#Fiberglass Cloth Market

Explore tagged Tumblr posts

Text

Drywall, also known as gypsum board or plasterboard, is a fundamental element in interior construction. Over time, it can be subject to damage from various sources like accidental impacts, holes from nails or screws, moisture, or settling. Learning effective patching and repair techniques is essential for maintaining walls' aesthetics and structural integrity.

Flow Drywall : Importance of Drywall Repairs

Structural Integrity Properly repaired drywall ensures the structural stability of walls and ceilings, preventing further damage and maintaining their strength.

Aesthetic Restoration Repairing holes, cracks, or blemishes restores the visual appeal of walls, creating a seamless and polished finish.

Property Value Well-maintained walls contribute to the overall value and marketability of a property, making timely repairs essential for homeowners and property managers.

Types of Drywall Damage Small Holes and Dents Commonly caused by nails, screws, or accidental impacts, small holes and dents can be easily patched and smoothed out.

Large Holes and Punctures Larger holes resulting from doorknob impacts, furniture, or more significant damage require more intricate repair methods.

Cracks and Water Damage Cracks can form due to settling, temperature fluctuations, or moisture issues. Water damage can cause swelling, bubbling, or staining, requiring thorough repair and sometimes mold remediation.

Tools and Materials Required Patching Compound Patching compound, available in various forms such as spackling or joint compound, is used to fill holes and cracks. Lightweight compounds are ideal for smaller repairs.

Drywall Patch Kits Patch kits contain self-adhesive mesh or patches designed to cover larger holes, providing a stable base for applying compound.

Drywall Tape For reinforcing seams and preventing cracks, paper or fiberglass mesh tape is used with joint compound.

Sandpaper and Sanding Blocks Used for smoothing the patched areas and achieving a flush finish.

Putty Knife and Drywall Trowel Essential tools for applying patching compounds and spreading them evenly.

Primer and Paint To finish the repair, primer helps the patched area blend with the surrounding wall, and paint provides a uniform appearance.

Steps for Drywall Patching and Repairs Small Hole and Dent Repairs Preparation: Clean the damaged area, removing loose debris or chipped edges. Ensure the surface is dry and free from dust.

Application of Patching Compound: Using a putty knife, fill the hole or dent with patching compound. Feather the edges to blend with the surrounding wall. Let it dry as per manufacturer instructions.

Sanding: Once dry, sand the patched area gently to smoothen the surface. Wipe away dust with a damp cloth.

Priming and Painting: Apply primer to the patched area, allowing it to dry completely. Then, paint the repaired area to match the existing wall.

Large Hole Repairs using Drywall Patch Kits Prepare the Hole: Cut away any damaged or uneven edges around the hole to create a clean, rectangular shape.

Apply Patch: Affix the self-adhesive mesh or patch from the kit over the hole, ensuring it covers the entire area. Press firmly to secure it in place.

Layering Compound: Using a putty knife or trowel, apply multiple thin layers of joint compound over the patch, feathering each layer for a smooth transition. Allow drying between coats as recommended.

Sanding and Finishing: Once dry, sand the patched area gently to achieve a flush surface with the wall. Clean the dust, apply primer, and paint to match the wall color.

Repairing Cracks and Water Damage Assess the Damage: Identify the extent of the crack or water damage. For minor cracks, use joint compound directly. For larger or structural cracks, consider professional assessment.

Fill and Seal Cracks: Apply joint compound or spackling into the crack, using a putty knife or trowel. For better reinforcement, embed drywall tape in the compound for larger cracks.

Dry and Sand: Allow the compound to dry thoroughly, then sand the area to create a smooth surface. Clean the dust before applying primer and paint.

Tips for Successful Drywall Repairs Patience is Key: Allow sufficient drying time between compound layers for better adhesion and smoother finishes.

Feathering Technique: Blend the compound outward from the repair area to seamlessly merge it with the surrounding wall.

Proper Sanding: Use fine-grit sandpaper for a smoother finish. Sand lightly to avoid over-smoothing or creating uneven surfaces.

Quality Materials: Use high-quality patching compounds and tools for better results and durability.

Color Matching: Ensure primer and paint match the existing wall color to achieve a cohesive look.

Drywall repairs are essential for maintaining the integrity and aesthetics of interior spaces. Understanding the types of damage, necessary tools, and step-by-step repair processes empowers homeowners and DIY enthusiasts to effectively restore damaged drywall, achieving seamless and professional-looking results.

By following these techniques and tips, individuals can confidently address various types of drywall damage, ensuring a flawless finish that blends seamlessly with the surrounding walls.

#drywall#Flow Drywall#Drywall Repair#DRYWALL PATCHING#WALL & CEILING TEXTURE#BATHROOM UPGRADES#BASEMENT REMODELING#KITCHEN IMPROVEMENTS#Drywall Vacuum Sanding

2 notes

·

View notes

Text

Logan Energy Efficient Windows: The Key to a Comfortable, Energy-Saving Space

Switching to energy efficient windows in Logan, Utah, is a smart decision for property owners. These windows not only help maintain a cozy indoor environment but also reduce utility expenses throughout the seasons. At Accent Windows, we specialize in offering top-notch window options that suit your needs. Here, we’ll cover the benefits of Logan energy efficient windows, how to choose the right ones, and why Accent Windows is your go-to Logan window company.

The Perks of Energy Efficient Windows in Logan, Utah

Energy efficient windows deliver numerous advantages, making them a valuable upgrade. Firstly, they improve your home’s insulation. These windows reduce heat exchange, keeping your home warmer during colder months and cooler in summer. As a result, your HVAC system operates less, saving you money on utilities.

Additionally, energy efficient windows can reduce external noise. If you live in a bustling area of Logan, UT, these windows create a quieter indoor space. They also protect your interiors from damaging UV rays, which cause furniture and flooring to fade over time.

Finally, installing energy efficient windows enhances your property’s market value. Buyers in Logan often favor homes with modern, cost-saving features like advanced windows.

How to Pick the Best Energy Efficient Windows

Selecting the right windows for your home requires considering a few key elements. Look for the ENERGY STAR® label, which guarantees the windows meet rigorous efficiency criteria. Next, evaluate the U-factor and solar heat gain coefficient (SHGC). These ratings indicate the window’s insulation and heat-blocking properties.

Consider the window frame material as well. Vinyl, fiberglass, and wood frames all have unique benefits. Vinyl frames, for instance, are durable and easy to maintain, making them a top choice among Logan UT window contractors.

Why Accent Windows Leads as the Best Logan Window Company

When looking for reliable window installers in Logan UT, Accent Windows is unmatched. With years of expertise, we understand the specific preferences of Logan homeowners. Our team ensures every installation is precise, efficient, and tailored to your expectations.

Accent Windows puts customer satisfaction first. We offer a broad selection of designs and materials to complement your home’s style. Whether you prefer double-hung windows, casement designs, or custom options, we have you covered. Moreover, our commitment to using premium products guarantees long-lasting results.

The Installation Process: What to Expect

Our window installation process is designed to be smooth and hassle-free. First, we’ll schedule an in-home consultation to understand your needs and provide a detailed estimate. During this visit, we’ll help you choose the perfect Logan energy efficient windows for your residence.

