#Epoxy Composite Market

Explore tagged Tumblr posts

Text

Key Players in Epoxy Composite Market: A Competitive Landscape Overview

The global epoxy composite market size is expected to reach USD 55.97 billion by 2028, registering a CAGR of 8.3% over the forecast period, according to a new report by Grand View Research, Inc. Growing usage of advanced lightweight functional materials in various industries, such as automotive & transportation, aerospace & defense, and wind energy, is expected to drive the market.

Increasing demand for composites in the automotive industry is anticipated to boost the market growth over the forecast period. Rising fuel prices have triggered the need for fuel-efficient vehicles, which is expected to increase the usage of composites. Composites are majorly utilized as the replacement for aluminum, wood, and steel on account of their higher strength-to-weight ratio.

The high manufacturing cost of composites is challenging the growth and profitability of the market across the world. In addition, initial capital investment is anticipated to pose a challenge over the forecast period. Companies, such as Toray Industries and Teijin Ltd., are integrated across the value chain of composites ranging from raw material supply to distribution activities and have also diversified their product offerings.

Gather more insights about the market drivers, restrains and growth of the Epoxy Composite Market

Epoxy Composite Market Report Highlights

• The glass fiber reinforced epoxy composites segment accounted for the highest revenue share of more than 60% in 2020 as a result of high demand due to their superior characteristics along with cost-effectiveness

• The automotive & transportation application segment dominated the global market and is expected to register a significant CAGR over the forecast period

• The wind energy application segment is expected to witness the fastest CAGR of more than 9% due to high product demand in this application or ensuring shape stability, structural strength, and damage resistance to wind turbine rotor blades

• Asia Pacific led the global market in 2020, in terms of revenue share, owing to the presence of a robust automotive manufacturing base in the region

• Key companies have undertaken various initiatives, such as technology innovations, R&D, partnerships, and mergers & acquisitions, to manufacture cost-effective and lightweight composite products

Epoxy Composite Market Segmentation

Grand View Research has segmented the global epoxy composite market on the basis of fiber type, end-use, and region:

Epoxy Composite Fiber Type Outlook (Revenue, USD Million, 2017 - 2028)

• Glass Fiber

• Carbon Fiber

• Other Fibers

Epoxy Composite End-use Outlook (Revenue, USD Million, 2017 - 2028)

• Automotive & Transportation

• Aerospace & Defense

• Wind Energy

• Electrical & Electronics

• Sporting & Consumer Goods

• Other End-uses (Oil & Gas, Marine, Construction)

Epoxy Composite Regional Outlook (Revenue, USD Million, 2017 - 2028)

• North America

o U.S.

o Canada

o Mexico

• Europe

o U.K.

o Germany

o France

o Italy

• Asia Pacific

o China

o India

o Japan

o Australia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o South Africa

Order a free sample PDF of the Epoxy Composite Market Intelligence Study, published by Grand View Research.

#Epoxy Composite Market#Epoxy Composite Market Analysis#Epoxy Composite Market Report#Epoxy Composite Market Size#Epoxy Composite Market Share

0 notes

Text

The global epoxy composite market size reached US$ 34.3 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 54.9 Billion by 2032, exhibiting a growth rate (CAGR) of 5.3% during 2024-2032.

0 notes

Text

#Epoxy Composite Resin#Epoxy Composite Resin Market#Epoxy Composite Resin Market Size#India Market News

0 notes

Text

Bonding Excellence: Navigating Trends in the Epoxy Adhesive Market

Adhesives are essential products that are often overlooked. They’re noticed, until they fail. If your supports aren’t correctly fused, it could bring about disjointed parts, damaged equipment, and worn-out piping systems.

So, this blog has the ins and outs of epoxy adhesives, which can help you secure the pipe supports with confidence.

What Is an Epoxy Adhesive?

From time-to-time epoxy adhesives are confused with bonding products like glue. However, they’re far more complex than most adhesives. These are often called structural adhesives These terms make their role clearer: They’re high-performance adhesives meant for applications calling for powerful bonding, such as aircraft, automobiles, aerospace technology, or heavy process piping systems.

Uses of Epoxy Adhesives Coming to process piping systems, the epoxy adhesives have a vital role to play. These systems frequently require to join unlike materials together, like composite pipe shoes and metal piping. Besides, adhesives need to hold structures together in heavy vibrations, high pressure, and corrosive environments.

