#End Effectors

Explore tagged Tumblr posts

Text

The Essential Guide to Robotic Grippers: From End Effectors to Automation

Introduction: The rise of automation has revolutionized countless industries, and robotic grippers play a fundamental role in this transformation. These ingenious mechanisms, also known as end effectors, act as the “hands” of robotic arms, enabling them to grasp, manipulate, and transport objects with precision. This comprehensive guide delves deep into the world of robotic grippers. We’ll…

View On WordPress

#automation#Dexterous Grippers#End Effectors#Gripper Design#Machine Tending#Robotic Arms#Robotic Grippers

0 notes

Note

howdy! I'm also a robot enthusiast and I'm trying to get better at designing robot characters. I absolutely adore all of your robot designs, especially the sweet salt cosmonauts! do you have any advice for designing robots?

Ohh thank you~!! ✨✨

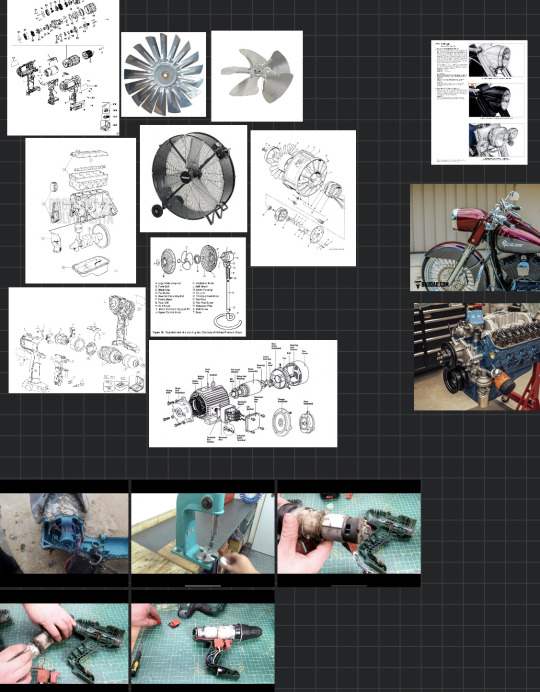

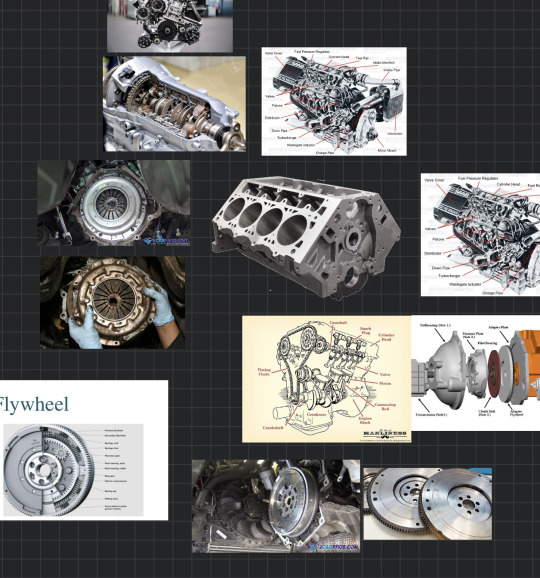

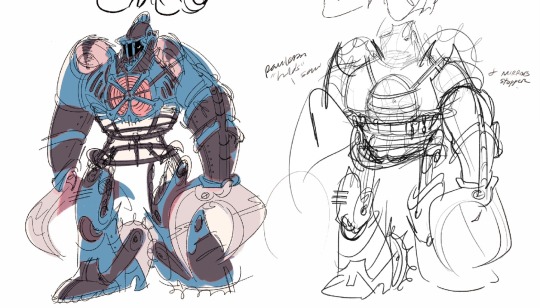

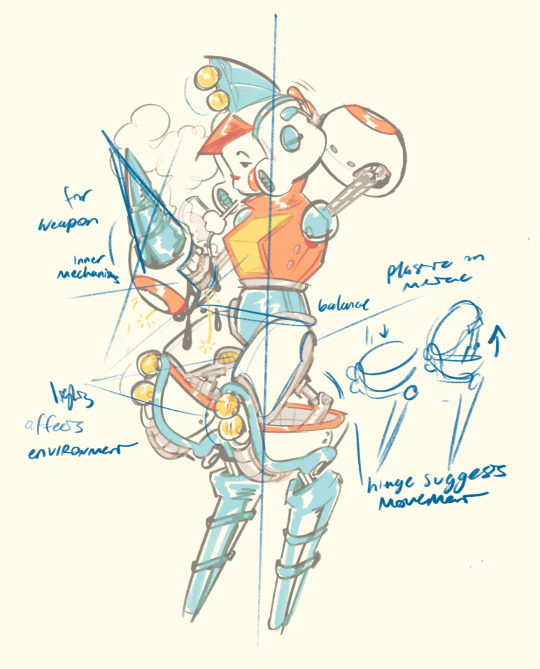

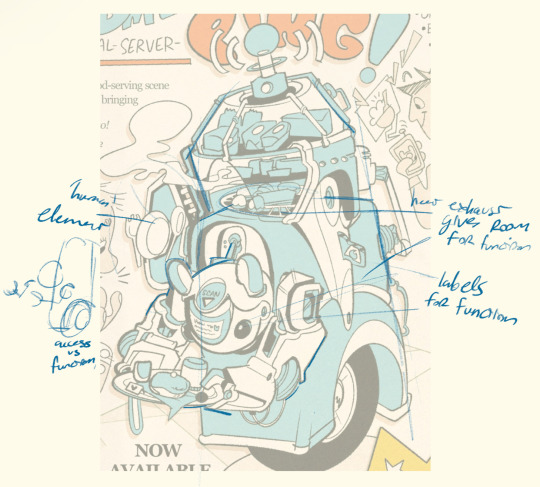

The biggest advice I can give is to study the functionality! That’s the most interesting part of robots to me, and influences all my designs. You definitely don’t have to understand the mechanics completely, but getting an idea of the basics, and knowing what the function and purpose of the robot is, and what parts help to carry out that function, is always a good starting place!

Here’s an example of how I was mostly focused on the saw mechanics of the shoulder, because that’s what was important to the story, and made the rest mostly aesthetic driven.

