#Food Packaging Technology and Equipment Market

Explore tagged Tumblr posts

Text

Top Business Ideas in the UAE for Entrepreneurs

Starting a business in UAE is an exciting venture, as the country offers numerous opportunities across various sectors. The UAE is home to some of the most lucrative industries in the world, whether you're an experienced professional looking for new growth opportunities or an aspiring entrepreneur searching for the ideal niche. There is a lot of potential to tap into, including in the areas of real estate, e-commerce, tourism, healthcare, and IT. We'll look at the best business concepts in this blog to help you start a profitable company in the United Arab Emirates.

Why Entrepreneurs Find Success in the United Arab Emirates

In addition to being a prime location for companies, the UAE provides an environment that encourages development and creativity. It is a desirable location for entrepreneurs due to its tax-free zones, sophisticated infrastructure, and business-friendly laws. Whether you're looking to launch a local business or expand your global reach, the UAE is the place to be. However, which industries are the most lucrative and appropriate for would-be business owners?

Profitable Sectors for Starting a Business in the UAE

1. Real Estate

One of the most profitable industries in the UAE is real estate, and international investors are drawn to Dubai and Abu Dhabi on a regular basis. The nation is the perfect place for real estate services and property investment because of its expanding population, influx of tourists, and creation of famous landmarks.

Innovative Business Ideas in Real Estate:

Property Management Services: Providing property management services can be a profitable choice in an ever-growing market.

Real estate brokerage: Helping foreign customers purchase or rent real estate can generate a consistent income in this cutthroat industry.

Flexible office spaces are becoming more and more in demand as the entrepreneurial culture expands.

2. E-Commerce

Due to the widespread use of smartphones and the growing number of tech-savvy people, the e-commerce sector has grown rapidly in recent years. Starting a business in UAE’s e-commerce market can be an excellent choice, especially as the country embraces digital transformation.

Innovative Business Ideas in E-Commerce:

Online Retail Store: Selling specialized goods, such as electronics or clothing, can give you a firm footing in this cutthroat market.

Marketplace Platforms: In order to take advantage of the UAE's booming retail industry, establish a platform for local vendors to sell goods online.

Subscription Boxes: Provide specialized subscription boxes for niche markets, such as gourmet foods, wellness, or cosmetics.

3. Tourism

With millions of tourists visiting the UAE each year, tourism plays a major role in the economy of the nation. There are plenty of options for entrepreneurs with sights like the Palm Jumeirah, the Burj Khalifa, and the desert safari experiences.

Innovative Business Ideas in Tourism:

Luxury Travel Services: Provide wealthy people with unique and personalized travel packages.

Services for Tour Operators: Focus on speciality tours, like eco-tourism, adventure, or cultural experiences.

Travel Technology Solutions: Offer cutting-edge platforms or applications for travel that improve visitors' experiences.

4. Healthcare

The UAE's healthcare industry is expanding quickly, with an emphasis on offering both locals and visitors top-notch medical care. The government's drive for top-notch medical facilities and health technology innovation can help entrepreneurs in the healthcare sector.

Innovative Business Ideas in Healthcare:

Offering online medical consultations and healthcare services, telemedicine has become more and more popular in the post-pandemic world.

Fitness and Wellness: Open a yoga studio, fitness center, or wellness app to appeal to the health-conscious population in the United Arab Emirates.

Medical Equipment Supply: Provide medical devices and equipment to clinics, hospitals, or home care agencies.

5. IT and Technology

Fintech, AI, blockchain, and cybersecurity are among the rapidly growing tech-driven industries in the United Arab Emirates.. Starting a business in UAE in the IT sector is a smart move, as the government is heavily investing in technological infrastructure.

Innovative Business Ideas in IT:

AI Solutions: Create AI-driven solutions for companies in a range of industries, including retail, healthcare, and real estate.

Cybersecurity Services: Provide cybersecurity services to companies that want to safeguard their systems and data in a world that is digitizing quickly.

Blockchain Solutions: Develop blockchain-based software for logistics, finance, or supply chain management.

How to Enter These Markets

Understanding the local market, adhering to legal and regulatory requirements, and making the appropriate technological and infrastructure investments are all crucial for capitalizing on these lucrative industries. Starting a business in UAE requires careful planning, market research, and a solid business strategy. Operating in one of the numerous free zones can provide substantial tax benefits and streamlined business setup procedures for foreign business owners.

Start Your Business in the United Arab Emirates

Are you prepared to begin your business endeavors in the United Arab Emirates? The UAE provides business owners with a multitude of options, regardless of their interests in IT, e-commerce, real estate, or healthcare. Working with a reputable business setup company that can help you navigate local regulations and guide you through the process is essential to turning your vision into a reality.

Starting a business in UAE has never been easier. Establishing a successful business in one of the most dynamic and business-friendly environments in the world is possible with the correct business idea, strategy, and support.

#StartingABusinessInUAE#UAEEntrepreneurs#BusinessIdeasUAE#UAEStartups#EntrepreneurshipInUAE#UAEOpportunities#ProfitableBusinessesUAE#DubaiBusinessIdeas#BusinessSetupUAE#EntrepreneurialSuccess

3 notes

·

View notes

Text

How Indian rice manufacturers are shaping the global market

Indian rice has long held a place of pride in global kitchens, from the aromatic basmati grains that grace royal banquets to the nutritious non-basmati varieties that make up everyday meals worldwide. India is the world’s largest rice exporter, meeting over 40% of global rice demand (Source: FAO). Behind this success is the dedication and innovation of rice manufacturers in India, who are constantly adapting to meet international standards and market needs.

In this blog, we explore how Indian rice manufacturers are shaping the global market, promoting sustainability and securing India’s position as a rice exporting powerhouse.

Key factors driving Indian rice exports

Quality and Variety Rice manufacturers offer a diverse range of rice, from aromatic basmati to versatile non-basmati rice varieties. Each variety caters to different cuisines and preferences, ensuring steady demand in countries such as the United States, the Middle East, and Africa.

Competitive Pricing India's favorable agricultural conditions and cost-effective manufacturing processes enable competitive pricing. Combined with bulk export capabilities, this ensures that India remains a preferred supplier for global buyers.

Government policies and support Supportive government policies such as export incentives and trade agreements have contributed significantly to India's global dominance. For example, the recent removal of export restrictions on certain Indian rice varieties has boosted international trade opportunities.

Technological advances in rice manufacturing

Technology is transforming rice production in India, increasing efficiency and quality while reducing waste.

Modern milling equipment: Automated milling units maintain uniform grain size, texture and polish, which are critical to meeting international quality standards.

AI-powered sorting: Advanced sorting systems powered by artificial intelligence help eliminate impurities, ensuring that premium-grade rice reaches global markets.

Packaging innovations: Innovative vacuum-sealing and biodegradable packaging materials have made Indian rice more attractive to environmentally conscious buyers.

Rice manufacturers in India are adopting these advancements to maintain their competitive edge while meeting global priorities.

Sustainability initiatives by Indian manufacturers

As environmental concerns grow, rice exporters in India are adopting sustainable practices to meet global expectations.

Water-efficient farming: Techniques such as alternate wetting and drying (AWD) reduce water consumption, which is crucial for regions facing water scarcity.

Low carbon footprint: Adoption of renewable energy in processing units and adoption of eco-friendly logistics have reduced emissions in the rice supply chain.

Waste Utilization: By-products such as rice husk are being reused for bioenergy and building materials, thereby reducing waste and generating additional revenue streams.

These initiatives not only enhance India’s reputation but also align with the sustainability goals of global buyers.

Conclusion: The future of Indian rice on the global stage

The success of rice manufacturers in India is not just about meeting current demands, but also about shaping the future of the global rice trade. By prioritizing quality, leveraging technology, and adopting sustainable practices, Indian manufacturers have solidified their position as reliable partners in the global food supply chain.

As international markets evolve, India’s ability to adapt and innovate will continue to drive its leadership in the rice export industry, ensuring that Indian rice remains a staple in households around the world.