Once you’ve made your selection, our skilled professionals will install the windows with expertise and attention to detail. We’ll ensure a proper fit and leave your space clean upon completion. If you have any questions or issues, our team is always ready to assist.

Caring for Your New Energy Efficient Windows

Regular maintenance extends the lifespan of your windows. Start by cleaning the glass frequently with a gentle cleaner and soft cloth. Steer clear of harsh substances that could damage the protective coating.

Check the seals and weatherstripping periodically to ensure they remain intact. If you notice any issues, contact Accent Windows for prompt repairs. By following these simple steps, your windows will stay efficient and attractive.

Why Logan UT Window Contractors Recommend Energy Efficient Upgrades

Professional contractors recognize the value of energy efficiency. By upgrading to modern window technology, you can significantly cut your carbon footprint. Logan contractors also note that energy efficient windows offer better long-term returns than outdated models.

Accent Windows has worked with countless satisfied clients to meet their energy-saving goals. Our skill and dedication make us the leading Logan window company for many homeowners.

Contact Accent Windows Today

Ready to transform your home with Logan energy efficient windows? Accent Windows is here to help. As trusted window installers in Logan UT, we deliver exceptional service and outstanding results. Visit our contact page to get started today!

Accent Windows is committed to helping you create a more comfortable and energy-efficient home. With our superior products and expert installation, you’ll enjoy the benefits of energy efficient windows for years to come. Don’t wait—reach out now and take the first step toward improving your home.

0 notes

Text

Thar Hardtop Installation: Key Tips for a Seamless Upgrade

The Mahindra Thar has carved its niche as a go-to SUV for off-road enthusiasts and adventurers. Renowned for its rugged build and versatility, the Thar is a symbol of freedom and exploration. While its soft top is a popular choice for many, upgrading to a Thar hardtop offers a wealth of benefits, from enhanced durability to improved comfort. However, installing a Thar hardtop requires careful preparation and execution to ensure a perfect fit and long-lasting performance. In this comprehensive guide, we’ll cover everything you need to know for a seamless Thar hardtop installation, ensuring your SUV is ready for any adventure with added protection and style.

Why Upgrade to a Thar Hardtop?

A Thar hardtop is more than just an accessory—it’s an investment in your vehicle’s performance, comfort, and safety. Some solid reasons for upgrading are as follows:

Improved Durability: Hardtops are designed to withstand harsh weather conditions, from scorching heat to heavy rain. Unlike soft tops, they provide better resistance to wear and tear, ensuring longevity.

Enhanced Security: A hardtop offers superior protection against theft and vandalism. Its robust construction makes it difficult for intruders to break in, giving you peace of mind.

Noise Reduction: Driving on highways or rough terrains often comes with a lot of noise. A hardtop significantly reduces road and wind noise, creating a quieter and more enjoyable ride.

Weather Protection: Whether you’re tackling extreme heat, cold, or heavy rain, a hardtop ensures your cabin remains insulated and comfortable.

Aesthetic Appeal: Hardtops add a sleek and sophisticated look to your Thar, making it stand out on the road and off.

With these advantages in mind, upgrading to a hardtop becomes a logical choice for anyone seeking a better driving experience.

Preparation for Thar Hardtop Installation

Installing a Thar hardtop is not a task to be taken lightly. Proper preparation is key to ensuring a seamless process. Here’s how to get started:

Choose the Right Hardtop

The market offers a variety of Thar hardtops, from factory-made options to custom designs. When selecting a hardtop, consider the following factors:

Material Quality: Look for hardtops made of durable materials like fiberglass or ABS plastic.

Design Compatibility: Ensure the hardtop matches your Thar’s model and year.

Features: Some hardtops come with additional features like sunroofs, roof racks, or soundproofing. Choose one that aligns with your needs.

Budget: Quality hardtops can range from affordable to premium. Choose on a budget and look at possibilities that fit it.

Inspect Your Vehicle

Before installation, thoroughly inspect your Thar to ensure it’s in good condition. Pay special attention to the roof frame and mounting points. Before continuing, take care of any damage or misalignment that you find.

Gather Necessary Tools and Materials

Having the appropriate equipment on hand will facilitate the installation procedure:

Socket wrench set

Screwdrivers

Sealing adhesive or weatherstrip sealant

Cleaning supplies (cloth, mild detergent)

Installation manual or guide

Plan Your Installation

Decide whether you want to install the hardtop yourself or hire a professional. While a DIY approach can save money, professional installation ensures precision and avoids potential mistakes.

Step-by-Step Guide to Installing a Thar Hardtop

Now that you’re prepared, it’s time to get into the installation process. Follow these steps for a hassle-free upgrade:

Step 1: Remove the Existing Soft Top

If your Thar currently has a soft top, start by carefully removing it. This involves:

Unscrewing and unclamping the frame and fabric.

Removing all mounting brackets without damaging the bodywork.

Cleaning the area to remove dirt, adhesive, or debris left behind.

Step 2: Clean the Mounting Area

A clean surface is essential for a secure fit. Use a mild detergent and a soft cloth to clean the roof frame and mounting points. Ensure there’s no rust or residue that could affect the installation.

Step 3: Position the Hardtop

With the help of another person or a professional, lift the hardtop and position it on the roof frame. To make sure it fits correctly, line it up with the mounting holes. Because misalignment can result in gaps or uneven fitment, take your time.

Step 4: Secure the Hardtop

Once the hardtop is aligned, use the bolts, screws, and brackets provided in the installation kit to fasten it to the vehicle. Tighten each screw evenly to distribute pressure and avoid distortion. Refer to the installation manual for specific instructions.

Step 5: Apply Sealing Adhesive

To prevent water leakage and ensure a snug fit, apply a waterproof sealing adhesive or weatherstrip sealant along the edges of the hardtop. According to the manufacturer's instructions, let it dry.

Step 6: Test the Fit and Functionality

After installation, thoroughly inspect the hardtop. Check for:

Gaps or misalignments

Smooth operation of doors, windows, and latches

Proper sealing to prevent water or dust entry

To make sure everything is safe and functioning, make any necessary modifications.

Post-Installation Maintenance Tips

To maximize the lifespan and performance of your Thar hardtop, follow these maintenance tips:

Regular Inspections: Periodically check for cracks, leaks, or loose fittings. Address issues promptly to avoid further damage.

Cleaning: Use a soft cloth and a mild cleaner to maintain the hardtop’s appearance. Abrasive materials that might scratch the surface should be avoided.

Protect Against Overloading: If your hardtop includes a roof rack, avoid exceeding its weight limit to prevent structural damage.

Store Properly: If you ever need to remove the hardtop, store it in a safe and dry place to avoid warping or damage.

DIY vs Professional Installation: Which is Better?

Deciding between DIY and professional installation depends on your expertise and resources. Here’s a quick comparison:

DIY Installation

Pros: Cost-effective, rewarding experience for enthusiasts.

Cons: Requires time, effort, and the right tools. Mistakes can end in damage or incorrect installation.

Professional Installation

Pros: Ensures precision and a hassle-free process. Professionals have the expertise to handle potential challenges.

Cons: Additional cost, but often worth the investment for peace of mind.

If you’re confident in your skills and have access to the necessary tools, DIY installation can be a fun project. However, for first-timers or those with complex hardtops, professional help is recommended.

