#Fluoropolymer Coating Manufactures

Explore tagged Tumblr posts

Text

Innovative Fluoropolymer Coatings Transform Industrial Surfaces with Unmatched Protection

Fluoropolymer coatings are protective coatings made of fluorine-containing polymers. They are commonly used to increase resistance to chemicals, solvents, heat, and wear. Fluoropolymer coatings can also protect against corrosion and abrasion and can be applied to a variety of surfaces such as metal, plastics, and ceramics. Fluoropolymer coatings have grown in popularity in recent years due to…

View On WordPress

#Fluoropolymer Coating#Fluoropolymer Coating Demand#Fluoropolymer Coating Manufactures#Fluoropolymer Coating Market#Fluoropolymer Coating Market analysis#Fluoropolymer Coating Market growth#Fluoropolymer Coating Market opportunity#Fluoropolymer Coating Market overview#Fluoropolymer Coating Market report#Fluoropolymer Coating Market research#Fluoropolymer Coating Market share#Fluoropolymer Coating Market size#Fluoropolymer Coating Price#Global Fluoropolymer Coating Market

0 notes

Text

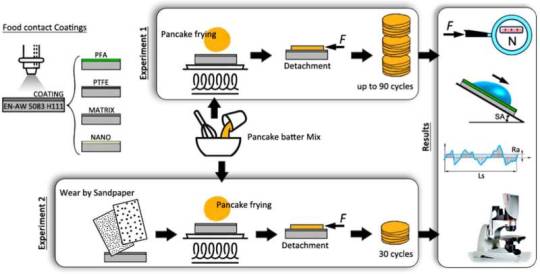

The technological challenge of non-stick pans: Teflon is still more effective than other coatings

A protocol designed by the University of Cordoba yields a simple and robust evaluation of the efficiency and durability of different commercial non-stick coatings used for food preparation By the time a dish reaches a table, science has already been applied to a myriad of processes. From growing techniques that achieve sustainable, high-quality food to technology that prevents food from sticking to the cookware used to prepare it. In fact, non-stick coatings have been enhancing the relationship between pans and food for more than 60 years thanks to the invention of polytetrafluoroethylene, better known by its trade name, Teflon. These fluoropolymer coatings, standing out for their anti-adhesive power, seem to have their days numbered; however, as the European Union's medium-term strategy is to reduce or eliminate their use due to possibly harmful effects on health and the environment produced during their manufacture, though this is still being debated in the international scientific community.

Read more.

#Materials Science#Science#Polytetrafluorethylene#PTFE#Coatings#Polymers#Toxicity#University of Cordoba#Food science

10 notes

·

View notes

Text

Types Of Functional Coatings For Paper Applications

Functional coatings for paper enhance its properties, making it suitable for various applications across industries. These coatings can improve durability, water resistance, printability, and barrier properties, catering to the specific needs of products in sectors such as packaging, publishing, and labeling. Here, we’ll explore the different types of functional coatings commonly used in paper applications and their benefits.

1. Water-Repellent Coatings

Water-repellent coatings are designed to provide resistance against moisture and water damage, making them ideal for applications such as packaging and outdoor products. These coatings typically use hydrophobic materials, like fluoropolymers or wax emulsions, to create a barrier that prevents water from penetrating the paper. This is particularly useful for food packaging, where moisture control is essential to maintain freshness and product integrity.

2. Oil and Grease-Resistant Coatings

Oil and grease-resistant coatings enhance paper’s ability to repel oils, fats, and greases, which is crucial in food packaging applications. These coatings often incorporate fluorinated compounds or polymeric materials that create a strong barrier against oily substances. This protection not only maintains the quality of food products but also prevents leakage and contamination, ensuring consumer safety.

3. Barrier Coatings

Barrier coatings are engineered to prevent the passage of gases, moisture, and other external elements, extending the shelf life of products. These coatings are commonly used in packaging applications, such as those for perishable goods. Common barrier materials include polyethylene, polyvinylidene chloride (PVDC), and aluminum oxide. Barrier coatings can help reduce food spoilage and maintain flavor and aroma by limiting exposure to oxygen and moisture.

4. Printable Coatings

Printable coatings are designed to enhance the surface characteristics of paper, making it more suitable for high-quality printing. These coatings improve ink adhesion, color vibrancy, and overall print quality, which is essential in publishing and packaging. Common types of printable coatings include clay coatings, which provide a smooth finish, and polymer coatings, which can enhance glossiness and brightness. These coatings allow for sharp, clear images and text, making them ideal for labels, brochures, and packaging materials.

5. Antimicrobial Coatings

Antimicrobial coatings are gaining traction in paper applications, especially in healthcare and food packaging. These coatings contain agents that inhibit the growth of bacteria, fungi, and other microorganisms on the paper surface. By providing an additional layer of protection, antimicrobial coatings help reduce the risk of contamination and promote hygiene in products like food packaging, medical supplies, and consumer goods.

6. Sustainable Coatings

With increasing awareness of environmental issues, sustainable functional coatings are becoming more prominent in the paper industry. These coatings are derived from renewable resources and designed to be biodegradable or recyclable. Examples include coatings made from natural waxes, starches, or bio-based polymers. Sustainable coatings not only enhance the functional properties of paper but also align with the growing demand for eco-friendly products. Functional coatings play a vital role in enhancing the performance of paper for various applications. By selecting the appropriate type of coating, manufacturers can improve paper's resistance to water, oil, and gases, as well as its printability and antimicrobial properties. As technology advances, the development of innovative coatings, including sustainable options, will continue to shape the future of paper products, offering improved functionality while addressing environmental concerns. This evolution highlights the importance of functional coatings in meeting the diverse needs of consumers and industries alike.

0 notes

Text

Industrial Coatings Market Landscape: Trends, Drivers, and Forecast (2023-2032)

The global Industrial Coatings Market is valued at approximately USD 38,395 million and is projected to grow at a compound annual growth rate (CAGR) of 5.95% over the forecast period, reaching around USD 60,965.2 million by 2032.

Industrial coatings are specialized protective coatings applied to various substrates, such as metals, concrete, and plastics, to protect them from corrosion, wear, chemicals, and environmental damage. These coatings are essential in industries such as manufacturing, automotive, aerospace, oil and gas, and construction, where materials are exposed to harsh conditions. Industrial coatings are designed to enhance durability, improve performance, and extend the lifespan of equipment and structures. They are available in various types, including epoxy, polyurethane, acrylic, and fluoropolymer coatings, each offering specific properties like chemical resistance, heat resistance, and abrasion resistance. In addition to protection, industrial coatings can also provide aesthetic enhancements, reduce maintenance costs, and contribute to safety by offering anti-slip or fire-resistant properties.

The industrial coatings market is influenced by several key dynamics that shape its growth, demand, and innovation. These factors include:

Growing Demand for Corrosion Protection: One of the primary drivers of the industrial coatings market is the need to protect infrastructure, machinery, and equipment from corrosion. Industries such as oil and gas, construction, and marine are particularly reliant on coatings that offer strong corrosion resistance to extend the lifespan of their assets in harsh environments.

Technological Advancements in Coating Materials: Advancements in coating technologies, such as nanotechnology and the development of high-performance polymers, are creating new opportunities in the industrial coatings market. These innovations enhance the durability, chemical resistance, and environmental friendliness of coatings, driving their adoption across industries.

