time, hoses and seals may wear out, so keep an eye out for any signs of degradation.

Tip: Flush the cooling system periodically, especially if you’ve had issues with overheating. This helps prevent the buildup of scale and debris in the radiator.

7. Store It Properly

If you’re not using your old tractor for a while, proper storage is key to its long-term care. Store it in a dry, sheltered location to avoid exposure to the elements. Covering the tractor with a weatherproof tarp can protect it from dust, dirt, and UV damage. If you store it outside, consider investing in a tractor cover designed for your model to prevent rusting and other environmental damage.

Tip: If possible, elevate the tractor slightly off the ground to prevent moisture buildup and rust on the tires. Also, regularly check for any signs of critters making a home in the engine bay or other parts.

Final Thoughts

Maintaining an old tractor is a bit of work, but the effort you put in will pay off with years of reliable service. By following these seven tips—checking oil regularly, inspecting the air filter, monitoring the battery, greasing moving parts, checking the fuel system, maintaining the cooling system, and storing it properly—you can ensure your tractor stays in top condition. Whether you use it for farming, landscaping, or simply as a piece of nostalgia, these tips will help your old tractor keep running like new for years to come.

0 notes

Text

Dodge Performance Maintenance: Keep Your Muscle Car Roaring

Dodge muscle cars are built for power, speed, and performance. Whether you own a Challenger, Charger, or a classic Viper, keeping your Dodge in peak condition requires a proactive maintenance routine. Here’s a complete guide to ensuring your muscle car stays robust and reliable for years to come.

1. Regular Servicing: The Foundation of Performance

Routine maintenance is key to maintaining the power and reliability of your Dodge muscle car. Stick to the manufacturer’s recommended service intervals, which typically include:

Oil and Filter Changes: Use high-performance synthetic oil to protect engine components.

Brake System Checks: High-speed driving puts more strain on brakes, so regular inspections are crucial.

Coolant and Fluid Checks: Prevents overheating and ensures smooth operation.

Diagnostic Scans: Detects potential issues before they become costly repairs.

2. Engine Maintenance: Power and Efficiency

Dodge engines, especially HEMI models, require special care to maintain their legendary performance.

Use Premium Fuel: Higher octane fuel prevents knocking and maintains efficiency.

Replace Spark Plugs Regularly: Worn spark plugs reduce power and fuel efficiency.

Keep the Air Intake Clean: A clogged air filter reduces horsepower and performance.

Monitor for Overheating: Ensure proper coolant levels to avoid damage to engine components.

3. Transmission and Gearbox Maintenance: Smooth and Responsive Shifting

The transmission is critical for delivering power to the wheels. Proper maintenance prevents issues like gear slipping and rough shifts.

Check Transmission Fluid Levels Regularly: Low or dirty fluid can cause shifting problems.

Use Manufacturer-Approved Fluids: Avoids damage and extends the lifespan of the transmission.

Flush and Replace Transmission Fluid as Recommended: Prevents overheating and wear.

Watch for Delayed Shifting or Unusual Noises: If you experience rough shifting, consult a specialist car gearbox repair service in Dubai immediately.

4. Tire and Suspension Care: Stability and Grip

Muscle cars require high-performance tires and a well-maintained suspension for stability and handling.

Check Tire Pressure Regularly: Proper inflation ensures optimal grip and fuel efficiency.

Rotate Tires Every 5,000-7,000 Miles: Ensures even tread wear and longevity.

Inspect Shock Absorbers and Struts: Worn suspension components affect ride quality and handling.

Get Regular Wheel Alignments: Prevents uneven tire wear and improves stability.

5. Exterior Protection: Keep Your Dodge Looking Aggressive

Muscle cars deserve to look as good as they perform. Protect the exterior with these maintenance steps:

Wash and Wax Regularly: Removes dirt and prevents paint damage.

Use Ceramic Coating: This provides a durable layer of protection against the elements.

Inspect for Paint Chips and Rust: Address small issues before they worsen.

