#Flue Gas Desulfurization (FGD) System manufacturers

Explore tagged Tumblr posts

Text

FRP Pipes: The Future of Corrosion-Resistant Piping Solutions

D Chel Oil & Gas is an established FRP pipe manufacturer in India. FRP pipe is corrosion-resistant, easy to build and transport, has a long service life, and requires minimal maintenance. It transports sewage and wastewater from homes and businesses. Our FRP pipe operates well under a variety of soil and weather conditions. When put in harsh environments, they may have to perform at high temperatures and pressures. FRP pipes are often utilised in a wide range of sectors, including power production, irrigation, gas, and chemical facilities.They are often regarded as the most successful petrochemical industry commodity solutions.

What Are FRP Pipes?

FRP pipes are composite materials made by combining a polymer matrix (typically resin) with fiberglass reinforcements. This combination results in pipes that are lightweight, durable, and highly resistant to corrosion. Unlike traditional metal pipes, FRP pipes do not rust or degrade when exposed to moisture, chemicals, or extreme temperatures, making them ideal for challenging environments.

The manufacturing process involves winding layers of fiberglass filaments with resin to create pipes that possess exceptional strength and longevity. Depending on the application, different resins like epoxy, polyester, or vinyl ester are used to tailor the FRP pipe’s performance.

Key Benefits of FRP Pipes

Corrosion Resistance One of the standout features of FRP pipes is their resistance to corrosion. Traditional materials like steel and iron often corrode when exposed to chemicals, saltwater, or industrial waste. FRP pipes remain unaffected, which significantly reduces maintenance costs and downtime.

Lightweight yet Strong FRP pipes are lightweight compared to metal alternatives, making transportation, handling, and installation much easier and less expensive. Despite their lightweight nature, they are incredibly strong and can withstand high-pressure conditions.

Low Maintenance The durability and corrosion resistance of FRP pipes mean they require minimal maintenance over their lifespan. This makes them a cost-effective solution in the long run, as they outlast most traditional piping materials.

Thermal and Chemical Resistance FRP pipes can handle a wide range of temperatures and chemicals without compromising their structural integrity. This makes them suitable for industries like chemical processing, desalination, and oil & gas.

Long Service Life Thanks to their robust construction and resistance to external factors, FRP pipes can last 50 years or more when properly installed. Their extended service life makes them a reliable investment for large-scale infrastructure projects.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes are widely used in various industries due to their versatility and superior performance. Some common applications include:

Water and Wastewater Treatment: FRP pipes are used for water transmission, sewage lines, and desalination plants, as they are resistant to corrosion and chemicals.

Chemical Industry: They are ideal for transporting acidic or alkaline chemicals without the risk of degradation.

Oil and Gas Sector: FRP pipes are used for flow lines, offshore platforms, and refinery applications due to their durability and resistance to harsh environments.

Power Plants: FRP pipes are used in cooling water systems and flue gas desulfurization (FGD) applications where traditional materials fail to withstand the chemical exposure.

Marine Industry: FRP pipes perform exceptionally well in marine environments due to their resistance to saltwater corrosion.

Why Choose FRP Pipes Over Traditional Materials?

While traditional materials like steel, PVC, and concrete have been widely used in piping systems, they come with limitations such as corrosion, heavy weight, and high maintenance costs. FRP pipes eliminate these drawbacks, offering a longer service life, minimal upkeep, and superior performance in aggressive environments.

For industries seeking to optimize costs and improve operational efficiency, FRP pipes provide a practical and sustainable solution.

FRP Pipe Manufacturers in India

India is home to numerous famous FRP pipe manufacturers who provide high-quality goods that match international specifications.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that clients receive long-lasting and efficient pipe systems. We are also one of the biggest FRP grating manufacturers in India.

#FRP Pipe Manufacturers in India#FRP pipe manufacturers#FRP Pipe Suppliers in India#FRP Grating Manufacturers in India

0 notes

Text

Saudi Arabia Air Quality Control Systems Market

Saudi Arabia Air Quality Control Systems Market Size, Share, Trends: General Electric Leads

Rising Adoption of Hybrid and Multi-Pollutant Control Systems

Market Overview:

The Saudi Arabia Air Quality Control Systems Market is projected to grow at a CAGR of 6.5% from 2024 to 2031, reaching a value of SAR YY billion by 2031. The Central region currently dominates the market, accounting for a significant share. Key metrics include installation volume, emission reduction efficiency, and adoption rates across different industrial sectors. The industry is expanding rapidly, owing to strict environmental regulations, increased industrialisation, and growing awareness of the health risks of air pollution. Government measures encouraging renewable energy and sustainable development are accelerating market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The Saudi Arabia Air Quality Control Systems market is seeing a substantial transition towards hybrid and multi-pollutant control technologies, driven by the need for more efficient and cost-effective emission reduction solutions. Leading environmental technology companies are responding to this trend by developing integrated systems capable of addressing multiple pollutants simultaneously, such as particulate matter, sulfur dioxide, and nitrogen oxides. For instance, a leading global air quality control system manufacturer reported a 60% year-on-year growth in sales of advanced multi-pollutant control solutions in Saudi Arabia in 2023.

Market Segmentation:

Flue Gas Desulfurization (FGD) systems dominate the market, driven by stringent sulfur emission regulations. The FGD sector now commands the greatest market share in Saudi Arabia's Air Quality Control Systems market. According to recent data from the Saudi General Authority of Meteorology and Environmental Protection, FGD systems helped reduce sulfur dioxide emissions from large industrial sites by 60% in 2023 compared to 2018. Technological advancements in FGD systems, such as the development of seawater FGD for coastal facilities and dry sorbent injection for smaller applications, have increased their usefulness across various industries.

Market Key Players:

General Electric (GE)

Siemens

Babcock & Wilcox

Mitsubishi Hitachi Power Systems

Saudi Environmental Projects Ltd.

Advanced Pollution Control Company

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Top Air Pollution Control Equipment Manufacturers in India

Air pollution is one of the major concerns in India due to rapid industrialization and urbanization. To combat this growing issue, industries are turning to Air Pollution Control Equipment (APCE) to reduce harmful emissions. These technologies ensure compliance with environmental standards and contribute to a healthier atmosphere. In this post, we will explore the top Air Pollution Control Equipment Manufacturers in India offering innovative solutions.

Top Air Pollution Control Equipment Manufacturers in India

Par Boiler Limited (www.parboiler.com) Par Boiler is a pioneer in providing air pollution control solutions. They offer a wide range of systems, including bag filters, scrubbers, and electrostatic precipitators (ESPs). Known for energy-efficient and sustainable technologies, Par Boiler serves diverse industries like power, cement, steel, and chemicals.

BHEL (Bharat Heavy Electricals Limited) BHEL is a government-owned enterprise with decades of expertise in industrial equipment manufacturing. They design and deliver efficient electrostatic precipitators and flue gas desulfurization (FGD) systems. BHEL's focus on innovation and reliability makes it a top choice for industries.

GEA India GEA Group specializes in air filtration and purification systems, offering advanced solutions like wet scrubbers, cyclones, and air filtration systems. Their technology is widely used in food processing, pharmaceuticals, and chemical sectors.

KC Cottrell India KC Cottrell is renowned for its Electrostatic Precipitators (ESPs) and dust collection systems. With global experience, KC Cottrell provides innovative solutions for reducing particulate emissions in industries.

A.T.E. Group A.T.E. Group offers a comprehensive range of air pollution control systems, including bag filters, scrubbers, and VOC control systems. Their eco-friendly equipment ensures compliance with emission standards while enhancing operational efficiency.

Lodha Environmental Solutions Specializing in scrubbers, bag filters, and fume extraction systems, Lodha Environmental Solutions delivers tailored air pollution control technologies for the steel, cement, and pharmaceutical industries.