Sustainability and Environmental Regulations: Stricter environmental regulations are significantly impacting the industrial coatings market, especially regarding volatile organic compound (VOC) emissions. This has led to increased demand for eco-friendly coatings, such as water-based coatings, powder coatings, and high-solid formulations, as industries seek to comply with regulations while minimizing their environmental footprint.

Rise in Infrastructure Development: Infrastructure development, particularly in emerging markets, is driving demand for industrial coatings. Growing investments in transportation, energy, and construction projects require coatings to protect materials from the elements and improve the longevity of infrastructure, contributing to the market’s expansion.

Increasing Focus on Energy Efficiency: Industrial coatings that enhance energy efficiency are gaining attention, particularly in sectors such as construction and automotive. Reflective and insulating coatings, which reduce heat transfer and energy consumption, are becoming more popular as industries aim to improve energy efficiency and reduce costs.

Expansion of Automotive and Aerospace Sectors: The automotive and aerospace industries are major consumers of industrial coatings, particularly for protecting vehicle exteriors, interiors, and mechanical components. As these sectors grow, driven by increasing demand for electric vehicles and air travel, the need for advanced coatings that offer durability, UV resistance, and aesthetic appeal will continue to rise.

Demand for Anti-Microbial and Specialty Coatings: The increasing emphasis on hygiene, particularly in the wake of the COVID-19 pandemic, has spurred demand for anti-microbial coatings in industrial and commercial applications. These coatings are used in healthcare, food processing, and public spaces to prevent the spread of pathogens. Similarly, specialty coatings that offer unique properties like fire resistance or anti-slip surfaces are gaining popularity in safety-critical applications.

Maintenance and Repair Requirements: Maintenance and repair of aging infrastructure and industrial equipment continue to drive the market for industrial coatings. As industries look to reduce operational downtime and costs, the demand for protective coatings that extend the service life of assets is increasing.

Rising Raw Material Costs: Fluctuations in the cost of raw materials, such as resins, pigments, and solvents, can impact the profitability and pricing of industrial coatings. Manufacturers may face challenges related to the rising cost of these materials, which may influence product pricing and margins in the market.

Customization and Innovation in Application Methods: With the growing demand for customized solutions, industrial coating manufacturers are focusing on creating tailored formulations that meet the specific requirements of different industries. Additionally, innovations in application methods, such as robotics and automation in coating processes, are improving the precision, efficiency, and speed of coating applications, driving further growth in the market.

Access Complete Report - https://www.credenceresearch.com/report/industrial-coatings-market

Key Player Analysis:

Akzo Nobel N.V.

Axalta Coating Systems

BASF Coatings

Beckers Group

Berger Paints India Limited

Chugoku Marine Paints, Ltd.

Hempel A/S

Jotun

Kansai Paint Co., Ltd.

KCC Corporation

NIPSEA Group

PPG Industries, Inc.

Teknos Group

The Chemours Company

The Sherwin-Williams Company

The industrial coatings market offers several growth opportunities driven by technological advancements, environmental regulations, and evolving industry demands. Key opportunities include:

Expansion of Eco-Friendly Coatings: As environmental regulations tighten and industries prioritize sustainability, the demand for eco-friendly coatings is growing. Water-based coatings, powder coatings, and low-VOC (volatile organic compound) formulations provide significant growth opportunities. Companies that invest in developing coatings with reduced environmental impact are likely to capture a larger share of the market as industries seek greener alternatives.

Growth in Emerging Markets: Industrialization and infrastructure development in emerging markets, particularly in Asia-Pacific, Latin America, and Africa, offer substantial growth opportunities. Rapid urbanization, construction projects, and expanding manufacturing industries in these regions are driving demand for industrial coatings to protect infrastructure and equipment from corrosion, wear, and environmental damage.

Advancements in Smart Coatings: Smart coatings, which can respond to environmental changes or external stimuli, represent a growing segment within the industrial coatings market. These include self-healing coatings, corrosion-sensing coatings, and coatings with anti-fouling or anti-icing properties. Industries such as automotive, aerospace, and energy are increasingly adopting smart coatings for their ability to enhance performance and reduce maintenance needs.

Increased Demand for Corrosion-Resistant Coatings: Corrosion is a major concern in industries like oil and gas, marine, and construction. The rising demand for long-lasting corrosion-resistant coatings presents an opportunity for companies to develop innovative solutions that offer extended protection and performance in harsh environments. This is particularly important for infrastructure projects, pipelines, and offshore platforms where corrosion can lead to significant operational challenges and costs.

Automotive and Aerospace Sector Growth: The growing automotive and aerospace industries present substantial opportunities for the industrial coatings market. As electric vehicles (EVs) and lightweight materials gain traction, coatings with enhanced durability, heat resistance, and aesthetic appeal are in high demand. The aerospace industry, with its need for coatings that provide corrosion protection, thermal stability, and weight reduction, will continue to be a key market for high-performance industrial coatings.

Expansion of Anti-Microbial Coatings: The rising focus on hygiene and cleanliness, particularly after the COVID-19 pandemic, is driving demand for anti-microbial coatings in various industrial sectors. These coatings are especially relevant in healthcare, food processing, and public infrastructure, where preventing the spread of pathogens is critical. The growing awareness of health and safety provides an opportunity for companies to expand their anti-microbial product offerings.

Development of High-Performance Coatings for Renewable Energy: The global shift toward renewable energy sources, such as wind, solar, and hydropower, creates opportunities for industrial coatings designed to protect renewable energy infrastructure. Wind turbines, solar panels, and hydroelectric dams require coatings that offer protection from environmental factors like UV radiation, saltwater, and extreme temperatures. Companies that provide coatings for these applications can capitalize on the growing renewable energy market.

Customization for Niche Markets: There is an increasing demand for highly customized coatings that meet specific industry needs. This includes coatings with specialized properties, such as fire resistance, chemical resistance, or thermal insulation. Manufacturers that offer tailored solutions for niche markets, such as defense, chemical processing, and electronics, can differentiate themselves and capture unique opportunities in the market.

Automated and Robotic Coating Application: The growing use of automation and robotics in industrial coating applications provides opportunities for more efficient, precise, and consistent coating processes. As industries invest in modernizing their operations, the demand for automated application systems and coatings designed for robotic use will rise, driving growth in this segment.

Investment in R&D and Innovation: Companies that invest in research and development (R&D) to create innovative, high-performance coatings will be well-positioned to capitalize on future market opportunities. Developing new materials, improving coating formulations, and advancing application technologies will allow companies to meet the evolving needs of various industries and expand their market reach.

Segmentation:

Based on Product Type:

Epoxy Coatings

Polyurethane Coatings

Acrylic Coatings

Alkyd Coatings

Other Specialty Coatings

Based on Technology:

Solvent-Borne Coatings

Water-Borne Coatings

Powder Coatings

UV-Cured Coatings

Other Advanced Coating Technologies

Based on End User:

Automotive

Aerospace

Construction

Marine

Electronics

Industrial Equipment

Other End Users

Browse the full report – https://www.credenceresearch.com/report/industrial-coatings-market

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

PTFE Micronized Wax Market Outlook: Global Trends and Forecast Analysis (2023-2032)

PTFE (Polytetrafluoroethylene) micronized wax is a finely ground form of PTFE that is used as an additive in various industrial applications to enhance surface properties. Its primary benefits include providing excellent lubrication, reducing friction, and improving wear resistance. Due to its low coefficient of friction and non-stick properties, PTFE micronized wax is commonly incorporated into coatings, inks, and plastics to improve their performance. Additionally, it enhances water and chemical resistance and can impart a smoother surface finish, making it ideal for applications in automotive, industrial machinery, and consumer products.