An area where epoxy adhesives have advantage is when you’re including pipe supports like wear pads, pipe shoes, and Flat Plates. That’s since this mixture enables to install without welding.

Benefits of Epoxy Adhesives? • By safeguarding pipes or adding wear pads to the system, raw piping can be insulated. Suddenly, you’ve protected pipes from metal-on-metal contact deprived of the high cost of specialized labor. Also, by eliminating welding, you’ll be evading susceptible spots requiring special heat treatments. • These pipe supports can increase the life of the systems, need to be held together. These adhesives work pretty well since they are sturdy and can stand extreme environments. • An epoxy can also work as a sealant filling open gaps. This guards pipes and supports from corrosion.

Different Kinds of Epoxy Adhesives There are numerous epoxy adhesives, but they can be split into two one-component and two-component

One-Component Adhesives These more often than not come as a single paste. Though, the name can deceive a few. Though they come as only a single physical substance, they still require external elements to start the curing process. That means they require moisture, heat treatment, or special lighting for bonding.

Two-Component Adhesives These require you to blend two elements. When applied properly, the outcome is a powerful bond. Though, since two-part adhesives need mixing, there’s the likelihood for a human error.

What’s the Solution? If you desire to get the paybacks of a two-component adhesive without mixing the right ratio or getting it on the skin, use a static applicator. This loads onto a standard epoxy cartridge and brings a two-part epoxy in a flawless mixing ratio, saving the mess and guesswork that from time to time come with physically mixing two-component epoxies.

Due to the increasing demand for these adhesives in numerous industries, the total value of the epoxy adhesives will reach $13,484 million by 2030.

#epoxy adhesive#adhesive technology#market trends#industrial applications#construction industry#global market outlook#bonding solutions#market dynamics#epoxy resin#research and development#composite materials#market growth factors#aerospace applications

0 notes

Text

Revolutionising Electrical Systems – The Rise of Customised Epoxy Insulators

In the realm of electrical engineering and power distribution, innovation is the key to efficiency, reliability, and safety. One such groundbreaking development is the rise of customised epoxy insulators. Epoxy insulators are transforming the landscape of electrical systems, providing superior performance and durability. As epoxy insulators manufacturers in India continue to push the boundaries of technology, the benefits of these innovative products are becoming increasingly evident. This blog explores the revolutionary impact of customised epoxy insulators on electrical systems, highlighting their applications, advantages, and the leading manufacturers driving this transformation.

Understanding Epoxy Insulators

Epoxy insulators are a type of electrical insulator made from epoxy resin, a material known for its excellent electrical properties, mechanical strength, and resistance to environmental factors. These insulators are designed to withstand high voltage and harsh conditions, making them ideal for a wide range of applications in power distribution and electrical engineering.

Traditionally, electrical insulators have been made from materials such as porcelain and glass. However, epoxy insulators offer several advantages over these conventional materials, including higher mechanical strength, lighter weight, and better resistance to environmental degradation. This has led to a growing adoption of epoxy insulators in various sectors, from industrial power distribution to transportation systems.

The Advantages of Customised Epoxy Insulators

Customisation is a significant trend in the epoxy insulator market, allowing for tailored solutions that meet specific requirements and challenges. Here are some of the key advantages of customised epoxy insulators:

Enhanced Performance and Reliability

Customised epoxy insulators are designed to meet the unique demands of specific applications, ensuring optimal performance and reliability. By tailoring the design and composition of the insulator, manufacturers can enhance its electrical and mechanical properties, resulting in better performance under high voltage and extreme conditions.

Improved Durability and Longevity

Epoxy insulators are known for their durability and resistance to environmental factors such as moisture, chemicals, and UV radiation. Customisation further enhances these properties, ensuring that the insulators can withstand the rigours of their operating environments and provide long-lasting performance.

Cost-Effective Solutions

While the initial cost of customised epoxy insulators may be higher than standard insulators, their enhanced performance and longevity result in lower maintenance and replacement costs over time. This makes them a cost-effective solution for businesses looking to improve the reliability and efficiency of their electrical systems.

Flexibility in Design

The customisation process allows for flexibility in design, enabling manufacturers to create insulators that meet specific dimensional and performance requirements. This is particularly beneficial for applications with unique challenges or constraints, such as limited space or high-stress environments.

Environmental Benefits

Epoxy insulators are often more environmentally friendly than their traditional counterparts, as they require fewer resources to produce and have a longer lifespan. Customisation can further enhance these benefits by optimising the design for reduced material usage and improved energy efficiency.

Applications of Customised Epoxy Insulators

The versatility of customised epoxy insulators makes them suitable for a wide range of applications across various industries. Some of the key applications include:

Power Distribution and Transmission

In the power distribution and transmission sector, customised epoxy insulators are used in high-voltage applications to ensure the safe and efficient transfer of electricity. Their superior electrical properties and durability make them ideal for use in substations, transformers, and switchgear.

Transportation Systems

One of the critical applications of epoxy insulators is in transportation systems, particularly in railways. Epoxy insulators for third rail systems are essential components that ensure the safe and reliable transmission of power to trains. These insulators need to withstand high voltage, mechanical stress, and environmental factors, making customisation crucial for optimal performance.

Industrial Applications

In industrial settings, customised epoxy insulators are used in a variety of applications, including machinery, equipment, and power distribution networks. Their ability to withstand harsh conditions and high voltage makes them ideal for use in manufacturing plants, chemical facilities, and other industrial environments.

Renewable Energy

The renewable energy sector also benefits from the use of customised epoxy insulators, particularly in wind and solar power systems. These insulators are designed to handle the unique challenges of renewable energy applications, such as exposure to harsh weather conditions and fluctuating power loads.

Leading Epoxy Insulators Manufacturers in India

India is home to several leading manufacturers of epoxy insulators, who are at the forefront of innovation and customisation in this field. Some of the top epoxy insulators manufacturers in India include:

Radiant Enterprises

Radiant Enterprises is a prominent name in the epoxy insulator market, known for its commitment to quality and innovation. The company offers a wide range of customised epoxy insulators for various applications, including power distribution, transportation, and industrial use. Radiant Enterprises' focus on research and development ensures that its products meet the highest standards of performance and reliability.

ABC Insulators

ABC Insulators is another leading manufacturer in India, specialising in the production of high-quality epoxy insulators. The company offers customised solutions to meet the specific needs of its clients, ensuring optimal performance and durability. ABC Insulators' state-of-the-art manufacturing facilities and experienced team make it a trusted partner for businesses across various industries.

XYZ Electricals

XYZ Electricals is a renowned name in the electrical insulator market, offering a wide range of epoxy insulators for different applications. The company's customised solutions are designed to meet the unique requirements of its clients, providing superior performance and reliability. XYZ Electricals' commitment to quality and innovation has made it a leading player in the Indian market.

The Future of Customised Epoxy Insulators

The future of customised epoxy insulators looks promising, with several trends and developments set to drive further innovation and growth in this field. Some of the key trends to watch include:

Advancements in Material Science

Ongoing research and development in material science are expected to lead to the creation of new epoxy resin formulations with enhanced properties. These advancements will further improve the performance and durability of customised epoxy insulators, making them even more effective for a wide range of applications.

Increased Focus on Sustainability

As businesses and industries place greater emphasis on sustainability, the demand for environmentally friendly insulators will continue to grow. Customised epoxy insulators, with their long lifespan and reduced environmental impact, are well-positioned to meet this demand. Manufacturers will likely focus on developing even more sustainable solutions in the future.

Integration with Smart Technologies

The integration of epoxy insulators with smart technologies, such as sensors and IoT devices, is another trend to watch. This integration will enable real-time monitoring and diagnostics, improving the reliability and efficiency of electrical systems. Customisation will play a crucial role in developing smart insulators that meet the specific needs of different applications.

Expansion into New Markets

The market for customised epoxy insulators is expected to expand into new regions and industries as awareness of their benefits grows. This expansion will create new opportunities for epoxy insulators manufacturers in India, driving further innovation and growth in the market.

Conclusion

Customised epoxy insulators are revolutionising electrical systems, offering superior performance, durability, and cost-effectiveness. As epoxy insulators manufacturers in India continue to innovate and push the boundaries of technology, the future looks bright for this transformative product. By leveraging the advantages of customised epoxy insulators, businesses across various industries can enhance the reliability and efficiency of their electrical systems, ensuring long-term success and sustainability.

#Epoxy insulator for third rail#Epoxy insulators#Epoxy Insulators manufacturers in India#Customised epoxy insulators manufacturers in India

4 notes

·

View notes

Text

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

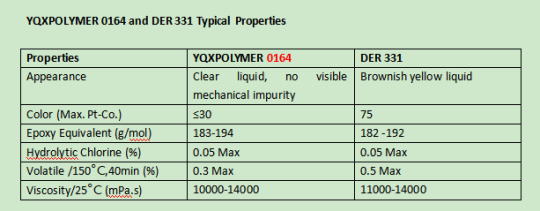

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

A Guide To Choose The Right Concrete Sealers For Home

Maintaining the efficiency of the commercial property is extremely important especially the concrete that makes the floor pitch perfect. In fact, not just maintaining but preventing the damage to concrete is equally essential. Concrete is one of the crucial construction elements owing to its strength and longevity. However, because concrete is porous, it can absorb soluble salts and water, which can be harmful. Furthermore, the absorption of salts by the concrete, especially chlorides, can eventually lead to corrosion problems when steel reinforcement is inserted in the concrete to strengthen it.

As a result, opting for the right type of concrete sealers is of utmost necessity. It ensures protection by shielding surfaces from a wide range of water-related issues caused by the cycles of thawing and freezing, stains from dirt, oil, and other impurities. In addition, it also prevents an individual from investing unnecessarily.

Understanding The Role Of Concrete Sealers

The sealers for concrete are intended to provide protection for the concrete's surface against degradation, rust, and discolouration over time. Most concrete surface degradation is usually caused by surface moisture penetration. It's essential to safeguard and preserve the concrete surfaces while doing regular maintenance to increase their lifespan. Concrete sealers function by covering your concrete's surface or by penetrating into its pores and attaching to its inherent attributes. There are several types of sealers and choosing the right one can be the game changer.

How To Choose The Right Concrete Sealers?

In order to choose the right kind of sealers for a concrete surface, one must be aware of the different types of concrete sealers in the market and their benefits.

Waterproof Concrete Sealers

A sealer should be a product that has the ability to penetrate deep into the surface as well as the substrate in order to seal and act as a protective covering. A waterproof sealer protects the concrete surface from penetrating water deep into the seal on which it turns into a solid form enclosing all alkali and lime in its impenetrable layer.

As a result, the concrete surface coated with waterproof sealers becomes water resistant along with other dirt, grease and acid which extends the overall life of the surface.

Epoxy Concrete Sealers

Epoxy concrete sealers are a great option for heavily utilized interior floors. This specific sealer not only offers a durable finish but also deters excessive abrasion. The most popular applications for epoxy coatings are concrete flooring and countertops. As a matter of fact, this type of sealer offers a glossy finish with a thick composition.

Depending on the requirement of an individual, pigments can be added to the sealers for better colours and one can choose either some mid-level sheen or highly glossy one.

Acrylic Concrete Sealers

If an individual is looking for a cost-effective option, acrylic sealers are the best. Not only is it easy to apply but is also best suited for the interiors and exteriors for sealing the concrete. In addition, this type of sealer is well resistant to UV and therefore doesn’t fade away with time.

If one is looking for sealers for the garage or wants to seal the pool decks and walkways, individuals can opt for acrylic sealers as they offer protection against chlorine water. The paint dries really fast and enhances colours while protecting against damage.

Final Thoughts

Choosing the right concrete sealers perth and applying them correctly is extremely crucial. To find the ideal balance of protection, durability, and affordability, consider the specific needs, surface, and location.

Spraypave Pro is a concrete sealer expert in Perth and can help with the process of concrete sealing.

2 notes

·

View notes

Text

Copper-Clad Laminates Market Research Trends 2025: Insights Driving the Future

At Straits Research, published a new research publication on "Copper-Clad Laminates Market Insights, to 2032" and enriched with self-explained Tables and charts in presentable format. In the Consider you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting Market associated stakeholders. The development of the Copper-Clad Laminates Market was primarily driven by the expanding R&D investing over the world.

Copper-clad laminates (CCLs) are composite materials made by bonding a thin layer of copper foil to a reinforcing base material, such as epoxy resin, paper, or glass fabric, under heat and pressure. These laminates serve as a fundamental component in the production of printed circuit boards (PCBs), which are essential for electronic devices and systems. CCLs are widely used in industries like consumer electronics, automotive, telecommunications, aerospace, and healthcare due to their excellent electrical conductivity, thermal stability, and mechanical strength.

Request Sample Report at : https://straitsresearch.com/report/copper-clad-laminates-market/request-sample

Some of the key players profiled in the study are:

Kingboard Holdings Ltd

Shengyi Technology (SYTECH)

ITEQ Corporation

Panasonic Corp

Isola Group

Nan Ya Plastics Corp

FINELINE Ltd

Doosan Corporation Electro-Materials (South Korea)

Grace Electron Corp (Wuxi city and Guangzhou city)

Taiwan Elite Material Co. Ltd

Taiwan TAIFLEX Scientific Co. Ltd

UBE Industries Ltd

Goldenmax International Technology Ltd

Guagndong Chaohua Technology Co

The titled segments and sub-section of the market are illuminated below:

By Product

Paper Board

Composite Substrate

FR-4

Halogen-free Board

Others

By Type

Rigid

Flexible

By Application

Computers

Communication Systems

Consumer Appliances

Vehicle Electronics

Healthcare Devices

Defense Technology

By Reinforcement Fiber

Glass Fiber Base

Paper Base

Composite Base

By Resin

Epoxy

Phenolic

Polyimide

Polyester (PET)

Fluoropolymer/PTFE

Polyphenylene Ether (PPE)

Polyphenylene Oxide (PPO)

Others (Polyethylene Naphthalate [PEN], etc.)

By End Use

Automotive

Aerospace & Defense

Consumer Electronics

Healthcare

Industrial

Others

Browse Complete Summary and Table of Content @ https://straitsresearch.com/report/copper-clad-laminates-market/toc

Global Copper-Clad Laminates Market report highlights information regarding the current and future industry trends, growth patterns, as well as it offers business strategies to makes a difference the partners in making sound choices that may offer assistance to guarantee the benefit direction over the forecast years. Key Discoveries Of The Study: By benefit, the overseen administrations fragment is anticipated to witness most elevated development amid the forecast period. Based on Copper-Clad Laminates Market type, the outdoor Copper-Clad Laminates Market segment accounted for highest market share. Depending on enterprise size, the SMEs segment is anticipated to exhibit biggest growth during the forecast period. In terms of industry vertical segment, telecom & IT segment held the biggest share in Copper-Clad Laminates Market in 2019. Region Included are: Global, North America, Europe, APAC, South America, Middle East & Africa, LATAM. Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc. At long last, Copper-Clad Laminates Market is a important source of direction for people and companies.

Buy Now & Get Exclusive Report at : https://straitsresearch.com/buy-now/copper-clad-laminates-market

Thanks for reading this article you can also get region wise report version like Global, North America, Europe, APAC, South America, Middle East & Africa, LAMEA) and Forecasts, 2024-2032

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Copper-Clad Laminates Market Market#Copper-Clad Laminates Market Market Share#Copper-Clad Laminates Market Market Size#Copper-Clad Laminates Market Market Research#Copper-Clad Laminates Market Industry#What is Copper-Clad Laminates Market?

0 notes

Text

0 notes

Text

Explore Durofill Glass Epoxy Products

With its ground-breaking Glass Epoxy, Durofill has completely changed the industry norms for tile joint solutions. Durofill's epoxy for floor tiles combines creativity, toughness, and artistic genius to provide a smooth, glossy finish that turns tiled surfaces into pieces of art. Durofill is the well-known brand for high-quality tile joint fillers, and it is available for purchase in over 300 retail tile stores throughout Kerala.

What is Glass Epoxy?

After much investigation and testing, Durofill created Glass Epoxy, also called Glass Bond Epoxy, in 2017 as a cutting-edge epoxy tile joint filler. This special product produces results that are unmatched by combining the strength and durability of epoxy with the luster of a glass finish. Its unique composition not only guarantees solid and smooth tile joints but also gives any tiled surface a glistening, opulent luster.

The idea to transform tile joint solutions was the starting point for Durofill Glass Epoxy's journey. It wasn't an easy task to bring this cutting-edge device to market. At first, 95% of tile workers were reluctant to use this new application technique. But the 5% who welcomed the shift and started using Durofill played a crucial role in highlighting its advantages.

Demand increased quickly as consumers became aware of Durofill Glass Epoxy's better polish and enhanced hygiene. Durofill is now the go-to option for glass epoxy for tiles in Kerala and beyond thanks to customer questions that increased popularity among stores and employees. It now connotes excellence, robustness, and visual attractiveness.

Benefit of Glass Epoxy

Seamless Finish: A smooth, faultless tile seam is guaranteed by the glass-like gloss.

Improved Aesthetics: Gives tiled surfaces a more opulent and glittering look.

Durability: Provides long-lasting performance by fusing the strength of epoxy with the luster of glass.

Hygiene: It is a sanitary option because of its easily cleaned surface, which keeps dirt and grime from building up.

Adaptable Use: Perfect for both business and residential settings.

Why Opt for Durofill?

Glass Epoxy pioneers: Durofill is pleased to have created Glass Epoxy, which has raised the bar for tile joint solutions.

Proven Track Record: Known for its outstanding quality and performance, tile workers and customers alike trust it.

Wide Distribution: Found in more than 300 tile stores in Kerala.

Client-Centric Approach: Durofill's path demonstrates its dedication to excellence, from training tile workers to satisfying client requests.

Glass Epoxy Applications for Tiles

The ideal uses for Durofill Glass Epoxy are:

Living rooms, baths, and kitchens are examples of residential spaces.

Commercial spaces include retail stores, eateries, and offices.

Specialized Areas: Expensive interiors that need a dash of style and toughness.

Discover the Durofill Distinction

Durofill Glass Epoxy is an example of quality and innovation. It is the best option for anyone looking for high-end tile joint solutions because of its flawless polish, stunning appearance, and unparalleled endurance. Because your tiles deserve nothing less than perfection, elevate your tiled surfaces with Durofill.

Conclusion

More than just a tile joint filler, Durofill Glass Epoxy Solutions is a revolutionary product that yields unparalleled results by fusing strength, durability, and beauty. Whether you're remodeling your house or creating a business, Durofill's glass epoxy for tiles guarantees a smooth and sophisticated finish. With its high-quality and inventive products, Durofill is a reliable option that will improve your spaces over time.

Contact us right now or stop by your local tile store in Kerala for more details or to witness the wonders of Durofill Glass Epoxy!

#epoxy tile joint filler#glass bond epoxy#glass epoxy#benefits of glass epoxy#epoxy for floor tiles#glass epoxy for tiles#what is glass epoxy

0 notes

Text

0 notes

Text

Powder Coating Market

Powder Coating Market Size, Share, Trends: AkzoNobel N.V. Leads

Adoption of Smart Powder Coatings with Advanced Functionalities

Market Overview:

The global powder coating market is expected to develop at a 6.8% CAGR from 2024 to 2031. Asia-Pacific now dominates the industry, accounting for the vast majority of worldwide sales. Key factors include rising demand from diverse end-use industries, technological breakthroughs in coating processes, and increased awareness of the environmental benefits of powder coatings. The market is expanding rapidly due to the increasing use of powder coatings in various industries for their superior finish, durability, and environmental friendliness. Technological advancements in powder coating compositions and application procedures enhance product performance while broadening the spectrum of applications. Furthermore, severe environmental rules in developed economies encourage the use of low-VOC coatings, which contributes to market growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The use of smart technology in powder coatings is changing the industry landscape. This trend is driven by an increase in demand for coatings that do more than just protect and look good. Manufacturers are creating powder coatings with self-healing, anti-microbial, and even energy-harvesting qualities. For example, several companies are working with powder coatings that change colour in response to temperature changes or contain conductive materials for electromagnetic shielding. This shift towards multi-functional powder coatings not only addresses specific industrial needs but also opens up new application areas, driving market development and innovation.

Market Segmentation:

The Thermoset powder coatings segment, which includes epoxy, polyester, and hybrid formulations, now dominates the powder coating industry. These coatings have exceptional durability, chemical resistance, and an aesthetically pleasing finish, making them appropriate for a wide range of applications across multiple industries. Demand from the automotive, appliance, and architectural sectors is driving the segment's growth. Recent technology improvements, such as low-temperature cure thermoset powder coatings, have significantly increased the substrate materials that can be coated, including heat-sensitive materials like wood and plastics.

Market Key Players:

The powder coating industry is characterized by fierce competition among significant companies, with an emphasis on product innovation, global expansion, and strategic alliances. Major firms such as AkzoNobel N.V., PPG Industries, Inc., Sherwin-Williams Company, Axalta Coating Systems, Jotun A/S, Tiger Coatings GmbH & Co. KG, Nippon Paint Holdings Co., Ltd., Asian Paints Limited, RPM International Inc., and Kansai Paint Co., Ltd. dominate the market. These companies are investing extensively in R&D to introduce coating formulations with improved performance attributes and broader application ranges.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Curing Agents Market

Curing Agents Market Size, Share, Trends: Huntsman Corporation Leads

Growing demand for waterborne and eco-friendly curing agents

Market Overview:

The global Curing Agents market is projected to grow at a CAGR of 6.2% from 2024 to 2031. The market value is expected to increase significantly during this period. Asia-Pacific currently dominates the market, accounting for the largest share of global revenue. Key metrics include increasing demand from the construction and automotive industries, growing adoption of eco-friendly curing agents, and rising investments in research and development for innovative products.

The Curing Agents market is growing steadily, driven by expanding end-use industries and an increasing need for high-performance materials in a variety of applications. Technological improvements in curing agent formulations are driving market growth, with a focus on increasing curing efficiency, lowering environmental impact, and improving overall product quality.

DOWNLOAD FREE SAMPLE

Market Trends:

The curing agents market is undergoing a considerable change towards waterborne and eco-friendly formulations, owing to rigorous environmental regulations and rising consumer awareness. This trend is especially noticeable in the coatings and adhesives markets, where low-VOC (Volatile Organic Compound) and solvent-free solutions are gaining popularity. Manufacturers are investing in bio-based curing agents made from renewable resources like plant oils and natural amino acids. These ecologically friendly options perform similarly to standard curing chemicals while lowering carbon emissions and enhancing workplace safety. Waterborne epoxy curing chemicals, for example, are becoming increasingly popular in industrial flooring applications due to their high chemical resistance and durability without the environmental concerns associated with solvent-based systems.

Market Segmentation:

The Epoxy curing agents segment dominates the worldwide Curing Agents market. This dominance is due to the widespread usage of epoxy resins in a variety of applications, including paints, adhesives, composites, and electrical laminates. Epoxy curing agents have an important role in establishing the final attributes of cured epoxy systems, including strength, chemical resistance, and durability.

Epoxy curing agents' market leadership is due in large part to their versatility. Amine-based curing agents, including as aliphatic and aromatic amines, are particularly popular due to their superior curing qualities and ability to impart high performance attributes to the finished product. Cycloaliphatic amine curing agents, for example, are commonly employed in marine coatings due to their higher water resistance and corrosion prevention.

Market Key Players:

Huntsman Corporation

Evonik Industries

BASF SE

Hexion Inc.

Dow Chemical Company

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

“Garage Floor Coatings vs. Traditional Paints: Why Choose Epoxy?”

Introduction

When it comes to enhancing the durability and aesthetics of your garage floor, two primary options are often considered: traditional paints and epoxy coatings. While both can provide a fresh new look, the advantages of choosing epoxy for garage floors far outweigh those of traditional paint. This article delves deep into the world of garage flooring creative Artcrete designs solutions, comparing garage floor coatings with traditional paints, and explaining why epoxy is the superior choice.

Understanding Garage Floor Coatings vs. Traditional Paints

What exactly differentiates garage floor coatings like epoxy from traditional paints? At first glance, they might seem similar; however, their composition, application process, durability, and overall performance reveal stark contrasts.

Traditional Paints:

Composition: Typically made from latex or oil-based materials. Durability: Generally offers limited resistance against stains, chemicals, and abrasions. Longevity: Tends to wear out quickly under heavy traffic or exposure to harsh conditions. Application: Easier to apply but requires multiple coats for adequate coverage.

Epoxy Coatings:

Composition: A combination of resin and hardeners that create a robust bond with the concrete surface. Durability: Highly resistant to stains, chemicals, impacts, and abrasions. Longevity: Can last up to 20 years when properly installed and maintained. Application: Requires precise mixing and application techniques but offers a seamless finish.

In this comprehensive guide, we’ll explore various aspects of epoxy flooring compared to traditional paint options for garages.

1. What Are Epoxy Floors?

Epoxy floors are a type of flooring created by mixing resin with hardeners that cure to form a solid plastic material. This unique combination results in a highly durable surface suitable for high-traffic areas such as garages.

1.1 The Composition of Epoxy Floors

The primary components in epoxy floors include:

Resin: Provides flexibility and adhesion. Hardener: Reacts with resin to create a hardened surface.

This mixture creates a strong bond with concrete surfaces, resulting in long-lasting durability.

1.2 Benefits of Epoxy Floors

Choosing epoxy for your garage floors has numerous benefits:

Durability: Withstands heavy loads without cracking or chipping. Resistance: Offers excellent protection against oils, chemicals, and stains. Aesthetic Appeal: Available in various colors and finishes including metallic epoxy floors that can elevate the visual appeal of any space. 2. Types of Epoxy Flooring Options

There are several types of epoxy flooring options available on the market today:

2.1 Solid Color Epoxy Floors

These offer a simple yet elegant finish that is easy to maintain and clean.

2.2 Metallic Epoxy Floors

A stunning option that provides depth and shine due to its unique reflective properties.

0 notes

Text

High Performance Adhesives Market

High Performance Adhesives Market Size, Share, Trends: Henkel AG & Co. KGaA Leads

Growing adoption of sustainable and bio-based high performance adhesives drives market growth.

Market Overview:

The High Performance Adhesives Market is projected to grow at a CAGR of 7.3% from 2024 to 2031. The market value is expected to increase significantly during this period. Asia-Pacific is anticipated to be the dominant region in this market. Key metrics include increasing demand from end-use industries such as automotive and electronics, growing trend towards lightweight and high-strength materials, and rising focus on sustainable adhesive solutions. The market is experiencing robust growth driven by technological advancements in adhesive formulations and expanding applications in various industries.

The high performance adhesives market is shifting significantly towards sustainable and biobased solutions. This shift is being driven by stricter environmental restrictions, growing consumer knowledge of environmentally friendly products, and corporate sustainability programs. Manufacturers are investing in R&D to develop high-performance adhesives made from sustainable resources such plant-based polymers, recycled materials, and bio-based monomers. For example, a well-known glue producer recently introduced a bio-based structural adhesive manufactured from 80% renewable raw ingredients, aimed at the automotive and aerospace sectors. The trend is also evident in the packaging industry, where bio-based adhesives are gaining popularity for applications that require great performance and sustainability. According to current industry data, the global bio-based adhesives market is predicted to rise at a 4.5% CAGR between 2023 and 2028, indicating an increase in demand for these sustainable alternatives. This change to eco-friendly formulations not only addresses environmental concerns, but it also creates new market opportunities, with the ability to reshape the competitive landscape of the high performance adhesives business.

DOWNLOAD FREE SAMPLE

Market Trends:

The high performance adhesives market is shifting significantly towards sustainable and biobased solutions. This shift is being driven by stricter environmental restrictions, growing consumer knowledge of environmentally friendly products, and corporate sustainability programs. Manufacturers are investing in R&D to develop high-performance adhesives made from sustainable resources such plant-based polymers, recycled materials, and bio-based monomers. For example, a well-known glue producer recently introduced a bio-based structural adhesive manufactured from 80% renewable raw ingredients, aimed at the automotive and aerospace sectors. The trend is also evident in the packaging industry, where bio-based adhesives are gaining popularity for applications that require great performance and sustainability. According to current industry data, the global bio-based adhesives market is predicted to rise at a 4.5% CAGR between 2023 and 2028, indicating an increase in demand for these sustainable alternatives. This change to eco-friendly formulations not only addresses environmental concerns, but it also creates new market opportunities, with the ability to reshape the competitive landscape of the high performance adhesives business.

Market Segmentation:

Epoxy adhesives are expected to maintain their dominance in the high performance adhesives market due to their higher bonding strength, chemical resistance, and versatility in a wide range of applications. These adhesives provide excellent adhesion to a wide range of substrates, including metals, plastics, and composites, making them perfect for usage in demanding industries including automotive, aerospace, and electronics.

Recent industry advances demonstrate the expanding importance of epoxy adhesives in advanced applications. In 2023, a top glue producer launched a new fast-curing epoxy adhesive intended exclusively for the installation of electric vehicle batteries, with better heat and vibration resistance. This breakthrough exemplifies the ongoing R&D efforts to improve epoxy adhesive performance for future technologies.

Advancements in curing technology and compositions aid the epoxy industry as well. A recent study published in the Journal of Adhesion Science and Technology described a unique epoxy formulation with self-healing characteristics that can repair microcracks and increase the life of bonded structures. This study has prompted attention in businesses that deal with high-stress situations, such as aviation and wind energy.

Market Key Players:

Henkel AG & Co. KGaA

3M Company

Sika AG

H.B. Fuller Company

Bostik SA (Arkema Group)

Dow Inc.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes