#Epoxy coating

Text

Earrings with white pansies in epoxy resin 🤍

For more please visit my Facebook page VinteWera ❤️ and instagram wercix014

#handmade#my photos#vintage#epoxy clay#unique jewelry#fairycore#żywica epoksydowa#craft#charming#book#handmade ideas#handmade items#faerie#pancy#my artwrok#artists on tumblr#art photography#vintage jewelry#vintage earrings#gardencore#cottagecore#natural#naturecore#pressed flowers#flowers#gorgeous#ethereal#epoxy resin#epoxy coating#girlycore

21 notes

·

View notes

Text

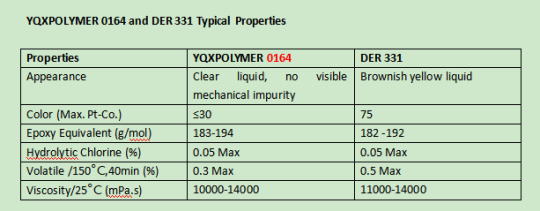

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

Make Sure to Inspect Your Magnets for Rust!

Make Sure to Inspect Your Magnets for Rust!

Magnets are a marvel of the modern world and they are integral to the aquarium hobby being found in a huge range of devices and accessories. Without the attractive field of magnets we wouldn’t have water pumps, return pumps, dosing pumps, and everything they power not to mention the magnet mounts for those pumps, magnetic frag racks, algae clips, or…

#Coating#Custom magnets#epoxy coating#gold magnets#magnet coating#magnet plating#magnetic performance#NdFeB Coating#NdFeB Plating#Neodymium magnets#Nickel plating#Nickel-Copper-Nickel coating#parylene coating#Passivation plating#plastic coating magnets#Teflon#Teflon Neodymium Magnet

0 notes

Text

Sea-Shield After Care Products

Welcome to the Sea-Shield After Care Products Collection, your number one choice for high-quality aftercare goods made especially for boat repair and maintenance. We provide a wide selection of Sea-Shield coatings, rust stain removers, and boat soaps in our collection, all of which have been professionally produced to maintain your boat's durability and perfect condition.

Why Choose Sea-Shield After Care Products

Yacht crew and boat enthusiasts both choose Sea-Shield Coatings because of our dedication to providing high-quality and innovative boat maintenance products. Our selection includes everything you need to maintain the best possible appearance and performance from your boat or yacht, no matter your level of experience as a skipper or sailor.

Above all, our collection of boat soaps provides mild yet effective cleaning options designed to meet the specific needs of maritime surfaces. Our boat soaps have been developed to remove filth, grime, and salt residue from boats without removing necessary protective coatings, leaving the finish looking brand new and shining.

Rust Stain Remover, Boat Repair Soaps, and More

We provide an effective rust stain remover that removes unattractive rust stains from metal surfaces on your yacht and boat soaps. The specially formulated composition of our rust stain remover allows it to deeply penetrate and remove rust spots without harming the surrounding surface, restoring the elegance and soundness of the metal parts of your boat.

Check out our selection of Sea-Shield coatings to improve longevity and provide additional protection from the elements on your boat. Our coatings offer exceptional protection against corrosion, UV rays, and environmental damage since they have been developed using cutting-edge technology. Your boat's durability and worthiness are preserved for years to come with Sea-Shield coatings, providing you peace of mind that it is protected from the resentful boat environment.

Shop Our After-Care Products Today at Sea-Shield Coating.

Explore our collection today and discover the difference that Sea-Shield Coatings can make in your boat’s surface shine and maintenance routine. We offer everything you need to maintain the finest possible look and performance for your boat, season after season, from boat soaps to rust stain removers to Sea-Shield coatings.

#boating product#boat#yacht#ceramic coating#yacht paint polish#yacht product#glass polishing#boating#aftercare#marine shield coating#fur coat#sea shield#metal coating#powder coating#epoxy coating

0 notes

Text

Epoxy Adhesives & Glue For Maintenance- Astral Adhesive

Astral epoxy glue is perfect superior bonding solution for repairing metal, wood, plastic, or rubber. It has strong resistance to heat, chemicals, and weathering.