Keep Headlights and Taillights Clean: Improves visibility and aesthetics.

6. Interior Care: Maintain a Premium Feel

The interior of your Dodge muscle car should be as impressive as its performance.

Vacuum and Wipe Down Surfaces Regularly: Keeps dust and dirt from accumulating.

Use Leather or Vinyl Conditioner: Prevents cracking and fading.

Check for Electrical Issues: Test infotainment, climate control, and other electronic features.

Replace Cabin Air Filters: Ensures clean air inside the vehicle.

7. Battery Maintenance: Keep Your Muscle Car Ready to Roar

A well-maintained battery is crucial for starting your high-performance engine reliably.

Test Battery Health Annually: Avoid unexpected failures.

Clean Battery Terminals: Prevents corrosion and connection issues.

Use a Trickle Charger if Storing the Car: Maintains battery charge during long periods of inactivity.

Avoid Excessive Use of Electronics When Idle: Helps preserve battery life.

8. Seasonal Maintenance: Adapting to Weather Conditions

Winter Care:

Use Winter Tires: Enhances traction on snow and ice.

Check Antifreeze Levels: Prevents freezing and engine damage.

Wash Undercarriage Frequently: Removes salt buildup to prevent rust.

Inspect Wipers and Defrosters: Ensures clear visibility in winter conditions.

Summer Care:

Monitor Coolant Levels: Prevents overheating.

Check Air Conditioning Performance: Ensures comfort during hot weather.

Park in Shade or Use a Car Cover: Protects the interior from sun damage.

9. Performance Upgrades and Tuning: Maximize Your Dodge’s Potential

Many Dodge owners enjoy tuning and upgrading their vehicles. To avoid performance issues, ensure modifications are done correctly by a trusted Dodge Workshop in Dubai.

Use High-Quality Performance Parts: Avoid cheap, unreliable aftermarket components.

Tune Your ECU Properly: Optimizes engine performance and fuel efficiency.

Upgrade Your Exhaust System: Improves airflow and adds a deeper exhaust note.

Install Performance Brakes: Enhances stopping power for high-speed driving.

10. Safe Driving Habits: Extend the Life of Your Muscle Car

Your driving style directly impacts the lifespan of your Dodge. Follow these habits for longevity:

Warm Up the Engine Before Hard Acceleration: Helps protect internal components.

Avoid Excessive Revving in Neutral: Can damage engine components.

Drive Smoothly and Avoid Sudden Stops: Reduces wear on brakes and suspension.

Use Sport Mode Only When Necessary: Prolong transmission and engine health.

11. Professional Inspections: Trust the Experts

While DIY maintenance is important, professional inspections ensure that your Dodge remains in top condition.

Annual Full Inspections: Detects underlying mechanical issues.

High-Performance Specialist Check-Ups: Essential if you track or race your Dodge.

Software and ECU Updates: Keeps electronic systems functioning optimally.

Conclusion

Dodge muscle cars are built for speed, power, and thrill. With proper maintenance, your Challenger, Charger, or Viper will remain a roaring beast for years to come. By following these essential care tips, you can enjoy peak performance, aggressive styling, and legendary muscle car dominance on the road. Keep up with regular servicing, drive responsibly, and let your Dodge shine as the ultimate powerhouse it was designed to be!

0 notes

Text

Why a Reliable Fuel Oil System in the UAE is Essential for Efficient Operations?

If you are dealing with a backup power, heating, and other fuel services you need to have a good-designed fuel oil system in UAE. From fuel oil systems for generators to industrial boilers to large-scale fuel oil storage, an efficient fuel oil system can help ensure uninterrupted operations while remaining safe and compliant with regulatory requirements. In a landscape with abundant energy solely complimented by the additional power generation, energy security is paramount for business and infrastructure projects.

Key Components of a Fuel Oil System

This oil system includes several key components to keep the fuel storage and transfer process seamless:

Fuel Storage Tanks

These tanks un evil tank safe and efficient and will never result in contamination or leakage. Based on each requirement, businesses can opt for underground, above-ground or double-walled tanks, and all tanks meet UAE safety standards.

