#Ferro Alloys Manufacturers

Explore tagged Tumblr posts

Text

Industrial Benefits of Ferro Titanium Cored Wire & Lumps in Metal Processing!

Ferro titanium cored wire and lumps are essential materials in modern metal processing industries. As key offerings from ferro alloys suppliers in India, these additives play a crucial role in refining steel and alloys by enhancing mechanical properties, improving deoxidation, and reducing impurities. As industries strive for superior quality and efficiency, Ferro Titanium products have become indispensable in metallurgy. This article explores the industrial benefits of metal processing and their impact on manufacturing and production quality.

Role of Ferro Titanium Cored Wire in Metal Processing

Ferro Titanium Cored Wire is widely used in steelmaking and foundries to refine and improve the properties of molten metal. The wire is composed of finely controlled Ferro Titanium powder encapsulated in a steel sheath, allowing for precise additions to the molten bath.

Key Benefits:

Deoxidation & Desulfurization: Ferro Titanium Cored Wire effectively removes oxygen and sulfur, reducing unwanted inclusions in steel.

Grain Refinement: It promotes fine grain structure, improving strength, toughness, and ductility in the final product.

Carbide Formation: The addition of Titanium forms stable carbides and nitrides, enhancing wear resistance and hardness.

Precise Alloying: Controlled feeding of cored wire ensures consistent composition, minimizing wastage and improving process efficiency.

Reduction of Slag Formation: The wire enhances steel cleanliness by minimizing non-metallic inclusions, leading to high-quality end products.

Applications of Ferro Titanium Lumps in Metallurgy

Ferro Titanium Lumps are widely used in steelmaking, welding electrode manufacturing, and alloy production. Their role extends beyond alloying, influencing the overall quality and durability of metal components.

Key Industrial Benefits:

Titanium Enrichment: Ferro Titanium Lumps are a rich source of Titanium, contributing to the formation of strong, lightweight, and corrosion-resistant alloys.

Welding Industry Applications: These lumps are used in welding electrodes to enhance arc stability and reduce porosity.

Improved Casting Performance: Ferro Titanium helps prevent gas porosity and shrinkage, ensuring smooth and defect-free castings.

Resistance to High Temperatures: The presence of Titanium improves heat resistance, making the material suitable for high-performance applications.

Cost-Effective Additive: Compared to pure Titanium, Ferro Titanium Lumps offer a cost-effective solution for improving metal properties.

Impact on Steel and Alloy Manufacturing

Both Ferro Titanium Cored Wire and Lumps contribute significantly to the steel and alloy industry, optimizing the refining process and enhancing final product quality. These materials are particularly beneficial in producing high-strength low-alloy (HSLA) steel, stainless steel, and superalloys used in aerospace, automotive, and heavy machinery sectors.

Advantages in Steelmaking:

Enhanced Mechanical Properties: Increases toughness, wear resistance, and impact strength.

Improved Corrosion Resistance: Makes alloys suitable for marine, aerospace, and chemical processing applications.

Environmental Benefits: Reduces the need for excessive raw material consumption and minimizes metal waste.

Conclusion

Ferro titanium cored wire and lumps have become indispensable in modern metal processing, offering numerous industrial benefits. From improving deoxidation and grain refinement to enhancing corrosion resistance and mechanical strength, these materials play a critical role in steelmaking and alloy production. As industries continue to evolve, the demand for high-performance Ferro Titanium products will only grow, reinforcing their importance in metallurgical advancements.

By incorporating Ferro Titanium into metal processing, manufacturers can achieve superior quality, improved efficiency, and long-term cost savings, making it a valuable investment for the future of metallurgy.

#FerroTitaniumCoredWire #FerroTitaniumLumps #FerroAlloysSuppliers #FerroTitanium

#ferro titanium#ferro titanium alloys#ferro alloys suppliers#ferro titanium lumps#ferro titanium suppliers#ferro titanium manufacturer#ferro titanium scrap#ferro titanium producers#ferro titanium powder#ferro titanium cored wire

0 notes

Text

Top Ferro Alloys Manufacturers in India | Leading Companies 2024-2025

Discover the top ferro alloys manufacturers in India for 2024-2025. Learn about the leading companies driving innovation and quality in the ferro alloys industry.

0 notes

Text

Bharat Engineering: Leading the Way as Manufacturers of Ferro Alloys in India

In the industrial world, ferro alloys are crucial components in the production of steel and other alloys, serving as essential materials that enhance the properties of base metals. Bharat Engineering, one of India’s leading manufacturers of ferro alloys, has earned a strong reputation for delivering high-quality products that meet the diverse needs of the steel and metallurgy industries. With a commitment to excellence, innovation, and sustainable practices, Bharat Engineering has become a key player in the ferro alloy manufacturing landscape.

Understanding Ferro Alloys and Their Importance

Ferro alloys are alloys of iron combined with one or more metals, typically silicon, manganese, chromium, and others. These alloys are primarily used in the steelmaking process to enhance the quality and properties of the steel, such as its hardness, strength, and resistance to corrosion. Ferro alloys are also used in the production of stainless steel, special alloys, and other materials that require specific metal characteristics.

In the steel manufacturing industry, ferro alloys play a critical role in improving the mechanical properties of steel. For instance, manganese enhances toughness and hardness, silicon is used for deoxidizing steel, and chromium imparts corrosion resistance. As a result, the demand for high-quality ferro alloys has steadily risen, especially with the growth of India’s steel industry and the increasing focus on producing advanced and specialty steels.

Bharat Engineering: A Trusted Name in Ferro Alloy Production

Bharat Engineering has positioned itself as one of India’s leading manufacturers of ferro alloys, catering to the growing demand from both domestic and international markets. With decades of experience in the ferro alloys sector, the company has established a robust manufacturing process, ensuring the highest quality standards in every batch of ferro alloys produced.

State-of-the-Art Manufacturing Facilities

Bharat Engineering operates advanced manufacturing facilities that are equipped with the latest technology and machinery to produce a wide range of ferro alloys. The company specializes in the production of manganese, silicon, chromium, and other custom ferro alloys, catering to the diverse needs of steel manufacturers across industries.

The company’s state-of-the-art induction furnaces and electric arc furnaces are designed to deliver precise control over the alloying process. This level of control is crucial in producing ferro alloys with consistent quality and precise composition, which is vital for steelmakers who demand high-quality inputs for their products.

Commitment to Quality

As one of the leading manufacturers of ferro alloys in India, Bharat Engineering prioritizes quality at every step of its production process. The company follows stringent quality control procedures to ensure that all ferro alloys meet international standards and specifications. From raw material procurement to final product delivery, Bharat Engineering ensures that every batch undergoes rigorous testing for composition, consistency, and purity.

The company’s dedicated quality assurance team conducts multiple checks throughout the production cycle. This commitment to quality ensures that the ferro alloys produced are highly reliable and perform optimally in various industrial applications, including steel manufacturing, construction, and automotive industries.

Expertise in Ferro Alloy Production

Bharat Engineering's team consists of skilled metallurgists, engineers, and technicians with in-depth knowledge and expertise in ferro alloy production. The company’s extensive experience allows them to produce a wide range of ferro alloys with customized specifications, ensuring that each product meets the specific needs of their clients.

Whether it's for the production of high-carbon ferro manganese for steelmaking, low-carbon ferro chrome for stainless steel production, or silicon alloys for deoxidization, Bharat Engineering can deliver ferro alloys that meet the precise requirements of the end user.

Wide Range of Ferro Alloys Manufactured

Bharat Engineering specializes in the production of various types of ferro alloys that are critical to the steel and metallurgy industries. Some of the key ferro alloys manufactured by the company include:

Ferro Manganese (High and Low Carbon)

Ferro manganese is one of the most commonly used ferro alloys in steelmaking. Bharat Engineering produces both high-carbon and low-carbon ferro manganese, each catering to specific steel grades and applications. High-carbon ferro manganese is used in the production of carbon steel, while low-carbon ferro manganese is used for producing stainless steel and other special alloys.

Ferro Silicon

Ferro silicon is an essential deoxidizing agent in steel production. Bharat Engineering manufactures high-quality ferro silicon that is used to remove oxygen from molten steel and control the carbon content during the steelmaking process. Ferro silicon also contributes to the hardness and strength of the steel, making it a vital component in alloy steels.

Ferro Chrome

Ferro chrome is a key ingredient in the production of stainless steel and other chromium alloys. Bharat Engineering produces both high-carbon and low-carbon ferro chrome, each with distinct properties suitable for different applications. Ferro chrome is used to impart corrosion resistance and improve the hardness of steel.

Ferro Vanadium

Ferro vanadium is used to enhance the strength and toughness of steel. Bharat Engineering produces high-quality ferro vanadium, which is essential for producing high-performance steels used in applications like aerospace, automotive, and heavy machinery.

Technological Innovation

Bharat Engineering is committed to continuous innovation and improving its manufacturing processes. The company invests in cutting-edge technology to enhance production efficiency and product quality. This commitment to innovation allows Bharat Engineering to produce ferro alloys that meet the ever-evolving needs of the global market.

Conclusion

Bharat Engineering has emerged as one of India’s premier manufacturers of ferro alloys, offering a wide range of products that meet the rigorous demands of the steel and metallurgy industries. Through its state-of-the-art manufacturing facilities, commitment to quality, and dedication to innovation, Bharat Engineering continues to play a vital role in supplying high-quality ferro alloys to clients across the globe.

For businesses seeking reliable and cost-effective ferro alloys, Bharat Engineering offers the expertise, technology, and resources to deliver superior products that meet the highest industry standards. Whether it’s manganese alloys, chromium alloys, or silicon alloys, Bharat Engineering stands as a trusted name in the Indian ferro alloys manufacturing sector, committed to driving success for its customers and contributing to the growth of the global steel industry.

0 notes

Text

Ferro Alloy Powder | Ferro Alloy Powder Supplier in India

Jayesh Group is a leading ferro alloy powder manufacturer in India, offering a wide range of products including ferro silicon, ferro manganese, and ferro chrome. With a state-of-the-art facility and experienced professionals, they deliver high-quality products for diverse industries. Their commitment to innovation, quality, and customer satisfaction makes them a trusted global supplier. Visit their website to learn more.

1 note

·

View note

Text

Driving Efficiency: Ferro Silicon Market Soars with Deoxidizer and Inoculants Applications

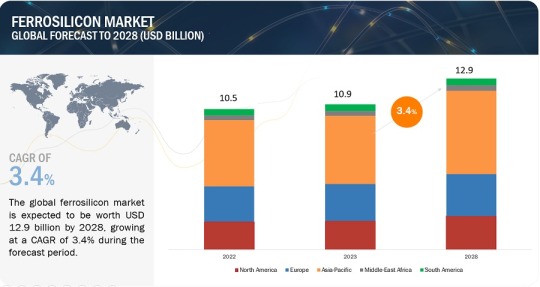

The report “Ferro Silicon Market by Type (Atomized Ferrosilicon, Milled ferrosilicon), Application (Deoxidizer, Inoculants), End-use Industry (Stainless Steel, Cast Iron, Magnesium), and Region (Asia Pacific, Europe, North America, MEA, SA) – Global Forecast to 2028″, is projected to reach USD 12.9 billion by 2028, at a CAGR of 3.4% from USD 10.9 billion in 2023. The ferrosilicon market is…

View On WordPress

#Atomized Ferrosilicon#Deoxidizer#Ferro Silicon#Ferro Silicon Alloy Market#Ferro Silicon Analysis#Ferro Silicon Consumption#Ferro Silicon Demand#Ferro Silicon Export Market#Ferro Silicon Growth#Ferro Silicon Industry#Ferro Silicon Manufacturer#Ferro Silicon Market#Ferro Silicon Market Dynamics#Ferro Silicon Market Forecast#Ferro Silicon Market Graph#Ferro Silicon Market Outlook#Ferro Silicon Market Research#Ferro Silicon Market Segmentations#Ferro Silicon Market Segments#Ferro Silicon Powder Market#Ferro Silicon Pricing#Ferro Silicon Production#Ferro Silicon Regional Growth#Ferro Silicon Supply#Ferro Silicon Trends#Global Ferro Silicon Market#Inoculants#Milled Ferrosilicon

0 notes

Text

Sarda Metals: Forging Excellence in the Indian Metal Industry

In the vast landscape of the Indian metal manufacturing industry, Sarda Metals stands as a stalwart, shaping the future of metal production with a blend of innovation, quality, and sustainability.

Introduction

India's prowess in metal manufacturing has been on a steady rise, and companies like Sarda Metals have played a pivotal role in this growth story. Established with a vision to redefine the standards of excellence in metal production, Sarda Metals has emerged as a distinguished player in the industry. The company's commitment to quality and innovation has solidified its position as a leading metal manufacturer in India. With a focus on technological advancements and sustainability, Sarda Metals continues to shape the landscape of the Indian metal manufacturing sector.

Sarda Metals: A Pioneer Metal Manufacturer In India

Company Background and History

Sarda Metals, with its roots deeply embedded in the Indian industrial landscape, boasts a rich history of contributing to the nation's economic growth. The company's journey is a testament to its resilience, adaptability, and commitment to excellence.

Core Values and Mission Statement

At the core of Sarda Metals' success are its unwavering values and a mission to be at the forefront of technological advancements in metal manufacturing. The company's commitment to integrity, customer satisfaction, and ethical practices sets it apart in a competitive market.

Product Portfolio

Sarda Metals takes pride in its diverse product portfolio, offering a comprehensive range of metal products catering to various industries. Specializing in the production of iron and steel products, the company ensures that each product meets the highest standards of quality and reliability.

Quality Assurance and Standards

The cornerstone of Sarda Metals' success lies in its uncompromising commitment to quality. The company adheres to stringent national and international standards, implementing robust quality assurance processes at every stage of production.

State-of-the-Art Manufacturing Facilities

Central to Sarda Metals' ability to deliver top-notch products is its state-of-the-art manufacturing facilities. Equipped with cutting-edge technology and driven by a passion for innovation, these facilities enable the company to stay ahead in a dynamic market.

Sustainability Initiatives

In an era where environmental consciousness is paramount, Sarda Metals, as a leading metal manufacturer in India, takes proactive steps to minimize its ecological footprint. The company is dedicated to integrating sustainable practices into its manufacturing processes, ensuring a harmonious balance between industrial growth and environmental preservation. By prioritizing sustainability, Sarda Metals not only contributes to the well-being of the planet but also sets a noteworthy example for the broader Indian metal manufacturing industry.

Market Presence and Global Reach

Conclusion

In conclusion, Sarda Metals stands as a beacon of excellence in the Indian metal manufacturing industry. With a robust product portfolio, a commitment to quality, and a forward-looking approach, the company has not only weathered industry challenges but has also set new benchmarks for others to follow.

Frequently Asked Questions (FAQs)

Q: What makes Sarda Metals a leader in the metal manufacturing industry?

A: Sarda Metals' leadership stems from its unwavering commitment to quality, innovation, and sustainability.

Q: How does the company contribute to environmental sustainability?

A: Sarda Metals incorporates eco-friendly practices in its manufacturing processes to minimize its environmental impact.

Q: Can customers request customized metal products from Sarda Metals?

A: Yes, Sarda Metals prioritizes customer satisfaction and offers customization options for clients.

Q: What recognition has Sarda Metals received in the industry?

A: The company has received several awards for its contributions to the metal manufacturing sector.

Q: What are Sarda Metals' future plans and expansion strategies?

A: Sarda Metals has ambitious plans for the future, including expansion and diversification initiatives.

🏠 Address: 50-96-4/1, 2nd & 3rd Floor, Sri Gowri Nilayam, Seethammadhara NE, Visakhapatnam, Andhra Pradesh, 530013 - India.

📞 Phone: 9493549632

📧 Email: [email protected]

#ferro alloys producer in india#silico manganese#metals manufacturer in india#sarda metals and alloys ltd#ferro alloys suppliers in india#metal suppliers in india#sardametals#sarda#ferro manganese

1 note

·

View note

Text

Sustainable Steel Production and Eco-Friendly Innovations

The steel industry is evolving rapidly with a strong emphasis on sustainability and eco-friendly innovations. With increasing environmental concerns, manufacturers are adopting cleaner technologies to reduce carbon emissions and enhance efficiency. In Karnataka, several advancements are being made at iron and steel plants in Karnataka, setting new standards for green steel production.

Eco-Friendly Manufacturing Practices

A key strategy in sustainable steel production is optimizing the use of raw materials. Companies are transitioning to energy-efficient methods that reduce reliance on traditional coal-based fuels. One such approach is the use of coke metal in blast furnaces, which helps in minimizing waste and maximizing energy utilization. Additionally, the recycling of ingots and billets has become a standard practice, promoting resource efficiency and reducing the carbon footprint of steel manufacturing.

Advancements in Steel Alloys

Innovations in steel compositions are paving the way for more durable and environmentally friendly products. What is MS steel? Mild steel (MS) is a widely used material known for its versatility and recyclability, making it a sustainable option in construction and manufacturing. Furthermore, the development of cold twisted bars (CTD bars) has improved structural integrity while reducing material waste, making them ideal for eco-conscious construction projects.

Innovations in Alloying Elements

The incorporation of advanced alloying elements is further enhancing the sustainability of steel production. The use of ferro silicon and ferro silicon magnesium in the refining process improves steel quality while reducing impurities. These additives help in producing high-strength, low-weight materials that contribute to sustainable construction and manufacturing. Additionally, monitoring the ferro silicon price ensures cost-effective and efficient production strategies.

Sustainable Production of Billets and Ingots

The production of billet ingot is undergoing a transformation with improved energy-efficient casting methods. By implementing electric arc furnaces and hybrid energy solutions, manufacturers are significantly cutting down emissions while maintaining high-quality output. Moreover, sustainable cooling techniques and waste heat recovery systems are being integrated into production processes to further enhance energy conservation.

CONCLUSION:

The push for sustainability in steel production is stronger than ever, with innovative practices and eco-friendly technologies reshaping the industry. From advancements in CTD bars to the optimized use of ferro silicon magnesium, the steel sector is moving towards a greener future. As more iron and steel plants in Karnataka embrace these sustainable measures, the industry is set to become a key player in eco-friendly manufacturing and responsible resource utilization.

0 notes

Text

Key Points for Optimizing the Production Process of Inoculants | Barium & Calcium inoculant!

In the metallurgical industry, barium inoculant and calcium inoculant play a crucial role in refining grain structures, enhancing mechanical properties, and improving cast iron quality. Optimizing the production process of these inoculants is essential to ensure consistency, efficiency, and cost-effectiveness. This article explores key strategies to enhance the manufacturing process of these vital foundry materials, including the role of ferro silicon magnesium in improving overall performance.

1. Selection of High-Quality Raw Materials

The quality of inoculants begins with the selection of superior raw materials. Ferroalloys such as ferrosilicon, calcium, and barium-based compounds are commonly used. Ensuring high purity minimizes impurities and enhances the inoculation effect.

Key Considerations:

Use of high-grade ferroalloys to maintain consistency.

Reduction of oxide inclusions through refined material selection.

Stringent quality checks to eliminate contaminants.

2. Optimized Alloying and Melting Techniques

The melting process significantly impacts the final quality of inoculants. Proper temperature control, furnace selection, and optimized alloying techniques contribute to enhanced performance and reduced production losses.

Optimization Methods:

Maintaining an optimal melting temperature range to prevent oxidation.

Using induction furnaces for precise temperature control.

Controlled alloying to achieve uniform chemical composition.

3. Precision in Composition Control

Ensuring a consistent chemical composition is crucial for effective inoculation. Implementing real-time chemical analysis and spectrometry testing helps maintain the ideal ratio of elements such as silicon, calcium, and barium.

Effective Control Measures:

Regular spectral analysis to verify elemental composition.

Fine-tuning of alloy proportions based on customer specifications.

Implementation of automated dosing systems to minimize human error.

4. Advanced Refining and Deoxidation Techniques

Unwanted oxides and non-metallic inclusions can degrade the effectiveness of barium and calcium inoculants. Utilizing refining agents and optimizing deoxidation techniques improve the purity of the final product.

Refinement Strategies:

Application of vacuum degassing to eliminate unwanted gases.

Addition of active deoxidizers to enhance metal purity.

Filtration techniques to remove non-metallic inclusions.

5. Efficient Casting and Solidification Process

Once the molten metal is prepared, the casting and solidification process must be carefully controlled to avoid segregation of elements and to maintain uniform microstructure.

Key Optimization Factors:

Using precise mold temperatures to control solidification rates.

Proper inoculant size distribution for enhanced dissolution in molten iron.

Implementing automated pouring systems for consistency.

6. Rigorous Quality Control & Testing

A robust quality control system is essential for ensuring that inoculants meet industry standards. Testing methods should include both laboratory analysis and real-world performance testing in foundry applications.

Essential Quality Checks:

Chemical composition verification through spectrometry.

Particle size analysis for consistent dispersion in molten iron.

Performance trials in controlled foundry conditions to test effectiveness.

7. Sustainable and Cost-Effective Production Methods

With growing environmental regulations, optimizing the production process must also focus on sustainability and cost reduction without compromising quality.

Sustainable Practices:

Waste minimization through optimized raw material usage.

Energy-efficient furnace operations to lower carbon footprint.

Recycling and reuse of byproducts to reduce material costs.

Conclusion

Optimizing the production process of barium and calcium inoculant involves careful control over raw materials, alloying, refining, and quality assurance. By implementing advanced manufacturing techniques and rigorous testing, foundries can achieve superior product consistency and enhanced casting performance. Ensuring efficiency in these processes not only improves quality but also leads to cost savings and sustainability in metallurgical applications.

By adopting these key strategies, manufacturers can enhance their inoculant production process, ensuring better results in casting applications and reinforcing their position as industry leaders.

#Inoculant #BariumInoculant #CalciumInoculant #FerroSiliconMagnesium #FeSiMgAlloys

#inoculants#bb inoculant#fesimg#ferro silicon magnesium cored wire#ferro silicon magnesium in india#ferro silicon magnesium#barium inoculant#nodularisers#calcium inoculants

0 notes

Text

High Nickel Alloys – Leading Supplier & Dealer in India | Vardhman Ferro Alloys

Vardhman Ferro Alloys is a trusted supplier and dealer of High Nickel Alloys and nickel alloys scrap in India. We offer premium-quality High Nickel Alloy Metal Scrap for industrial and manufacturing needs. Explore our reliable solutions and competitive pricing. Contact us today for your nickel alloy requirements!

#High Nickel Alloys#Nickel Alloys Scrap#High Nickel Alloy Metal Scrap Dealer in India#Nickel Alloy Supplier#Industrial Nickel Alloys.

0 notes

Text

Magazine Subscription — Minerals and Metals Industry

India stands among Earth’s major mineral and metallic suppliers as it engages multiple industrial sectors. The nation has substantial natural deposits containing iron ore, bauxite, chromium, manganese ore, barite, rare earth and mineral salts. Numerous people show strong interest in learning about the forthcoming developments of the minerals and metals industries within India because of its optimistic possibilities. Steel insights subscriptions provide up-to-date information to all its readers through best practices.

1. Forgings Today Magazine

Forgings Today Magazine — The publication exists as one of the most prominent resources within the forging industry that investigates active market developments as well as forging technological progress. Professionals in manufacturing and engineering fields obtain materials research together with process analysis and machine insights while receiving market data from this publication. Follow the newsletter to access updates on market trends of the forging industry and new technological advances together with expert analysis and industrial news.

2. India Steel Market Watch Daily Report

India Steel Market Watch Daily Report — The latest news about India’s steel industry including market patterns and price fluctuations and manufacturing statistics together with governmental alterations is delivered through this report. The essential daily report provides industry professionals with detailed analysis, market insights and forecast predictions in addition to trade information. The accurate time-sensitive precise focused coverage for steel manufacturers and traders and industry analysts allows you to achieve market leadership in the competitive steel industry. Subscribe now!

3. Steel Market Watch

India Steel Market Watch — Weekly Basic Raw Material Report — A valuable source examining the Indian steel industry demonstrates price evolution with supply-demand assessment and materials market changes between iron ore coal and scrap. You should regularly obtain expert forecasts as well as policy updates and global sector influences that shape the industry. The subscription service delivers complete data-driven market reports which support confident business decisions within the flexible steel industry.

4. India Steel Market Watch: Weekly Ferro Alloys Report

India Steel Market Watch: Weekly Ferro Alloys Report — This service conducts an extensive evaluation which includes tracking ferro alloys market patterns together with pricing changes and supply and demand fluctuations while providing sector-related updates. Current information about manganese, silicon, and chromium alloys allows professionals to follow their effects on the steel industry. This subscription provides perfect market intelligence to both traders and manufacturers and industry professionals who want to maintain their leadership position.

5. India Steel Market Watch — Weekly Scrap & Steel Metallic Report

India Steel Market Watch — Weekly Scrap & Steel Metallic Report — The report delivers comprehensive research about the Indian scrap and steel metallic business sector. The reported data is provided on a weekly basis to track price changes and market developments together with supply-demand data along with information about the industry. The platform serves essential data to traders and manufacturers as well as stakeholders who need to monitor the ongoing developments in the steel market. You can subscribe to receive professional insights for remaining ahead of your competition in the steel sector.

6. India Steel Market Watch: Weekly Steel Flat Product Report

India Steel Market Watch: Weekly Steel Flat Product Report -The report delivers comprehensive study about price movements together with market requirement and industrial developments within India’s steel market. The report delivers crucial market data about hot-rolled steel products along with cold-rolled steel products and coated steel products to businesses each week. This data tool serves as an excellent resource for manufacturers and traders along with analysts because it enables strategic decision-making through current market intelligence. Subscribe now for expert insights!

7. India Steel Market Watch — Weekly Steel Long Product Report

India Steel Market Watch — Weekly Steel Long Product Report -The publication delivers real-time information about India’s steel industry that specifically explores long products. A subscription-based publication tracks steel price trends with information about market analysis together with supply-demand dynamics and policy changes. The platform serves business needs specifically targeting trading entities alongside manufacturing companies and industries by delivering analytical research with market assessments that support efficient steel market navigation. The magazine allows you to access current information about industry trends.

8. Iron & Steel Magazine Review

Iron & Steel Magazine Review — All industry professionals along with engineers who work in the metal sector should read this publication. The magazine delivers comprehensive expert details about current advancements together with market trends and technological innovations. Your access to unique interviews and industry reports alongside worldwide industry updates will stay informed when you are subscribed. Become a subscriber to receive the latest authoritative analysis on manufacturing and trading iron and steel as well as production industry news.

9. Metal Asia Magazine

Metal Asia Magazine — As a prominent media organization the magazine specializes in worldwide coverage about steel industries together with aluminum and non-ferrous metals. The publication presents extensive market statistics together with industry data about technological innovations and sector evaluations. The magazine provides vital market-related content concerning innovations and policies to business professionals alongside manufacturing and trading representatives. Customers who subscribe to the publication receive the latest news updates from the metal industry field.

10. Metal World Magazine

Metal World Magazine — The magazine showcases thorough market reports about mineral and metal pricing together with supply-vs.-demand assessments as well as external conditions analysis. The market analysis presented in the publication helps readers develop wise judgments for remaining ahead of market competitors. Modern industry technology developments receive coverage in Metal World Magazine. The publication delivers breaking information about industrial technology that includes advancements in metalwork processes and automation and artificial intelligence integration.

Conclusion

By subscribing to a Minerals and Metals Industry magazine, you can gain valuable insights into the mining, minerals, and metals sector. Stay updated with industry news, market trends, technological advancements, and project updates. Choose the best Minerals and Metals Industry magazine subscription that suits your preferences and requirements. Enhance your knowledge, stay informed, and make informed decisions in the dynamic world of minerals and metals. The minerals and metals review magazine needs to be referred for the best of information updates at all times.

0 notes

Text

Ferro Titanium Manufacturers & Suppliers in India | Top Producers of Quality Alloys

As leading ferro titanium suppliers and manufacturers in India, we specialize in producing high-quality ferro titanium alloys used in a variety of industrial applications. Our products are known for their superior strength, corrosion resistance, and excellent performance in the production of steel, titanium alloys, and other metallurgical processes.

We are committed to providing the finest ferro titanium with precise composition and tailored solutions to meet the specific requirements of our clients. Whether you are in the aerospace, automotive, or steel industries, our ferro titanium products enhance the quality and durability of your final products.

Partner with us for reliable supply and high-performance ferro titanium alloys, ensuring efficiency and reliability in all your manufacturing processes.

Visit: https://www.ferrotitanium.in/

#ferro alloys suppliers#ferro titanium#ferro titanium manufacturer#ferro titanium alloys#ferro titanium producers#ferro titanium suppliers#ferro titanium lumps#ferro titanium powder#ferro titanium cored wire#ferro titanium scrap

0 notes

Text

https://www.articleted.com/article/855105/292639/Ferro-Alloys-Manufacturers-in-India--Pioneering-Industrial-Growth

Top Ferro Alloys Manufacturers in India | Pioneering Industrial Growth

Explore leading ferro alloys manufacturers in India driving industrial innovation and growth. Learn about high-quality alloys like ferro manganese, ferro silicon, and more, essential for steelmaking and other critical industries.

0 notes

Text

Bharat Engineering: Pioneers in Ferro Alloys Manufacturing in India

In the world of metallurgy, ferro alloys play a critical role in the production of high-quality steel and other metal products. Bharat Engineering, a leading name among manufacturers of ferro alloys in India, has established itself as a trusted partner for industries relying on superior alloy materials. With a legacy of quality, precision, and innovation, Bharat Engineering continues to push the boundaries in the production of ferro alloys, catering to both domestic and international markets.

What Are Ferro Alloys?

Ferro alloys are essential components in the steelmaking process. These alloys consist of iron mixed with other elements like silicon, manganese, and chromium. By enhancing the properties of steel—such as its hardness, strength, and resistance to wear—ferro alloys are indispensable for industries ranging from construction to automotive, aerospace, and beyond.

Bharat Engineering's Expertise in Ferro Alloy Manufacturing

Bharat Engineering specializes in the production of a variety of ferro alloys, each tailored to meet the specific needs of its clients. The company produces key ferro alloys such as:

Ferro Silicon: Known for its ability to deoxidize steel and prevent oxidation, ferro silicon is a crucial element in steel production, making the end product more durable and resistant.

Ferro Manganese: Widely used to add toughness and hardness to steel, ferro manganese also plays a vital role in desulfurizing and deoxidizing the steelmaking process.

Ferro Chrome: Essential for producing stainless steel, ferro chrome enhances corrosion resistance and gives steel its shiny appearance.

Each of these alloys is manufactured with precision to meet stringent quality standards and ensure consistent performance.

Commitment to Quality

At Bharat Engineering, quality control is not just a process but a philosophy. The company’s ferro alloy manufacturing facilities are equipped with cutting-edge technologies, allowing for precise control over the chemical composition of alloys. Stringent testing protocols are applied at every stage—from raw material sourcing to final product delivery—ensuring that the alloys meet global standards for strength, purity, and consistency.

Technological Innovation

Bharat Engineering stays ahead of the curve by continuously investing in the latest metallurgical technologies. The company’s R&D team is dedicated to exploring new methods of alloy production that reduce energy consumption, minimize waste, and enhance the environmental sustainability of its operations. By embracing technological advancements, Bharat Engineering is able to deliver ferro alloys that not only meet today’s requirements but also anticipate future market needs.

Sustainability and Environmental Responsibility

In an industry that traditionally consumes a significant amount of energy, Bharat Engineering is committed to minimizing its environmental footprint. By adopting eco-friendly production methods and optimizing energy usage, the company strives to make its ferro alloy manufacturing processes as sustainable as possible. This includes utilizing renewable energy sources, implementing efficient waste management systems, and reducing emissions through cleaner technologies.

Customer-Focused Approach

Bharat Engineering prides itself on its customer-centric approach, which prioritizes the needs of its clients across diverse industries. Whether working with large-scale steel producers or niche manufacturers, Bharat Engineering offers tailored ferro alloy solutions that align with the specific requirements of each project. This flexibility in production, combined with a commitment to timely delivery, has made Bharat Engineering a preferred partner for companies both in India and abroad.

Future Prospects

As global demand for high-quality steel continues to grow, the need for superior ferro alloys becomes more critical than ever. Bharat Engineering is well-positioned to meet this rising demand, both in India and on the global stage. With ongoing investments in technology, sustainability, and talent, the company is prepared to lead the ferro alloy industry into the future, providing the essential materials that drive modern manufacturing and infrastructure development.

Conclusion

Bharat Engineering stands out as one of the premier manufacturers of ferro alloys in India, offering a range of high-quality alloys that enhance the performance of steel and other metal products. With a focus on quality, innovation, and customer satisfaction, Bharat Engineering continues to be a driving force in the metallurgical industry. Whether for large-scale industrial applications or specialized requirements, Bharat Engineering remains the go-to partner for ferro alloy solutions that deliver performance, reliability, and sustainability.

0 notes

Text

Ferro Vanadium Market Overview Impacting Factors and Forecast of Growth Dynamics and Potential

The ferro vanadium market plays a crucial role in the global steel industry, where the alloy is used to enhance the strength, toughness, and wear resistance of steel. Ferro vanadium is a vital ingredient in the production of high-strength low-alloy (HSLA) steel, which is used in a wide range of applications, from automotive and construction to energy and manufacturing. As industrial demands continue to rise globally, the ferro vanadium market is experiencing significant growth, influenced by a range of factors including technological innovations, economic trends, and increasing demand for specialized materials.

Market Overview

Ferro vanadium is primarily produced by reducing vanadium pentoxide (V2O5) with iron in a furnace. The resulting product is used in small quantities to enhance the performance of steel, making it more resistant to wear and improving its toughness. The steel industry is the largest consumer of ferro vanadium, accounting for the bulk of its demand. With ongoing developments in infrastructure, automotive manufacturing, and the shift toward green technologies, the ferro vanadium market is positioned for long-term growth.

Impacting Factors

Rising Steel Demand The growing global demand for steel, driven by infrastructure projects, automotive production, and the expansion of manufacturing industries, is a key driver of the ferro vanadium market. Steel's essential role in the construction and transportation sectors ensures that the need for high-performance, durable materials like HSLA steel remains strong. Ferro vanadium is crucial in meeting these needs by improving steel's mechanical properties.

Technological Advancements in Steel Production The development of advanced steelmaking technologies, such as electric arc furnaces (EAF) and integrated steel plants, is another factor propelling the ferro vanadium market. These innovations improve the efficiency of alloying processes, allowing for better use of ferro vanadium in producing high-quality steels. The shift toward automation and more precise control over steel composition further enhances the role of ferro vanadium in modern steel production.

Growth of Green Technologies Emerging green technologies, particularly in the renewable energy and electric vehicle (EV) sectors, present new opportunities for ferro vanadium. Vanadium-based energy storage systems, such as vanadium redox flow batteries (VRFBs), are gaining traction for large-scale energy storage, particularly in renewable energy grids. As the world transitions toward more sustainable energy sources, the demand for vanadium, and by extension ferro vanadium, is expected to grow. Ferro vanadium also plays a role in creating lighter, stronger materials for EVs, further fueling market demand.

Geopolitical Factors and Supply Chain Stability The global supply chain for ferro vanadium is impacted by geopolitical factors such as trade policies, mining regulations, and resource availability. Vanadium is primarily sourced from countries such as China, Russia, and South Africa, and disruptions in these regions can affect market prices and supply stability. As such, the market is vulnerable to price fluctuations, which can influence production volumes and cost structures across various industries.

Forecast of Growth Dynamics and Potential

The ferro vanadium market is forecast to experience steady growth over the next decade, driven by the ongoing demand for high-performance steel and the rise of new applications in energy storage and electric vehicles. Industry experts predict that the global market for ferro vanadium could grow at a compound annual growth rate (CAGR) of 5-7% through 2030, supported by the increasing demand for HSLA steel in emerging markets and the expanding adoption of vanadium-based battery technologies.

The Asia-Pacific region is expected to be a significant contributor to this growth, owing to the rapid industrialization and infrastructure development in countries like China and India. Additionally, the European Union and North America are also likely to see increased demand for ferro vanadium as their steel industries adopt more sustainable practices and green technologies.

Conclusion

The ferro vanadium market is witnessing a positive growth trajectory, driven by strong demand from the steel industry, technological advancements, and new opportunities in renewable energy and electric vehicles. However, challenges related to supply chain volatility and geopolitical risks remain potential hurdles. As the world continues to embrace green technologies and advanced materials, ferro vanadium will remain a critical component in shaping the future of steel production and industrial applications.

Request Sample PDF Report : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NjIz&RD=Ferro-Vanadium-Market-Report

#FerroVanadiumMarket#FerroVanadiumMarketTrends#FerroVanadiumMarketInsights#FerroVanadiumMarketGrowth#FerroVanadiumMarketForecast#FerroVanadiumMarketOpportunities

0 notes

Text

Exploring the Legacy of Sarda Metals: India's Premier Metal Manufacturer in India

Introduction

In the heart of India's industrial landscape, Sarda Metals and Alloys Ltd. (SMAL) stands as a beacon of sustainability and innovation. As a leading metal manufacturer in India, their commitment to becoming the largest and most preferred manganese alloy producer is coupled with a dedication to minimizing their carbon footprint. This article delves into Sarda's ethos, their core values, and their relentless pursuit of a sustainable future.

Core Values: Quality, Technology, and Sustainability

At the nucleus of Sarda's strategy lies an unwavering commitment to quality, technology, and sustainability. Since its inception, Sarda has aimed to build a Ferro manganese business that not only meets global standards but surpasses them. This commitment extends beyond production, seeping into their practices in Environment, health, and safety. Sarda is resolute in its pursuit of being a company with the least carbon footprint and a record of zero incidents and accidents.

Innovative Solutions

With a rich history spanning decades, Sarda Metals has left an indelible mark on India's metallurgical industry. Their innovative solutions have positioned them as a trusted Ferro Alloys producer. Sarda's ability to adapt and evolve with changing times has allowed them to maintain a robust reputation in the market.

Specialization in Manganese Ferro Alloys

Sarda Metals takes pride in being India's leader in manganese ferro alloys. Their specialization lies in the production of high-quality Silico Manganese, tailored to diverse industrial needs. The company operates with a passion for excellence and a commitment to synergizing energy.

Sustainability Goals

Striving for sustainability through technology and innovation is the driving force behind all Sarda's endeavors. The ambition to become the largest and most preferred manganese alloy producer in India is coupled with a conscious effort to reduce their carbon footprint continually. Sarda Metals embraces change, challenging the status quo daily in their quest to become a better version of themselves.

Community Impact

Sarda Metals understands the importance of community development. Actively involved in creating a positive impact on the socio-economic fabric, they extend their commitment to sustainability to the communities around them. With a vision for a carbon-neutral footprint, Sarda Metals is not just a business; it's a force for positive change.

Conclusion

In conclusion, Sarda Metals and Alloys Ltd. exemplify how a company can marry industrial success with environmental responsibility. As a leading metal manufacturer in India, their journey towards sustainability is not just a corporate goal but a commitment to future generations. Sarda's emphasis on quality, technology, and sustainability positions them as leaders in the industry, setting a benchmark for others to follow.

FAQs

What makes Sarda Metals and Alloys Ltd. a leading metal manufacturer in India?

Sarda's commitment to quality, technology, and sustainability makes them a leader in the metallurgical industry in India.

How does Sarda Metals contribute to community development?

Actively involved in community initiatives, Sarda Metals strives to create a positive impact on the socio-economic fabric.

What is Sarda Metals' primary focus in its sustainability goals?

Sarda aims to become the largest and most preferred manganese alloy producer in India with the least carbon footprint.

#metals manufacturer in india#silico manganese#ferro alloys producer in india#sardametals#ferro alloys suppliers in india#metal suppliers in india#ferro manganese#sarda metals and alloys ltd

1 note

·

View note

Text

Leading Manufacturer of Ferro Silicon Magnesium & Cored Wire Injection Solutions

We are a trusted manufacturer delivering high-quality ferro silicon magnesium, essential for enhancing the properties of ductile iron in foundries and steel production. Used primarily for modularization and desulfurization, it improves strength, ductility, and overall metallurgical performance.

To ensure efficient alloying, we offer advanced cored wire injection technology, which enables precise control over element addition, enhances reaction efficiency, and reduces material wastage. This method ensures uniform distribution of additives in molten metal, optimizing the production process for better consistency and cost-effectiveness.

With a commitment to quality and innovation, we provide tailored solutions to meet the evolving demands of the steel and foundry industries, ensuring high performance and reliability in every application.

#ferro silicon magnesium#cored wire injection#barium inoculants#calcium inouclant#magnesium cored wire#cored wire injection system#inoculants#high recovery for ferro silicon magnesium

0 notes