2 notes

·

View notes

Text

VIETFOOD & PROPACK VIETNAM 2024 exhibition

As a gathering place for hundreds of businesses with diverse business fields, Vietfood & Propack Vietnam 2024 exhibition has become an ideal place to bring organic products and rare opportunities to connect with partners. DARAVIN - booth Z44 - Z45 promises to bring the optimal solution for safe goods protection.

What's hot at Vietfood & Propack Vietnam 2024 exhibition? VIETFOOD & PROPACK VIETNAM 2024 is one of the largest and most prestigious trade events in Vietnam's industry and trade industry, especially in the food and beverage sector. This exhibition is not only a place to display and introduce processed food and beverage products, but also has the participation of hotel and restaurant supply services, along with processing equipment and packaging technology. and the most advanced food and beverage packaging.

With an ever-expanding scale and ever-improving quality, Vietfood 2024 has been receiving high appreciation from departments, businesses and visitors. This is not only an opportunity for domestic businesses to expand their business and develop their markets, but also a place for foreign companies to find distribution partners in Vietnam.

This year's exhibition promises to be an explosive event with a series of attractive and useful activities, from seminars and expert talks to experiential activities, business connections and product introductions. new product.

2 notes

·

View notes

Text

What are the Advantages of Mini Dairy Plant?

Advantages of Mini Dairy Plants

1. Local Sourcing and Freshness

One of the most significant advantages of mini dairy plants is their ability to source milk locally. This reduces transportation costs and ensures that milk is processed and distributed quickly, thereby preserving its freshness and nutritional value. Consumers today are increasingly conscious of where their food comes from and prefer products that are locally sourced and minimally processed.

2. Quality Control

With a mini dairy plant, producers have greater control over the entire production process. From milk collection to processing and packaging, every step can be closely monitored to maintain hygiene standards and ensure product quality. This level of control is crucial in meeting regulatory requirements and in building consumer trust.

3. Flexibility and Efficiency

Mini dairy plants are designed to be versatile and efficient. They can be set up in smaller spaces compared to traditional dairy facilities, making them ideal for rural areas or communities where space and resources may be limited. Moreover, these plants can often be operated with fewer staff, reducing labor costs and improving overall operational efficiency.

4. Support for Small-Scale Producers

For small-scale dairy farmers, mini dairy plants offer a viable solution to add value to their milk production. By processing their own milk into products like cheese or yogurt, farmers can increase their profitability and reduce dependency on volatile milk prices. This empowerment of local producers contributes to sustainable agricultural practices and strengthens rural economies.

What is a Mini Dairy Plant?

Challenges and Considerations

While mini dairy plants offer numerous benefits, there are some challenges to consider. Initial setup costs, regulatory compliance, and ensuring consistent product quality are among the primary concerns. However, with proper planning, investment, and adherence to industry standards, these challenges can be effectively managed.

Future Outlook

The future looks promising for mini dairy plants as consumer preferences continue to evolve towards healthier and locally sourced food options. Advances in technology and innovations in processing equipment are further enhancing the efficiency and sustainability of these facilities. Moreover, the ability of mini dairy plants to adapt to changing market demands and produce niche products presents exciting opportunities for growth and diversification within the dairy industry.

Conclusion

In conclusion, mini dairy plants represent a significant shift towards localized, sustainable, and high-quality dairy production. By bringing processing closer to the source, these plants not only ensure freshness and quality but also support local economies and empower small-scale producers. As we move towards a future that prioritizes transparency and sustainability in food production, the role of mini dairy plants is set to become increasingly pivotal in meeting consumer expectations and driving positive change in the dairy industry.

For more information, please visit our website:

Website : www.99businessvyapar.com

Contact No. : +91–9560336670, +91–8076381705, +91–9631021248

Email : [email protected], [email protected]

#Mini Dairy Plants#Mini Dairy Plants manufacturer#Mini Dairy Plants supplier in India#99 business vyapar

2 notes

·

View notes

Text

Printing Press in Sharjah: The Type of Service Your Business Needs

In the bustling emirate of Sharjah, where business and innovation thrive, the demand for reliable and high-quality printing services in Dubai is ever-present. A crucial aspect of marketing and brand communication, printing plays a pivotal role in shaping the identity of businesses. In this dynamic environment, choosing the right printing press in Sharjah becomes paramount. This article explores the various types of printing services available in Sharjah and how businesses can make informed decisions to meet their unique needs.

The Landscape of Printing Press in Sharjah

A Flourishing Industry

Sharjah, often referred to as the cultural capital of the United Arab Emirates, is home to a thriving printing industry. The emirate has witnessed significant growth in recent years, with numerous printing presses catering to the diverse needs of businesses ranging from small startups to large corporations.

Technological Advancements

One of the key reasons behind the success of the printing company Sharjah is its adoption of cutting-edge technologies. From offset printing to digital printing, these presses leverage state-of-the-art equipment to ensure efficiency, precision, and a wide range of capabilities.

Types of Printing Services Offered

1. Offset Printing

Offset printing remains a popular choice for businesses requiring large quantities of printed materials. This traditional method involves transferring ink from a plate to a rubber sheet, which then makes contact with the printing surface. Offset printing is known for its high-quality results, making it suitable for items like brochures, catalogs, and business cards.

2. Digital Printing

In the era of quick turnarounds and short print runs, digital printing has gained prominence. This method eliminates the need for printing plates, allowing for on-demand printing with minimal setup time. Digital printing is ideal for projects that require customization, such as personalized marketing materials, variable data printing, and short print runs.

3. Large Format Printing

For businesses looking to make a bold visual impact, large-format printing is the go-to option. This service is capable of producing oversized prints on various materials, including banners, posters, and signage. Large-format printing is crucial for events, trade shows, and outdoor advertising, providing businesses with a powerful tool to capture attention.

4. Promotional Items Printing

Printing press in UAE also offers services for printing on promotional items. This includes branded merchandise like pens, mugs, and T-shirts. Businesses can enhance their marketing efforts by incorporating their logos and messaging onto these items, creating tangible and memorable connections with their target audience.

5. Packaging Printing

In the competitive landscape of retail, packaging plays a crucial role in attracting customers. Printing press in Sharjah provides specialized services for packaging printing, ensuring that products stand out on the shelves. Whether it's food packaging, cosmetic boxes, or product labels, these presses deliver high-quality packaging solutions.

Choosing the Right Printing Press In Sharjah

1. Understanding Your Needs

Before selecting a printing press in Sharjah, it's essential for businesses to clearly define their printing needs. Consider the type of materials to be printed, the desired quantity, and any specific customization requirements. This initial assessment sets the foundation for finding a printing press that aligns with the unique goals of the business.

2. Quality and Technology

The quality of printed materials reflects directly on a business's image. When choosing a printing press, inquire about the technologies they employ and the quality control measures in place. High-resolution printing, color accuracy, and attention to detail are crucial factors that contribute to the overall quality of the final product.

3. Turnaround Time

In the fast-paced business environment of Sharjah, turnaround time is a critical consideration. Different printing presses may have varying production timelines. Businesses should communicate their timelines and deadlines upfront to ensure that the printing press can meet or exceed expectations.

4. Cost Considerations

While quality is paramount, businesses must also consider the cost implications of their printing projects. Obtain detailed quotes from the potential printing press in Sharjah, including any additional charges for customization or expedited services. Comparing costs against the expected quality and services helps businesses make informed decisions.

5. Customer Reviews and Reputation

Before finalizing a choice, it's advisable to research the reputation of the printing press. Customer reviews, testimonials, and case studies provide valuable insights into the experiences of other businesses. A printing press with a positive track record of customer satisfaction is more likely to deliver reliable and satisfactory results.

Conclusion

In the vibrant business landscape of Sharjah, choosing the right printing press is a strategic decision that can significantly impact a company's success. Whether it's traditional offset printing for large quantities or cutting-edge digital printing for on-demand needs, the diverse range of services offered by the printing press in Sharjah caters to the multifaceted requirements of businesses. By understanding their unique printing needs, and considering factors like quality, turnaround time, cost, and reputation, businesses can forge lasting partnerships with printing presses that elevate their brand presence and communication.

2 notes

·

View notes

Text

Ad It Up

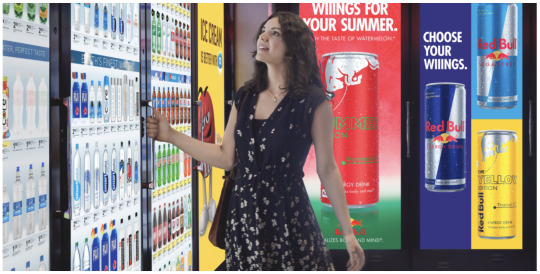

You only thought it was difficult to escape the marketer’s voice. From traditional media like outdoor, print, and broadcast, to a variety of ads littering our social media feeds, web pages, and search results, marketers have been seemingly everywhere trying to get our attention. And the more they tried, the louder they had to shout, because it’s crowded out there, and the decibel level—whether audible or visual—is increasing.

Except perhaps in stores and at the gas pump, where we felt like we at least had a few minutes of quiet. That, too, is changing rapidly, as in-store advertising has gone digital, to the point of it being called “broadcast-level scale.” Gas pumps too are now coming equipped with video screens to sell to us while we are filling our tank.

It’s all a mixed bag right now of ads, with gas stations able to deliver hyper-local advertising for third-party advertisers nearby. Inside the store, the campaigns are aimed at the masses instead of using an audience-of-one approach.

I see the day coming, though, in which advertising at the pump will be increasingly one-to-one (remember, you have to insert or tap your card first, which could then quickly allow them to access a profile of you).

And the same goes for inside the store, especially once retail formats like Amazon’s “Just Walk Out” technology are deployed widespread. Your presence and unique data would be detected wherever you go in the store as the system monitors your shopping basket, and messages could be directed straight to you when you ponder the pasta sauces or wherever you go.

We’ve come a long way when it comes to in-store advertising. The majority of what we have seen usually involves massive stacks of soft drinks, the red, white, and green packages from Coca-Cola cleverly arranged to spell words or form images. The same goes for snack foods and beer leading up to the Super Bowl. Otherwise, maybe some small shelf hangers might try to whisper a marketing message.

Now, though, there is the possibility of smart screens attached to the clear refrigerator doors, behind which beverages of all kinds reside. Stand-alone screens can also welcome customers as they walk in. The possibilities are limitless, because LCD screens are cheap, and can all be managed remotely.

All of which speaks to this emerging truth: the retail store and gas stations are now viable platforms for advertising, a rentable space little different from billboards, TV, and the internet. The battle for our attention just found a new place to stage that fight. It allows retailers to boost their revenues and bottom lines above and beyond just selling things.

It’s happening in the online arena as well. Have you noticed how many sponsored spots there are on any Amazon results page? Amazon scored $12 billion in ad revenues in Q3 2023 alone. That’s impressive, especially when you consider that Amazon’s total revenue that quarter was $143 billion. In other words, advertising made up one in every 12 dollars of its revenues.

I predict a similar such cascade of revenues for any retailer willing to parse out its interior—and exterior—space for advertising purposes. After all, why not? If you can hit people right when they are coming to spend money anyway, this is pretty simple.

Truthfully, I do not mind the ads, especially if they point me to things I might be interested in. Elevate it to audience-of-one capability, and it is even better. I know…some people will be creeped out by this, just like they have been with all the targeted advertising we see online. I would much rather hear and see ads for things I am likely to buy, as opposed to things I will never buy. Every time I hear that Tampax ad on one of my podcasts, I think about how they’re foolishly wasting half of their ad spend on men like me.

Others may see such ubiquitous advertising as further invasion of their private space, a harbinger of a dystopian society to come. Or maybe it has already arrived. To each their own, but there is no ad blocker yet for the brick and mortar world, and the best you can do is shut your eyes and ears, and walk on by.

Or out.

Dr “Talk To Me” Gerlich

Audio Blog

3 notes

·

View notes

Text

5 Tips to Identify the Perfect Customer Cohorts for Your New Product Line: Ken Research

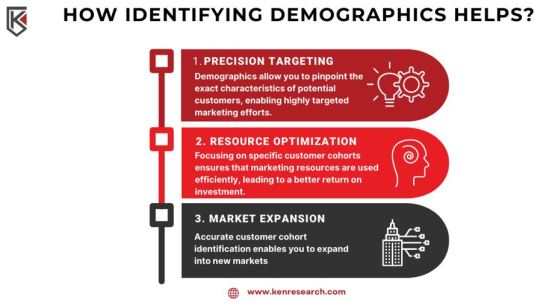

It is always an exciting journey for any brand to launch a new product line. But knowing your audience inside out is one of the critical aspects of success. By pointing to the right cohorts of your targeted consumer, you can tailor your marketing efforts and product features that resonate with your consumers. So, how can you identify those cohorts? Here is a list of 5 ways that can enable you to tap perfect customer cohorts for your new product line.

1. Data-Driven Demographics:

To identify the segments that align with your product line, begin with demographics. Determine the age, gender, location, income, and education of your targeted consumer.

For example, Apple identified a cohort that focused on a more budget-friendly iPhone option without compromising performance. So, they introduced the iPhone SE that targeted individuals who look for the latest technology in a smaller affordable package. That’s how Apple catered to a specific segment of the market after understanding this cohort’s preference for a compact and cost-effective device.

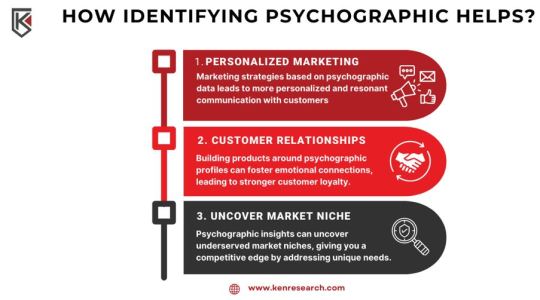

2. Psychographic Profiling:

Demographics are important but if you want to flourish in the market, it is not enough. You need to delve into psychographics- the attitudes, values, and lifestyle choices of your potential consumers.

Lululemon, the activewear brand that is known for its premium women’s activewear, diversified its product line to include men's activewear as well. It is because they recognized the rising cohort of health-concern males seeking stylish yet comfortable workout apparel. That’s how Lululemon tapped into a previously underserved segment, and capitalized it.

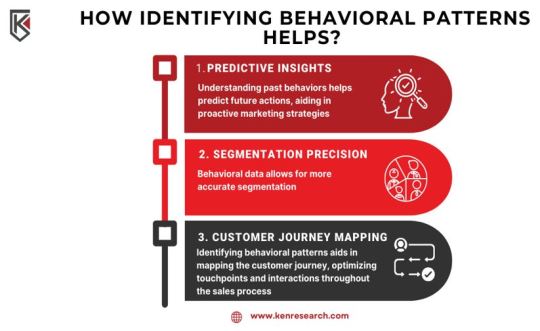

3. Behavioral Patterns:

The third comes to behavioral patterns. It is another important way to determine the right cohort. Examine consumer behavior to unleash some actionable insights. Just like Beyond Meat did.

Beyond Meat analyzed a cohort of environmentally and health-conscious individuals who were looking for alternatives to traditional meat. That’s when they launched plant-based burgers that replicate the exact taste and texture of meat. This also addressed sustainability and health which became one of the attributes behind the success of Beyond Meat. They wonderfully created a product line that served the requirement for ethical and nutritious food options.

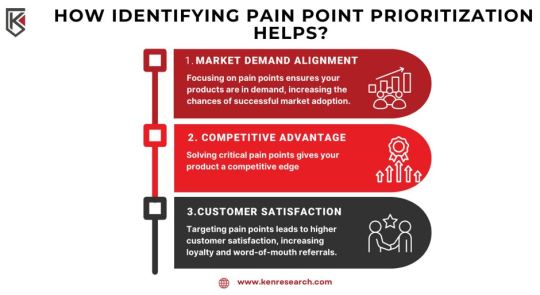

4. Pain Point Prioritization:

Addressing the pain point of your customer and offering them the right solution is the best way to thrive in the market. Hence, identify the issues or challenges that your services or products can resolve just like Peloton did.

Wish to know the pain points of your consumers? Book a free discovery call with Market experts

It recognized a cohort of fitness enthusiasts who seek a convenient and engaging place for workouts and that’s it. Peloton launched a wide range of connected exercise equipment and online classes that cater to consumers who prefer personalized fitness experiences from the comfort of their homes. This resulted in the rapid growth and success of the brand.

However, not everyone gets lucky in tapping the whitespaces in the market. That’s why over 500+ CXOs chose Ken Research to enable them to identify the consumer’s challenges and make a successful business by offering solutions to those issues.

Do you also wish to determine the pain points of your targeted consumers and build a thriving business? Visit the website now or fill in the details to receive a Free 30 minutes of call with Ken Consultants today.

5. Social Influences and Networks:

While you are trying to find out cohorts, it’s important to consider the social dynamics that may influence your key audience or clients.

Casper an e-commerce company that sells sleep products online and in retail locations, spotted a cohort of young adults, especially millennials who appreciated convenience and a seamless online shopping experience. And there they disrupted the whole mattress industry by launching memory foam mattresses in a compact box and leveraging a direct-to-customer model. This helped Casper gain a strong foothold in the market simply by offering this cohort’s preferences for hassle-free purchasing.

To sum it all up, understanding your consumer cohorts is an excellent way for launching a successful new product line. Several brands have demonstrated the impact of applying these strategies in various contexts and you can do it. Just make use of data, understand psychographics, focus on customer behaviors, address their pain points, and not to forget, consider their social dynamics. Doing this will surely help you tailor your strategy to resonate with a specific group and make a significant business impact. In case, you need some consumer data to back your business strategy, consider Ken research to get some authentic customer insights. Visit the website now.

2 notes

·

View notes

Text

Box Compression Tester Manufacturer and Supplier in India

Source of Info: https://www.perfectgroupindia.co.in/blog/box-compression-tester-manufacturer-and-supplier-in-india

Introduction

Indian manufacturers and suppliers of Box Compression Tester guarantee that packaging materials fulfill strength requirements for secure product delivery. By choosing the boxes' and cartons' compression strength, these testers help in avoiding damage. Reducing losses and maintaining quality during transport are advantageous to industries. Purchasing trustworthy testing equipment raises the standard of packaging as a whole. Modern testing tools are offered by Perfect Group India to help manufacturers fulfill high standards. These testers guarantee that packaging maintains its strength under pressure with reliable results and easy-to-use features. Using excellent technology improves product safety and helps businesses in successfully following packaging standards.

What is a Box Compression Tester?

A unique instrument called a Box Compression Tester offers the highest load that a box or carton can support before deforming. The box is compressed smoothly by the machine until it collapses. The test guarantees that products stay safe while in transportation and helps manufacturers to measure the overall strength of packaging materials.

Applications of Box Compression Tester

A device is widely used in various industries where product safety and packaging strength are important.

1. Corrugated Packaging Industry

Corrugated boxes get used a lot for storage and transportation. The capacity of these boxes to withstand outside pressures while being transported is guaranteed by Perfect Group India.

2. E-commerce Sector

As e-commerce advances it's important to make sure the products arrive undamaged. E-commerce businesses can reduce product returns and maintain packaging standards.

3. Pharmaceutical Industry

Pharmaceuticals and medical supplies must be packaged securely. This Instrument analyzes the packaging's strength to protect against delicate products being harmed.

4. Food and Beverage Industry

Maintaining product quality in the food industry depends on the quality of the packaging. Making sure the packaging can withstand the pressures of stacking and shipping is made easier with the use of a equpiment.

Benefits of Using a Box Compression Tester

1. Improved Packaging Quality

By guaranteeing that product packaging satisfies required standards, a Box Compression Tester lowers the possibility of product damage.

2. Cost Reduction

Manufacturers can make well-informed decisions about improving quality, reducing losses and decreasing returns by identifying weak packaging materials.

3. Compliance with Industry Standards

Manufacturers can guarantee that their products are prepared for international markets by using Testers to help them follow national and international packaging standards.

4. Customer Satisfaction

Product damage is decreased by strong and dependable packaging, increasing customer satisfaction and lowering complaints.

How to Use a Box Compression Tester?

To guarantee accurate results, using the device requires following a step by step process.

Step 1: Prepare the Box Sample

• Select the box or carton to be tested.

• Provide that the box is clean and free from defects.

Step 2: Place the Box on the Tester

• Open the compression plates and place the box between them.

• Make sure the box is properly aligned to prevent skewed results.

Step 3: Set the Test Parameters

• Use the control panel to enter the desired test parameters, such as the load and duration.

• Select the mode of testing based on industry requirements.

Types of Box Compression Tester

1. Digital Tester

Results from a Digital Tester are provided on a digital screen in real time. It offers easy data interpretation and high accuracy.

2. Manual Tester

Manual testers are suitable for smaller tasks because they require the operator to manually apply force. They might not provide as much accuracy as digital testers.

3. Computerized Tester

Automated control, data recording and analysis are made possible by digital models. Large-scale production settings that need thorough testing reports are the perfect fit for them.

Factors to Consider When Choosing a Box Compression Tester

1. Load Capacity

Select a tester capable of withstanding the highest load expected for the materials you use for packaging.

2. Accuracy and Precision

Select a model that reduces errors and provides consistent, dependable results.

3. User Interface

Management is made simpler and user errors are less likely with a user-friendly interface.

Why Choose Perfect Group India?

Perfect Group India is manufacturer and supplier of equipment known for their reliability and durability. Our testers are designed to meet the highest industry standards and offer the following benefits:

• Advanced Technology: Modern technology is used in the manufacture of our equipment to deliver reliable and accurate results.

• Customizable Solutions: We provide solutions that are made to satisfy the demands of various industries.

• Exceptional Customer Support: We provide comprehensive training and ongoing support to improve smooth users.

Conclusion

In the packaging industry Box Compression Tester is an important tool to measure the compressive strength of corrugated boxes, cartons and other packaging materials. It finds the amount of force a box can withstand before collapsing guaranteeing that the packaging will hold up through handling, storage and transport. A Packaged tester is important for guaranteeing product safety in sectors that depend on higher packaging. Container compression testers that are reliable, high-performing and made to the highest industry standards are offered by Perfect Group India trusted manufacturer and supplier.

0 notes

Text

Bakery Processing Equipment Market Global Market Size 2025–2035

Market Overview

The Bakery Processing Equipment Market was valued at USD 14.75 Billion in 2024 and is projected to reach USD 29.8 Billion by 2035, growing at a CAGR of 6.6% between 2025 and 2035. This market includes equipment like mixers, ovens, proofers, slicers, depositors, and packaging machines essential for producing baked goods such as bread, cakes, cookies, and pastries. Request Sample- https://www.metatechinsights.com/request-sample/1795

Market Drivers

Urbanization & Consumer Preferences: Increased demand for baked items driven by urban lifestyles and changing food habits.

Health-Conscious Trends: Rising demand for gluten-free, organic, and healthy baked goods pushes innovation in baking technology.

Automation & Innovation: Advanced, automated equipment ensures efficiency, consistent quality, and reduced operational costs.

Emerging Markets: Rapid expansion of bakery chains in regions like Asia-Pacific creates demand for high-capacity, automated machinery.

Full Report- https://www.metatechinsights.com/industry-insights/bakery-processing-equipment-market-1795

Market Restraint

High Initial Investment: Cost barriers for small-scale or start-up bakeries limit their ability to invest in modern, automated equipment.

Market Opportunity

Specialized Equipment: Rising interest in health-conscious baked items boosts demand for gluten-free and organic-friendly machinery.

Cold Chain Solutions: Increased demand for frozen bakery products fuels the need for cold-chain-compatible baking systems.

Segmental Analysis

By Equipment Type

Mixers – Crucial for uniform ingredient blending.

Ovens & Proofers – Aid in baking and fermentation, ideal for artisanal breads.

Dividers & Sheeters – Enhance dough shaping efficiency.

Molders – Essential for standardizing shapes.

Slicers & Packaging – Meet consumer demand for ready-to-eat and pre-packaged options.

By Application

Bread Processing – Dominates due to high global consumption.

Cakes & Pastries – Gaining traction with growing demand for premium, indulgent bakery items.

Cookies & Biscuits – Growing demand for portable, snackable baked goods.

Pizza Crust Processing – One of the fastest-expanding segments worldwide.

Regional Overview

North America

Dominant due to a mature bakery industry and constant demand for frozen and healthy baked goods.

Innovations include AI-integrated mixers and energy-efficient ovens.

Asia-Pacific

Rapidly expanding due to urbanization, rising disposable incomes, and shifting dietary habits.

Countries like India and China lead the frozen bakery sector.

Buy Now- https://www.metatechinsights.com/checkout/1795

Competitive Landscape

Top players include: GEA Group, Ali Group, Heat and Control, John Bean Technologies (JBT), Baker Perkins, among others.

GEA innovates in mixing/baking systems.

Ali Group develops energy-efficient baking systems.

JBT launches holistic bakery lines.

Heat and Control emphasizes automation in mass production.

Recent Developments

Dec 2024: UN WFP donated $870,000 worth of equipment to Ukrainian bakeries near the frontlines.

Nov 2024: Monomoy Capital Partners acquired Oliver Packaging and Equipment, enhancing its portfolio in the food processing sector.

#Bakery Equipment Market#Baking Machinery Trends#Automated Bakery Processing#Global Bakery Industry#Baking Equipment Forecast#Bread Processing Equipment#Industrial Baking Technology#Bakery Machines Market Growth

0 notes

Text

Top 5 Oil and Gas Suppliers in UAE | Trusted Partners for Industrial Excellence

The UAE stands at the forefront of the global energy market, with its robust oil and gas industry playing a pivotal role in driving economic growth and industrial development. From upstream exploration to downstream distribution, the country is home to some of the world’s most reliable and innovative oil and gas suppliers.

1. Takmeel Trading

Location: Dubai, UAE Specialization: Industrial lubricants, base oils, greases, fuel additives, and specialty chemicals

At the top of our list is Takmeel Trading, one of the most trusted oil and gas suppliers in the UAE. Known for its client-centric approach and high-quality product range, Takmeel Trading serves a wide array of industries, including automotive, marine, construction, energy, and manufacturing.

We offer:

Premium-grade engine and hydraulic oils

Marine lubricants and industrial greases

High-performance base oils

Specialty chemicals and fuel treatment solutions

Bulk and packaged delivery options across UAE

What sets Takmeel Trading apart is our focus on quality assurance, timely delivery, and customized solutions tailored to your industry’s specific needs. Our team works closely with global brands and refineries, ensuring clients get access to international-grade products with local support.

2. ENOC (Emirates National Oil Company)

Location: Headquartered in Dubai Specialization: Oil refining, marketing, lubricants, aviation fuel, and natural gas

ENOC is one of the largest integrated oil and gas companies in the Middle East, backed by the government of Dubai. Operating across the energy value chain, ENOC provides everything from exploration and refining to fuel retail and supply chain management.

Its lubricants division — ENOC Lubricants—caters to sectors such as transport, marine, aviation, and industrial manufacturing with internationally certified products.

ENOC’s strong retail presence and infrastructure, combined with its emphasis on innovation and environmental sustainability, make it a go-to choice for many businesses across the UAE.

3. ADNOC Distribution

Location: Abu Dhabi, UAE Specialization: Fuel distribution, lubricants, natural gas, and aviation fuel

A subsidiary of ADNOC Group, ADNOC Distribution is a powerhouse in the UAE’s energy sector. With a network of over 500 service stations and strong logistics capabilities, ADNOC ensures reliable delivery of petroleum products, especially across Abu Dhabi and the Northern Emirates.

ADNOC’s Voyager Lubricants brand has gained popularity for its extensive range of engine oils, gear oils, and greases that meet global standards. Their industrial and marine clients benefit from ADNOC’s expertise, long-standing credibility, and state-of-the-art storage and delivery systems.

4. TotalEnergies Marketing Middle East

Location: Dubai, UAE Specialization: Automotive and industrial lubricants, fuel solutions, and gas distribution

A global name in the energy sector, TotalEnergies operates actively within the UAE, offering a broad portfolio of lubricants and fuel products for industries such as automotive, power generation, transportation, and food manufacturing.

Known for their technologically advanced formulations, TotalEnergies provides lubricants that enhance equipment lifespan, reduce maintenance costs, and optimize performance. Their extensive R&D investment ensures innovation in eco-friendly and energy-efficient solutions.

TotalEnergies also partners with various sectors for bulk fuel and gas supply, supported by an efficient local distribution network.

5. Chevron Al Khalij (Gulf Oil Lubricants)

Location: Dubai, UAE Specialization: Premium lubricants, greases, and industrial oils

Chevron Al Khalij, operating under the Gulf Oil and Texaco brands, has a strong foothold in the UAE market. The company supplies high-quality lubricants and chemicals to clients in the oilfield, industrial, automotive, and transport sectors.

With global R&D support and strong local operations, Chevron Al Khalij provides solutions that meet international safety and performance standards. Their customer service, technical consultation, and distribution capabilities make them a reliable partner for businesses seeking durability and performance.

Why Choosing the Right Supplier Matters

The UAE’s demanding industrial sectors require more than just fuel — they need efficiency, reliability, compliance, and cost optimization. The right supplier ensures:

Timely and safe product delivery

Product quality that matches global standards

Technical support for application and compatibility

Competitive pricing for long-term sustainability

Certifications and environmental compliance

Partner with Takmeel Trading — Your Trusted Oil & Gas Supplier in UAE

With years of industry expertise, a commitment to excellence, and a client-first approach, Takmeel Trading stands as your ideal partner for all oil, gas, and lubricant needs across the UAE.

Whether you need bulk deliveries, technical consultation, or custom product solutions — we are ready to support your operations with quality, trust, and unmatched service.

📞 Get in touch today to request a quote or learn more about how we can support your business.

#OilAndGasUAE#OilandGasSuppliers#UAEEnergySector#OilSuppliersUAE#GasSuppliersUAE#IndustrialLubricantsUAE#EnergySolutionsUAE#TakmeelTrading#UAEOilIndustry#DubaiOilAndGas#AbuDhabiEnergy#OilAndGasDistribution#FuelSuppliersUAE#BaseOilsUAE#LubricantSuppliersUAE

0 notes

Text

Kafal Spices: Leading the Way Among Spices Manufacturers in India

India is globally renowned for its vibrant and diverse spice heritage, and at the heart of this legacy stands Kafal Spices, a name that resonates with quality, authenticity, and trust. As one of the top spices manufacturers in India, we take pride in preserving the traditional essence of Indian spices while integrating modern manufacturing processes to meet international standards.

In this blog, we take you through what makes Kafal Spices a trusted brand among Indian spice manufacturers, highlighting our specialization as a garam masala manufacturer, our growing reputation among garam masala wholesale suppliers, and our commitment to quality as a top red chilli powder manufacturer and one of the leading red chilli powder suppliers in the market.

The Lgacy of Indian Spices

India’s spices are the soul of its culinary culture. From the aromatic blend of garam masala to the fiery punch of red chilli powder, these ingredients not only add flavor but also hold medicinal and cultural significance. As leading Indian spice manufacturers, Kafal Spices is proud to be a part of this tradition, bringing authentic Indian flavors to kitchens across the world.

Kafal Spices: A Trusted Name Among Spices Manufacturers in India

As a brand, Kafal Spices is committed to quality, consistency, and customer satisfaction. What sets us apart from other spices manufacturers in India is our emphasis on purity, our modern processing units, and our direct sourcing from the finest farms across the country.

Our state-of-the-art manufacturing facility adheres to strict hygiene and safety standards, ensuring that our spices retain their natural aroma, flavor, and nutritional value. From sorting and cleaning to grinding and packaging, every step is carefully monitored to maintain premium quality.

Why hoose Kafal Spices?

Farm-to-Fork Approach We work closely with farmers to source the best raw materials, ensuring full traceability and transparency. This helps us maintain high standards as a trusted red chilli powder manufacturer and garam masala manufacturer.

Cutting-Edge Technology Our processing units are equipped with the latest machinery that guarantees hygienic and uniform grinding, essential for bulk spice supply.

Bulk Supply & Wholesale Network As leading garam masala wholesale suppliers and red chilli powder suppliers, we cater to bulk orders for businesses, retailers, restaurants, and international buyers.

Quality Assurance Our products undergo rigorous quality checks at every stage, from raw material procurement to final packaging.

Customizable Packaging We offer private labeling and customizable packaging solutions to meet the specific needs of B2B clients.

Garam Masala Manufaturer: Our Signature Blend

Garam masala is more than just a spice blend; it's the soul of Indian cuisine. As a seasoned garam masala manufacturer, Kafal Spices has perfected the art of blending spices like cardamom, cumin, cinnamon, cloves, and more to create a balanced and aromatic mix that enhances any dish.

Our garam masala is crafted using traditional recipes passed down through generations, while incorporating modern manufacturing techniques to ensure consistency and purity in every batch.

Being recognized as one of the top garam masala wholesale suppliers, we are proud to supply bulk garam masala to supermarkets, restaurants, and spice retailers across India and beyond.

Red Chilli Powder Manufacturer: Bringing the Heat

India produces some of the spiciest and most flavorful chillies in the world. At Kafal Spices, we carefully select sun-dried red chillies from top chili-growing regions, grind them using advanced techniques, and pack them in hygienic conditions to deliver the finest red chilli powder.

Our chili powder is known for its vibrant color, pungent flavor, and consistent quality—earning us recognition as a leading red chilli powder manufacturer in India. Whether you're a food brand or a retailer looking for trusted red chilli powder suppliers, Kafal Spices is your go-to source.

We offer multiple varieties of red chilli powder such as:

Regular Hot Red Chilli Powder

Kashmiri Red Chilli Powder (for rich color and mild heat)

Blended Red Chilli Powders (as per client specifications)

Kafal Spices for Export and Global Supply

Our commitment to quality has helped us expand beyond Indian borders. Today, Kafal Spices is a globally recognized exporter, catering to international markets with a wide range of Indian spices. From garam masala wholesale supply to bulk red chilli powder exports, our global distribution network ensures timely and safe delivery.

We follow international standards and certifications, making us a trusted name among Indian spice manufacturers in the global marketplace.

Our Product Range

While garam masala and red chilli powder are our flagship products, we offer a wide assortment of Indian spices, including:

Turmeric Powder

Coriander Powder

Cumin Seeds

Whole Spices

Blended Masalas (customized for different cuisines)

This diverse portfolio positions Kafal Spices as one of the most versatile spices manufacturers in India.

Partne With Kafal Spices

Whether you're a food manufacturer, distributor, wholesaler, or private label brand, Kafal Spices is equipped to meet your needs. With competitive pricing, consistent supply, and unmatched quality, we are among the most reliable garam masala wholesale suppliers and red chilli powder suppliers in the industry.

Here’s why businesses love working with us:

Bulk ordering and timely fulfillment

Customizable spice blends

Reliable logistics and export documentation

Transparent communication and partnership

Final Thoughts

The Indian spice market is competitive, but quality always stands out. At Kafal Spices, we’re proud to lead with integrity, innovation, and a passion for excellence. As top-tier spices manufacturers in India, our goal is to bring the richness of Indian spices to homes and businesses around the world.

Whether you're looking for a reliable garam masala manufacturer, trusted red chilli powder suppliers, or experienced Indian spice manufacturers, your search ends with Kafal Spices.

Get in ouch Today! Explore our full range of spices, request a sample, or discuss your bulk requirements. Visit our website or contact us to discover why Kafal Spices is the preferred choice among spices manufacturers in India.

#spices manufacturers in india#indian spice manufacturers#garam masala manufacturer#garam masala wholesale suppliers#red chilli powder manufacturer#red chilli powder suppliers

0 notes

Text

Refrigerated Truck Body Builders: Powering the Cold Chain Industry

Introduction: Keeping It Cool on the Move

The world of logistics is rapidly evolving, especially for industries that rely on temperature-controlled transport. From pharmaceuticals and seafood to dairy and frozen foods—delivering these products safely is only possible through well-built refrigerated trucks. That’s why the expertise of refrigerated truck body builders becomes essential.

These experts design, fabricate, and build specialized truck bodies equipped with insulation and cooling systems that ensure temperature stability during transit. If you’re in the market for a reliable refrigerated truck, understanding the importance of a high-quality build is essential.

What is a Refrigerated Truck Body?

A refrigerated truck body, often called a reefer truck, is a specially designed vehicle equipped with an insulated cargo area and a refrigeration unit. This setup ensures that perishable or temperature-sensitive items are transported within the necessary temperature range. But the efficiency of a reefer truck doesn’t just depend on the cooling unit—it heavily relies on the quality of the truck body construction.

Why Refrigerated Truck Body Builders Matter

A good refrigerated truck body builder understands more than just metal and insulation—they understand the science of cold chain logistics. Here's why their expertise matters:

Precision Engineering: The cargo area must be perfectly sealed and insulated to prevent temperature loss.

Custom Solutions: Different industries have different needs—builders provide tailor-made sizes, compartmentalization, and cooling systems.

Compliance & Safety: Well-built truck bodies follow national and international food safety and transportation regulations.

Durability: Trucks often run across rough terrains—expert builders ensure long-lasting and resilient bodies.

Key Features of a High-Quality Refrigerated Truck Body

When evaluating refrigerated truck body builders, here are the top features to look for:

High-density PUF insulation ensures the interior stays consistently cool, even when outside temperatures are high.

Leak-Proof and Rust-Free Materials: Stainless steel or FRP (Fibre-reinforced plastic) panels ensure hygiene and longevity.

Custom Refrigeration Units: From deep freezing to simple chilling, systems can be customized for the client’s needs.

Robust Flooring: Anti-slip and heavy-duty flooring for safety and load durability.

Easy-to-Clean Interiors: Smooth internal walls allow for simple maintenance, especially for food-grade transport.

Applications Across Industries

Many sectors rely heavily on refrigerated trucks for smooth operations.

Pharmaceuticals – For vaccine and medicine transport.

Dairy & Ice Cream – To prevent spoilage and melting.

Seafood & Meat – To maintain freshness from port to plate.

Flowers & Plants – For preserving life span during long-distance travel.

Processed Foods – For retail-ready chilled or frozen foods.

Each use-case demands a specialized approach—which only experienced refrigerated truck body builders can deliver.

How to Choose the Right Refrigerated Truck Body Builder

Selecting the right builder is a long-term investment. Consider the following factors:

Industry Background – How many years have they been serving in this field?

Customization – Can they tailor builds based on your cargo needs?

Technology Integration – Are they using the latest insulation and cooling tech?

After-Sales Support – Do they provide maintenance or service packages?

Client Portfolio – Trusted builders will have worked with major cold chain companies or logistics firms.

Why Quality Matters in Cold Chain Logistics

Poorly constructed truck bodies can lead to temperature leaks, damaged cargo, and failed deliveries. This not only leads to financial losses but also affects a company’s reputation. That’s why working with top-rated refrigerated truck body builders is crucial—they ensure performance, safety, and reliability.

Final Thoughts

As the demand for cold chain logistics continues to rise, the role of refrigerated truck body builders becomes more significant than ever. Whether you're expanding your fleet or entering the cold logistics space for the first time, choosing a skilled builder is key to long-term success.

Well-built reefer trucks aren’t just vehicles—they’re moving temperature-controlled rooms, and they need to be designed with precision, care, and industry know-how.

#Refrigerated Truck Body Builders#Refrigeration for Trucks in Chandigarh#Refrigerated Truck Manufacturers in Punjab

0 notes

Text

Temperature Data Logger Market: Growth Driven by Cold Chain Expansion and Regulatory Compliance Demands

The temperature data logger market has witnessed significant growth in recent years, driven by a confluence of technological advancements, increasing regulatory standards, and rising demand across diverse industry verticals. A temperature data logger is a compact, self-contained device used to record temperature readings over time, which can then be analyzed for a variety of applications. These tools are crucial in ensuring product quality, maintaining regulatory compliance, and optimizing supply chain operations.

1. Growing Demand for Cold Chain Monitoring

One of the primary drivers of the temperature data logger market is the expanding global cold chain logistics sector. Industries such as pharmaceuticals, food and beverages, and chemicals require precise temperature control during storage and transportation to ensure product efficacy and safety. Vaccines, in particular, need to be maintained within strict temperature thresholds. The COVID-19 pandemic further amplified this demand as global vaccine distribution relied heavily on robust cold chain systems, accelerating the adoption of temperature monitoring solutions like data loggers.

2. Regulatory Compliance and Quality Assurance

Governments and industry regulatory bodies worldwide have established stringent guidelines for temperature-sensitive goods. Compliance with standards such as Good Distribution Practice (GDP), Good Manufacturing Practice (GMP), and the U.S. FDA’s 21 CFR Part 11 necessitates the use of temperature data logging equipment. These regulations ensure that proper storage conditions are met and that any temperature excursions are documented and analyzed. The growing pressure to meet these regulatory requirements is a strong driver for market growth.

3. Advancements in IoT and Wireless Technology

The integration of Internet of Things (IoT) and wireless technologies has revolutionized the temperature data logger landscape. Modern loggers now feature real-time monitoring, wireless data transmission, cloud storage, and mobile app integration. These innovations provide greater visibility and control over environmental conditions, enabling proactive responses to potential issues. The convenience and efficiency offered by connected devices have attracted a broader range of users, further propelling market expansion.

4. Increasing Use in Healthcare and Pharmaceuticals

The healthcare and pharmaceutical industries are among the largest users of temperature data loggers. These devices are used in hospitals, laboratories, and during the transportation of temperature-sensitive drugs and biological samples. The global rise in personalized medicine, biotechnology products, and biologics—many of which require strict temperature control—has contributed to increased demand. As the pharmaceutical industry continues to grow and innovate, so too does the need for reliable monitoring tools.

5. Rising Adoption in the Food and Beverage Sector

Ensuring food safety and maintaining product quality from farm to fork is critical in the food and beverage industry. Temperature data loggers are used extensively during food processing, packaging, storage, and distribution to ensure perishable goods remain within required temperature ranges. Consumer awareness and regulatory scrutiny regarding food safety have also heightened demand for temperature monitoring solutions, especially as global trade of perishable goods increases.

6. Cost Reduction and Product Innovation

Technological developments have enabled manufacturers to produce more cost-effective and compact temperature data loggers without compromising on features. Today’s models offer improved battery life, enhanced accuracy, increased memory capacity, and user-friendly interfaces. This has made them accessible to a wider range of businesses, including small and medium enterprises. The competitive landscape has also led to product differentiation, with some companies offering specialized loggers for unique applications, such as ultra-low temperature logging for cryogenic environments.

7. Environmental Monitoring and Sustainability Goals

Temperature data loggers are also gaining traction in environmental monitoring, agriculture, and climate research. As climate change continues to impact weather patterns and ecological systems, there is a growing need for accurate and long-term temperature data. Additionally, companies focused on sustainability are using these devices to monitor energy efficiency in facilities, ensuring HVAC systems are optimized and reducing overall carbon footprints.

8. Expansion of E-commerce and Global Trade

The global e-commerce boom has driven a need for enhanced logistics and delivery infrastructure. Temperature-sensitive products, including gourmet foods, cosmetics, and pharmaceuticals, are increasingly sold online and shipped across long distances. Data loggers play a crucial role in preserving product integrity during last-mile delivery. As cross-border e-commerce continues to expand, especially in emerging markets, so does the need for reliable temperature monitoring.

Conclusion

The temperature data logger market is poised for robust growth, fueled by the convergence of technological innovation, regulatory demands, and the need for precision in modern logistics. As industries become more reliant on data-driven decision-making and real-time monitoring, temperature data loggers are no longer a luxury but a necessity. Whether for ensuring the safety of a life-saving drug or maintaining the freshness of perishable goods, these devices are playing a pivotal role in modern supply chain and quality assurance systems. Continued investment in R&D and evolving customer needs are expected to further drive market innovation and adoption in the years to come.

0 notes

Text

Label Maker: Driving Tamper-Proof Label Innovation in the FMCG Sector

In today’s fast-moving consumer goods (FMCG) market, ensuring product authenticity and safety has become a top priority for brands worldwide. With the growing threat of counterfeit goods and heightened consumer awareness, tamper-proof labelling is no longer just an option—it is a necessity. Hologram labels, in particular, have emerged as a leading solution for safeguarding product integrity while elevating brand identity. Thanks to advancements in label maker technology, it is now easier than ever for FMCG brands to adopt secure, reliable, and visually compelling labelling solutions.

Super Labels stands at the forefront of this innovation, offering cutting-edge solutions in custom sticker printing, hologram labels, and roll form labels using state-of-the-art sticker label printers. Our expertise in printing labels ensures every product is equipped with tamper-proof protection without compromising on design or shelf appeal. Whether you're looking to secure packaged food products, beverages, cosmetics, or pharmaceuticals, our hologram solutions help brands achieve unparalleled levels of security and consumer trust.

Tamper-proof hologram labels play a crucial role in protecting consumers and preserving brand reputation. A single instance of tampering can severely impact customer confidence and pose serious health risks. By using our advanced label printers and specialized printing methods, Super Labels produces holograms that are highly secure and virtually impossible to replicate. These labels serve as visible proof of authenticity, deterring counterfeiters and reassuring customers that the product they are purchasing is genuine and safe to use.

Our sticker label printers offer exceptional quality and precision, making it possible to create detailed holograms with advanced visual effects. Combined with our roll form label formats, brands can scale their production while maintaining consistent label performance across different packaging types. From high-security seals to decorative labels with embedded features, our solutions deliver both functionality and aesthetic appeal.

As the demand for secure labelling grows, Super Labels continues to lead the industry with forward-thinking technology and unmatched expertise. Our goal is to help FMCG brands stay ahead of the curve by providing tamper-proof labelling that not only safeguards the product but also enhances consumer engagement and loyalty.

#sticker label printer#stickers#holograms#roll form labels#tamper-proof labels#label maker technology#FMCG labelling#secure product packaging#anti-counterfeit solutions#printing labels

0 notes

Text

Automation Programming in Edwardsville, Illinois | Smarter Industrial Control

Automation programming involves developing the software and logic that controls machines, equipment, and production lines. It’s the “brain” behind any automated system, enabling precise, repeatable, and adaptable actions without constant human intervention.

Key components include:

PLC Programming: Writing logic-based code to control equipment such as motors, sensors, and actuators.

HMI Design: Developing visual interfaces that operators use to monitor and interact with automated systems.

SCADA Integration: Supervisory control systems that collect and analyze data from across an entire facility.

Custom Automation Scripts: Logic tailored to unique processes and workflows.

In Edwardsville, automation programming is essential for companies that want to minimize downtime, improve product quality, and remain competitive.

Why Automation Programming Matters for Edwardsville

With its strong economic base and proximity to major markets like St. Louis, Edwardsville is home to a growing number of industrial operations. Whether it's a mid-sized packaging firm or a large-scale manufacturer, local businesses face increasing pressure to improve efficiency and throughput. That’s where automation programming comes in.

1. Operational Efficiency: Well-programmed systems eliminate manual tasks, speed up production, and reduce the likelihood of human error.

2. Quality Control: Automation ensures consistency across batches, helping companies meet strict quality standards.

3. Cost Savings: By reducing labor costs and minimizing material waste, automation delivers a strong return on investment.

4. Data Utilization: Modern systems provide actionable data insights, allowing operators and managers to make smarter decisions in real-time.

In Edwardsville, this translates into better-performing factories, safer work environments, and increased economic resilience.

Core Services Provided by Automation Programmers

Local automation programming companies in Edwardsville offer a range of services to support manufacturers across sectors. These include:

Custom PLC Programming: Tailored logic to manage specific machines or entire production lines.

HMI Interface Development: Easy-to-use control panels that display system data and allow for quick troubleshooting.

SCADA System Setup: Centralized control systems that integrate data from multiple sources.

Retrofit and Upgrade Services: Modernizing older machines with new control logic and communication protocols.

Process Optimization: Using analytics and automation logic to fine-tune production flow.

These services ensure systems operate at peak performance, even in complex, multi-stage production environments.

Industries in Edwardsville Benefiting from Automation Programming

Automation programming is not limited to one field. It plays a critical role across many Edwardsville industries:

Food & Beverage: Automating mixing, filling, and packaging for hygiene and speed.

Warehousing & Logistics: Conveyor control and sorting systems that reduce shipping delays.

Pharmaceuticals: Precision dosing and environmental controls for product safety.

Automotive Components: Robotic assembly coordination and inspection programming.

Metal Fabrication: CNC machine integration and real-time production monitoring.

These industries depend on accurate, flexible programming to respond to market demands while maintaining operational control.

Tools and Platforms Used in Edwardsville

Automation programming professionals in Edwardsville are proficient in a wide range of technologies and platforms, including:

Allen-Bradley / Rockwell Automation

Siemens TIA Portal

Mitsubishi PLCs

Omron and ABB Systems

Ignition SCADA

Wonderware (AVEVA)

Beckhoff TwinCAT

These platforms offer robust tools for machine control, process visualization, and data management—all essential for high-performance automation systems.

Workforce Training and Local Support

Edwardsville benefits from strong academic institutions like Southern Illinois University Edwardsville (SIUE), which offers programs in engineering, computer science, and industrial technology. These institutions help build a local talent pipeline of engineers and programmers equipped to design and maintain next-generation automation systems.

Additionally, ongoing partnerships between automation companies and local manufacturers ensure that workforce development aligns with real-world needs. On-the-job training and technical certifications are increasingly available to support career growth in automation programming.

Looking Ahead: Smarter Factories on the Horizon

With the rise of Industry 4.0, the future of manufacturing in Edwardsville is smart, connected, and data-driven. Automation programming is a key enabler of this future. Companies are beginning to adopt:

Remote Monitoring and Control

Cloud-Based Data Storage and Analytics

AI-Enhanced Predictive Maintenance

Digital Twin Simulations

These technologies offer unprecedented visibility and flexibility, allowing businesses to operate more efficiently and react quickly to changes in demand or supply chain conditions.

Your Edwardsville Automation Partner: Xtreme Automation LLC

If you're seeking professional automation programming services in Edwardsville, turn to the experts at Xtreme Automation LLC. With deep experience in PLC programming, HMI development, SCADA integration, and smart system upgrades, Xtreme Automation delivers tailored solutions that boost performance and cut downtime. Whether you're building a new line or upgrading legacy systems, their team ensures seamless automation from design to deployment. Learn more at xtremeautomationllc.com.

#Automation Programming Edwardsville IL#PLC Programming Services Illinois#Industrial Automation Edwardsville#HMI Systems Integration#Custom Control Systems Illinois#Manufacturing Automation Solutions#Programmable Logic Controllers#SCADA Systems Edwardsville#Industrial Software Engineering#Automation Services Metro East IL

0 notes

Text

Why Valency Agro is Emerging as the Top Beans Brand in India

India, known for its rich agricultural heritage, has always had a strong affinity for pulses and beans in its daily cuisine. Among the various agro commodities, beans hold a special place for their nutritional value, versatility in cooking, and long shelf life. With the increasing demand for premium-quality agricultural products, one name that is fast becoming synonymous with trust and excellence in the bean market is Valency Agro.

As a reliable and innovative Beans Brand in India, Valency Agro stands out by offering superior quality, stringent quality control, and consistent supply to meet both domestic and international demands.

Why Beans Matter in Indian Households

Before diving into the expertise of Valency Agro, let’s take a quick look at why beans are so important:

Rich in Protein: Beans are a major source of plant-based protein, especially important in vegetarian Indian diets.

Good Source of Fiber: They help with digestion and maintaining a healthy gut.

Affordable and Accessible: Beans are a cost-effective source of nutrition, making them a staple in Indian kitchens.

Versatile Usage: From rajma to lobia, beans are used in curries, snacks, salads, and even desserts.

Given their significance, it's essential that consumers have access to trustworthy brands that deliver nothing but the best. That’s where Valency Agro makes its mark.

Valency Agro: A Trusted Beans Brand in India

Valency Agro has carved a niche for itself in the Indian agro-industry through dedication, consistency, and a focus on quality. With years of experience and a strong supply chain network, the company has become one of the fastest-growing Beans Brands in India. Whether you're a household consumer or a large-scale food manufacturer, Valency Agro ensures that you receive the best quality beans at competitive prices.

What Sets Valency Agro Apart?

Premium Quality Beans

At Valency Agro, quality begins from the source. They partner with trusted farmers and maintain strict quality checks during harvesting, processing, and packaging. This ensures every batch meets the highest industry standards.

Wide Variety

From kidney beans (rajma) to black-eyed beans (lobia), Valency Agro offers a comprehensive range of beans suitable for diverse culinary applications.

Sustainable Farming Practices

Valency Agro promotes environmentally friendly agricultural methods. By supporting sustainable sourcing, the company contributes to better farming ecosystems.

Customer-Centric Approach

Customer satisfaction is a priority. The brand offers transparent dealings, timely delivery, and responsive service, making it a go-to Beans Brand in India.

Leading the Way as Top Beans Suppliers in India

Beyond being just a consumer-facing brand, Valency Agro is also recognized among the most reliable Beans Suppliers in India. The company caters to a wide range of industries including:

Food processing units

Retail grocery chains

Export houses

Institutional buyers

With large-scale warehousing, modern logistics, and advanced packaging technology, Valency Agro is equipped to handle bulk orders efficiently. This makes them one of the preferred Beans Suppliers in India for businesses looking for consistency and reliability.

Strengthening Supply Chains: Trusted Beans Dealers in India

A strong distribution network is the backbone of any agricultural company. Valency Agro has invested heavily in building a solid network of Beans Dealers in India. These dealers act as crucial links between the brand and end consumers, ensuring products are available across urban and rural markets.

Dealer Support: Valency Agro offers excellent support systems for their dealers, including training, marketing resources, and attractive incentives.

Availability Across India: Whether you’re in a metro city or a smaller town, Valency Agro beans are readily accessible through a growing number of local dealers and wholesalers.

By working closely with their partners, Valency Agro ensures their products reach millions of kitchens without compromising quality or service.

Beans Export Potential: Valency Agro on the Global Map

With Indian agricultural products gaining popularity globally, the export of beans is also rising. Valency Agro has started establishing its presence in international markets by exporting premium-grade Indian beans that meet global food safety and packaging standards. This positions Valency Agro not only as a leading Beans Brand in India, but also as a rising exporter with global ambitions.

Health-Conscious India: Fueling the Demand for Quality Beans

As Indian consumers become more health-conscious, the demand for clean-label, chemical-free, and nutrient-rich beans is soaring. Valency Agro has aligned its vision to meet these emerging trends by:

Offering organically sourced beans

Ensuring zero use of harmful preservatives

Maintaining high hygiene and food safety standards

These initiatives further strengthen Valency Agro’s position as a trusted Beans Company in India committed to wellness and nutrition.

How to Identify the Best Beans Brand?

When choosing the right Beans Brand in India, here are a few checkpoints that Valency Agro excels at:

Certifications and food safety compliance

Traceability and transparency

Customer feedback and reviews

Availability across various channels

Competitive pricing

Valency Agro ticks all these boxes and more, making it the ideal choice for households and businesses alike.

Final Thoughts

As the demand for high-quality, nutritious beans continues to grow, the importance of reliable agricultural brands cannot be overstated. With its strong focus on quality, trust, and innovation, Valency Agro has become a benchmark in the industry.

Whether you're a retailer, food processor, or a health-conscious consumer, you can count on Valency Agro—the leading Beans Brand in India—for the finest beans that support your health and culinary needs.

From sourcing and processing to supplying and supporting local dealers, Valency Agro stands tall as a holistic Beans Company in India. Their rapid growth as top Beans Dealers in India and Beans Suppliers in India is a testament to their commitment to excellence.

So, the next time you think of stocking your kitchen with healthy, high-protein beans, remember the name that’s trusted across the nation—Valency Agro.

0 notes