The PTFE micronized wax market is driven by several key dynamics, reflecting the growing demand across various industries. Here are some major factors influencing the market:

1. Increasing Demand for High-Performance Coatings

PTFE micronized wax is widely used in high-performance coatings due to its exceptional properties like low friction, wear resistance, and chemical inertness. Sectors such as automotive, aerospace, and industrial machinery are increasingly adopting PTFE-based coatings to improve the durability and efficiency of their products, driving demand.

2. Rising Application in Printing Inks

The packaging and printing industries are seeing increased use of PTFE micronized wax as it improves surface smoothness, gloss, and durability of printing inks. Its ability to enhance scuff and rub resistance makes it a preferred additive for high-quality printing.

3. Growth in the Plastics Industry

The plastics sector benefits from PTFE micronized wax as it improves the slip, mold release, and anti-blocking properties of plastic products. The growing use of engineered plastics in various industries is further boosting the demand for this additive.

4. Expanding Applications in Lubricants and Greases

PTFE micronized wax is also utilized in the formulation of lubricants and greases for machinery and automotive applications, where its low friction properties extend the life of moving parts and improve performance under high stress.

5. Environmental and Regulatory Concerns

There is increasing scrutiny on the environmental impact of chemical additives, including PTFE. As a fluoropolymer, PTFE faces regulatory challenges, particularly regarding its production and disposal. Stricter regulations on environmental sustainability may impact market growth or drive innovation toward eco-friendlier alternatives.

6. Technological Advancements

Ongoing advancements in micronization and particle processing technologies have led to the production of more efficient and specialized PTFE wax products. This allows manufacturers to develop custom formulations that cater to specific industry needs, contributing to market growth.

7. Regional Market Growth

North America and Europe: These regions dominate the market due to their established industries, stringent quality standards, and focus on high-performance materials.

Asia-Pacific: The market is witnessing significant growth in Asia-Pacific, driven by the booming manufacturing, automotive, and electronics sectors in countries like China, India, and South Korea.

8. Price Volatility of Raw Materials

Fluctuations in the cost of raw materials used to produce PTFE, such as fluorospar, can affect the pricing and profitability of PTFE micronized wax products. Supply chain disruptions and rising production costs may pose challenges to market players.

Access Complete Report - https://www.credenceresearch.com/report/ptfe-micronized-wax-market

Key Players

BASF

Sasol

Clariant

Honeywell

Lubrizol

MÃœNZING Corporation

MPI

Nanjing Tianshi

Michelman

Shamrock Technologies

Ceronas

The future outlook for the PTFE micronized wax market is promising, with various trends and developments shaping its growth. Here's a detailed look at what to expect in the coming years:

1. Increased Demand for High-Performance Materials

Industries such as automotive, aerospace, electronics, and industrial machinery will continue to prioritize performance, durability, and efficiency. PTFE micronized wax, known for its low friction, wear resistance, and non-stick properties, will play a critical role in meeting these requirements. As industries seek materials that can withstand extreme conditions and reduce maintenance costs, the demand for PTFE wax is likely to grow.

2. Growth in Emerging Economies

Rapid industrialization and expanding manufacturing sectors in emerging economies, particularly in Asia-Pacific and Latin America, will be a key driver of market growth. Countries like China, India, and Brazil are seeing increased demand for PTFE micronized wax due to growing infrastructure projects, automotive production, and consumer electronics. These regions are expected to be focal points for investment and market expansion.

3. Focus on Sustainability and Regulatory Compliance

Environmental concerns and regulatory pressures surrounding the use of fluoropolymers, such as PTFE, may lead to stricter controls on production and disposal. The industry is likely to respond with innovation, focusing on sustainable alternatives or reducing the environmental footprint of PTFE-based products. In the long term, the shift towards eco-friendly, biodegradable, or non-fluorinated alternatives could reshape the market landscape, but PTFE micronized wax will remain relevant in high-performance applications where few substitutes exist.

4. Advancements in Manufacturing and Customization

The development of advanced manufacturing techniques, such as improved micronization processes, will enable the production of PTFE waxes with more precise particle sizes and optimized performance characteristics. This will cater to industry-specific needs, allowing manufacturers to create highly tailored formulations for niche applications in coatings, plastics, lubricants, and inks.

5. Technological Integration in Electronics and 5G

The rising demand for miniaturization and heat management in electronics, particularly in the 5G era, is expected to push the demand for PTFE micronized wax in specialized coatings and polymers. Its properties, such as heat resistance and low friction, make it ideal for use in electronic components and devices that require high-performance materials to operate reliably at elevated speeds and temperatures.

6. Innovation in Coatings and Inks

The future will likely see a higher adoption of PTFE micronized wax in smart coatings and advanced inks that need enhanced durability, water repellency, and scratch resistance. These applications are expected to grow due to demand in packaging, consumer goods, and protective coatings for infrastructure projects.

7. Strategic Collaborations and Mergers

With increasing competition, market players may focus on strategic partnerships, mergers, and acquisitions to enhance their product offerings and geographical presence. Companies may also seek collaborations with R&D institutions to stay ahead in the innovation curve and comply with evolving environmental standards.

8. Challenges in Raw Material Supply

The volatility in raw material supply chains, especially those tied to fluoropolymers, could continue to pose challenges. Companies will need to adapt by securing stable supply chains and investing in alternative sources of raw materials or substitutes for PTFE where possible.

Segmentation

By Application:

Lubrication

Release Agents

Coatings

Plastics Processing

Textile and Apparel

By End-Use Industry:

Automotive

Machinery and Equipment

Plastics and Polymers

Coatings and Paints

Construction

Textiles and Apparel

By Particle Size:

Submicron

Micronized

Coarse

Browse the full report – https://www.credenceresearch.com/report/ptfe-micronized-wax-market

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Something used the wrong plastic batteries. They're mostly concerned about acidity and corrosion... But they're not protecting for temperature heat or cold!

So they could layer the battery plastic. So you can have an internal liner, and the external will be the traditional plastic. So the internal liner would act as the insulation.

Polytetrafluoroethylene (PTFE), also known as Teflon, is a synthetic fluoropolymer that is highly resistant to corrosion and a wide range of chemicals. PTFE is often used in applications that involve handling corrosive liquids or gases.

PTFE Coatings

Corrosion Resistant - PTFE Coatings

A wide range of colours is also available where colour coding or clear identification purposes are a requirement. These coatings are available in either solvent...

You could use it as an external layer and then used other plastic as an internal give thickness.

And I don't know what the plastic they use with electric car batteries... So they're not using the correct plastic or the electric car batteries either. You can combine these, but in general, they need to add the above or somehow improved the plastic that is existing.

Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS)

Its robustness ensures the safe and long-lasting operation of vital battery components, contributing significantly to the overall safety and efficiency of automotive batteries.

https://richfieldsplastics.com

Electric car batteries use a variety of plastics, including:

Foamed polypropylene

A lightweight, recyclable material that's used for insulation and shock protection.

Polypropylene

A lightweight, chemical-resistant plastic that's used for battery cases and covers. It's also used in lead-acid battery cases.

