#Electrostrictive Materials

Explore tagged Tumblr posts

Text

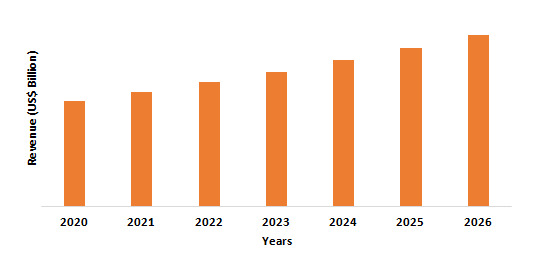

The Smart Materials Market was valued at USD 70.14 billion in 2021 and is predicted to reach USD 251.20 by 2030 with a CAGR of 15.5% from 2022 to 2030.

#SmartMaterialsMarket#Piezoelectric Materials#Electrostrictive Materials#Magnetostrictive Materials#Shape-memory Alloy Materials#Electrochromic Materials#Phase Change Materials#Transducers#Actuators & Motors#Sensors#Packaging#Structural & Building Materials#Industrial#Defense & Aerospace#Healthcare#Automotive#Consumer Electronics

1 note

·

View note

Text

Sound waves and spark oscillations:

Premise: Jazz has a different playlist for different things- and this includes missions, and off time.

Thesis: Jazz's choice of music in each playlist affects his performance in the positive.

Hypothesis: Sound waves actually affect spark oscillations thanks to Brillouin scattering.

Evidence: In electromagnetism, Brillouin scattering (also known as Brillouin light scattering or BLS), named after Léon Brillouin, refers to the interaction of light with the material waves in a medium (e.g. electrostriction and magnetostriction). It is mediated by the refractive index dependence on the material properties of the medium; as described in optics, the index of refraction of a transparent material changes under deformation (compression-distension or shear-skewing).

Broken down: Sound waves interact with light by changing its momentum into preferential directions. This means, for example, the higher the BPM of a particular track, the faster it spins the spark- creating extra energy without the frame having to utilize its own fuel source. It's only by a fraction of a percentage: .25% or so- but enough that Jazz can use it for surprise maneuvers.

Or even that extra burst of speed.

Conversely, a slower BPM or RPM on music can slow down a spark's oscillating spin- making the mechanism sleepier or destressing them to the point their processor can shut down- ESPECIALLY if they have extrasensory equipment like doors, audio horns, or sensor panels.

This is also evidence of why mechanisms like Blaster, Jazz, and Soundwave are so deadly: music can save or end a life.

#headcanons#look#acoustic science is absolutely fascinating#even if I don't understand half of it#I can appreciate what it can DO

5 notes

·

View notes

Text

An approach to enhancing relaxors for energy storage devices

Relaxor ferroelectrics are materials with ferroelectric properties and high electrostriction (i.e., the ability to contract or deform in response to electric fields). These materials can be used to create highly efficient energy storage devices, such as capacitors. Capacitors are key electronic components composed of two electrical conductors with a given distance between them. These components can temporarily store electric charge, reducing the noise transmitted by individual integrated circuits (ICs) and thus improving the overall performance of electronics. Researchers at Tsinghua University and other institutes in China recently introduced a new strategy to engineer effective relaxor ferroelectrics for energy storage devices. Their paper, introduced in Nature Energy, suggests using a so-called configurational entropy to evaluate the local inhomogeneity of a relaxor's composition.

Read more.

4 notes

·

View notes

Text

Electroactive Polymers Market — By Type , By Application , By Geography — Global Opportunity Analysis & Industry Forecast, 2024–2030

Electroactive Polymers Market Overview

Request Sample :

Electroactive Polymers Market COVID-19 Pandemic

The outbreak of Covid-19 is having a huge impact on the economy of electronic devices. The COVID-19 pandemic caused an unprecedented increased demand for some medical devices, as well as significant disruptions in the manufacturing and supply chain operations of global medical devices. The FDA monitors the supply chain of medical products and works closely with producers and other stakeholders to assess the risk of disruption and to prevent or reduce its impact on patients, health care providers, and the general public’s health. In addition, there is a delay in imports and exports of medical devices due to the import-export restriction by the governments in various regions. All these factors are having a major impact on the Electroactive Polymers Market during the pandemic.

Report Coverage

The report: “Electroactive Polymers Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the electroactive polymers Industry.

By Type: Ionic Electroactive Polymers (Ionic Polymer Gels (IPG), Ionic Polymer Metal Composites (IPMC), Conductive Polymers (CP), and Carbon Nanotubes (CNT)), Electronic Electroactive Polymers (Ferroelectric Polymers, Electrostrictive Graft Elastomers, Dielectric Elastomers, Electro VIscoelastic Elastomers, Liquid Crystal Elastomer (LCE), and Others), and Others.

By Application: Actuators, Sensors, Plastic, Aviation Technology, Energy Generation, Automotive Devices, Prosthetics, Robotics, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the Electroactive Polymers Market owing to the increasing demand for the electroactive polymers industry in the region. The increasing urbanization coupled with the rising population in APAC is the major factor driving the demand for electroactive polymers.

Electroactive polymers are extensively used for corrosion-preventing coatings in ferrous and non-ferrous alloys, actuators, damped harmonic oscillator, metamorphic biomaterials, and protective fabrics points. These properties of electroactive polymers are projected to increase market growth.