Whereas with Thylo, I had an idea of how I wanted his legs to look, and built the mechanics around that, to serve the aesthetic, but it also plays into his motion, and how he stands, and his balance.

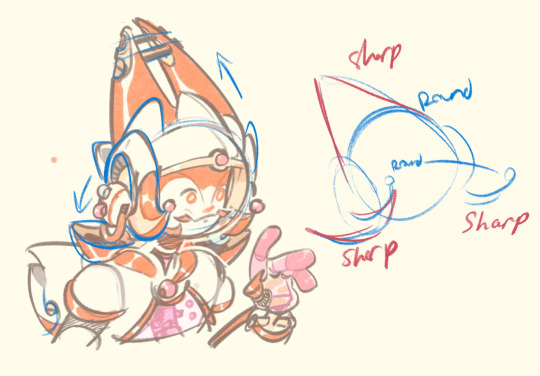

For Snap, both her new and older designs are more personality driven, and wanted to keep her more ‘human’ elements more round and approachable, and her mechanical parts sharper, to sell that they’re weaponry, and that she’s both kind and a fighter. But even her sharp aspects are never perfectly straight, keeping it fun and light-hearted.

Her’s is also a transforming design, and every little piece serves that function, especially the head area, and I consider how the panels will fall or open, or attach. Again, it doesn’t have to be mechanically accurate, but if you’ve got a solid idea of how the physics work for the character, it really sells the design!

Even for less humanish designs, you can give a clear idea of the robot’s function through decals, or how it affects the environment/other characters.

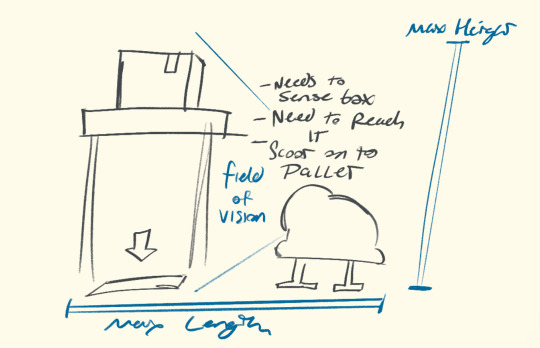

Here’s a little example: let’s say I wanna make a robot whose purpose is to lift boxes on top-shelves, and bring them down to a pallet. It would need a way to see the box, a way to reach it, and to push it onto the pallet.

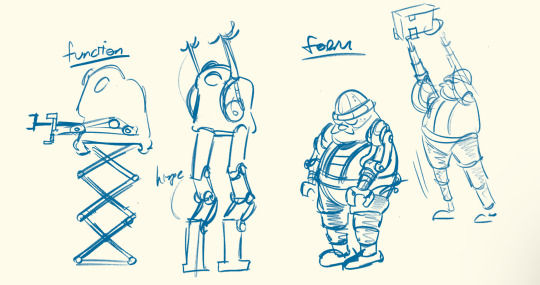

So, I’ll play with the idea of his functionality first. I could go with some sort of scissor lift, or hydraulic system, but I settle on mostly a telescoping mechanism, and build a little warehouse, or dock worker aesthetic around him.

In short, I’d say just study mechanism that interest you, play with their shapes, their motion, figure out the purpose or character of your robot, and how they function, and what ways you can best convey that through their design! Hope this helps! ✨

#sorry if that’s too rambly or incoherent I could go on for days about robots so I tried to keep it short#I didn’t even get into the degrees of freedom or end effectors lol#I guess it’s similar to drawing clothing in that it doesn’t have to be practical or realistic so long as it makes sense for the character#or the story or environment#but thanks so much for asking and hope this helps at least a little! ✨⭐️#asks#Thylo#Snap

83 notes

·

View notes

Text

Analyzing the Market Dynamics of Robot End Effector Market

The global robot end effector market size is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%.

Growing demand for modular end effectors, increasing adoption of cobots, penetration of automation in SMEs, and increasing adoption in the warehousing, pharmaceutical, and food industry are the main drivers for the growth of the robot end effector market.

The robot end-effector market will grow significantly due to its various applications in several industries, such as automotive, electrical & electronics, food & beverage, and pharmaceutical. Various key players in the market adopt different strategies such as acquisitions, product launches, collaborations, and partnerships to grow in the robot end effector market.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819

Driver: Increasing demand for modular end effectors by various industries. Due to the fast-changing nature of industries, the demand for modular end effectors is increasing. This scenario is observed in the consumer goods industry, specifically packaging, where the shape, size, surface, or weight of the packaging is constantly changing. This shortens the life cycle of an end effector to 1 to 2 years and thereby increases the cost of replacement for the company. Modular end effectors have the capability to accommodate and handle a large variety of objects as required. A modular vacuum bar from Schmalz (Germany) can perfectly seal and lift objects regardless of their size; Zimmer Group (Germany) and Schunk (Germany) introduced a modular gripping system – MATCH with an unlimited range of uses from production and assembly to warehouse logistics, shipping, and even laboratory automation. This modularity ensures that the grippers do not have to be changed from time to time, thereby reducing the cost of redesigning and downtime associated with its change and replacement.

Restraint: High cost of deployment, especially for SMEs. Small and medium-sized enterprises (SMEs) differ from large-scale industries such as automotive or electronics manufacturing in various ways. SMEs typically have a low threshold for capital expenditure, a low-risk appetite, and limited time to generate returns on their investment. Additionally, their applications are often specific and on a case-by-case basis. For instance, Saint-Gobain, a glass manufacturing company in France, required automation of its glass polishing process that was previously carried out manually. Robotiq successfully automated the process by programming its torque sensor to replicate the hand movements and pressure applied by a human. Unlike large industries, many SMEs have not built their infrastructure around deploying robots, and must often integrate them into their existing floor space at a later stage.