Polycarbonate

A high-impact plastic that's used for battery cases and covers. It's resistant to chemicals and high temperatures.

Polyamide

A high-strength, stiff plastic that's used for battery holders and housings. It's stable at high temperatures.

Microporous plastic

Used for the separator, which prevents short circuits by separating the cathode and anode. When a cell gets too hot, the separator melts and closes up the micropores, preventing a fire.

Noryl NHP6011 and NHP6012

Glass-fiber-reinforced resins that trim the weight of EV batteries and boost safety.

Plastics Machinery & Manufacturing

Plastics trim EV batteries' weight, boost safety

Feb 15, 2022 — Noryl NHP6011 and NHP6012 are new glass-fiber-reinforced resins featuring a proprietary polyphenylene ether copolymer. They support demand for ...

And another thing it's good impact resistant! Making batteries safe during a crash, and the car designer does not protect the battery during crashes.

LAPP Tannehill

https://www.lapptannehill.com

Zeus 26 AWG Extruded PTFE Lightweight Wall Tubing - Natural

Zeus PTFE extruded tubing offers high flexibility, protection from chemicals, high temperature resistance, highly lubricious, good impact resistance and

And that's a problem with cars is the fluids empty out in accidents.... And that causes another hazard!!!!

So with the sensor system, they could draw fluids into retainer systems that are impact resistant. The system would still maintain a minimum coating But you don't need the excess fluid.... Yes, adding these components will bring up the weight.But I doubt if they need to be extremely heavy, so it should be minimal. But they can sense where the accident is coming from and then reallocate the fluids to a place where you know they're protected from the impact.... Yes you need a vacuum system. So again then I'll add some weight. But you can put the fluids in a protective area. Somewhere centralized on a vehicle. So that means during impact, the fluids won't add to any possible hazards to the humans, whether fire or chemical hazards. And won't leave chemical deposits on the roadway, preventing environmental issues.... So they really need to start thinking about car design better... 🤔 My house, they have some things right, but again, improving makes a difference.....

So you would have to address these disadvantages.....

Disadvantages

…

what are the disadvantages of ptfe coating

The main disadvantage of PTFE is that it does not actually melt when heated and is therefore difficult to process.

https://adtech.co.uk

PTFE: Properties, benefits & uses - Adtech Polymer Engineering

Limited heat resistance: When exposed to temperatures above 260°C, Teflon will begin to decompose, releasing harmful gases, making it unsuitable for …Nov 5, 2018

https://www.quora.com

What are the disadvantages of Teflon? - Quora

Durability: While Teflon is durable, it can scratch or peel over time, which can reduce its non-stick properties and potentially release harmful chemicals …

https://www.krayonnz.com

What is teflon? Mention its advantages and disadvantages? - Krayonnz

But the point is, designing it, so competition can't come in and take your business.....

Well, there's a process that you can do to add certain nanofibers to overcome these disadvantages...

Electrospinning is a process by which polymer nanofibers are produced from polymer solutions or polymer melt by the application of a strong electric field [102].

https://www.sciencedirect.com

Polymer Nanofibers - an overview | ScienceDirect Topics

Electrospinning is a process that can be used to add nanofibers to plastics:

Apply an electric field: A high voltage power supply (HVPS) is used to apply an electric field to a viscous polymer solution.

Eject the polymer: The polymer solution is ejected from a nozzle as a cone shape.

Evaporate the solvent: As the polymer travels to the collector, most of the solvent evaporates.

Collect the nanofibers: The dry nanofibers collect on a metal collector plate to form a membrane.

Electrospinning is a versatile technique that can be used on a variety of natural and synthetic polymers. It can produce nanofibers with controllable diameters, porosities, and compositions.

Electrospun nanofibers have many applications, including:

Biomedical research

Nanofiber mats can mimic the extracellular matrix, allowing cells to attach and receive nutrients.

Drug delivery

Nanofibers can encapsulate drugs, which can increase drug solubility and bioavailability.

Plastic waste management

Recycled polymers can be used to create value-added products through nanocomposite fabrication.

ScienceDirect.com

Nanofiber - an overview | ScienceDirect Topics

4.5. ... Melt spraying is a unique and one-step process for producing self-

So you'll have to do testing to figure out the trade offs, they get the formula, correct.... And believe me, the racing industry would be after this immediately, and we'd be happy to do the research and create it, because it protects their own drivers!!!!!

That's one good thing about racing teams is they're always looking for innovation. You can bring them a product and they might be willing to implement it. And you have to work out the concessions, but they're happy.The test it... Can you can pay them if you don't want to give away anything for them to implement and test.... So you can get them to test under extreme conditions...

Both to test it in all kinds of environments, and you can bring it into motorcycle racing as well and to water sports racing as well.It's a tested in different types of environment... Then, yes, they're gonna need lots of batteries for the space program, so you can test it in zero gravity, an extreme cold...

There are many types of professional car races, including:

Stock car racing

This category originated in Prohibition-era America when moonshiners modified stock cars to outrun authorities. NASCAR is an organization that grew out of this practice.

Rallycross

This type of motorsport combines rally and racing on closed circuits with a mix of gravel and tarmac surfaces. The cars are a combination of rally and racing cars.

Formula 1

This is the highest class of single-seater open-wheel and open-cockpit professional motor racing contest. The FIA (Fédération Internationale de l'Automobile) governs and sanctions Formula One racing.

Touring car racing

This is a motorsport road racing competition with heavily modified road-going cars. It has similarities to stock car racing, but there are also significant differences.

Drag racing

This is a legal and organized competition that takes place on a closed track.

Open wheel

This type of racing includes Formula One (F1) and IndyCar, which feature vehicles with exposed wheels.

Rallying

This type of auto racing takes place with normal or modified road cars on public roads that are closed for competition.

Indianapolis 500

This is the flagship event of IndyCar, which is considered the fastest form of motor racing in America.

Business Insider

Different Types of Auto Racing - Business Insider

May 23, 2014 — IndyCar is fastest form of motor racing in America. Its flagship event, the Indy 500, is an American

So you can get different racing teams and different sports and even yes aircraft racing teams...

There are several types of aircraft racing, including:

Air Race E World Cup

This electric aircraft championship is based on Formula One rules and involves aircraft flying in groups around a 5 km oval course.

Bendix Trophy

This transcontinental, point-to-point race began in 1931 as part of the National Air Races.

Formula 1 pylon races

These races are held regularly, mainly at Reno, Nevada.

Biplane Blue

This race class is for aircraft with two main lifting wings, including tandem configurations.

Aerobatic competitions

The EXTRA/330SC is a popular plane for aerobatic competitions, with a slim and sharp body and a 315Hp engine. The Pitts S-2C Series Planes are also popular for aerobatics, with a patented propeller and a wingspan of 20 feet.

The Air Racing Council of the United States (ARCUS) recognizes several fixed-race classes, including Formula 1, Formula V, Biplane, T-6, T-28, Sport Class, and Unlimited.

Britannica

Air racing | Sport, Aircraft & Competitions - Britannica

The Air Racing Council of the United States (ARCUS) recognizes several fixed-race classes, including Formula 1, Formula V, Biplane, T-6, T-28, Sport Class, and ...

There are many types of water sports racing, including:

Kayaking

A flat-water racing event where athletes can compete solo or in pairs.

Sailing

A sport where boats race around a course marked by buoys or other fixed marks. Small boats often race each other in one-design racing.

Jet skiing

A water sport similar to powerboat racing, where riders compete on jet skis.

Sport diving

A competitive version of scuba diving.

And obviously you can test us in submersibles for pressure related to diving.....

Most diving competitions fall into three categories:

Springboard diving: Includes 1 meter and 3 meter springboard diving

Platform diving: A type of diving competition

Synchronized diving: A type of diving competition

FINA: The governing body for international diving and swimming competitions

Here are some other types of diving:

Advanced open-water diving

A certification that allows divers to dive up to 100 feet (30 meters) deep. Divers learn skills like deep diving, underwater navigation, and night diving.

Technical diving

A highly advanced form of scuba diving that requires more equipment and training than recreational diving.

Military diving

Similar to commercial diving, but also involves underwater surveillance and military research.

Spearfishing

An underwater sport that's popular in many parts of the world.

Saturation diving

A type of diving where the diver stays underwater long enough for their tissues to reach equilibrium with the breathing air.

Epic Sports

Diving Competition Rules and Regulations | Epic Sports

Most diving competitions involve three general categories: Springboard diving (1 meter and 3 meter), platform diving, and synchronized diving. World class divin...

Swahili Divers

ALL 18 Different Types of Diving Explain (With Images) — Swahili ...

Nov 11, 2023 — Advanced open-water diving is a certification that builds on the skills learned in the open-water course and allows divers to dive to depths of up t...

Wikipedia

Scuba set - Wikipedia

A scuba set, originally just scuba, is any breathing apparatus that is entirely carried by an underwater diver and provides the diver with breathing gas at the ...

Ikelite

Safety Advice for Underwater Photographers

We call diving a sport but it is not a competition. As with any adventurous activity you'll be wanting to push your boundaries occasionally. Just be mindful tha...

Wikipedia

Saturation diving - Wikipedia

Saturation diving is diving for periods long enough to bring all tissues into equilibrium with the partial pressures of the inert components of the breathing ..

Wikipedia

Divemaster - Wikipedia

A divemaster (DM) is a role that includes organising and leading recreational dives, particularly in a professional capacity, and is a qualification used in ...

scuba.com

How to Spearfish: A Step-by-Step Guide

Jul 11, 2018 — Spearfishing is a unique underwater sport that is widely recognized and practiced in many parts of the world. If you're a diver or an avid swimmer w...

TRI Air Testing

SCUBA Grade E Compressed Air Testing

Military Diving. Military diving is similar to commercial diving but also involves such tasks as underwater surveillance and military research. TRI can test you...

AQUA DIVERS – Dahab

Scuba and Technical Diving Courses in Dahab - The Complete List

Technical diving is a highly advanced sport form of scuba diving, it takes qualified and experienced divers far deeper than the widespread recreational diving i...

Generative AI is experimental. Learn more

So if you put it through the testing and these actual extreme environments than for the average environment....

And I don't know if walmart sponsors any of these teams since they have both automotive and walmarts and sam's club!!!! Which sam's club is limited and walmart has a more extensive automotive program. I guess they could expand the program at sam's club!!!

0 notes

Text

Unlocking the Benefits of Nickel-Phosphor-PTFE Coatings

Nickel-Phosphor-PTFE coatings have become a significant innovation in the world of material science, offering unique properties that are invaluable across a range of industries. This advanced coating technology combines the corrosion resistance of nickel, the lubricity of polytetrafluoroethylene (PTFE), and the hardness and wear resistance provided by phosphorus. This article explores the various benefits of Nickel-Phosphor-PTFE coatings, their applications, and the science behind why they are so effective.

Understanding Nickel-Phosphor-PTFE Coatings

Nickel-Phosphor-PTFE coatings are composite coatings created through a process called electroless plating. Unlike traditional electroplating, electroless plating doesn’t require an electrical current to deposit the coating. Instead, a chemical reduction process is used, which allows for a uniform coating even on complex shapes and surfaces.

The coating consists of three main components:

Nickel: Known for its excellent corrosion resistance and mechanical properties, nickel forms the primary matrix of the coating.

Phosphorus: Incorporated within the nickel matrix, phosphorus enhances the hardness and wear resistance of the coating. The percentage of phosphorus can vary, leading to different characteristics in the coating, such as low-phosphorus (2-5%), medium-phosphorus (6-9%), or high-phosphorus (10-13%) content.

PTFE (Polytetrafluoroethylene): This fluoropolymer, widely recognized under the brand name Teflon™, is embedded within the nickel-phosphorus matrix, providing a low coefficient of friction and non-stick properties.

Production Process

The production of Nickel-Phosphor-PTFE coatings involves immersing the substrate in a solution containing nickel ions, a phosphorus source (typically sodium hypophosphite), and PTFE particles. The process typically occurs at an elevated temperature, which facilitates the reduction reaction that deposits the nickel-phosphorus alloy and encapsulates the PTFE particles within it.

The resulting coating is highly uniform, adheres well to the substrate, and offers a combination of properties that are difficult to achieve with other types of coatings.

Key Benefits of Nickel-Phosphor-PTFE Coatings

Exceptional Corrosion Resistance

One of the standout features of nickel-phosphor-PTFE coatings is their superior corrosion resistance. Nickel is naturally resistant to oxidation and corrosion, especially when combined with phosphorus, which further enhances this property. Adding PTFE creates a barrier that prevents corrosive agents from reaching the underlying substrate.

This makes Nickel-Phosphor-PTFE coatings ideal for applications in harsh environments, such as marine or chemical processing industries, where exposure to corrosive substances is common. The coatings protect critical components, reducing maintenance costs and extending the lifespan of equipment.

Low Coefficient of Friction

The PTFE component of the coating provides a low coefficient of friction, which is crucial in applications where sliding contact occurs. This lubricity reduces wear and tear on moving parts, minimizes energy loss due to friction, and prevents sticking or galling.

Industries such as automotive, aerospace, and manufacturing benefit significantly from these properties. For example, Nickel-Phosphor-PTFE coatings are used in engine components, gears, and bearings to enhance performance and longevity.

Enhanced Wear Resistance

Nickel-phosphor-PTFE coatings are highly resistant to wear, thanks to the hardness provided by the nickel-phosphorus matrix. This wear resistance is particularly important in high-stress environments where components are subject to abrasion, impact, or repeated motion.

The coating’s ability to withstand wear extends the life of parts, reduces the frequency of replacements, and improves the reliability of machinery. In industries like oil and gas, mining, and heavy machinery, where components are exposed to extreme conditions, the durability of Nickel-Phosphor-PTFE coatings is invaluable.

Chemical Resistance

In addition to corrosion resistance, these coatings offer excellent chemical resistance. PTFE is known for its inertness and ability to withstand exposure to a wide range of chemicals without degrading. When combined with nickel and phosphorus, the resulting coating can resist acids, bases, solvents, and other corrosive substances.

This makes Nickel-Phosphor-PTFE coatings suitable for use in chemical processing equipment, storage tanks, and pipelines, where they protect against chemical attack and prevent contamination of the materials being processed.

Uniform Coverage

The electroless plating process used to create Nickel-Phosphor-PTFE coatings ensures that the coating is applied uniformly, even on complex geometries and internal surfaces. This uniformity is critical for ensuring consistent performance across the entire coated surface, without weak points or areas prone to failure.

This feature is particularly beneficial in applications such as aerospace and electronics, where precision and reliability are paramount. Uniform coverage also means that less material is needed to achieve the desired protection, making the process more efficient and cost-effective.