Key Air Pollution Control Equipment and Their Applications

Electrostatic Precipitators (ESPs) Used to remove fine dust particles from industrial emissions. Commonly used in cement, steel, and power plants.

Bag Filters Bag filters capture particulate matter effectively. They are ideal for cement kilns, food processing, and chemical industries.

Scrubbers Scrubbers help neutralize gaseous pollutants by using liquid or chemical solutions. They are commonly used in chemical and power industries.

Cyclone Separators Cyclones use centrifugal force to separate dust particles from gas streams, widely used in wood, pulp, and agriculture industries.

Flue Gas Desulfurization (FGD) Systems FGD systems reduce sulfur dioxide (SO₂) emissions and are critical in coal-based power plants.

Benefits of Air Pollution Control Equipment

Compliance with Environmental Standards: Ensures adherence to emission norms.

Improved Air Quality: Reduces harmful pollutants, protecting human health.

Enhanced Efficiency: Minimizes operational disruptions caused by pollution.

Sustainability: Supports a cleaner and greener environment.

India's top air pollution control equipment manufacturers play a significant role in tackling industrial emissions. With advanced solutions like ESPs, scrubbers, and bag filters, these companies ensure industries meet environmental standards while promoting sustainability. Investing in air pollution control systems not only benefits businesses but also contributes to a cleaner and healthier future.

#AirPollutionControl#CleanAirSolutions#EnvironmentalEquipment#PollutionControlManufacturers#IndustrialSolutions#SustainableIndustries#AirQualityManagement#AirPollutionIndia#Thermax#BHEL#AirFiltration#PollutionControlSystems#GreenTechnology#IndustrialEquipment#CleanerAir#TopManufacturersIndia#Sustainability#EnvironmentalCompliance#IndustrialEmissionControl#AirPollutionSolutions

0 notes

Text

Synthetic Gypsum Market: A Growing Alternative with Sustainable Potential

In recent years, the synthetic gypsum market has witnessed a substantial rise, largely propelled by industries that value sustainable, cost-effective alternatives to natural resources. Synthetic gypsum, produced as a byproduct from various industrial processes, has carved out a vital role across sectors like cement production, building materials, gypsum board manufacturing, soil amendments, and even dentistry. This market trend is not just about substituting natural gypsum but also about supporting industries with a more environmentally friendly and accessible option.

Synthetic gypsum market size is projected to grow from USD 1.4 billion in 2024 and is projected to reach USD 1.8 billion by 2030, at a CAGR of 4.3%.

Let’s delve into the unique dynamics and potential of synthetic gypsum, highlighting its applications, challenges, and emerging opportunities for industries that are increasingly focused on sustainable growth.

What is Synthetic Gypsum?

Synthetic gypsum is chemically identical to natural gypsum—both composed of calcium sulfate dihydrate. However, unlike natural gypsum that is mined, synthetic gypsum is a byproduct, often generated from industrial processes like flue gas desulfurization (FGD) in coal-fired power plants. When these plants capture sulfur dioxide emissions to reduce air pollution, the process yields synthetic gypsum as a usable byproduct. This environmentally beneficial cycle transforms waste into a resource, aligning with broader sustainability goals.

This "upcycled" form of gypsum can be used almost interchangeably with natural gypsum in many applications, thus reducing the demand for mining activities and conserving natural resources.

Key Factors Driving Market Growth

Sustainable Construction and Building Materials: In today’s world, there’s a growing demand for greener building solutions. Since synthetic gypsum comes from recycled industrial byproducts, it’s an attractive option in the construction industry. It conserves natural gypsum reserves, reduces waste, and helps minimize environmental damage, making it an ideal choice for eco-conscious builders and contractors.

Increasing Regulatory Focus on Environmental Protection: Environmental regulations around air quality have driven more facilities to adopt FGD systems, inadvertently boosting synthetic gypsum supply. Governments worldwide have implemented strict environmental policies to reduce industrial emissions, further encouraging the use of synthetic gypsum. The fact that this byproduct can be reused in critical industries only strengthens its appeal.

Surge in Demand for Gypsum Board: The construction boom, particularly in urbanized and rapidly developing regions, has led to an increased demand for drywall. Synthetic gypsum plays a critical role in gypsum board production, offering a fire-resistant, durable, and easy-to-install building material that is highly valued in the construction industry. With this demand on the rise, synthetic gypsum is increasingly essential to meet production needs.

Growing Agricultural Applications: Agriculture is an emerging avenue for synthetic gypsum, where it acts as a soil conditioner. Gypsum helps improve soil structure, enhance water absorption, and prevent erosion. This application has gained attention worldwide, especially in arid and semi-arid regions where synthetic gypsum can provide essential nutrients like calcium and sulfur, improving crop yield and soil health.

Dental and Medical Fields: While perhaps less known, synthetic gypsum is also used in dentistry to create molds and impressions. Its uniformity and purity make it a great choice for this precision-driven field. This niche application is opening up new avenues for synthetic gypsum, as dental professionals recognize its benefits over traditional materials.

Key Applications of Synthetic Gypsum

Cement Production: In cement production, synthetic gypsum is added to clinker to control the setting time. This not only helps improve the consistency of cement but also enhances its structural properties. With synthetic gypsum as an alternative, cement producers can opt for a sustainable and cost-efficient material, supporting their production processes without compromising quality.

Gypsum Board (Drywall) Manufacturing: Synthetic gypsum has a pivotal role in gypsum board manufacturing, particularly in regions like North America and Europe. Gypsum board, made of a gypsum core sandwiched between paper liners, is essential for interior construction. It offers fire resistance, ease of use, and cost-effectiveness. As construction activities increase globally, especially with new housing and commercial projects, synthetic gypsum's demand is set to grow significantly in this segment.

Soil Conditioner in Agriculture: For agricultural use, synthetic gypsum has shown promise as an effective soil amendment. It can improve soil quality by adding calcium and sulfur, enhancing root growth, and aiding in water absorption. This is particularly beneficial in saline or sodic soils, where gypsum helps to balance the soil structure, allowing for better crop growth and soil health.

Dental and Medical Uses: In the dental industry, synthetic gypsum is highly valued for its use in creating dental molds, impressions, and casts. Due to its chemical consistency and purity, synthetic gypsum is a preferred choice in this field, meeting the precision requirements necessary for high-quality dental applications.

Challenges and Future Opportunities

While synthetic gypsum holds numerous advantages, the market does face a few challenges. Transportation costs can be high due to the weight and bulk of gypsum, which may limit its usage in areas far from production facilities. Quality control is another consideration, as synthetic gypsum derived from different sources can vary, making consistent standards necessary, especially for high-end uses in industries like construction and healthcare.

However, the future looks bright for synthetic gypsum. As sustainable materials gain popularity and industries continue to prioritize recycled content, synthetic gypsum is well-positioned to meet the growing demand. Emerging markets, in particular, offer significant potential as they expand infrastructure and prioritize environmentally friendly resources. Additionally, advancements in synthetic gypsum production processes could further enhance its quality, expanding its application potential across new sectors.

To know more Download PDF Brochure :

The synthetic gypsum market is more than just a substitute for natural gypsum—it’s a sustainable alternative that holds unique value across multiple industries. By repurposing industrial waste, synthetic gypsum helps conserve natural resources, supports sustainable manufacturing practices, and meets the needs of diverse applications. From construction and agriculture to healthcare, synthetic gypsum is making a positive environmental impact, helping industries reduce their carbon footprint and promote greener practices. As industries continue to move towards sustainability, synthetic gypsum’s role is only set to grow, carving a more substantial presence in the global marketplace and contributing to a greener future.