Conclusion

Upgrading to a Thar hardtop is a fantastic way to enhance the durability, security, and comfort of your Mahindra Thar, making it better equipped for all kinds of adventures. Whether you choose a DIY approach or opt for professional installation, following the proper steps ensures a seamless and long-lasting upgrade. By selecting the right hardtop, preparing your vehicle properly, and performing the installation with care, you can enjoy the benefits of a more robust and stylish Thar. Regular maintenance will help preserve its functionality, ensuring that your hardtop continues to serve you well for years to come. Whether tackling rough terrains or cruising on highways, a Thar hardtop provides the protection and peace of mind you need for every journey.

Website: https://bimbra.in/

#4x4offroad#tharhardtop#mahindra thar accessories#off road car accessories#car accessories#thar#thar hardtop

0 notes

Text

0 notes

Text

Technical Textile Market: Key Developments in Protective Fabrics

The Technical Textile Market represents a dynamic sector in the textile industry, providing innovative and high-performance solutions for diverse applications. Driven by advancements in material science, sustainable practices, and increasing demand across industries, the market is poised for significant growth. Key end-use sectors include automotive, healthcare, agriculture, construction, and defense.

Read Complete Report Details of Technical Textile Market: https://www.snsinsider.com/reports/technical-textile-market-2849

Market Segmentation

By Raw Materials

Natural Fibre

Description: Includes cotton, wool, jute, and silk.

Growth Drivers: Rising awareness of eco-friendly materials.

Trends: Development of bio-enhanced and treated natural fibers for durability.

Synthetic Polymer

Description: Covers polyester, nylon, aramid, polypropylene, and polyethylene.

Growth Drivers: Superior performance characteristics like strength and flexibility.

Trends: Increased use in industrial and automotive textiles.

Mineral

Description: Comprises basalt and fiberglass.

Growth Drivers: High resistance to heat and corrosion.

Trends: Growing applications in construction and infrastructure projects.

Others

Description: Includes hybrid fibers and blends.

Growth Drivers: Demand for specialized solutions combining multiple properties.

Trends: Exploration of innovative composites for niche applications.

By Manufacturing Process

3D Weaving

Description: Advanced technique for creating multi-dimensional textiles.

Growth Drivers: Increasing use in composites for aerospace and automotive industries.

Trends: Development of lightweight yet robust fabrics.

3D Knitting

Description: Focuses on creating seamless and customizable textiles.

Growth Drivers: High demand in sportswear and medical textiles.

Trends: Integration of functional elements like sensors.

Thermoforming

Description: Heat-based molding process for technical textiles.

Growth Drivers: Usage in automotive interiors and protective equipment.

Trends: Adoption in lightweight, rigid structural applications.

Finishing Treatments

Description: Enhancements like coating, laminating, and dyeing.

Growth Drivers: Rising demand for water-repellent and flame-retardant textiles.

Trends: Increased focus on antimicrobial and stain-resistant finishes.

Nanotechnology

Description: Application of nanomaterials for improved properties.

Growth Drivers: Use in smart textiles and medical applications.

Trends: Development of self-cleaning and UV-resistant fabrics.

Handmade Elements

Description: Artisan-based production for unique designs.

Growth Drivers: Demand for premium, custom-made textiles.

Trends: Revival of traditional techniques integrated with modern aesthetics.

Heat-set Synthetics

Description: Process to stabilize and enhance synthetic fibers.

Growth Drivers: Increasing need for wrinkle-free and durable fabrics.

Trends: Use in industrial and home furnishing applications.

Others

Description: Emerging and hybrid manufacturing methods.

Growth Drivers: Experimentation with advanced material technologies.

Trends: Customization for specific industry needs.

By End Use

Clothtech Textile

Applications: Used in apparel and clothing accessories.

Trends: High-performance and comfortable wearables.

Agro Textiles

Applications: Crop protection, soil conservation, and irrigation.

Trends: Development of biodegradable and UV-resistant fabrics.

Indutech Textile

Applications: Filtration, conveyor belts, and abrasive materials.

Trends: Increased use in industrial machinery.

Sportech Textile

Applications: Sportswear, equipment, and gear.

Trends: Lightweight, moisture-wicking, and impact-resistant textiles.

Buildtech Textiles

Applications: Construction and architectural textiles.

Trends: Growth in geotextiles for infrastructure projects.

Hometech Textile

Applications: Upholstery, curtains, carpets, and bedding.

Trends: Demand for functional and aesthetically pleasing fabrics.

Protech Textile

Applications: Protective clothing for military, firefighters, and industrial workers.

Trends: Focus on flame resistance, chemical protection, and durability.

Transtech Textile

Applications: Automotive, aerospace, and maritime textiles.

Trends: Lightweight and fuel-efficient materials.

Packtech Textile

Applications: Packaging solutions like sacks, bags, and wraps.

Trends: Increasing use of eco-friendly materials.

Medtech Textile

Applications: Medical textiles for wound care, surgical gowns, and implants.

Trends: High demand for antimicrobial and bio-compatible fabrics.

Others

Applications: Specialized and emerging sectors.

Trends: Tailored solutions for unique applications.

By Region

North America

Growth Drivers: Robust demand in healthcare, automotive, and defense sectors.

Trends: High investment in research and development.

Europe

Growth Drivers: Strong focus on sustainability and advanced manufacturing.

Trends: Adoption of eco-friendly and recyclable textiles.

Asia-Pacific

Growth Drivers: Rapid industrialization and urbanization.

Trends: Growth in agriculture and construction sectors.

Latin America

Growth Drivers: Expanding agro-textile and industrial applications.

Trends: Shift towards locally sourced materials.

Middle East & Africa

Growth Drivers: Infrastructure development and increased healthcare investments.

Trends: Use of geotextiles in large-scale projects.

Market Trends and Opportunities

Sustainability: Focus on bio-based and recyclable materials.

Smart Textiles: Integration of sensors and advanced functionalities.

Customization: Demand for tailored solutions across industries.

Innovation: Advances in nanotechnology and manufacturing techniques.

Market Outlook

The Technical Textile Market is expected to see robust growth, fueled by innovation and expanding end-use applications. The Asia-Pacific region is anticipated to dominate the market, with strong contributions from North America and Europe.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Wax Emulsion Market - Forecast(2024 - 2030)

Wax Emulsion Market Overview

Sample Report:

The emergence of COVID-19

The outbreak of COVID-19 has negatively impacted the wax emulsion market. The abrupt closure of production centers in China, and its impact caused chaos among global auto manufacturers in European Union, US, India, and South America region. For instance, Toyota Motor Corporation reported a YoY sales decline of 26%, May’s unit sales were almost double that of April, which fell 56% YoY.

Additionally, Sales of new-energy vehicles (NEVs) in China in June fell 35% YoY to 85,600 units, following a drop of 26% in May and 30% in April. The demand for wax emulsion lowered due to the declining automotive industry. In addition, a decrease in purchasing capital lowered construction activities and demand for apparel. According to the National Bureau of Statistics of China, the online retail sales of clothing goods decreased by 18.1 percent, substantially hampering the growth of the wax emulsion market.

Inquiry Before Buying:

Wax Emulsion Market Report Coverage

The report: “Wax Emulsion Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Wax Emulsion Market.