0 notes

Text

Epoxy Floor Coating Manufacturers in India - MB Enterprises

#epoxy coating#resin manufacturers#epoxy resin manufacturers#epoxy resin manufacturers in india#epoxy flooring manufacturers#epoxy floor coating manufacturers

0 notes

Text

Epoxy Resin Manufacturers in India | Bhor Chemicals

Explore Bhor’s advanced Resin Matrix Systems, engineered for superior performance across various industries. As leading Epoxy Resin Manufacturers in India, Bhor offers high-quality, durable solutions tailored to meet the specific demands of composite applications, ensuring strength, flexibility, and long-lasting results.

0 notes

Text

Installing Epoxy During Hot Installation Conditions

Installing epoxy at high temperatures can present several challenges, which can affect the performance and durability of the epoxy. Here are some common issues:

Accelerated Curing

High temperatures can cause the epoxy to cure much faster than intended. This can reduce the working time and make it difficult to properly mix and apply the epoxy before it begins to set.

Bubbles and…

#Epoxy#epoxy coating#epoxy resin#epoxy systems#epoxy.com#epoxy.com 100% solids products#Epoxy.com low VOC products#Epoxy.com Zero (0) VOC Products#high temperature of epoxy#hot#hot temperature#hot temperature epoxy installation#Low VOC

0 notes

Text

Conquer Crumbling Floors: Your Guide to Floor Repair in Indore

Introduction

Is your once-pristine floor now marred by cracks, unevenness, or stubborn stains? Don't despair! SK Enterprises, Indore's trusted floor repair specialists, are here to help. We offer a comprehensive range of floor repair services to restore your floors to their former glory and enhance the beauty and value of your property.

Common Floor Repair Issues in Indore

Indore's climate can present unique challenges for flooring. Here are some common issues we address:

Cracks and gaps: Caused by foundation settling, moisture fluctuations, or improper installation.

Uneven surfaces: Uneven subfloors, improper leveling during installation, or wear and tear.

Stains and discoloration: Spills, pet accidents, sun damage, or improper cleaning products.

Tile lifting or cracking: Moisture issues, improper installation, or heavy object impact.

Scratches and scuffs: High foot traffic, furniture movement, or dropping objects.

SK Enterprises: Your One-Stop Floor Repair Solution

At SK Enterprises, we provide expert solutions for all your floor repair needs. Here's what sets us apart:

Skilled and experienced technicians: Our team is equipped with the knowledge and expertise to handle any floor repair challenge.

Wide range of services: We handle repairs for various flooring types, including tile, wood, laminate, vinyl, and concrete.

High-quality materials: We use only the best materials to ensure long-lasting repairs.

Competitive pricing: We offer fair and transparent pricing without compromising quality.

Efficient and timely service: We understand the inconvenience of floor repairs. We prioritize completing the job efficiently while maintaining meticulous standards.

Beyond Repair: When to Consider Floor Replacement

While we're skilled at revivifying floors, there are situations where replacement might be a better option. Here are some signs:

Extensive damage: When the repair cost is comparable to replacement.

Moisture problems: If the subfloor or underlying structure is damaged by water.

Outdated or incompatible flooring: If the existing flooring is incompatible with your renovation plans.

Maintaining Your Repaired Floors for Lasting Beauty

Preventive maintenance is key to extending the life of your repaired floors. Here are some tips:

Use appropriate cleaning products: Harsh chemicals can damage the floor's surface.

Place mats and rugs in high-traffic areas: Reduce wear and tear.

Regularly sweep and vacuum: Prevent dirt and grit from accumulating.

Address spills promptly: Avoid stains and potential damage.

Contact SK Enterprises Today!

Don't let damaged floors detract from your property's charm. Contact SK Enterprises, Indore's leading floor repair specialists, for a free consultation. We'll assess your floor's condition, recommend the most suitable repair solution, and provide a competitive quote. Breathe new life into your floors and reclaim the beauty of your space.

0 notes

Text

Expert Tips for Varnishing Wood: Enhance and Protect with Make Wood Good Products.

Varnishing wood is an essential step in protecting and enhancing its natural beauty. Whether you are a seasoned woodworker or a DIY enthusiast, understanding the best practices for varnishing can make a significant difference in the final outcome. Here's a comprehensive guide with tips for varnishing wood, inspired by the expertise and products available on the Make Wood Good website.

Understanding Varnish and Its Benefits

Varnish is a transparent, hard, protective finish or film primarily used in wood finishing. It is traditionally a combination of a drying oil, a resin, and a thinner or solvent. Varnishing provides several benefits:

Protection: Shields the wood from moisture, UV rays, and physical damage.