#Synthetic Gypsum Market#Sustainability#Cement Industry#Building Materials#Gypsum Board#Soil Amendments#Eco-Friendly Solutions

0 notes

Text

Limestone Market: Trends, Growth, and Future Prospects

The Limestone Market is a sedimentary rock composed mainly of calcium carbonate, has been a crucial material in various industries for centuries. Its wide range of applications, from construction to industrial uses, makes it an essential commodity in the global market. In recent years, the demand for limestone has witnessed a steady increase, driven by infrastructure development, the growth of the steel and cement industries, and environmental sustainability efforts. This blog explores the key trends, growth drivers, and future prospects of the limestone market.

Overview of the Limestone Market

Limestone is a naturally occurring mineral that plays a critical role in a wide range of industrial processes. Its versatility is reflected in its numerous uses, such as in the production of cement, steel, glass, and chemicals. Additionally, it is used as a soil conditioner in agriculture and as a filler in various products like paints, plastics, and toothpaste.

The global limestone market is expansive, with key regions including North America, Europe, Asia Pacific, and the Middle East & Africa. In 2023, the limestone market was valued at approximately USD 76.5 billion, and it is expected to grow significantly over the next few years, driven by rising demand across multiple sectors.

Key Trends Shaping the Limestone Market

Rising Construction and Infrastructure Development One of the most prominent drivers of limestone demand is the booming construction industry. Limestone is a key component in cement production, which is used in building infrastructure projects, such as highways, bridges, and residential and commercial buildings. The surge in urbanization, especially in emerging economies like China, India, and Brazil, has created a heightened need for limestone in construction materials.Countries like China, with its ambitious infrastructure projects under the Belt and Road Initiative, are leading the demand for limestone. Similarly, large-scale housing and road development projects in India are contributing to the expansion of the limestone market.

Growth in the Steel Industry The steel industry is another major consumer of limestone. Limestone is used in the production of steel as a flux to remove impurities like sulfur and phosphorus from the molten iron. The growth of the steel industry, particularly in Asia Pacific, is fueling limestone demand.The Asia Pacific region, home to major steel producers like China, India, Japan, and South Korea, is witnessing increased limestone consumption. China's steel production alone accounts for a significant portion of the global limestone market. As the steel industry continues to grow, particularly with the expansion of manufacturing and automotive industries, limestone will remain in high demand.

Environmental Sustainability and Green Construction Environmental sustainability is becoming a key focus for industries across the globe. In the construction sector, green building practices are gaining popularity, and limestone plays a vital role in this shift. The material is known for its durability and low carbon footprint compared to other construction materials, making it a popular choice for sustainable construction projects.Additionally, limestone is used in flue-gas desulfurization (FGD) systems in power plants to reduce sulfur dioxide emissions. With stricter environmental regulations being implemented worldwide, the demand for limestone in pollution control applications is expected to rise.

Technological Advancements in Limestone Processing Advancements in limestone extraction and processing technologies are also shaping the market. Improved mining techniques, coupled with automation and digitization in limestone processing, have increased production efficiency and reduced operational costs. These innovations are helping limestone producers meet the rising demand while maintaining cost-effectiveness.Additionally, innovations in the use of limestone in composite materials and new applications, such as in carbon capture and storage (CCS) technologies, are opening up new opportunities for the limestone market.

Market Segmentation

The limestone market can be segmented based on various factors, including product type, application, and region.

By Product Type:

High-calcium Limestone: High-calcium limestone contains more than 95% calcium carbonate and is used in industries like steel, construction, and chemicals.

Magnesium-rich Limestone (Dolomitic Limestone): Dolomitic limestone contains significant amounts of magnesium carbonate and is used in the production of refractory materials, fertilizers, and as a flux in steelmaking.

By Application:

Construction: The construction industry is the largest consumer of limestone, primarily for cement production. Limestone aggregates are also used in road construction, rail ballast, and as a building material.

Steel Manufacturing: As mentioned earlier, limestone is crucial in the production of steel, where it acts as a flux to remove impurities from molten iron.

Chemical Manufacturing: Limestone is used in various chemical processes, including the production of lime, a key component in water treatment, flue-gas desulfurization, and the manufacture of glass.

Agriculture: Limestone is used in agriculture to neutralize acidic soils, promoting healthier plant growth. It is also used as a feed additive for livestock.

Environmental Applications: Limestone is increasingly used in environmental applications, such as in FGD systems for reducing sulfur dioxide emissions from power plants and in water treatment facilities to control pH levels.

By Region:

North America: The North American limestone market is driven by the robust construction and steel industries in the United States and Canada. Additionally, the region's environmental regulations are contributing to the increased use of limestone in pollution control applications.

Europe: Europe is another significant market for limestone, with strong demand from the construction and steel sectors. Countries like Germany, France, and the UK are major consumers of limestone, particularly in cement production.

Asia Pacific: Asia Pacific is the largest and fastest-growing market for limestone, driven by rapid industrialization and urbanization in countries like China, India, and Japan. The region's booming construction and steel industries are key factors behind the growth of the limestone market.

Middle East & Africa: The limestone market in the Middle East & Africa is driven by the region's construction boom, particularly in countries like Saudi Arabia, the UAE, and Qatar. The region's steel industry also contributes to the demand for limestone.

Latin America: In Latin America, the limestone market is expanding due to growing infrastructure projects and the development of the construction and steel industries, particularly in Brazil and Mexico.

Future Prospects and Growth Opportunities

The future of the limestone market looks promising, with several growth opportunities on the horizon:

Increasing Infrastructure Investments: As countries continue to invest in infrastructure development, particularly in emerging economies, the demand for limestone in cement production and construction materials is expected to rise.

Expansion of the Steel Industry: With the steel industry set to grow in response to rising demand from the automotive, construction, and manufacturing sectors, limestone will remain a key raw material in steel production.

Environmental Regulations: Stricter environmental regulations will drive the use of limestone in pollution control applications, particularly in flue-gas desulfurization systems in power plants.

New Applications in Carbon Capture: Limestone's potential use in carbon capture and storage (CCS) technologies presents a new avenue for growth. As industries seek ways to reduce carbon emissions, limestone-based CCS systems could play a crucial role in achieving sustainability goals.

Conclusion

The global limestone market is poised for steady growth, driven by demand from the construction, steel, and environmental sectors. With technological advancements, new applications, and increasing infrastructure investments, the future of the limestone market looks bright. As industries continue to evolve, limestone will remain a versatile and essential material, ensuring its continued importance in the global economy.

Browse More

Kombucha Market Overview

Iron Deficiency Anemia Therapy Market Trends

Mustard Market Analysis

0 notes

Text

Flue Gas Desulfurization Systems Market - Forecast(2024 - 2030)

FGD systems is utilizing in the industry to extract to remove Sulphur dioxide (SO2) from the flue gases, it assist in lowering the amount of SO2 in flue gas and assist greenhouse gas emission. Dry, wet and semi dry FGD systems is the key technology to the market. wet FGD is mostly use in the market that is high priced as compare to the dry FGD system and it have low maintenance and operating cost feature also. Dry FGD system perform efficiently in power plant with the capacity of 300MW while wet FGD system efficiency is more than 300MW. Some of the country is growing the flue gas desulfurization market for thermal power generation, the control of SO2 emission from thermal power plant is examined in developing commercial process.

Request Sample

The worldwide Flue Gas Desulfurization Systems Market has been analyzed on the basis its types and the process and different absorbers of flue gas desulfurization and their applications. FGD process are segmented as throwaway product, saleable product process. It has many applications in different industry such as to produce the power, to provide energy to metal smelters, and for cement kilns.

What is Flue Gas Desulfurization Systems Market?