By Type: Natural (Animal, Vegetable and Minerals), and Synthetic (Polyethylene, Polypropylene, Paraffin, poly tetrafluoroethylene (PTFE), Fischer-Tropsch, and Others)

By Application: Wood Coatings, Adhesive & Sealants, Printing Inks, Fiberglass Insulation, Metal Polish, Lubricants, Textile Finish, cold creams, lipsticks, Tires, and Others

By End-Use Industry: Paint & Coatings, Building & Construction (Residential, Commercial, Industrial, and Infrastructure), Textile & Leather, Pulp & Paper, Cosmetics and Personal care, Automotive (Passenger Cars, Light Commercial Vehicle, and Heavy Duty Vehicles), Packaging, Wood Processing, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia & New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (the Middle East, and Africa)

Schedule a Call:

Key Takeaways

● The U.K has shown significant growth in the wax emulsion market due to its high demand from wood processing industries for the protection of woods from water and prevent rotting.

For More Details on This Report — Request for Sample

Wax Emulsion Market Segment Analysis — By Type

Synthetic segment held the largest share of more than 60.23% in the Wax Emulsion market in 2023. Synthetic wax emulsions are synthesized from synthetic polymers such as polyethylene, polypropylene, polytetrafluoroethylene, and many more. Synthetic wax emulsions are long-lasting, abrasion-resistant and provide good protection from contaminants like dust, grime, and corrosion. Thus, the availability of synthetic wax emulsion with varied properties makes it suitable for numerous applications including paints & coatings, cosmetics, and construction, significantly augmenting the market growth. However, increasing environmental concerns are driving the demand for natural wax emulsions such as Lanolin, Beeswax, Carnauba, and Candellila waxes.

Polyethylene wax segment consists of low-density polyethylene (LDPE) and High Density Polyethylene (HDPE) and is obtained by polymerization of Ethylene monomers. Physical attributes such as water-repellence, abrasion resistance, slip control, lubrication, and anti-blocking are contributing to the growth of polyethylene wax emulsion. Polyethylene wax emulsion manufactures more easily and is cost-effective. Surging use of polyethylene wax emulsion in lithographic and flexographic inks for an improved rub and mar resistance and slip characteristics also aids the market growth.

Wax Emulsion Market Segment Analysis — Application

Wood Coatings segment is projected to witness the highest CAGR of 6.4% during the forecast period. Wax emulsions are extensively used in paints & coatings as they provide a consistent neutral color and offer formulators maximum flexibility in pigmented applications. Wax emulsions also improve the durability of water-based paints, by offering excellent scratch- and abrasion resistance. An increase in building and constructions has proliferated the demand for paint & coatings.

Hence, surging demand for paints and coatings as a consequence of huge constructional activities may bolster the growth of the wax emulsion market.

Buy Now:

Wax Emulsion Market Segment Analysis — End-Use Industry

Textile and leather segment held the largest share of more than 26% in the wax emulsion market in 2023. Wax emulsions are used in the textile and leather industry for waterproofing of textile and leather substrates, modifying the frictional properties of fibers, yarns, and sewing threads for better processability, and for enhancing the performance of finishing compounds such as softeners, silicones, and resins. They also provide superior fabric properties such as improved flex abrasion resistance, tear strength, and sewability. Owing to the above benefits the demand for wax emulsions is increasing from textile and leather industries. The Advanced Functional Fabrics of America Institute (AFFOA) brought over $300 million in public-private investment to develop futuristic fabrics and textiles helping to accelerate the revival of textile manufacturing in the United States. The thriving textile industry across the globe and vast technological advances may boost the global demand for wax emulsion.

Wax Emulsion Market Segment Analysis — By Geography

Asia Pacific dominated the Wax Emulsion market with a share of more than 41% in 2023 followed by North America and Europe. Increasing per-capita income and adoption of western culture in emerging economic nations especially in China, and India has boosted the growth of fashion industry and also increased the demand for leather. Increasing demand for apparel and expansion of textile industries across the country is also aiding the growth of market.

With the rising popularity of functional textiles that offer additional properties like water repellency, UV protection, and stain resistance, the demand for wax emulsions in textile coatings and finishes is on the rise. The growing demand for leather and apparel products in emerging markets, coupled with increasing disposable incomes and changing consumer preferences, presents significant opportunities for wax emulsion manufacturers to expand their presence and capture a larger market share in these regions. Thus huge spending on apparels and leather articles escalate the growth of the wax emulsion market.

Wax Emulsion Market Drivers

Growing demand from automotive industries

Wax Emulsions are water repellent, hence its use in automotive paints and polishes prevents water from accumulating in nooks and crannies of car’s surface thereby reducing the risk of corrosion and prevents the formation of water stains and spots on the surface. Wax emulsion are also used as lubricants and in car’s interior leather for matt effect and smoothness. Increase in standard of living coupled with high disposable income boosts the demand for automotive.

Automotive manufacturers prioritize the aesthetic appeal of vehicles to attract customers. Wax emulsions contribute to achieving a glossy finish and enhancing the appearance of automotive coatings, making vehicles more visually appealing to consumers. Continuous innovations in wax emulsion formulations cater to the evolving needs of the automotive industry. Advanced wax emulsions offer improved performance characteristics such as enhanced durability, scratch resistance, and water repellency, meeting the stringent requirements of automotive manufacturers and contributing to market growth. Thus rise in automotive demand augments the growth of the wax emulsion market.

Increasing use of paper and pulp as a substitute for plastics

Increasing environmental concerns and the use of paper as a substitute for plastics drive the growth of the wax emulsion market. In paper coatings, the wax emulsion is added to the coating mixture to reduce dusting during calendaring, to increase water repellency, to improve flexibility, and to raise gloss. When used as sizing in the paper, the wax emulsion helps prevent aqueous solutions, such as ink, from soaking into the paper and paperboard. According to an environmental paper network (EPN), paper use is steadily increasing year on year and exceeded 412 million tons per year in 2023. Also, total paper and paperboard demand for domestic applications such as tissue paper, newsprint, boxboard, etc. reached to 26,592 thousand metric tons in 2023 in Japan, according to the Japan paper association. Therefore, accelerating use for paper augments the demand for wax emulsions for paper sizing.

Wax Emulsion Market — Challenges

Volatility in prices of raw material

The raw materials often used for manufacturing waxes emulsion such as paraffin, polyethylene, and polypropylene are derived from the crude oil. So, fluctuation in oil prices also hampers the prices of wax emulsions. According to, BP Statistical Review of World Energy, in the recent year there is been an increase in the price volatility of crude oil, such as the crude oil price increased from $81.12 in 2022 to a price of $97.67 per barrel in the financial year 2023 hovering a high price rise, and because of this uncertainty in crude oil prices, the price of wax emulsions also increases. The volatility in crude oil prices is expected to be a significant challenge for wax emulsion manufacturers during the forecast period.

Wax Emulsion Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Wax Emulsion market report. Major players in the Wax Emulsion market are:

1. The Dow Chemical Company

2. Exxon Mobil Corporation

3. Momentive Performance Materials Inc.

4. Michelman, Inc.

5. Lubrizol Corporation

6. BASF SE

7. Croda International Plc

8. Arkema SA

9. Lanxess AG

10. Huntsman Corporation and others

Acquisitions / Technology Launches:

● Münzing Group’s Production Plant Inauguration (July 21, 2022): The Münzing Group inaugurated a state-of-the-art production plant in Zeitz Chemical and Industrial Park. This significant investment of EUR 50 million resulted in the creation of 40 new jobs.

For more Chemicals and Materials Market reports, please click here

0 notes

Text

0 notes

Text

Everything You Need to Know About Electric Tape Roll, PVC Tape Roll, and Insulation Tape Roll

When it comes to safeguarding electrical systems, ensuring proper insulation, and preventing potential hazards, choosing the right type of tape is crucial. Whether you’re an electrician, a DIY enthusiast, or a business owner, understanding the various types of electric tape roll, PVC tape roll, and insulation tape roll available in the market is essential. In this guide, we’ll cover everything you need to know, including the electric tape roll price, the benefits of different types of tapes, and where to find the best PVC tape manufacturers in Delhi.

1. What is an Electric Tape Roll?

An electric tape roll is a type of adhesive tape specifically designed for electrical applications. It is used to insulate electrical wires and cables, providing a protective barrier that prevents short circuits and other potential electrical hazards. These tapes are typically made from materials such as vinyl, rubber, or fiberglass cloth, ensuring durability and resistance to heat, moisture, and abrasion.

1.Benefits of Using Electric Tape Roll

Electrical Insulation: Provides effective insulation for electrical wires and cables.

Durability: Resistant to wear, tear, and extreme temperatures.

Safety: Helps in preventing electrical shocks and short circuits.

2. What is a PVC Tape Roll?

PVC tape roll, also known as polyvinyl chloride tape, is widely used for insulation and protection purposes in electrical systems. It is highly versatile, offering excellent resistance to UV light, abrasion, moisture, and varying temperatures. Due to its flexibility and durability, it is often preferred for wrapping electrical wires, insulation cables, and bundling harnesses.

2.1. Features of PVC Tape Roll

High-Quality Insulation: Offers superior insulation properties for electrical wiring.

Weather-Resistant: Suitable for both indoor and outdoor applications.

Flame Retardant: Reduces the risk of fire in case of short circuits or overheating.

3. Understanding Insulation Tape Roll

An insulation tape roll is a broad term encompassing various types of tapes used for electrical insulation purposes, including both electric and PVC tapes. Insulation tapes provide a protective coating that prevents the flow of electrical current outside the desired pathway.

3.1. Why Choose Insulation Tape Roll?

Versatility: Suitable for a wide range of electrical and non-electrical applications.

Protection: Prevents the risk of electrical shocks, short circuits, and wire damage.

Ease of Use: Easy to apply and provides long-lasting protection.

4. Electric Tape Roll Price: What You Need to Know

When it comes to the electric tape roll price, several factors can influence the cost:

Material Quality: Higher-quality materials like vinyl or rubber tend to be more expensive.

Brand: Well-known brands often come at a premium price due to their reliability.

Size and Length: The length and width of the tape roll can also affect the price.

Retailer: Prices can vary significantly from one retailer to another, so it is advisable to compare prices for the best deals.

5. PVC Tape Manufacturers in Delhi: Finding the Best Quality Tapes

If you are looking for reliable PVC tape manufacturers in Delhi, it’s essential to consider factors such as product quality, durability, and cost-effectiveness. Delhi is home to numerous PVC tapes manufacturers who offer a wide range of products suited for different applications.

5.1. Top PVC Tape Manufacturers in Delhi

When choosing PVC tapes in Delhi, look for manufacturers that offer:

High-Quality Products: Ensure that the tapes meet industry standards for safety and durability.

Customization Options: Some manufacturers provide customized tape rolls based on your requirements.

Competitive Pricing: Find a manufacturer that offers quality products at reasonable prices.

6. Buying PVC Tape in Delhi: What to Look For?

When purchasing PVC tape in Delhi, consider the following tips to ensure you get the best product for your needs:

Thickness and Width: Choose the appropriate thickness and width based on the application.

Adhesion Strength: Opt for tapes with strong adhesive properties to ensure they stay in place.

Temperature Resistance: For outdoor applications, ensure the tape is resistant to extreme temperatures.

7. PVC Tapes in Delhi: Where to Buy?

If you are looking to buy PVC tapes in Delhi, you can find them at various hardware stores, electrical supply shops, or directly from manufacturers. It’s advisable to buy in bulk from reputable PVC tape manufacturers in Delhi for better pricing and quality assurance.

Conclusion

Choosing the right type of tape—whether it’s an electric tape roll, PVC tape roll, or insulation tape roll is essential for ensuring safety and efficiency in any electrical project. Understanding the different options available, the electric tape roll price, and where to find quality PVC tapes in Delhi can help you make informed decisions for your electrical needs.

#electric tape roll#pvc tape roll#electric tape roll price#insulation tape roll#PVC tape manufacturers in Delhi#PVC tape in Delhi#PVC tapes in Delhi

0 notes

Text

Old Insulation Removal: A Guide to Improving Home Efficiency and Safety

Why Remove Old Insulation?

Decreased Efficiency

Insulation plays a vital role in maintaining your home's temperature by preventing heat loss in the winter and keeping heat out in the summer. Over time, insulation materials can settle, compact, or deteriorate, reducing their effectiveness. This decrease in efficiency can lead to higher energy bills and a less comfortable living environment.

Health Concerns

Old insulation, particularly materials like asbestos or fiberglass, can pose health risks if they become damaged or disturbed. Asbestos insulation, used in many homes built before the 1980s, can release harmful fibers into the air, leading to serious respiratory issues. Similarly, Old Insulation Removal damaged fiberglass insulation can release small particles that can irritate the skin, eyes, and respiratory system.

Pest Infestations

Old insulation can become a nesting ground for pests such as rodents, insects, and birds. These pests can cause significant damage to insulation, wiring, and other structural components of your home. Removing old insulation helps eliminate these infestations and reduces the risk of future pest problems.

Mold and Moisture Issues

Water damage from leaks or high humidity can lead to mold growth within your insulation. Mold not only compromises the insulation's effectiveness but also poses serious health risks. Removing and replacing moldy insulation is essential to maintaining a healthy living environment.

The Process of Removing Old Insulation

Safety Precautions

Before beginning the removal process, it's important to take safety precautions. Wear protective clothing, gloves, goggles, and a high-quality respirator to protect yourself from dust, mold, and potentially hazardous materials. If you suspect asbestos is present, it's best to hire a professional removal service to handle the job safely.

Preparation

Clear the area of any items and cover surfaces to protect them from dust and debris. Ensure proper ventilation in the workspace to reduce the concentration of airborne particles.

Removal

The removal process varies depending on the type of insulation. For blown-in insulation, use a high-powered vacuum to extract the material. For batt insulation, carefully roll up the sections and place them in heavy-duty trash bags. Handle all materials gently to minimize dust and fiber release.

Disposal

Dispose of the old insulation according to local regulations. Many municipalities have specific guidelines for disposing of hazardous materials like asbestos. Contact your local waste management authority for proper disposal instructions.

Clean-Up

Thoroughly clean the area after insulation removal to eliminate any remaining dust and debris. Use a HEPA vacuum for best results and consider using a damp cloth to wipe down surfaces.

