#Foundry molding machine

Explore tagged Tumblr posts

Text

youtube

Automatic green sand molding machine with sand mold handling system, foundry horizontal sand molding machine

0 notes

Text

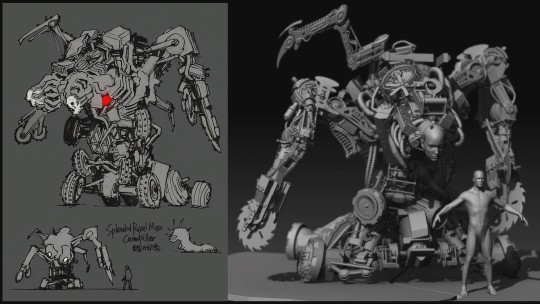

KARL HEISENBERG CONCEPT ART

● Karl Heisenberg

↳ Heisenberg's main concept is based on Frankenstein. We wanted to create a cool gray-haired character who was a little rough around the edges. He smokes his favorite Cuban cigars.

↳ An early draft of Heisenberg's family. The biggest difference was that Heisenberg was going to be a twin and his mother was a subject for brain experiment.

● Mutated Heisenberg

↳ We went for a look that was the opposite of his human form, a giant mechanical monster. The design based on the idea that he uses scrap left scattered around the factory. He owns weapons from tanks and planes, and has mountains of scrap for his mass-produced experiments.

● Mutated Heisenberg in Detail

↳ The original design was based on the splendid royale moth caterpillar. We wanted him to look like he moved on treads and be faster than any other boss monster.

↳ Heisenberg's father was going to be the leader of the village, and the boss fight with the mechanical mutation was originally going to be with him.

↳ Concept art of a day in the life of Heisenberg. Night after night his modified henchmen dig up corpses from the graveyard to be used in his metal army.

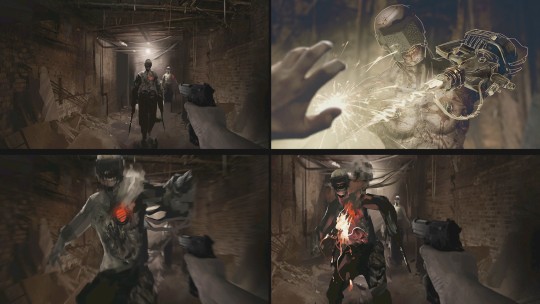

● Soldat Eins

↳ We called these enemies "Drillman" for a long time during development because one arm was replaced with a drill. The idea for these enemies is they have a reactor inside their chests with the parasite inside that acts like an internal combustion engine. The goggles are units that Heisenberg uses to control them.

↳ Designs for various Soldat reactors, but the final design was a grotesque mechanical heart.

● Soldat Panzer

↳ We consciously created the enemies in the factory to be different so they didin't just terrify players but also created a strong sense of anticipation. The design was based on Western medieval armor and helmets.

● Soldat Jet

↳ We were really attached to the name "Jet Drill" during development. They use jets on their backs and their heads look like fighter planes. The design is similar to the horseshoe crab. We designed the front and back with different amounts of detail so the back would be particularly shocking.

● Sturm

↳ The propeller on his head is made from three chainsaw blades. He chopped his own arms off when they got in the way of the spinning blades. There was one plan to have the Sturm be Heisenberg's real father. And during development he was called "Propeller Man."

● Bridge Ruins

↳ Concept art for the bridge to Heisenberg's factory. It was initially going to be just to the side of the path leading to the Altar ruins.

● Sturm Attacks

↳ Sturm chasing Ethan down a narrow corridor, destroying everything in his way.

● Giant Cavern

↳ The concept art for Heisenberg kicking Ethan down into the hole and the giant cavern under the factory.

● Casting Machine

↳ A casting machine which uses molds to create objects made out of cast iron. This concept for a puzzle was around since early development as a way to create a key.

● Foundry

↳ This room was once only used for casting iron but Heisenberg ended up utilizing it for his experiments. This room links to the hidden engine room.

● Engine Room

↳ An engine room powered by giant pistons.

↳ Concept art for Heisenberg's factory where Ethan is chased by the Soldat series. If the reactors in their chests are destroyed then the parasite inside will attempt to escape.

● Grinder Shaft Fight

↳ A fight inside the grinder shaft. These were early designs for the Soldat Jet. We originally imagined a space where they could freely fly about.

● Heisenberg's Key

↳ We went with a design that had a powerful looking horse just like the one on Heisenberg's crest.

● Start of the Battle With Heisenberg

↳ Concept art for the flow of events leading up to the battle with Heisenberg. We pictured Ethan falling into the pit around dusk and returning from it to a dark stormy night sky. The general layout of events didin't change much from early development.

● Mutated Heisenberg-Fight 1

↳ Concept art for the boss fight with Heisenberg. Even early on in development this battle was going to commence with a self-propelled artillery. The only difference is that in the final version, Heisenberg is not defeated using falling transmission towers.

● Mutated Heisenberg-Fight 2

↳ We figured that Heisenberg's yard would be full of scrap and vehicles, which he uses during the fight.

↳ Boss fight with mutated Heisenberg where he turns into his final form.

#resident evil 8#resident evil 8 village#resident evil village#re8#re8 village#re village#Lord Heisenberg#Karl Heisenberg#Heisenberg

146 notes

·

View notes

Text

When Is The Investment Casting Employed?

A wax pattern is used in the industrial process of Investment casting China, sometimes referred to as precision casting or lost-wax casting, to create a disposable ceramic mold. The exact shape of the object to be cast is captured in a wax pattern. A ceramic substance that is refractory is applied to this design. After the ceramic material solidifies, it is heated and flipped upside down until the wax melts and runs out. The ceramic shell hardens into a disposable investment mold. The mold is filled with molten metal, which is then allowed to cool. After that, the metal casting is broken out of the used mold.

When to employ investment casting

Investment casting is a rather expensive technique because of its labor needs and intricacy, but the advantages frequently exceed the drawbacks. Almost any metal may be cast for an investment.

Excellent as-cast surface finishes may be achieved in complicated items produced by investment casting. Since the ceramic shells of investment castings break away from the part when it cools, a taper does not need to be incorporated to extract the components from their molds. With the use of this manufacturing feature, castings with 90-degree angles may be created without any shrinkage allowance and without the need for further machining to achieve such angles.

Parts made using the investment casting technique by Investment casting Supplier have excellent dimensional precision, are readily net-shaped, and are frequently produced without the need for further machining. To create wax patterns, a new die is needed for every distinct casting run.

The time and effort saved by reducing or eliminating secondary machining more than offsets the expense of new tools for high-volume orders. Lesser casting runs will probably not pay for itself.

A new wax pattern to a finished casting typically takes seven days, most of which is spent making and curing the ceramic shell mold. To make castings more rapid, certain foundries can quick-dry. Cost is not the only factor affected by investment casting's time- and labor-intensive process. Longer lead times for the investment casting process are typical at foundries because of their restricted production capacity and equipment.

More Information: Mastering the Art of Investment Casting: A Deep Dive into the Process

#Investment casting Supplier#Investment casting manufacturer China#Investment casting manufacturer#Investment casting China

2 notes

·

View notes

Photo

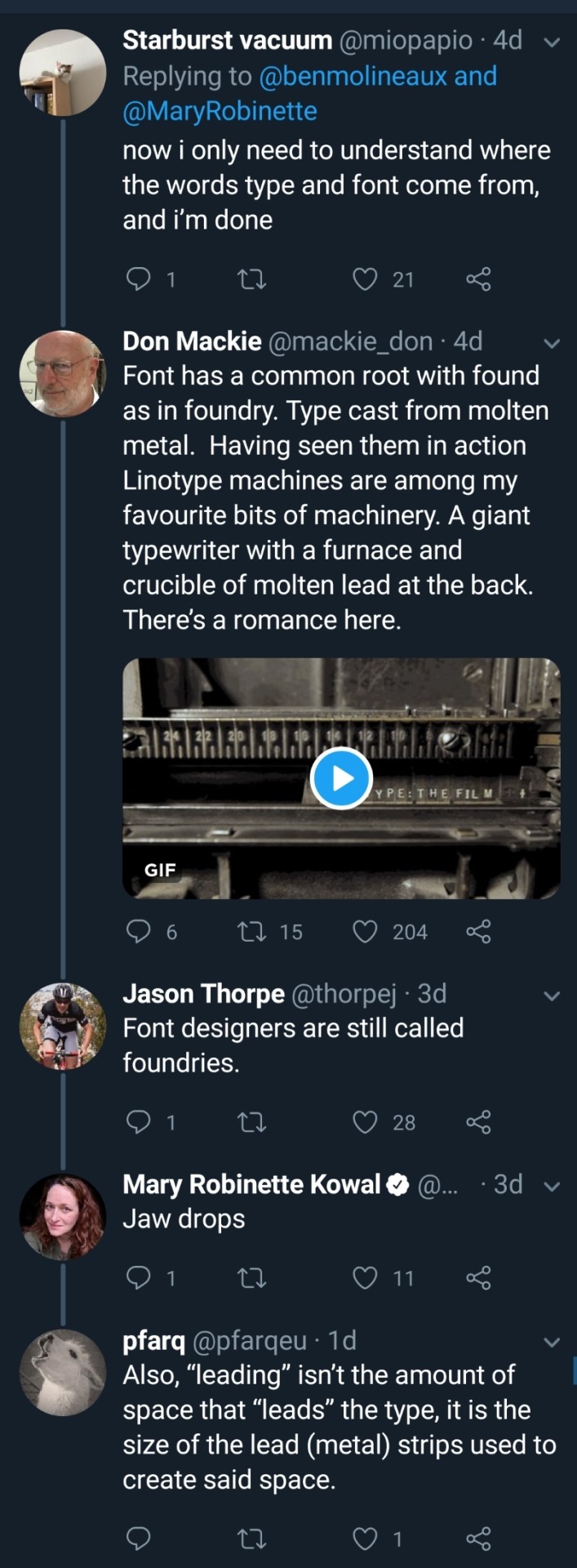

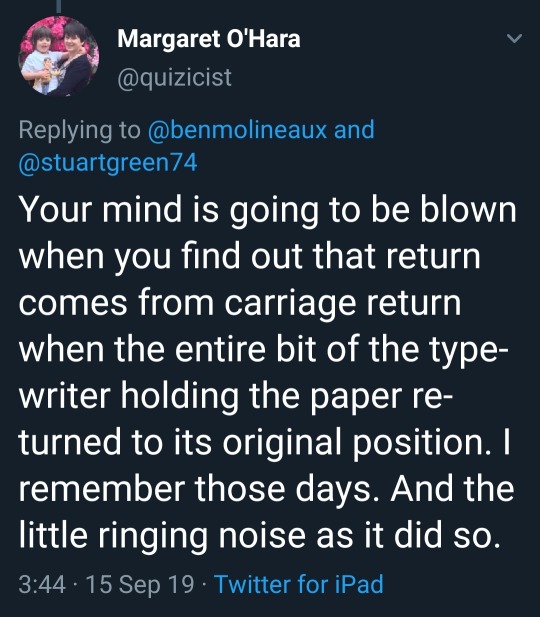

This is actually my field of research (broadly speaking), so I wanted to throw in a few more things:

Being "out of sorts" comes from literally running out of sorts (characters of type) in your case.

Stereotypes are made from molds made from set type. So once you've put together the text you want to be able to reproduce quickly, you take a mold of the type, and then make a stereotype plate from that mold. Printers sometimes offered stereotyping services, which could include storing the plates indefinitely, as with Rand, Avery & Co.

The linotype machine is named that because it literally makes a line o' type on demand. I can't explain all the mechanics, but when you type a line, the machine casts it into a single line of lead type. This was hugely helpful for printing things quickly, especially things with tight deadlines like newspapers. But I do want to mention that typesetters (who were assembling texts with single characters instead of lines of type) could be extremely fast, to the point that typesetting races were an actual spectator sport in the 19th century in the US.

Before standardized point sizes, typefounders in the US used actual names for their sizes, like diamond, primer, and pica, but there was a ton of variation as to how big these sizes were in practice, both between and within foundries. The switch to point sizes was complicated, but clearly stuck. If you want to know more about the switch, Wesley Washington Pasko talks about this under Standards of Type in American History of Printing and Bookmaking (1894).

TiL (click to go to the thread, which probably has more interesting tidbits I missed).

Bonus:

#unironically if you have a printing/book history question I may be able to help you find the answer#I'm not an expert and my focus is mostly on 19th century US printing but#printing history#book history#undescribed#describe later

165K notes

·

View notes

Text

Resins for Shell Molding Market, Global Outlook and Forecast 2024-2030 Professional Edition

The global Resins for Shell Molding market size was valued at US$ 423.5 million in 2024 and is projected to reach US$ 567.8 million by 2030, at a CAGR of 5.0% during the forecast period 2024-2030.

The United States Resins for Shell Molding market size was valued at US$ 111.2 million in 2024 and is projected to reach US$ 145.6 million by 2030, at a CAGR of 4.6% during the forecast period 2024-2030.

Download FREE Sample of this Report @ https://www.24chemicalresearch.com/download-sample/281195/global-resins-for-shell-molding-forecast-edition-market-2024-2030-946

Specialized synthetic resins used in shell molding processes for metal casting, providing precise dimensional control and surface finish in foundry applications.

Report Overview

Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. The resin used in the process is phenolic resin.