Term flue gas desulfurization referred to wet scrubbers which remove Sulphur dioxide (SO2) from emissions of coal combustion. Flue gas desulfurization is commonly named as FGD, this technology is generally used in power plants to extract the Sulphur dioxide (SO2) from the exhaust combustion gases, this combust gases comes when they burn coal or oil to produce steam for turbines that drive electricity generators. In FGD we use acid rain or acid control system interchangeably to segment a wide range of control system design. FGD system can be categorized as dry FGD, semi-dry FGD, and wet FGD system.

Inquiry Before Buying

What are the applications of Flue Gas Desulfurization Systems Market?

Flue gas desulfurization system has various role to the environment, their sub process such as lime plays a key role to air pollution control. It has many typical industrial application such as pollution control in utility combustion in industry like stationary coal and oil fired, other combustion unit such as medical and municipal waste incinerators, petroleum refineries, glass furnaces, metal smelters, and cement and lime kilns manufacturing facilities.

Market Research and Market Trends of Flue Gas Desulfurization Systems Market:

Many of the country with high pollution rate are working for new advanced feature of FGD system, which is one of the outcomes to their continuous innovation over years. This new AFGD system is more efficient as compare to FGD system efficiency.

FGD scrubbers system creates a wastewater stream which contains high suspended solids, metals and chloride content that is very difficult to handle and recycling for reuse in power plant. So without disposing that waste water they take it into the Zero-liquid discharge (ZLD) water treatment process which completely recycle water under certain limitations.

Schedule a Call

Who are the Major Players of Flue Gas Desulfurization Systems Market?

The major players in this market are Siemens, Chinaboqi, Babcock & Wilcox Company and XX other companies.

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2023.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Buy Now

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#flue gas desulfurization systems market#flue gas desulfurization systems market price#flue gas desulfurization systems market size#flue gas desulfurization systems market shape#flue gas desulfurization systems market report#flue gas desulfurization systems market research#flue gas desulfurization systems market forecast#Sulphur dioxide (SO2)#flue gases#exhaust combustion gases

0 notes

Text

Flue Gas Desulfurization System Market 2024 : Size, Growth Rate, Business Module, Product Scope, Regional Analysis And Expansions 2033

The flue gas desulfurization system global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Flue Gas Desulfurization System Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size - The flue gas desulfurization system market size has grown strongly in recent years. It will grow from $19.59 billion in 2023 to $20.77 billion in 2024 at a compound annual growth rate (CAGR) of 6.1%.The growth in the historic period can be attributed to stringent environmental regulations, rising global focus on air quality, increased coal-fired power generation, public awareness and environmental activism, expansion of industrial manufacturing.

The flue gas desulfurization system market size is expected to see strong growth in the next few years. It will grow to $26.25 billion in 2028 at a compound annual growth rate (CAGR) of 6.0%.The growth in the forecast period can be attributed to transition to renewable energy, market expansion for fgd by-products, government support for clean energy, increasing use of natural gas, focus on circular economy practices. Major trends in the forecast period include integration of digital technologies, shift towards dry fgd technologies, byproduct utilization, collaborations and partnerships, technological advancements in fgd systems.

Order your report now for swift delivery @ https://www.thebusinessresearchcompany.com/report/flue-gas-desulfurization-system-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers - The increasing number of coal-fired power plants is expected to propel the flue gas desulfurization system market. Coal-fired power plants refer to power stations that generate electricity by burning coal. The increasing number of coal-fired power plants requires flue gas desulfurization systems to reduce the emission of harmful gases. For instance, in August 2022, according to the U.S. Energy Information Administration, a US-based principal agency for collecting, analyzing, and disseminating energy information, published an article according to which in the US the coal-fired generation of power has increased by 16% to reach 898,679 GWh in 2021 . Therefore, the increasing number of coal-fired power plants is driving the growth of the flue gas desulfurization system market.

Market Trends - Collaboration is a key trend in the flue gas desulfurization system market. Major players are associating themselves with various companies to sustain in the market. For instance, in January 2022, General Electric (GE), a US-based conglomerate, associated with Apollo International Limited for MB Power Madhya Pradesh Ltd to design the whole Wet Flue Gas Desulfurization (WFGD) system. The project entails the design, engineering, and supply of vital WFGD system components. Once completed, it will help the client clean 7.4 million cubic meters of flue gas per hour and eliminate 51,000 tons of SO2 annually.

The flue gas desulfurization system market covered in this report is segmented –

1) By Type: Wet FGD Systems, Spray Dry FGD System, Dry and Semi-dry FGD Systems 2) By Installation: Greenfield, Brownfield 3) By End-Use: Power Generation, Chemical, Iron and Steel, Metal Processing and Mining, Cement Manufacturing, Paper and Pulp, Other End Uses

Get an inside scoop of the flue gas desulfurization system market, Request now for Sample Report @ https://www.thebusinessresearchcompany.com/sample.aspx?id=8889&type=smp

Regional Insights - Asia-Pacific was the largest region in the flue gas desulfurization system market share in 2023. The regions covered in the flue gas desulfurization system market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Key Companies - Major companies operating in the flue gas desulfurization system market report are Mitsubishi Heavy Industries Ltd., General Electric Company, Doosan Lentjes GmbH, Babcock & Wilcox Enterprises Inc., Rafako S.A, Siemens AG, FLSmidth & Co. A/S, Hamon Corporation, Marsulex Environmental Technologies Corporation, Thermax Limited, Ducon Technologies Inc., Clyde Bergemann Power Group, Andritz AG, Valmet Corporation, Hitachi Power Systems America Ltd., Chiyoda Corporation, China Energy Engineering Group Co. Ltd., Tri-Mer Corporation, Umicore, Veolia Water Technologies, Wärtsilä Corp., Wheelabrator Technologies Inc., Xcel Energy Inc., Yokogawa Electric Corporation, Zhejiang Feida Environmental Science & Technology, Zhejiang DunAn Artificial Environment, Zhejiang Shuanghuan Environmental Protection, Dürr AG, GEA Group AG

Table of Contents 1. Executive Summary 2. Flue Gas Desulfurization System Market Report Structure 3. Flue Gas Desulfurization System Market Trends And Strategies 4. Flue Gas Desulfurization System Market – Macro Economic Scenario 5. Flue Gas Desulfurization System Market Size And Growth ….. 27. Flue Gas Desulfurization System Market Competitor Landscape And Company Profiles 28. Key Mergers And Acquisitions 29. Future Outlook and Potential Analysis 30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Hastelloy C22 Sheets & Plates

Introduction :

Used for various mechanical, helper and general building purposes, the Hastelloy C22 Sheets plates coils are largely being proclaimed because of their stunning built and higher capability to fight against environmental, or artificial damages. The wide range of these products features smooth surfaces, uniform properties and tight flexibility as per the requirements. The wide application of these Hastelloy C22 Sheets plates coils can also be witnessed in solid and sugar plant contraption along with designing plants and the steel plants.

Product Overview : The Hastelloy C22 coils can be easily cold worked due to the ductility and also because the cold forming is a preferred method of forming. These nickel alloy C22 sheets are considered as beneficial in various multipurpose plants in which certain upsetting situation might occur and damage the whole area easily. Application of such plates includes acetic anhydride, acetic acid, acid etching, chlorination systems, cellophane manufacturing and a lot more.

Hastelloy C22 Sheets, Plates & Coils Specification

Specifications : ASTM / ASME SB 575 Size : 6 mm to 120 mm. Length : Single Random, Double Random & Cut Length Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. Specialize : Shim Sheet, Perforated Sheet, B. Q. Profile.

Applications :

Chemical Processing: Used in equipment such as reactors, heat exchangers, and piping systems handling aggressive chemicals like chlorides and acids.

Pollution Control: Components for flue gas desulfurization (FGD) systems, particularly in environments with sulfuric acid and other corrosive compounds.

Pharmaceutical and Food Processing: Ideal for equipment that requires resistance to contamination and corrosion from harsh cleaning agents and processing chemicals.

Conclusion : Hastelloy C22 sheets and plates offer exceptional corrosion resistance, making them indispensable in industries like chemical processing, pollution control, and marine applications.

#Hastelloy C22 Sheets & Plates#Hastelloy C22 Sheets & Plates Suppliers#Hastelloy C22 Sheets & Plates Stockists#Hastelloy C22 Sheets & Plates Exporters#Hastelloy C22 Sheets & Plates Suppliers in India#Hastelloy C22 Sheets & Plates Stockists in India#Hastelloy C22 Sheets & Plates Exporters in India

0 notes

Text

Wet Scrubbers Manufacturers In India

Understanding Wet Scrubbers: The Pioneers of Pollution Control in India

Introduction

In the quest for cleaner air and a sustainable environment, wet scrubbers have emerged as a critical technology in pollution control. As industries in India continue to expand, the need for effective air pollution control devices becomes increasingly essential. Wet scrubbers, with their ability to remove contaminants from exhaust gases, play a significant role in this landscape. This article explores the role of wet scrubbers in India, their functioning, applications, and the broader impact on the environment and industry.

What are Wet Scrubbers?

Wet scrubbers are pollution control devices designed to remove particulate matter and gases from industrial exhaust streams. They operate by introducing the contaminated gas stream to a liquid, usually water or a chemical solution, which absorbs or reacts with the pollutants. The clean gas is then released into the atmosphere, while the pollutants are collected in the liquid phase.

There are various types of wet scrubbers, including:

Absorption Scrubbers: These use a liquid to absorb specific gases from the exhaust stream.

Venturi Scrubbers: These employ high-velocity gas streams and a scrubbing liquid to remove particulate matter.

Packed Bed Scrubbers: These use a packed bed of materials to promote the contact between the gas and the scrubbing liquid.

The Indian Context: Importance of Wet Scrubbers

India, with its rapidly growing industrial sector, faces significant air quality challenges. The country's industrial growth, urbanization, and vehicular emissions have led to increased levels of pollutants, including particulate matter (PM), sulfur dioxide (SO2), nitrogen oxides (NOx), and volatile organic compounds (VOCs). Wet scrubbers are integral to mitigating these issues due to their versatility and effectiveness in removing a broad range of pollutants.

Regulatory Compliance: Indian environmental regulations, such as those set by the Central Pollution Control Board (CPCB), mandate stringent emission standards for industries. Wet scrubbers help industries comply with these regulations by effectively reducing emissions of harmful substances.

Health and Environmental Impact: Air pollution is linked to various health problems, including respiratory diseases and cardiovascular issues. By controlling emissions, wet scrubbers contribute to improved air quality and, consequently, better public health.

Industrial Efficiency: Beyond pollution control, wet scrubbers can enhance industrial efficiency by recovering valuable by-products and reducing maintenance needs caused by corrosion and fouling.

Key Applications of Wet Scrubbers in India

Chemical and Petrochemical Industries: These industries often release hazardous gases and vapors. Wet scrubbers are used to capture these pollutants, ensuring that they do not contribute to air pollution.

Power Plants: Thermal power plants are significant sources of sulfur dioxide and other pollutants. Wet scrubbers, particularly flue gas desulfurization (FGD) systems, are employed to remove SO2 from flue gases.

Steel and Metal Processing: The production of steel and other metals involves high-temperature processes that emit various pollutants. Wet scrubbers are used to control particulate matter and acidic gases.

Pharmaceutical and Food Processing: In these industries, wet scrubbers help manage emissions from processes that generate volatile organic compounds and dust.

Waste Incineration: Wet scrubbers are used to treat the gases produced during waste incineration, helping to control emissions of dioxins, furans, and other harmful substances.

Advantages of Wet Scrubbers

High Efficiency: Wet scrubbers are highly efficient in removing both particulate matter and gaseous pollutants. They can handle a wide range of contaminants, including those that are difficult to capture using other technologies.

Versatility: They can be tailored to specific needs, including the choice of scrubbing liquid and the design of the scrubber system, making them suitable for various industries.

Reduced Maintenance: By removing corrosive and abrasive pollutants, wet scrubbers can extend the life of equipment and reduce maintenance costs.

Recovery of By-products: In some applications, wet scrubbers can recover valuable by-products, such as sulfuric acid from SO2 removal, which can be recycled or reused.

Challenges and Considerations

Operational Costs: Wet scrubbers can involve significant operational costs, including the purchase and maintenance of the scrubbing liquid and the disposal of sludge or spent chemicals.

Water Usage: The need for large quantities of water or other liquids can be a concern, particularly in water-scarce regions. Efficient management of the scrubbing liquid and water recycling practices are crucial.

Sludge Disposal: The collected pollutants in the scrubbing liquid form sludge, which needs to be managed and disposed of properly. This can add to the overall cost and environmental footprint.

Space Requirements: Wet scrubbers often require substantial space for installation and operation, which may be a limiting factor in some industrial settings.

Future Trends and Innovations

The field of wet scrubbers is continually evolving with advancements in technology and materials. Innovations include:

Enhanced Materials: Development of more durable and efficient materials for scrubber components to improve performance and reduce maintenance.

Improved Designs: Advances in scrubber design, such as modular and compact systems, to address space and cost constraints.

Water Recycling: Technologies for recycling and reusing the scrubbing liquid to minimize water usage and reduce environmental impact.

Integration with Other Technologies: Combining wet scrubbers with other pollution control technologies, such as electrostatic precipitators or catalytic converters, to achieve even higher levels of emission control.

Conclusion

Wet scrubbers are an essential technology for controlling industrial emissions and ensuring compliance with environmental regulations in India. Their ability to efficiently remove a wide range of pollutants makes them invaluable in various industries, from chemical manufacturing to power generation. As India continues to address its air quality challenges, the role of wet scrubbers will remain crucial in achieving cleaner air and a healthier environment. With ongoing advancements and innovations, wet scrubbers are poised to contribute even more significantly to pollution control in the future.

URL: For more information, visit Essar Air Systems - wet scrubbers manufacturers in India

0 notes

Text

Global Top 5 Companies Accounted for 77% of total Flue Gas Desulfurizer (FGD) market (QYResearch, 2021)

Flue gas desulfurizer (FGD) is equipment which can remove sulfur dioxide (SO2) from flue gas emissions, often chemically. Sulfur dioxide in gases is produced by the combustion of fossil fuels and many industrial processes such as gasoline refining as well as cement, paper, glass, steel, iron and copper production. Sulfur dioxide emissions are a primary contributor to acid rain and have been regulated by every industrialized nation in the world.

FGD processes vary depending on the amount of SO2 involved, the solution being used to absorb the SO2, and the particular equipment used in the absorption tower.

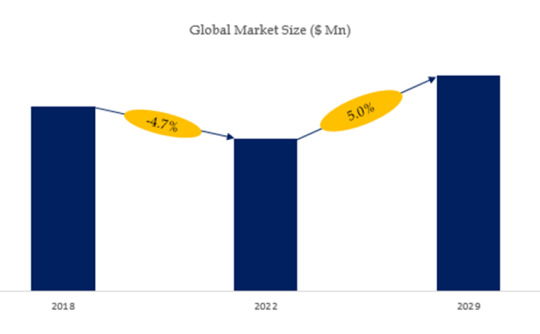

According to the new market research report “Global Flue Gas Desulfurizer (FGD) Market Report 2023-2029”, published by QYResearch, the global Flue Gas Desulfurizer (FGD) market size is projected to reach USD 6.29 billion by 2029, at a CAGR of 5.0% during the forecast period.

Figure. Global Flue Gas Desulfurizer (FGD) Market Size (US$ Million), 2018-2029

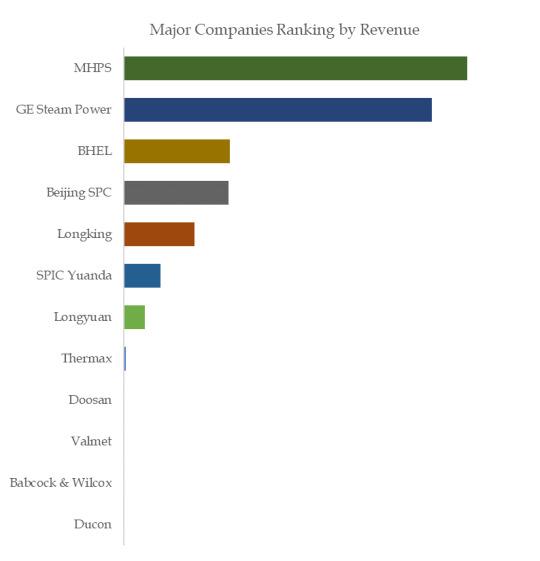

Figure. Global Flue Gas Desulfurizer (FGD) Top 12 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Flue Gas Desulfurizer (FGD) include MHPS, GE Steam Power, BHEL, Beijing SPC, Longking, SPIC Yuanda, Longyuan, Thermax, Ducon, Babcock & Wilcox, etc. In 2020, the global top five players had a share approximately 77.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

FLUE GAS DESULFURIZATION (FGD) SCRUBBER MANUFACTURER

By Waterman Engineers Australia

FLUE GAS DESULFURIZATION (FGD) SCRUBBER MANUFACTURER

FLUE GAS DESULFURIZATION (FGD) SCRUBBER Desulfurization of flue gases

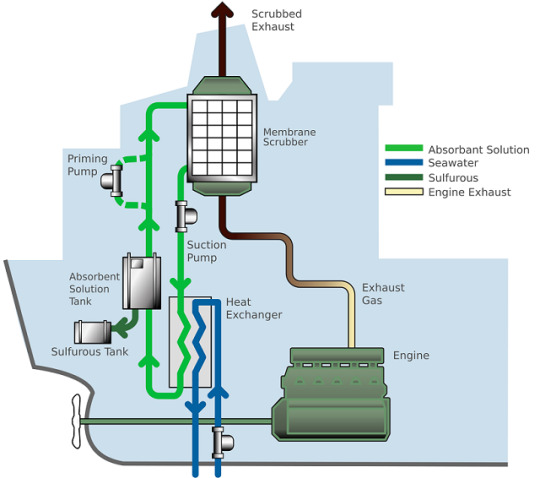

FGD, commonly known as a wet scrubber, is a form of air pollution management device used to remove sulphur dioxide (SO2) from industrial process and power plant exhaust flue gases. Sulfur dioxide, a hazardous gas, produced by the combustion of coal and oil, it contributes to acid rain and other environmental hazards as well.

The FGD process involves spraying a liquid solution, usually a mixture of water and limestone or lime, into the flue gas stream. The solution reacts with the sulfur dioxide in the gas stream, forming a solid compound that can be collected and disposed of. The FGD equipment typically consists of a scrubbing tower or vessel, a recirculation system for the liquid solution, and a solid handling system for the by-products.

There are several types of FGD systems, including spray tower, venturi scrubber, and packed bed scrubber systems. Each system has its own unique advantages and disadvantages, depending on the specific application and operating conditions.

One of the main advantages of FGD equipment is its effectiveness in removing sulfur dioxide from flue gas streams. With proper design and operation, FGD systems can remove up to 99% of the sulfur dioxide emissions from power plants and industrial processes. This can significantly reduce the environmental impact of these operations and help to meet regulatory requirements.

Another advantage of FGD equipment is its ability to produce useful by-products. The solid compounds formed during the FGD process, such as gypsum and calcium sulfite, can be sold or reused in other applications, such as cement manufacturing and agriculture. This can provide a cost savings and environmental benefit for the facility.

However, there are some disadvantages to FGD equipment. The expense of installation and operation is one of the most significant challenges. To function properly, FGD systems necessitate a large capital investment as well as continual maintenance. The liquid solution used in the process can be costly as well, and the solids handling system must be carefully managed to avoid environmental issues.

One type of Flue gas desulfurization is given below.

a) Packed Tower Gas Scrubber:

Tower Gas in Packing In scrubbers, a tower of packing material is used to increase the surface area of the gas-liquid contact region. As the gas stream moves through the tower, the liquid stream that removes contaminants interacts with it. By entering through tower the intake near the bottom and moving through the support plate and packed bed in the opposite direction as the scrubbing liquid flow, gas eliminates contaminants. After passing through the packed bed, the cleaned gas continues its journey towards the top of the tower through a mist eliminator section. In this case, any entrained liquid is removed before the pure air is released through the exit. These types of scrubbers work best when the gases being handled are clear of particles, as these have a tendency to clog the packing.

Advantages:

Packed Tower Gas Scrubbers are effective at removing a wide range of pollutants, including particulate matter, acid gases, and organic compounds.

Application:

Packed Tower Gas Scrubbers are commonly used in industries such as chemical manufacturing, pharmaceuticals, and wastewater treatment

2. Packaged Scrubber:

Packaged Scrubbers are compact air pollution control systems that combine several different air pollution control technologies into a single unit. They typically consist of a wet scrubber, followed by a mist eliminator and a fan.

Advantages:

Packaged Scrubbers are compact and easy to install and can be used to control a wide range of air pollutants. They are particularly effective at removing particulate matter and acid gases.

Application:

Industries like food processing, pharmaceuticals, wastewater treatment, and water-soluble VOC cleaning all frequently employ packaged scrubbers to remove chlorine, HCI, ammonia, and SO2 or H2S.

3. WET Electrostatic Precipitators:

An electrostatic precipitator known as a WET Electrostatic Precipitator (ESP) removes contaminants from gas streams by using a liquid medium. A high voltage electrode is used to charge the pollutants in the gas stream, which attracts them to the liquid medium. In an ESP chamber, contaminated air is drawn in and ionised by electron emitting electrodes. The electron field charges the suspended particles, which then move to a collection plate. Rapping or beating the collection plates with rappers periodically removes accumulated particle matter from the plates. Heavy particles fall to the ESP's base where they are collected in hoppers for disposal.

Advantages:

WET ESPs are effective at removing a wide range of pollutants, including fine particulate matter and acid gases. They are also relatively easy to operate and maintain.

Application:

WET ESPs are commonly used in industries such as power generation, cement manufacturing, and metal processing.

4. Kitchen Exhaust Scrubber:

Kitchen Exhaust Scrubbers are used to remove grease, smoke, and other pollutants from commercial kitchen exhausts. To clean up the gas stream, they often employ a wet scrubbing method. Pollutants are drawn into a liquid mist that is passed through a gas stream.

Advantages:

Kitchen Exhaust Scrubbers are effective at removing grease and smoke from commercial kitchen exhausts. They can also improve air quality in the surrounding area.

Application:

Kitchen Exhaust Scrubbers are commonly used in commercial kitchens, such as those found in restaurants, hospitals, and schools.

5. Boiler Wet Scrubbers:

Boiler Wet Scrubbers are used to remove pollutants such as sulfur dioxide and nitrogen oxides from boiler emissions. These contaminants are frequently chemical substances like ammonia, chlorine, or sulfur compounds. To clean up the gas stream, they often employ a wet scrubbing method. A liquid mist is used to pass through the gas stream, reacting with the contaminants to eliminate them.

Advantages:

Boiler Wet Scrubbers are effective at removing a wide range of pollutants from boiler emissions. They can also help to improve boiler efficiency and reduce fuel costs.