Versatility and Customization

Nickel-Phosphor-PTFE coatings can be customized to meet specific application requirements by adjusting the phosphorus content, PTFE particle size, and coating thickness. This versatility allows for tailoring the coating’s properties, such as hardness, lubricity, and corrosion resistance, to match the needs of different industries and applications.

For instance, a higher phosphorus content might be chosen for applications requiring increased hardness and wear resistance, while a thicker PTFE layer may be selected for applications prioritizing low friction and non-stick properties.

Applications of Nickel-Phosphor-PTFE Coatings

Automotive Industry

In the automotive industry, Nickel-Phosphor-PTFE coatings are used in various engine components, such as pistons, cylinder liners, and valves. The coatings reduce friction, enhance wear resistance, and improve fuel efficiency, leading to longer engine life and reduced emissions.

Aerospace Industry

Aerospace components, including landing gear, actuators, and hydraulic systems, benefit from the corrosion resistance and low friction provided by these coatings. The coatings help reduce maintenance requirements and improve the reliability of critical systems in demanding environments.

Oil and Gas Industry

The oil and gas industry relies on nickel-phosphor-PTFE coatings to protect equipment such as pumps, valves, and drill bits from corrosion, wear, and chemical attack. These coatings are essential for ensuring the durability and performance of equipment operating in harsh conditions.

Chemical Processing

In chemical processing plants, nickel-phosphor-PTFE coatings are applied to reactors, heat exchangers, and piping systems to prevent corrosion and chemical degradation. The coatings contribute to the longevity and safety of processing equipment.

Electronics

In the electronics industry, these coatings are used to protect connectors, switches, and other components from corrosion and wear, ensuring reliable performance in sensitive electronic devices.

Conclusion

Nickel-Phosphor-PTFE coatings offer a unique combination of properties that make them indispensable in a variety of industries. Their ability to resist corrosion, reduce friction, withstand wear, and provide chemical resistance, all while being customizable to specific needs, makes them a go-to solution for extending life and enhancing the performance of critical components.

As technology advances and industries continue to demand higher performance from materials, the role of nickel-phosphor-PTFE coatings is likely to grow, providing innovative solutions to meet these challenges. Whether in the harsh environments of the oil and gas industry, the precision-driven aerospace sector, or the ever-evolving automotive field, these coatings are unlocking new possibilities for durability, efficiency, and reliability.

0 notes

Text

The Fluoropolymer Film industry is set for significant growth, with projections indicating a rise from USD 1989.66 million in 2024 to an estimated USD 3065.1 million by 2032. This represents a compound annual growth rate (CAGR) of 5.55% over the eight-year period.Fluoropolymer films, renowned for their exceptional chemical resistance, electrical insulation, and thermal stability, have seen a remarkable surge in demand across various industries. This growth is attributed to their diverse applications in sectors such as automotive, aerospace, electronics, and construction. This article delves into the key drivers of the fluoropolymer film market, emerging trends, and the future outlook for this dynamic industry.

Browse the full report at https://www.credenceresearch.com/report/fluoropolymer-film-market

Market Overview

Fluoropolymer films are thin sheets made from polymers that contain fluorine atoms, which impart unique properties such as non-stick characteristics, high chemical resistance, and superior thermal stability. These films are used in applications where durability and performance are critical, including insulation for wires and cables, protective coatings, and as a component in high-performance membranes.

The global fluoropolymer film market has experienced significant growth due to the increasing demand for high-performance materials across various end-use industries. According to recent market research, the market is projected to continue its upward trajectory, driven by technological advancements and expanding industrial applications.

Key Drivers of Market Growth

1. Technological Advancements: Innovations in fluoropolymer film manufacturing have led to the development of new products with enhanced properties. Advances in polymer technology have improved the film's performance in extreme conditions, making them suitable for a broader range of applications.

2. Rising Demand in Automotive and Aerospace Industries: The automotive and aerospace sectors are significant contributors to the growth of the fluoropolymer film market. These industries require materials that can withstand harsh environments, including extreme temperatures and corrosive substances. Fluoropolymer films meet these requirements, providing protection and reliability in critical applications.

3. Increased Use in Electronics: The electronics industry is another major driver of market growth. Fluoropolymer films are used in electronic components, such as insulation for wires and cables, where high performance and reliability are essential. The rapid advancement of electronic devices and the growing demand for high-tech gadgets continue to drive the need for these films.

4. Growing Construction Sector: In the construction industry, fluoropolymer films are used in various applications, including as protective coatings and in building facades. Their durability and resistance to environmental factors make them ideal for use in both residential and commercial construction projects.

Emerging Trends

1. Green and Sustainable Solutions: With increasing environmental concerns, there is a growing emphasis on developing eco-friendly fluoropolymer films. Manufacturers are exploring ways to produce fluoropolymer films with reduced environmental impact, such as by using recyclable materials and implementing sustainable production processes.

2. Customization and Specialized Products: The demand for customized fluoropolymer films tailored to specific applications is on the rise. Companies are focusing on developing specialized films with unique properties to meet the diverse needs of different industries, from high-temperature applications to specialized protective coatings.

3. Expanding Applications: The versatility of fluoropolymer films is leading to their adoption in new and innovative applications. For example, their use in medical devices and renewable energy technologies, such as solar panels, is becoming more prevalent. This expansion into new markets is expected to drive further growth in the industry.

Future Outlook

The fluoropolymer film market is poised for continued growth, driven by technological advancements, increasing demand from key industries, and a shift towards more sustainable practices. As industries evolve and new applications emerge, the market is likely to see a diversification of products and an expansion of its global footprint.

Key Player Analysis:

AGC Chemicals Americas

Asahi Glass Co. Ltd.

Arkema Group

Daikin Industries Ltd.

Dongyue Group Ltd

Flurotek Ab

Honeywell International Inc.

Nitto Denko Corporation

3M Company

Saint Gobain S.A.

Solvay SA

Rogers Corporation

The Chemours Company

Polyflon Technology Ltd.

Segmentation:

By Type

Polytetrafluoroethylene (PTFE)

Polyvinylidene fluoride (PVDF)

Fluorinated ethylene propylene (FEP)

Others

By Application

Insulation

Protective coatings

Gaskets

Films for medical

Electronic uses

By End User

Electronics

Automotive

Aerospace

Healthcare

Industrial sectors.

Based on Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Global Top 15 Companies Accounted for 39% of total Waterproof Fabrics market (QYResearch, 2021)

Waterproof fabrics are fabrics that are inherently, or have been treated to become, resistant to penetration by water and wetting. They are usually natural or synthetic fabrics that are laminated to or coated with a waterproofing material such as rubber, polyvinyl chloride (PVC), polyurethane (PU), silicone elastomer, fluoropolymers, and wax.

In this report we focus on raw membrane material.

According to the new market research report “Global Waterproof Fabrics Market Report 2023-2029”, published by QYResearch, the global Waterproof Fabrics market size is projected to reach USD 2.12 billion by 2029, at a CAGR of 3.9% during the forecast period.

Figure. Global Waterproof Fabrics Market Size (US$ Million), 2018-2029

Figure. Global Waterproof Fabrics Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Waterproof Fabrics include Gore, Performax, Toray Industries, Polartec Neoshell, Swmintl, Sympatex, DSM, Carrington Textiles, Derekduck, Porelle Membranes, etc. In 2021, the global top five players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Future Trends and Growth Projections in the Textile Waterproofing Agents Market

The global high-speed rail coating market, valued at USD 900 million in 2023, is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2024 to 2034. By the end of this forecast period, the market is expected to reach USD 1.8 billion.