Opportunity: Advancement in robotics has surged the demand for soft grippers. Advances in soft robotics, coupled with the increasing need to handle delicate items, have enabled rapid progress in soft grippers. Unlike traditional grippers that are made of rigid materials, these end effectors are fabricated from soft and flexible components. Earlier, most end effectors were able to only manipulate objects of fixed size and shape. However, industry requirements are slowly shifting toward the use of components that can grasp and manipulate a large variety of objects. Due to the material softness of the gripper arms, they can be used for sensitive applications such as in the food & beverage or glass manufacturing industries that can handle objects without damaging them. Fruits or vegetables have varying sizes, making soft grippers ideal due to their consistent clamping force irrespective of slight differences in size and shape. Soft grippers are mainly adopted by the food & beverage industry, one of the fastest-growing clients for soft grippers. Hence, the high penetration rate of automation in the food & beverage industry is expected to stimulate the adoption of soft grippers in the next 4 to 5 years.

Challenge: Interoperability and integration issues related to end effectors with existing facilities. Interoperability is a very important function in any factory or manufacturing unit. There must exist a modular framework for both hardware and software to connect and coordinate various end effector systems. The focus is not only on the software side, which is used for programming, diagnosing, and monitoring but also the interchangeability of hardware between the end effector and robot arm. There have been cases in the robot end effector industry where a client has bought a robot arm and an end effector separately that were not fully compatible with each other, and the setup was a huge challenge from the onset.

0 notes

Text

Cobot End Effector Market: A Roadmap to Enhanced Productivity

Introduction:

According to the study by Next Move Strategy Consulting, the global Cobot End Effector Market size is predicted to reach USD 2.66 billion with a CAGR of 12.8% by 2030. This forecast underscores the growing significance of cobot end effectors in reshaping industrial processes and enhancing productivity. As industries across the globe continue to embrace automation to streamline operations and improve efficiency, cobot end effectors have emerged as pivotal components in this transformative journey. In this comprehensive article, we delve into the various facets of the cobot end effector market, exploring its evolution, applications, technological advancements, and the roadmap to achieving enhanced productivity.

Request for a sample PDF report: https://www.nextmsc.com/cobot-end-effector-market/request-sample

Evolution of Cobot End Effectors:

Cobot end effectors, also known as end-of-arm tools, have undergone a remarkable evolution since their inception. Traditionally, industrial robots were equipped with rigid, single-purpose grippers designed for specific tasks. However, advancements in robotics technology, materials science, and engineering have led to the development of more versatile and adaptable cobot end effectors.

Unlike their conventional counterparts, cobot end effectors are designed to work collaboratively with human operators, augmenting their capabilities rather than replacing them. This collaborative approach not only enhances productivity but also improves safety and efficiency in the workplace. The evolution of cobot end effectors reflects a broader shift towards flexible automation solutions that can adapt to the changing needs of modern manufacturing environments.

Applications Across Industries:

Cobot end effectors find applications across a wide range of industries, spanning automotive manufacturing, electronics assembly, aerospace, food processing, pharmaceuticals, logistics, and more. In automotive manufacturing, cobot end effectors are used for tasks such as material handling, assembly, welding, and painting. In electronics assembly, they facilitate precision gripping, soldering, and inspection processes. In the food industry, cobot end effectors handle packaging, palletizing, and quality control tasks with ease.

The versatility of cobot end effectors makes them well-suited for diverse applications, allowing manufacturers to optimize workflows, reduce cycle times, and improve overall efficiency. By automating repetitive and mundane tasks, cobot end effectors free up human operators to focus on more value-added activities, such as problem-solving, innovation, and process improvement.

Technological Advancements:

Advancements in technology have played a crucial role in driving the evolution of cobot end effectors. Today's cobot end effectors are equipped with advanced sensors, actuators, and control systems that enable precise and efficient manipulation of objects. Vision systems, for example, allow cobots to identify and adapt to changes in the environment, while force-torque sensors enable them to apply the right amount of pressure during gripping and manipulation tasks.

Furthermore, the integration of artificial intelligence and machine learning algorithms has empowered cobots to learn from experience, optimize performance, and make real-time adjustments based on changing conditions. This adaptive intelligence enables cobot end effectors to handle a wide range of tasks with greater efficiency and reliability.

Roadmap to Enhanced Productivity:

Achieving enhanced productivity with cobot end effectors requires a strategic approach that encompasses several key considerations:

Task Analysis: Begin by conducting a thorough analysis of the tasks that can be automated using cobot end effectors. Identify repetitive, high-volume, and ergonomically challenging tasks that can benefit from automation.

Integration Planning: Collaborate with robotics experts and integrators to develop a comprehensive integration plan. Consider factors such as workspace layout, safety requirements, payload capacity, and compatibility with existing systems.

Training and Education: Invest in training programs to familiarize operators with cobot end effectors and ensure proper utilization. Provide ongoing support and education to empower employees to maximize the potential of cobot technology.

Performance Monitoring: Implement robust monitoring and analytics systems to track the performance of cobot end effectors in real-time. Analyze data to identify bottlenecks, optimize workflows, and improve overall efficiency.

Continuous Improvement: Embrace a culture of continuous improvement by soliciting feedback from operators, identifying areas for optimization, and implementing iterative upgrades to cobot end effectors and processes.

Safety Considerations: Prioritize safety when implementing cobot end effectors in the workplace. Conduct risk assessments, establish safety protocols, and integrate safety features such as protective barriers, emergency stop buttons, and collision detection systems to ensure the well-being of human operators.

Scalability and Flexibility: Choose cobot end effectors that offer scalability and flexibility to accommodate changing production demands. Opt for modular designs that allow for easy reconfiguration and adaptation to different tasks and environments.

Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis to evaluate the return on investment (ROI) of implementing cobot end effectors. Consider factors such as upfront costs, labor savings, productivity gains, and long-term maintenance expenses to make informed decisions.

Collaboration with Suppliers: Collaborate closely with cobot end effector suppliers to customize solutions that meet specific operational requirements. Leverage their expertise to optimize performance, minimize downtime, and address any technical challenges that may arise during implementation.

Regulatory Compliance: Ensure compliance with regulatory standards and industry guidelines when deploying cobot end effectors. Stay abreast of evolving regulations pertaining to safety, data privacy, and ethical considerations in robotics and automation.

Environmental Sustainability: Consider the environmental impact of cobot end effector deployment and seek opportunities to minimize energy consumption, reduce waste, and promote sustainability in manufacturing processes.

Employee Engagement and Empowerment: Involve employees in the implementation process and foster a culture of collaboration and empowerment. Provide training and upskilling opportunities to enable workers to adapt to the changing technological landscape and take ownership of cobot-assisted tasks.