Application:

Boiler Wet Scrubbers are commonly used in industries such as power generation, chemical manufacturing, and paper and pulp production

6. Scrubber for Jet Venturi Fumes:

The Jet Venturi Fume Scrubber is a type of wet scrubber that sucks in the gas stream to be treated by creating a vacuum with a high-velocity water stream. The gas stream is then accelerated and combined with the water stream after being driven via a Venturi throat. As a result, there is extensive contact between the gas and liquid, which effectively removes contaminants.

Advantages:

Jet Venturi Fume Scrubbers can manage a wide range of gas flow rates and pollutant concentrations and are relatively simple and straightforward to operate. They are particularly good in eliminating acid gases and particle materials.

Application:

Jet Venturi Fume Scrubbers are commonly used in industries such as chemical manufacturing, pharmaceuticals, and metal processing.

7. Vent Gas Scrubber System:

Vent Gas Scrubber Systems are used to remove pollutants from gas streams that are vented from storage tanks, reactors, and other equipment. To clean up the gas stream, they use a combination of wet scrubbing and gravity separation.

Advantages:

Particulate matter, sulphur dioxide, and nitrogen oxides are just a few of the contaminants that Vent Gas Scrubber Systems are good at getting rid of. They are also rather easy to understand and use.

Application:

Vent Gas Scrubber Systems are commonly used in industries such as oil and gas, chemical manufacturing, and petrochemicals.

8. High Energy Venturi Scrubber System:

High Energy Venture Scrubber Systems, which combine a High Energy Venture Scrubber and a Cyclon Separator, are intended to remove fine micron and submicron material from industrial and commercial effluent gases. These scrubbers are efficient at removing a wide range of air pollutants, including dust, fumes, vapours, and mists. Because there is so much contact between the gas and the liquid because of the turbulence, pollutants can be removed effectively.

Advantages:

High Energy Venturi Scrubber Systems are particularly effective at removing fine particulate matter and other pollutants such as sulfur dioxide and nitrogen oxides.

Application:

High Energy Venturi Scrubber Systems are commonly used in industries such as power generation, cement manufacturing, and steel production.

9. Fume Scrubber:

Fume Scrubbers are used to remove harmful fumes and gases from industrial processes. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Fume Scrubbers are effective at removing a wide range of pollutants, including corrosive gases and acid mists. They can also help to improve workplace safety and air quality.

Application:

Fume Scrubbers are commonly used in industries such as metal processing, chemical manufacturing, and pharmaceuticals.

10. Foundry Wet Scrubbers:

Foundry Wet Scrubbers are used to remove pollutants such as particulate matter and volatile organic compounds from foundry emissions. To clean up the gas stream, they often employ a wet scrubbing method.

Advantages:

Foundry Wet Scrubbers are effective at removing a wide range of pollutants from foundry emissions. They can also help to improve workplace safety and air quality.

Application:

Foundry Wet Scrubbers are commonly used in industries such as metal casting, aluminum production, and iron and steel manufacturing.

11. Food Industries Wet Scrubber:

Food Industries Wet Scrubbers are used to remove pollutants such as odours, smoke, and grease from food processing emissions. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Food Industries Wet Scrubbers are effective at removing a wide range of pollutants from food processing emissions. They can also help to improve workplace safety and air quality.

Application:

Food Industries Wet Scrubbers are commonly used in food processing facilities, such as those that produce baked goods, meat products, and dairy products.

12. Chemical Factory Wet Scrubber:

Chemical Factory Wet Scrubbers are used to remove pollutants such as acid gases, particulate matter, and volatile organic compounds from chemical manufacturing emissions. They typically use a wet scrubbing system to remove pollutants from the gas stream.

Advantages:

Chemical Factory Wet Scrubbers are effective at removing a wide range of pollutants from chemical manufacturing emissions. They can also help to improve workplace safety and air quality.

Application:

Chemical Factory Wet Scrubbers are commonly used in industries such as pharmaceuticals, petrochemicals, and plastics manufacturing.

13. Generator Wet Scrubber:

Generator Pollutants including nitrogen oxides and sulfur dioxide are removed from diesel generator exhaust using wet scrubbers. NOX, HC, CO, and PM, which includes any observable smoke and soot, are among the exhaust emissions from diesel-powered generators. Our dust collector technology completely captures the pollutants in the exhaust flow and emits only clean air. To clean up the gas stream, they often employ a wet scrubbing method.

Advantages:

Generator Wet Scrubbers are effective at removing a wide range of pollutants from diesel generator emissions. They can also help to improve air quality and reduce environmental impacts.

Application:

Generator Wet Scrubbers are commonly used in industries such as power generation, data centers, and backup power systems.

FGD & Venturi Scrubbers Frequently Asked Questions

Q. What is an FGD scrubber for air pollution control?

A. An FGD scrubber, also known as a Flue Gas Desulfurization scrubber, is a device used to remove sulfur dioxide (SO2) from flue gases emitted by industrial processes or power plants.

Q. How does an FGD scrubber work to control air pollution?

A. An FGD scrubber uses a chemical process to absorb sulfur dioxide from flue gases. Typically, a slurry containing a sorbent, such as a limestone or lime, is sprayed into the flue gas stream. The sorbent reacts with sulfur dioxide, forming a solid byproduct that can be disposed of safely.

Q. What are the main components of an FGD scrubber system?

A. An FGD scrubber system consists of several key components, including an absorber tower, a reagent storage and preparation system, a slurry circulation system, a mist eliminator, and a wastewater treatment system.

Q. What types of pollutants can an FGD scrubber remove?

A. FGD scrubbers are primarily designed to remove sulfur dioxide (SO2) from flue gases. However, they can also capture other pollutants such as mercury, particulate matter, and some trace metals.

Q. What are the advantages of using an FGD scrubber for air pollution control?

A. The advantages of using an FGD scrubber include the effective removal of sulfur dioxide, which helps reduce acid rain and respiratory issues. Additionally, it can capture other pollutants, improve air quality, and comply with environmental regulations.

Q. What are the environmental benefits of using Venturi scrubbers?

A. Venturi scrubbers provide environmental benefits by reducing particulate matter emissions, which can contribute to improved air quality and human health. They also aid in the removal of certain gases and odors, helping to minimize potential environmental nuisances. By controlling pollution at its source, Venturi scrubbers contribute to sustainable and responsible industrial practices.

Q. How effective are FGD scrubbers in reducing air pollution?

A. FGD scrubbers are highly effective in reducing sulfur dioxide emissions. They can achieve removal efficiencies of up to 90-99% for sulfur dioxide, depending on the design and operating conditions.

Q. Are there different types of FGD scrubbers available?

A. Yes, there are various types of FGD scrubbers, including wet scrubbers (such as limestone/gypsum and seawater scrubbers), dry scrubbers (such as spray dry and dry injection scrubbers), and electrostatic precipitators.

Q. What is a venturi scrubber for air pollution control?

A. Venturi scrubber is an air pollution control device that uses the principle of a venturi nozzle to remove pollutants from industrial exhaust gases. It is particularly effective in capturing particulate matter and some gases.

Q. How does a venturi scrubber work to control air pollution?

A. Venturi scrubber operates by creating a high-velocity gas stream through a narrow throat section, which creates a pressure drop. Polluted gases are forced through the venturi throat, where they collide with liquid droplets. The pollutants adhere to the liquid droplets, which are then separated and collected.

Q. What are the key components of a venturi scrubber system?

A. Venturi scrubber system typically includes a venturi scrubber chamber, a liquid or water injection system, a gas inlet, a mist eliminator, and a collection and disposal system for the captured pollutants.

Q. What types of pollutants can a venturi scrubber remove?

A. Venturi scrubbers are effective in removing various pollutants, including particulate matter, dust, aerosols, gases such as sulfur dioxide and hydrogen chloride, and certain volatile organic compounds (VOCs).

Q. What are the advantages of using a venturi scrubber for air pollution control?

A. Venturi scrubbers offer high collection efficiencies for particulate matter, including fine particles. They are also effective for capturing gases and certain volatile organic compounds. Venturi scrubbers have a simple design, require minimal maintenance, and can handle high gas temperatures and high particulate loadings.

Q. How effective are venturi scrubbers in reducing air pollution?

A. Venturi scrubbers can achieve high collection efficiencies for larger particles, typically above 90%. However, their efficiency for smaller particles may vary depending on factors such as particle size, inlet concentration, and operating conditions.

Q. Are Venturi scrubbers suitable for high-temperature applications?

A. Venturi scrubbers can be designed to handle high-temperature gas streams, but there are limitations. The materials of construction and thermal insulation must be carefully selected to withstand the temperature without compromising the scrubber's performance or integrity. Higher temperatures can also affect the choice of liquid used for scrubbing and may require additional heat management measures.

Q. Are there different types of venturi scrubbers available?

A. Yes, there are different types of venturi scrubbers, including single-stage venturi scrubbers, multi-stage venturi scrubbers, and high-energy venturi scrubbers. Each type has specific applications and operating principles.

Q. Can FGD scrubbers and venturi scrubbers be used together in an air pollution control system?

A. Yes, FGD scrubbers and venturi scrubbers can be used together in an air pollution control system. FGD scrubbers primarily target sulfur dioxide removal, while venturi scrubbers are effective in capturing particulate matter and certain gases. Combining these technologies can enhance overall pollutant removal efficiency.

Q. How do Venturi scrubbers compare to other air pollution control devices?

A. Venturi scrubbers have certain advantages over other air pollution control devices. Compared to electrostatic precipitators, they can handle higher gas flow rates and are more effective for removing fine particles. Compared to wet scrubbers, Venturi scrubbers have a more compact design and can handle higher gas velocities. However, the choice of the most suitable control device depends on the specific requirements of the application.

Q. What industries or applications commonly use FGD scrubbers?

A. FGD scrubbers are commonly used in industries such as power generation, coal-fired plants, oil refineries, cement production, and waste incineration, where sulfur dioxide emissions need to be controlled.

Q. What industries or applications commonly use venturi scrubbers?

A. Venturi scrubbers find applications in various industries, including metal refining, chemical processing, pulp and paper manufacturing, pharmaceuticals, food processing, and incineration plants.

Q. Are there any regulations or standards related to the use of FGD scrubbers and venturi scrubbers for air pollution control?

A. Regulations and standards regarding the use of FGD scrubbers and venturi scrubbers vary across countries and regions. Environmental agencies and regulatory bodies typically set emission limits and guidelines for air pollution control technologies, including scrubbers, to ensure compliance with air quality standards and environmental protection. It is important for industries to adhere to these regulations and standards when implementing scrubber systems.

Q. Can Venturi scrubbers be used for removing heavy metals from emissions?

A. Venturi scrubbers are primarily designed for particulate matter removal and may have limited effectiveness in removing heavy metals from emissions. For the efficient removal of heavy metals, specialized control technologies such as wet scrubbers with specific chemical reagents or electrostatic precipitators with high-efficiency collection plates are often employed.

1 note

·

View note

Text

Understanding FRP Pipes: A Comprehensive Guide to Benefits and Applications

D Chel Oil & Gas is a recognised FRP pipe manufacturer in India. FRP pipes are well-known for their exceptional durability, corrosion resistance, and lightweight construction. These pipes are utilised in a variety of sectors, including chemical processing, water treatment, and oil and gas, where they must withstand high pressures and extreme environmental conditions. FRP pipes' non-corrosive nature makes them perfect for long-term applications, lowering maintenance costs and assuring consistent performance.

What Are FRP Pipes?

FRP pipes are composite structures composed of thermosetting resins, such as polyester, vinyl ester, or epoxy, reinforced with fiberglass. These materials are layered to form a robust yet lightweight structure, creating pipes with superior mechanical and chemical properties. The use of advanced manufacturing techniques, such as filament winding and centrifugal casting, ensures consistent quality and performance.

Key Features and Advantages of FRP Pipes

Corrosion Resistance One of the standout properties of FRP pipes is their excellent resistance to corrosion. Unlike steel, which is prone to rusting, or concrete, which degrades over time when exposed to harsh chemicals, FRP pipes maintain their integrity in aggressive environments. They are ideal for transporting corrosive fluids in chemical plants, wastewater treatment facilities, and marine applications.

Lightweight and High Strength Despite their lightweight nature, FRP pipes are incredibly strong. Their high strength-to-weight ratio makes them easier to handle, transport, and install compared to heavier materials like steel or concrete. This reduces labor costs and minimizes the need for heavy equipment during installation.

Longevity and Low Maintenance FRP pipes have an impressive lifespan, often exceeding 50 years when properly maintained. Their resistance to wear and tear, combined with their immunity to chemical attacks, means they require minimal maintenance, saving costs over time.

Thermal and Electrical Insulation FRP pipes are excellent insulators, both thermally and electrically. This makes them suitable for applications where temperature fluctuations or electrical conductivity pose challenges.

Customization and Versatility FRP pipes can be customized in terms of size, shape, and resin composition to suit specific industrial needs. Their adaptability ensures they can be tailored to meet the exact requirements of various applications.

We Supply In Various Countries Llike :

FRP Supplier in Qatar

FRP Supplier in Saudi Arabia

FRP Supplier in Bangladesh

FRP Supplier in Oman

FRP Supplier in Malaysia

Applications of FRP Pipes

FRP pipes have found applications in diverse industries, thanks to their unique properties. Some of the key sectors where they are widely used include:

Chemical and Petrochemical Industries FRP pipes are extensively used for transporting corrosive chemicals, acids, and alkalis in chemical and petrochemical plants. Their ability to withstand extreme pH levels and high temperatures makes them a preferred choice.

Water and Wastewater Management Municipalities and industries use FRP pipes for sewage systems, desalination plants, and water treatment facilities. Their corrosion resistance ensures long-term performance in handling potable and non-potable water.

Oil and Gas Industry In oil and gas operations, FRP pipes are used for offshore platforms, pipelines, and storage tanks. Their lightweight nature and resistance to saltwater and hydrocarbons make them indispensable in this sector.

Power Plants FRP pipes are commonly employed in cooling water systems, flue gas desulfurization (FGD) units, and other power plant infrastructure due to their durability and thermal insulation properties.

Marine and Offshore Applications FRP pipes are well-suited for marine environments, where exposure to salt water can corrode traditional materials. They are used in shipbuilding, docks, and offshore platforms.

FRP Pipe Manufacturers in India

India is home to numerous famous FRP pipe manufacturers who provide high-quality goods that match international specifications.FRP Pipe Suppliers in India provide a wide range of solutions tailored to specific industrial requirements, ensuring that clients receive long-lasting and efficient pipe systems. These producers are well-known across the world for their long-lasting and cost-effective FRP pipe solutions, which are the result of modern manufacturing procedures and strict quality control. We are also one of the leading FRP grating manufacturers in India.

0 notes

Text

Sulfur Dioxide Market Size, Scope, Growth Opportunities, Trends by Manufacturers And Forecast to 2030

The global sulfur dioxide market size is likely to reach US$ 8.15 Billion in 2023 and is expected to reach US$ 10.01 Billion by 2030, and register a rapid revenue CAGR of 4% from 2023 to 2030. The market is driven by the increasing demand for SO2 in various applications, including the production of sulfuric acid, the bleaching of paper and pulp, the refrigeration of food and beverages, and the preservation of food.