The surge in need for environmentally-friendly water repellency is boosting the textile waterproofing agents market revenue. Eco-friendly perfluorinated compound-free water repellents are in high demand in the textiles sector due to rise in the number of environmentally conscious consumers. This trend is leading to the high adoption of C0 textile hydrophobic treatments.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86336

Market Segmentation

By Service Type

Durable Water Repellent (DWR) Coatings: These agents are commonly used for outdoor clothing and gear, providing long-lasting water repellency.

Polyurethane (PU) Coatings: Widely used for both apparel and industrial applications, offering flexibility and durability.

Fluoropolymer Coatings: Known for their superior water repellency and stain resistance, often used in high-performance outdoor wear.

By Sourcing Type

Natural Waterproofing Agents: Derived from natural sources, these are gaining popularity due to the rising demand for sustainable and eco-friendly products.

Synthetic Waterproofing Agents: These include chemically synthesized agents, which are more widely used due to their efficiency and cost-effectiveness.

By Application

Clothing and Apparel: The largest segment, driven by the increasing consumer preference for waterproof and breathable garments.

Industrial Textiles: Used in applications such as protective clothing, tents, and awnings.

Home Textiles: Includes waterproof treatments for items like upholstery and curtains.

By Industry Vertical

Fashion and Apparel: The leading vertical, driven by consumer trends and innovations in textile manufacturing.

Outdoor and Sports Gear: Significant growth due to the rising popularity of outdoor activities and sports.

Industrial and Institutional: Includes applications in protective gear and institutional textiles such as hospital fabrics.

By Region

North America: A mature market with steady growth, driven by high consumer spending and advanced textile technologies.

Europe: Strong demand for high-performance waterproof textiles, particularly in outdoor and fashion sectors.

Asia-Pacific: The fastest-growing region, with significant contributions from emerging economies like China and India.

Latin America: Moderate growth, driven by the expanding textile industry.

Middle East and Africa: Emerging markets with potential for growth, particularly in industrial applications.

Regional Analysis

North America: Dominated by the U.S., this region benefits from a well-established textile industry and high consumer demand for performance apparel.

Europe: Countries like Germany, the UK, and France are key markets, with a strong focus on sustainability and eco-friendly products.

Asia-Pacific: China and India are major contributors to the market's growth, driven by their large manufacturing bases and increasing domestic demand.

Latin America: Brazil and Mexico lead in this region, with growth supported by expanding industrial applications.

Middle East and Africa: Emerging markets with growing interest in advanced textile applications and technologies.

Market Drivers and Challenges

Drivers

Rising Demand for Performance Apparel: Increasing consumer preference for outdoor activities and sports boosts demand for waterproof textiles.

Technological Advancements: Innovations in textile treatments and coatings enhance product performance and expand application areas.

Sustainability Trends: Growing awareness and demand for eco-friendly and sustainable waterproofing agents drive market growth.

Challenges

Environmental Concerns: The use of synthetic waterproofing agents poses environmental challenges, pushing manufacturers towards sustainable alternatives.

Regulatory Hurdles: Stringent regulations regarding chemical treatments in textiles may impact market dynamics.

High Costs: Advanced waterproofing treatments can be expensive, potentially limiting their adoption in price-sensitive markets.

Market Trends

Eco-friendly Waterproofing Agents: Increasing focus on sustainable products, with innovations in natural and bio-based waterproofing agents.

Smart Textiles: Integration of waterproofing with other functionalities, such as breathability and thermoregulation, in smart textiles.

Technological Integration: Use of nanotechnology and advanced materials to enhance the efficiency and durability of waterproofing treatments.

Future Outlook

The textile waterproofing agents market is expected to continue its upward trajectory, driven by technological advancements, increasing consumer demand for high-performance textiles, and a growing focus on sustainability. The development of innovative, eco-friendly waterproofing solutions will be key to capturing market share and meeting evolving consumer preferences.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86336<ype=S

Key Market Study Points

Analysis of market size and growth projections.

Examination of market segmentation by service type, sourcing type, application, industry vertical, and region.

Evaluation of market drivers, challenges, and trends.

Regional analysis to identify key markets and growth opportunities.

Insights into the competitive landscape and recent developments.

Competitive Landscape

The market is characterized by the presence of several key players, including:

3M Company

The Dow Chemical Company

Huntsman Corporation

Wacker Chemie AG

Chemours Company

These companies are focusing on research and development, strategic partnerships, and mergers and acquisitions to strengthen their market position and expand their product offerings.

Recent Developments

Innovation in Sustainable Waterproofing: Leading companies are investing in the development of eco-friendly waterproofing agents to meet regulatory requirements and consumer demand.

Expansion in Emerging Markets: Companies are expanding their presence in emerging markets, particularly in Asia-Pacific and Latin America, to capitalize on growing demand.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Asia-Pacific Metal Packaging Coatings Market - Forecast(2024 - 2030)

Asia-Pacific Metal Packaging Coatings Market Overview

Asia-Pacific Metal Packaging Coatings Market size is forecast to reach US$1,990.4 million by 2027, after growing at a CAGR of 7.3% during 2022-2027. The preference for metal food & beverage containers in the Asia-Pacific region has been increasing rapidly, owing to its range of benefits such as better product protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging. The development of new coating technologies which include Bisphenol A non-intent (BPA-NI) coatings are further fueling the growth of the market in the Asia-Pacific region. Moreover, increasing demand for metal packaging coatings from the pharmaceutical industry are further accelerating the growth of the market in the Asia-Pacific region. Also, strict regulations regarding the use of plastics in various countries across the Asia-Pacific region along with increasing product launches and developments associated with metal packaging is expected to increase the demand for metal packaging coatings for use in various end-use industries over the forecast period.

Covid-19 Impact

The COVID-19 outbreak led to major economic problems and challenges for the food & beverage, pharmaceutical, cosmetic, and other industries in the Asia-Pacific region. According to the International Monetary Fund (IMF), the GDP growth of the Asia declined by 1.3% and Australia by 2.4% as indicated in the graphs, owing to the economic impact of COVID-19. The governments all across the Asia-Pacific region announced strict measures to slow the spread of the coronavirus and only the production of essential commodities were allowed, which impacted the non-essential commodity industries, thereby impacting the production of metal packaging coatings as well. However, economic stimulus packages allotted for multiple sectors in the Asia-Pacific region and the start of industrial production activities since 2021 is improving the metal packaging coatings market growth in the Asia-Pacific region by its increasing utilization in various industries.

Report Coverage

The report: “Asia-Pacific Metal Packaging Coatings Market Report – Forecast (2022-2027)”, by IndustryARC, covers an in-depth analysis of the following segments of the Asia-Pacific metal packaging coatings industry.

By Packaging Types: Food (2 piece and 3 piece), Caps & Closure (External and Internal), and General Line (External and Internal) By Coating Types: Water based, Solvent based, and Powder based. By Resins Type: Acrylic, Fluoropolymer, Urethanes, Epoxy (BPA and Non-BPA), Amines, and Others. By Application: Food (Sea Food, Meat, Infant Nutrition & Dairy, Vegetables, Catering, Biscuits, Cookies & Confectionary, Fats & Oils, Toppings, and Others), Pharmaceutical, Cosmetics, Personal Care, and Others. By Country: China, Japan, Thailand, Vietnam, India, Indonesia, Malaysia, and Rest of Asia-Pacific.

Request Sample

Key Takeaways

China dominated the Asia-Pacific Metal Packaging Coatings Market in the year 2021. One of the key drivers driving the market is increasing use of metal packaging in food products such as fruits, vegetables, infant nutrition & dairy, bakery, and other similar products in order enhance the durability of metal packaging.

Increasing product launches for phenolic resins that are primarily used in a wide range of metal packaging coatings employed in food, pharmaceuticals, and other applications which require a smooth, durable, and spotless finish, has driven the market growth. For instance, In June 2020, companies such as Allnex GMBH, which has its presence in the Asia-Pacific region launched its new eco-friendly phenolic resin for use in BPAni application for metal packaging coatings.

Strict environmental regulations are driving metal packaging coating manufacturers in the Asia-Pacific region to adopt environmentally conscious practices, thus, the demand for water-based coatings are increasing significantly in the region.

Asia-Pacific Metal Packaging Coatings Market Segment Analysis – By Coating Types

The water based coating segment held the largest share in 2021 and is expected to grow at a CAGR of 8.2% by 2027. Water-based coating is an environmentally friendly surface treatment that disperses the resin used in the coatings using water as a solvent. They have a high degree of flexibility and reduce moisture and solar radiation absorption, thereby, resulting in fewer solvent emissions. The VOC (Volatile Organic Compounds) content in the water-based coating is significantly low, and since there are regulations restricting the high VOC content in Asia-Pacific is resulting in its increasing adoption by metal packaging coating manufacturers based in the region. For instance, in 2021, China launched its 14th Five-Year Plan, the chemical sector refocused its environmental protection goals on low-carbon transformation and comprehensive control of VOC emissions, as well as a considerable emphasis on encouraging low VOC products. Furthermore, as compared to solvent-based coatings, water-based coatings for metal packaging require less coating to cover the same surface area, cost less, and do not require any additives, thinners, or hardeners because they provide higher adherence. Thus, water-based barrier coatings are utilized to protect the metal packaging from external and internal effects by sealing the substrate surface.

Inquiry Before Buying

Asia-Pacific Metal Packaging Coatings Market Segment Analysis - By Application

Food sector held the largest share with 66% in the Asia-Pacific Metal Packaging Coatings Market in 2021 and is anticipated to grow at a CAGR of 7.4% during the forecast period 2022-2027. Metal packaging cans, containers, tins, and more are utilized for the packaging of the food because these types of packaging maintain the food filling's flavors and nutritional content ranging from months to several years. However, the direct contact between the metal packaging and food content filled inside the cans and other types of packaging are not safe. The direct contact between metal and food can degrade the food content, owing to this food-friendly coating are applied to safeguard the packaged food from corroding metal. The shifting the focus of Asia-Pacific packaging manufacturers from plastic to metal is expected to drive up the demand for metal packaging coatings for food cans. This is further projected to expand the market growth in the Asia-Pacific region. According to UACJ Corporation, between 2019 and 2022, global demand for aluminium used in cans will rise 11% to 6.61 million tons per year. Southeast Asian countries are likely to account for half of that demand, according to the report. Thus, rising demand for cans will accelerate the production for aluminium cans, which further benefits the metal packaging coatings demand.

Asia-Pacific Metal Packaging Coatings Market Segment Analysis – By Country

China dominated the Asia-Pacific Metal Packaging Coatings Market in terms of revenue with a share of 59% in 2021 and is projected to dominate the market during the forecast period (2022-2026). In China, the metal packaging coatings market is fueled by the growth of the country’s food & beverage sectors. For instance, according to the China Chain Store & Franchise Association, China’s food and beverage sector was valued at around US$ 595 billion in 2019, an increase of 7.8% in comparison to 2018. Metal cans offer a range of benefits such as better food protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging such as paper or plastic packaging. In August 2020, ORG technology, the Chinese manufacturer of food cans, launched its white paper on the strategic development of food cans. The company focused on coated iron metal cans with moisture-proof, environmental protection, safety, corrosion resistance, anti-extrusion, and other characteristics to gain traction in the market. In this way, such increasing food production along with the development of food cans in China, owing to its various benefits as mentioned above, is expected to increase the demand for metal packaging coatings to further enhance the durability of such food cans. This is expected to accelerate the growth of the market in China during the forecast period.

Schedule a Call

Asia-Pacific Metal Packaging Coatings Market Driver

Increasing Preference for Metal Containers in Food & Beverage Sector

Metal packaging coatings are primarily used to coat different metals such as steel, aluminum, tin-plate, and more that are used for food & beverage packaging in order to enhance its ability to resist corrosion. Metal containers offer a range of benefits such as better product protection, durability, sustainability, affordability, light-weight, and more in comparison to other types of packaging such as paper or plastic packaging. For instance, vegetables, fruits, pet food, soups, and meats are often packaged in metal cans. Canning foods help prolong their shelf life and can help people afford to make healthy dietary choices. Similarly, soda, beer, and even wine are usually packaged in aluminum cans since aluminum beverage cans are the most recycled category for aluminum products, with nearly 50 percent of all cans recycled annually. Thus, all of these benefits of metal containers are driving its demand over other types of packaging. As a result, many companies in the Asia-Pacific region have begun packaging their food & beverages in metal containers. For instance, in February 2021, Responsible Whatr, a brand based in India, launched spring water in aluminum beverage cans made by Ball Corporation, a leading manufacturer of aluminum packaging. The company intends to create a brand that signifies sustainability and become a significant contributor to the circular economy. In July 2020, Showa Aluminum Can Corporation (SAC), metal packaging manufacturer, launched its third aluminum can manufacturing facility in Vietnam with an overall plant capacity of 1.3 billion cans per year in order to meet the growing demand for metal packaging from the food & beverage sectors of the country. Thus, such increasing preference and use of metal containers in the Asia-Pacific region are expected to increase the demand for metal packaging coatings to further enhance the durability of the metal containers, thus, accelerating the growth of the market in the Asia-Pacific region.

Growing Demand from the Pharmaceutical Industry

Metal packaging coatings are primarily used in the pharmaceutical industry in order to provide protection to the metal from atmospheric corrosion and support decoration, labeling, and consumer information. Its range of benefits such as impermeability to light, moisture, gases, and water, durability, light-weight, and ease of printing labels directly onto the metal surface make them ideal for use in the pharmaceutical industry. Thus, an increase in pharmaceutical production in the Asia-Pacific region is expected to drive the market growth during the forecast period. According to Vietnam’s Ministry of Health, the pharmaceuticals industry is expected to grow at the rate of 10% per year from 2017 to 2028, owing to an increase in pharmaceutical production and sales in the country. Also, according to International Trade Administration, the local pharmaceutical production in Japan reached up to US$59,958 in 2017, US$62,570 in 2018, US$87,027 in 2019, and US$84,600 in 2020 respectively. thus, indicating an increase in pharmaceutical production in Japan per year. An increase in pharmaceutical production is expected to drive the demand for metal packaging coatings in the pharmaceutical industry, thus accelerating the growth of the market in the upcoming years.

Buy Now

Asia-Pacific Metal Packaging Coatings Market Challenges

Volatility of Raw Material Prices