#Face Veneer manufacturer India

Explore tagged Tumblr posts

Text

Flush Door Manufacturers in India: Crafting Doors to a Better Future

In the heart of India's booming construction and interior design industry, flush doors have carved out a prominent place. Renowned for their sleek appearance, durability, and cost-effectiveness, these doors are a favorite among homeowners, architects, and builders alike. This article delves into the world of flush door manufacturers in India, highlighting their contributions, diversity, and the emotional connections they foster through their craft.

The Essence of Flush Doors

Flush doors are characterized by their plain, smooth surfaces which are ideal for both interior and exterior use. They are constructed from a wooden framework filled with solid core material, often laminated or veneered for a polished finish. The key attributes that make flush doors highly sought after include:

Aesthetic Appeal: Clean, minimalist design that complements modern and traditional interiors.

Durability: Strong and resistant to warping, making them ideal for varied climatic conditions.

Affordability: Cost-effective without compromising on quality and appearance.

Versatility: Available in a range of finishes, styles, and sizes to suit different tastes and applications.

Leading Manufacturers in India

India boasts a myriad of flush door manufacturers who offer high-quality products catering to diverse needs. Here are some notable names in the industry:

1. Century Plyboards (India) Ltd.

Overview: A leader in the plywood and laminate industry, Century Ply is renowned for its superior quality flush doors.

Specialty: Offers a range of flush doors that are termite-proof, waterproof, and fire-retardant.

Innovation: Known for incorporating advanced technology and sustainable practices in manufacturing.

2. Greenply Industries Limited

Reputation: A trusted name in the industry, Greenply is known for its eco-friendly and durable products.

Product Range: Offers a wide variety of flush doors with options for different core materials and finishes.

Sustainability: Emphasizes environmentally responsible practices, ensuring their products are both high-quality and eco-friendly.

3. DURO (Sarda Plywood Industries Ltd.)

Heritage: With decades of experience, DURO is synonymous with reliability and craftsmanship.

Quality: Focuses on producing flush doors that meet stringent quality standards, ensuring longevity and strength.

Customer Focus: Provides excellent after-sales service and customization options to meet specific client needs.

4. Kitply Industries Limited

Legacy: One of the oldest and most reputed plywood manufacturers in India, Kitply offers an extensive range of flush doors.

Innovation: Known for their continuous innovation in product development, ensuring top-notch quality and design.

Accessibility: Wide distribution network ensures easy availability across the country.

5. National Plywood Industries Limited

Brand Value: National Plywood is known for its commitment to quality and affordability.

Variety: Offers a diverse range of flush doors catering to different budget segments without compromising on quality.

Support: Provides excellent customer support, including detailed product information and installation guidance.

The Human Touch: Emotions in the Craft

The relationship between flush door manufacturers and their clients is steeped in mutual respect, trust, and shared visions. The emotional fabric of this industry is woven with threads of:

Pride: Manufacturers take immense pride in knowing their products are integral to the beauty and functionality of countless homes and buildings across the country.

Dedication: The commitment to crafting doors that are not just functional but also beautiful reflects a deep passion for the craft.

Connection: Building lasting relationships with clients and stakeholders fosters a sense of community and shared growth.

Conclusion: Opening Doors to Possibilities

The landscape of flush door manufacturers in India is a testament to the country's rich tradition of craftsmanship combined with modern innovation. These manufacturers, with their unwavering commitment to quality, sustainability, and customer satisfaction, are not just producing doors; they are creating gateways to better living spaces and contributing to the nation's architectural splendor.

As we look to the future, the synergy between advanced technology and human ingenuity promises even greater advancements. The flush door manufacturers in India will continue to play a crucial role in shaping the built environment, one door at a time.

0 notes

Text

Top Veneer Manufacturing and Customization: Enhance Your Space with Stunning Designs

Discover the top veneer manufacturing and customization services, bringing you the best in quality and design. Whether you're looking for veneer customization in India or specifically in Delhi, our expert manufacturers can create stunning veneer designs for your bedroom, flooring, doors, and more. Explore a wide range of options, including laminate veneer sheets and door veneer sheets, to transform your space with beautiful veneer. Trust the top veneer brands in India and find the nearest veneer suppliers to bring the latest veneer door designs to life. Enhance your space with exquisite veneer craftsmanship today.

#best veneer manufacturing#best veneer customization#veneer customization India#veneer customization Delhi#veneer customization manufacturer#veneer bedroom designs#veneer flooring#laminate veneer sheets#door veneer sheets#veneer for doors#veneer wood doors#veener door design#veneer brands in india#face veneer#veneer near me#latest veneer door design

0 notes

Text

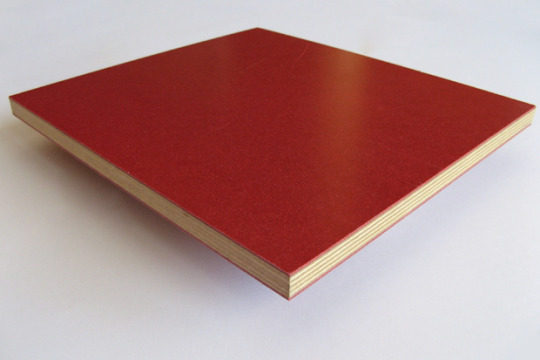

Best Film Faced Shuttering Plywood Manufacturers in India – Jagramji Plywood

Jagramji Plywood is well-known as one of the best Film Faced Shuttering Plywood Manufacturers in India. Compared to other shuttering plywood, we, as expert film-faced shuttering plywood manufacturers, provide plywood that has superior compression, which improves nailing and allows screws to hold more securely. The compression also enhances the product's load-bearing capacity. It is guaranteed to perform better regardless of the required application, as it is manufactured using quality veneers that are impregnated with high-quality liquid phenol formaldehyde synthetic resins produced at the company's in-house resin plant.