Market Trends and Competitive Analysis: Stay informed about emerging trends, market dynamics, and competitive landscape in the cobot end effector market. Monitor competitor activities, technological advancements, and customer preferences to identify opportunities for differentiation and innovation.

Customer Satisfaction and Feedback: Solicit feedback from customers and end-users to assess their satisfaction levels and identify areas for improvement. Use customer insights to refine product offerings, enhance user experience, and drive continuous innovation.

Inquire before buying: https://www.nextmsc.com/cobot-end-effector-market/inquire-before-buying

Conclusion:

The global cobot end effector market is poised for exponential growth in the coming years, driven by advancements in technology, rising labor costs, and the increasing demand for flexible automation solutions. By leveraging cobot end effectors, businesses can achieve enhanced productivity, improve efficiency, and gain a competitive edge in today's rapidly evolving market landscape. However, realizing the full potential of cobot technology requires careful planning, strategic integration, and a commitment to continuous improvement. With the right roadmap in place, the journey towards enhanced productivity with cobot end effectors is well underway, heralding a new era of automation and innovation in manufacturing.

0 notes

Text

Robot End Effector Market Size, Share, Growth Analysis 2024 - 2030

0 notes

Text

Two Finger Adaptive Grippers Are Ready For Delivery To USA

Two Finger Adaptive Grippers from Tallman Robotics Limited Are finished for client from USA.

Two finger adaptive grippers are robotic end-effectors that are capable of grasping and manipulating objects with varying shapes and sizes. Unlike traditional grippers that use a fixed jaw to grasp objects, adaptive grippers use two flexible fingers that can conform to the object's shape, providing a more secure and versatile grip. These types of grippers are used in a variety of industries, including manufacturing, logistics, and healthcare, and can be found on robots and automated systems in factories and warehouses. They offer several advantages over traditional grippers, including improved dexterity, increased efficiency, and reduced risk of damaging fragile objects. Two finger adaptive grippers are a type of robotic gripper that use two fingers to grasp and manipulate objects. These grippers are designed to be adaptable to a wide range of shapes and sizes of objects, allowing them to be used in a variety of applications. The two fingers of the gripper are typically made of a flexible material, such as silicone or rubber, which allows them to conform to the shape of the object being grasped. The fingers are attached to a rigid structure that provides support and stability. The gripper may also be equipped with sensors that allow it to detect the size and shape of the object being grasped, enabling it to adjust its grip accordingly. One advantage of two finger adaptive grippers is their versatility. Because they can adapt to different sizes and shapes of objects, they can be used for a wide range of applications, from picking up small parts in a manufacturing line to grasping irregularly shaped objects in a warehouse or distribution center. Another advantage of two finger adaptive grippers is their ease of use. Unlike more complex robotic grippers that require extensive programming and training to operate, two finger adaptive grippers can be used by anyone with minimal training. This makes them an ideal solution for small businesses or organizations that need a flexible and easy-to-use gripper. Finally, two finger adaptive grippers are also relatively inexpensive compared to other types of robotic grippers. This makes them accessible to a wider range of businesses and organizations that may not have the budget to invest in more advanced grippers. In conclusion, two finger adaptive grippers are a versatile, easy-to-use, and affordable type of robotic gripper that can be used in a variety of applications. With their ability to adapt to different shapes and sizes of objects, they are an ideal solution for businesses and organizations that need a flexible and cost-effective gripper. You are welcome to https://www.youtube.com/@tallmanrobotics to watch our video centre for more projects or visit our website to check other series or load down e-catalogues for further technical data. Read the full article

#2-FingerAdaptiveRobotGripper#3-FingerAdaptiveRobotGripper#Electric2FingerRobotGripper#end-effectors#Flexible2-FingerAdaptiveRobotGripper#Flexibleadaptivegripper#intelligentroboticgripperswithadaptiveforce#roboticend-effectors#SoftRoboticCompliantTwo-FingerGripper#two-fingeredroboticgrippers

0 notes

Text

Viktor and Sevika: The Cause and the Effector

Or another installment in "What Could Have Been, if Only Riot had Kept Arcane Between Piltover and Zaun."

Before season 2 did Sevika so dirty, she was, with some certainty, my second favorite character in Arcane, and I'll always be upset about how they squandered her character in the end. And there was just so much more they could have done - including merge her politics with Viktor's (wasted) time back inside Zaun. Just imagine a conversation between them!

So let's rewind to season 1 and consider both Viktor and Sevika's goals, which are a lot less disparate than they seem...

Sevika's Cause

One of my very favorite lines in Arcane is from Silco in 1x03, to Vander: "You'll die for a cause, but you won't fight for one?"

This is a profound question throughout season 1. Vander, in the pursuit of somewhat naive pacifism, shies away from any and all conflict between Zaun and the Enforcers. At first, he seems reluctant on account of his kids (as that one background character points out: "You're just protecting your kids!") but Silco and Vander's confrontation in the Shimmer plant makes the point stronger.

At the start of season 1, we understand that Zaun is an ideal for Silco, a symbol of beating back classist oppression that has left the undercity's denizens in financial ruin, turned them against each other, and wrecked their physical health (!!!). When Vander abandons this idyllic dream, on account of the fact that achieving it requires violence, he is acquiescing to a less-than existence for Zaun, which Silco cannot abide.

Sevika comes into play when she abandons Vander after he fails to stick up for them against the Enforcers in 1x02:

"No. You look weak."

She, too, sees the ideal of Zaun crumbling within Vander, so she allies herself with Silco to make sure that dream happens. She doesn't mind his methods because she doesn't follow the individual. She follows the cause. THIS is Sevika's most profound trait - she cares not for the figurehead, but for what that figurehead represents.

This is especially interesting when we consider the emotional toil that other figureheads endure (and inflict) Arcane - Jayce crumbles under "The Man of Progress" moniker; Caitlyn struggles to uphold her legacy in a way even remotely similar to her mother; Jinx as revolutionary in season 2 is a bust. But Sevika will always be there, championing the cause, holding the line, while never taking the mantle of Revolutionary Figure because it's just not in her nature. She holds on to her loyalty for Silco, despite his operation falling apart (largely in part due to Jinx), as a last-ditch hope that things are still possible for Zaun's liberation.

And yet, still, when it seems that Jinx is branded as the symbol of Zaun against all odds, Sevika swallows her pride, holds down the fort, and fights alongside Jinx - the cause must always go on.

Viktor's Dream

Viktor's cause isn't superficially outwardly political, nor is he bound by the same revolutionary codes Sevika is. But, as an outsider in Piltover, despite Jayce's best efforts and intentions, his desire for an end to Zaunite suffering through official Piltover channels is inherently at odds with the Council's political goals, therefore making it political.

Viktor leaps on Jayce's "Hextech Theory," risking the success and accolades he's so painstakingly earned, because he sees his own cause alive within it: making the world a better place. He can alleviate the needless suffering through Jayce's revolutionary invention; he can make his ideal/dream a reality. Much like Sevika, he's found the individual who champions his cause and aligns himself accordingly.

(Of course, UNLIKE Sevika's relationships to Silco and Vander and the rest, Jayce becomes an inextricable part of Viktor's personal life, happiness, etc. They are markedly different in that way, but I still don't see Viktor as the kind to exalt the individual over the cause itself. It just so happens that Jayce and Viktor are star-crossed science partners in every universe <3)

Arcane makes a pretty distinct attack on the idea of Hextech being a product of an individual (seeing as though so much of Viktor's arc across both seasons is about him being ostracized, kept away from his legacy) via the infamous Progress Day mug eclipse:

All this is to say that Viktor's cause is to help Zaun, just as Sevika's is. Importantly, neither character follows an individual that represents their cause. They follow their goals to the end, even if it costs Viktor his closest friend, and even if it costs Sevika all that she holds dear in Zaun as she knows it.

3 more interesting comparisons stand:

Their polar opposite methods. Viktor would never tolerate Sevika's immediate resort to violence, and Sevika would think Viktor weak-willed.

Competing notions of sacrifice. Sevika endures sacrifice as a public figure; people rely on her outwardly for organization, support, muscle, etc. Meanwhile, Viktor's sacrifice takes place behind the scenes. This contrast can be attributed to their respective positions of power: Sevika is high up in Zaun, while Viktor struggles for recognition throughout season 1.

Being overshadowed. While Viktor's experience in this regard is more obvious, seeing Sevika be continuously sidelined to the number 2 when she's clearly THE most dedicated to Zaun's liberation was so heartbreaking.

Sevika shadowed by Vander's image...

...and Viktor stifled by Jayce.

What Could Have Been

I have so, so many ideas, down to specific scenes and lines of dialogue, for how to bring Sevika and Viktor together. Don't get me wrong - they would likely detest each other. Like I said, Viktor would be disgusted by how quickly she resorts to violence and she would think him weak-willed. But in the perfect season 2 world, wherein the story stayed between Piltover and Zaun, and Viktor could have returned to Zaun as a potential ally to Sevika's movement (since their causes are, at their base value, the same!), they could have made it work.

Sevika would see the cause in Viktor, and he in her. Viktor as the Herald (the Machine Herald, ideally) could rally the Undercity under his mythos. The mysterious healer, whether by the arcane, engineering, what have you, takes away the suffering Piltover's negligence and police brutality cause. He gives Zaunites hope. He fulfills his dream.

And, since nothing can be apolitical in the Piltover/Zaun conflict, Viktor would see Sevika's value and her passion. She is the executor of the cause, the figure who spreads it to the masses. He can affect change and she can give it a voice. She fulfills her dream. She can raise her people from their oppression.

Neither would exalt themselves as a savior, a leader, a fanatic, etc. They would stand apart from Silco, who became obsessive, and Piltover, whose leaders were so divorced from reality that they couldn't smell burgeoning armed conflict while it stewed right beneath their noses.

We obviously got something radically different for the both of them, however, so this is all just fun, whimsical conjecture.

I really think this was a squandered unlikely duo. it would have showed Viktor the reality of Piltover/Noxus' militarization and would have forced Sevika to let her walls down and allow other perspectives into the conversation. Neither would ever fully empathize with the other, but it would have been a riveting narrative challenge that I wish we could have seen play out.

#i may or may not have a rewrite in the works that features them together a LOT#so i don't want to give too much away LOL#also thanks to everyone (like 120 of you!!!) who voted in my poll abt what to post next#this is a dynamic that i'm always throwing around in my head#literally so much could have been done cross-character-wise had there been no noxus but#i digress#that's for a different post#arcane#arcane season 2#arcane s2#viktor arcane#sevika#sevika arcane#viktor propaganda#jayce talis#silco#vander arcane

84 notes

·

View notes

Text

Old-school planning vs new-school learning is a false dichotomy

I wanted to follow up on this discussion I was having with @metamatar, because this was getting from the original point and justified its own thread. In particular, I want to dig into this point

rule based planners, old school search and control still outperform learning in many domains with guarantees because end to end learning is fragile and dependent on training distribution. Lydia Kavraki's lab recently did SIMD vectorisation to RRT based search and saw like a several hundred times magnitude jump for performance on robot arms – suddenly severely hurting the case for doing end to end learning if you can do requerying in ms. It needs no signal except robot start, goal configuration and collisions. Meanwhile RL in my lab needs retraining and swings wildly in performance when using a slightly different end effector.

In general, the more I learn about machine learning and robotics, the less I believe that the dichotomies we learn early on actually hold up to close scrutiny. Early on we learn about how support vector machines are non-parametric kernel methods, while neural nets are parametric methods that update their parameters by gradient descent. And this is true, until you realize that kernel methods can be made more efficient by making them parametric, and large neural networks generalize because they approximate non-parametric kernel methods with stationary parameters. Early on we learn that model-based RL learns a model that it uses for planning, while model free methods just learn the policy. Except that it's possible to learn what future states a policy will visit and use this to plan without learning an explicit transition function, using the TD learning update normally used in model-free RL. And similar ideas by the same authors are the current state-of-the-art in offline RL and imitation learning for manipulation Is this model-free? model-based? Both? Neither? does it matter?

In my physics education, one thing that came up a lot is duality, the idea that there are typically two or more equivalent representations of a problem. One based on forces, newtonian dynamics, etc, and one as a minimization* problem. You can find the path that light will take by knowing that the incoming angle is always the same as the outgoing angle, or you can use the fact that light always follows the fastest* path between two points.