Enhancement: Enhances the wood's natural grain and color.

Durability: Provides a hard, long-lasting finish that can withstand wear and tear.

Choosing the Right Varnish

Make Wood Good offers a variety of high-quality varnishes tailored to different needs. When selecting a varnish, consider the following factors:

Type of Wood: Different woods may react differently to certain varnishes.

Intended Use: Indoor vs. outdoor, high-traffic areas, etc.

Desired Finish: Glossy, semi-gloss, or matte finishes.

Environmental Impact: Low-VOC or eco-friendly options are preferable for indoor projects.

Preparing the Wood Surface

Clean the Wood: Ensure the wood is clean, dry, and free from dust, dirt, and grease. Use a damp cloth to wipe it down if necessary.

Sand the Surface: Sand the wood to create a smooth surface. Start with a medium-grit sandpaper (120-150 grit) and finish with a fine-grit sandpaper (220-240 grit). Always sand in the direction of the wood grain.

Remove Dust: After sanding, thoroughly remove all dust using a vacuum or a tack cloth. Dust can ruin the finish by creating a rough texture.

Applying the Varnish

Stir the Varnish: Gently stir the varnish to mix the contents. Avoid shaking the can as it can introduce bubbles.

Test the Varnish: Apply a small amount of varnish on a hidden area or a scrap piece of the same wood to test the color and finish.

First Coat: Apply the first coat using a high-quality, natural-bristle brush or a foam brush. Use long, even strokes in the direction of the wood grain.

Let it Dry: Allow the first coat to dry completely. Drying times can vary depending on the type of varnish and environmental conditions. Refer to the product instructions for specific drying times.

Sanding Between Coats

Light Sanding: Once the first coat is dry, lightly sand the surface with a fine-grit sandpaper (320-400 grit). This helps to smooth out any imperfections and provides a better surface for the next coat.

Clean the Surface: Remove all sanding dust with a vacuum or a tack cloth before applying the next coat.

Applying Additional Coats

Second Coat: Apply the second coat of varnish in the same manner as the first, using smooth, even strokes. Ensure that the coat is thin and well-distributed.

Repeat the Process: Depending on the desired finish and the type of varnish, you may need to apply multiple coats. Typically, 2-3 coats are sufficient for most projects. Sand lightly between each coat and clean the surface before the next application.

Final Touches

Final Sanding: After the final coat has dried completely, you may perform a very light sanding with ultra-fine sandpaper (600 grit) if a super-smooth finish is desired.

Polishing: For a high-gloss finish, you can polish the surface using a soft cloth and a suitable polishing compound. This step is optional and should be done carefully to avoid damaging the finish.

Maintaining the Varnished Surface

Regular Cleaning: Clean the varnished surface with a damp cloth and mild soap. Avoid abrasive cleaners that can scratch the finish.

Avoid Moisture: Minimize exposure to excessive moisture to prevent the varnish from becoming cloudy or peeling.

Touch-Ups: For minor scratches or wear, lightly sand the affected area and apply a thin coat of varnish to restore the finish.

Common Mistakes to Avoid

Skipping Surface Preparation: Proper preparation is crucial for a smooth and durable finish.

Applying Thick Coats: Thick coats can lead to drips, uneven drying, and a less durable finish. Thin, even coats are better.

Ignoring Drying Times: Rushing through drying times can result in a tacky or uneven finish.

Not Sanding Between Coats: Sanding between coats ensures better adhesion and a smoother final result.

Choosing Make Wood Good Products

Make Wood Good offers a range of products that cater to various wood finishing needs. Here are a few recommendations:

Bonda Wood Hardener: Ideal for strengthening and stabilizing rotted or decayed wood before varnishing.

Timberguard Varnish: Provides excellent protection against UV rays and moisture, suitable for both indoor and outdoor use. Eco Varnish: An environmentally friendly option with low VOCs, perfect for indoor projects.

Conclusion

Varnishing wood is a rewarding process that enhances the natural beauty and durability of the material. By following these tips for varnishing wood and using high-quality products from Make Wood Good, you can achieve a professional finish that will protect your wood for years to come. Whether you're working on furniture, flooring, or outdoor projects, the right varnish and proper technique are key to a successful outcome. For more detailed information and to explore their full range of products, visit the Make Wood Good website.

#using varnish on wood#tips for varnishing wood#epoxy coating#marine premium wood sealer#wood epoxy sealer

0 notes

Text

Garage epoxy is a coating applied to garage floors to provide a durable and long-lasting finish. It is made of a two-part resin and hardener mixture that, when combined, creates a chemical reaction that results in a hard and durable surface. Garage epoxy is an excellent choice for any type of property because it is resistant to stains, chemicals, and abrasions, making it ideal for high-traffic areas such as garages and workshops.

It also provides a non-slip surface that is safe for walking and working on, even when wet. Also, garage epoxy is available in several decorative finishes, allowing you to create a customized look that complements your home or business. Overall, garage epoxy is an excellent investment for anyone looking to improve the functionality and appearance of their garage or workshop.

The garage epoxy installation process typically involves several steps. The first step is to prepare the garage floor’s surface by thoroughly cleaning it and repairing any cracks or imperfections. Next, the epoxy coating is applied to the floor in multiple layers, with each layer allowed to cure before the next one is applied. The exact number of layers depends on the specific type of epoxy being used and the condition of the garage floor.

After the final layer of epoxy has been applied, a topcoat is typically added to provide additional protection and a glossy finish. The installation process usually takes several days to complete, with the floor needing time to cure between layers. Our process is proven efficient and sets us apart from other companies in the area.

#Epoxy Flooring#Epoxy Coating#Concrete Polishing#Concrete Sealing#Concrete Coating#Metallic Epoxy Floor

0 notes

Text

Epoxy Self-Leveling is Ideal for Commercial & Industrial Flooring

Epoxy self-leveling, also known as epoxy self-flowing floor and epoxy ground, is made of epoxy resin as the main material, curing agent, diluents, solvents, dispersants, defoamers and some fillers and other mixed processing of epoxy floor coating, combined with a specific floor construction process, on-site ground decorative construction of a class of flooring. This process can be based on the unevenness of the ground downstream flow, the ground for automatic leveling, and rapid drying, after curing the ground will form a smooth, flat, seamless mirror effect surface layer. In addition, self-leveling also has moisture-proof, antibacterial, anti-corrosion and other characteristics.

Main characteristics of epoxy self-leveling

Epoxy self-leveling has chemical properties such as water resistance, oil resistance, acid and alkali resistance, salt spray corrosion resistance, and physical properties such as abrasion resistance, stamping resistance and scrub resistance. And the surface is bright, flat, beautiful, no joints, easy to clean, easy maintenance, durable, can meet the needs of modern industry on the floor, in the flooring materials occupy an important position, is the ideal long-lasting flooring materials for modern industry, and has been widely used in medicine, automobile, electronics, food, electricity, chemical industry and other industrial floor decoration.

Epoxy self-leveling composition

Epoxy self-leveling includes two parts: concrete base and epoxy self-leveling floor coating.

Concrete grass-roots level: The concrete with strength level not less than C25 is poured and moulded at one time, when the floor has the requirement of pressure resistance and impact resistance, the concrete grass-roots level can be processed by two-way reinforcing steel mesh.

Epoxy self-leveling floor coating: bottom coating, middle coating, putty layer, top coating.

The bottom coating is epoxy primer, using penetration and adhesion of epoxy primer, continuous and uniform coating film, no leakage, to enhance the adhesion of the grass-roots surface.

The middle coating is epoxy mortar layer, epoxy two-component add appropriate amount of 100 mesh quartz sand, enhance the smoothness of the coating surface and the strength of the coating.

Putty layer for epoxy putty layer, epoxy two-component add appropriate amount of putty powder, further leveling of the coating surface, to achieve a flat surface, smooth.

The top coating is coated with colour paint, and the self-leveling epoxy top coating is evenly troweled.

Epoxy self-leveling construction precautions

Epoxy self-leveling floor coating is a kind of epoxy resin, it is widely used in building construction, is a kind of environmentally friendly and harmless paint. It can ensure that the ground after the construction of non-skinning, as well as the flatness of the grass-roots level and surface strength, but also to fill the ground base of the original cuts or cracks, to ensure that the surface effect of self-leveling and anti-cracking. At the same time, the product can also be high-pressure washing of the grass-roots level to ensure that the ground clean.

However, epoxy self-leveling floor coating in the use of the process there are some precautions that must be observed, otherwise it will cause some irreparable damage to the building construction.

Construction temperature needs to be ≥5℃, if you want to construct in <5℃ need to choose special formula. Humidity is recommended for construction below 75%.

Construction to ensure air circulation, modulation of the amount of use, not more than 30 minutes.

Construction process to do a good job of maintenance, to avoid the intrusion of dust and debris, affecting the effect of paint.

After the construction is completed, it needs to be maintained for at least 7 days before being put into use. During the maintenance period, especially can not have water or all kinds of solution infiltration.

It is strictly prohibited to mix with other paints.

Must be strictly in accordance with the prescribed proportion of the addition of curing agent.

Keep the surface of the coated material clean, and the water content of the coated material must be less than 7%.

Keep the painting environment clean, it is strictly prohibited to construct in the environment with a lot of dust.

Epoxy self-leveling coating characteristics

Epoxy self-leveling coating is made of epoxy resin and special curing agent as main material, and is processed by adding various auxiliaries, pigments and fillers through strict proportioning. It not only has excellent chemical properties such as water resistance, oil resistance and chemical corrosion resistance, but also has the advantages of good adhesion, high mechanical strength, low shrinkage of paint film after curing, and can be coated into a thick film at a time, so it is widely used in modern industrial flooring.

The coating film is tough, wear-resistant, good chemical resistance, non-toxic and non-flammable.

The surface is smooth and clean, with good decorative properties, and can meet the requirements of class 100 cleanliness level.

It has high adhesion, strong mechanical strength, chemical resistance and good electrical properties.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#epoxy self-leveling#epoxy self-leveling flooring#epoxy self-leveling floor coating#self-leveling epoxy#epoxy coating

0 notes

Text

FAQ of Plastic & Rubber Coating Magnets

FAQ of Plastic & Rubber Coating Magnets

Here is a collection of questions that people commonly ask about plastic and rubber coated magnets.

Variety packs of strong, colorful plastic coated neodymium magnets

What is a plastic or rubber coated magnet?

A plastic or rubber coated magnet is simply a nickel plated magnet with a an additional coating of plastic or rubber. This coating not only provides…

#Coating#Custom magnets#epoxy coating#gold magnets#magnet coating#magnet plating#magnetic performance#NdFeB Coating#NdFeB Plating#Neodymium magnets#Nickel plating#Nickel-Copper-Nickel coating#parylene coating#Passivation plating#plastic coating magnets#Teflon#Teflon Neodymium Magnet

0 notes

Text

Professional Epoxy Flooring Singapore

Epoxy flooring is a versatile and durable flooring solution increasingly popular in Singapore for both residential and commercial properties. When it comes to installing epoxy flooring, engaging professional services like AS DECO & CONSTRUCTION PTE. LTD. ensures optimal results. Let's explore the importance of professional epoxy flooring services and what AS DECO & CONSTRUCTION PTE. LTD. has to offer.

Introduction to Epoxy Flooring

Epoxy flooring is a type of surface coating made from epoxy resin and hardeners. It creates a smooth, seamless, and highly durable finish suitable for various applications, including garages, warehouses, showrooms, kitchens, and industrial spaces. Professional installation is crucial to achieve the desired level of performance and longevity.

Benefits of Epoxy Flooring

Durability and Longevity

Epoxy flooring is renowned for its exceptional durability, capable of withstanding heavy foot traffic, impact, and chemical spills. With proper maintenance, epoxy floors can last for decades, making them a cost-effective flooring solution in the long run.

Easy Maintenance

Unlike other flooring options that require regular waxing or polishing, epoxy floors are easy to clean and maintain. They resist stains, moisture, and dirt buildup, requiring only routine sweeping and occasional mopping to keep them looking pristine.

Aesthetic Appeal

Epoxy flooring offers endless design possibilities, ranging from solid colors to intricate patterns and metallic finishes. It can enhance the visual appeal of any space while providing a seamless and polished surface.

Choosing the Right Epoxy Flooring Service

When selecting an epoxy flooring service provider in Singapore, it's essential to consider the following factors:

Experience and Expertise: Choose a company with a proven track record and extensive experience in epoxy flooring installation.

Quality of Materials: Ensure that high-quality epoxy resins and coatings are used to achieve durable and long-lasting results.

Customer Satisfaction: Look for testimonials and reviews from previous clients to gauge the level of customer satisfaction and service quality.

