#Fasteners for Oil & Gas

Text

WCB GATE VALVEwith matching flanges, fasteners and gasketsHigh quality for industry, natural gas, water, oil

#WCB GATE VALVEwith matching flanges#fasteners and gasketsHigh quality for industry#natural gas#water#oil#gatevalve#imdustrialvalve#naturalgasvalve#steelgatevalve#wcbgatevalve

0 notes

Text

Fasteners for Oil & Gas | Roll Fast

Roll-Fast is a Fasteners Manufacturer bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4" to 4". We have 25 years of World Class Manufacturing experience in nuts and bolts we manufactures and exports ss fasteners manufacturers, automotive fastener, Industrial Fasteners and Fasteners for Oil & Gas from our plant in India.

0 notes

Text

Gibson - Reverb Echo - GA-4RE '66

"Adineko oil can delay system by Ray Lubow inside. It's a kind of magic when you look on this system detailed and understanding it could delaying the sound.

Three RCA tubes on board -- 12AU7 and 2x 6EU7."

Have a look at that snap fastener for the footswitch!

cred: facebook.com/Al Soulman

35 notes

·

View notes

Text

Horizontal Directional Drilling Market Demand, Trends, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the Global Horizontal Directional Drilling Marketsize at USD 9.46 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects Global Horizontal Directional Drilling Marketsize to grow at a significant CAGR of 5.7% reaching a value of USD 13.21 billion by 2029. Major growth drivers for the Global Horizontal Directional Drilling Marketinclude the increasing adoption of HDD technology for precise and minimally invasive drilling operations. This technique facilitates the drilling and reverse reaming of pipes with precision, navigating through obstacles in the underground terrain while minimizing harm to ecosystems. Market expansion is further fueled by increasing investments in shale gas projects and the ongoing development of high-speed connectivity in the telecom industry. Notably, The global surge in oil and gas activities has spurred an increase in horizontal directional drilling (HDD) worldwide. Recognizing the environmental impact of conventional drilling methods, there is a growing emphasis on employing eco-friendly drilling technology, leading to the expansion of the Global Horizontal Directional Drilling Market. The horizontal directional drilling approach stands out for its precision and reduced power consumption compared to vertical maneuvering techniques. Another significant driving force is the rapid globalization and urbanization, fueled by the escalating energy and fuel demand in developing nations. This surge in demand is closely tied to ongoing infrastructure development, utility system construction, and advancements in the telecommunications sector, including 5G testing. These factors, along with related developments, are anticipated to contribute significantly to the market's swift growth during the forecast period. The increasing utilization of horizontal directional drilling products in surveying, designing, and installing subsurface electrical systems for subterranean cables further propels the expansion of the market. Also, the rising demand for natural gas and electricity distribution in middle and upper pipeline lines is expected to drive market growth. The use of horizontal directional drilling fasteners in utility, communications, and oil and gas industries offers benefits such as increased stability, enhanced device management, and improved treatment and monitoring outcomes. However, high costs and technical challenges are anticipated to restrain the overall market growth during the forecast period.

Impact of Escalating Geopolitical Tensions on Global Horizontal Directional Drilling Market

The Global Horizontal Directional Drilling Market has been significantly impacted by intensifying geopolitical disruptions in recent times. For instance, the ongoing Russia-Ukraine conflict has disrupted supply chains decreased service demand, and increased uncertainty for businesses. This turmoil extended to energy markets, causing turbulence due to Russia's significant role as a major gas supplier, resulting in noticeable price fluctuations. In addition, the sanctions imposed on Russia by the United States and other have had widespread implications, injecting a level of risk for investors across various sectors. Beyond the war zones and disputed areas, the ongoing crisis jeopardizes stability on a global scale. It becomes imperative for businesses and investors alike to comprehend and adeptly manage these interconnected challenges.

Despite the current challenges posed by geopolitical tensions, there are potential growth opportunities for the Global Horizontal Directional Drilling Market. The ongoing infrastructure projects, utility installations, and the continuous expansion of the telecommunications industry. This demand underscores the market's resilience. Emphasizing strategic adaptation is crucial in navigating these complex circumstances, ensuring sustained success amid global challenges and uncertainties.

Sample Request @ https://www.blueweaveconsulting.com/report/biodegradable-sanitary-napkins-market/report-sample

Global Horizontal Directional Drilling Market – By End User

On the basis of end user, the Global Horizontal Directional Drilling Market is divided into Oil & Gas Excavation, Utilities, and Telecommunication segments. The oil & gas excavation segment holds the highest share in the Global Horizontal Directional Drilling Market by end user. The existing and robust infrastructure generates a significant demand for drilling rigs, contributing to the predominant market position of the oil and gas excavation segment. Also, efforts to manage the increasing expenses linked to exploration and production endeavors in untapped regions are anticipated to strengthen the prominence of this segment. Meanwhile, the telecommunications segment holds the highest share in the Global Horizontal Directional Drilling Market. The increasing need for faster broadband access propels telecommunications operators to adopt advanced and reliable drilling services, including horizontal directional drilling. This method facilitates the expansion of optic fiber cable networks by deploying conduits and pipes through holes nearly 4 feet in diameter and 6,500 feet in length, particularly in offshore locations. The growing demand for 4G and 5G networks is expected to contribute significantly to the segment's growth throughout the forecast period.

Global Horizontal Directional Drilling Market – By Region

The in-depth research report on the Global Horizontal Directional Drilling Market covers various country-specific markets across five major regions: North America, Europe, Asia Pacific, Latin America, and Middle East and Africa. North America holds the highest share in the Global Horizontal Directional Drilling Market. According to the U.S. Energy Information Administration, liquid fuel consumption in 2022 was reported at 8.8 billion barrels per day. The growing prevalence of infrastructure and utility projects in North America is a key driver for the increased demand in horizontal directional drilling equipment and services. The Middle East and Africa (MEA) region emerged as the second-largest user of drilling services for oil and gas excavation activities.

Competitive Landscape

Major players operating in the Global Horizontal Directional Drilling Market include Baker Hughes Company, Barbco Inc., China Oilfield Services Limited, Ellingson Companies, Halliburton Company, Helmerich & Payne Inc., Herrenknecht AG, Nabors Industries Ltd, NOV Inc., Schlumberger Limited, The Toro Company, Vermeer Corporation, Weatherford International plc, Drillto Trenchless Co. Ltd, Laney Directional Drilling, Prime Drilling GmbH, XCMG Group, and TRACTO. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

2 notes

·

View notes

Text

hey if youre on turtle island or still tuesday and feel like trying a quick silly browser game you should check out tradle. (i think it updates at midnight based on time zones?) todays is real fun i prommy.

you get five guesses to figure out a country from its export data, and after each guess they tell you how far away you are and what direction the county youre looking for is. i know it sounds like a ridiculous challenge but this one has a bunch of easy hints and giveaways that are accessible to your average westerner

if its wednesday by now or you want to see the data presented differently check out this silly economy under the cut (bolded 'spoilers' ig)

total export value: 371b (usd)

gold: 86.7b (23%}

packaged meds: 48.5b (13%)

vaccines, blood, cultures, etc: 40.3b (11%)

base metal watches: 15.2b (4%)

nitrogen heterocyclic compounds: 14.2b (4%)

jewlery: 9.35b (2.5%)

precious metal watches: 8.97b (2.5%)

orthopedic appliances: 7.02b (2%)

hormones: 3.38b

coffee: 3.36b

electricity: 3.19b

medical instruments: 3.09b

machinery w indv functions: 3.04b

platinum: 2.54b

chemical analysis instruments: 2.27b

nucleic acids: 2.17b

valves: 2.17b

silver: 2.01b

electric motors: 1.78b

scented mixtures: 1.72b

sulfonamides: 1.71b

diamonds: 1.64b

planes, helicopters, and spacecraft: 1.63b

beauty products: 1.58b

other heating machinery: 1.43b

flavored water: 1.43b

gas turbines: 1.38b

low voltage protection eq: 1.34b

gas and liquid flow measuring inst: 1.3b

carboxyamide compounds: 1.26b

other measuring instruments: 1.24b

air pumps: 1.16b

motor vehicles, parts, and acc: 1.14b

petroleum gas: 1.12b

electrical transformers: 1.11b

aluminum plating: 1.07b

other plastic products: 1.01b

metal working machine parts: 988m

vitamins: 965m

polyamides: 963m

washing and bottling machines: 925m

chocolate: 887m

oxygen amino compounds: 885m

integrated circuits: 884m

iron fasteners: 881m

paintings: 873m

transmissions: 855m

special pharmaceuticals: 837m

insulated wire: 828m

electrical power accessories: 826m

plastic lids: 818m

cheese: 800m

antibiotics: 797m

liquid pumps: 797m

cars: 789m

ink: 752m

non mechanical removal machinery: 737m

trunks and cases: 734m

centrifuges: 730m

interchangeable tool parts: 728m

high voltage protection eq: 705m

hand saws: 693m

other edible preparations: 680m

electric heaters: 679m

electrical control boards: 672m

polyacetals: 664m

plastic pipes: 636m

electric soldering equipment: 616m

precious metal compounds: 608m

industrial fatty acids, oils, and alcohols: 608m

hot rolled iron bars: 590m

self propelled rail transport: 582m

refined petroleum: 577m

hydrazine or hydroxylamine derivatives: 565m

precious stones: 563m

rubber working machinery: 561m

unpackaged meds: 557m

other iron products: 553m

precious metal scraps 550m

computers: 545m

surveying equipment: 523m

other plastic sheetings: 519m

metal finishing machines: 516m

scrap copper: 514m

semiconductor devices: 511m

raw plastic sheeting: 494m

documents or title and stamps: 490m

rolled tobacco: 487m

malt extract: 469m

other electrical machinery: 467m

other paper machinery: 450m

oxygen heterocyclic compounds: 441m

non knit mens suits: 441m

synthetic coloring matter: 436m

locomotive parts: 432m

non knit womens suits: 428m

iron structures: 424m

leather footwear: 421m

industrial printers: 415m

lifting machinery: 415m

scrap iron: 412m

therapeutic appliances: 410m

office machine parts: 410m

other clocks and watches: 405m

metal molds: 403m

other furniture: 403m

glaziers putty: 377m

liquid dispersing machines: 376m

knitting machine accessories: 370m

other small iron pipes: 369m

broadcasting equipment: 367m

aircraft parts: 363m

industrial food prep machinery: 362m

glues: 357m

pesticides: 349m

oscilloscopes: 344m

raw aluminum: 344m

knit sweaters: 339m

optical fibers and bundles: 334m

excavation machinery: 332m

non iron/steel slag ash and residue: 319m

carboxylic acids: 315m

xray equipment: 315m

electric motor parts: 315m

watch straps: 313m

tanks and armoured vehicles: 310m

forging machines: 309m

cleaning products: 306m

metalworking transfer machines: 298m

animal food: 294m

combustion engines: 282m

engine parts: 271m

electric generating sets: 254m

scrap aluminum: 249m

laboratory reagents: 249m

perfumes: 244m

other rubber products: 241m

photo lab equipment: 240m

wheat: 236m

lubricating products: 234m

printed circuit boards: 233m

aluminum bars: 230m

explosive ammunition: 230m

brooms: 224m

lcds: 223m

refrigerators: 223m

motorcycles and cycles: 221m

large construction vehicles: 221m

coal briquettes: 221m

corn: 220m

aluminum cans: 219m

textile footwear: 217m

thermostats: 207m

coffee and tea extracts: 206m

other aluminum products: 204m

ball bearings: 203m

knives: 199m

machines for additive mnf: 195m

raw iron bars: 187m

delivery trucks: 185m

milling stones: 176m

aluminum foil: 170m

collectors items: 169m

soybean oil: 169m

wood fiberboard: 166m

other stainless steel bars: 164m

sculptures: 160m

cutting blades: 159m

baked goods: 150m

navigation equipment: 146m

hydrometers: 137m

watch cases and parts: 134m

laboratory ceramic wear: 134m

wood carpentry: 124m

mirrors and lenses: 117m

#the plastic lids is the most astonishing thing out of all this i think. 800m usd in exports.... to go on what??#i wanted to visualize the data by smaller category#ig sharing my autism again stayed up til 3 last night transfering this lol

2 notes

·

View notes

Text

Exploring the Strength and Versatility of Incoloy 925 Fasteners!

In fasteners, strength, corrosion resistance, and durability are paramount. Incoloy 925 fasteners have gained recognition as a reliable and robust choice for various applications. In this blog post, we will dive into the world of Incoloy 925 fasteners, exploring their properties, applications, and advantages.

What Is Incoloy 925?

Incoloy 925 is a nickel-iron-chromium alloy with the addition of molybdenum, copper, titanium, and aluminium. This combination of elements gives it outstanding corrosion resistance in various harsh environments. Incoloy 925 is known for its excellent strength, making it suitable for applications requiring high tensile strength.

Properties of Incoloy 925 Fasteners

Corrosion Resistance: Incoloy 925 fasteners exhibit remarkable resistance to various corrosive environments, including sulfides and chlorides. This makes them ideal for use in chemical and petrochemical industries where exposure to harsh chemicals is common.

High Strength: Incoloy 925 has excellent tensile and yield strength, making it suitable for high-stress resistance applications. These fasteners maintain their integrity under extreme mechanical loads.

Heat Resistance: These fasteners offer excellent thermal stability and can withstand high-temperature applications, making them a popular choice in power generation and aerospace industries.

Applications of Incoloy 925 Fasteners

Oil and Gas Industry: Incoloy 925 fasteners are commonly used in the oil and gas sector, particularly in offshore drilling platforms and downhole equipment. Their resistance to sour gas environments and high-pressure conditions makes them a preferred choice.

Chemical Processing: The chemical industry utilizes Incoloy 925 fasteners to resist corrosive chemicals and solutions. They are essential components in pumps, valves, and vessels.

Aerospace Industry: Incoloy 925's high strength and heat resistance properties make it a valuable material for critical aerospace applications. It is used in jet engines, turbine blades, and other high-temperature components.

Power Generation: Incoloy 925 fasteners find applications in power generation facilities, such as gas turbines and nuclear power plants, where they are exposed to high temperatures and aggressive environments.

2 notes

·

View notes

Text

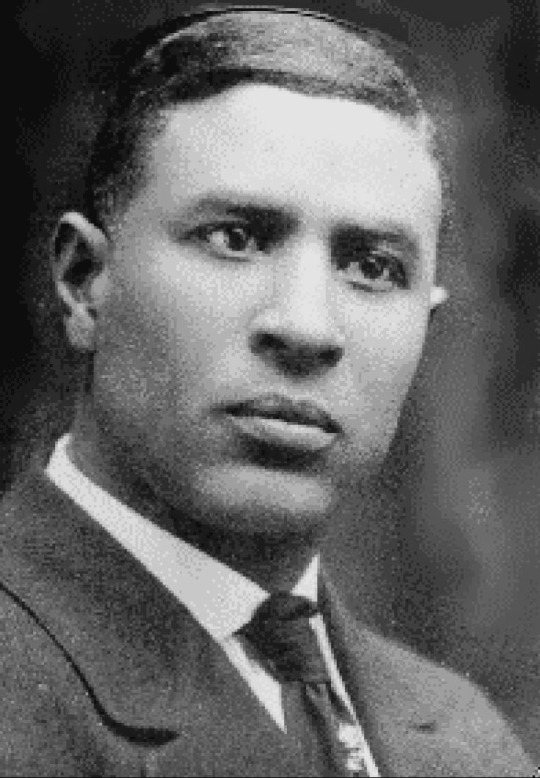

Garrett Morgan was an American inventor that dabbled in a few things. He invented a belt fastener and a zig zag attachment for a sewing machine, womens liquid hair straighter, black hair oil dye and a hair straightening comb. Most notable inventions were a smoke hood (a predecessor to the gas mask) and a three position traffic light.

#garrett morgan#love#inventions#black lives#black history month#transportation#health and beauty products#sewing

1 note

·

View note

Text

Leading B8M Stud Bolts Manufacturer - Delta Fitt Inc.

Delta Fitt Inc. is a prominent ASTM A193 B8M Stud Bolts Manufacturer in India, known for delivering high-quality fasteners to a global clientele. With a strong commitment to precision engineering and stringent quality control, the company has established itself as a trusted ASTM A193 B8M Stud Bolts Supplier in India. These stud bolts are widely used in industries like oil & gas, petrochemicals, power plants, and construction due to their excellent resistance to corrosion and high temperatures. We ensures that their stud bolts are manufactured from superior materials, such as AISI 316 stainless steel, ensuring durability and reliability in critical applications.

As a leading ASTM A193 B8M Stud Bolts Manufacturer, Our company offers a comprehensive range of stud bolts that meet various industry standards and specifications. Their products are designed to endure harsh environmental conditions, making them ideal for both onshore and offshore applications. The company’s reputation as a top ASTM A193 B8M Stud Bolts Supplier is built on a foundation of customer satisfaction, timely delivery, and competitive pricing.

With extensive industry experience and state-of-the-art manufacturing facilities, Delta Fitt Inc. continues to be a preferred choice for clients looking for reliable and high-performance ASTM A193 B8M Stud Bolts Manufacturer in India.

We are also leading B7 Stud Bolts Manufacturers in India, and B8 Stud Bolts Manufacturers in India.

Website: deltafitt.com

#B8MStudBoltsManufacturerinIndia#B8MStudBoltsManufacturer#B8MStudBoltsSupplierinIndia#B8MStudBoltsSupplier

0 notes

Text

Choosing Hydraulic Bolt Tensioners or Hydraulic Torque Wrenches: Suitable for Your Application?

Hydraulic bolt tensioners and hydraulic torque wrenches are widely used tools in several industries. They apply significant usage in construction, oil and gas production, and power generation tasks that may require certain fasteners' accurate tightness—ensuring the preservation of intact machinery and structures. Even though they both tighten bolts, it works differently and is better for their applications. What matters depends on your project—its accuracy, load, and the kind of assembly you're tightening. Here's a guide to help you decide which tool best fits your application needs.

Understanding Hydraulic Torque Wrenches

A hydraulic torque wrench applies rotational force to fasten or loosen a bolt to a measured amount of torque. Hydraulics is the pressure at which it requires force, making hydraulic torquing ideal for very precise torque values. Hydraulic torque wrenches are highly used in the industries of construction, manufacturing, and maintenance. In such operations, the bolts need to be tightened to very accurate specifications.

Key Advantages of Hydraulic Torque Wrench

Accuracy: Hydraulic torque wrenches provide unmatched accuracy in the tightening of bolts to stipulated torque values. This rules out the possibility of over-tightening or under-tightening, which forms a big source of equipment failure.

Versatility: Hydraulic torque wrenches can be applied on large sizes of bolts. Further, these are ideal applications of bolts for repeat or cyclic tightening with the requirement of higher precision.

Ease of Use: Hydraulic torque wrenches are considered easy to use and don't require much effort to operate, which makes them best suited for jobs that require the application of consistent torque.

Best Uses of Hydraulic Torque Wrench

Tightening of bolts with the application of rotational force

Projects where the amount of torque applied is very important

Projects with general maintenance and assembly in high factories or construction.

Understanding Hydraulic Bolt Tensioners

Hydraulic bolt tensioners work by axially stretching the bolt to build up the required preload without torque force since the friction between the bolt and the nut can be nullified. It proves effective at high loads that demand leveling, for instance, in power generation or oil and gas sectors.

The key advantages of hydraulic bolt tensioners include:

Uniform Loading: Hydraulic bolt tensioners stretch the bolt directly and in this way, the loads are evenly distributed and the relaxation of bolts is reduced.

Friction Factor Removal: Tensioners eliminate the friction factor involved in tightening. In this way, consistency is ensured on all fasteners and hence are applied on high precision processes

Improved Safety: Hydraulic bolt tensioners minimize over-tightening possibilities, leading to damage to the bolts hence causing a breakdown on the secured structures.

Hydraulic Bolt Tensioners Ideal Use

High-load or high-pressure applications, for example in pipelines or turbines

Applications where several fasteners are used and uniform tension has to be achieved

Making Your Decision

Between hydraulic bolt tensioners and hydraulic torque wrenches, your application will determine which one you should opt for.

Hydraulic bolt tensioners are probably your best choice when your application contains high-pressure systems or uniform load distribution across multiple fasteners. They are particularly suited to applications in which conditions that may cause the bolts to relax may result in catastrophic failure.

Hydraulic torque wrenches are ideal if you require the amount of torque applied to each bolt, working on general assembly or maintenance. They are versatile and highly accurate for a wide range of industrial applications.

Conclusion

The hydraulic torque wrench and hydraulic bolt tensioner apply in industries where precision fastening is a must. It all comes down to knowing what your project requires so that you can make an informed decision. An application of torque control would be where the use of a torque wrench is required, whereas bolt tensioners will be superior for a high-load application or environment with even load distribution.

0 notes

Text

All You Need to Know: Cupronickel and Hastelloy Steel Grades

For industries like marine engineering, petrochemical, chemical processing, or aerospace, where materials are exposed to extreme conditions, understanding steel grades ensures the longevity and reliability of structures, machinery, and piping systems. Different grades offer unique combinations of strength, corrosion resistance, temperature tolerance, and other key factors that directly influence their suitability for various environments.

What are Steel Grades?

Steel grades are classifications based on the properties of the metal and its alloying elements. For Cupronickel and Hastelloy, grades are determined by their composition, mechanical strength, and resistance to corrosion, oxidation, and temperature.

Cupronickel Grades: Marine-Grade Material for Extreme Conditions

Cupronickel (Cu-Ni) is an alloy primarily made of copper and nickel. It contains trace elements such as iron and manganese to boost its corrosion resistance, particularly in seawater.

Grades of Cupronickel:

1. Cupronickel 90/10 (C70600):

Composition: 90% copper and 10% nickel.

Properties: High corrosion resistance in seawater, good thermal conductivity.

Applications: Marine hardware, desalination plants, and heat exchangers.

2. Cupronickel 70/30 (C71500):

Composition: 70% copper and 30% nickel.

Properties: Greater strength and corrosion resistance than 90/10, especially in high-velocity seawater.

Applications: Offshore oil and gas platforms, seawater cooling systems, and condensers.

Key Properties of Cupronickel Grades:

1. Corrosion Resistance: Both 70/30 and 90/10 grades are resistant to biofouling and seawater corrosion.

2. Mechanical Strength: 70/30 offers higher mechanical strength than 90/10.

3. Thermal Conductivity: Both grades provide excellent thermal conductivity, making them ideal for heat exchangers and piping systems.

Hastelloy Steel Grades: Superalloys for Extreme Chemical Resistance

Hastelloy is a superalloy made of nickel, molybdenum, and chromium. It’s known for its ability to withstand extreme conditions, such as exposure to aggressive chemicals, high temperatures, and oxidation.

Common Grades of Hastelloy:

1.Hastelloy C-276:

Composition: High nickel, molybdenum, and chromium content with a small amount of tungsten.

Properties: Exceptional resistance to a wide range of severe chemicals and oxidizing agents.

Applications: Petrochemical industry, chemical processing, pollution control, and pulp and paper production.

2. Hastelloy B-3:

Composition: High nickel and molybdenum with limited iron content.

Properties: Excellent resistance to hydrochloric acid at all temperatures and concentrations.

Applications: Chemical reactors, distillation equipment, and piping systems in petrochemical and chemical industries.

Key Properties of Hastelloy Grades:

1. Corrosion Resistance: Hastelloy alloys can withstand acidic environments that would corrode most other materials.

2. High-Temperature Stability: Hastelloy maintains its strength and resistance at high temperatures, making it ideal for industries with extreme heat and corrosive conditions.

3. Oxidation Resistance: It resists oxidation in both static and dynamic conditions, raising its longevity in industrial settings.

Comparing Cupronickel and Hastelloy Steel Grades

Though both Cupronickel and Hastelloy are known for their durability, they serve different industries based on their distinct properties.

Cupronickel 90/10 & 70/30 / Hastelloy C-276 & B-3

Corrosion Resistance Excellent in seawater, Exceptional in aggressive chemicals

Temperature Tolerance Moderate, High (up to 1000°C for some grades)

Applications Marine, Oil & Gas, Chemical processing, aerospace

Understanding the role of advanced alloys of best steel grades and classifying between them accordingly like Cupronickel or Hastelloy and Inconel 600 or Monel Fasteners helps businesses make informed decisions. Choosing the right alloy guarantees your application is protected, reduces costs, and improves performance, even in tough environments.

At Online Fittings, we offer a comprehensive range of Cupronickel and Hastelloy steel grades, ensuring you get the best material for your industrial needs. Explore our products today to find the perfect solution for your next project!

0 notes

Text

Trunnion Clamps Market Trends and Evolution Analysis 2024 - 2031

The trunnion clamps market was valued at approximately $4.12 billion in 2023. It is projected to grow to $4.3 billion in 2024 and reach $6.12 billion by 2032. This growth corresponds to a compound annual growth rate (CAGR) of around 4.51% during the forecast period from 2024 to 2032. With increasing applications in various industries, the trunnion clamps market is set for steady expansion in the coming years.

The trunnion clamps market plays a crucial role in various industries, including oil and gas, construction, and manufacturing. These components ensure stability and support in a range of applications, making them essential for equipment performance and safety. This article explores the trunnion clamps market, examining its growth factors, key players, trends, and future outlook.

Introduction to Trunnion Clamps

What Are Trunnion Clamps?

Trunnion clamps are mechanical devices used to secure and stabilize equipment, particularly in heavy machinery and piping systems. They allow for easy adjustment and maintenance while providing robust support to prevent movement during operation.

Applications of Trunnion Clamps

Trunnion clamps are widely used in various sectors:

Oil and Gas: For securing pipelines and drilling equipment.

Construction: To stabilize heavy machinery and scaffolding.

Manufacturing: In assembly lines to hold components in place during production.

Market Overview

Market Size and Growth

The trunnion clamps market has been experiencing steady growth. According to industry reports, the market is projected to grow at a CAGR of approximately 5% over the next five years. Factors contributing to this growth include:

Increasing investments in infrastructure development.

Rising demand from the oil and gas sector.

Growth in the manufacturing industry.

Key Trends Driving Market Growth

Technological Advancements: Innovations in material science and design are leading to more efficient and durable trunnion clamps.

Sustainability Focus: There is a growing emphasis on eco-friendly materials and manufacturing processes, pushing companies to innovate.

Automation and Industry 4.0: The integration of smart technologies in manufacturing processes is enhancing the efficiency of trunnion clamp usage.

Competitive Landscape

Key Players in the Trunnion Clamps Market

The trunnion clamps market features several prominent players, including:

Cameron: A leader in oil and gas equipment, known for its high-quality trunnion clamps.

Parker Hannifin: Offers a wide range of industrial clamps and fastening solutions.

Hilti: Specializes in construction tools and fasteners, including trunnion clamps.

Market Share Analysis

These key players hold significant market share, driven by their strong distribution networks and continuous innovation. Collaborations and partnerships are common strategies to enhance market presence.

Challenges Facing the Market

Regulatory Compliance

The trunnion clamps market is subject to various regulations, especially in industries like oil and gas. Compliance with safety and environmental standards can be challenging for manufacturers.

Price Fluctuations of Raw Materials

The costs of raw materials used in manufacturing trunnion clamps can fluctuate significantly, affecting overall production costs and pricing strategies.

Future Outlook

Opportunities for Growth

The future of the trunnion clamps market appears promising, with several opportunities on the horizon:

Emerging Markets: Growth in developing countries presents new opportunities for market expansion.

Innovation in Design: There is a constant need for improved designs to meet specific industry requirements.

Conclusion

The trunnion clamps market is poised for growth as industries continue to expand and innovate. Key players will need to navigate challenges such as regulatory compliance and raw material costs while seizing opportunities in emerging markets and technological advancements. As the demand for robust and reliable clamps increases, the market is likely to evolve, offering new solutions to meet the needs of various sectors.

0 notes

Text

Fasteners Manufacturer | Roll Fast

Roll-Fast is a Fasteners Manufacturer bolts and nuts in High tensile grade and high tensile fasteners, stainless steel, carbon steel and alloy steel since 1989. We manufacture bigger diameter bolts and nuts from M-20 till M-120 and in inches and Unc from 3/4" to 4". We have 25 years of World Class Manufacturing experience in nuts and bolts we manufactures and exports ss fasteners manufacturers, automotive fastener, Industrial Fasteners and Fasteners for Oil & Gas from our plant in India.

#Fasteners Manufacturer#Industrial Fasteners#automotive fastener#Fasteners for Oil & Gas#Precision Turned components manufacturer

0 notes

Text

Connecting the dots the essential role of industrial cable gland connectors

Introduction

Industrial Cable Gland Connectors are vital components in electrical and mechanical systems, designed to securely fasten, seal, and protect cables as they enter electrical enclosures or machinery. These connectors are widely used across a variety of industries, including manufacturing, oil and gas, telecommunications, automation, and construction, where they provide critical protection for cables in harsh environments.

In this blog post, we’ll explore the purpose, types, and benefits of industrial cable gland connectors and why they are essential to the safety and performance of electrical systems.

What Are Industrial Cable Gland Connectors?

Industrial cable gland connectors are mechanical devices that attach and secure electrical cables to equipment, junction boxes, and panels. They provide strain relief to prevent damage to cables, while also protecting against environmental factors such as dust, moisture, and chemicals. Cable glands are typically made from materials like brass, stainless steel, nylon, or plastic, depending on the specific application and environment.

Key Functions of Industrial Cable Gland Connectors

Strain Relief

One of the primary functions of cable gland connectors is to provide strain relief, preventing cables from being pulled out of place or damaged due to mechanical stress, tension, or vibrations. This is critical in industrial settings where machinery and equipment are constantly in motion.

Environmental Protection

Industrial cable glands create a seal that protects cables from environmental factors such as water, dust, and chemicals. This ensures that electrical systems remain safe and operational, even in harsh or hazardous conditions. In industries like oil and gas or mining, this protection is essential for maintaining the integrity of electrical systems.

Cable Sealing

Cable glands provide a watertight and airtight seal around the cable entry points, preventing moisture and contaminants from entering electrical enclosures. This feature is crucial for preventing short circuits, equipment failure, and safety hazards.

Electrical Safety

By securely anchoring and sealing cables, industrial cable glands contribute to the overall safety of electrical systems, reducing the risk of fire, electric shock, and equipment malfunctions.

Types of Industrial Cable Gland Connectors

Single Compression Cable Glands

These are commonly used for general-purpose industrial applications. They provide effective sealing for standard cables but are typically used in less harsh environments.

Double Compression Cable Glands

Designed for more demanding applications, double compression cable glands offer enhanced protection against dust, moisture, and extreme temperatures. They are often used in hazardous areas, such as oil rigs and chemical plants.

EMC Cable Glands

These cable glands are designed to prevent electromagnetic interference (EMI), making them ideal for sensitive electrical and communication systems where signal integrity is crucial.

Explosion-Proof Cable Glands

Explosion-proof or flameproof cable glands are used in hazardous environments where flammable gases, vapors, or dust are present. These glands prevent sparks or flames from traveling through the cable entry points, ensuring safety in areas prone to explosions.

Benefits of Using Industrial Cable Gland Connectors

Improved System Longevity

By protecting cables from environmental damage and strain, cable glands help extend the life of electrical systems and reduce the need for maintenance or replacements.

Enhanced Safety

Cable glands reduce the risk of accidents, electrical failures, and fires by providing secure connections and protecting cables from external hazards.

Cost-Effective

Investing in high-quality cable glands helps reduce downtime and maintenance costs by protecting electrical systems from damage and wear.

Choosing the Right Cable Gland Connectors for Your Application

When selecting industrial cable gland connectors, consider factors such as the type of cable, environmental conditions, material requirements, and safety regulations. For hazardous environments, it's essential to choose cable glands that are certified for explosion-proof or flameproof applications. Additionally, ensure that the gland material—whether brass, stainless steel, or plastic—matches the demands of the environment to prevent corrosion or degradation over time.

Conclusion

Industrial cable gland connectors are indispensable components in maintaining the safety, efficiency, and longevity of electrical systems in demanding environments. Whether you are working in manufacturing, oil and gas, or construction, the right cable gland ensures that your electrical systems remain protected and perform optimally under challenging conditions. Choosing the right type of cable gland for your specific application is a critical step in ensuring the safety and reliability of your entire setup.

0 notes

Text

Stainless Steel Nuts Manufacturer and Supplier in Dubai, UAE

Shashank Stainless is a reputable manufacturer and supplier of premium stainless steel products in Dubai, UAE, specializing in stainless steel nuts. Their nuts are known for their excellent strength, corrosion resistance, and durability, making them ideal for demanding industrial environments. Available in grades like 304, 304L, 316, 316L, and 321, these nuts are designed to meet the needs of industries such as construction, oil & gas, and marine. Shashank Stainless delivers high-quality, reliable fastening solutions tailored to diverse applications.

Our other grades: Stainless Steel 201 Nuts, Stainless Steel 301 Nuts, Stainless Steel 304 Nuts, Stainless Steel 304H Nuts,

Contact Us:

Mail:- [email protected]

Website:- https://www.shashankstainless.ae/

0 notes

Text

Heat Exchangers Market 2024: Industry Analysis and Opportunity Assessment, Forecast to 2030

Heat Exchangers Industry Overview

The global heat exchangers market size was estimated at USD 18.19 billion in 2023 and is expected to expand at a compounded annual growth rate (CAGR) of 5.4% from 2024 to 2030.

Rising focus on efficient thermal management in various industries, including oil & gas, power generation, chemical & petrochemical, food & beverage, and HVAC & refrigeration, is expected to drive the demand for heat exchangers over the forecast period. Rising demand from chemical industry coupled with increasing technological advancements and a growing focus on improving efficiency standards is expected to drive heat exchangers market growth. Most processes in petrochemical facilities involve high pressure and temperature, thus, necessitating the optimization of heat transfer and enhancement of energy savings, which, in turn, is likely to boost the demand for energy-efficient heat exchangers.

Gather more insights about the market drivers, restrains and growth of the Heat Exchangers Market

U.S. dominated the North America heat exchanger market in 2023, owing to high electricity demand, industrialization, and investments in renewable power generation. Rising investments by oil & gas companies in exploration & production activities in the U.S. are expected to boost the demand for these products in oil & gas industry.

Significant power markets such as China, U.S., India, Russia, and Japan are restructuring their operating models to adopt the structure of renewable energy and efficient utilization of energy by installing heat exchangers and shifting from traditional energy use. This is expected to drive the demand for heat exchangers.

Technological advancements such as tube inserts in heat exchangers are expected to complement the market growth. Furthermore, ongoing technological improvements to improve energy efficiency, total life cycle cost, durability, and compactness of heat exchangers are expected to drive industry growth.

Manufacturers of these products face a long list of difficult supply chain challenges, including increasing demand variability, intense global competition, more environmental compliance regulations, increasing human- and nature-based risks, and inventory proliferation. COVID-19 pandemic has created new challenges, which are compelling manufacturers to innovate their supply chains at a faster speed.

Heat Exchangers Market Segmentation

Grand View Research has segmented the global heat exchangers market report based on product, end-use, material and region:

Product Outlook (Revenue, USD Billion, 2018 - 2030)

Plate & Frame Heat Exchanger

Brazed Plate & Frame Heat Exchanger

Gasketed Plate & Frame Heat Exchanger

Welded Plate & Frame Heat Exchanger

Others

Shell & Tube Heat Exchanger

Air-Cooled Heat Exchanger

Others

End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Chemical & Petrochemical

Oil & Gas

HVAC & Refrigeration

Power GenerationFood & Beverage

Pulp & Paper

Others

Material Outlook (Revenue, USD Billion, 2018 - 2030)

Metals

Alloys

Others

Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

Spain

UK

Asia Pacific

China

Japan

India

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

The global wood plastic composites market size was estimated at USD 7.15 billion in 2023 and is expected to grow at a CAGR of 11.6% from 2024 to 2030.

The global industrial fasteners market size was estimated at USD 95.57 billion in 2023 and is expected to grow at a CAGR of 4.7% from 2024 to 2030.

Key Companies & Market Share Insights

Global heat exchangers industry is characterized by presence of multinational as well as regional players that are engaged in designing, manufacturing, and distributing these products. Product manufacturers strive to obtain a competitive edge over their competitors by increasing application scope of their products.

Strategies adopted by manufacturers include new product development, diversification, mergers & acquisitions, and geographical expansion. These strategies aid the companies in expanding their market penetration and catering to changing technological demand across various end-use industries.

Key Heat Exchangers Companies:

Alfa Laval

Danfoss

Kelvion Holding GmbH

Güntner Group GmbH

Xylem Inc

API Heat Transfer

Mersen

Hisaka Works, Ltd.

Chart Industries, Inc

Johnson Controls International

HRS Heat Exchangers

SPX FLOW, Inc.

Funke Wärmeaustauscher Apparantebau GmbH

Koch Heat Transfer Company

Southern Heat Exchanger Corporation

Recent Developments:

For instance, in April 2023, Kelvion launched dedicated air cooler series for natural refrigerants. The CDF & CDH ranges are dual discharge air coolers highlighting a similar proficient tube system.

In May 2023, Alfa Laval is enhancing its brazed plate heat exchanger capacity to bolster the global energy transition. The establishment of new facilities in Italy, China, Sweden, and the U.S. signifies significant progress in their initiative to advance manufacturing intelligence and efficiency throughout the entire supply chain.

In January 2021, Alfa Laval, opened a new facility for the production of brazed heat exchangers in San Bonifacio, Italy. The new facility will have more capacity to fulfill the increasing customer demand.

Order a free sample PDF of the Heat Exchanger Market Intelligence Study, published by Grand View Research.

0 notes

Text

Hydraulic Torque Wrenches: A Cost-Effective Solution for Large-Scale Projects

In the world of large-scale industrial projects, precision and efficiency are critical. Whether it’s assembling complex machinery, maintaining oil rigs, or constructing large infrastructure, using the right tools can make a significant difference in project costs and timelines. Among such priceless tools are hydraulic torque wrenches, which become indispensable pieces of apparatus in offering precision and power for their heavy-duty operations. On the other hand hydraulic bolt tensioners have emerged as great importance concerning safety, efficiency, and durability. Taken together, these devices make a cost-effective solution for industrial projects, as they save labor time and prevent operational errors.

Understanding Hydraulic Torque Wrench

A hydraulic torque wrench is a tool designed for providing a particular amount of torque to be applied on the fastener, which could be a nut or bolt. Hydraulic devices using hydraulic pressure to achieve this torque offer accuracy and strength that cannot be rivaled in manual wrenches. They are widely applied in oil and gas, power generation, and construction areas.

Hydraulic torque wrenches are especially crucial for large projects, as they consume much less time to pull in or loosen bolts than traditional methods. Such efficiency can save huge amounts of money, especially when most projects involve hundreds or thousands of fasteners.

Benefits of Hydraulic Torque Wrenches for Large Projects

Precision and Accuracy

Another important reason hydraulic torque wrenches are favored in big projects is that they ensure well-achieved torque every time, so that the bolts are never either loosely nor overtightened, thus avoiding equipment breakage. Bolt tightening correctly means long-time stability and service lives of the structure or machine, preventing expensive repairs or lost time in the future.

Time Convenience

Hydraulic torque wrenches dramatically slash the time needed to tighten or loosen bolts. In big projects where hundreds of bolts need to be tightened, this time factor cut down can be directly translated in terms of labor cost cuts and shortened time spans in a project timeline. Properly tightened bolts ensure the stability and longevity of the structure or machinery, preventing costly repairs or downtime in the future.

Versatility

These wrenches come in different models and configurations. Therefore, they can be used to answer the requirements of their various applications. Whether it is working in confined spaces, with heavy equipment, or if there is a need for high torque hydraulic torque wrenches can change according to the needs of the project. That's why they are also advisable in large operations, which, naturally, reduces the number of specialized tools needed.

Reduced Risk of Fatigue

Manual straining of over-sized bolts is heavy labor work mainly when working in extreme environments such as construction sites or oil rigs. Hydraulic torque wrenches offer systems that are easy to use thus reducing the personal strain on workers, meaning fewer injuries and higher productivity.

Hydraulic Bolt Tensioners: Supplementing the Torque Wrench

Hydraulically operated wrenches are excellent tightening tools for bolts, but they are used individually in very few cases; instead, they are used with hydraulic bolt tensioners to get the best results. Hydraulic bolt tensioners operate on the principle of stretching a bolt rather than using a radial force to secure the bolt, thereby ensuring that all the fasteners share the same amount of load. It is mostly used in critical applications such as pressure vessels, turbines, and other even stressed parts.

In big projects, hydraulic torque wrenches and hydraulic bolt tensioners ensure fasteners are tightened up to the exact detail. In such a scenario, safety and operational efficiency in general is automatically saved. Common problems such as bolt relaxation or uneven load distribution, which might be hazardous because of expensive failures, are usually eliminated through use of both tools.

Cost saving Through Efficiency

The hydraulic torque wrenches and hydraulic bolt tensioners also save significant amounts of money in large-scale projects. This can be in the following ways:

Reduced labor costs: Labor cost is saved by reducing the time taken on the tightening and loosening process. The hours taken to accomplish a task are reduced. Fewer workers are needed, and those who are employed can work more efficiently.

Prevention of Equipment Failure: Hydraulic torque wrenches and bolt tensioners can provide accuracy that will not let any bolts be overtightened or under-tightened. It consequently avoids costly repair works and contributes less to the likelihood of expensive downtime from machinery failures.

Extended Life for Equipment: The machinery and structures extended longer thereby ensuring that properly torqued bolts are obtained as well as avoid such major drivers like replacement or overhaul, which are cost-centric in industries like construction and energy.

Conclusion

Cost-effective efficiency in large-scale industrial projects can be achieved by employing a combination of hydraulic torque wrenches and hydraulic bolt tensioners These are tools that provide the accuracy, speed, and reliability required to complete a project well within the time limit and budget. The investment by the businesses made here in advanced tools enables them to reduce labor costs while avoiding costly mistakes and guaranteeing the long-term durability of their equipment and structures, which makes hydraulic torque wrenches an asset for today's industries.

For more information visit Prime Tools India

0 notes