I'd like to argue that there's a similar but underappreciated analog in AI research. Almost all problems come down to optimization. And in this regard, there are two things that matter -- what you're trying to optimize, and how you're trying to optimize it. And different methods that optimize approximately the same objective see approximately similar performance, unless one is much better than the other at doing that optimization. A lot of classical planners can be seen as approximately performing optimization on a specific objective.

Let me take a specific example: MCTS and policy optimization. You can show that the Upper Confidence Bound algorithm used by MCTS is approximately equal to regularized policy optimization. You can choose to guide the tree search with UCB (a classical bandit algorithm) or policy optimization (a reinforcement learning algorithm), but the choice doesn't matter much because they're optimizing basically the same thing. Similarly, you can add a state occupancy measure regularization to MCTS. If you do, MCTS reduces to RRT in the case with no rewards. And if you do this, then the state-regularized MCTS searches much more like a sampling-based motion planner instead of like the traditional UCB-based MCTS planner. What matters is really the objective that the planner was trying to optimize, not the specific way it was trying to optimize it.

For robotics, the punchline is that I don't think it's really the distinction of new RL method vs old planner that matters. RL methods that attempt to optimize the same objective as the planner will perform similarly to the planner. RL methods that attempt to optimize different objectives will perform differently from each other, and planners that attempt to optimize different objectives will perform differently from each other. So I'd argue that the brittleness and unpredictability of RL in your lab isn't because it's RL persay, but because standard RL algorithms don't have long-horizon exploration term in their loss functions that would make them behave similarly to RRT. If we find a way to minimize the state occupancy measure loss described in the above paper other theory papers, I think we'll see the same performance and stability as RRT, but for a much more general set of problems. This is one of the big breakthroughs I'm expecting to see in the next 10 years in RL.

*okay yes technically not always minimization, the physical path can can also be an inflection point or local maxima, but cmon, we still call it the Principle of Least Action.

#note: this is of course a speculative opinion piece outlining potentially fruitful research directions#not a hard and fast “this will happen” prediction or guide to achieving practical performance

28 notes

·

View notes

Text

youtube

youtube

youtube

youtube

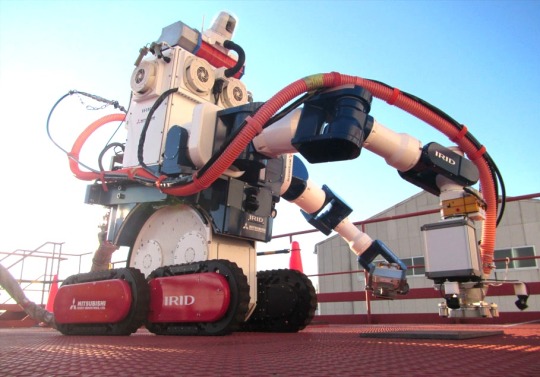

MEISTeR II (Maintenance Equipment Integrated System of Telecontrol Robot II), Mitsubishi Heavy Industries, Tokyo, Japan (2015). After the accident at Fukushima Daiichi Nuclear Power Plant in 2011, the interior of the reactor building is highly radioactive, and cannot be accessed by human workers. Remote controlled robots like MEISTeR II can carry out decontamination tasks using a range of specialised end-effectors. It can climb stairs, and it has a new "narrow space mode" that enables it to fold itself up into a compact form with a relatively tiny 85cm diameter footprint to navigate tight stairway landings. It even comes with its own decontamination train (second photo) for those stubborn radiological hazards.

59 notes

·

View notes

Text

Cancelled Missions: Testing Shuttle Manipulator Arms During Earth-Orbital Apollo Missions (1971-1972)

In this drawing by NASA engineer Caldwell Johnson, twin human-like Space Shuttle robot arms with human-like hands deploy from the Apollo Command and Service Module (CSM) Scientific Instrument Module (SIM) Bay to grip the derelict Skylab space station.

"Caldwell Johnson, co-holder with Maxime Faget of the Mercury space capsule patent, was chief of the Spacecraft Design Division at the NASA Manned Spacecraft Center (MSC) in Houston, Texas, when he proposed that astronauts test prototype Space Shuttle manipulator arms and end effectors during Apollo Command and Service Module (CSM) missions in Earth orbit. In a February 1971 memorandum to Faget, NASA MSC's director of Engineering and Development, Johnson described the manipulator test mission as a worthwhile alternative to the Earth survey, space rescue, and joint U.S./Soviet CSM missions then under study.

At the time Johnson proposed the Shuttle manipulator arm test, three of the original 10 planned Apollo lunar landing missions had been cancelled, the second Skylab space station (Skylab B) appeared increasingly unlikely to reach orbit, and the Space Shuttle had not yet been formally approved. NASA managers foresaw that the Apollo and Skylab mission cancellations would leave them with surplus Apollo spacecraft and Saturn rockets after the last mission to Skylab A. They sought low-cost Earth-orbital missions that would put the surplus hardware to good use and fill the multi-year gap in U.S. piloted missions expected to occur in the mid-to-late 1970s.

Johnson envisioned Shuttle manipulators capable of bending and gripping much as do human arms and hands, thus enabling them to hold onto virtually anything. He suggested that a pair of prototype arms be mounted in a CSM Scientific Instrument Module (SIM) Bay, and that the CSM "pretend to be a Shuttle" during rendezvous operations with the derelict Skylab space station.

The CSM's three-man crew could, he told Faget, use the manipulators to grip and move Skylab. They might also use them to demonstrate a space rescue, capture an 'errant satellite,' or remove film from SIM Bay cameras and pass it to the astronauts through a special airlock installed in place of the docking unit in the CSM's nose.

Faget enthusiastically received Johnson's proposal (he penned 'Yes! This is great' on his copy of the February 1971 memo). The proposal generated less enthusiasm elsewhere, however.

Undaunted, Johnson proposed in May 1972 that Shuttle manipulator hardware replace Earth resources instruments that had been dropped for lack of funds from the planned U.S.-Soviet Apollo-Soyuz Test Project (ASTP) mission. President Richard Nixon had called on NASA to develop the Space Shuttle just four months before (January 1972). Johnson asked Faget for permission to perform 'a brief technical and programmatic feasibility study' of the concept, and Faget gave him permission to prepare a presentation for Aaron Cohen, manager of the newly created Space Shuttle Program Office at MSC.

In his June 1972 presentation to Cohen, Johnson declared that '[c]argo handling by manipulators is a key element of the Shuttle concept.' He noted that CSM-111, the spacecraft tagged for the ASTP mission, would have no SIM Bay in its drum-shaped Service Module (SM), and suggested that a single 28-foot-long Shuttle manipulator arm could be mounted near the Service Propulsion System (SPS) main engine in place of the lunar Apollo S-band high-gain antenna, which would not be required during Earth-orbital missions.

During ascent to orbit, the manipulator would ride folded beneath the CSM near the ASTP Docking Module (DM) within the streamlined Spacecraft Launch Adapter. During SPS burns, the astronauts would stabilize the manipulator so that acceleration would not damage it by commanding it to grip a handle installed on the SM near the base of the CSM's conical Command Module (CM).

Johnson had by this time mostly dropped the concept of an all-purpose human hand-like 'end effector' for the manipulator; he informed Cohen that the end effector design was 'undetermined.' The Shuttle manipulator demonstration would take place after CSM-111 had undocked from the Soviet Soyuz spacecraft and moved away to perform independent maneuvers and experiments.

The astronauts in the CSM would first use a TV camera mounted on the arm's wrist to inspect the CSM and DM, then would use the end effector to manipulate 'some device' on the DM. They would then command the end effector to grip a handle on the DM, undock the DM from the CSM, and use the manipulator to redock the DM to the CSM. Finally, they would undock the DM and repeatedly capture it with the manipulator.

Caldwell Johnson's depiction of a prototype Shuttle manipulator arm with a hand-like end effector. The manipulator grasps the Docking Module meant to link U.S. Apollo and Soviet Soyuz spacecraft in Earth orbit during the Apollo-Soyuz Test Project (ASTP) mission.

Johnson estimated that new hardware for the ASTP Shuttle manipulator demonstration would add 168 pounds (76.2 kilograms) to the CM and 553 pounds (250.8 kilograms) to the SM. He expected that concept studies and pre-design would be completed in January 1973. Detail design would commence in October 1972 and be completed by 1 July 1973, at which time CSM-111 would undergo modification for the manipulator demonstration.

Johnson envisioned that MSC would build two manipulators in house. The first, for testing and training, would be completed in January 1974. The flight unit would be completed in May 1974, tested and checked out by August 1974, and launched into orbit attached to CSM-111 in July 1975. Johnson optimistically placed the cost of the manipulator arm demonstration at just $25 million.

CSM-111, the last Apollo spacecraft to fly, reached Earth orbit on schedule on 15 July 1975. By then, Caldwell Johnson had retired from NASA. CSM-111 carried no manipulator arm; the tests Johnson had proposed had been judged to be unnecessary.

That same month, the U.S. space agency, short on funds, invited Canada to develop and build the Shuttle manipulator arm. The Remote Manipulator System — also called the Canadarm — first reached orbit on board the Space Shuttle Columbia during STS-2, the second flight of the Shuttle program, on 12 November 1981."

source

#Apollo–Soyuz#Apollo Soyuz Test Project#ASTP#Apollo CSM Block II#CSM-111#Rocket#NASA#Apollo Program#Apollo Applications Program#Canadarm#Shuttle Manipulator Arms#Skylab Orbital Workshop#Skylab OWS#Skylab#Skylab I#Skylab 1#SL-1#Space Station#Apollo Telescope Mount#ATM#Cancelled#Cancelled Mission#my post

42 notes

·

View notes

Text

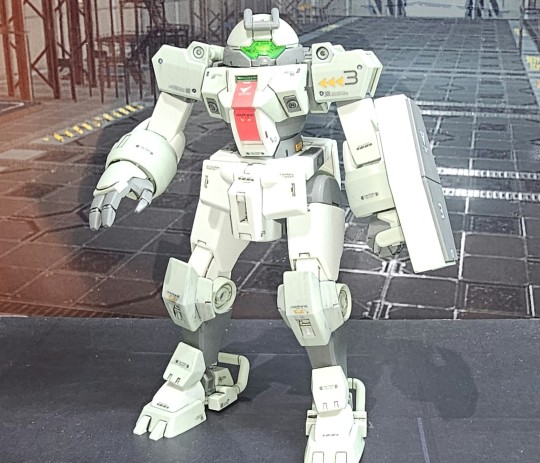

Developed by Burion-sha for the Asticassia School of Technology, the MSJ-121 Demi Trainer is the latest model in the line.

The Demi Trainer is a basic model mobile suit, perfect for aspiring pilots and mechanics alike to hone their skills. The suit is easily configurable and repaired with simple tools, and the end-effectors can be replaced by a variety of tools.

As expected with Asticassia's love of dueling, the Demi can be fitted with a shield along with various weapons, but it is overmatched by more combat-oriented suits like the MD-0064 Darilbalde or MD-0031 Dilanza, let alone advanced Gundams like the Aerial.

This is Bandai's HG kit with panel lining and G-Rework's decals.

22 notes

·

View notes

Text

There is nothing more fearful than to have to face even one of Cobra's Battle Android Troopers. Though not particularly built for endurance, B.A.T.s can still take tremendous amount of damage and continue fighting. They serve as nothing more than cannon fodder. As long as their trigger finger is in contact with a gun (or their weapons-based end effectors still have ammunition), they'll do as they were designed until absolutely nothing is left but scrap. B.A.T.s can be manufactured cheaply, quickly, and en masse. To ensure their inexpensiveness, they aren't equipped with very sophisticated logic circuits. As a result, they react poorly to changes in battlefield conditions and have a potential to mow down foes and allies alike.

Due to their inability to identify targets as friendly or hostile, they are not used in conjunction with normal Cobra troops. Cobra deploys B.A.T.s when their side is losing. They would also use the threat of B.A.T. deployment to keep demoralized troops from fleeing. On their own, they would move forward aimlessly until they spot a target — a moving heat signature — and they will attack it until it stops moving. They can be controlled remotely, but this leaves the units open to enemy disruption or control, so it is rarely done. When controlled, they can be given basic movement or targeting orders. Later models are a little more autonomous and can perform more sophisticated actions.

