#Flexible Electronics Market Research

Explore tagged Tumblr posts

Text

Flexible Electronics Industry Analysis, Opportunities And Forecast Report, 2030

The global flexible electronics market was valued at USD 24.94 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2023 to 2030. This growth can be attributed to the increasing consumer adoption of laptops and smartphones, as well as the expanding application of flexible electronics such as flexible batteries and displays in the consumer electronics industry. Manufacturers in the consumer electronics space are focusing on developing innovative, compact products with enhanced functionality. The integration of flexible displays and batteries in these devices contributes to the creation of lightweight, durable, bendable, and rugged products, aligning with consumer demands for advanced features.

In addition to consumer electronics, the healthcare industry is experiencing rapid advancements in medical devices, surgical procedures, and diagnostic tools. There is a growing demand for minimally invasive surgical and diagnostic procedures, which necessitates the use of medical devices that possess excellent electrical properties, flexibility, and stretchability. The demand for flexible batteries and sensors in the healthcare sector is expected to rise as these devices cater to such needs. For example, in May 2022, Vivalink, a provider of digital healthcare solutions, introduced a multi-vital blood pressure patch designed for commercial and research applications. This patch captures essential medical data, such as ECG traces, heart rates, and respiratory rates, through electrical signal-based technology, showcasing the potential of flexible electronics in medical advancements.

Furthermore, the automotive industry in regions like the U.S., China, and India has been witnessing substantial growth due to rising consumer spending on vehicles. To cater to this demand and differentiate their models, vehicle manufacturers are increasingly incorporating advanced features into vehicles, such as thin-film heaters, flexible backlighting, and capacitive touch surfaces. This wide range of applications for printed sensors and flexible batteries in the automotive sector is expected to drive the growth of the flexible electronics market. Consumers seek vehicles with modern interiors and technology, pushing automakers to adopt flexible electronics solutions.

Gather more insights about the market drivers, restrains and growth of the Flexible Electronics Market

Component Segmentation Insights:

The flexible electronics market is segmented based on components, with the displays segment accounting for the largest revenue share over 53.0% in 2022. This segment is expected to experience the highest CAGR during the forecast period. The growth of the flexible display market is driven by increasing consumer demand for advanced display technologies that are capable of bending, rolling, or providing a certain degree of flexibility. Flexible displays offer significant advantages over traditional displays, including reduced power consumption, making them more energy-efficient.

The batteries segment is also expected to witness considerable growth over the forecast period. Flexible batteries are gaining popularity due to their easy integration into various products, including wearable electronics and flexible devices. Additionally, flexible batteries offer benefits such as flame resistance, waterproofing, and the ability to withstand bending, folding, and stretching, which further increases their demand in electric vehicles. The need for seamless integration of electronics into everyday objects such as clothing, medical devices, and even within the human body has also spurred the demand for flexible batteries. These advancements cater to the growing market for flexible electronics in a range of industries.

In conclusion, the global flexible electronics market is experiencing robust growth, driven by rising consumer demand for advanced, portable, and energy-efficient devices in industries such as consumer electronics, healthcare, and automotive. The widespread applicability of flexible displays, batteries, and sensors is propelling innovation across sectors, positioning flexible electronics as a key enabler of future technological advancements.

Order a free sample PDF of the Flexible Electronics Market Intelligence Study, published by Grand View Research.

#Flexible Electronics Industry#Flexible Electronics Market Research#Flexible Electronics Market Forecast#Flexible Electronics Market Overview

1 note

·

View note

Text

Flexible Electronics Industry Analysis And Segment Forecast till 2030

The global flexible electronics market was valued at USD 24.94 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 10.5% from 2023 to 2030. This growth can be attributed to the increasing consumer adoption of laptops and smartphones, as well as the expanding application of flexible electronics such as flexible batteries and displays in the consumer electronics industry. Manufacturers in the consumer electronics space are focusing on developing innovative, compact products with enhanced functionality. The integration of flexible displays and batteries in these devices contributes to the creation of lightweight, durable, bendable, and rugged products, aligning with consumer demands for advanced features.

In addition to consumer electronics, the healthcare industry is experiencing rapid advancements in medical devices, surgical procedures, and diagnostic tools. There is a growing demand for minimally invasive surgical and diagnostic procedures, which necessitates the use of medical devices that possess excellent electrical properties, flexibility, and stretchability. The demand for flexible batteries and sensors in the healthcare sector is expected to rise as these devices cater to such needs. For example, in May 2022, Vivalink, a provider of digital healthcare solutions, introduced a multi-vital blood pressure patch designed for commercial and research applications. This patch captures essential medical data, such as ECG traces, heart rates, and respiratory rates, through electrical signal-based technology, showcasing the potential of flexible electronics in medical advancements.

Furthermore, the automotive industry in regions like the U.S., China, and India has been witnessing substantial growth due to rising consumer spending on vehicles. To cater to this demand and differentiate their models, vehicle manufacturers are increasingly incorporating advanced features into vehicles, such as thin-film heaters, flexible backlighting, and capacitive touch surfaces. This wide range of applications for printed sensors and flexible batteries in the automotive sector is expected to drive the growth of the flexible electronics market. Consumers seek vehicles with modern interiors and technology, pushing automakers to adopt flexible electronics solutions.

Gather more insights about the market drivers, restrains and growth of the Flexible Electronics Market

Component Segmentation Insights:

The flexible electronics market is segmented based on components, with the displays segment accounting for the largest revenue share over 53.0% in 2022. This segment is expected to experience the highest CAGR during the forecast period. The growth of the flexible display market is driven by increasing consumer demand for advanced display technologies that are capable of bending, rolling, or providing a certain degree of flexibility. Flexible displays offer significant advantages over traditional displays, including reduced power consumption, making them more energy-efficient.

The batteries segment is also expected to witness considerable growth over the forecast period. Flexible batteries are gaining popularity due to their easy integration into various products, including wearable electronics and flexible devices. Additionally, flexible batteries offer benefits such as flame resistance, waterproofing, and the ability to withstand bending, folding, and stretching, which further increases their demand in electric vehicles. The need for seamless integration of electronics into everyday objects such as clothing, medical devices, and even within the human body has also spurred the demand for flexible batteries. These advancements cater to the growing market for flexible electronics in a range of industries.

In conclusion, the global flexible electronics market is experiencing robust growth, driven by rising consumer demand for advanced, portable, and energy-efficient devices in industries such as consumer electronics, healthcare, and automotive. The widespread applicability of flexible displays, batteries, and sensors is propelling innovation across sectors, positioning flexible electronics as a key enabler of future technological advancements.

Order a free sample PDF of the Flexible Electronics Market Intelligence Study, published by Grand View Research.

#Flexible Electronics Industry#Flexible Electronics Market Research#Flexible Electronics Market Forecast#Flexible Electronics Market Overview

1 note

·

View note

Text

Analyzing Key Components in the Flexible Electronics Materials Market

In today’s rapidly evolving technological landscape, medical, automotive, and consumer electronics industries display a growing need for compact, lightweight, and cost-effective devices. In this regard, flexible electronics have captured the attention of these sectors, offering innovative solutions that enable the development of bendable systems with versatile shapes. Triton’s analysis signifies that the global flexible electronics market is anticipated to progress with a CAGR of 8.88% during the forecast period 2023-2030. The applications for organic photovoltaics (OPV), RFID, organic light-emitting diodes (OLED), and compacted printed electronic systems are experiencing a significant upsurge, which drives the demand for flexible electronics substrates.

Another notable trend fueling the market expansion is advancements in display technology, driven by the increasing demand for digital visuals. Expanding applications for advanced displays have influenced companies to pioneer advancements in flexible displays.

TCL, for instance, introduced the world’s first rollable extendable smartphone concept utilizing flexible AMOLED display technology. Additionally, haptic touch screens have recently been developed to provide users with tactile feedback via various textures or low electrical currents.

As the demand for compact products and innovative displays continues to rise, there is a promising landscape for the application of various flexible electronic components.

From Rigid to Resilient: Exploring the Potential of Key Flexible Components

Flexible Displays, typically made of OLED technology, are designed to withstand folding, bending, and twisting. Hence, they are increasingly used in foldable devices like smartphones, providing a compact storage option with a larger screen size for media display. As per Triton’s analysis, the flexible display category captured the highest share at $20263.22 million in 2022 in terms of components.

The initial appeal of folding displays lies in their novelty nature, which garnered significant attention for products like the Samsung Galaxy Fold and Motorola Razr. China’s Royole, for example, made advancements in flexible displays with its FlexPai Phone and even ventured into wearable applications such as flexible displays on t-shirts and hats.

Moreover, flexible consumer electronics are gaining popularity due to their unique characteristics, such as lightweight design, bendability, ruggedness, and lack of brittleness. In this regard, OLED displays, commonly found in smartphones, tablets, and TV screens, offer enhanced picture quality and energy efficiency through higher contrast and vibrant colors. The market holds promise for curved displays, allowing mobile phones to enhance user comfort. In terms of application, the consumer electronics category is likely to advance with 9.01% of CAGR over 2023-2030.

Flexible Sensors, also known as bend sensors, have gained significant attention for their exceptional properties like high stretchability, excellent biocompatibility, great conformability, and low cost. This has prompted various company initiatives, widening their applications in emerging fields like industrial IoT, healthcare, etc. For instance, Japan Display Inc developed the world’s first flexible low-temperature polysilicon thin-film transistor tactile sensor.

In recent years, wearable biosensors for health monitoring have gained considerable attention as they enable real-time health status monitoring, measuring various parameters like glucose, lactate, pH, cholesterol, pulse rate, temperature, etc. In this regard, using solution-based nanomaterials processed through printing techniques holds promise for cost-efficient manufacturing on flexible polymeric substrates. Per our analysis, the medical and healthcare category is estimated to witness the fastest growth at a CAGR of 9.23% during the 2023-2030 forecast period.

Flexible Photovoltaics is projected to emerge as the fastest-growing component between 2023 and 2030, growing at a CAGR of 9.30%. Thin film PV, a cost-effective alternative to traditional crystalline Si-based PV, offers flexibility and new design possibilities for solar cells. Flexible PV devices are highly sought-after for indoor and outdoor applications due to their ability to integrate with structures of different shapes and sizes. Furthermore, flexible PV modules possess faster payback than conventional ones. As a result, various PV materials have been developed using different deposition methods on flexible substrates.

Flexible Electronics Market: Industry 4.0 and Smart Homes to Accommodate Opportunities

With advancing technology, factories are increasingly embracing automation and connectivity, leading to the rise of Industry 4.0. This paradigm shift involves automating manufacturing processes and upgrading architectures to enhance productivity. Within the industrial platform, electronic design, development, manufacturing, assembly, and distribution hold significant importance.

Furthermore, there is a surge in the adoption of wearables, portable devices, and remotely connected devices across various sectors, such as automotive and smartphones. In this context, flexible electronic devices play a pivotal role, enabling machine-to-machine and human-to-machine connections. Moreover, they offer numerous advantages over non-flexible counterparts, including cost-effectiveness, reduced energy consumption, and lightweight construction.

Integrating physical manufacturing activities with machine learning, artificial intelligence, big data, Industry 4.0, and industrial IoT further drives the application of flexible electronic materials in industrial manufacturing. For instance, robots, sensors, and RFID tags find extensive use in tracking product movement and other operational functions.

Therefore, the proliferation of connected devices contributes heavily to the growing demand for flexible electronics in smart homes, which opens new avenues for the flexible electronics market.

FAQs:

Q1) What is the global flexible electronics market size?

In 2022, the global flexible electronics market attained $37634.72 million and is expected to garner $74779.19 million by 2030.

Q2) What are the key applications of flexible electronics?

The key applications of flexible electronics include consumer electronics, medical and healthcare, automotive, and energy sectors.

#Flexible Electronics Market#Consumer Goods & Services#Consumer Electronics#triton market research#market research reports

0 notes

Text

Stretchable electronics might make their way onto the market thanks to roll-to-roll process

Electronics have evolved over the years to supersede simply enhancing day-to-day life to becoming almost seamlessly integrated with daily life. People have become accustomed to wearable electronics, but what about stretchable ones? There is a growing demand for this type of technology, but the current methods are not easily scalable for mass production to make these devices available to the public. However, mass development may be possible using the roll-to-roll (R2R) process, which prints various layers on a flexible rolled substrate, cutting out the manual nature of the process. By rolling these types of electronics out onto the market, the possibility for stretchable electronics and even smart packaging could become commonplace. Researchers published their results in Advanced Materials Technologies on June 9.

Read more.

#Materials Science#Science#Electronics#Flexible electronics#Materials processing#Yokohama National University

11 notes

·

View notes

Note

Okay. So. I have a question about academia and completely understand if you’d rather set this one aside. It’s a bit of a long-winded one on my part.

I started a masters program abroad last fall but had to leave after the first term because of serious illness (compounded by homesickness and burnout of course of course). I’m so happy that I made that decision, despite it grating against everything I have been telling myself for years about what it takes to live a fulfilling life. In truth, my illness revealed that I’d thrown myself deeper into academia for the wrong reasons. I’m grateful to have that insight now.

However, I’ve also gained a lot of new insight now that I’ve been working a normal office job for several months now. It’s a good job, maybe a little too disorganized on the leadership side, but the pay is good and my supervisor is great.

But I’m also really missing my research and classroom discussions and academic library access. If I give grad school another try, I wont be filling out any apps until next winter. I definitely can recognize I need more time (plus I have an idea for a research paper that I’d love to use as a writing sample — my research interests shifted A LOT in the one semester I spent in school).

Of course, that’s also nerve-wracking, considering how poorly I handled grad school the first time around. In addition to that, there’s the frustration with how academia is treated both internally and externally, as well as the fact that the job market for professors is just.. not great.

All of this is to say, what would you tell a grad-school-dropout who’s thinking about making a comeback? Is it worth the money, the time, the job insecurity once the PhD is hanging on the wall?

Thanks so much for taking the time (and congrats on the new bed!!) <3

Welp. Hmm. As ever, I both deeply sympathize with your desire to return to academia and also want to stand on your shoulder as a little Kronk shoulder angel (and/or devil) going BUT ARE YOU SURE???

(Yes, as the most pathologically Eternal Academite possibly to ever, I have zero ability to tell anyone else not to do it, but just picture me as a Greek chorus of worms standing on the passage as your ship sails in, spookily singing BEEEEEEEEWARE.)

As you note, you have a reasonably fulfilling setup now, you're making decent-ish money (surely more than you would make as an academic, BUT LET US NOT TALK ABOUT THAT) and you crashed and burned the last time you tried grad school. Now, that is not a reason NOT to do it again, since as you point out, things have changed, you're in a better place, you know what you want out of the experience, you changed research interests, etc. All of that means that yes, it is possible that you can rejigger yourself and try again, but I would definitely advise taking it very carefully.

First of all, don't apply for a masters-to-PhD program directly, as that will put more pressure on you and lead to the feeling that you HAVE to finish it if you've applied for the terminal degree. Apply for a master's program in your new field, check out flexible or part-time options for attendance, see what the financial aid is like (I have by far the most student debt from my master's degree, not my BA or PhD, which is... not great) and everything else to see how you can best ease yourself back in and make sure that you haven't committed too much money, time, and irreversible changes if it all goes FUBAR again. Trust me, I KNOW that deep deep yearning for research, academic credentials, and library database logins; witness me singing to the heavens when I got this job and LO, ALL MY BELOVED ELECTRONIC JOURNALS RETURNED TO ME, I HAVE WANDERED IN THE DESERT. I'm researching a new book chapter now, 18 months-ish later, and I still get drunk with power over being able to JUST OPEN FULL TEXT PDFS and USE A UNIVERSITY LIBRARY TO ORDER OBSCURE ACADEMIC BOOKS. It really does just tickle some deep KNOWLIDGE!!! button in your brain, and I get it. I really very much do. So yes, if you still feel that itch despite all the Horrors of last time, it might be worth following up.

I would not recommend uprooting your entire life again to go somewhere else, unless you get a really gangbusters financial-aid offer and/or there's some compelling reason that makes it worthwhile. There may be a school nearer you that offers what you want and which may allow you to stay in your current place and work at your current job, even part-time. Or there might be an online option; plenty of reputable name-brand schools are expanding into online programs, so it's not just scammy diploma mills and the University of Phoenix in that arena. If you want to have the traditional campus in-person experience and don't feel as if a virtual degree is bang for your buck, that is something else to consider, but yes: do take it carefully, apply for only the master's first (as I have said before, if you can be happy doing anything other than a PhD especially in the humanities, please do that), see what your part-time options are, don't rush, reach out to faculty at some potential schools, reach out to the financial aid department, generally do your homework and make sure it feels right. I'm absolutely not going to say don't do it, since as noted that would make me a blazing hypocrite. Just take the hard-earned lessons of last time and put them to careful and thoughtful use, and I'm sure you'll discover what's best for you.

Good luck!

10 notes

·

View notes

Text

FPGA Market - Exploring the Growth Dynamics

The FPGA market is witnessing rapid growth finding a foothold within the ranks of many up-to-date technologies. It is called versatile components, programmed and reprogrammed to perform special tasks, staying at the fore to drive innovation across industries such as telecommunications, automotive, aerospace, and consumer electronics. Traditional fixed-function chips cannot be changed to an application, whereas in the case of FPGAs, this can be done. This brings fast prototyping and iteration capability—extremely important in high-flux technology fields such as telecommunications and data centers. As such, FPGAs are designed for the execution of complex algorithms and high-speed data processing, thus making them well-positioned to handle the demands that come from next-generation networks and cloud computing infrastructures.

In the aerospace and defense industries, FPGAs have critically contributed to enhancing performance in systems and enhancing their reliability. It is their flexibility that enables the realization of complex signal processing, encryption, and communication systems necessary for defense-related applications. FPGAs provide the required speed and flexibility to meet the most stringent specifications of projects in aerospace and defense, such as satellite communications, radar systems, and electronic warfare. The ever-improving FPGA technology in terms of higher processing power and lower power consumption is fueling demand in these critical areas.

Consumer electronics is another upcoming application area for FPGAs. From smartphones to smart devices, and finally the IoT, the demand for low-power and high-performance computing is on the rise. In this regard, FPGAs give the ability to integrate a wide array of varied functions onto a single chip and help in cutting down the number of components required, thereby saving space and power. This has been quite useful to consumer electronics manufacturers who wish to have state-of-the-art products that boast advanced features and have high efficiency. As IoT devices proliferate, the role of FPGAs in this area will continue to foster innovation.

Growing competition and investments are noticed within the FPGA market, where key players develop more advanced and efficient products. The performance of FPGAs is increased by investing in R&D; the number of features grows, and their cost goes down. This competitive environment is forcing innovation and a wider choice availability for end-users is contributing to the growth of the whole market.

Author Bio -

Akshay Thakur

Senior Market Research Expert at The Insight Partners

2 notes

·

View notes

Text

SEOUL, South Korea — In fried-chicken-obsessed South Korea, restaurants serving the nation's favourite fast-food dish dot every street corner.

But Kang Ji-young's establishment brings something a little different to the table: a robot is cooking the chicken.

Eaten at everything from tiny family gatherings to a 10-million-viewer live-streamed "mukbang" -- eating broadcast -- by K-pop star Jungkook of BTS fame, fried chicken is deeply embedded in South Korean culture.

Paired with cold lager and known as "chimaek" -- a portmanteau of the Korean words for chicken and beer -- it is a staple of Seoul's famed baseball-watching experience.

The domestic market -- the world's third largest, after the United States and China -- is worth about seven trillion won ($5.3 billion).

However, labour shortages are starting to bite as South Korea faces a looming demographic disaster due to having the world's lowest birth rate.

Around 54 percent of business owners in the food service sector report problems finding employees, a government survey last year found, with long hours and stressful conditions the likely culprit, according to industry research.

Korean fried chicken is brined and double-fried, which gives it its signature crispy exterior, but the process -- more elaborate than what is typically used by US fast food chains -- creates additional labour and requires extended worker proximity to hot oil.

Enter Kang, a 38-year-old entrepreneur who saw an opportunity to improve the South Korean fried chicken business model and the dish itself.

"The market is huge," Kang told AFP at her Robert Chicken franchise.

Chicken and pork cutlets are the most popular delivery orders in South Korea, and the industry could clearly benefit from more automation "to effectively address labour costs and workforce shortages," she said.

Kang's robot, composed of a simple, flexible mechanical arm, is capable of frying 100 chickens in two hours -- a task that would require around five people and several deep fryers.

But not only does the robot make chicken more efficiently -- it makes it more delicious, says Kang.

"We can now say with confidence that our robot fries better than human beings do," she said.

Investing in 'foodtech'

Already a global cultural powerhouse and major semiconductor exporter, South Korea last year announced plans to plough millions of dollars into a "foodtech" fund to help startups working on high-tech food industry solutions.

Seoul says such innovations could become a "new growth engine," arguing there is huge potential if the country's prowess in advanced robotics and AI technology could be combined with the competitiveness of Korean food classics like kimchi.

South Korea's existing foodtech industry -- including everything from next-day grocery delivery app Market Kurly to AI smart kitchens to a "vegan egg" startup -- is already worth millions, said food science professor Lee Ki-won at Seoul National University.

Even South Korea's Samsung Electronics -- one of the world's biggest tech companies -- is trying to get in on the action, recently launching Samsung Food, an AI-personalised recipe and meal-planning platform, available in eight languages.

Lee predicted South Korea's other major conglomerates are likely to follow Samsung into foodtech.

"Delivering food using electric vehicles or having robots directly provide deliveries within apartment complexes, known as 'metamobility,' could become a part of our daily lives," he said.

"I am confident that within the next 10 years, the food tech industry will transform into the leading sector in South Korea."

'Initially struggled'

Entrepreneur Kang now has 15 robot-made chicken restaurants in South Korea and one branch in Singapore.

During AFP's visit to a Seoul branch, a robot meticulously handled the frying process -- from immersing chicken in oil, flipping it for even cooking, to retrieving it at the perfect level of crispiness, as the irresistible scent of crunchy chicken wafted through the shop.

Many customers remained oblivious to the hard-working robotic cook behind their meal.

Kim Moon-jung, a 54-year-old insurance worker, said she was not sure how a robot would make the chicken differently from a human "but one thing is certain -- it tastes delicious."

The robot can monitor oil temperature and oxidation levels in real time while it fries chicken, ensuring consistent taste and superior hygiene.

When Kang first started her business, she "initially struggled" to see why anyone would use robots rather than human chefs.

"But after developing these technologies, I've come to realise that from a customer's perspective, they're able to enjoy food that is not only cleaner but also tastier," she told AFP.

Her next venture is a tip-free bar in Koreatown in New York City, where the cocktails will feature Korea's soju rice wine and will be made by robots.

youtube

Entrepreneur aims to improve South Korea's dish using robot

11 September 2023

#South Korea#chimaek#fried chicken#beer#Korean fried chicken#Robert Chicken#Kang Ji-young#advanced robotics#AI technology#Samsung Food#Samsung Electronics#metamobility#Youtube#robot

9 notes

·

View notes

Text

Loans for Short Term Cash: Assistance without a Debit Card

Do you live in a city in the United Kingdom and are in dire need of an advance to meet your basic needs? Because of your bad credit narrative, are you unable to obtain one? Are you always looking for funding where you may get flexible return options? In the event that this is what you're looking for, don't worry; short term cash loans are here to assist you in resolving any issues you've been having. These advances enable you to quickly and affordably obtain cash to immediately resolve all of your pressing financial difficulties.

Financial assistance is provided by short term cash loans to cover unexpected expenses. The principal characteristics of these loans are their fast approval and lack of a debit card need. Because these loans are unsecured, no collateral pledge is necessary. For a period of 14 to 31 days, you can obtain cash advances in the range of £100 to £1,500. Because these loans have a short term and rapid approval, the interest rate charged is rather higher.

You must follow simple eligibility requirements, such as the borrower having to be a citizen of the United Kingdom and older than 18, in order to be eligible for short term loans. The borrower needs to be actively involved in earning up to £750 per month from a claimed corporation and have an active inspection account in their own name. Short term loans direct lenders primary drawback is their exorbitant interest rates, but thorough market research can help you obtain fleet funds at reasonable rates. Renters and homeowners can also take advantage of this financial assistance. If you file an appeal, the lenders may occasionally additionally grant an extension of the repayment schedule.

One can pay for all of their short-term, inescapable expenses—such as tuition for college or school, hospital or medical bills, grocery bills, auto or shop repairs, etc.—with short term loans UK direct lender. Payday loans demand a few presses requirements to be fulfilled in order to be approved. The lender will quickly lend the short term loans UK direct lender without requiring a debit card after the aforementioned terms are proven. The cash amount will be electronically deposited into the borrower's account by the lender, who will not require usage of the funds.

We at Classic Quid are committed to responsible lending practices. As a result, we will only make loans to borrowers who can repay them. When you need emergency credit, we're here to assist you get it fast and at reasonable prices. Subject to completing our credit and affordability checks, new clients can borrow between £100 and £1000, while current customers can borrow up to £2,500. A Classic Quid short term loans UK has a minimum repayment period of two installments, with a maximum repayment length of six months. Depending on when you get paid, these installments could be weekly or monthly. This implies that you are not required to pay back the whole amount of the loan on your subsequent payment.

https://classicquid.co.uk/

5 notes

·

View notes

Text

Making a hundred dollars in a day is an achievable goal, even if you’re working from home or have limited resources. In this blog post, we will discuss some ways to make 100 dollars in a day.

1. Sell Your Unused Items: One of the easiest and quickest ways to earn money is to sell your unused items. You can list your items on online platforms like eBay, Facebook Marketplace, or Craigslist. This could include clothes, electronics, books, furniture, and more.

2. Complete Online Surveys: If you have some spare time, you can take online surveys and get paid. There are several websites where you can sign up for surveys, such as Swagbucks, Toluna, and InboxDollars.

3. Rent Out Your Space: If you have a spare room in your house, you can rent it out on Airbnb. This platform allows you to host travelers and make extra cash. You can set your own prices, and Airbnb takes care of the payments.

4. Participate in Focus Groups: Many market research companies look for people to participate in focus groups or online surveys. You can find these opportunities on websites like FocusGroup.com or FindFocusGroups.com.

5. Do Freelance Work: If you have a skill, such as writing, graphic design, or programming, you can use sites like Upwork, Fiverr or Freelancer to offer your services to clients who are looking for work. You can charge an hourly rate or a flat fee.

6. Deliver Food: You can sign up to be a delivery driver for companies like UberEats, DoorDash or Grubhub. It’s a flexible way to earn money, and you can choose your own hours.

7. Sell Your Crafts: If you have a hobby, such as knitting or woodworking, you can sell your creations on platforms like Etsy. You can also sell your products at local markets.

8. Do Odd Jobs: You can find odd jobs on websites like TaskRabbit or Craigslist. These can include anything from cleaning, lawn care, or moving furniture.

9. Pet Sitting or Dog Walking: If you love animals, you can sign up to be a pet sitter or dog walker with companies like Rover. You can set your own schedule and get paid per job.

10. Offer Your Professional Services: If you have expertise in a specific field, such as accounting or financial planning, you can offer your services to clients. You can find people who need help on sites like LinkedIn or Fiverr, or even offer to help people in your community.

In conclusion, there are several ways to make $100 a day. Whether you’re selling your unused items, doing odd jobs, or offering your professional services, you can earn extra cash with a little bit of effort and determination. Try out some of these methods and see which ones work best for you.

10 notes

·

View notes

Text

Isolator Gloves Market Size, Type, segmentation, growth and forecast 2023-2030

Isolator Gloves Market

The Isolator Gloves Market is expected to grow from USD 141.10 Million in 2022 to USD 228.10 Million by 2030, at a CAGR of 7.11% during the forecast period.

Get the Sample Report: https://www.reportprime.com/enquiry/sample-report/11101

Isolator Gloves Market Size

Isolator Gloves are a type of protective gloves that are designed to provide a barrier between the wearer's hands and harmful substances such as chemicals, viruses, and bacteria. The Isolator Gloves market research report includes an analysis of the market segment based on type, application, and region. The types of Isolator Gloves include Nitrile, Hypalon, EPDM, Neoprene, Latex, and Butyl. The primary applications of Isolator Gloves are in Electronics, Pharmaceutical, Food, Chemical, and Laboratory industries. The report covers the market players such as Ansell, PIERCAN, Renco Corporation, Safetyware Group, Inert Corporation, Jung Gummitechnik, Terra Universal, Honeywell, Nichwell, and Hanaki Rubber. The report also covers regulatory and legal factors specific to market conditions. Isolator Gloves are subject to strict regulations due to their use in critical industries, and market players must ensure compliance with standards set by regulatory bodies. The report provides an in-depth analysis of the Isolator Gloves market, including its market size, growth rate, competitive landscape, and future prospects.

Isolator Gloves Market Key Player

Ansell

PIERCAN

Renco Corporation

Safetyware Group

Inert Corporation

Buy Now & Get Exclusive Discount on this https://www.reportprime.com/enquiry/request-discount/11101

Isolator Gloves Market Segment Analysis

The Isolator Gloves market caters to a niche customer base, which includes pharmaceutical manufacturers, biotechnology companies, healthcare institutions, and medical device manufacturers. These gloves are extensively used in cleanroom environments to maintain hygiene, prevent contamination and ensure aseptic handling of drug substances and medical devices.

The driving factors for revenue growth in the Isolator Gloves market are the increasing demand for sterile pharmaceutical products, the growing prevalence of chronic diseases, and the strict regulatory requirements for cleanroom environments. Furthermore, the Isolator Gloves market is experiencing growth due to the ongoing research and development activities and technological advancements in the field of medical devices.

The latest trends followed in the Isolator Gloves market include the adoption of non-latex gloves to reduce the risk of latex allergy, increasing demand for powder-free gloves to minimize the transfer of allergens, and the use of vibration-dampening gloves to reduce hand fatigue in workers. Moreover, manufacturers are focusing on developing gloves with improved tactile sensitivity and flexibility, which can provide better user comfort and dexterity.

The major challenges faced by the Isolator Gloves market include the high cost of raw materials and production, stringent regulations for cleanroom environments, and increasing competition from local players in the market. Additionally, the COVID-19 pandemic has disrupted the supply chain and logistics operations, resulting in the temporary closure of manufacturing facilities and delays in delivering products to customers.

The report's main findings suggest that the Isolator Gloves market is projected to grow at a significant rate over the forecast period due to the increasing demand for sterile pharmaceutical products and the stringent regulatory requirements for cleanroom environments. Furthermore, the report recommends that manufacturers focus on developing eco-friendly and biodegradable gloves, as the demand for sustainable products is increasing. Moreover, manufacturers should prioritize improving their supply chain management and logistics operations to meet the market demands and maintain a competitive edge.

In conclusion, the Isolator Gloves market caters to a niche customer base, and the major factors driving revenue growth are the increasing demand for sterile pharmaceutical products and the strict regulatory requirements for cleanroom environments. The Isolator Gloves market is experiencing growth due to technological advancements and ongoing research and development activities. The latest trends in the market encompass the adoption of non-latex gloves, powder-free gloves, and vibration-dampening gloves. However, the Isolator Gloves market is also facing challenges due to high production costs, stringent regulatory requirements, and increasing competition from local players. The report's main recommendations include focusing on sustainable products, improving supply chain management, and logistics operations.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

Purchase This Report: https://www.reportprime.com/checkout?id=11101&price=3590

Market Segmentation (by Application):

Electronics

Pharmaceutical

Food

Chemical

Laboratory

Information is sourced from www.reportprime.com

2 notes

·

View notes

Text

Best cloud technology will be adapted in the USAF F-35s

Fernando Valduga By Fernando Valduga 03/01/2023 - 16:00 in Military

The U.S. Air Force wants to operate its aircraft in a more integrated way and has hired Lockheed Martin to research and develop a more advanced generation IT infrastructure based on cloud technology for its F-35 fighters.

The F-35 Lightning II is the most sustainable tactical aircraft there is, according to Lockheed Martin, but the U.S. Department of Defense wants to further optimize its fleet sustain and readiness performance.

On February 23, the Pentagon granted the designers and manufacturer of the F-35, Lockheed Martin, a $32.5 million contract modification from a previous order for a fleet of stealth aircraft.

This modification adds scope to design, develop and establish the F-35 NextGen Open Mission services. Lockheed will cover the use of modern cloud-based technologies and modern software methodologies for the Joint Strike Fighter program.

Cloud-based technologies are increasingly being invested and are beginning to play an integral part of the defense industry. The concept of shared IT infrastructure offers flexibility, resource efficiency and economy.

GlobalData states that the cloud allows sensors, services and agencies to interconnect, giving forces the necessary superiority to subdue enemies that are left behind in such force multipliers.

Lockheed Martin initially adapted its Autonomous Logistics Information System (ALIS) for its first launch of F-35s. However, this logistics system - which intended to monitor all aspects of the maintenance of the F-35 and the fleet in general - demonstrated inaccurate or absent data problems according to the Government Accountability Office (GAO) in 2020.

The successor system to ALIS, the Integrated Operational Data Network (ODIN), was introduced in 2021. Since then, ODIN has proven to be a great improvement.

"ODIN will be a cloud-native system that incorporates a new integrated data environment and a new set of user-centered applications; it will be a significant step to improve the support and readiness performance of the F-35 fleet."

As much as this system is working perfectly now, the fact remains that the Pentagon's modification suggests that it has new demands for the IT backbone of its largest vehicle asset.

What is known - from this modification and the success of ODIN - is that the cloud is identifiable as the future system of the F-35 fighter. But what cloud resources should Lockheed Martin dedicate to R&D with the investment of the U.S. government?

As the war in Ukraine has shown, opposing forces can deploy electronic warfare (EW) resources that depend on heavy interference outputs that can easily disrupt telecommunications. In such an environment, cloud computing would face serious challenges.

Part of Lockheed's development modification for F-35 logistics may seek to strengthen the security of its cloud infrastructure.

There has already been a growing interest in this area in the first quarter of 2023. On February 23, NV5 Global acquired Axim Geospatial, which offers "cloud services" and "critical infrastructure and security". This acquisition demonstrates the growing concern for cloud security in the defense and intelligence industry.

In addition, another important target of the research concern would be to improve the continuous flow of data collected from the sensors.

The aerial objects shot down over North America so far this year have given the high-altitude surveillance market greater attention. The Chinese spy balloon particularly attracted U.S. concern about protecting its intelligence, especially critical data.

It seems reasonable that attention should be paid to the data flow between the sensors and the broader cloud network.

The GlobalData report on Cloud Computing in Defense tells us that the U.S. Air Force (USAF), which relies heavily on the continuous flow of data from various sensors, is changing the operational approach from the sensor-shooter cycle to one of data for decision. It is much broader than it refers to the central capacity of this period, the collection and analysis of data, to make an informed decision.

If this modification tells us anything, it is that the demand for cloud-based technologies and their secure maintenance should only increase as we enter a phase of modern war that uses data as an asset to be exploited.

Tags: Military AviationF-35 Lightning IILockheed MartinUSAF - United States Air Force / U.S. Air Force

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, he has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has works published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work throughout the world of aviation.

Related news

MILITARY

Saudi Arabia will join the UK-led FCAS program

01/03/2023 - 19:13

HELICOPTERS

Australia will replace its Tiger helicopters with Apaches from 2025

01/03/2023 - 14:00

MILITARY

Boeing receives $1.2 billion to work on USAF's new E-7 AEW&C aircraft

01/03/2023 - 11:00

MILITARY

United Arab Emirates company presents MPA solution to "fill gap" of the P-8 Poseidon

01/03/2023 - 09:00

Australia wants to replace its Hawk 127 advanced training jet fleet.

MILITARY

Competitors present solutions for RAAF's new advanced jet coach

01/03/2023 - 08:04

MILITARY

Satellite images of airfield in Belarus show Russian A-50 aircraft after alleged attack by opponents

28/02/2023 - 23:17

homeMain PageEditorialsINFORMATIONeventsCooperateSpecialitiesadvertiseabout

Cavok Brazil - Web Creation Tchê Digital

Commercial

Executive

Helicopters

HISTORY

Military

Brazilian Air Force

Space

Specialities

Cavok Brazil - Web Creation Tchê Digital

4 notes

·

View notes

Text

Adaptive Robotics Market

Adaptive Robotics Market Size, Share, Trends: ABB Ltd. Leads

Integration of AI and Machine Learning Enhances Adaptive Capabilities of Robots

Market Overview:

The global Adaptive Robotics Market is projected to grow at a CAGR of 22.5% during the forecast period of 2024-2031. The market value is expected to rise from USD XX billion in 2024 to USD YY billion by 2031. North America currently dominates the market, accounting for the largest share of global revenue. Key metrics include increasing adoption in manufacturing sectors, growing demand for automation in healthcare, and rising investments in robotics research and development. Advances in artificial intelligence, machine learning, and sensor technology are driving the rapid growth of the adaptive robotics market. The market is driven by an increase in demand for flexible and intelligent robotic systems that can adapt to changing environments and work with humans. The emphasis on Industry 4.0 and smart manufacturing is driving market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The integration of artificial intelligence (AI) and machine learning (ML) is revolutionizing the field of adaptive robotics. These technologies enable robots to learn from their previous experiences, adapt to new environments, and make autonomous decisions. The trend is driven by the rising demand for robots that can efficiently operate in unstructured environments and handle complex tasks. AI-powered adaptive robots are being utilized in various sectors, including manufacturing and healthcare, to enhance efficiency and safety. According to industry forecasts, the application of AI in robotics is expected to grow by 30% annually over the next five years, significantly enhancing the adaptive capabilities of robotic systems.

Market Segmentation:

Collaborative Robotics dominates the type segment, accounting for the largest market share. Collaborative robots continue to lead the adaptive robotics market due to their flexibility, safety features, and capability to work alongside humans. These robots are equipped with advanced sensors and control systems that allow them to adapt to their surroundings and interact safely with humans, making them suitable for a wide range of industrial applications. The growing demand for flexible automation solutions in manufacturing and logistics reinforces the leading position of collaborative robots. Recent advancements in force-sensing technologies and easy programming interfaces have made collaborative robots more affordable and easier to implement, especially for small and medium-sized businesses.

Collaborative robots have gained significant traction in the automotive and electronics industries. For instance, a major automotive manufacturer recently reported a 25% increase in production efficiency after integrating collaborative robots into their assembly lines. This achievement has driven industry acceptance, with analysts projecting a 35% year-over-year increase in collaborative robot installations in just the automotive sector.

Market Key Players:

ABB Ltd.

KUKA AG

Fanuc Corporation

Yaskawa Electric Corporation

Kawasaki Heavy Industries, Ltd.

Universal Robots A/S

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Unlocking Digital Marketing’s Potential in the Modern Era

The revolutionary potential of digital marketing is too important for organizations to overlook in today’s fast-paced, digitally connected society. Digital marketing is always changing as we enter the digital age, providing new tools and approaches for efficiently reaching and interacting with target consumers. Let’s examine the main developments, tactics, and advantages of digital marketing for companies hoping to prosper in this ever-changing environment.

Digital marketing: what is it?”

All forms of marketing that make use of electronic devices and the internet are referred to as digital marketing. Through digital marketing, which includes social media platforms, email marketing, search engine optimization (SEO), and paid advertising, firms may reach potential customers online, where they spend most of their time.

Why is Digital Marketing Important?

🌍 Global Reach: Digital marketing enables companies to achieve a worldwide audience at a significantly lower cost than traditional marketing techniques.

💰 Cost-Effectiveness: Small and medium-sized enterprises (SMEs) can compete with larger companies by using targeted, data-driven campaigns.

📏Measurable Outcomes: Analytics technologies give firms accurate information on how well their campaigns are performing, enabling them to make real-time strategy adjustments.

🤝 Customer Engagement: Email campaigns, social media, and interactive content build deep relationships with audiences that promote trust and loyalty.

2024’s Top Digital Marketing Trends

🎥 Video Marketing: Users’ attention is dominated by platforms such as Instagram Reels, YouTube, and TikTok. Live streaming and short-form videos increase brand visibility and engagement.

🌟 Influencer Marketing Evolution: Working with micro and nano influencers is beginning to work better for genuine engagement and niche targeting.

🌱 Sustainability and Ethical Marketing: Customers are favoring brands that share their values, such as social responsibility and sustainability.

Essential Digital Marketing Strategies

🔍 Search Engine Optimization (SEO): To increase organic visibility, spend money on technical SEO, keyword research, and excellent content.

📱 Social Media Marketing: strategically engage your target audience by using Facebook, Instagram, LinkedIn, and Pinterest.

✍️ material Marketing: Provide your audience with engaging, educational, and entertaining material. Videos, podcasts, infographics, and blogs are all great forms.

💳 Pay-Per-Click (PPC) Advertising: Paid advertisements on social media and Google Ads guarantee that your material is seen by the right people in a timely manner.

📧 Email Marketing: One of the best strategies for nurturing leads and keeping clients is still using personalized email marketing.

Methods for Assessing the Success of Digital Marketing

The performance of campaigns may be clearly understood by looking at metrics like website traffic, conversion rates, click-through rates (CTR), and return on investment (ROI).

📊 Analytics Tools: Websites such as HubSpot, SEMrush, and Google Analytics assist in tracking and analyzing data to make well-informed decisions.

Digital Marketing’s Future Digital marketing will be further incorporated into daily lives as technology develops. Leading companies will be those who value customer-centric strategy, embrace innovation, and keep up with trends.

Conclusions: Digital marketing is a crucial component of contemporary corporate strategy, not merely a passing fad. Businesses may improve brand loyalty, establish closer ties with their consumers, and achieve sustainable growth by utilizing the newest technologies and strategies. The secret to success in the rapidly evolving digital landscape is to be flexible and innovative, regardless of your level of experience as a marketer. In 2025, embrace digital marketing to see your company reach new heights!

#digital marketing#digital marketing in gandhinagar#social media marketing#website development#seo services

0 notes

Text

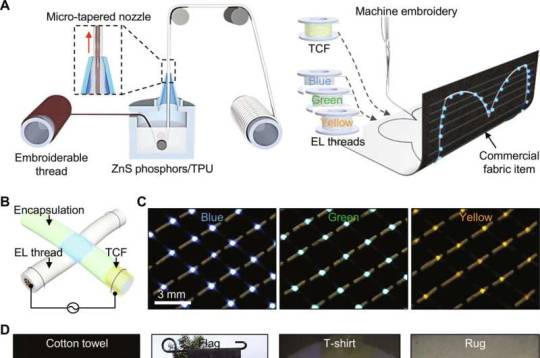

Light-emitting textiles for diverse flexible and wearable displays

Textile research has highlighted the advances in electroluminescent threads as suitable biomaterials for driving growth in the wearable electronics market. While the direct embroidery of textiles with custom designs and patterns can offer substantial benefits, machine embroidery can challenge the integrity of these threads. In a new report of applied science and engineering published in Science Advances, Seungse Cho and a team of scientists in biomedical engineering and medicine in the U.S., present embroiderable, multicolor, electroluminescent threads in blue, green, and yellow, that show compatibility with standard embroidery methods. The researchers used the threads to stitch decorative designs onto a variety of consumer fabrics, without compromising their wearability or light-emitting capacity. The scientists illuminated specific messages or designs on the consumer products for the purpose of developing emergency alerts on helmet liners and as physical hazard signs.

Read more.

15 notes

·

View notes

Text

Two-Dimensional Materials Market: Growth, Trends and Opportunities Through 2024-2031

The Two-Dimensional Materials Market is creating waves across multiple industries, from electronics and energy to healthcare and automotive. Characterized by ultra-thin structures just one atom thick, materials such as graphene, molybdenum disulfide, and hexagonal boron nitride offer exceptional electrical, thermal, and mechanical properties. These qualities have led to widespread interest and investment in the 2D Materials Market, which promises to reshape sectors dependent on lightweight, durable, and conductive materials.

According to BIS Research, the Two-Dimensional Materials Market is set to grow from $526.1 million in 2022 to $4 billion by 2031, with a CAGR of 25.3% over the forecast period.

Market Growth and Trends

Driven by breakthroughs in nanotechnology, the Two-Dimensional Materials Market is expected to expand rapidly in the coming years. Electronics and energy storage are two of the fastest-growing applications, where 2D materials enhance efficiency and sustainability. The market is further propelled by demand for flexible and miniaturized electronics, particularly in the semiconductor and photovoltaic industries, making these materials an attractive choice for next-generation applications.

Request a Free Sample Report on the Two-Dimensional Materials Market

Key Technologies Shaping the Market

Several notable 2D materials are leading the transformation in this sector:

· Graphene: Known for its incredible strength and conductivity, graphene is ideal for high-performance sensors, batteries, and flexible electronic devices.

· Molybdenum Disulfide (MoS₂): Frequently used in transistors and photodetectors, MoS₂ is popular for its stability and flexibility in nanoelectronics.

· Hexagonal Boron Nitride: This material acts as an excellent insulator and is widely used in high-performance thermal management systems.

Demand Drivers

Key drivers shaping the Two-Dimensional Materials Market include:

· Rising Demand for Miniaturized Electronics: As industries shift towards compact and lightweight electronic devices, 2D materials offer a sustainable solution without compromising performance.

· Sustainability Goals in Energy: The demand for energy-efficient materials in solar cells, fuel cells, and batteries fuels the growth of 2D materials.

· Medical and Biotechnology Applications: With exceptional biocompatibility and electrical conductivity, 2D materials support the development of advanced medical devices and sensors. Download Complete TOC of the Two-Dimensional Materials Market Report

On-Field to Lead the Two-Dimensional Materials Market

On-field applications of 2D materials are expected to lead the market, especially in sectors like flexible electronics and wearable technologies, where adaptability and durability are critical. These materials’ unique attributes facilitate the development of cutting-edge products, from transparent conductive films to biocompatible implants, opening avenues for real-world, on-field applications across industries.

Key Players

Company Type 1 (by Material Type): Graphene

· NanoXplore Inc.

· Cabot Corporation

And many others

Company Type 2 (by Material Type): Black Phosphorus

Smart-elements GmbH

Ossila Ltd.

Company Type 3 (by Material Type): Mxene

· Ossila Ltd.

· ACS Material LLC

And many others

Company Type 4 (by Material Type): TMDCs

Ossila Ltd

6 Carbon Technology

PlanarTECH LLC

And many others

Get More Market Insights on Advanced-materials-chemicals

Conclusion

The Two-Dimensional Materials Market is on an upward trajectory as demand for advanced materials grows across diverse applications. With their superior physical properties and versatility, 2D materials are set to redefine the future of electronics, energy storage, and biomedical applications. BIS Research, recognized as a best market research company, provides premium market intelligence reports on deep technologies poised to cause significant market disruption in the coming years.

At BIS Research, we focus exclusively on technologies related to precision medicine, medical devices, diagnostics, life sciences, artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), big data analysis, blockchain technology, 3D printing, advanced materials and chemicals, agriculture and FoodTech, mobility, robotics and UAVs, and aerospace and defense, among others

0 notes

Text

Polymer Solar Cells Market: Revolutionizing Renewable Energy Solutions with Cost-Effective Technology Advances

The global push for renewable energy solutions has highlighted the transformative potential of polymer solar cells (PSCs) in addressing modern energy demands. PSCs, also referred to as organic photovoltaics, employ organic polymers as semiconducting materials, offering several advantages, such as lightweight design, flexibility, and cost efficiency. This article delves into the polymer solar cells market key dynamics, including trends, challenges, and opportunities reshaping this innovative sector.

Market Overview and Growth Drivers

The polymer solar cells market has been gaining significant traction owing to rising environmental concerns, coupled with the increasing adoption of renewable energy technologies. Key growth drivers include:

Cost-Effectiveness: Unlike traditional silicon-based solar cells, polymer solar cells require lower production costs, making them accessible for wider applications.

Flexibility and Lightweight Nature: Their unique physical properties allow for integration into diverse platforms such as wearables, architectural materials, and portable electronics.

Rising R&D Investments: Substantial investments in research and development are fostering advancements in material performance, durability, and efficiency.

Key Trends Shaping the Market

Focus on Flexible Electronics: Flexible polymer solar cells are becoming integral to emerging electronic devices such as foldable smartphones and e-textiles.

Enhanced Energy Efficiency: Breakthroughs in materials science are enhancing efficiency levels, bringing PSCs closer to traditional solar cell efficiency benchmarks.

Green Manufacturing Practices: Industry leaders are adopting sustainable production methods to align with global carbon-neutrality goals.

Collaborations and Partnerships: Partnerships between material suppliers, manufacturers, and research institutes are accelerating product innovation and commercialization.

Regional Insights

The Asia-Pacific region dominates the polymer solar cells market, attributed to robust industrial growth, supportive government policies, and a thriving electronics sector. Meanwhile, North America and Europe are also key players due to their focus on green technologies and ongoing advancements in photovoltaic research.

Challenges and Opportunities

While the polymer solar cells market showcases immense potential, challenges like lower stability compared to inorganic alternatives and scalability issues remain. However, advancements in encapsulation techniques and hybrid materials are expected to overcome these hurdles.

On the opportunity front, the growing interest in building-integrated photovoltaics (BIPV) presents an untapped avenue for polymer solar cells, particularly in urban infrastructure. Similarly, the rising need for clean energy in remote areas and wearable technology is fueling demand for flexible PSC solutions.

Future Outlook

The polymer solar cells market is poised for sustained growth, with global energy transitions and sustainable energy investments paving the way for increased adoption. By leveraging advancements in material science and engineering, PSCs are set to redefine renewable energy paradigms across industries.

0 notes