To know more information about our products, you can directly contact us at +91-7900608167 or visit our official website: https://www.jagramjiply.com/products/film-faced-shuttering-plywood/

#Top 10 Shuttering Plywood Manufacturers#Pallet For Brick Machine Manufacturers#Chequered Plywood Manufacturers#Best Shuttering Plywood Manufacturers#Film Faced Plywood Manufacturers#Shuttering Plywood Manufacturers in India#Shuttering Plywood Manufacturers

0 notes

Text

Exploring the Rise of Merino Industries Share Price

Introduction

In the realm of interior solutions, one company has been making significant strides not only in transforming spaces but also in the financial markets. Merino Industries Ltd., with its commitment to innovation and quality, has witnessed a notable surge in Merino Industries Share Price, reflecting the growing confidence of investors in its capabilities and market positioning. Merino Industries Ltd. emerges as a multifaceted powerhouse within the realm of Interior Solutions, offering a vast array of products tailored to cater to the diverse needs of residences, workplaces, commercial spaces, and public areas. With a steadfast presence in the market spanning numerous years, the company has garnered substantial brand recognition across various customer demographics, solidifying its position as a trusted industry leader.

The company operates across three distinct business verticals: Interior & Architecture, IT Services, and Agro-tech. Within the Interior and Architecture segment, Merino Industries boasts a comprehensive product portfolio, encompassing decorative laminates, plywood, melamine-faced particle boards, MDF boards, post-formed panels, tailor-made furniture solutions, restroom and locker systems, and solid surfaces. The diverse range of offerings caters to a wide spectrum of interior design requirements, ensuring utmost customer satisfaction.

Moreover, Merino Industries extends its reach into the IT and business consulting domain, providing value-added services such as the design and implementation of various business solutions for clients and business associates. In the realm of Interior & Architecture, the company offers an extensive selection of over 10,000 SKUs, spanning assorted designs, colors, and finishes, catering to the diverse tastes and preferences of its clientele.

With an impressive installed capacity capable of manufacturing 215 lakh sheets per annum, Merino Industries emerges as India's largest laminate company, contributing significantly to its overall revenue. Additionally, the company has diversified its portfolio to include offerings in the Agro Business segment, leveraging its integrated approach to provide customers with a range of products spanning from raw materials to finished goods. Notably, Merino Group's foray into the FMCG market has seen the launch of potato flakes and ready-to-eat snack mixes under the brand name 'Legit,' further expanding its presence across diverse industries.

Merino Industries operates through a network of 20 Merino Experience Centers spanning 22 cities in India, supplemented by an additional 4 centers internationally. With a vast network of 16,000 dealers and retailers, the company boasts a workforce exceeding 6,238 employees, collaborating closely with approximately 88,000 carpenters and architects. Furthermore, Merino Industries extends its global footprint by exporting its products to 81 countries worldwide.

Established in 1965 by Shri Man Kumar Lohia, Merino Industries Limited initially operated under the name Century Laminating Co. Ltd. Headquartered in Kolkata, India, the company operates as a privately owned non-government entity, driven by a relentless commitment to excellence, innovation, and customer satisfaction.

Merino Industries: A Multifaceted Producer

Merino Industries Ltd. stands as a multifaceted producer and promoter of interior solutions, offering a diverse range of products suitable for various settings including residences, workplaces, commercial spaces, and public areas. With a keen focus on delivering quality products that cater to evolving customer needs, the company has established itself as a trusted name in the industry.

Product Portfolio and Market Presence

Central to Merino Industries' success is its comprehensive product portfolio, encompassing a wide array of interior solutions ranging from laminates and veneers to engineered wood and solid surfaces. This diverse offering allows the company to cater to a broad spectrum of customer requirements, thereby solidifying its presence across different market segments. Additionally, Merino Industries' extensive distribution network ensures widespread accessibility of its products, further enhancing its market reach and visibility.

Innovation and Quality Assurance

Merino Industries' commitment to innovation and quality assurance has been instrumental in driving its share price upwards. The company invests significantly in research and development to stay ahead of industry trends and technological advancements, thereby continuously enhancing its product offerings. Moreover, stringent quality control measures ensure that Merino Industries maintains its reputation for delivering superior products that meet the highest standards of durability and aesthetics.

Strategic Partnerships and Expansion

Strategic partnerships and expansion initiatives have played a pivotal role in Merino Industries' growth trajectory. Collaborations with architects, designers, and industry stakeholders have enabled the company to leverage synergies and tap into new market opportunities. Furthermore, targeted expansion into emerging markets and untapped geographies has facilitated Merino Industries' expansion beyond its traditional strongholds, thereby fueling its growth momentum.

Financial Performance and Investor Confidence

Merino Industries' robust financial performance and consistent growth have garnered the confidence of investors, driving its share price upwards. With impressive revenue figures and profitability metrics, the company demonstrates its ability to generate value for shareholders. Additionally, Merino Industries' transparent communication and proactive investor relations initiatives further reinforce investor confidence in its long-term prospects.

Challenges and Future Outlook

Despite its success, Merino Industries faces a set of challenges including market competition, raw material price fluctuations, and evolving consumer preferences. However, with its focus on innovation, quality, and customer-centric approach, the company is well-positioned to navigate these challenges and capitalize on emerging opportunities in the interior solutions market. As it continues to innovate and expand its market presence, Merino Industries' share price is expected to reflect its continued growth and leadership in the industry.

Conclusion

The rise of Merino Industries' share price is a testament to its relentless pursuit of excellence, innovation, and customer satisfaction. With a diverse product portfolio, strong market presence, and strategic growth initiatives, the company is poised to maintain its upward trajectory in the interior solutions market. As Merino Industries continues to push boundaries and redefine industry standards, its share price is likely to remain a reflection of its unwavering commitment to success and leadership.

#Merino Industries Share Price#Merino Industries Pre IPO#Merino Industries Unlisted Shares#Merino Industries Upcoming IPO#Merino Industries IPO

0 notes

Text

Leading Innovations with the Best R&D-Based Plywood Manufacturing Units in India

Plywood manufacturing faces several key challenges including maintaining quality, reducing costs, and ensuring sustainability. To address these issues efficiently:

Quality Assurance: Implementing advanced quality control systems and precision manufacturing technology can significantly improve consistency and durability of plywood products. This includes the use of automated grading systems for veneers and real-time monitoring tools to ensure product uniformity.

Cost Reduction: Streamlining production processes through the integration of lean manufacturing techniques helps minimize waste and optimize resource use. Employing modern, energy-efficient machinery reduces operational costs and enhances productivity.

Sustainability Focus: Adopting green manufacturing practices is essential. This involves using environmentally friendly adhesives, sourcing sustainably harvested wood, and investing in recycling systems to handle waste products effectively.

To overcome these pain points, collaboration with the Best R&D Based Plywood Manufacturing units in India can provide access to cutting-edge research and development resources. These units are renowned for their innovative approaches to tackling industry challenges, making them invaluable partners in achieving high standards of quality, efficiency, and sustainability in plywood manufacturing.

#Best R&D Based Plywood Manufacturing units in India#Best R&D Based Plywood Manufacturing#best plywood in india#plywood#like#share

0 notes

Text

Flushdoor Manufacturers in karnataka near Delhi

Introducing our Brownies Plywood We are the top Flushdoor manufacturers in Karnataka. Because, our flush Doors are made of carefully chosen, well-seasoned Pinewood, which is inherently resistant to termites and borers. Moreover, Sylvester Pine is the species we are utilizing because it is the best.

The block board core is encased in face veneers that enclose both sides of the core and is finger-joined (according to BIS Specification) with seasoned pinewood battens (stile & rail). All of these are joined together under extreme pressure and heat using phenol formaldehyde adhesive and long-lasting preservatives. Maximum heat, dust, and noise insulation are ensured by this method. Several sizes range from 25mm to 55mm in thickness. This ISO 2202 and ISO 9001-certified product is of the highest caliber.

Flush door manufacturers in Karnataka

KEEP UP-TO-DATE

Sign up for our newsletter and follow us on social

Visit Us: Flushdoor manufacturers in Karnataka

Contact Information:

Ambika Board Industries

khidripura bundki nagina road najibabad dist bijnor up 246763

Mr. Shobhit Agarwal

+91-9997604863

0 notes

Text

Embrace the Radiance: Positive MDF Board, Illuminating Spaces with Style and Strength

Positive Chipboard India Private Limited is a renowned manufacturer and supplier based in India that places customer satisfaction as its top priority. They provide outstanding products, including particle boards and MDF, which are versatile building materials belonging to the composite board and fiberboard product family. MDF, similar in application to plywood, finds widespread use in various home and professional projects for furniture and interior works. Positive MDF offers two grades: Plain and Pre-Laminated MDF (Medium Density Fiberboard).

The notable characteristic of MDF lies in its homogeneous construction, free from layers. By employing advanced technology that ensures the application of compression pressure throughout the boards, even reaching the core, we achieve a densified core essential for superior routing capabilities. As a result, our boards exhibit exceptional routing features.

MDF stands for Medium Density Fiberboard. It is a type of engineered wood product that is commonly used in construction, furniture manufacturing, and other applications. MDF is made by breaking down hardwood or softwood fibers into small particles, which are then combined with a resin binder and compressed under high pressure and heat to form panels.

· Plain Exterior MDF Board Manufacturers and Suppliers

The boards exhibit remarkable water resistance and can be customized to improve their resistance to fungus and termites, according to the customer’s preferences. They offer several benefits such as a consistent and uniform structure that provides equal strength in every direction. Additionally, they maintain their dimensional stability even when exposed to different atmospheric conditions.

· Plain Interior MDF Board Manufacturers and Suppliers

If you’re seeking the highest quality MDF Board. This remarkable material possesses a homogeneous structure and uniform properties, ensuring a consistent strength that is evenly distributed in all directions. It is free from knots or grains, resulting in a reliable strength throughout. Notably, it excels in screw retention strength, both on its face and edges, without any splintering or flaking. Similar to natural wood, it is easy to cut, staple, turn, and join. Moreover, it offers the versatility to be laminated, veneered, lacquered, painted, printed, or coated with PVC.

Here are some key characteristics and features of MDF:

Density: MDF has a higher density compared to other types of fiberboard, such as particle board. The density of MDF typically ranges from 600 to 800 kg/m³, which gives it good strength and stability.

Composition: MDF is composed of small wood fibers that are bound together with synthetic resins or binders. This composition provides MDF with a smooth and uniform surface, making it suitable for painting, veneering, or laminating.

Strength and Durability: MDF is known for its high strength and durability. It’s homogeneous structure and dense composition make it resistant to warping, cracking, and splitting.

Versatility: MDF is a highly versatile material. It can be easily machined, cut, drilled, and shaped using standard woodworking tools. Its uniform composition allows for precise and intricate detailing. MDF is also compatible with a variety of finishes, such as paint, laminate, or veneer, giving it a wide range of decorative possibilities.

Affordability: MDF is generally more affordable than solid wood or plywood, making it a cost-effective choice for many applications. It provides a balance between quality and price, making it popular in both commercial and residential projects.

Applications: MDF has a wide range of applications in various industries. It is commonly used in furniture manufacturing for items such as cabinets, shelves, and tabletops. MDF is also used for interior trim work, wall panels, doors, and flooring underlayment. Its smooth surface and stability make it an ideal choice for painting or adding decorative finishes.

Overall, MDF is a versatile and cost-effective engineered wood product that offers strength, durability, and a smooth surface for various applications in construction and furniture manufacturing.

0 notes

Text

Who Is The Top Company For Film Face Shuttering Plywood In India?

In India, one of the top companies for film face shuttering plywood in India. the company is a renowned manufacturer and supplier of a wide range of plywood products, including film face shuttering plywood. With a strong presence in the Indian market, the company has established itself as a trusted and reliable brand.

Film face shuttering plywood is an essential material used in the construction industry, particularly for formwork and shuttering applications. It is known for its durability, strength, and resistance to moisture, making it ideal for concrete formwork and other construction purposes. The film face surface of the plywood provides a smooth finish to concrete structures, allowing for easy stripping and reusability.

Yeti Ply Industries Limited offers a comprehensive range of film face shuttering plywood products that cater to the diverse needs of the construction industry. Their plywood is manufactured using high-quality wood veneers and is treated with special chemicals and resins to enhance its strength and durability. The film face surface is made of high-density phenolic film, which ensures excellent resistance to water, chemicals, and abrasion.

The company's film face shuttering Plywood Manufacturers in India using advanced technology and stringent quality control measures. Greenply has state-of-the-art manufacturing facilities equipped with modern machinery and equipment to ensure the production of plywood that meets international standards. The company also adheres to eco-friendly practices by sourcing raw materials from sustainable forests and implementing responsible manufacturing processes.

Greenply's film face shuttering plywood is highly regarded in the construction industry for its superior performance and reliability. It is widely used in various applications such as concrete formwork, false ceilings, paneling, and partitions. The plywood's high strength allows for multiple reuses, reducing overall construction costs and contributing to sustainable construction practices.

Apart from its excellent product quality, Greenply Industries Limited also provides exceptional customer service. The company has a widespread distribution network across India, ensuring timely delivery of products to customers in different regions. They also offer technical support and guidance to assist customers in choosing the right plywood for their specific requirements.

In addition to Yeti Ply, there are other reputable companies in India that manufacture Plywood Suppliers In India, including CenturyPly, Kitply Industries Limited, and Sarda Plywood Industries Limited. These companies have also established themselves as leaders in the plywood industry and offer high-quality products.

In conclusion, Yeti Ply Industries Limited is one of the top companies for Best Plywood Used in Government Tenders in India. Their commitment to quality, sustainable practices, and customer satisfaction has earned them a strong reputation in the construction industry. With a comprehensive range of plywood products and excellent service, Yeti Ply continues to be a preferred choice for contractors, builders, and architects across the country.

0 notes

Text

Top 10 Largest Plywood Manufacturers in India

Black Marble is a well known brand of Best Plywood Manufacturer & Supplier in the market. We are manufacturing the best quality of plywood along with our team of trained and professional engineers. As the trend has come to try out new things and make the living place or work place look beautiful and attractive.

The plywood is the best option for it. The people are searching for the best plywood suppliers in the market so here are we to help you out in finding the array of plywood at a single place. The company is professionally managed by ites Directors having more than 15 years of eperience in production and marketing of all types of plywood and related products.

We have a team of experienced, Qualified and dedicated staff at all levels. We have own Laboratory equipped with most modern testing facilites to access all physical and chemical properties of product prior to dispatch. All our products are ISI approved.

The organization believes in innovation and one can find the reflection of the same in each product under its umbrella. We believe in keeping the long term relationship with our customer by providing them tailor made products. The company also believes in proper follow-up of any query from the customers side thereby making services an important of the working culture. We are visionary thinkers, creating opportunities every day. This entrepreneurial spirit brought us to the forefront of the Plywood Industry. Now we are improving beyond what we expect.

BLACK MARBLE is the recognized brand of Plywood Manufacturers in Maharashtra, India. We are working with a proficient team of trained and professional engineers who are working with their combined efforts to manufacture the best quality of plywood. Plywood Manufacturers; Plywood has now become a dream of today’s time to design the interiors and modify the decors with the most beautiful furniture and design. Plywood Manufacturer; This plywood is made with the help of thin layers of wood veneers glued together with the best quality adhesive to make them strong and more durable.

The plywood is made with fine quality material and designed to give an attractive look at several places. Offered products by BLACK MARBLE are known for their high strength & weather resistance nature. The company believes in delivering a product that can be useful for its abode. Therefore, if you want to improve your home décor with extra elegance then immediately get in touch with one of the leading Plywood Manufacturers in Bihar – BLACK MARBLE, that will be the perfect choice for your abode.

Black Marble is a prominent and well-renowned Block Board Manufacturers in Uttar Pradesh, India who delivers block boards of top-notch quality. We have been venturing superior quality wooden products for decades hence we earned the name and fame of being a trustworthy supplier in India. We have established various dealers around the country to facilitate our valuable customers.

Black Marble is a premium quality board with high resistant properties against borer and termite attacks. All the three components of this block board i.e. Face Veneer, Core Veneer & wooden battens are well matched. The wooden battens are thoroughly seasoned in scientifically run seasoning kiln plants and then cut with great precision to obtain uniform thickness.

We can export and Block Board Manufacturers in Andhra Pradesh is made up of high quality timber and innovative machines under the supervision of our diligent professionals.

Black Marble Ply is counted as the best quality Shuttering Plywood Manufacturers in Telangana, India. It is manufactured by selecting quality vendors impregnated with modified RPF resin for longer life and better performance in all applications. Impregnation of resin in veneers is more than 30% to the weight of veneers.

Shuttering Plywood are compressed and densified panels used mainly for formworks in construction. These panels are composed by aligning several layers of phenolic resin-coated veneers, each placed at right angles to the other. The top and bottom veneers are coated with a resistant double layer of water repellent phenolic films such that the top film on either side is backed by a highly absorbent kraft sheet which increases resistant and water-resistant properties. We also provide our services as Shuttering Plywood Manufacturers in Jharkhand.

Black Marble Ply is the leading name of Flush Door Manufacturers in Gujarat & Supplier India. We are engaged in the making of Flush Doors. We have a team of experts who are using the superior quality of natural wood to make the flush doors. We are making the flush door which enables the strong screw holding capacity. The flush doors are designed with the best lamination that helps in making the looks and surface of the flush doors appear lustrous.

We are one of the Leading Flush Door Manufacturers in Karnataka India, and they aim to become the first choice with their finished products. These doors are made by expert manufacturers with the highest grade of raw materials.

For more info visit: https://www.blackmarbleply.com

Address. Haldaur Road,Opp Sugar Mill, Chadpur, Distt. Bijnor 246725 (U.P) India

Phone. +91-9837516516

Email. [email protected]

You may also visit:

Plywood Manufacturers in Rajasthan,

Flush Door Manufacturers in Maharashtra,

Shuttering Plywood Manufacturers in Andhra Pradesh,

Flush Door Manufacturers in Uttar Pradesh,

Plywood Manufacturers in Madhya Pradesh

#Plywood Manufacturers in Rajasthan#Flush Door Manufacturers in Maharashtra#Block Board Manufacturers in Uttar Pradesh#Plywood Manufacturers in Madhya Pradesh

1 note

·

View note

Text

Discovering the most incredible and best explored Marble Granite and Stone Company on Earth

Discovering the most incredible and best explored Marble Granite and Stone Company on Earth:

#BhandariMarbleWorld

The Pioneer company of marble granite & natural stone

We are an India Government recognized Exports House Associate in and limited liability company registered underneath the Indian corporations act promoted by a bunch of committed men with the expertise of quite Artifacts in Natural stones Manning, Building Construction and building materials offer, The key success issue of our organization is an old and qualified team and this team expertise facilitate to serve you in economical good and efficient manner.

Different types of stones, tiles, and slabs provide our home interior and exterior a brand new, charming, and exquisite look. Moon Exports is an Associate in Nursing Indian stone company and therefore the leading Exporter, Manufacturer, Supplier, merchandiser of natural and finest quality stones.

Why we are?

We are renowned for introducing several new stones and finishes. We provide totally different styles of natural stones, like Marble, Granite, Limestone, Slate, are nacreous rock and rock, Cobbles, Palisades, Circles, Pebbles, and Walling Stones, etc Stone Articles, etc Associate in nursing an assortment of Floor Tiles, Paving Tiles, Wall Tiles, and alternative ornamental Tiles. Additionally, we have a tendency to deal with numerous kinds of landscaping stones, tiles and slabs, and wall panels in a very big selection of finishes.

Infrastructure

With the association of large Quarry area for Quartzite & Sandstone and the factories equipped with excellent infrastructural facilities-based Jaipur Capital of Rajasthan India. We can entertain any kind of your requirements with the minimum lead time.

With our skilled procurement team and tie-up with the most reliable sources Direct Quarries and well-established. We can cater you to any kind of demand for Indian natural stones like Marble, Granite, Limestone, Slate, Sandstone and Quartzite, Cobbles, Palisades, Circles, Pebbles, Walling Stones, etc Stone Articles, etc and an assortment of Floor Tiles, Paving Tiles, Wall Tiles, and other Decorative Tiles.

Our Product Range

Marble granite and stone, Tiles and Slab, Granite, Sandstone, Marbles, Limestone, Stone Veneer, Landscaping, Thin Ledge stone Veneer, Stone Circles, Stone Pebbles, Stone Gazebo, Walling Stone, Wall Cladding, Wall Tiles, Rock Face, Stone Wall Murals, Wall Panels, Mosaic Tiles, Artifacts.

Plant and machinery

We have such modern machines which help cut stone blocks from the quarries, designing the required shapes and polishing the stone according to the demand of our valuable customers. We use wire cutters, wire saw heavy-duty excavator and other necessary machines for private excavation works and day-to-day projects.

Our establishment:

Was established in 1631, since then we have enjoyed exponential growth and sale globally. Our success is based upon our ability to respond flexibly to our customer’s individual needs for both large and small projects. We are manufacturers & Exporters of Indian stones like Slates, Sandstones, Limestone’s, Quartzite, and Marble & Granite. We make finishes like hand cut & machine cut, sawn, honed, polished, brushed, tumbled, calibrated, natural cleft on both sides.

Marble, Granite, and Stones of India

We have evolved into the production and manufacturing of blocks, flooring slabs, structural slabs, monuments, tombstones, sculptures, cobbles, pebbles, and landscape garden stones.

Marble

Marble was used for building tombs, temples, and palaces. For a time, it was considered as Royal Stone. It is, however, now used in hotels and homes too.

Granite

India has varieties of granite in over 300 shades. As of 2019, Granite reserves in India were 48500 million cubic meters and ranked fifth in the export of the processed product. Resources are found in Madhya Pradesh, Orissa, Tamil Nadu, Karnataka, Jharkhand, Chhattisgarh, Rajasthan, Telangana, and Andhra Pradesh.

Sandstone

India is among the leading countries when it comes to mining and export of sandstone. The best part with Sandstone from India is that it is available in different colors and considered best for interior as well as exterior use. Few most popular sandstone products from India include names like Tint Mint, White Mint, Mint Fossils, Modak, Agra Red, Rainbow Sandstone, Raj Green, Teak, Buff Brown, Dholpur Chocolate, Beige, Dholpur Pink, Lalitpur Pink, Mandana Red, Jodhpur pink, Jodhpur red, Jaisalmer yellow, etc.

Slate

Slate reserves in India are found in Rajasthan, Behror, Haryana, Himachal Pradesh, Andhra Pradesh, and Madhya Pradesh. Deposits in Rajasthan are spread over the districts of Alwar, Ajmer, Bharatpur, Tonk, Sawai Madhopur, Pali, Udaipur, Churu, and Chittorgarh. Few important names in slate are Jak Black, Silver Shine, Silver grey, Panther, Deoli Green, Peacock, Peacock Multi, Kund Black, Kund Multi, and so on. Being to some extent fragile in nature, it is good for interior use only and can be used even as washboards.

Which Company is the largest producer of marble in India?

Bhandari Marble World in Kishangarh Rajasthan is the largest producer and resource holder of marble in India The state accounts for 90% of India’s marble, Italian marble, Imported marble, International marble, granite, and Natural stone. Marble City in India Kishangarh which is switched in Rajasthan is one of the largest producers of dimensional stone in the world. The production of dimensional stone accounts for almost 30% of the world’s stone and 90% of Indian production.

Where it is located

In Kishangarh marble market:

We are India’s best supplier and manufacturer of high-quality granite, sandstone, and marble in Kishangarh that are procured from the best marble suppliers in the Mable market. We at Bhandari Marble World self-praise over selves as one of the most well-known suppliers of Natural stone from India delivering irreproachable products that the requirement of our respected clients. Our high-quality and good design collection of Imported and Indian marbles that are available in many colors and finishes for your home, restaurants, offices, hospitals, and many more places.

White Marble Manufacturer

Bhandari Marble World is a top white marble and granite manufacturer in India. This marble company is also a renowned marble supplier as it offers a vast array of Italian/Imported marble.

Supplier Traders

Kishangarh Marble Market now becomes Asia’s Biggest Marble Mandi (Market). Here More Than 9000 Marble seller, supplier, Manufacturer and exporter available. We are amongst the best manufacturers and dealers of this enticing natural stone supplying imported marble at factory price from Rajasthan to Delhi, all over India.

Italian marble manufacturer supplier

Marble is one of the most exquisite creations of nature, Italian marble is the most popular and sought-after stone, which comes from the Carrara region of Italy. Italian marble is the ultimate symbol of purity and durability, which was used to create high ended sculptures and edifices earlier. Today you can see marble at every office, home, or luxurious hotel for that elegant look. It gives a rich and luxurious look to any place or setting it is applied to, whether it is your luxurious office table or designer bathroom at home, it is the stone that can bring luxuriously and the most opulent look to your space.

Bhandari Marble World

Kishangarh is the marble capital of India where you will get an extensive array of local and imported marble of every quality. We at Bhandari Marble World get the best quality raw material from Italy and all over the world and get it processed meticulously to bring you the finest quality Italian Marble in Kishangarh. We are amongst the best manufacturers and dealers of this enticing natural stone supplying imported marble at factory price from Rajasthan to Delhi, all over north India. We have a lavish manufacturing unit in Kishangarh, well equipped with world-class machinery and infrastructure to handle large slabs cautiously. Our sumptuous warehouse has a wide range of imported marble at factory price.

Added by an expert team of marble granite and natural stone supplier

3 notes

·

View notes

Text

Cosmetic Dentistry Market Driving Growth on Multiple Trends

Latest Research Study on Global Cosmetic Dentistry Market published by AMA, offers a detailed overview of the factors influencing the global business scope. Cosmetic Dentistry Market research report shows the latest market insights with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors, Challenges and Current Scenario Analysis of the Cosmetic Dentistry. This Report also covers the emerging player’s data, including: competitive situation, sales, revenue and global market share of top manufacturers are Danaher Corporation (United States),Institut Straumann (Switzerland),Dentsply International (United States),Sirona Dental Systems (United States),A-Dec (United States),3M (United States),Align Technology, Inc. (United States),BIOLASE, Inc. (United States),Dentsply Sirona (United States),Align Technology (United States),Planmeca Oy (Finland),.

Brief Summary of Cosmetic Dentistry: Cosmetic dentistry is a method of professional oral care that focuses on improving the appearance of mouth, teeth and smile. In addition, although cosmetic dentistry procedures are usually elective, rather than essential, some cases of treatment provide restorative benefits. Cosmetic dentistry is on the rise, and even a few reality shows have highlighted how a dentist can transform almost anyone’s teeth to give them the smile they desire. Free Sample Report + All Related Graphs & Charts @ : https://www.advancemarketanalytics.com/sample-report/10746-global-cosmetic-dentistry-market-1 Cosmetic Dentistry Market Report offers a detailed overview of this market and discusses the dominant factors affecting the growth of the market. The impact of Porter's five armies on the market over the next few years has been discussed for a long time in this study. We will also forecast global market size and market outlook over the next few years. Types of Products, Applications and Cosmetic Dentistry Market Report Geographical Scope taken as the Main Parameter for Market Analysis. This Research Report Conducts an assessment of the industry chain supporting this market. It also provides accurate information on various aspects of this market, such as production capacity, available production capacity utilization, industrial policies affecting the manufacturing chain and market growth. The Global Cosmetic Dentistry Market segments and Market Data Break Down are illuminated below: by Type (Teeth Whitening, Dental Veneers, Dental Bonding, Dental Implants, Dental Crowns, Inlays & Onlays, Others), Application (Hospitals, Cosmetic Centers, Dental Clinics), End Users (Men, Women, Children) What's Trending in Market: Materials Used Today Are More Durable and Natural Looking Than Those Used In The Past

Restraints: A High Cost of Cosmetic Dentistry May hinder the Adoption

Lack of Reimbursement for Cosmetic Procedures

Market Growth Drivers: Rising Disposable Income of an Individual

Upsurging Demand for Smile Makeover Owing to Increased Awareness among the Consumers

Increase in Demand for Medical Aesthetics

Increasing Incidences of Diastema Worldwide

Region Included are: North America, Europe, Asia Pacific, Oceania, South America, Middle East & Africa

Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc. Enquire for customization in Report @: https://www.advancemarketanalytics.com/enquiry-before-buy/10746-global-cosmetic-dentistry-market-1 Strategic Points Covered in Table of Content of Global Cosmetic Dentistry Market:

Chapter 1: Introduction, market driving force product Objective of Study and Research Scope the Cosmetic Dentistry market

Chapter 2: Exclusive Summary – the basic information of the Cosmetic Dentistry Market.

Chapter 3: Displaying the Market Dynamics- Drivers, Trends and Challenges & Opportunities of the Cosmetic Dentistry

Chapter 4: Presenting the Cosmetic Dentistry Market Factor Analysis, Post COVID Impact Analysis, Porters Five Forces, Supply/Value Chain, PESTEL analysis, Market Entropy, Patent/Trademark Analysis.

Chapter 5: Displaying the by Type, End User and Region/Country 2015-2020

Chapter 6: Evaluating the leading manufacturers of the Cosmetic Dentistry market which consists of its Competitive Landscape, Peer Group Analysis, BCG Matrix & Company Profile

Chapter 7: To evaluate the market by segments, by countries and by Manufacturers/Company with revenue share and sales by key countries in these various regions (2021-2026)

Chapter 8 & 9: Displaying the Appendix, Methodology and Data Source Finally, Cosmetic Dentistry Market is a valuable source of guidance for individuals and companies in their decision framework. Data Sources & Methodology The primary sources involves the industry experts from the Global Cosmetic Dentistry Market including the management organizations, processing organizations, analytics service providers of the industry’s value chain. All primary sources were interviewed to gather and authenticate qualitative & quantitative information and determine the future prospects. In the extensive primary research process undertaken for this study, the primary sources – Postal Surveys, telephone, Online & Face-to-Face Survey were considered to obtain and verify both qualitative and quantitative aspects of this research study. When it comes to secondary sources Company's Annual reports, press Releases, Websites, Investor Presentation, Conference Call transcripts, Webinar, Journals, Regulators, National Customs and Industry Associations were given primary weight-age. Get More Information: https://www.advancemarketanalytics.com/reports/10746-global-cosmetic-dentistry-market-1 What benefits does AMA research studies provides?

· Supporting company financial and cash flow planning

· Latest industry influencing trends and development scenario

· Open up New Markets

· To Seize powerful market opportunities

· Key decision in planning and to further expand market share

· Identify Key Business Segments, Market proposition & Gap Analysis

· Assisting in allocating marketing investments

Definitively, this report will give you an unmistakable perspective on every single reality of the market without a need to allude to some other research report or an information source. Our report will give all of you the realities about the past, present, and eventual fate of the concerned Market.

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Asia. About Author:

Advance Market Analytics is Global leaders of Market Research Industry provides the quantified B2B research to Fortune 500 companies on high growth emerging opportunities which will impact more than 80% of worldwide companies' revenues.

Our Analyst is tracking high growth study with detailed statistical and in-depth analysis of market trends & dynamics that provide a complete overview of the industry. We follow an extensive research methodology coupled with critical insights related industry factors and market forces to generate the best value for our clients. We Provides reliable primary and secondary data sources, our analysts and consultants derive informative and usable data suited for our clients business needs. The research study enable clients to meet varied market objectives a from global footprint expansion to supply chain optimization and from competitor profiling to M&As. Contact Us:

Craig Francis (PR & Marketing Manager) AMA Research & Media LLP Unit No. 429, Parsonage Road Edison, NJ New Jersey USA – 08837 Phone: +1 (206) 317 1218 [email protected] Connect with us at https://www.linkedin.com/company/advance-market-analytics https://www.facebook.com/AMA-Research-Media-LLP-344722399585916 https://twitter.com/amareport

1 note

·

View note

Text

Marine Plywood Manufacturing in India: A Comprehensive Overview

Marine plywood, known for its durability and resistance to moisture, has become a crucial material in the construction and marine industries. India, with its rich forests and growing manufacturing capabilities, has established itself as a significant player in the marine plywood market. This article explores the process of Marine Plywood manufacturers India, the emotional connection workers and manufacturers have with this vital product, and its implications for the industry.

Understanding Marine Plywood

Marine plywood is a specialized type of plywood designed to withstand humid and wet conditions, making it ideal for boat building, docks, and other marine applications. Here are some key characteristics:

Water Resistance: Treated with waterproof adhesives to prevent delamination.

Durability: Made from high-quality wood veneers, ensuring longevity.

Structural Integrity: Stronger and more resilient than standard plywood, suitable for heavy loads.

The Manufacturing Process

The process of manufacturing marine plywood in India involves several stages, each critical to ensuring the final product meets industry standards.

1. Raw Material Selection

Timber Sourcing: High-quality hardwood species like teak, mahogany, and eucalyptus are preferred.

Sustainable Practices: Many manufacturers are now focusing on sustainable forestry to protect the environment.

2. Veneer Production

Log Preparation: Logs are debarked and cut into manageable sizes for veneer production.

Veneer Cutting: Using rotary or slicing methods, the wood is transformed into thin sheets.

3. Drying Process

Moisture Control: Veneers are dried to a specific moisture content to prevent warping and ensure adhesive bonding.

Kiln Drying: This method is commonly used for efficient moisture removal.

4. Adhesive Application

Waterproof Adhesives: Special adhesives are used to bond the veneers, enhancing water resistance.

Pressing: Veneers are stacked and pressed under high pressure to ensure a strong bond.

5. Finishing Touches

Trimming: The edges of the plywood are trimmed to achieve uniform dimensions.

Quality Control: Rigorous testing ensures the plywood meets the necessary standards for marine applications.

6. Packaging and Distribution

Safe Packaging: Plywood is packaged to protect it from moisture during transportation.

Distribution Networks: Efficient logistics ensure timely delivery to customers across India and abroad.

The Emotional Connection of Manufacturers and Workers

The journey of marine plywood manufacturing is not just about the technical process; it is also about the people involved. Workers and manufacturers often share a deep emotional connection to the products they create, which can be observed in various aspects.

Pride in Craftsmanship

Skill Development: Workers take pride in honing their skills and mastering the intricacies of plywood production.

Quality Assurance: A commitment to producing high-quality products fosters a sense of pride in the workplace.

Environmental Responsibility

Sustainability Initiatives: Many manufacturers are motivated by a sense of duty to promote sustainable practices.

Community Impact: By using sustainable materials, manufacturers contribute to the well-being of local communities and ecosystems.

Challenges Faced

Economic Pressures: Fluctuations in demand and rising costs can create stress for workers and manufacturers alike.

Job Security: Uncertainties in the market can lead to anxiety about job stability.

Building Relationships

Teamwork: The collaborative nature of the manufacturing process fosters strong relationships among workers.

Customer Connections: Many manufacturers develop long-lasting relationships with clients, which adds a personal touch to business transactions.

Conclusion

The marine plywood manufacturing industry in India plays a vital role in meeting the demands of construction and marine applications. Through careful selection of raw materials, rigorous manufacturing processes, and a commitment to quality, manufacturers produce a product that is not only durable but also essential for various industries.

Key Takeaways

Importance of Marine Plywood: A crucial material for construction and marine applications, offering water resistance and durability.

Complex Manufacturing Process: Involves multiple stages, each requiring skill and attention to detail.

Human Element: The emotional connection of workers and manufacturers to their craft enhances the quality and integrity of the product.

As India continues to grow as a leader in marine plywood manufacturing, it is essential to balance innovation with sustainable practices, ensuring that the industry thrives while respecting the environment and the communities involved. This balance will not only benefit manufacturers but will also enrich the lives of those who depend on this essential material for their livelihoods.

0 notes

Text

Film Faced Shuttering Plywood Manufacturers

We are a recognized brand of Film Faced Shuttering Plywood Manufacturers in India. We designed this plywood with selected quality of veneer. It's known for its advanced features and elegant look. Now, it’s available in all standard sizes and thicknesses with high strength at the lowest cost.

More Info Visit us: https://www.kangaroplywood.in/film-faced-shuttering-plywood/

1 note

·

View note

Text

Things to know about Film Faced Shuttering Plywood

Shuttering plywood is a term quite commonly used in the construction industry. The shuttering process – pouring the concrete into moulds – cannot happen without using shuttering plywood. This is a kind of plywood which is designed in a way to prevent concrete from coming out of the mould. This material is not used for aesthetic purposes, but to hold concrete till it densifies to form a solid structure. It is weather-resistant and doesn’t stick to the concrete itself. Advance Decorative Laminates is the largest shuttering plywood manufacturer in India that offers a wide range of options.

Advance film faced shuttering plywood rates are more affordable and its most effective constructions.

It has a smooth mirror-like superior finishing on both surfaces and saves costs to quiet an extent when compared to other similar products due to more repetition during shuttering work. It’s the cross-laminated structure between face veneer, core veneer, and the film again enhances the strength of ply.

Application: It is being used widely shuttering in construction of bridges, flyovers, metro projects, shipbuilding, water tanks, cooling towers, all high rise buildings, etc., which need maximum strength and security.

Source: https://advancelam.com/film-faced-shuttering-ply/

1 note

·

View note

Text

Enhancing Plywood Manufacturing: Resolving Core Challenges

Plywood manufacturing, a critical sector for many industries, often encounters a variety of production challenges. Addressing these effectively can significantly improve the quality of the final product.

Key Challenges and Solutions:

Material Selection and Preparation: Opt for high-quality, defect-free logs like pine, spruce, and fir, ensuring they're straight and devoid of knots or rot. Pre-condition logs by soaking to make them pliable and reduce splitting during peeling.

Plywood Defects: Common issues include weak bonding, low wood failure rate, delamination, warping, adhesive penetration, and discoloration of face veneer. Address these by ensuring optimal hot pressing conditions, like correct temperature and pressure, appropriate veneer moisture content, and using high-quality adhesives.

Moisture Management: Since plywood is susceptible to water damage, proper drying techniques like kiln drying to a controlled moisture content are essential. This not only prevents warping and cracking but also enhances adhesive bonding.

Cutting and Finishing Challenges: Plywood's perpendicular grain layers can make it difficult to cut and prone to splintering. Utilize precise cutting tools and techniques. Edges often require finishing with laminate or veneer due to their roughness.

Health and Safety Concerns: The manufacturing process involves risks, such as exposure to volatile organic compounds (VOCs) from adhesives. Ensure adequate ventilation and protective measures for workers.

Quality Control and Grading: Implement rigorous quality control procedures throughout the manufacturing process, from sorting and grading veneers based on appearance and strength to tracking the drying and gluing processes.

Technology Adoption: Incorporating advanced technologies like CNC machining can enhance precision and efficiency, allowing for complex designs and superior product quality.

By tackling these challenges with a comprehensive approach, plywood manufacturers can enhance their production quality and efficiency. It's also crucial to keep abreast of the latest trends and technological advancements in the industry.

In conclusion, exploring the practices and products of the top ten plywood companies in India can offer valuable insights into successful strategies and innovations in plywood manufacturing.

#Top Ten Plywood Companies in India#plywood manufacturing#manufacturer#like#share#best shuttering plywood

0 notes

Text

Marine Plywood Manufacturers in karnataka near Delhi

Introducing our Marine Plywood Manufacturers in Karnataka. We are the top flush door manufacturers in Karnataka. Because, our flush Doors are made of carefully chosen, well-seasoned Pinewood, which is inherently resistant to termites and borers. Moreover, Sylvester Pine is the species we are utilizing because it is the best.

The block board core is encased in face veneers that enclose both sides of the core and is finger-joined (according to BIS Specification) with seasoned pinewood battens (stile & rail). All of these are joined together under extreme pressure and heat using phenol formaldehyde adhesive and long-lasting preservatives. Maximum heat, dust, and noise insulation are ensured by this method. Several sizes range from 25mm to 55mm in thickness. This ISO 2202 and ISO 9001-certified product is of the highest caliber.

Visit Us: Marine Plywood Manufacturers in Karnataka

Contact Information:

Ambika Board Industries

khidripura bundki nagina road najibabad dist bijnor up 246763

Mr. Shobhit Agarwal

+91-9997604863

0 notes