10 notes

·

View notes

Text

MONSTERVERSE

x

MURDER DRONES

==============

MECHAGODZILLA - PART 2

note: I've decided to make N's text blue to avoid confusion (and maybe a bit of symbolism). limitations of mobile tumblr, amiright?

-------------------------------------------

[Fwoosh-]

[Slam!]

"Thanks."

"No problem!"

Ugh. Those idiots make me sick. Just why do I deal with this?

..no use complaining. Nothing I can do but follow along.

like always.

"Hey, idiots! Let's get going."

"Bite me! I'm on it."

-

...I don't know what i expected when I followed Uzi down here.

It definitely wasn't..this.

Not..uhm, all of this tech.

I was expecting a JCJenson logo- or anything to signify this was ours.

..we only found something labelled "Apex".

..I think I have a bad feeling about this.

I mean- yeah, sure. What could go wrong? In a..place like this.

[gulp.]

..stay positive, N. Stay positive..

---

3 drones; 2 with installed disassembly and one of hosting nigh-cosmic absolution.

Optics scan all surrounding locality, though not without the caution- the slowness of alert systems.

Sensory data extrapolating a layout by the tick, plausible exits and entrances arranged upon CPU through visor, like clockwork.

"Looks reeeeal maintained. How?" Suspicion seeps by indifference. A tilt of the neck and she's facing upward, studying incremental detail and fine-polished metals which make up their overhang.

"..maybe worker's have been visiting?"

"Doubt it. This place is in the middle of nowhere. No worker's coming, let alone to clean of all things. It would of been scrubbed clean by now, not have so much stuff in it." Emphasis proceeds through a leg that strikes a steel box on it's side softly, sound reverberating; almost painful to hear compared to former silence.

Uzi is once again staring at coated metal and refined black, multitudes of questions laying dormant- yet where would I get the answers? Before the gaze travels downward.

A hint of apprehension when her optics register.

"Found a way forward, guys."

"Finally." "Oh! Good work, Uzi."

Footfall makes it's way down silver-lined halls- barring a level of resistance in the structure despite it's years, considered admirable.

For a wall, that is.

"This place looks advanced. We sure none of us didn't stumble into a secret science project?"

"Wouldn't put it past humans.."

"Come on now, it can't be that bad, right?"

"Oh, to live in your mind.."

"Hey! he's just being optimistic."

"Optimistic 'til shutdown, right?"

"Ugh, do you ever shut up?" Anger coils around digits, constricting openness to fists.

"Only if I have to."

"Urgh!- whatever! We need to go, so shut it and follow me. Can you do that?"

"Y-" [Sigh.] "Fine."

Silence permeates space, forceful tension infiltrating effector processors- No doubt due to her.

..

The sound of boots hitting steel is what Uzi decides to focus on.

The way sound waves impact then register, the way fabric twists and adjusts with each micro-movement, the way she doesn't have to pay attention to her almost-tangible thoughts.

It helps, it really helps. Though, she wouldn't usually just say that.

What's gotten into me?

Though- as much as she'd like to focus on that thought, the wall something-meters ahead is giving 50 different warnings that she really can't be bothered to read right now.

All because I hit a tree last time? Seriously?

So, purple regrettably turns left.

Ugh.

--

PART 2 - FINISHED

AFTER NOTES:

next chapter is gonna be the main meat of interaction (because they’re gonna meet mg)

accidentally posted this but i kinda wrote myself into a corner at the end so it’s fine and i can continue like nothing happened next part

#monsterverse x murder drones#monsterverse#murder drones#serial destination v#serial designation n#uzi doorman#mechagodzilla 2021#mechagodzilla

5 notes

·

View notes

Text

Robot End Effector Market is Register to Grow at a CAGR of 13.5% during 2023-2028

The global robot end effector market is expected to grow from USD 2.3 billion in 2023 to USD 4.3 billion by 2028, registering a CAGR of 13.5%. Increasing demand for modular end effectors and the growing adoption of collaborative robots due to the fast-changing nature of industries are among a few major factors driving the growth of the robot end effector market. Key players operating in the robot end effector market include Schunk (Germany), Schmalz (Germany), Zimmer Group (Germany), Tünkers (Germany), and Destaco (US) are the top five players in the robot end effector market. Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=251736819 Grippers is expected to register a higher CAGR during the forecast period. The market for grippers is largely driven by their handling application in a wide range of workpieces considering their various shapes and size. The increasing application of soft grippers and vacuum grippers in different varieties of handling and assembly applications across several industries would present several growth opportunities to players operating in the gripper segment. Collaborative industrial robots to record the highest CAGR during the forecast period. Robot end effector market for collaborative industrial robots is to grow at the highest CAGR during the forecast period. This is due to the adoption of collaborative robots, especially for small and medium-sized companies, to easily adapt to different tasks and enable a faster return on investment (ROI). These robots are witnessing widespread adoption in small and medium-sized enterprises and large-scale, traditional industries such as automotive. With the growing adoption of cobots in many new use cases, such as remote monitoring and remote manufacturing are being enabled, this factor is expected to propel the growth of the end effector market for collaborative industrial robots. China is expected to account for the largest market share in Asia Pacific market from 2023 to 2028. China accounted for the largest share of the robot end effector market in Asia Pacific in 2022 and is expected to remain the largest market throughout the forecast period. As many Asian countries are highly populated, and the geriatric population is becoming a concern for the future, the aging population, especially in China, is prompting companies toward automation and industrial robots to reduce costs. With the rise in industrial robots for automation, the demand for their associated end effectors is also expected to increase.

0 notes

Text

I want an ExForce/Culture crossover for the sole purpose of having Skippy be on the receiving end of snark from a Mind.

That and seeing everyone in the war collectively losing their mind over things like an Effector.

3 notes

·

View notes

Text

i need to learn to mod doom. i want to play a doom wad where doomguy has been replaced with perseverance (rover). your map based off a RIMFAX reading, and you can scout the area with ingenuity. it drops explosives instead of soil samples. PIXL and SHERLOC have been replaced with an end effector that can aim a gun

like this:

6 notes

·

View notes