Benefits of Upgrading Insulation

Improved Energy Efficiency

New insulation materials are designed to be more efficient and durable. Upgrading your insulation can significantly reduce energy consumption, Florida Spray Foam Insulation leading to lower heating and cooling costs.

Enhanced Comfort

With improved insulation, your home will maintain a more consistent temperature, making it more comfortable year-round. This is particularly important in regions with extreme weather conditions.

Increased Home Value

Energy-efficient homes are highly desirable in today's real estate market. Upgrading your insulation can increase your home's value and appeal to potential buyers.

Better Indoor Air Quality

New insulation materials are less likely to release harmful particles into the air, improving indoor air quality and reducing health risks.

0 notes

Text

Why Choose Stainless Steel Undermount Kitchen Sink?

However, stainless steel undermount kitchen sinks have become increasingly popular in recent years due to their many benefits. In this post, we'll explore why you should choose a stainless steel undermount kitchen sink for your home.

1 Durability: Stainless steel is an incredibly durable material that can withstand daily wear and tear. It's resistant to corrosion, stains, and scratches, making it an ideal material for a high-traffic area like the kitchen. Unlike other materials, such as porcelain or cast iron, stainless steel won't chip or crack easily, ensuring that your sink will last for many years to come.

2 Hygiene: Stainless steel is also a very hygienic material, which is important in the kitchen where cleanliness is key. It's non-porous, which means that bacteria and germs can't penetrate the surface, making it easy to keep clean and sanitized. This is particularly important if you have young children or if you frequently prepare raw meat in your kitchen.

3 Easy to Clean: Another benefit of stainless steel undermount kitchen sinks is that they're very easy to clean. Simply wipe them down with a damp cloth and mild soap, and they'll look as good as new. Unlike other materials, such as cast iron, stainless steel won't stain or discolor over time, so you don't have to worry about your sink looking dirty or dingy.

4 Design: Stainless steel undermount kitchen sinks come in a wide range of designs and styles, so you can easily find one that complements your kitchen's décor. Whether you prefer a modern and sleek look or a more traditional design, there's a stainless steel sink that will suit your needs. Additionally, stainless steel sinks can be paired with a variety of countertop materials, making them a versatile option for any kitchen.

5 Affordability: Finally, stainless steel undermount kitchen sinks are an affordable option for homeowners. While they may be slightly more expensive than other materials, such as acrylic or fiberglass, they're also much more durable and long-lasting. This means that you won't have to replace your sink as often, which can save you money in the long run.

Conclusion

There are many reasons to choose a stainless steel undermount kitchen sink for your home. From its durability and hygiene to its easy maintenance and versatility, a stainless steel sink is a great investment for any kitchen. So if you're in the market for a new sink, consider a stainless steel kitchen sink or an ss sink, and you won't be disappointed with your choice.

0 notes

Text

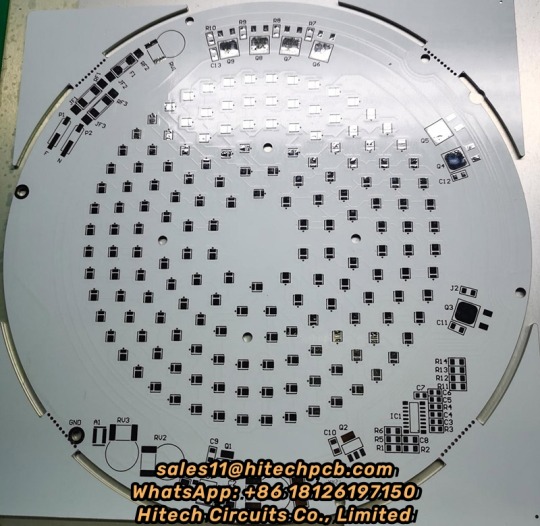

Aluminium PCB

1. What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Aluminum LED PCB with White Solder Mask

The retail price of Aluminum LED lights has dropped dramatically in recent years, while the energy efficiency and brightness of LED lights have improved. These technological advances have led some to predict annual growth of 45% over the next five years. With the development of the LED industry, the demand for LED PCBS and solder masks is also increasing. Solder shield is a protective coating applied to exposed printed circuit boards. The exposed PCB board is covered with a mask to prevent accidental solder bridging during PCB assembly and to protect the PCB from the environment. Solder masks are traditionally green, and are expected to withstand the high temperatures that occur in reflow soldering, as different colors such as blue, red, or black will occasionally appear. Increased production of Hitch Aluminum LED PCB requires increased whiteness and color stability of the mask. Aluminum LED PCB commonly used LPI welding color is white and black, of which white welding color is the most commonly used to achieve high brightness and perfect light reflection. White Aluminum LED PCB ensures no darkening and will not affect the color temperature of LED smd. At the same time, it also helps to increase the life of LED applications. Looking for reliable Aluminum LED PCB suppliers, Hitech is a good choice.

6. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

7. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

8. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

9. Technical requirements for Aluminum LED PCB

The main technical requirements are:

1. Dimensional requirements: including panel size and deviation, thickness and deviation, perpendicularity and warpage; Appearance, including cracks, scratches, burrs and delimitation, aluminum oxide film, etc.

2. Performance requirements, including peel strength, surface resistively, minimum breakdown voltage, dielectric constant, combustion and thermal resistance requirements.

10. Special test method for Aluminum-based copper clad plates

One is the measurement method of dielectric constant and dielectric loss factor. It is the series resonance method with variable Q value. The sample and tuned capacitor are connected to the high-frequency circuit in series to measure the Q value of the series circuit.

The other is the measurement method of thermal resistance, which is calculated by the ratio of temperature difference and heat conduction between different temperature measurement points.

11. The Aluminum LED PCB manufacturing process in Hitechpcba

(1)Substrate cutting

a. cutting process: material → cutting

b. Note: ① Check the size of the first piece; ② Pay attention to Aluminum surface scratching and copper surface scratching; ③ Pay attention to the layering of the board edge and the tip.

(2)Plate drilling

a, drilling process: pin → drilling → inspection plate

b, matters needing attention: ① check the number of drilling holes, the size of the empty chestnut chain; ② Check the plate burr, hole deviation; ③ Avoid scratching the substrate; ④ Check and replace the drill nozzle.

(3) Imaging transfer

a, graphic imaging process: grinding plate → film → exposure → development

b, precautions: ① Check whether there is an open circuit after development; ② Pay attention to the poor line caused by the board wipe; ③ There can be no air residual exposure to prevent poor exposure; ④ Whether there is deviation in developing counterpoint; ⑤ After exposure, the development should be done at rest for more than 15 minutes.

(4)Solder mask and Silkscreen process

a, kill row silk printing resistance welding, character process: screen printing → pre-baking → exposure → development → character

b, matters needing attention: ① Check whether there is foreign body on the board; ② Pay attention to the cleaning of the net board; ③ Pre-bake for more than 30 minutes after screen printing, to avoid bubbles in the line; ④ Pay attention to the thickness and uniformity of screen printing; ⑤ After the pre-baked plate to completely mutual cooling, avoid touching film or damage to the ink surface gloss.

(5)E-test or flying probe test

a, test process: line test → withstand voltage test

b, precautions: ① How to distinguish after the test how to store qualified and unqualified products.

(6)FQC, FQA, packaging, shipping

a. Process: FQC→FQA→ Packaging → shipping

b. Note: ① FQC should pay attention to the confirmation of the appearance of the finished Aluminum LED PCB in the process of eye inspection and make a reasonable distinction; ② FQA does spot check and verify the inspection standards of FQC; ③ We should confirm the number of packages to avoid mixed plates, wrong plates and package

12. Application of Aluminum LED PCB

1. Audio devices: input, output amplifier, balance amplifier, audio amplifier, preamplifier, power amplifier.

2. Power Supply: switching voltage regulator, DC/AC converter, SW voltage regulator, etc.

3. Communication electronic equipment: high frequency amplifier, filter, transmitter circuit

4. Office automation equipment: motor drive, etc

5. Automobile: electronic regulator, ignition device, power controller, etc.

6. Computer :CPU board, floppy disk drive, power equipment, etc.

7. Power module: converter, solid relay, rectifier bridge, etc

8. Lamps and lighting: A variety of colorful LED energy-saving lamps are well received by the market, and Aluminum LED PCB used in LED lights has also begun to be applied on a large scale.

13. Aluminum LED PCB Storage Conditions

Aluminum LED PCB are generally stored in a dark and dry environment. Most Aluminum LED tube lighting metal core pcb are prone to dampness, yellowing, and blackening. Generally, they should be used within 48 hours after opening the vacuum package.

14. Specification for the manufacture of Aluminum LED PCB

a. Aluminum LED PCB is often used in power devices, power density is high, so the copper foil is thicker. If copper foils over 3oz are used, the etching of thick copper foils requires engineered line width compensation, otherwise the line width will be out of tolerance after etching.

b. The aluminum base surface of aluminum substrate must be protected by protective film in advance during PCB processing, otherwise, some chemicals will etch the aluminum base surface, resulting in appearance damage. And the protective film is easy to be hurt, resulting in gaps, which requires the whole PCB processing process must be inserted.

c. The hardness of the milling cutter used by the glass fiber board gong board is relatively small, and the hardness of the milling cutter used by the aluminum substrate is large. In the process of manufacturing glass fiber board milling cutter speed, while the production of aluminum substrate is at least two thirds slower.

d, computer milling glass fiber board is just the use of the machine's own cooling system, but the processing of aluminum substrate must be in addition to alcohol heat dissipation for the gong head.

15. Aluminum LED PCB circuit fabrication

(1) Mechanical processing: Drilling of aluminum substrate can be done, but no burr is allowed on the edge of the inner hole after drilling, which will affect the pressure test. Milling the shape is very difficult. And punching shape, need to use advanced mold, mold production is very skilled, as one of the difficulties of aluminum substrate. After shape punching, the edge should be very neat, without any burr, and do not hurt the welding resistance layer on the edge of the plate. Usually the use of soldier die, hole from the line, shape from the aluminum surface, circuit board punching force is cut down, and so on are skills. After punching the shape, the warpage of the board should be less than 0.5%.

(2) The whole production process is not allowed to wipe the aluminum base surface: aluminum base touch, or by a certain chemical will produce surface discoloration, blackening, which is absolutely unacceptable, re-polishing aluminum base some customers do not receive, so the whole process does not touch the aluminum base surface is one of the difficulties in the production of aluminum base plate. Some enterprises use passivation process, some in hot air leveling (spray tin) before and after each pasted protective film.

(3) Over-high voltage test: the aluminum base board of the communication power supply shall be tested at 100% high voltage. Some customers require direct current or alternating current. The voltage shall be 1500V or 1600V, and the time shall be 5 seconds or 10 seconds. Dirt on the board, holes and aluminum edge burr, line saw tooth, damage to any little insulation layer will lead to high voltage test fire, leakage, breakdown. Pressure test board stratification, foaming, are rejected.

1 note

·

View note

Text

What’s Aluminium LED PCB?

Aluminum LED PCB substrate is a metal - based copper-clad sheet with good heat dissipation. A single panel is generally composed of three layers of structure, namely the circuit layer (copper foil), insulation layer and metal base layer. It is commonly found in LED lighting products. There are two sides, the white side is used to weld the LED pins, and the other side is the natural color of aluminum, which is usually coated with heat-conducting gel and then in contact with the heat-conducting part. Among all metal core PCBS, Aluminum LED PCB is the most common type. The base material consists of an aluminum core and standard FR4. It features a thermal cladding that dissipates heat in an efficient manner while cooling components and improving the overall performance of the product. Currently, aluminum-backed PCBS are considered solutions for high power and tight tolerance applications.

2. Aluminum LED PCB with Copper Layer, Dielectric Layer & Aluminum Layer

Aluminum LED PCB has a similar layout to any other printed circuit boards with copper layer(s), solder mask layer(s) and silkscreen(s). Instead of having a fiberglass or plastic substrate, Aluminum LED PCB is made from metal core substrate, which consists of copper layer, dielectric layer and aluminum layer. This substrate is called as Aluminum based copper clad laminate (CCL). The glass reinforced and ceramic filled dielectric layer in-between copper layer and aluminum layer is very thin, but plays a very important role of electric insulation and thermal conductivity (because of minimum thermal resistance) from copper layer to aluminum base. The copper is etched into conductors and metal base is to withdraw thermal (/heat). The superior heat transfer capacity of Aluminum-based PCB helps cooling components while eliminating problems associated with managing fragile ceramics.

3. Thermal conductivity of Aluminium LED PCB

The general thermal conductivity of Aluminum LED PCB is 0.3, 0.6, 1.0, 1.5, 2.0, 3.0, 5.0, 122W/m.k, etc., among which 0.3-1.0w /m.k is the general conductive Aluminum LED PCB, 1.5W/m.k is the middle conductive Aluminum LED PCB, 2.0-3.0w /m.k is the high conductive Aluminum LED PCB. 5.0W/m.k is thin abasal substrate, and 122W/m.k is ultra-high conductivity Aluminum LED PCB, also known as ALC Aluminum LED PCB.

At present, the common Aluminum LED PCB on the market has a thermal conductivity of 1.0, 1.5, 2.0W/m.k high conductivity type Aluminium LED, wherein the thermal conductivity of 1.0W/m.k Aluminum LED PCB is called general Aluminum LED PCB, its insulation layer is composed of epoxy glass cloth bonded sheet; Aluminum LED PCB with thermal conductivity of 1.5W/m.k is called high heat dissipation Aluminum LED PCB, and its insulation layer is composed of epoxy resin or other resins with high thermal conductivity; The Aluminum LED PCB with a thermal conductivity of 2.0W/m.k is called the Aluminum LED PCB for high-frequency circuit, and the insulating layer is composed of polyolefin resin or Polyimide resin glass cloth bonded sheet. The thermal conductivity of Aluminum LED PCB varies according to the copper layer in the circuit. Different processes produce different levels of thermal conductivity.

We currently support Aluminum based CCLs from Ventec, GDM and BoYu with thermal conductivity from 1.0 ~ 7 W/m•K. The Aluminum LED PCB prices of Ventec is much higher than that with GDM and BOYU since material cost, and the prices of high thermal conductivity is higher than low thermal conductivity. Hitechpcb provides a wide range of electrical and thermally conductive interface pads, thermally conductive gap filler, thermal phase change materials and thermally conductive electrically insulating materials, as well as specialized equipment for high volume Aluminum LED PCB manufacturing. Choosing Hitech Circuits PCB as your Aluminum LED PCB supplier, just send your Gerber files and fabrication notes to us, we will deliver qualitied PCB boards to you on time.

4. Dielectric Constant of Aluminium LED PCB

The dielectric constant of Aluminum LED PCB substrate is a special detection method for Aluminum LED PCB. It is a variable Q value series resonance method through the measurement of dielectric constant and dielectric loss factor. The sample and tuning capacitor are connected in series to the high frequency circuit to measure the series circuit The principle of Q value.

The performance of Aluminum LED PCB includes requirements such as peel strength, surface resistivity, minimum breakdown voltage, dielectric constant, flammability and thermal resistance.

5. Classification of Aluminum LED PCB Substrate

Aluminum LED PCB-based copper clad plates are divided into three categories:

The first is the universal aluminum-based copper clad plate, the insulation layer is composed of epoxy glass cloth bonded sheet;

The second is the high heat dissipation aluminum-based copper-clad plate, the insulation layer is composed of high thermal conductivity epoxy resin or other resins;

Third, high frequency circuit aluminum base copper plate, insulation layer by polyolefin resin or Polyimide resin glass cloth bonded sheet.

The biggest difference between aluminum clad copper plate and conventional FR-4 clad copper plate is heat dissipation. Compared with 1.5mm thickness of FR-4 clad copper plate and aluminum clad copper plate, the former thermal resistance of 20 ~ 22 ℃, the latter thermal resistance of 1.0 ~ 2.0℃, the latter is much smaller.

6. Aluminum LED PCB Performance:

(1) Heat dissipation

Many double panel, multi - layer plate high density, power, heat distribution is difficult. Conventional printed board substrates such as FR4, CEM3 are bad conductors of heat, insulation between layers, heat does not escape. Local heating of electronic equipment is not excluded, leading to high temperature failure of electronic components, and Aluminum LED PCB can solve this problem of heat dissipation.

(2) Thermal Expansibility

Thermal expansion and cold contraction is the common nature of substances, and the coefficient of thermal expansion of different substances is different. Aluminum based printed board can effectively solve the problem of heat dissipation, so that the printed board components of different substances on the thermal expansion and contraction problem, improve the durability and reliability of the whole machine and electronic equipment. Especially solve SMT (surface mount technology) thermal expansion and shrinkage problems.

(3) Dimensional stability

Aluminum-based printed boards are obviously much more stable in size than those made of insulating materials. Aluminum base printed board, aluminum sandwich board, heating from 30℃ to 140~150℃, the size change is 2.5~3.0%.

(4) Other reasons

Aluminum based printed board, with shielding effect; Instead of brittle ceramic substrate; Safe use of surface mounting technology; Reducing the real effective area of the printed board; Instead of radiator and other components, improve the heat resistance and physical properties of products; Reduce production costs and labor.

7. Why choose Aluminum LED PCB from Hitechpcb? What are the advantages of Aluminum LED PCB?

(1) Good heat dissipation performance: Aluminum LED PCB can reduce the thermal resistance to the minimum, has a smaller thermal resistance, thermal expansion coefficient is closer to copper foil, so that Aluminum LED PCB has excellent thermal conductivity and heat dissipation performance, reduce the module operating temperature, prolong the service life.

High current load: Using the same thickness, the same line width, Aluminum LED PCB substrate can carry higher current.

(2) Good machinability: can replace ceramic substrate, better mechanical endurance. At the same time, high strength and toughness, can realize large area printed board manufacturing and component mounting.

(3) Good electromagnetic shielding: In order to ensure the performance of electronic circuits, some components of electronic products need to prevent electromagnetic radiation and interference. Aluminum LED PCB can act as a shield plate, play the role of shielding electromagnetic wave

(4) Environmental protection: The Aluminum LED PCB used in the raw material is non-toxic and can be recycled. Meet RoHs requirements.

(5)Light weight: Aluminum LED PCB has a surprisingly light weight with excellent strength and elasticity, which is very convenient.

Hitech Circuits can provide high quality and affordable Aluminum LED PCB products for you.

0 notes

Text

0 notes

Text

Copper Clad Laminate for 5G Base Station Market Future Aspect Analysis and Current Trends

The competitive analysis of the Copper Clad Laminate for 5G Base Station Market include a comprehensive analysis of market trends, competitor landscape, consumer behavior, and potential opportunities. It should cover key demographics, market size, growth projections, and risk factors. The report should also highlight the methodology used for data collection and analysis, presenting findings with visual aids such as charts and graphs. Additionally, recommendations and strategic insights for stakeholders to make informed decisions are crucial. The report should be concise, well-organized, and provide actionable information for businesses aiming to navigate the market effectively.

Key Function:

A Copper Clad Laminate for 5G Base Station market research report serves to assess market dynamics, identify opportunities, and mitigate risks for businesses. It analyzes consumer preferences, competitor strategies, and economic trends. The report facilitates informed decision-making by presenting data on market size, growth potential, and emerging patterns. It aids in product development, pricing strategies, and market positioning. Additionally, market research reports help businesses understand their target audience, enhance marketing efforts, and optimize resource allocation. By offering actionable insights, these reports empower organizations to stay competitive, adapt to changing market conditions, and foster sustainable growth in a dynamic business environment.

Key Dynamics:

Market research reports capture vital dynamics, including market trends, competitive analysis, and consumer behavior. They reveal market size, growth projections, and regional nuances. SWOT analysis examines internal strengths and weaknesses, along with external opportunities and threats. Consumer insights delve into preferences, impacting product development and marketing strategies. The competitive landscape unveils key players, strategies, and market shares. Regulatory factors and industry challenges are explored, aiding risk assessment. Timely and accurate information empowers businesses to adapt strategies, capitalize on opportunities, and navigate challenges, ensuring informed decision-making and sustained competitiveness in dynamic markets.

Receive the FREE Sample Report of Copper Clad Laminate for 5G Base Station Market Research Insights @ https://stringentdatalytics.com/sample-request/copper-clad-laminate-for-5g-base-station-market/8469/

Market Segmentations:

Global Copper Clad Laminate for 5G Base Station Market: By Company • Panasonic • Rogers • AGC • Isola Group • Taconic • Chukoh • BDStar Navigation • Ventec International Group • Taiwan Union Technology Corporation • Zhuhai Guoneng • Zhejiang Wazam • Guangdong Chaohua • Zhejiang Yuanji New Material Technology • Changzhou Zhongying • Linzhou Zhiyuan Electronic • Linzhou Chengyu Electronic Material • Guangdong Shengyi Global Copper Clad Laminate for 5G Base Station Market: By Type • Resin Copper Clad Laminate • Fiberglass Cloth Copper Clad Laminate • Others Global Copper Clad Laminate for 5G Base Station Market: By Application • Power Amplifiers • Antenna Systems • Telematics • Active Safety • Others

Regional Analysis of Global Copper Clad Laminate for 5G Base Station Market

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Copper Clad Laminate for 5G Base Station market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Click to Purchase Copper Clad Laminate for 5G Base Station Market Research Report @ https://stringentdatalytics.com/purchase/copper-clad-laminate-for-5g-base-station-market/8469/

Reseason To Purchase: