#Fertilizer Granulator

Explore tagged Tumblr posts

Text

In the pursuit of sustainable agricultural development today, organic fertilizer production is not only the key to improve soil health, but also an important way to achieve green agriculture. In order to achieve this goal, we need to integrate the concept of energy conservation and green production in the production process of organic fertilizer, and modern organic fertilizer equipment is the practitioner of this concept.

First, let's focus on the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Granulator. These two granulators lead the energy saving trend of organic fertilizer production with their efficient energy utilization and excellent granulation effect. By optimizing the granulation process, they reduce energy consumption while ensuring uniform particles and nutrient stability, providing great convenience for subsequent packaging, transportation and use.

In raw material treatment, the application of Chain Crusher and Straw Crusher has effectively reduced the crushing energy consumption of raw materials, reduced dust pollution, and realized the resource utilization of waste. With its strong crushing capacity and stable performance, these shredders provide a high-quality raw material base for organic fertilizer production.

In terms of mixing uniformity, the Double Shafts Mixer, with its efficient mixing capacity, ensures full mixing of raw materials and additives, improving the overall quality of the fertilizer. At the same time, these mixers are designed to pay attention to energy saving and consumption reduction, contributing to green production.

As an important link in the production of organic fertilizer, Drum screener machine accurately separates different particle sizes of fertilizer particles with its continuous and efficient working mode, which not only ensures the uniformity of products, but also avoids the waste of energy. The flexible application of Vibrating Screen further improves the screening efficiency and reduces the energy consumption.

In the Fertilizer drying and cooling stage, Drum Fertilizer Dryer and Drum Fertilizer Cooler achieve low temperature drying and rapid cooling by optimizing thermal efficiency, effectively reducing energy consumption and emissions. These devices not only improve the quality of the finished fertilizer, but also meet the requirements of green production.

Finally, the application of Coating Machine puts on a protective film for organic fertilizer, extends the shelf life of fertilizer and improves the utilization rate of nutrients. Although this link seems simple, it is yet another interpretation of the concept of green production, because it reduces the waste of fertilizer and improves the economic and environmental benefits of agricultural production.

0 notes

Text

In the pursuit of sustainable agricultural development today, organic fertilizer production is not only the key to improve soil health, but also an important way to achieve green agriculture. In order to achieve this goal, we need to integrate the concept of energy conservation and green production in the production process of organic fertilizer, and modern organic fertilizer equipment is the practitioner of this concept.

First, let's focus on the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Granulator. These two granulators lead the energy saving trend of organic fertilizer production with their efficient energy utilization and excellent granulation effect. By optimizing the granulation process, they reduce energy consumption while ensuring uniform particles and nutrient stability, providing great convenience for subsequent packaging, transportation and use.

In raw material treatment, the application of Chain Crusher and Straw Crusher has effectively reduced the crushing energy consumption of raw materials, reduced dust pollution, and realized the resource utilization of waste. With its strong crushing capacity and stable performance, these shredders provide a high-quality raw material base for organic fertilizer production.

In terms of mixing uniformity, the Double Shafts Mixer, with its efficient mixing capacity, ensures full mixing of raw materials and additives, improving the overall quality of the fertilizer. At the same time, these mixers are designed to pay attention to energy saving and consumption reduction, contributing to green production.

As an important link in the production of organic fertilizer, Drum screener machine accurately separates different particle sizes of fertilizer particles with its continuous and efficient working mode, which not only ensures the uniformity of products, but also avoids the waste of energy. The flexible application of Vibrating Screen further improves the screening efficiency and reduces the energy consumption.

In the Fertilizer drying and cooling stage, Drum Fertilizer Dryer and Drum Fertilizer Cooler achieve low temperature drying and rapid cooling by optimizing thermal efficiency, effectively reducing energy consumption and emissions. These devices not only improve the quality of the finished fertilizer, but also meet the requirements of green production.

Finally, the application of Coating Machine puts on a protective film for organic fertilizer, extends the shelf life of fertilizer and improves the utilization rate of nutrients. Although this link seems simple, it is yet another interpretation of the concept of green production, because it reduces the waste of fertilizer and improves the economic and environmental benefits of agricultural production.

#organic fertilizer machine#organic fertilizer#organic fertilizer production line#fertilizer machine#fertilizer production line#fertilizer granulator machine#fertilizer granulator#fertilizer

0 notes

Text

In modern agriculture, the application of organic fertilizers is increasingly widespread, which not only improves soil quality, but also promotes the healthy growth of crops. The fermentation process of organic fertilizer is a crucial part of the entire production process. By introducing and optimizing the use of the above organic fertilizer equipment, not only can significantly improve the fermentation efficiency and product quality of organic fertilizer, but also reduce energy consumption and labor costs, and contribute to the sustainable development of modern agriculture.

Detailed explanation of organic fertilizer fermentation process

The fermentation process of organic fertilizer is mainly divided into several stages: raw material preparation, compost fermentation, maturation stabilization and post-treatment. Raw materials need to be processed by equipment such as Straw Crusher to ensure uniform particle size and facilitate microbial decomposition. Subsequently, the compost fermentation is carried out under the appropriate temperature, humidity and ventilation conditions. At this stage, a Horizontal Mixer can be introduced to turn the pile regularly to ensure sufficient oxygen and accelerate the fermentation process.

Efficiency improvement strategy

Efficient granulation: The use of New Type Organic Fertilizer Granulator or Hydraulic Roller Granulator, through physical extrusion molding, improve the uniformity of particles and yield, reduce the follow-up screening workload, significantly improve production efficiency.

Fine grinding: The use of Chain Crusher and Half-Wet Material Crusher to fine raw materials, to ensure that the size of raw materials meet the requirements of fermentation, accelerate the microbial decomposition speed, shorten the fermentation cycle.

Intelligent mixing: The introduction of automatic control of the Double Axis Mixer or BB Fertilizer Mixer, to achieve accurate ratio and uniform mixing, reduce manual intervention, improve mixing efficiency and quality.

Optimization of drying and cooling: The Drum Fertilizer Dryer is combined with the Drum Fertilizer Cooler unit, which uses the heat exchange principle to quickly remove water, while controlling the temperature, protecting the activity of beneficial microorganisms, and laying a good foundation for subsequent granulation and packaging.

Screening and coating: Accurate screening by Rotary Screener Machine and Vibration Screener Machine ensures consistent product size. Subsequently, the Coating Machine is used for coating treatment to enhance the slow-release and anti-caking properties of the fertilizer and enhance the added value of the product.

0 notes

Text

In the fine process of organic fertilizer production, cooling technology plays a pivotal role, which is not only a key part of ensuring product quality, but also an important means to improve production efficiency and save energy.

Cooling technology is necessary

In the production process of organic fertilizer, whether through the high pressure molding of the Double Roller Press Granulator, or the innovative process of the New Type Organic Fertilizer Granulator, the particles often have a higher temperature and a certain humidity in the early stage of formation. If not cooled in time, these high temperature and high humidity particles are not only easy to caking, affecting the appearance and fluidity of the product, but also may lead to nutrient loss due to accelerated internal chemical reactions. Therefore, cooling technology has become an indispensable bridge between granulation and packaging.

Practice case sharing

Taking a large organic fertilizer production plant as an example, the plant introduced an advanced Rotary Drum Granulator, combined with an efficient cooling system, to achieve an integrated production from granulation to cooling. Inside the drum, the raw material is thoroughly mixed and granulated and goes directly into the cooling section below. The cooling section uses an advanced air circulation system to adjust the wind speed and temperature to ensure that the particles are evenly cooled to the appropriate level in a short period of time, preserving the integrity and nutritional content of the particles, while improving the overall efficiency of the production line.

Innovative application of cooling technology

With the advancement of technology, cooling technology is also constantly innovating. For example, some manufacturers have begun to try to combine the cooling system with an intelligent control system to automatically adjust the cooling parameters through real-time monitoring of the temperature and humidity of the particles to achieve accurate control. This intelligent cooling method not only improves the cooling efficiency, but also greatly reduces energy consumption and labor costs.

#fertilizer machine#Organic fertilizer production line#fertilizer granulator#fertilizer granulator price person

0 notes

Text

ट्राईकोडर्मा विरिडी एक उच्च गुणवत्ता वाला जैविक एजेंट है। Tricoderma viride की तेजी से विकास होती है, और यह मिट्टी में पोषक तत्वों और ऑक्सीजन को जल्दी से उपयोग कर सकता है, जिससे पौधों की बीमारी के रहने का वातावरण बिगड़ जाता है और फफूंद को नष्ट कर्ता हेl

#biopesticide#fertilizer granules compaction machine#fertilization#organic fertilizer production line#organic fertilizer equipment

2 notes

·

View notes

Text

youtube

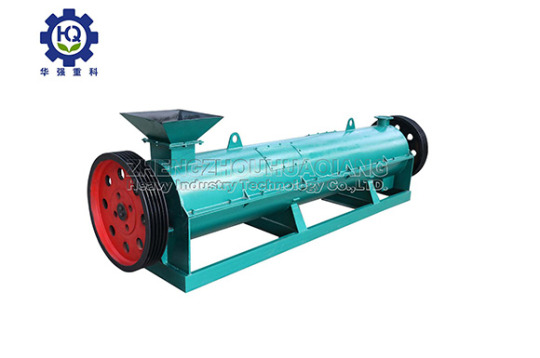

Extrusion Granulator: Efficient and Eco-Friendly Solution for Fertilizer and Feed Production

#rotary drum granulator#disc granulator#organic fertilizer granulator#double roller press granulator#fertilizer granulator price#Youtube

2 notes

·

View notes

Text

"Farming teaches us the virtues of patience, hard work, and the beauty of watching something grow from a mere seed."

#agribusiness#agricoltura#agriculture#agritech#agrobisnis#business#crops#education#farmers#farming#organic fertilizer equipment#fertilizers#organic fertilizer production line#organic fertilizer granulator

2 notes

·

View notes

Text

Balancing Nutrients with Organic Fertilizers: A Practical Approach

In farming and gardening, it's vital to strike the perfect nutrient balance in the soil to ensure plants thrive and yield abundantly. Organic fertilizers offer a practical and environmentally conscious way to maintain that essential nutrient balance in the soil. In this article, we'll dive into the importance of keeping the soil's nutrient levels in check, the benefits of using organic fertilizers, and some helpful advice on making the most of them.

Understanding Nutrient Balance:

Plants require a variety of essential nutrients for their growth, including macronutrients like nitrogen (N), phosphorus (P), and potassium (K), and micronutrients like iron, zinc, and manganese. Imbalances in these nutrients can lead to various issues. For instance, an excess of nitrogen can promote lush foliage but hinder fruit or flower production, while a phosphorus deficiency can limit root development.

Soil naturally contains some of these nutrients, but over time, continuous farming and gardening can deplete them. To maintain healthy and productive plants, it's essential to supplement the soil with the nutrients it lacks.

The Benefits of Organic Fertilizers:

Organic fertilizers are derived from natural sources, such as plant matter, animal products, or microbial activity. They offer several advantages when it comes to nutrient balance and soil health:

1. Slow Release: Organic fertilizers release nutrients gradually as they break down, preventing the risk of nutrient imbalances or leaching. This slow-release nature ensures that plants receive a steady supply of nutrients over time.

2. Improving Soil Structure: Organic fertilizers enhance soil structure and increase water-holding capacity. This allows the soil to retain nutrients better and provides a hospitable environment for beneficial microorganisms.

3. Microbial Activity: Many organic fertilizers contain beneficial microorganisms that contribute to nutrient cycling in the soil. These microbes help break down organic matter and make nutrients more available to plants.

4. Reduced Environmental Impact: Organic fertilizers are environmentally friendly as they do not contribute to water pollution or harm beneficial soil organisms. They are a sustainable alternative to synthetic chemical fertilizers.

Practical Tips for Balancing Nutrients with Organic Fertilizers:

1. Soil Testing: Before adding any fertilizers, it's essential to perform a soil test to understand your soil's current nutrient status. This will guide you in choosing suitable organic fertilizers and determining the required application rates.

2. Choose the Right Organic Fertilizers: Select organic fertilizers that match your soil's nutrient deficiencies. For example, bone meal is a good source of phosphorus, while compost provides a mix of nutrients.

3. Follow Application Guidelines: Organic fertilizers come with recommended application rates. Follow these guidelines to avoid over-fertilization, which can harm plants and the environment.

4. Use Compost: Compost is an excellent organic fertilizer. It not only supplies a variety of nutrients but also improves soil structure. Adding compost to your garden or agricultural plot helps maintain nutrient balance.

5. Crop Rotation: Practicing crop rotation can help prevent nutrient depletion in the soil. Different crops have varying nutrient requirements, so rotating them can ensure the soil remains balanced.

6. Mulching: Applying organic mulch, such as straw or wood chips, can help retain soil moisture and reduce nutrient loss. As the mulch breaks down, it also contributes to the nutrient pool.

In conclusion, achieving nutrient balance in your soil is a critical factor in successful gardening and farming. Organic fertilizers not only deliver vital nutrients but also enhance soil quality and boost microbial life, fostering the overall health of your soil. By adhering to these user-friendly recommendations, you can tap into the advantages of organic fertilizers, ensuring the thriving condition of your plants and the environment.

#agriculture#biotechnology#organic#organic fertilizer#fertilizer#fertilizers for plants#organic fertilizer granulator

4 notes

·

View notes

Text

Organic fertilizer granulator for material moisture requirements

In the production of organic fertilizer, what is the moisture requirement of the material for organic fertilizer granulation? This problem is a lot of organic fertilizer production line industry friends concerned about the topic. Too much or too little water won't do the trick.

Material moisture requirements:

In the production process of organic fertilizer granulator, the material is required to have a certain viscosity. Some raw materials are loose after fermentation and not easy to granulate. Some water or adhesive should be added to increase the viscosity of the material. The water content is about 45%. The organic fertilizer disc granulator and rotary drum granulator adopt wet granulation. Water or adhesive is added in the process of granulation to ensure smooth granulation of materials. New type organic fertilizer granulator using wet granulation, fermentation materials can be directly granulated, without other operations. Double roller press granulator is produced by non - dry normal temperature process, suitable for granulating materials with low viscosity. If the water content of the material is too high, you can add some relatively dry material to neutralize the low water content. If the water content is too low, appropriate amount of water can be added to facilitate granulation.

Moisture requirements of materials:

High water content materials to add some dry plants, such as wood chips, humic acid, straw and other materials, can absorb water, increase the specific gravity, increase nutrients. New organic fertilizer pelletizing machine is with the development of agriculture, the improvement of technology, the diversification of demand and continuous improvement of organic fertilizer pelletizing equipment. The new organic fertilizer wet granulator can realize the selection of material size. All kinds of materials after fermentation as long as through the organic fertilizer granulator can break the traditional process and barriers, there is no need to stop the material before granulation. Disposal crushing can achieve indirect discharge and direct granulation, so as to achieve the effect of granulation.

2 notes

·

View notes

Text

What does the rapid development of organic fertilizer equipment bring to agriculture?

The progress of science and technology drives the development of all walks of life in our country, and agriculture is no exception. Not only has agriculture made great progress, but new farming methods have also emerged, and agriculture has begun to turn green. So far, almost 80% of organic fertilizer equipment has completed the process of agricultural cycle development. Just like the biogas we learned in the textbooks, it's recyclable. The organic fertilizer production line is improving day by day. This development mode has played a role in protecting the environment, effectively preventing pollution and improving the utilization rate of waste. Turning waste into treasure. Now organic fertilizer granulator machine and press granulator machine has also realized the green environmental protection function. Organic fertilizer equipment actually converts animal manure into organic fertilizer, which can also add some crop straw to animal manure. Organic fertilizer equipment is actually the best way to dispose of agricultural waste. Now with the continuous progress of technology, the technical level of organic fertilizer equipment has also reached a new level, and now the strength of organic fertilizer equipment manufacturers is also growing. Our company mainly produces complete sets of chemical fertilizer equipment, installation and debugging of chemical fertilizer equipment, and provides customers with comprehensive services such as chemical fertilizer production process design. We always adhere to high quality, high standard of product requirements, and constantly improve product quality, standing in the forefront of the domestic fertilizer equipment industry.

2 notes

·

View notes

Text

Any high-quality organic fertilizer production must go through the composting fermentation process. Composting is a process in which organic matter is continuously degraded and stabilized by the action of microorganisms under certain conditions. The end result is a product suitable for the land. Soil diseases can be suppressed by using well-rotted organic fertilizers. In addition, the presence of antagonistic bacteria after the high-temperature phase of the composting process can lead to high bacterial numbers. Moreover, the organic matter in the composting process is not easily decomposed and stable under the action of microorganisms, and is easily absorbed by crops. At the same time, microorganisms play a role in reducing the toxicity of heavy metals within a certain range. It can be seen that composting is a simple and effective method of making organic fertilizer.

3 notes

·

View notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

0 notes

Text

In the green transformation of modern agriculture, the automatic control and intelligent monitoring technology of organic fertilizer production line is gradually becoming the key to improve production efficiency and ensure product quality. The wide application of this technology not only realizes the precise regulation of the production process, but also significantly reduces labor costs and energy consumption, and injected a strong impetus for the intelligent upgrading of the organic fertilizer industry.

Automation control technology:

In the organic fertilizer production line, the core equipment such as the New Type Organic Fertilizer Granulator and Hydraulic Type Roller Press Granulator realizes the fully automated operation from raw material delivery to finished product output through the integrated PLC control system. According to the preset parameters, the system automatically adjusts the speed, pressure and other key indicators of the granulator to ensure uniform particle size and regular shape. At the same time, mixing equipment such as Horizontal Mixer and Vertical Mixer have also joined the ranks of automatic control, which improves the mixing efficiency of raw materials and the quality of finished products through accurate matching and uniform mixing.

Intelligent monitoring technology:

In order to monitor the running status and product quality of the production line in real time, key equipment such as Drum Fertilizer Dryer and Drum Fertilizer Cooler are equipped with intelligent sensors and monitoring systems. These systems can monitor equipment temperature, humidity, speed and other key parameters in real time, once found abnormal immediately alarm and automatically adjust to the safety state, effectively avoid the occurrence of production accidents. Through intelligent identification technology, screening equipment such as Drum screener machine and Vibrating Screen can accurately screen finished products to ensure the consistency of product particle size and improve screening efficiency and accuracy.

More advanced is that the intelligent monitoring technology is also applied to post-processing equipment such as the Coating Machine , which ensures that the fertilizer has good slow release and anti-caking by monitoring the thickness and uniformity of the coating layer in real time. Combined with big data analysis technology, the operation data of the whole production line is collected and analyzed, which provides a scientific basis for production optimization and decision-making.

The automatic control and intelligent monitoring technology of organic fertilizer production line is leading the industry to develop in a more efficient and intelligent direction. With the continuous progress of technology and the in-depth promotion of application, it is believed that the organic fertilizer industry will usher in a broader development prospect.

#organic fertilizer machine#fertilizer machine#organic fertilizer#fertilizer production line#fertilizer granulator machine#fertilizer granulator

0 notes

Text

In the process of organic fertilizer production, the mixing uniformity is one of the key factors to determine its quality. High-quality mixing is not only related to the balanced distribution of nutrients, but also directly affects the fertilizer efficiency release and crop absorption efficiency of organic fertilizers. So, how to ensure the mixing uniformity, so as to improve the quality of organic fertilizer? The key lies in choosing suitable equipment and taking scientific operation measures.

Fertilizer mixer series equipment such as Horizontal Mixer、Vertical Mixer and Double Shafts Mixer play a core role in the mixing process. These devices ensure adequate contact and mixing between raw materials through different mixing mechanisms, such as rotation, flipping, shearing, etc., effectively avoiding the problem of uneven nutrient distribution. In particular, the double-axis mixer, with its powerful mixing capacity and uniform mixing effect, is especially suitable for handling large quantities of organic fertilizer raw materials with high viscosity.

Only advanced mixing equipment is not enough, optimized operational measures are also important. Before mixing, it should be ensured that the degree of crushing of raw materials is consistent, which depends on the use of crushing equipment such as Chain Crusher and Half-wet Material Crusher, which fine raw materials to uniform particles, creating favorable conditions for subsequent mixing.

Reasonable mixing time and speed are also important factors affecting mixing uniformity. Too short a mixing time may result in inadequate mixing, while too long a mixing time may result in increased energy consumption and material wear. Therefore, the operating parameters of the mixer should be adjusted according to the actual production situation to achieve the best mixing effect.

The finished product after mixing also needs to be processed by screening equipment such as Drum screener machine or Vibrating Screen to remove large impurities and insufficiently mixed particles, and further improve the purity and uniformity of organic fertilizer. At the same time, this also contributes to the stable operation and efficient production of the subsequent fertilizer granulator series equipment.

Mixing uniformity has a crucial effect on the quality of organic fertilizer. Through the use of advanced mixing equipment, optimized operational practices and enhanced screening processing, we can significantly improve the mixing uniformity and overall quality of organic fertilizers, providing better and more efficient fertilizer support for agricultural production.

#Fertilizer granulator#fertilizer granulator price#organic fertilizer granulator#organic fertilizer production line

1 note

·

View note

Text

Organic fertilizer screening and grading technology: a key step to improve product quality

In the production process of organic fertilizer, screening and grading technology is not only an important link between granulation and packaging, but also a key step to improve product quality and meet market demand. Today, we'll take a closer look at this technology and how it works with a variety of fertilizer granulators to create high-quality organic fertilizer products.

Screening: Fine separation to remove impurities

Screening technology through the physical separation of organic fertilizer particles, effectively remove large impurities in the particles, not fully formed particles and over-fine powder, to ensure the purity and consistency of the product. In this process, the particles produced by the Disc Granulaor (Pan Granulator) and the Rotary Drum Granulator are fine-screened by the screening machine, which can further improve their quality and lay a solid foundation for subsequent classification.

Classification: Accurate classification to meet diverse needs

The grading technology is to further subdivide the particles after screening, and divide the particles into different grades according to the particle size, shape and other factors to meet the fertilization needs of different crops and different soil types. This process not only requires the equipment to have high-precision classification capabilities, but also needs to be closely matched with organic fertilizer Ring die Granulator, Flat Die Granulator and other granulation equipment to ensure that the produced particles are uniform in size and stable in quality. Through classification, organic fertilizer products can more accurately position the market and enhance competitiveness.

Technical collaboration, quality improvement

It is worth noting that screening and grading technologies do not exist in isolation, they are closely linked to the entire organic fertilizer production process. From the pretreatment of raw materials, mixing and mixing, to granulation, drying and cooling, each link affects the quality of the final product. Therefore, in the production process of organic fertilizer, we should pay attention to the technical coordination of each link, optimize the process flow, and ensure that each link can reach the best state. Only in this way can we truly improve the quality of organic fertilizer products.

Conclusion

Organic fertilizer screening and classification technology as a key step to improve product quality, its importance is self-evident. Through fine screening and grading, we are able to remove impurities, precise classification, to provide the market with higher quality, more diversified organic fertilizer products. In the future, with the continuous progress of technology and the increasing expansion of the market, we have reason to believe that organic fertilizer screening and grading technology will play a more important role in improving product quality and promoting the development of the industry.

#fertilizer machine#Fertilizer granulator#fertilizer granulator price#organic fertilizer production line

0 notes

Link

Choose the appropriate organic fertilizer granulator according to the specific process requirements. There are many types of granulator, such as npk fertilizer granulator, disc granulator machine, drum granulator, etc. The fertilizer granulator machine price varies. The specific use is very different. For strict particle size control, it is recommended to use a double-roll extrusion granulator. For general particle size requirements, it is recommended to use an organic fertilizer drum granulator.

4 notes

·

View notes