This report provides a deep insight into the global Resins for Shell Molding market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

The analysis helps the reader to shape the competition within the industries and strategies for the competitive environment to enhance the potential profit. Furthermore, it provides a simple framework for evaluating and accessing the position of the business organization. The report structure also focuses on the competitive landscape of the Global Resins for Shell Molding Market, this report introduces in detail the market share, market performance, product situation, operation situation, etc. of the main players, which helps the readers in the industry to identify the main competitors and deeply understand the competition pattern of the market.

In a word, this report is a must-read for industry players, investors, researchers, consultants, business strategists, and all those who have any kind of stake or are planning to foray into the Resins for Shell Molding market in any manner.

Global Resins for Shell Molding Market: Market Segmentation Analysis

The research report includes specific segments by region (country), manufacturers, Type, and Application. Market segmentation creates subsets of a market based on product type, end-user or application, Geographic, and other factors. By understanding the market segments, the decision-maker can leverage this targeting in the product, sales, and marketing strategies. Market segments can power your product development cycles by informing how you create product offerings for different segments.

Key Company

Sumitomo Bakelite

ASAHI YUKIZAI CORPORATION

Gunei Chemical Industry

Meiwa Plastic Industries

Hebei Zetian Chemical

EKRUN New Material

Laiwu Runda New Material

SQ Group

Market Segmentation (by Type)

Alkaline Phenolic Resin

Other

Market Segmentation (by Application)

Machine Parts

Pump Body

Other

Geographic Segmentation

North America (USA, Canada, Mexico)

Europe (Germany, UK, France, Russia, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific)

South America (Brazil, Argentina, Columbia, Rest of South America)

The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA)

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Resins for Shell Molding Market

Overview of the regional outlook of the Resins for Shell Molding Market:

Key Reasons to Buy this Report:

Access to date statistics compiled by our researchers. These provide you with historical and forecast data, which is analyzed to tell you why your market is set to change

This enables you to anticipate market changes to remain ahead of your competitors

You will be able to copy data from the Excel spreadsheet straight into your marketing plans, business presentations, or other strategic documents

The concise analysis, clear graph, and table format will enable you to pinpoint the information you require quickly

Provision of market value (USD Billion) data for each segment and sub-segment

Indicates the region and segment that is expected to witness the fastest growth as well as to dominate the market

Analysis by geography highlighting the consumption of the product/service in the region as well as indicating the factors that are affecting the market within each region

Competitive landscape which incorporates the market ranking of the major players, along with new service/product launches, partnerships, business expansions, and acquisitions in the past five years of companies profiled

Extensive company profiles comprising of company overview, company insights, product benchmarking, and SWOT analysis for the major market players

The current as well as the future market outlook of the industry concerning recent developments which involve growth opportunities and drivers as well as challenges and restraints of both emerging as well as developed regions

Includes in-depth analysis of the market from various perspectives through Porter’s five forces analysis

Provides insight into the market through Value Chain

Market dynamics scenario, along with growth opportunities of the market in the years to come

6-month post-sales analyst support

Customization of the Report

In case of any queries or customization requirements, please connect with our sales team, who will ensure that your requirements are met.

Chapter Outline

Chapter 1 mainly introduces the statistical scope of the report, market division standards, and market research methods.

Chapter 2 is an executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the Resins for Shell Molding Market and its likely evolution in the short to mid-term, and long term.

Chapter 3 makes a detailed analysis of the market's competitive landscape of the market and provides the market share, capacity, output, price, latest development plan, merger, and acquisition information of the main manufacturers in the market.

Chapter 4 is the analysis of the whole market industrial chain, including the upstream and downstream of the industry, as well as Porter's five forces analysis.

Chapter 5 introduces the latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry.

Chapter 6 provides the analysis of various market segments according to product types, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 7 provides the analysis of various market segments according to application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 8 provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and capacity of each country in the world.

Chapter 9 introduces the basic situation of the main companies in the market in detail, including product sales revenue, sales volume, price, gross profit margin, market share, product introduction, recent development, etc.

Chapter 10 provides a quantitative analysis of the market size and development potential of each region in the next five years.

Chapter 11 provides a quantitative analysis of the market size and development potential of each market segment (product type and application) in the next five years.

Chapter 12 is the main points and conclusions of the report.

Get the Complete Report & TOC @ https://www.24chemicalresearch.com/reports/281195/global-resins-for-shell-molding-forecast-edition-market-2024-2030-946 Table of content

Table of Contents 1 Research Methodology and Statistical Scope 1.1 Market Definition and Statistical Scope of Resins for Shell Molding 1.2 Key Market Segments 1.2.1 Resins for Shell Molding Segment by Type 1.2.2 Resins for Shell Molding Segment by Application 1.3 Methodology & Sources of Information 1.3.1 Research Methodology 1.3.2 Research Process 1.3.3 Market Breakdown and Data Triangulation 1.3.4 Base Year 1.3.5 Report Assumptions & Caveats 2 Resins for Shell Molding Market Overview 2.1 Global Market Overview 2.1.1 Global Resins for Shell Molding Market Size (M USD) Estimates and Forecasts (2019-2030) 2.1.2 Global Resins for Shell Molding Sales Estimates and Forecasts (2019-2030) 2.2 Market Segment Executive Summary 2.3 Global Market Size by Region 3 Resins for Shell Molding Market Competitive Landscape 3.1 Global Resins for Shell Molding Sales by Manufacturers (2019-2024) 3.2 Global Resins for Shell Molding Revenue Market Share by Manufacturers (2019-2024) 3.3 Resins for Shell Molding Market Share by Company Type (Tier 1, Tier 2, and Tier 3) 3.4 Global Resins for Shell Molding Average Price by Manufacturers (2019-2024) 3.5 Manufacturers Resins for Shell Molding Sales Sites, Area Served, Product Type 3.6 Resins for Shell Molding Market Competitive Situation and Trends 3.6.1 Resins for Shell Molding Market Concentration Rate 3.6.2 Global 5 and 10 Largest Resins for Shell Molding Players Market Share by Revenue 3.6.3 Mergers & Acquisitions, ExpansiCONTACT US: North Main Road Koregaon Park, Pune, India - 411001. International: +1(646)-781-7170 Asia: +91 9169162030

Follow Us On linkedin :- https://www.linkedin.com/company/24chemicalresearch/

0 notes

Text

Top Trends Transforming Foundry Equipment Manufacturing in 2025

The foundry industry performs an essential position in generating a large kind of metal merchandise which might be important for numerous sectors like automobile, advent, and industrial gadget. As era evolves and needs for performance and precision grow, the foundry tool manufacturing quarter is gift manner a huge transformation. In 2025, numerous traits are set to revolutionize how foundries perform and manufacture gadget. Let’s discover a number of the ones thrilling tendencies.

1. Automation and Robotics in Foundries

Automation has been a key trend throughout industries, and the foundry sector isn't any exception. In 2025, more foundry operations are predicted to adopt robotic systems and automated device for responsibilities like mildew handling, material handling, and casting. Automation reduces human errors, will growth manufacturing speed, and guarantees steady great. Robots can artwork throughout the clock without breaks, supporting foundries meet the developing call for brilliant steel products. The integration of Artificial Intelligence (AI) with robotics similarly boosts productivity with the aid of permitting machines to research and adapt to wonderful eventualities, enhancing efficiency through the years. Foundry Equipment manufacturers

2. Additive Manufacturing (three-D Printing)

Additive manufacturing, or 3-D printing, is gradually making its manner into the foundry system manufacturing vicinity. This generation lets in for the production of complex Molds and components that could in any other case be tough or expensive to create with traditional methods. In 2025, 3-D printing is expected to play a terrific large position, allowing foundries to layout and produce complex elements faster and with less fabric waste. This shifts no longer simplest reduces production charges but also offers foundries the electricity to supply custom designed components for specific desires. Furthermore, it supports sustainable practices through decreasing the quantity of scrap steel and waste generated sooner or later of the manufacturing way.

3. Sustainability and Eco-pleasant Equipment

As environmental worries keep to rise, sustainability is becoming a top priority for industries global, and the foundry area isn't always any exception. In 2025, foundry device producers are specializing in growing eco-friendly device that reduces energy consumption and minimizes emissions. Foundries are adopting cleaner generation, together with electric powered melting furnaces, which are more strength-green than traditional gasoline-powered systems. Additionally, the usage of recycled materials inside the production of foundry device is gaining momentum. With these innovations, foundries no longer only make contributions to reducing their carbon footprint but additionally assist meet stricter environmental policies.

4. Smart Manufacturing and IoT Integration

The upward push of the Internet of Things (IoT) and clever production is reworking the foundry enterprise. By 2025, foundry device may be prepared with sensors that offer actual-time statistics approximately the production way. This information may be used to reveal device overall performance, song preservation schedules, and are expecting capability disasters in advance than they arise. IoT-enabled systems permit for the seamless integration of several machines and device, creating a associated manufacturing unit surroundings in which each issue communicates and stocks statistics to optimize the producing method. This results in advanced overall performance, reduced downtime, and higher beneficial useful resource management, all of which make contributions to higher profitability for foundries.

5. Advanced Materials and Alloys

The demand for greater durable and specialised substances is developing in industries like aerospace, automobile, and heavy machinery. To meet this name for, foundry tool production is evolving to house the processing of advanced substances and alloys. By 2025, new sorts of foundry device is probably designed to work with high-standard performance alloys which incorporates titanium, aluminium, and superalloys. These substances are more hard to paintings with due to their immoderate melting factors and specific residences, but with superior gadget, foundries can collect superior consequences in casting and melding. This style additionally aligns with the frenzy for lighter, more potent, and extra warmness-resistant additives in present day merchandise.

6. Data-Driven Decision Making

With the growing significance of information in production procedures, foundry device manufacturers are incorporating information analytics into their operations. By 2025, using statistics-driven preference-making may be extra conventional, allowing foundries to optimize everything from manufacturing schedules to tremendous manipulate techniques. The potential to investigate records from numerous sources, consisting of machines, sensors, and people, offers foundries with actionable insights that enhance selection-making and help reduce operational costs. For instance, by using the usage of monitoring manufacturing records in actual-time, foundries should make modifications to enhance product exceptional or reduce waste, ultimately leading to higher efficiency and decreased production charges.

7. Customization and Flexible Manufacturing Systems

Foundries are dealing with growing strain to deliver customized merchandise that meet the specific desires of customers in various industries. To deal with this task, foundry gadget manufacturers are shifting closer to flexible production structures (FMS) that can be resultseasily reconfigured to deliver a variety of merchandise with out large downtime. These systems permit foundries to fast adapt to new manufacturing necessities and provide tailor-made answers to their customers. In 2025, the capability to all at once transfer between production techniques, together with fantastic mildew types or steel alloys, may be a important problem in staying aggressive inside the market.

8. Augmented Reality (AR) and Virtual Reality (VR) for Training and Maintenance

Augmented Reality (AR) and Virtual Reality (VR) technology are making their way into the foundry device manufacturing place, mainly for schooling and protection purposes. In 2025, AR and VR are predicted to play a bigger role in imparting immersive training reviews for operators and technicians. These technologies allow human beings to simulate actual-international foundry situations, practice complicated techniques, and troubleshoot system troubles in a virtual environment. This results in greater relaxed work environments, quicker training instances, and reduced mistakes on the shop floor.

Conclusion

The foundry device production enterprise is rapidly evolving with the advent of automation, smart technology, and sustainable practices. As we pass into 2025, foundries are embracing tendencies like robotics, additive production, IoT, and statistics-driven selection-making to stay competitive and meet the developing wishes of the marketplace. These improvements are not only making foundry operations extra efficient and price-effective but also are allowing producers to produce first rate, custom designed products that meet the ever-changing wishes of industries worldwide. The future of foundry device production seems promising, driven by way of innovation and technological progress.

0 notes

Text

Why Barium and Calcium Inoculants Are Crucial for Superior Metal Production!

In the world of metallurgy, achieving superior metal quality is an ongoing challenge. Foundries and metal production facilities rely on advanced technologies and materials to optimize the characteristics of metals. Among these materials, barium inoculant and calcium inoculant stand out as crucial agents for improving the microstructure and mechanical properties of metals. These inoculants play a significant role in enhancing casting performance, reducing defects, and ensuring high-quality production. Let’s delve deeper into why these inoculants are indispensable in metal production.

The Role of Inoculants in Metallurgy

Inoculants are substances added to molten metal to influence its solidification process. Their primary function is to refine the grain structure, promote uniformity, and reduce casting defects such as porosity and shrinkage. This ensures that the final product meets stringent quality standards required in various industries, including automotive, aerospace, and construction.

Among the wide range of inoculants available, barium and calcium-based inoculants have gained prominence due to their unique properties and effectiveness in enhancing metal quality.

Barium Inoculant: Key Benefits

Barium inoculant is widely used in the production of gray iron and ductile iron. Its addition to molten metal provides several benefits:

Refined Grain Structure: This inoculant promotes the formation of fine, evenly distributed graphite flakes in gray iron and nodules in ductile iron. This leads to improved mechanical properties, including strength and durability.

Reduction of Chill Formation: In iron casting, chill is the formation of hard carbides, which can compromise machinability and toughness. Its minimizes chill, ensuring a smoother and more consistent casting surface.

Improved Fluidity: Barium enhances the fluidity of molten metal, making it easier to fill molds completely. This reduces the likelihood of defects and ensures intricate designs can be cast effectively.

Stabilization of Graphite Formation: Barium inoculant ensures consistent graphite precipitation during solidification, preventing the formation of irregular structures.

Calcium Inoculant: Key Benefits

Calcium inoculants are another essential component in high-quality metal production. They are particularly effective in cast iron and steel manufacturing processes. Here are the key points on how they contribute to superior metal quality:

Nucleation Sites for Graphite: these inoculants provide nucleation sites for graphite precipitation, resulting in a refined and uniform microstructure. This enhances the mechanical and thermal properties of the metal.

Reduction of Sulfur Content: Calcium reacts with sulfur in molten metal to form calcium sulfide, which prevents the formation of harmful sulfides that can weaken the metal’s structure. This makes These type of inoculants particularly useful in applications requiring high ductility and toughness.

Prevention of Carbide Formation: Like Ba, Ca inoculants inhibit the formation of carbides, which can negatively impact machinability and overall metal performance.

Improved Surface Finish: (Ca) inoculants help achieve a smoother casting surface by promoting uniform solidification, which is critical in industries requiring precise and aesthetic components.

Applications of Barium and Calcium Inoculants

The versatility of (Ba and Ca) inoculants makes them valuable in various applications. Here are some of the common uses:

Automotive Industry: Inoculants are crucial in the production of engine blocks, cylinder heads, and brake components, where strength, durability, and machinability are paramount.

Aerospace Industry: High-performance materials with refined microstructures are essential in aerospace applications. (Ba and Ca) inoculants ensure the reliability of critical components.

Construction Equipment: Heavy machinery and construction tools require robust and defect-free components. These inoculants help achieve the necessary quality standards.

Piping and Fittings: Cast iron pipes and fittings benefit from the enhanced properties imparted by these inoculants, including resistance to pressure and corrosion.

Choosing the Right Inoculant

The choice between inoculants depends on the specific requirements of the metal production process. Factors such as the type of alloy, desired mechanical properties, and casting conditions play a role in determining the most suitable inoculant.

Barium inoculant is often preferred for applications where the elimination of chill and improved graphite morphology are critical.

Calcium inoculants are ideal for reducing sulfur content and preventing carbide formation, making them indispensable in processes requiring high ductility and machinability.

Conclusion

In the quest for superior metal production, the importance of barium and calcium inoculants cannot be overstated. These materials not only enhance the physical and mechanical properties of metals but also ensure consistency and reliability in casting processes. By refining microstructures, reducing defects, and improving overall performance, (Ba and Ca) inoculants contribute significantly to the advancement of the metallurgy industry.

For foundries and metal production facilities aiming to achieve excellence, investing in high-quality inoculants is a strategic decision. Whether Ba inoculant can prevent chill formation or Ca inoculant’s sulfur-reducing properties, these agents are indispensable tools for producing metals that meet the highest standards of quality and performance.

#inouclant #bariuminouclant #calciuminoculant

0 notes

Text

How Robotics is Transforming Foundry Operations: From Casting to Material Handling

The foundry industry, traditionally known for its labor-intensive and hazardous processes, is undergoing a remarkable transformation. The integration of robotics into foundry operations has revolutionized the way casting, material transport, and quality control are managed. By leveraging automation, foundries are enhancing efficiency, safety, and productivity. Here, we explore the pivotal ways robotics is redefining this industry.

1. Robotics in Casting Processes

Robotic systems are increasingly employed in critical casting operations, including mold preparation, molten metal pouring, and product handling. These systems bring precision and reliability to tasks once prone to human error. Robotic arms, equipped with advanced tools, perform intricate tasks like pouring molten metal into molds with consistent accuracy, minimizing human exposure to extreme temperatures and hazardous materials.

For instance, FANUC’s robotic solutions are tailored for foundry applications, offering unparalleled precision in mold handling and metal pouring. By reducing the margin for error and boosting production rates, robotics ensure that foundries meet rigorous quality standards. Learn more about Leister Technologies' Projects in Foundry Automation.

Additionally, automated monitoring systems integrated with robotic technologies enable real-time adjustments during casting, ensuring the end products adhere to stringent specifications.

2. Enhancing Material Transport

Material transport, a critical aspect of foundry operations, has seen significant improvements with robotics. Handling heavy and hot components manually poses risks to workers, but autonomous guided vehicles (AGVs) and robotic transport systems mitigate these dangers while optimizing workflows.

Companies like KUKA and ABB have developed robotic transport solutions capable of operating under extreme conditions, such as high temperatures and substantial loads. These innovations improve safety and ensure efficient material movement throughout the production process. Explore Leister Technologies' Innovations in Material Handling to see how robotics streamline foundry operations.

3. Quality Control and Inspection

Robotics also play a vital role in quality assurance. Automated inspection systems equipped with advanced imaging and sensors can evaluate the quality of cast products more efficiently than manual methods. These systems enable continuous monitoring, detecting defects early and ensuring dimensional accuracy and surface perfection.

For example, Creaform's robotic inspection solutions employ non-destructive testing techniques that provide fast and accurate results. Foundries adopting these technologies benefit from reduced wastage and higher product consistency. Learn about Leister Technologies' Approach to Automated Quality Control for further insights.

4. Safety Enhancements

The adoption of robotics has significantly improved workplace safety in foundries. By automating high-risk tasks, companies have drastically reduced injuries associated with manual handling of heavy materials and exposure to hazardous environments.

Robots are designed with robust safety protocols, including emergency stop functions and collision detection systems, ensuring operations remain within safe parameters. This not only protects workers but also safeguards machinery and minimizes downtime.

5. Future Trends in Robotics for Foundries

As robotics technology evolves, the future of foundry operations looks increasingly automated and efficient. Innovations in artificial intelligence (AI) and machine learning are enabling robots to adapt to changing conditions and learn from their environments, making operations more flexible and productive.

AI-powered predictive maintenance ensures robotic systems are serviced proactively, reducing downtime and enhancing reliability. Collaborative robots (cobots), designed to work safely alongside humans, are further bridging the gap between manual and automated processes, fostering a harmonious and efficient workspace.

Conclusion

Robotics is transforming the foundry industry by automating processes, enhancing safety, and ensuring superior quality control. From casting to material transport, robotic systems are paving the way for a safer, more productive manufacturing environment. As technological advancements continue, the potential for robotics in foundries will only expand, unlocking new possibilities for innovation and efficiency.

To discover more about how robotics is shaping modern manufacturing, visit Leister Technologies and explore their groundbreaking projects and solutions.

0 notes

Photo

Vintage 1961 Hubley Battery Operated The Official Mr. Magoo Tin Car Top not incl

Vintage 1961 Hubley Battery Operated The Official Mr. Magoo Tin Car Removable Top Not IncludedVintage 1961 Hubley Battery Operated The Official Mr. Magoo Tin Car Removable Top Not Included. This item is in its factory box but the Magoo car will look used and have scratches on the car. The Magoo car was tested and still works. The removable top will not be included. The factory box will be a replica box and will not be the original factory box. "The vinyl Mr. Magoo head can not be removed from body because of the age of item".

Materials: tin, plastic, fabric, metalSize: 9" long 8" tall Made in Japan, distributed by Hubley of Lancaster, PA ©1961 Seats are made of plastic and Mr. Magoo's head is vinyl. Factory Box has colorful illustrations.1961 Hubley Official 'Mr. Magoo' toy car. Tin litho Magoo car. Detachable roof not included. Made in Japan, distributed by Hubley of Lancaster, PA. Steers. rocks, rattles. Runs on 2 D batteries (not included). Replica box. This would be a great addition to a metal car/toy collection.HISTORY:“The Hubley Manufacturing Company of Lancaster, Pennsylvania, one of the oldest and largest makers of toys in the United States, was founded in 1894 by John E. Hubley to manufacture equipment and accessories for electric trains. Financial difficulties forced Mr. Hubley to sell the entire stock in 1909. At this time the electric train business was discontinued and the cast iron toy business started. Among the first toys produced were a coal range, circus wagons and mechanical banks, all collector’s items today.Included in the 68,000 square feet of floor space in the Hubley plant were a die-cast room, warehouse, tool room, paint room and all the special assembly machinery. Besides making their cast iron toys, the company made castings for other companies in Lancaster which were without foundry equipment.By 1940 increased freight costs and foreign competition forced the company to look for other materials. During World War II scarcity of metal forced the company out of the toy business and into war-related items. After the Korean conflict ended and regulations on metal were suspended, cast iron toy production resumed.Following common manufacturing methods of the time, Hubley toys of the 1890s, and for a time thereafter, were cast in sand molds in two parts which were then riveted together to form the toy. All toys were designed by John Hubley, who had remained deeply interested in children’s playthings since the time he first made his own children’s wooden toys.In 1936 Hubley started casting in multiple cavity steel dies. Die castings were broken off, trimmed, and tumbled in revolving cylindrical machines. They were then taken to the paint department where they were given baked enamel or lacquer, air-dried paint finishes in various colors. At one time, a dozen girls were employed in the paint department. Portions of the earlier toys were hand painted and some were dipped.Each different toy was started on its own moving assembly line where parts were added, details sprayed on, oiling and inspection took place and the assembly completed. For example, a fire engine took shape on one line. It started as a red chassis. The rubber-tired wheels were added, followed by the spraying on of the radiator, bumpers and headlights. The driver was added, and the ladder, fire axes and other accessories followed. Near the end of the line, the toy was individually boxed and packed in a corrugated container. In 1949, due to union disputes, the foundry was closed. This was a difficult decision for the firm, since Hubley was one of the first companies to devote their entire factory to die casting.The Hubley Company maintained a designing department where ideas were conceived and developed for model forms. Design engineers kept up-to-date on the models and style changes by attending automobile shows and studying advertisements. Their designs changed when the larger counterparts changed. After items were conceived and models developed, the toys were analyzed for pricing. The more play features a model had, the more expensive it was.

Listing and template services provided by inkFrog

0 notes

Text

Alcast Company of Peoria, Illinois USA was founded in 1970 and is an ISO 9001:2015 registered permanent mold aluminum foundry, supplier, and manufacturer of high quality American made permanent mold aluminum castings with over 278,000 square feet of manufacturing space. We currently supply aluminum castings up to 220 pounds in quantities of 10 to 400 and one pound castings with volumes exceeding 500,000 pieces per year. The Alcast Company facilities also include a full CNC machine shop; therefore, our castings can be machined, balanced, broached, shaped and more in house.

1 note

·

View note

Video

youtube

Foundry Multi Piston Hydraulic Molding Machine | Green Sand Molding Mach...

0 notes

Text

The Contribution of Cast Iron Foundries in USA's Manufacturing Economy

The United States of America's cast iron foundries in USA have been considered a very crucial determinant of the country's manufacturing economy. Such facilities act as the building blocks for fabricating strong, high-quality parts for various other industries such as automotive, construction, agriculture, infrastructure development, and manufacturing. The comprehensive package of advanced technology, talented labor, and a heritage of excellence in manufacturing has given the United States of America an edge in the global foundry market.

What Are Cast Iron Foundries?

Cast iron foundries are companies that specialize in the manufacture of cast iron. This versatile product is especially known for its durability, resistance to wear, and cost-effectiveness. Foundries pour molten iron in molds so as to produce components used in many kinds of industries, from engine parts and piping systems to machinery and architectural features.

Types of cast irons produced:

Gray Iron: Gray iron offers good machinability and thermal conductivity, which is why it is the material of choice for casting engine blocks, pipes, and housings.

Ductile Iron: For casting gears, crankshafts and suspension parts, ductile iron is utilized for strength and ductility

White Iron: Very strongly operating industries utilize white iron due to good wear resistance, like in mining.

These differences give cast iron the ability to be versatile for every manufacturing purpose.

Role of Cast Iron Foundries in the US Economy

Cast iron foundries play an important role in the USA's economy, reaching far beyond the final products themselves. Their influence will be felt through multiple layers of the manufacturing economy:

1. Indicating Industrial Growth

Cast iron foundries feed most components to the automobile, machinery, and construction industries. Through the uninterrupted flow of such components, the industrial chains are operated uninterruptedly, hence boosting development in all various sectors.

2. Employment Generation

The cast iron foundry industry directly impacts the employability of the USA. The sector employs higher-skilled labor, middle-tier management, and top management, hence directly affecting local economies and societies.

3. Technological Development

Many of the US foundries have readily embraced current technologies, such as automation and precision casting. The advancement will raise productivity while keeping up the world standards of American manufacturing.

4. Green Activities

Contemporary cast-iron foundries optimize for sustainability by recycling scrap iron and embracing energy-saving processes. Such activities help reduce not only environmental impacts but also well to the increasing demands placed on eco-friendly practices among manufacturing activities.

Challenges and Opportunities for the Cast Iron Foundries in the USA

The US cast iron foundries are quite competitive. Still, some of the challenges they face include global competition, raw material price fluctuations, and regulations. However, they also offer opportunities for innovation:

Green Technology:

Most foundries invest in green technology to meet environmental standards and optimize efficiency.

Expansion of Markets:

With continued investment of the countries in new infrastructure, the quality cast iron component requirement increases. Thus, opportunities increase for American foundries.

Training of Skilled Labor force: Training programs and apprenticeships may help have a predictable supply of skilled labor to meet future requirements.

Industry Players

One such giant in the establishment is Akp Ferrocast. The company, Akp Ferrocast, is all about precision and innovation in the foundry industry. This has given the company a benchmark over quality and sustainability by bringing customer-centric solutions, marking a stamp over its name as a trusted entity in that sector.

Why are USA-Made Cast Iron Products?

Cast iron products manufactured in foundries in the USA are reputed for quality and permanence. Cast iron foundries from the USA, despite high standard requirements, utilize present technologies to manufacture parts that have a long useful life. Thus, choosing products from the USA will support the domestic industry, develop innovations, and adhere to regulations for environmental and safety protection.

The Future of Cast Iron Foundries in the USA

It is envisioned that the U.S.-based cast iron foundries will see an opportunity to make adjustments and expansion as changes in the manufacturing landscape take place. The infusion of smart technologies through IoT and analytics will make the processes for output both more efficient and better in quality.

Takeaways:

Cast iron foundries are crucial components of the USA's manufacturing economy.

They support a wide variety of industries, drive innovation and create jobs.

Blobs of global competition are well digested as technological progress while expanding market openness.

Companies like AKP Ferrocast are examples of the industry's ability to lead on issues of quality and sustainability.

Conclusion

Cast iron foundries in the USA continue to be one of the cornerstones of industrial success as far as the nation is concerned. Economic growth, technological advancement, and sustainability place them as indispensable players in the global manufacturing sector.

0 notes

Text

Exploring the Versatility of Quartz Powder and Its Industry Applications

One of the most prevalent minerals on Earth, quartz powder is a finely powdered version of the crystal. Because of its numerous industrial uses, it is an essential component of contemporary production processes. From construction and electronics to cosmetics and industrial applications, quartz powder serves as a fundamental ingredient in generating high-quality products. This post will discuss the Quartz Powder Manufacturers, its applications, and the significance of selecting a reliable supplier in guaranteeing product quality and uniformity.

What is powdered quartz?

Quartz powder is formed from the crystal quartz, which is made of silicon dioxide (SiO2). Rocks like granite, sandstone, and quartzite naturally contain this mineral. The extraction process involves mining the quartz and grinding it into a fine powder. The resulting quartz powder is normally white, though it can also be found in other vibrant colors depending on impurities and the source of the quartz. Quartz powder is a material that can be used in a variety of ways because of its reputation for strength and resistance to chemical reactions. It is a popular option for businesses that need raw materials that can tolerate high temperatures and challenging conditions because of its special qualities, which include high thermal stability, minimal thermal expansion, and high abrasion resistance.

Manufacturing Process of Quartz Powder

To guarantee the appropriate particle size, purity, and quality, the manufacture of quartz powder entails a number of procedures. Usually, the mining of quartz from natural sources is the first step in the manufacturing process. After the quartz is extracted, it is broken up into smaller pieces and sent through a number of grinding machines to turn it into a fine powder. To guarantee that the powder is uniformly sized, sifting is done after the grinding process. To improve its quality and get rid of contaminants, the quartz powder occasionally goes through further processes such as chemical cleaning. After that, the finished product is packaged and sent to different sectors for usage in a variety of applications.

Applications of Quartz Powder

Numerous industries employ quartz powder, and as new manufacturing techniques and technologies develop, so do the applications for this material. The following are some important industries that use quartz powder:

1. Building and Construction Supplies

Quartz powder is frequently used to make asphalt, cement, and concrete. It is included to improve the finished product's strength, toughness, and visual attractiveness. It is also utilized in the manufacturing of decorative aggregates, countertops, and tiles made of quartz.

2. Production of Glass

The glass manufacturing sector is one of the most frequent applications for quartz powder. Quartz powder works as a major element in the creation of glass, supplying the essential silica content for making transparent, strong, and durable glass products.

3. Semiconductors and Electronics

Quartz powder is crucial to the electronics industry's ability to produce capacitors, semiconductors, and other electronic components. It is the perfect material for these applications because of its electrical conductivity and resistance to high temperatures.

4. Coatings & Paints

Paints and varnishes frequently contain quartz powder as a filler. Along with increasing the paint's opacity and resistance to deterioration, it also helps to improve the texture and consistency of the paint.

5. Personal Care and Cosmetics

In the cosmetics sector, quartz powder is also utilized to make exfoliating scrubs, foundation, and powders. It can be used in skincare products because of its fine texture and non-abrasive properties.

6. Casting and Foundries

Quartz powder is used in foundries for making molds and cores in metal casting. The powder is a necessary component for the metalworking sector since it enhances the molds' strength and resilience to heat.

Why Pick a Trusted Producer of Quartz Powder?

Selecting a reputable and skilled manufacturer is crucial given the increasing need for premium quartz powder across a range of industries. When it comes to quartz powder, quality is crucial because it has a direct effect on the finished product's functionality and longevity. Reputable producers guarantee that the powder is made in compliance with stringent quality control guidelines, producing reliable and superior goods. Sudarshan Group is one such business that has become well-known for its high-quality quartz powder. With years of experience in manufacturing and delivering industrial minerals, Sudarshan Group stands out for its commitment to offering high-quality quartz powder that fits the unique needs of its customers. The company makes sure that its products meet the highest industry standards by concentrating on quality, innovation, and customer satisfaction.

In conclusion

With a vast array of uses in various industries, quartz powder is an essential commodity. Whether you work in manufacturing, electronics, construction, or cosmetics, quartz powder is essential to creating high-quality goods. You can be sure that your products satisfy the necessary requirements for strength, consistency, and durability by selecting a reliable manufacturer of quartz powder. Working with seasoned producers like Sudarshan Group can give businesses seeking to acquire the highest caliber quartz powder a competitive edge in producing outstanding outcomes.

0 notes

Text

Best Foundry in India: The Secret to Superior Metal Castings

India has emerged as a global leader in the production of high-quality metal casting components. With cutting-edge technology, skilled workers, and a focus on precision, the best foundry in India have set the benchmarks in this sector. From motor castings to intricate parts such as gearbox spares, casting for pumps, and three-wheeler parts, foundries in India offer excellence in various sectors. This article explores why India is a hub for high-quality metal foundries. It also emphasizes the critical role that significant foundries play in shaping the industry.

The Role of the Best Foundry in India in Metal Casting Excellence

Metal casting is a unique process that involves shaping molten metal into a desired shape using a mold.The best foundry in India is famous for combining traditional techniques with modern advancements to produce high-quality cast parts. Foundries in India serve various sectors, including automotive, agriculture and construction. They produce parts that meet strict quality standards. With a robust infrastructure, These foundries have positioned themselves as leaders in the global market. The secret lies in being able to balance innovation with the cost-benefit ratio. Guaranteed durability and superior performance at the same time.

What Makes the Best Foundry in India Stand Out?

Expertise in Diverse Metal Castings

Foundries in India specialize in manufacturing a wide range of products, including motor-casting three-wheeler parts casting, gearbox spares casting, and pump castings. Each casting requires precise engineering, attention to detail, and compliance with international standards. The best casting employs qualified engineers who design the mold and ensure that the metallurgical properties of the final product are perfect.

Advanced Technology and Automation

Integrating advanced technologies such as 3D modeling and automation. It is a trademark of top foundry manufacturers in India. These technologies improve accuracy and reduce errors. This makes parts foundries in India more reliable for customers across the world. Automating processes also helps improve efficiency. Guaranteed on-time delivery without compromising on quality.

Motor Casting: Precision and Performance Redefined

Motor casting is one of the flagship of the best foundries in India. The process involves creating complex components such as engine housings and supports, which are an essential part of machines and vehicles. Foundries in India have excelled in producing motor casting components with thermal conductivity properties. Mechanical strength and excellent corrosion resistance. Utilizing superior materials and advanced techniques, These casting parts meet the needs of various industries. Including automotive and heavy engineering

Applications of Motor Casting

Automotive Industry: Used in engine components and electric motors.

Industrial Equipment: Essential for pumps and machinery.

Renewable Energy: Found in wind turbine generators and other energy-efficient systems.

Three-Wheeler Parts Casting: Driving Efficiency and Durability

Three wheelers are the backbone of India's transport sector. Three wheeler components require exceptional durability and precision. The best foundries in India play an essential role in manufacturing three-wheeler parts casting, including engine components, suspension parts, and chassis components. These castings are known for their durability. Lightweight features and savings

Why Indian Foundries Excel in Three-Wheeler Parts Casting

Cost Advantage: Competitive pricing without compromising quality.

Custom Solutions: Tailored designs to meet client specifications.

Eco-Friendly Practices: Use of sustainable materials and energy-efficient processes.

Gearbox Spares Casting: Ensuring Smooth Operations

Gearboxes are essential for transmitting power in machines and vehicles, making gearbox spares casting an important process. Foundries in India specialize in manufacturing gearboxes, shafts, and other prominent parts, which are highly resistant to adhesion and wear. The precision involved in casting these components guarantees perfect functionality, reducing the risk of mechanical failure.

Features of Gearbox Spares Casting

Dimensional Accuracy: Ensures perfect fitting in assemblies.

Durability: Withstands high stress and operational loads.

Versatility: Compatible with various machinery and automotive applications.

Pump Casting: Reliable Solutions for Fluid Management

Pump casting involves creating components for pumps used in industries such as agriculture, water management, and oil and gas. India's top foundry manufacturer specializes in manufacturing pump housings, impellers and volutes that provide superior corrosion resistance and mechanical strength. This meticulous process ensures that the components Can withstand high pressure and harsh environments.

Benefits of Pump Casting from the Best Foundry in India

Extended Lifespan: Resistant to wear and tear.

Energy Efficiency: Improves the overall efficiency of the pump.

Custom Designs: Tailored to meet industry-specific requirements.

Top Foundry Manufacturers: Leaders in Innovation

Foundries in India are globally recognized for their innovation and excellence. Top foundry manufacturers invest heavily in research and development to stay ahead of the competition. By combining advanced materials, Optimizing production techniques and maintaining strict quality control. They guarantee that their products are unrivaled.

Key Practices of Top Foundry Manufacturers

Sustainability: Adoption of green technologies.

Quality Assurance: Compliance with ISO and other international standards.

Client-Centric Approach: Focus on delivering tailored solutions.

How to Identify the Best Foundry in India

Selecting the right foundry is crucial for ensuring the success of your projects. Here are some factors to consider:

Experience: Look for a foundry with a proven track record in producing high-quality castings.

Certifications: Ensure the foundry complies with global quality standards.

Technology: Advanced facilities and automated processes are essential.

Customer Reviews: Positive feedback from clients is a strong indicator of reliability.

The Future of Metal Casting in India

The foundry industry in India is growing rapidly. With increased investment in infrastructure and technology, the best foundry in India will need to expand their capabilities. Emerging trends such as additive manufacturing and IA-based quality control are expected to revolutionize the sector and make it more efficient and sustainable.

Conclusion:

In summary, the best foundry in India is a beacon of quality, innovation, and reliability in the foundry industry. Whether you are looking for motor castings, three-wheeler parts casting, gearbox spares casting or pump castings, Indian foundries deliver unmatched solutions tailored to your needs. With a commitment to excellence and sustainability, these foundries are not just manufacturers but also partners in success.

By selecting the best foundry in India. You are guaranteed superior performance, savings and lasting results. Partner with your trusted foundry today to experience the difference in quality and skill.

Sigma Malleable proudly stands as the best foundry in India, delivering unmatched quality and innovation in metal casting. With expertise in manufacturing critical components such as motor castings, three-wheeler parts casting, gearbox spares casting, and pump castings, Sigma Malleable caters to industries including automotive, agriculture, and heavy machinery.

Our state-of-the-art facilities, advanced technology, and commitment to excellence ensure precision and durability in every product. Trusted by clients nationwide, Sigma Malleable combines superior craftsmanship with cost-effective solutions, making it a leader among top foundry manufacturers in India. Contact Sigma Malleable for superior metal casting solutions tailored to your needs.

#Best Foundry in India#Top Foundry Manufacturers#Motor Casting#three wheeler parts casting#Gearbox Spares casting#Pump Casting

0 notes

Link

0 notes

Text

Discover the Best Sand Mixer Muller Manufacturers in India!

Pan Mixer is your trusted brand when it come to the best sand mixer muller manufacturer in India. our company are delivered top tier sand mixer muller that compete demand of the foundry industry. our sand mixer muller are design to optimize mixing of sand, clay and other additive to produce high quality molding sand. Pan-Mixer providing that improve efficiency, reduces operational cost and improve overall quality that involved in large scale production and specializied casting processes.

Pan-Mixer used advance technology with years of industry experience to manufacturer sand mixer muller in the market. we are focusing on innovation, reliability and customer satisfaction made us leading sand mixer muller manufacturer in India. Pan-mixer machine are manufactured to deliver unusual performance and that made easy to operation and maintainance features that make a valuable any foundry. Choose Pan-Mixer to experience the best in sand mixer muller technology, and see how our products can revolutionize your production process.

Discover why we first choice amoung sand mixer muller manufacturers in India to explore Pan-Mixer top quality sand mixer muller. Visit our website pan-mixer.in and contact with us. Trust Pan-Mixer for innovative and reliable solutions that enhance your production process.

http://pan-mixer.in/contact-us.php

#pan mixer machine#laboratory concrete mixer#fly ash mixer#sand mixer muller#pan mixer in ahmedabad#pan mixer machine suppliers#paver block machinery#pan mixer manufacturers#hardic engineering#pan-mixer

0 notes