Steps Involved in Professional Epoxy Flooring Installation

Professional epoxy flooring installation typically follows a systematic process:

Surface Preparation: Thoroughly clean and prepare the existing surface to ensure proper adhesion of the epoxy coating.

Application Process: Apply the epoxy resin and hardener mixture evenly onto the prepared surface using specialized equipment and techniques.

Curing and Drying: Allow the epoxy coating to cure and dry completely according to the manufacturer's instructions to achieve maximum durability and strength.

Cost Considerations

The cost of epoxy flooring installation varies depending on factors such as the size of the area, the condition of the existing surface, and the complexity of the design. While it may require a significant upfront investment, the long-term benefits, including durability and low maintenance, make it a worthwhile investment.

Maintenance and Care Tips

To prolong the lifespan of epoxy flooring and keep it looking its best, regular maintenance is essential:

Cleaning and Upkeep: Sweep or vacuum the floor regularly to remove debris and dirt. Mop with a mild detergent solution as needed to maintain its shine.

Preventive Measures: Use floor mats or rugs in high-traffic areas to protect the epoxy surface from wear and tear. Avoid dragging heavy furniture or equipment across the floor to prevent scratches.

Popular Epoxy Flooring Designs

In Singapore, popular epoxy flooring designs include:

Solid Colors: Choose from a wide range of solid colors to complement any interior design scheme.

Metallic Finishes: Create a luxurious and modern look with metallic epoxy flooring that mimics the appearance of polished metal.

Custom Patterns: Customize epoxy floors with intricate patterns, logos, or graphics to add a personal touch to any space.

Case Studies: Successful Epoxy Flooring Installations

AS DECO & CONSTRUCTION PTE. LTD. has a proven track record of successful epoxy flooring installations across Singapore. Here are some examples:

Case Study 1: Residential Garage Transformation

Case Study 2: Commercial Showroom Renovation

FAQs About Epoxy Flooring Installation

How long does epoxy flooring installation take?

The duration varies depending on the size and complexity of the project but typically ranges from a few days to a week.

Is epoxy flooring suitable for outdoor areas?

While epoxy flooring is primarily designed for indoor use, certain formulations are suitable for outdoor applications with proper preparation and sealing.

Can epoxy flooring be applied over existing surfaces?

Yes, epoxy flooring can be applied over concrete, tile, or other existing surfaces after proper preparation to ensure adhesion.

Is epoxy flooring slippery when wet?

Epoxy flooring can be slippery when wet, but adding slip-resistant additives during installation can improve traction and safety.

How long does epoxy flooring last?

With proper maintenance, epoxy flooring can last for 10-20 years or more, depending on usage and environmental factors.

Conclusion

Professional epoxy flooring installation services provided by AS DECO & CONSTRUCTION PTE. LTD. offer a durable, low-maintenance, and visually appealing flooring solution for residential and commercial properties in Singapore. By choosing experienced professionals and high-quality materials, property owners can enjoy long-lasting and aesthetically pleasing epoxy floors.

#epoxy flooring#epoxyfloorcoatings#epoxycoating#flooring#home decoartion#home & lifestyle#epoxy coating#homedecor#home decor#flooring contractor#flooring installation#interior design#home renovation#flooring services#home design#flooring company#bathroom remodeling#epoxy resin

0 notes

Text

Conkrete Ink: Expert Epoxy Floor Installers for Residences, Offices, and More

Transform your space with Conkrete Ink, your trusted epoxy floor installers. Our skilled team specializes in delivering high-quality, durable epoxy flooring solutions for residential, commercial, and industrial spaces. Whether you need a sleek, modern finish for your home or a robust, industrial-grade floor for your business, Conkrete Ink has you covered. Elevate your floors with Conkrete Ink today!

0 notes

Text

Explore the Best Epoxy Floor Coating Manufacturers

When exploring the best epoxy floor coating manufacturers, it's essential to consider quality, reliability, and expertise. Look for manufacturers with a proven track record of delivering durable and high-performance coatings. Check customer reviews and testimonials to gauge satisfaction levels and product effectiveness.

Additionally, consider factors like customization options, technical support, and industry certifications. With MB Enterprises, you get all these qualities and more. As a trusted brand in the epoxy flooring industry, MB Enterprises offers premium quality coatings, personalised solutions, and excellent customer service. Choose MB Enterprises for your epoxy floor coating needs and experience the difference in quality and performance.

0 notes