#Folding carton packaging company

Explore tagged Tumblr posts

Text

Give the food you serve a deserving upscale look with high quality folded carton trays, boxes, clams and wraps which are great to keep food hot and tasty for longer and stand out when served. We offer a broad choice of folded carton packaging for salads, sandwiches, burgers and other types of snack and finger foods. Our fluted packaging products have corrugated wall structure to keep food hot longer. We also manufacture a wide range of folding cartons for fast food restaurants.

Folded carton food boxes

0 notes

Text

Sustainability in Packaging: Dimple Packaging's Folding Carton Innovations

In the heart of Punjab, an unassuming yet remarkable company is making waves in the packaging industry. Dimple Packaging, based in this vibrant Indian state, has become synonymous with folding carton excellence, catering to a wide range of industries and clients. In a world where packaging plays a pivotal role in branding and product presentation, Dimple Packaging stands out for its innovation, quality, and commitment to sustainability.

Dimple Packaging's folding cartons are not just containers; they are a canvas for businesses to express their brand identity. With a keen understanding of the diverse needs of its clients, the company offers a variety of customization options, from materials and printing techniques to designs and finishes. Whether you're a food manufacturer, cosmetics brand, or pharmaceutical company, Dimple Packaging has a solution that will not only protect your products but also enhance their appeal on the market.

One of the key factors that set Dimple Packaging apart is its unwavering commitment to quality. The company uses state-of-the-art technology and the finest materials to ensure that every carton that leaves their facility meets the highest industry standards. This dedication to quality extends to their printing capabilities, with stunning graphics and vibrant colors that make every product stand out on the shelf. Their folding cartons are not just packaging; they are an integral part of a product's identity.

Dimple Packaging's commitment to sustainability is also worth noting. In an era where environmental consciousness is paramount, the company is at the forefront of sustainable packaging solutions. They use eco-friendly materials, implement energy-efficient production processes, and promote recycling and waste reduction. With Dimple Packaging, you can rest assured that your products will be packaged in a way that minimizes environmental impact.

The success of Dimple Packaging can be attributed to their tireless pursuit of customer satisfaction. Their dedication to providing the best solutions for their clients is evident in their ability to create packaging that not only protects the product but also adds value to it. This customer-centric approach has earned them the trust of a diverse clientele.

In conclusion, Dimple Packaging in Punjab is a shining example of excellence in the folding carton industry. Their unwavering commitment to quality, sustainability, and customer satisfaction has made them a preferred choice for businesses across various sectors. If you're looking for packaging that not only protects your products but also elevates your brand, Dimple Packaging is a name you can trust. With their innovative solutions, your products will make a statement on the market, all while contributing to a greener and more sustainable future.

#box packing punjab#carton box manufacturer punjab#packaging box punjab#box manufacturers punjab#packaging companies punjab#Dimple Packaging Punjab#Display folding cartons Punjab

0 notes

Text

365 Promises of God

Day 306 – We Are Presented Holy, Blameless, Above Reproach

in the body of His flesh through death, to present you holy, and blameless, and above reproach in His sight-- (Col 1:22 NKJV)

Read: Colossians 1:21-23

Many years ago, I worked for a company that made air conditioner registers, the very common variety that exist in almost every home with central heat and air. The plant that made these registers was located in Mexico, and I was sent there to train them how to use our computer system to properly plan to forecast. When I got there, I was given a tour of their seven million dollar production line. It was a simply amazing and complicated process of stamping and spot-welding metal parts, and a paint line that painted the finished products. They were sparkly when they were carefully set on a conveyor system after being professionally painted and dried. Beautiful parts moving back to back along a conveyor.

We followed the conveyor for what was about 50 yards, to a packaging station where 7 workers were packaging the parts. Each register was put in a fancy individual box buy guy #1, which was quickly folded and taped by guy#2, and guy #3 would take the completed individual boxes, and put six of them in a carton. Guy #4 would tape the cartons up and stack them on a pallet. Guy #5 would drive off with a full pallet, once complete, and guy #6 would place a fresh pallet in that place. Guy #7 was frantically forming cartons and individual boxes, and was always behind.

Since Guy #7 couldn’t keep up with demand, shiny registers passed everyone by, one by one, and fell on the concrete floor, getting marked and dented as a pile of finished not-so-new registers built up on the floor. I pointed at the guy waiting to put a pallet on the floor. “You should help that guy make boxes! He can’t keep up!”

His response was, “No, I’m the guy who places the pallet.”

I looked at guy #5. “You’re not doing anything while waiting for that pallet to fill up. You need to help that guy make boxes!”

He said, “No, I’m the guy that takes the pallets away.”

I spied a shiny red button by the end of the conveyor. I pointed to it and asked guy #7, “Why don’t you press that button and stop the production line until you can catch up?”

Everyone there started shaking their heads frantically, “NO NO NO NO! Only the plant manager can stop the production line!”

I then asked guys 5 and 6 to help guy 7, again, pointing at the stack of damaged registers. They repeated to me what their jobs were. I just shook my head as we walked away from that travesty in manufacturing.

I asked one of the supervisors why they were destroying expensive and perfectly good parts and why the workers couldn’t shift to fill the bottlenecks in the process. He said everyone had a specific job to do, and that they would get blamed if that job didn’t get done. Helping somebody else would expose them to getting blamed if that job wasn’t done right, and they were not required to do it anyway.

I mentioned that no matter how good a job they all did at their own pieces, they were all at fault if we shipped boxes of bent registers to our customers. He shrugged and said that the blame for that would go to the plant manager, who was the only one allowed to shut down a production line for any reason.

Less than a year later, the plant manager took the fall for this and many other manufacturing issues they discovered. He really did get the blame for them, and in a lot of respects, he deserved it. Compare this to the company I now work for, where workers freely move from position to position on a production line, helping each of them complete a production run. If anything is wrong with the parts at any stage, they can and do shut the production line down, because they all know that it’s better to fix an issue that caused 10 bad parts than to continue letting it run, producing a thousand bad parts.

You can bet that if we produce an entire run of mislabeled product, somebody is going to catch the blame for it, possibly losing their job. Blame is a painful thing to be on the receiving end of. I’ve gotten blamed for many things I didn’t do, and many other things I did. If you stacked those things I earned blame for, if each were an inch that blame train would be a thousand miles long. It might be the same for you too.

Isn’t it comforting to have a promise like this in the Bible, that we are going to be presented by Christ to God as holy, and blameless, and above reproach? All those things we did? The mistakes we made, the errors in judgement, even the willful sins we’re sorry about now, the ones we regret and hope nobody finds out about? Those have all been nailed to the cross, dear Christian, and you will NEVER have to get shouted at about them again.

Prayer:

Lord, thank you for this beautiful promise, that I won’t have to get blamed for what I’ve done, when I get to heaven. I can hardly wait. Help me, Lord, to keep short accounts with you, today. Amen

3 notes

·

View notes

Text

P1: Week 2 Planning and Creative Update

Through the five Rs assignment, I tried experimenting with the existing packaging to find if there was another way to get these packages to stay together.

I considered this more of a flexible exercise for my conceptualization rather than what was applicable to my project as I had already decided what the container would likely look like.

I found that even with the somewhat clumsy design of the BuzzBalls, stacking and arranging them allowed for many creative ways to keep them together. I was even partially inspired after the fact by comparing them to apple sauce cups. I even found the packaging could feasibly fit around the BuzzBalls.

However, I knew that most of this was adding on excess packaging. Although they would be on more interesting display that the companies original packaging of just a cardboard box, I knew my cartons would need to be stored in a different way.

I did also consider how the text would be displayed as I found that even the simple ball shape required a lot of manipulation from the hand and wrist to read.

I found altering the basic cartons design proved to be a significant challenge. Most ideas came from the need to make the package distinct enough from a regular milk carton.

Originally the need was to make sure that kids or their guardians would recognize this carton as an alcoholic beverage. It quickly became apparent that the distinction would have to made through the graphical design rather than the design of the package itself.

One fruitful package design had the folds of an original juice box that could be peeled to open it’s contents. However I felt that in this stage of the process it was becoming akin to re-inventing the wheel.

I stuck with the carton design with the sentiment that BuzzBoxes and BuzzBalls would likely be sold exclusively in liquor stores and bars and not be publicly available in super-markets like I originally thought.

I also found that changing the height of the main seam to make the package more box like didn't work well as the opening became to cramped to open. The likely hood of someone spilling the contents while trying to open became apparent. I switched back to the carton's original height to not over-complicate the design.

When it came to the first packaging design, feedback from other students leaned into making the carton more stylized and eye catching as the necessary body copy of the original package was minimal and allowed for creative imagery.

I Started with a simple orange swirl pattern subtracted with white waves to represent the liquid inside. I found this was more of an exercise in formatting and finding ways to organize the text on the box in an appealing way.

I would need to rework the graphics into making the simple stylized curves that I wanted.

1 note

·

View note

Text

Cosmetics ODM Market Report Key Statistics and Forecast for 2023-2031

Scope of the Cosmetics ODM Market Report and Research Methodology

The competitive landscape of the "Cosmetics ODM Market" is shaped by various factors, including product portfolios, technological advancements, financial health, mergers, acquisitions, and strategic partnerships. This report delivers an in-depth examination of the Cosmetics ODM Market, offering insights into pricing strategies, investment trends, expansion efforts, and market presence. A bottom-up approach was employed to estimate market size and growth rates, while identifying key drivers, challenges, opportunities, and restraints shaping the industry.

Download Sample Report PDF (Including Full TOC, Table & Figures) : https://straitsresearch.com/report/cosmetics-odm-market/request-sample

Data collection was conducted in its raw form and meticulously filtered to retain only the most relevant information. Following this, the remaining data underwent thorough validation to ensure its credibility. Our research also leverages insights from previous studies stored in a comprehensive internal database. Additionally, premium third-party databases were utilized to collect reliable data. This robust methodology ensures the accuracy and depth of our market analysis.

Regional Insights into the Market

The report includes an extensive regional analysis, covering North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. It evaluates factors such as market size, growth trends, and trade activities across these regions. By segmenting the market geographically, the report provides a detailed understanding of the market dynamics, challenges, and opportunities within each region.

Buy Now Latest Edition of Cosmetics ODM Market Report : https://straitsresearch.com/buy-now/cosmetics-odm-market

Market Segmentation

By Application

Skin Care

Creams

Lotions

Toners

Facial Cleansers

Sunscreen

Face Packs/ Masks

Others

Hair Care

Shampoos

Conditioners

Hair Rinses

Hair Dyes

Hair Tonics

Hair Styling Products

Makeup

Facial Products

Lip Products

Eye Products

Nail Products

Other Color Cosmetics

Body Care

Soaps

Shower Gels

Creams

Foot Creams

Others

Others

By Product

Organic

Synthetic

By Packaging Format

Bottles

Compact Cases

Droppers

Folding Cartons

Jars, Pallets

Pouches

Pumps and Dispensers

Roll On

Roll On Sticks

Sachets

Sticks

Tubes

Wraps

Others

By End Use

Prestige Brands

Private Labels

Mass Brands

Indie Brands

Leading Players in the Market

Cosmax

Intercoms

Kolmar

Nihon Kolmar Co. Ltd

Cosmo beauty

Nox Bellow Cosmetics

Ancorotti Cosmetics

COSMECCA

BioTruly Company

Toyo Beauty

Easycare Intelligence Tech

Homar

ANTE Cosmetics

Francia Cosmetics

Life-Beauty Cosmetics

Vellvette Lifestyle Pvt Ltd

Get Full TOC : https://straitsresearch.com/report/cosmetics-odm-market/toc

Key Questions Addressed in the Cosmetics ODM Market Report:

What defines Cosmetics ODM Market, and how is it evolving?

What is the projected growth rate of the Cosmetics ODM Market?

How is the Cosmetics ODM Market segmented?

What emerging trends and applications are shaping the Cosmetics ODM Market?

Who are the major players, and what are their core offerings?

Key Features of the Report

Market Dynamics: Insights into growth drivers, challenges, opportunities, and regional trends.

Segmentation Analysis: Detailed examination of key segments and sub-segments by region.

Competitive Landscape: Strategic profiles of leading players, categorized as market leaders, challengers, and regional players.

Benchmarking and Analysis: Competitive benchmarking of top players by region, along with PESTLE and Porter’s Five Forces analyses.

Supply Chain Analysis: Assessment of value chains and supply chains across regions.

Legal and Business Implications: Examination of regulatory and legal factors affecting businesses regionally.

Opportunities and SWOT Analysis: Identification of lucrative business prospects backed by SWOT analysis.

Browse More : -

#Cosmetics ODM Market#Cosmetics ODM Market Share#Cosmetics ODM Market Industry#Cosmetics ODM Market Size#Cosmetics ODM Market Research#What is Cosmetics ODM Market?#Cosmetics ODM Market Drivers#North America Cosmetics ODM Market#Europe Cosmetics ODM Market#Asia Pacific Cosmetics ODM Market#LAMEA Cosmetics ODM Market

0 notes

Text

Gabletop Pak: Pioneering the Future of Sustainable Packaging Solutions

The gable top box is a classic example of innovative and sustainable packaging. Characterized by its triangular-shaped top that can be folded over and sealed, the gabletop box has long been a staple in the packaging of liquids such as beverages, dairy, and oils. The design not only ensures an easy-to-open, convenient pouring experience but also offers excellent protection against air, light, and contaminants, which helps preserve the freshness of the product inside.

Made primarily from paperboard, gable top boxes are recyclable and biodegradable, offering a significant advantage over traditional plastic containers. With growing concerns about plastic pollution, the gable top box provides a solution that helps businesses reduce their environmental impact while still delivering high-quality, durable packaging.

Long-Lasting Oil Storage Cartons: Protecting Quality and the Environment

When it comes to storing cooking oils, protecting the product from light, air, and contamination is essential for maintaining its freshness. Traditional plastic bottles, while common, are not the ideal choice for preserving the quality of oils. Gabletop Pak's long-lasting oil storage cartons offer a superior alternative.

Made from high-quality paperboard, these cartons are designed with multiple layers to protect the oil from oxidation and spoilage. The long-lasting oil storage cartons feature a secure, tamper-evident seal and an easy-pour spout, ensuring that consumers can pour oil with precision and minimal mess. Moreover, these cartons are lightweight and fully recyclable, making them an environmentally friendly packaging option for businesses and consumers.

By switching to these sustainable cartons, businesses can improve their environmental footprint and meet the growing consumer demand for eco-conscious packaging.

Milk Carton Manufacturers: Sustainable Dairy Packaging Solutions

The dairy industry has long relied on plastic and glass bottles for packaging milk, cream, and other dairy products. However, with rising concerns about plastic waste and a growing demand for sustainable alternatives, many milk carton manufacturers are now turning to eco-friendly solutions like Gabletop Pak’s milk cartons.

Gabletop Pak’s milk cartons offer an effective barrier against light, air, and contaminants, helping to preserve the freshness and nutritional value of the milk. The cartons are made from recyclable paperboard and are designed with a gabletop closure for ease of storage and pouring. These cartons not only extend the shelf life of dairy products but also contribute to the reduction of plastic waste.

For milk carton manufacturers seeking sustainable packaging solutions, Gabletop Pak offers high-quality, cost-effective options that align with both consumer expectations and environmental goals.

Paper Bottles: The Next Step in Eco-Friendly Beverage Packaging

The future of beverage packaging is shifting toward sustainable solutions that reduce plastic consumption. Among the most exciting innovations is the paper bottle, a packaging solution designed to replace traditional plastic bottles with a more environmentally friendly alternative.

Made primarily from paperboard, with a minimal plastic lining for liquid containment, paper bottles are fully recyclable and lightweight. This design makes them a viable alternative to plastic bottles for a wide range of beverages, including water, juices, and soft drinks. By using paper bottles, companies can significantly reduce their carbon footprint, contribute to a circular economy, and meet the rising consumer demand for sustainable packaging options.

Gabletop Pak is proud to offer paper bottles as part of its commitment to providing innovative, eco-friendly packaging solutions. By adopting paper bottles, businesses can play a key role in the reduction of plastic waste and help create a cleaner, greener planet.

Why Choose Gabletop Pak?

Sustainable Packaging Solutions Gabletop Pak’s commitment to sustainability is evident in every product they offer. From the gable top box to long-lasting oil storage cartons and paper bottles, their packaging is made from renewable, recyclable materials that help reduce plastic waste and minimize environmental impact.

High-Quality and Reliable Gabletop Pak ensures that its packaging is not only environmentally friendly but also durable and reliable. Whether you're looking for milk cartons or oil storage cartons, Gabletop Pak's products provide a protective barrier against light, air, and contaminants, ensuring that your products remain fresh and safe.

Consumer Convenience Ease of use is a priority at Gabletop Pak. Their gable top boxes, long-lasting oil storage cartons, and milk cartons all feature user-friendly designs with easy-to-pour spouts or screw caps. The lightweight construction also makes these packages easier to transport and store, benefiting both manufacturers and consumers.

Comprehensive Product Range Gabletop Pak offers packaging solutions for a wide range of products, including beverages, oils, dairy, and more. This extensive range ensures that businesses from various industries can find the perfect packaging solution to meet their needs, all while contributing to environmental sustainability.

0 notes

Text

Printing Inks Market: Key Applications in Packaging, Commercial & Digital Printing 2021 - 2028

The global printing inks market size is expected to reach USD 23.8 billion by 2028, registering a CAGR of 2.8% over the forecast period, according to a new report by Grand View Research, Inc. Growing demand from end-use applications including flexible packaging & labels, corrugated cardboards, commercial letterpress, and folding cartons are the main factors expected to drive the market over the forecast period. Rise in consumer spending in Asia Pacific and North American regions, increasing demand for superior quality flexible packaging are some of the main parameters influencing the overall demand for printing inks globally.

Product innovations, technological progressions, new raw material sourcing models and expansion strategies are some of the major drifts the companies are focusing on to cater to the specific consumer requirements. The recent trends witnessed by this industry include rising significance of flexographic and digital toners, food-safe printing inks and a shift in consumer preference towards environment-friendly products.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

The regulatory framework also plays a crucial role in this industry dynamics. Stringent regulations regarding toxic metals in solvents & volatile organic compound (VOC) emissions in these inks are expected to hamper the growth of the overall market. This rationale has led to increased usage of cellulose and rosin derivatives as resins for manufacturing energy-efficient inks.

Digital ink is expected to be the fastest growing product segment owing to its superior properties and specific demands from textile, ceramic and 3D printing application sectors. The digital toners have observed a lower label costs as compared to conventional inks and its potential of switching among labels instantly have resulted in this product to be the fastest growing.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

The Central and South America automotive wrap films market size was valued at USD 165.7 million in 2024 and is projected to register a CAGR of 3.8% from 2025 to 2030.

The global thermal insulation coating market sizewas estimated at USD 10.45 billion in 2024 and is projected to grow at a CAGR of 6.6% from 2025 to 2030.

Printing Inks Market Segmentation

Grand View Research has segmented the global printing inks market on the basis of product, resins and application:

Printing Inks Product Outlook (USD Million, 2016 - 2028)

Gravure

Flexographic

Lithographic

Digital

Others

Printing Inks Resin Outlook (USD Million, 2016 - 2028)

Modified rosin

Modified cellulose

Acrylic

Polyurethane

Others

Printing Inks Application Outlook (USD Million, 2016 - 2028)

Packaging & labels

Corrugated cardboards

Commercial printing/Publishing

Others

Printing Inks Regional Outlook (Revenue, USD Million, 2016 - 2028)

North America

US

Canada

Mexico

Europe

Germany

Italy

UK

Asia Pacific

China

Japan

India

Central & South America (CSA)

Brazil

Middle East & Africa

Key Companies profiled:

Flint Group

DIC Corporation

Siegwerk Druckfarben AG & Co. KGaA

Sakata Inx Corporation

T&K TOKA Corporation

Dainichiseika Color & Chemicals Mfg. Co., Ltd.

DEERS I CO., Ltd.

Epple Druckfarben AG

TOYO INK SC HOLDINGS CO., LTD.

Hubergroup

TOKYO PRINTING INK MFG CO., LTD.

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

0 notes

Text

Cost-Effective Carton Box Making Machine: A Game-Changer for Packaging Solutions

In today’s competitive business landscape, finding a cost-effective solution for packaging can significantly impact operational efficiency and cost savings. For industries that rely heavily on consistent, durable, and customizable packaging, investing in a Heavy-Duty Box Maker Machine is essential. Not only do these machines offer robust performance, but they also streamline the entire packaging process, making it more efficient and scalable.

Understanding the Importance of Corrugated Box Machinery

Corrugated boxes are a cornerstone of secure packaging. Whether for shipping, storage, or product display, these boxes offer protection, durability, and branding potential. However, producing them at scale without a Corrugated Box Machinery solution can lead to increased costs and slower turnaround times. A Box Making Machine designed specifically for corrugated materials can efficiently handle large volumes, reducing both material waste and production time.

Advantages of a Cost-Effective Corrugated Box Manufacturing Machine

1. Enhanced Production Efficiency: With a Corrugated Box Manufacturing Machine, businesses can produce boxes quickly, meeting large demands without the need to outsource. This machinery simplifies the production process and allows companies to adjust box sizes based on specific requirements.

2. High-Quality Boxes: Investing in a Corrugated Box Making Machine ensures the production of high-quality boxes that meet industry standards. The machine’s precision technology enables consistent cutting, creasing, and folding, leading to uniform box quality.

3. Flexibility in Design: A Corrugated Box Machine can handle various box designs, accommodating different sizes, thicknesses, and specifications. This versatility is crucial for businesses that need to create packaging for diverse product lines or frequently update their box designs.

4. Cost Savings: By using a cost-effective Heavy-Duty Box Maker Machine, businesses can cut down significantly on costs associated with purchasing pre-made boxes or outsourcing packaging. This not only saves on overhead expenses but also gives companies better control over their packaging budgets.

5. Eco-Friendly Options: Many corrugated box machines allow for the use of recycled materials, aligning with sustainable business practices. This reduces the environmental footprint, appealing to eco-conscious consumers and helping companies meet sustainability targets.

Key Features to Look for in a Box Making Machine

When selecting a Corrugated Box Making Machine, it’s essential to focus on specific features that meet your operational needs. Key features include:

– Adjustable Box Dimensions: Look for machines that allow customization of box sizes to accommodate a variety of products.

– Durability: Choose a heavy-duty model that can withstand continuous use and has a robust build.

– Ease of Use: User-friendly interfaces and automation options ensure that your team can operate the machine with minimal training.

– Material Efficiency: Some machines are designed to reduce material waste, which can lead to significant cost savings over time.

– Speed and Precision: High-speed production capabilities, combined with precise cutting and folding, are crucial for maintaining production efficiency without compromising quality.

How a Cost-Effective Box Making Machine Impacts the Bottom Line

By integrating a cost-effective Corrugated Box Machine into the production process, businesses can streamline their operations, reduce outsourcing costs, and enhance product presentation with custom-made boxes. This machinery is ideal for small to medium businesses that aim to keep costs low while maintaining a high standard of packaging quality.

Conclusion

The demand for reliable, durable, and customizable packaging solutions is on the rise, and a cost-effective carton box making machine is the ideal investment for any business looking to optimize its packaging process. From increasing production speed to cutting down costs and supporting eco-friendly initiatives, this machinery offers several benefits that contribute to operational success. For companies ready to take their packaging solutions to the next level, a Heavy-Duty Box Maker Machine can be a transformative addition.

Contact us for cost-effective carton box making machine

Source: https://boxmakertech.com/cost-effective-carton-box-making-machine/

0 notes

Text

How Custom Product Boxes Boost Customer Engagement And Drive Brand Loyalty

Product boxes are highly customizable, lightweight, and designed to make your products stand out from the competition. These versatile, classic product boxes are cost-effective. Custom product boxes allow the addition of custom branding to handmade goods, cosmetics, snacks, and many more. You can share custom details on these packaging boxes. Product packaging boxes are designed to lure your targeted consumers to your brand. A wide range of personalization options are available according to your specifications. You can customize printed product packaging boxes by selecting the suitable packaging style, material, size, design, luxury add-ons, and printing methods. These factors help you to make your products innovative.

Enhance Brand Appeal With Customizable And Protective Product Packaging

Product packaging offers excellent packaging solutions to make your products protective and captivating for your product's safety. These personalized boxes help promote your brand and marketing. Custom product boxes with a brand logo are vital in boosting your business awareness. They are also excellent for product presentation. These packaging boxes are pleasing for the buyers who love to buy and try your products. Printed product packaging is highly customizable. You can choose the appropriate design, style, color scheme, and size. To create effective product boxes, you can select premium material and additional add-ons to make product packaging boxes. It includes embossing, debossing, coating, and foil stamping.

Eco Friendly Product Packaging Boxes With Remarkable Custom Styles

Eco-friendly and high-quality material is used to manufacture product packaging boxes. These customized product boxes are suitable for packaging like candles, soaps, skincare, and cupcake items. You can get custom product boxes made of kraft, corrugated, and cardboard. Cardboard and kraft boxes are eco-friendly packaging choices. Custom product packaging is a perfect choice for shipping your goods safely. Rigid material can be used for delicate, expensive, and gift products. You can select excellent packaging styles for product packaging boxes. They include reverse tuck end boxes, sleeve boxes, seal end boxes, gable boxes, tuck end boxes, hexagon boxes, and pyramid boxes.

Boost Brand Visibility With Secure And Sustainable Product Packaging Boxes

Eco-friendly material used for custom boxes helps to improve environmental responsibility. Creating memorable and beautiful packaging solutions enhances your company's visibility. Product packaging boxes offer added protection for your special items. You can select any size, design, color, or shape of these packaging boxes. These custom boxes are made of locking tabs to make your boxes more secure and protective. Custom product boxes are perfect for bakery, electronics, and cosmetics products. Customized boxes play a crucial role in marketing and advertising. You can hold these products easily during transit.

Affordable Printed Product Packaging For Enhanced Brand Value

Product packaging is environmentally friendly, high-quality, and affordable. Custom-printed product boxes are folding cartons to provide your products with a professional look. These packaging boxes are created to protect your products better. Custom product boxes enhance the perceived value of your products. These product boxes create eco-friendly packaging and exceptional brand loyalty. Custom product packaging reduces shipping costs and increases your brand value effectively. Customization helps you to achieve exclusivity in the market with a distinct customer experience. Printed product packaging provides different business advantages associated with sales and engagement. These packaging boxes are crafted to keep your products flawless.

Things To Consider Enhancing Brand And Customer Loyalty

These boxes provide complete protection to your products during transportation. Custom packaging should be affordable to make it an excellent branding strategy. Custom product boxes are a perfect option for subscription products. You can try various materials to promise durability and robustness. Kraft and cardboard materials use printed product packaging, which is great for enhancing the security of your products. Finishing and color schemes are essential things in the customization process. Furthermore, elegant designs and shapes of the boxes should be decided carefully. Custom product packaging benefits can help you to boost loyalty. Personalized packaging can make your customers feel special. It may lead to increased customer loyalty.

Attention Grabbing Custom Packaging For Enhanced Product Safety And Visibility

Product boxes create a memorable customer experience. This type of packaging is both functional and practical. These packaging boxes reduce shipping costs. Custom product boxes are incredible boxes that grab your customers' attention. These versatile boxes are perfectly suitable for your products. Custom packaging also helps you fulfill safety requirements. Cheap custom packaging also ensures your product will not move or get damaged during shipping. Customized packaging also permits the inclusion of add-ons. This packaging also boosts your shipping performance. They also enhance the value of your products as well. Cheap custom packaging offers added visibility during the delivery and distribution process. These packaging also offer unique packaging solutions to elevate your brand.

Versatile Product Packaging Solutions To Match Your Brand Identity

Order custom product packaging boxes with free design support and ship them from Verdance Packaging. Our custom product packaging is more appealing and versatile for individual products. We manufacture custom product boxes with highly customized options that are lightweight and of premium quality. We offer the freedom to manufacture packaging boxes to match your brand identity.

#Custom Product Boxes#Product Packaging Boxes#Custom Product Packaging#Printed Product Packaging#Cheap Custom Packaging#packaging boxes wholesale#custom packaging boxes#cardboard packaging#corrugated packaging#kraft product packaging

0 notes

Text

Why Two Piece Rigid Boxes Are a Must-Have for Premium Packaging

In today’s market, high-quality packaging can be just as important as the product itself. Two-piece rigid boxes are one of the most popular choices for brands looking to offer a luxurious, memorable unboxing experience. Known for their sturdiness and refined appearance, these boxes are versatile and add a premium touch to any item.

In this article, we will explore the features, benefits, and popular uses of two-piece rigid boxes and what makes them an ideal choice for brands seeking both functionality and elegance.

What Are Two Piece Rigid Boxes?

Two-piece rigid boxes are a type of packaging consisting of a base and a separate lid that fits securely on top. Constructed from durable chipboard or paperboard, these boxes are significantly more robust than standard folding cartons, offering excellent protection.

Unlike collapsible packaging, two-piece rigid boxes are designed to retain their structure and provide a stable, secure hold for their contents. These boxes are ideal for any brand wanting to present its products in a way that reflects quality and sophistication.

Key Advantages of Two-Piece Rigid Boxes

The advantages of two-piece rigid boxes go beyond just their attractive appearance. Here are some of the reasons why brands are choosing this packaging solution:

Superior Durability: The rigid construction of two-piece rigid boxes offers enhanced durability, keeping products safe during transport and storage. This makes them particularly suitable for delicate items, ensuring they arrive in perfect condition.

High-End Look and Feel: The premium look and tactile quality of two-piece rigid boxes immediately convey luxury. These boxes are often chosen by brands in the jewellery, cosmetics, and electronics industries, where the packaging is as much part of the product as the item itself.

Endless Customisation Options: One of the standout features of two-piece rigid boxes is their versatility in customisation. Brands can select from a range of finishes, colours, and materials to reflect their identity. Add-ons such as foil stamping, embossing, and custom inserts further enhance the unboxing experience.

Eco-Friendly Solutions: With the rising demand for sustainable packaging, many manufacturers now offer two-piece rigid boxes made from recyclable materials. By choosing these eco-friendly options, brands can appeal to environmentally-conscious customers without sacrificing quality or design.

Secure Fit and Protection: The base and lid of two-piece rigid boxes are crafted to fit snugly together, providing a secure enclosure for the product. This tight fit helps prevent damage during transit, which is especially beneficial for high-value items.

Industries That Use Two Piece Rigid Boxes

Two-piece rigid boxes are favoured across various industries for their protective qualities and upscale appearance. Below are some of the key sectors that benefit from this type of packaging:

Luxury Goods: From designer watches to exclusive jewellery, luxury brands rely on two-piece rigid boxes to showcase their products. The premium quality of these boxes adds to the perceived value of the item, creating a more immersive unboxing experience.

Beauty and Skincare Products: In the beauty industry, where presentation is essential, two-piece rigid boxes offer an elegant solution. High-end cosmetics and skincare items are often packaged in these boxes to align with their luxurious branding.

Tech and Electronics: Tech companies frequently use two-piece rigid boxes to package items like smartphones and tablets. These boxes provide the durability needed to protect delicate electronic devices while also conveying a modern, sleek look.

Gourmet Foods and Confectionery: Two-piece rigid boxes are commonly used to package gourmet chocolates, premium teas, and other edible gifts. The sturdy construction helps protect food items, while the elegant design adds a sophisticated touch to the presentation.

Customising Two Piece Rigid Boxes

The ability to personalise two-piece rigid boxes makes them an attractive option for brands looking to leave a lasting impression. Here are some popular customisation features:

Material Options: Depending on the brand’s needs, two-piece rigid boxes can be customised with various materials, including velvet, suede, or leather-textured finishes. These options add a tactile quality that enhances the customer experience.

Print and Design: Logos, patterns, and text can be printed on two-piece rigid boxes using techniques such as embossing, debossing, and foil stamping. These embellishments create a unique visual appeal and reinforce brand identity.

Colour Choices: Custom colours can make two-piece rigid boxes an extension of the brand. Some brands opt for minimalistic designs, while others go for bold, vibrant hues that capture attention and increase brand recognition.

Interior Inserts: Many two-piece rigid boxes come with tailored inserts, such as foam, velvet, or satin linings, to secure products in place. These inserts protect the item and enhance the luxury feel, ensuring a memorable unboxing experience.

The Unboxing Experience with Two-Piece Rigid Boxes

With unboxing videos becoming a trend, two-piece rigid boxes are ideal for brands wanting to create a shareable experience. The separate lid lifts off smoothly to reveal the product within, creating anticipation and excitement. This level of presentation often leaves a positive impression on customers, leading to potential shares on social media and increased brand visibility.

Eco-Friendly Two-Piece Rigid Boxes

Sustainability is now a priority for many consumers, and brands are responding by offering two-piece rigid boxes made from recyclable or biodegradable materials. These eco-friendly options allow companies to reduce their environmental impact and appeal to customers who prioritise sustainability. By choosing recyclable materials, brands can deliver a premium experience without compromising on environmental responsibility.

Why Two-Piece Rigid Boxes Stand Out

For brands looking to make an impression, two-piece rigid boxes are more than just packaging; they’re a strategic investment in brand perception. Their durability, luxurious appearance, and customisation options make them suitable for a wide range of products. Whether it’s luxury goods, cosmetics, or electronics, two-piece rigid boxes add value to the product and enhance the brand’s image.

Conclusion

In an era where presentation is essential, two-piece rigid boxes have become a preferred choice for brands aiming to deliver a memorable unboxing experience. For brands focused on quality and sustainability, eco-friendly two-piece rigid boxes offer a responsible yet premium packaging solution.

#2 piece rigid gift boxes#two piece rigid box#two piece rigid setup boxes#two piece rigid boxes#rigid boxes

0 notes

Text

Custom Packaging Box Solutions: Elevating Brands and Enhancing Customer Experience

In today's competitive market, packaging plays a pivotal role in shaping a brand's identity and influencing customer decisions. While products are the primary offering, how they're presented to customers can make a lasting impression. Custom packaging box solutions have emerged as a powerful tool for brands looking to stand out in the crowded marketplace, offering a unique blend of functionality, aesthetics, and marketing potential.

Why Custom Packaging Matters

Custom packaging boxes are more than just containers for products—they are an extension of the brand experience. Here are a few reasons why investing in custom packaging is essential for businesses:

Brand Differentiation In a sea of similar products, packaging can set your brand apart. With tailored designs, logos, and unique color schemes, custom packaging ensures that your product is easily recognizable on the shelf or online. It acts as a silent salesman, conveying your brand's story and values before the customer even interacts with the product.

Customer Engagement The unboxing experience has become a vital touchpoint in the customer journey. With the rise of social media, especially platforms like Instagram and YouTube, consumers often share their unboxing experiences. Custom packaging boxes that are visually appealing and thoughtfully designed can create memorable moments, encouraging customers to share their experiences and build brand loyalty.

Tailored Functionality Different products require different types of packaging. A one-size-fits-all approach may not protect or present your product optimally. Custom packaging solutions allow brands to tailor the packaging to fit the product’s size, shape, and specific needs. This not only ensures better protection during shipping but also enhances the overall user experience by providing ease of access and handling.

Sustainability With increasing consumer demand for eco-friendly practices, custom packaging allows brands to select sustainable materials. By choosing recyclable or biodegradable options, businesses can reduce their environmental footprint and appeal to eco-conscious customers. Custom packaging solutions enable companies to strike a balance between aesthetic appeal and environmental responsibility.

Cost Efficiency While it might seem like a luxury, custom packaging can actually lead to cost savings in the long run. By designing packaging that fits products perfectly, businesses can reduce material waste, minimize shipping costs, and prevent damage during transit. Custom packaging also allows companies to streamline their packaging processes, saving time and resources.

Types of Custom Packaging Solutions

There are various types of custom packaging boxes available to cater to different business needs. Each option offers unique benefits, depending on the nature of the product and the brand’s goals:

Corrugated Boxes Known for their durability, corrugated boxes are ideal for shipping and protecting fragile products. They are fully customizable in terms of size, print design, and finishing options. These boxes are versatile and widely used across various industries, from electronics to cosmetics.

Rigid Boxes Often associated with luxury items, rigid boxes exude a sense of elegance and quality. Their sturdy structure makes them perfect for high-end products such as jewelry, watches, and premium gifts. Rigid boxes can be customized with special finishes like embossing, foil stamping, and matte lamination to create an upscale look.

Folding Cartons Lightweight and flexible, folding cartons are widely used for retail packaging. These boxes can be printed with intricate designs, logos, and product information. They are suitable for various industries, including food, beverages, pharmaceuticals, and cosmetics.

Mailer Boxes Designed specifically for e-commerce businesses, mailer boxes provide a seamless unboxing experience. They are strong, easy to assemble, and can be customized with brand colors and graphics. Mailer boxes offer both functionality and brand visibility, making them an excellent choice for subscription boxes and online retail.

Custom Inserts For products that require extra protection, custom inserts (made from foam, cardboard, or molded pulp) can be added to the packaging. Inserts not only safeguard the product but also enhance the overall presentation, especially for delicate or multi-part items.

The Role of Design in Custom Packaging

Effective packaging design is crucial for making a strong impression. A well-designed custom packaging box communicates professionalism and can evoke emotions that align with your brand’s identity. Here are a few design elements to consider:

Color Scheme: Colors have psychological effects and can influence consumer behavior. Bold, vibrant colors can convey energy and excitement, while softer hues might suggest luxury and elegance. Choose a palette that resonates with your brand values.

Typography: The style and size of the text on packaging are just as important as the colors. Typography should be legible and consistent with your brand’s voice. Elegant fonts work well for luxury products, while playful fonts may be suitable for a youthful brand.

Imagery: High-quality images or illustrations can tell a story about your product and engage customers. Imagery should be cohesive and aligned with the overall branding to enhance product appeal.

Finishing Touches: Matte or glossy finishes, foil stamping, embossing, and spot UV can give your packaging a premium feel, making it more attractive to consumers. These finishing options can also add a tactile element, inviting customers to touch and feel the box.

Conclusion

Custom packaging box solutions are an investment in your brand’s success. They offer a powerful way to differentiate your products, create meaningful customer interactions, and even reduce costs through tailored designs. Whether you’re looking to protect fragile goods during shipping or create a memorable unboxing experience, custom packaging is a crucial element of modern business strategies. By working with a packaging partner like Boxloom Custom Solutions, businesses can create packaging that not only reflects their brand identity but also meets their functional needs, leaving a lasting impression on customers.

In an age where consumers expect more than just a product, custom packaging ensures that your brand delivers a complete and memorable experience.

#bakery boxes#chocolate boxes#drop boxes#corrugated boxes#custom boxes#boxes#gift boxes#rigid boxes#shipping boxes#mailer boxes

0 notes

Text

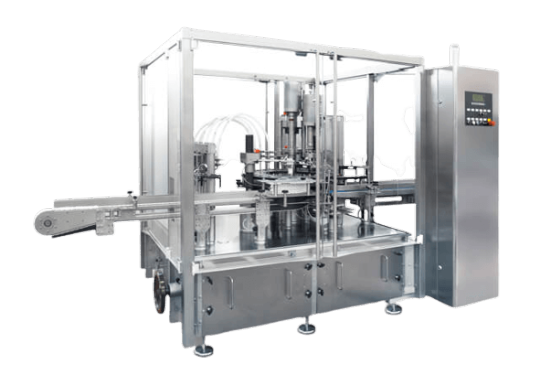

Carton packaging machines

Revolutionizing Packaging: The Role of Carton Packaging Machines in the Folding Carton Industry

In the dynamic world of packaging, businesses are constantly seeking innovative solutions to meet the growing demands of efficiency, sustainability, and quality. Among the various types of packaging equipment, carton packaging machines play a pivotal role, especially in the folding carton sector. At Robus India, we specialize in state-of-the-art folding carton machinery that enhances production processes and drives business success.

What Are Carton Packaging Machines?

Carton packaging machines are specialized equipment designed to automate the packaging of products into cartons. They streamline the entire process, from forming the carton to filling it with the product and sealing it securely. This automation not only speeds up production but also ensures consistent quality across all packaged products. In the folding carton industry, these machines are essential for delivering products that are not only functional but also aesthetically appealing.

Benefits of Using Carton Packaging Machines

Enhanced Efficiency: The primary advantage of carton packaging machines is their ability to operate at high speeds. In a fast-paced manufacturing environment, time is money. These machines minimize downtime and maximize output, allowing businesses to meet consumer demands promptly. With the ability to package hundreds of cartons per hour, companies can significantly increase their production capacity.

Improved Consistency: Manual packaging processes often lead to variations in packaging quality. Carton packaging machines, however, ensure uniformity in every carton produced. This consistency is crucial for maintaining brand integrity and meeting customer expectations, particularly in industries such as food, pharmaceuticals, and cosmetics, where packaging quality is paramount.

Cost-Effectiveness: While the initial investment in carton packaging machines may seem substantial, the long-term cost savings can be significant. By automating the packaging process, companies can reduce labor costs and minimize material waste. Furthermore, efficient packaging can lead to lower transportation costs due to optimized space utilization.

Versatility: Modern carton packaging machines are designed to handle a variety of carton styles and sizes. This versatility is particularly beneficial for businesses that offer diverse product lines. With Robus India's folding carton machines, you can easily switch between different packaging formats without the need for extensive reconfiguration, allowing for a more agile production process.

Why Choose Robus India for Your Carton Packaging Needs?

At Robus India, we pride ourselves on providing high-quality carton packaging machines tailored to the unique needs of our clients in the folding carton industry. Our machines are engineered with cutting-edge technology to deliver exceptional performance, durability, and low maintenance.

With over 410 installations across India, our commitment to quality and customer satisfaction is unmatched. We offer comprehensive services, including consultation, installation, and after-sales support, ensuring that you get the most out of your investment.

Conclusion

The importance of carton packaging machines in the folding carton industry cannot be overstated. They are essential for driving efficiency, ensuring quality, and reducing costs. As the packaging landscape continues to evolve, investing in advanced machinery is crucial for businesses aiming to stay competitive.

If you are looking to enhance your packaging operations, consider Robus India as your trusted partner. Our cutting-edge carton packaging machines are designed to meet the challenges of today’s packaging demands, helping you achieve success in a competitive market. Contact us today to learn more about our solutions and how we can assist you in revolutionizing your packaging processes!

1 note

·

View note

Text

Case Packer: Streamlining Packaging for Efficiency and Accuracy

A case packer is an essential piece of equipment used in various industries for automating the packaging process, specifically focusing on packing products into cases or cartons. These machines play a critical role in the end-of-line packaging process, improving efficiency, accuracy, and productivity for companies by reducing labor-intensive tasks and increasing output. Whether it’s in the food and beverage industry, pharmaceuticals, cosmetics, or consumer goods, case packer have become a valuable investment for businesses looking to enhance their packaging operations.

Types of Case Packers

Case packers are available in a variety of designs, depending on the specific needs of the industry and product type. Some of the most common types include:

Top-Load Case Packers: In a top-load case packer, products are placed vertically into the case from the top. This type is highly versatile and is commonly used in industries where products need to maintain a certain orientation, such as bottles or jars. Top-load case packers are often paired with robotic systems for added precision.

Side-Load Case Packers: In side-load case packers, products are inserted horizontally into the case. This method is ideal for items like boxes, cans, or cartons, which require careful placement and space optimization. Side-load case packers are well-suited for high-speed production lines due to their efficient packing capabilities.

Wrap-Around Case Packers: Wrap-around case packers are designed to wrap and fold a flat case or carton around the product, rather than placing the product into a pre-formed case. This design is popular in the beverage industry, where products like cans or bottles are grouped together and packed tightly for stability and space-saving during shipping.

Robotic Case Packers: Robotic case packers use advanced robotic arms to pack products into cases with precision and speed. These packers are flexible, easily programmable, and adaptable for a wide range of products and packaging patterns. Robotic case packers are becoming increasingly popular in industries where flexibility and custom packing configurations are required.

Benefits of Using a Case Packer

The adoption of case packers can bring numerous benefits to a company’s packaging line, making them indispensable in modern manufacturing environments. Some of the primary benefits include:

Increased Efficiency: Case packers significantly speed up the packaging process, allowing companies to pack more products per hour than manual labor can achieve. This results in higher throughput and the ability to meet large-scale production demands.

Cost Savings: By automating the packing process, businesses can reduce their reliance on manual labor, thereby lowering labor costs. Case packers also minimize product damage during packing, reducing waste and increasing overall product yield.

Consistency and Accuracy: Case packers ensure consistent packing of products, maintaining high quality and precision in every case. This uniformity is critical, especially in industries with strict packaging standards and regulations, such as pharmaceuticals or food processing.

Improved Safety: Automating the case packing process reduces the risks associated with manual handling of heavy products and repetitive tasks, improving workplace safety. Employees can focus on more skilled tasks, while machines handle the repetitive, labor-intensive work.

Space Optimization: Modern case packers are designed to pack products in the most efficient way possible, optimizing space usage within each case. This reduces shipping and storage costs, as more products can be packed into fewer cases.

Applications Across Industries

Case packers are versatile machines that serve a wide range of industries. Some key sectors that rely heavily on case sealer include:

Food and Beverage: From canned goods to bottled beverages, the food and beverage industry depends on case packers for high-speed, efficient packing. Ensuring products are securely packed for shipping and shelf presentation is crucial in this competitive market.

Pharmaceuticals: In the pharmaceutical industry, precision and consistency are paramount. Case packers are used to ensure that medications, medical devices, and other products are packed accurately in compliance with strict industry regulations.

Consumer Goods: Many consumer products, such as household items, electronics, and personal care products, require efficient packaging to meet market demands. Case packers ensure products are packaged quickly and securely for distribution.

Cosmetics: For cosmetics manufacturers, maintaining the integrity of fragile products is critical. Case packers are used to handle delicate items such as glass bottles, jars, and tubes, ensuring they are safely packed for transit.

Conclusion

As businesses continue to prioritize efficiency, precision, and cost-effectiveness, the role of case packers in the packaging industry will only grow. With a variety of designs suited for different applications and industries, case packers help streamline operations, improve output, and reduce costs. Whether for small or large-scale production, investing in a case packer can provide a significant return on investment by enhancing the overall packaging process and improving product handling throughout the supply chain.

0 notes

Text

Automotive Parts Packaging Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Automotive Parts Packaging Market – Industry Trends and Forecast to 2028

Global Automotive Parts Packaging Market, By Product Type (Bags and Pouches, Corrugated Boxes, Crates, Folding Carton, Pallets, Reusable Containers and Cases, Trays and Protective Packaging), Packaging Type (Reusable, Disposable), Component (Electrical Components, Automotive Filter, Battery, Cooling System, Engine Components, Lighting Component and Underbody Component), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- Packaging Type: The Automotive Parts Packaging market can be segmented based on packaging type, including folding cartons, plastic containers, bubble bags, corrugated boxes, and others. Different automotive parts require specific packaging types to ensure safe transportation and storage.

- Material: Segmentation based on material includes options such as paper & paperboard, plastic, metal, and others. Each material type offers specific properties that cater to the diverse packaging requirements of different automotive parts.

- Vehicle Type: Another crucial segmentation factor is the vehicle type, which categorizes packaging solutions based on applications in passenger vehicles, commercial vehicles, and others. Each vehicle type has distinct packaging needs that influence the market's dynamics.

**Market Players**

- DS Smith - Mondi - Sonoco Products Company - Schur Flexibles Group - Deufol SE - Goodpack Limited - Nefab Group

The global Automotive Parts Packaging market is witnessing significant growth fueled by the increasing demand for efficient packaging solutions in the automotive industry. With a focus on ensuring the safe and secure transportation of automotive parts, the market is segmented based on packaging type, materials, and vehicle types. Packaging types such as folding cartons, plastic containers, bubble bags, and corrugated boxes cater to different automotive part requirements. Material segmentation includes paper & paperboard, plastic, metal, and others, offering diverse properties to meet specific packaging needs. Vehicle types such as passenger vehicles and commercial vehicles further influence the packaging market dynamics by necessitating tailored packaging solutions.

Key market players driving the Automotive Parts Packaging market forward include DS Smith, Mondi, Sonoco Products Company, Schur Flexibles Group, Deufol SE, Goodpack Limited, and Nefab Group. These companies offer a range of packaging solutions tailored to the automotive industry's unique requirements, contributing to the market's overall growth and innovation. With a focus on sustainability, durability, and cost-effectiveness, these market players play a crucial role inThe global Automotive Parts Packaging market is experiencing substantial growth driven by the rising need for efficient packaging solutions in the automotive sector. The market segmentation based on packaging type allows for customized solutions to meet the unique requirements of various automotive parts. Folding cartons, plastic containers, bubble bags, and corrugated boxes are utilized based on the specific transportation and storage needs of different automotive components. The segmentation by material further enhances the market's flexibility, with options such as paper & paperboard, plastic, metal, and others providing distinct properties to cater to diverse packaging demands. This versatility ensures that automotive parts are adequately protected during transit and storage, contributing to the overall efficiency of the supply chain within the automotive industry.

The segmentation based on vehicle type is another crucial aspect shaping the Automotive Parts Packaging market. By categorizing packaging solutions according to their applications in passenger vehicles, commercial vehicles, and other vehicle types, manufacturers can tailor their offerings to suit the specific requirements of each segment. Passenger vehicles may require packaging solutions that focus on aesthetics and branding, while commercial vehicles may prioritize durability and stackability. Understanding these distinctions allows market players to develop targeted packaging solutions that effectively address the needs of different vehicle types, thereby driving market growth and innovation.

Key market players such as DS Smith, Mondi, Sonoco Products Company, Schur Flexibles Group, Deufol SE, Goodpack Limited, and Nefab Group are instrumental in advancing the Automotive Parts Packaging market. These companies bring a wealth of experience and expertise to the table, offering a wide range of packaging solutions designed to meet the automotive industry's stringent requirements. By focusing on sustainability, durability, and cost-effectiveness, these market players are driving innovation and setting new benchmarks in the automotive packaging sector. Their commitment to delivering high-quality solutions that provide both protection and efficiency further solidifies their position as market leaders, influencing trends and shaping the future of automotive parts packaging.

In conclusion, the Automotive Parts Packaging market is poised for continued growth, driven by the increasing demand for tailored**Segments**

- **Packaging Type**: The Automotive Parts Packaging market's segmentation based on packaging type plays a crucial role in meeting the diverse needs of the automotive industry. By offering options such as folding cartons, plastic containers, bubble bags, and corrugated boxes, the market can cater to specific transportation and storage requirements of various automotive parts.

- **Material**: The segmentation based on material type further enhances the market's flexibility and adaptability to different packaging needs. With options such as paper & paperboard, plastic, metal, and others, the market can provide tailored solutions that offer specific properties to ensure the safe and secure packaging of automotive components.

- **Vehicle Type**: Categorizing packaging solutions based on vehicle type, including passenger vehicles, commercial vehicles, and others, allows for the customization of packaging materials to meet the unique requirements of each segment. This segmentation ensures that packaging solutions align with the varied needs of different vehicle types, influencing market dynamics and driving innovation.

Global Automotive Parts Packaging Market, By Product Type (Bags and Pouches, Corrugated Boxes, Crates, Folding Carton, Pallets, Reusable Containers and Cases, Trays and Protective Packaging), Packaging Type (Reusable, Disposable), Component (Electrical Components, Automotive Filter, Battery, Cooling System, Engine Components, Lighting Component and Underbody Component), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium,

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Core Objective of Automotive Parts Packaging Market:

Every firm in the Automotive Parts Packaging Market has objectives but this market research report focus on the crucial objectives, so you can analysis about competition, future market, new products, and informative data that can raise your sales volume exponentially.

Size of the Automotive Parts Packaging Market and growth rate factors.

Important changes in the future Automotive Parts Packaging Market.

Top worldwide competitors of the Market.

Scope and product outlook of Automotive Parts Packaging Market.

Developing regions with potential growth in the future.

Tough Challenges and risk faced in Market.

Global Automotive Parts Packaging top manufacturers profile and sales statistics.

Browse Trending Reports:

Regenerated Fiber Market Cardiac Resynchronization Therapy Crt Devices Market Electronic Trial Master File Etmf Systems Market Starch Processing Market Acute Myeloid Testing Market Food Inclusions Market Industrial Dryers Market Neurosurgery Market Viral Hepatitis Market Glass Bottle Market Reclaimed Rubber Market Modified Wheat Starch Market Plant Genomics Market Digital Pump Controller Market Tofu And Tempeh Market Non Gmo Certification Market Linear Low Density Polyethylene Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Printing Inks Market Recent Trends and Growth Analysis Report, 2028

The global printing inks market size is expected to reach USD 23.8 billion by 2028, registering a CAGR of 2.8% over the forecast period, according to a new report by Grand View Research, Inc. Growing demand from end-use applications including flexible packaging & labels, corrugated cardboards, commercial letterpress, and folding cartons are the main factors expected to drive the market over the forecast period. Rise in consumer spending in Asia Pacific and North American regions, increasing demand for superior quality flexible packaging are some of the main parameters influencing the overall demand for printing inks globally.

Product innovations, technological progressions, new raw material sourcing models and expansion strategies are some of the major drifts the companies are focusing on to cater to the specific consumer requirements. The recent trends witnessed by this industry include rising significance of flexographic and digital toners, food-safe printing inks and a shift in consumer preference towards environment-friendly products.

The regulatory framework also plays a crucial role in this industry dynamics. Stringent regulations regarding toxic metals in solvents & volatile organic compound (VOC) emissions in these inks are expected to hamper the growth of the overall market. This rationale has led to increased usage of cellulose and rosin derivatives as resins for manufacturing energy-efficient inks.

Gather more insights about the market drivers, restrains and growth of the Printing Inks Market

Detailed Segmentation:

Printing Inks Market Trends

Initially, printing inks were majorly used in printing publications for newspapers, magazines, and journals. However, due to rapid urbanization and the growing digitalized needs of consumers, the application scope of printing inks has shifted from commercial printing & publication to the packaging industry. In the packaging industry, printing inks are used to print on packaging materials to make the packaging attractive to customers, as it is one of the powerful ways to promote and market products.

Flexible packaging offers better options for customized packaging. The demand for flexible packaging is driven by the food & beverage industry, supported by the strong growth in the snacks & confectionery category. Moreover, the growing demand for food, on account of the increasing global population, is one of the key trends augmenting the growth of the flexible packaging industry. The booming flexible packaging industry is anticipated to offer substantial growth opportunities for the printing inks market.

Product Insights

Lithographic segment accounted for a prominent share of the overall market in terms of value in 2020. The segment is expected to witness substantial growth over the forecast period owing to a combination of high-quality prints and efficiency in large-scale projects. This lithographic process is also suitable for flat media such as cloth, foil, paper, plastic, and flat cardboard.

Gravure printing inks are primarily used for printing photographs; they can be utilized on films, thin papers, metal foils, and paper cups. This process utilizes “liquid inks”. The flexibility of this ink technology allows these print processes to cover various applications in food packaging, tobacco products, and cosmetics on a variety of substrates such as cardboards, papers, plastics, foils, and labels.

Resin insights

Polyurethane is the fastest-growing resin segment and is expected to account for over 16% of the resin revenue in 2028. The composition of the resins is a significant factor for the type of ink produced. Hydrocarbons & modified rosins are used for producing lithographic solvents, polyamides & polyurethanes are used for manufacturing gravure and solvent-based-flexographic products. By resin type, acrylic is the predominantly used raw material for manufacturing solutions owing to its faster drying properties, availability, and cost-effective nature.

Application Insights

Packaging & labels segment is the largest and fastest ink application segment, which accounts for over 45% of the total segment revenue. The growth of this application has witnessed a flourishing trend in the last five years owing to the growing middle-class population in emerging nations such as India and Thailand, change in consumer preference for the convenience of food packaging & online retailing with extensive internet penetration, and requirement of bio-degradable products.

Regional Insights

Asia Pacific dominated the printing inks market and accounted for the highest revenue share of 35.60% in 2021. Asia Pacific dominated the global printing inks market in 2021 and is expected to continue its dominance over the forecast period. Rising consumption of packaged food items, coupled with robust growth in the packaging and labeling industry owing to the emergence of various businesses, including the food & beverage industry, consumer goods, health care sector, and e-commerce, has positively impacted market growth in the region.

Browse through Grand View Research's Paints, Coatings & Printing Inks Industry Research Reports.

• The global ceramic coating market size was valued at USD 11.16 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.1% from 2024 to 2030.

• The global nanocoatings market size was valued at USD 12.86 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 16.4% from 2024 to 2030.

Printing Inks Market Share Insight

The global ink industry is extremely competitive owing to the presence of vertically integrated key players with technologically advanced solutions & equipment and procurement & distribution channels. The industry has witnessed a strong consolidation period in different regions which include, expansions, mergers, and acquisitions, making the industry highly competitive. Some expansion strategies include Epple Druckfarben Italia S.r.I in Milan, Italy, subsidiary of Epple Druckfarben for superior quality German offset printing inks in Italy and Kansas, U.S. plant which was an expansion strategy of Sakata Inx Corporation.

Major market players include

• Flint Group

• DIC Corporation

• Siegwerk Druckfarben AG & Co. KGaA

• Sakata Inx Corporation

• T&K TOKA Corporation

• Dainichiseika Color & Chemicals Mfg. Co., Ltd.

• DEERS I CO., Ltd.

• Epple Druckfarben AG

• TOYO INK SC HOLDINGS CO., LTD.

• Hubergroup

• TOKYO PRINTING INK MFG CO., LTD.

Printing Inks Market Segmentation

Grand View Research has segmented the global printing inks market on the basis of product, resins and application:

Printing Inks Product Outlook (USD Million, 2016 - 2028)

• Gravure

• Flexographic

• Lithographic

• Digital

• Others

Printing Inks Resin Outlook (USD Million, 2016 - 2028)

• Modified rosin

• Modified cellulose

• Acrylic

• Polyurethane

• Others

Printing Inks Application Outlook (USD Million, 2016 - 2028)

• Packaging & labels

• Corrugated cardboards

• Commercial printing/Publishing

• Others

Printing Inks Regional Outlook (Revenue, USD Million, 2016 - 2028)

• North America

o U.S.

o Canada

o Mexico

• Europe

o Germany

o Italy

o UK

• Asia Pacific

o China

o Japan

o India

• Central & South America (CSA)

o Brazil

• Middle East & Africa

Order a free sample PDF of the Printing Inks Market Intelligence Study, published by Grand View Research.

#Printing Inks Market#Printing Inks Market size#Printing Inks Market share#Printing Inks Market analysis#Printing Inks Industry

0 notes

Text

Enhancing Packaging Efficiency with Automatic Carton Erector Machines

In the fast-paced world of manufacturing and packaging, efficiency is key. An automatic carton erector machine plays a crucial role in automating the packaging process, especially for industries such as pharmaceuticals. These machines are designed to form, fold, and seal cartons quickly, reducing manual labor and increasing production rates.

For companies in the pharmaceutical sector, where precision and speed are essential, automatic cartoning machines offer significant benefits. These machines seamlessly integrate with Pharma Packaging machines, ensuring the safe and secure packaging of products. With increasing demand for faster production times and error-free packaging, automatic carton erector machines meet industry needs by streamlining the packaging process.

Incorporating an automatic carton erector machine into the production line also complements High-speed liquid filling machines, which are commonly used in the pharmaceutical and cosmetics industries. Together, these technologies ensure that liquid products are filled and packaged with precision, maintaining high throughput without compromising quality.