Piping and Transfer Systems

Feed oil storage must be transferred seamlessly to equipment. Properly designed piping systems with pumps, valves, and filters ensure no obstructions and facilitate consistent fuel flow. Corrosion and leaks are usually the result of using low grade or unsuitable materials and improper installation.

Ensuring Efficiency and Compliance

In the UAE, the governing fuel oil systems are under stringent environmental and safety regulations. Complying with these standards helps you evade legal trouble, but also streamlines:

Regular Maintenance and Inspections

Routine checks enable the detection of leaks,monitoring of fuel quality, and prevention of system failure. Preventive maintenance increases the operating life of the system, reducing downtime.

Automation and Monitoring Systems

Real-time tracking of fuel levels, pressure and flow rates through advanced automation and remote monitoring technologies This decreases operational risks while returning the most efficient outcomes.

Fuel Oil System Company in UAE

At SkyTech LLC the use of fuel oil system in UAE becomes indispensable for delivering a continuous flow of fuel to generators as well as enhancing their efficiency and reliability. These systems are built specifically to manage fuel storage, transfer, and distribution to comply with safety and performance standards. Smooth operations require all elements to be properly functioning, from generator fuel pipelines to types of fuel tanks for generators. From correct calculation on fuel tanks to choose the right fuel tank shape for generators are the best route to optimal functioning.

Conclusion

Fuel oil system in UAE is an essential process for companies who need a constant supply of fuel. Each component contributes to the overall efficiency and compliance from safe storage solutions to advanced monitoring systems. The right system would allow various industries to operate uninterrupted, save costs, and ensure long-term reliability.

0 notes

Text

Buy the Premium Quality Used Car Engine

Car engines are undoubtedly the most crucial component of any car, be it any kind of vehicle. Therefore, you must maintain the engine regularly to keep it in perfect condition. Thus, when your car engine is not working because of an accident or fault, you must replace the car engine to avoid problems in the car. To save any further expenses, you can buy a used car engine. Moreover, we have some facts that will help you get the best-used car engine.

Different Parts in a Car Engine

The car engine has many parts and elements that protect your car's functions and roles. However, you can replace your car engine by buying a used car engine from our website, and our agents deliver across the USA.

Camshaft

The camshaft is a rod or shaft arranged in the shape of cams, called cam lobes. While the shaft rotates, the cam's shape provides a valve to act as a shield that is equivalent to the strength of its shape.

Piston

The piston converts the pressure the burning air-fuel mixture creates into a force acting on the crankshaft. The type of internal combustion depends on the shape of the piston.

Engine Valve

These are mechanical components used in internal combustion engines to grant or limit fluid flow to and through the combustion chambers or cylinders during engine operations.

The Crankshaft

However, the crankshaft converts the energy of a piston moving up and down into a circular motion, allowing your car wheels to move.

Also Read: 5 Signs of a Bad Camshaft Sensor: How to Fix

Oil Pumps and Filters

Oil pumps are necessary in engines because they grease and cool essential parts. Moreover, oil filters catch all impurities and pollutants without leaking.

What are the Symptoms to Replace the Car Engine?

When you find signs or symptoms that affect the engine, you must immediately replace it before any delay, as it can cause significant issues to your vehicle. You can check our website to purchase a used car engine, and we are offering a sale at the best price.

Tapping Sounds

It can cause worn-out bearings or internal damage, which can be because bearings support the crankshaft, and failure can lead to catastrophic damage.

Excessive Smoke

Blue Smoke indicates burning oil due to worn piston rings or valve seals.

Coolant leaks into the combustion chamber, causing white smoke and a sign of a broken engine block or blown head gasket.

Black Smoke is a rich fuel mixture, which could lead to engine failure if unaddressed.

Overheating Issues

Persistent overheating, even after repairs to the radiator, thermostat, or cooling system, causes cracked cylinder heads, engine block damage, or severe internal issues.

Check Engine Light Stays On

Despite addressing apparent issues, persistent check engine lights might indicate significant internal damage.

What are the Benefits of Buying a Used Car Engine?

However, buying a new car engine can be very expensive, yet a used car engine will also do the same work as a new engine will do. Meanwhile, it differs from the used car engine, which cannot work correctly or has faults. We have all used car products in perfect working condition, and currently, we have a car engine for sale.

Save Money

When purchasing a car engine, the best option is to buy a used one. This will save you a lot of money. If you check the prices for new and used car engines, you will see a difference of around 80% to 90%.

Reliability

You must look for whether the engine is durable when buying a used car engine. Yet, buying a used car engine for your car is better than a new one, as the used car engine is not only tested but is also used on the road.

Save the Nature

Selecting a used car engine will help prevent unnecessary waste. However, extending the life of your car with a used car engine also means recycling an engine and preventing a perfectly functional part from being thrown away.

How Much is a Used Car Engine in California?

Depending on your model and budget, you can buy different engine types on our website. When your car engine is completely damaged, you must replace it, as repairing it is temporary. Per your requirements, a used car engine might cost $400 to $15000.

Visit Cars Part Zone for more info. or call us at +1-844-524-3074

Frequently Asked Questions

Can I fix a damaged engine?

You can fix a damaged or faulty engine, but if your car engine requires a lot of internal parts to be replaced, you must buy a used car engine, as it is more beneficial than repairing it or buying a new engine.

What causes problems in a car engine?

Many causes can create problems in your car engine, such as overheating, broken belts, inadequate engine oil, or hydro-locking.

How many years does a car engine survive?

There are no specific expiry years for a car engine's survival. Moreover, a working car engine will work for almost 10 years or around 5 lakh kilometers.

What factors should you check when buying a used car engine?

Certain factors are involved when buying a used car engine, such as checking the history, cold start the car, oil leaks, coolant leakage, and checking the internal parts.

0 notes

Text

Why Every Construction Business Needs a Reliable Heavy Equipment Repair Plan

The construction industry relies heavily on heavy equipment to complete projects on time and within budget. These machines are the backbone of any construction business, helping teams move materials, dig foundations, and execute complex tasks efficiently. However, equipment breakdowns are inevitable, and when they occur unexpectedly, they can lead to costly delays, lost revenue, and potential safety hazards. This is why every construction business must have a reliable heavy equipment repair plan in place to minimize downtime and ensure seamless operations.

The Cost of Downtime in Construction

When heavy machinery stops functioning, it can bring an entire project to a halt. The longer a piece of equipment remains out of service, the more it impacts the project timeline, labor costs, and overall productivity. Here’s how downtime affects construction businesses:

Missed Deadlines – If critical machinery is not working, project completion dates may be pushed back, leading to potential contract penalties.

Higher Repair Costs – Emergency repairs often cost significantly more than scheduled maintenance. Delaying repairs can turn small issues into major mechanical failures, requiring expensive part replacements.

Reduced Productivity – A broken-down machine can slow or stop progress, leaving workers idle and increasing overall project costs.

Safety Risks – Malfunctioning equipment poses serious safety hazards to workers on-site. Ensuring that machines are in optimal working condition prevents accidents and injuries.

Lower Equipment Lifespan – Regular maintenance and timely repairs extend the life of heavy equipment, preventing premature replacements and saving businesses thousands of dollars.

Essential Elements of a Heavy Equipment Repair Plan

To keep your construction business running efficiently, a comprehensive repair and maintenance plan should include the following:

1. Routine Preventative Maintenance

A proactive maintenance strategy is key to preventing breakdowns. Regular inspections help detect early warning signs before they escalate into costly repairs. Essential maintenance tasks include:

Checking and replacing engine oil and filters

Inspecting the hydraulic system for leaks or wear

Monitoring tire or track conditions

Ensuring proper lubrication of moving parts

Examining the cooling system to prevent overheating

By performing preventative maintenance, construction businesses can significantly reduce the likelihood of equipment failure on-site.

2. Access to Reliable Repair Services

Even with the best maintenance practices, unexpected breakdowns still happen. When they do, having access to expert repair services ensures a quick resolution.

For instance, hydraulic hose repair services are crucial when dealing with heavy machinery that relies on hydraulic systems. A damaged hydraulic hose can cause a loss of pressure, affecting the machine’s performance or rendering it inoperable. Timely repairs prevent extended downtime and maintain operational efficiency.

Similarly, working with a skilled diesel mechanic is essential for construction businesses that rely on diesel-powered machinery. Diesel mechanics specialize in diagnosing and fixing engine issues, fuel system failures, and exhaust problems. Having a reliable diesel mechanic on call can save construction companies valuable time and money.

3. Emergency and On-Site Repairs

Transporting heavy machinery to a repair facility can be time-consuming and expensive. Partnering with repair professionals who offer mobile and on-site repair services can drastically reduce downtime and get equipment back to work faster. On-site repair services ensure that minor issues are fixed immediately without the need for lengthy transportation and shop wait times.

4. Keeping Maintenance Records

Maintaining detailed service logs is an often-overlooked yet vital aspect of an effective repair plan. Keeping track of repairs and maintenance history provides valuable insights into equipment performance and helps plan future maintenance schedules. Well-documented records also increase resale value if the equipment is ever sold.

The Long-Term Benefits of a Heavy Equipment Repair Plan

By implementing a structured repair plan, construction businesses can enjoy several long-term benefits:

Lower operating costs – Regular maintenance prevents major breakdowns that require costly repairs or replacements.

Increased efficiency – Well-maintained machines operate at peak performance, improving job site productivity.

Enhanced safety – Properly functioning equipment reduces the risk of workplace accidents and injuries.

Better project management – Predictable equipment availability helps keep projects on schedule and within budget.

Final Thoughts

A reliable heavy equipment repair plan is a must for any construction business that wants to stay competitive, avoid unnecessary downtime, and ensure worker safety. Whether it's scheduling routine maintenance, having quick access to hydraulic hose repair, or relying on a trusted diesel mechanic, taking a proactive approach to equipment care will save time, money, and headaches in the long run.

Construction companies that prioritize equipment maintenance and repair will see improved efficiency, reduced operational costs, and greater overall success. Don’t wait for a breakdown to disrupt your operations—invest in a solid repair plan today to keep your business running smoothly.

0 notes

Text

Smart Parts Exports: Delivering Mahle Genuine Spare Parts from India to the World

In the dynamic world of automobiles, automobile presentation, reliability, and long-term efficiency are closely linked to the classification of the spare parts used. Every element plays a critical role in ensuring smooth operation, along with that’s why fix on the right variety matters. For decades, Mahle has set the benchmark in the world automotive spare parts manufacturing, well known for its precision-engineered engine element, filters, pistons, gaskets, including thermal management order.

As the demand for Mahle Genuine Spare Parts continues to grow across worldwide markets, Smart Parts Exports come into view as a trusted and dependable Mahle parts exporter from India, delivering bona fide parts to workshops, retailers, and distributors worldwide with consistency, reliability, and unmatched service.

Why Mahle Spare Parts?

Founded in Germany, Mahle has habitual itself as a global superior in engine systems along with filtration technologies. With a powerful presence in over 30 countries, Mahle supplies components to both OEMs (Original Equipment Manufacturers) and the aftermarket sector. Their consequences are synonymous in the company of German engineering excellence, tested for performance, durability, and safety.

Mahle genuine spare parts are trusted worldwide because they:

Are manufactured under stringent quality standards

Offer compatibility with a wide range of vehicle models

Deliver high efficiency and durability

Are continually developed with cutting-edge technology

From oil and air filters to advanced thermal management systems, Mahle parts help vehicles perform at their best in all conditions.

Smart Parts Exports – Delivering Mahle Quality to the World

At Smart Parts Exports, we are proud to be in the company of almost all well founded Mahle parts exporters from India, committed to provide only Mahle genuine spare parts to workshops, distributors, also retailers over the globe. Our reputation is built on trust, fast delivery, excellent customer support, and unwavering dedication to quality.

As a global exporter, we realize the need for legitimacy in every part delivered. That’s why all Mahle spare parts we export come with proper documentation, branding, along with packing — make certain that what you receive is 100% original and built to last.

Extensive Product Range – One-Stop Solution

Whether you’re a repair shop in Africa, a wholesaler in the Middle East, or a fleet manager in South America, Smart Parts Exports has a wide selection of Mahle spare parts exports to meet your needs. Our Mahle catalog includes:

Oil Filters & Air EFilters: engineered for optimal flow and filtration, done up clean engine working.

Pistons & Piston Rings: accuracy-made for higher production along with reduced emissions.

Cylinder Components: Designed to be erect firm against high constraint along with temperatures.

Gaskets & Seals: subscription perfect fit with sealing to unit off leakage and make sure engine efficiency.

Thermal Management Components: Radiators, coolers, along in the company of thermostats to maintain optimal operating temperature.

Turbochargers & Intercoolers: High-showing parts that maximize engine power and fuel organization.

All Mahle parts are backed by global R&D and manufactured using the latest technologies — making them a preferred choice for engine rebuilders and vehicle service professionals.

Why Choose Smart Parts Exports?

There are several reasons why we’re a go-to Mahle parts exporter for clients across continents:

1. Authenticity Guaranteed

We supply Mahle genuine spare parts only — no substitutes, no imitations. Each product is sourced directly from authorized channels and carefully verified for authenticity.

2. Global Shipping Expertise

From customs documentation to wrappers together with planning, we manage every aspect of international shipping. Our experience in exporting to over 80 countries ensures well timed delivery along with hassle-free transactions.

3. Competitive Pricing

We leverage our strong sourcing network to offer the best possible prices without compromising on quality. Our bulk purchase options make us a preferred partner for distributors.

4. Customer-Centric Approach

Your satisfaction is our priority. From inquiry to delivery, we provide transparent communication, expert advice, and responsive customer support.

5. Wide Inventory

With a large record of Mahle spare parts exports, we fulfill orders with all speed — whether it’s a small parcel or a full repository load.

Supporting Garages, Distributors, and Retailers Worldwide

Whether you are looking to buy Maruti Suzuki cars, private plan of action trucks, or luxury sedans, Mahle parts offer concurrence and reliability for all major motorized vehicle brands. As a Mahle parts exporter, Smart Parts Exports overpass the gap between quality parts and along with occupations that depend on them. We ensure that your supply chain remains efficient and your customers stay satisfied.

We’ve successfully partnered with clients in Latin America, the Middle East, Africa, Southeast Asia, and Eastern Europe — helping them grow their businesses with consistent access to Mahle genuine spare parts from India.

Partner with Smart Parts Exports Today

When it comes to Mahle spare parts exports, Smart Parts Exports stands out as a trusted name in the industry. We bring together quality, service, and reliability under one roof, making it easier than ever to get authentic Mahle parts delivered to your doorstep.

Are you looking for a reliable Mahle parts exporter for your business?

Get in touch with Smart Parts Exports, the leading Mahle parts exporter from India, and experience seamless service, genuine products, and global delivery at its best.

Conclusion

In today’s competitive automotive landscape, quality and authenticity are non-negotiable — and that’s exactly what Mahle genuine spare parts represent. With unmatched engineering, global trust, and proven durability, Mahle parts continue to be a top choice for vehicle professionals around the world.

As a leading Mahle parts exporter from India, Smart Parts Exports is proud to make these world-class components easily accessible to our international clients. Whether you're a wholesaler, garage owner, or retailer, partnering with us ensures you receive only the best — backed by expert support and seamless export services.

Trust Smart Parts Exports for all your Mahle spare parts exports needs, and take your business performance to the next level with genuine quality, every time.

0 notes

Text

Understanding Diesel Exhaust and Cylinder Head: Key Components for Engine Performance

When it comes to diesel engines, two critical elements play a significant role in their performance, efficiency, and longevity: diesel exhaust and the cylinder head. Understanding how these components function and interact is vital for maintaining optimal engine performance. In this article, we will explore the importance of diesel exhaust and the cylinder head, along with their impact on your vehicle's performance.

What is Diesel Exhaust?

Diesel exhaust is the byproduct of the combustion process that occurs within a diesel engine. Unlike gasoline engines, diesel engines operate through compression ignition, which results in a distinct exhaust composition. Diesel exhaust contains various gases, particulates, and compounds such as:

Nitrogen oxides (NOx)

Carbon monoxide (CO)

Particulate matter (PM)

Sulfur dioxide (SO2)

Modern diesel engines incorporate advanced exhaust systems to minimize harmful emissions. Key components in a diesel exhaust system include:

Diesel Particulate Filter (DPF): Captures and eliminates soot particles, reducing air pollution.

Selective Catalytic Reduction (SCR): Uses a urea-based solution to convert harmful NOx gases into harmless nitrogen and water vapor.

Exhaust Gas Recirculation (EGR): Redirects a portion of exhaust gases back into the engine to lower combustion temperatures and reduce NOx formation.

Maintaining your diesel exhaust system is crucial for meeting emission standards and ensuring the longevity of your engine. Clogged filters, malfunctioning EGR valves, or damaged exhaust pipes can severely impact engine performance.

The Role of the Cylinder Head in Diesel Engines

The cylinder head is a vital engine component that sits atop the engine block, sealing the combustion chamber. It plays a key role in the internal combustion process by housing essential parts such as:

Valves: Control the intake of air and fuel, as well as the expulsion of exhaust gases.

Spark Plugs (in gasoline engines): Diesel engines rely on compression ignition rather than spark plugs.

Camshaft and Rocker Arms: Control the movement of the valves for proper timing and combustion.

A properly functioning cylinder head ensures efficient combustion, optimal power output, and effective cooling. Common issues with cylinder heads include cracks, warping, and gasket failures. These issues can lead to coolant leaks, compression loss, and engine overheating.

The Relationship Between Diesel Exhaust and Cylinder Head

The diesel exhaust and cylinder head are closely interconnected. A well-maintained cylinder head ensures proper sealing of the combustion chamber, allowing efficient fuel combustion and reducing harmful exhaust emissions. Conversely, a malfunctioning exhaust system can strain the cylinder head, causing increased heat buildup and pressure within the engine. For example, a clogged diesel particulate filter can create backpressure, forcing exhaust gases back into the engine. This added pressure may lead to cylinder head gasket failures or valve damage, further compromising engine performance.

Maintenance Tips for Diesel Exhaust and Cylinder Head

To keep your diesel engine running efficiently, follow these essential maintenance tips:

Diesel Exhaust Maintenance

Regularly inspect the DPF: Ensure the filter is not clogged to maintain optimal exhaust flow.

Monitor the EGR valve: Clean or replace it as needed to prevent carbon buildup.

Use high-quality diesel fuel: Premium fuel options can reduce soot formation and improve engine efficiency.

Cylinder Head Maintenance

Check coolant levels frequently: Overheating can warp the cylinder head.

Inspect for oil leaks: Oil contamination can cause gasket deterioration.

Schedule regular tune-ups: Professional maintenance can detect cracks, wear, or potential issues early on.

Conclusion

Both diesel exhaust and the cylinder head are essential to the overall health of your diesel engine. A well-maintained exhaust system ensures reduced emissions and optimal performance, while a properly functioning cylinder head maintains engine efficiency and power. By understanding their roles and following proper maintenance practices, you can ensure your diesel engine remains reliable, efficient, and environmentally friendly for years to come.

0 notes