Electroactive polymers due to its unique properties find application in different end-use industries. These are lighter in weight, more durable, and have better conductive properties, unlike conventional materials (metals). During the forecast period, this factor is anticipated to drive the market.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which the projects and operations of various industries such as energy generation and automotive are disruptively stopped, which is hampering the Electroactive Polymers Market growth.

Electroactive Polymers Market Segment Analysis — By Type

The conductive polymers segment held the largest share in the Electroactive Polymers Market in 2020 and is growing at a CAGR 8.10% over 2024–2030. The significant class of functional materials that have certain useful properties of both organic polymers (such as strength, plasticity, flexibility, strength, elasticity) and semiconductors (such as electric conductivity) are conducting polymers (CPs). The conductive polymers are often used in miniature boxes that have the ability to open and close, micro-robots, surgical tools, surgical robots that assemble other micro-devices. In addition, conductive polymers (CPs) are extensively used as an alternative to metallic interfaces within biomedical devices as a way of imparting electroactivity to normally passive devices such as tissue scaffolds. Thus, all these extensive characteristics of conductive polymers are the key factor anticipated to boost the demand for conductive polymers in various regions during the forecast period.

Schedule A Call :

Electroactive Polymers Market Segment Analysis — By Application

The actuator segment held the largest share in the Electroactive Polymers Market in 2020 and is expected to grow with a CAGR of 7.2% for forecast period. To maximize the actuation capability and durability, effective fabrication, shaping, and electrode techniques are being developed. Many engineers and scientists from many different disciplines are attracting attention with the impressive advances in improving their actuation strain. Due to their inherent piezoelectric effect, ferroelectric polymers, such as polyvinylidene fluoride (PVDF), are largely used in manufacturing electromechanical actuators. For biomimetic applications, these materials are especially attractive, as they can be used to make intelligent robots and other biologically inspired mechanisms. To form part of mass-produced products, many EAP actuators are still emerging and need further advancements. This requires the use of models of computational chemistry, comprehensive science of materials, electro-mechanical analytical tools, and research into material processing. Which will eventually drive is the Electroactive Polymers Market during the forecast period.

Electroactive Polymers Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the Electroactive Polymers Market in 2020 up to 38%, owing to the escalating medical device industry in the region. A key factor behind the growth of the region’s electroactive polymer market is the large demand for electroactive polymers for the manufacture of advanced implant devices for medical conditions. According to Invest India, the Indian medical device sector is projected to register a CAGR of 14.8% and is expected to reach $11.9 billion in 2021–22, and the sector is projected to reach $ 65 bn industry by 2024. According to the most recent official figures from the Ministry of Health, Labour and Welfare (MHLW), the Japanese medical devices market in 2018 was roughly $29.3 billion, up about 6.9 percent from 2017 in yen terms. And from 2018 to 2023, the medical device market in Japan is estimated to show an increment of 4.5% CAGR in yen terms. Furthermore, North America also holds a prominent market share of the Electroactive Polymers Market due to the escalating medical device industry. According to the Select USA, the United States medical device market is anticipated to rise to $208 billion by the year 2023. Thus, with the expanding medical device industry, the demand for electroactive polymers will also subsequently increase, which is anticipated to drive the Electroactive Polymers Market in the Asia Pacific and North America during the forecast period.

Electroactive Polymers Market Drivers

Increasing Automotive Production

In the automotive industry, electroactive polymers are used as actuators and sensors. For materials that are light in weight but strong and durable such as an electroactive polymer, there is high demand. By using modern electroactive polymers in numerous automotive electronic components, such as multiple sensors, accelerometers, and accelerator pedal modules, car manufacturers are attempting to achieve lightweight properties. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects the production of cars to reach 35 million by 2025. According to the International Trade Administration (ITA), in 2019 the Mexican market for electric, plug-in vehicles, and hybrid vehicles reached 25,608 units, representing a 43.8% growth over 2018. Thus, increasing automation production will require more electroactive polymers for manufacturing various automotive components, which will act as a driver for the Electroactive Polymers Market during the forecast period.

Increasing Application of Electroactive Polymers

Textiles called sensing and actuating microfibers can be directly woven into electromechanical systems such as sensors, actuators, electronics, and power sources. They can be used as smart fabrics because of the flexibility and low cost of electroactive polymers. In developing intelligent fabrics, polypyrrole and polyaniline are used. In addition, using electroactive polymers in robotics for muscle development is better, as it is more cost-effective than the semiconductor and metal materials. And robotics is widely used; hence the demand for electroactive polymers will also positively affect the market growth. Furthermore, Electroactive Polymers Market growth is increasing owing to its wide usage in areas such as medical devices, damped harmonic oscillator, electric displacement field, electrostatic discharge/electromagnetic interference, high-strain sensors, and biomimetic. Hence, the increasing application of electroactive polymers acts as a driver for the Electroactive Polymers Market.

Buy Now :

Electroactive Polymers Market Challenges

Environmental Hazards Related to the Electroactive Polymers

Raw materials which are used to produce electroactive polymers (EAPs) are difficult to extract and often harmful to the environment. The disposal of waste generated by electroactive polymers is one of the major concerns (EAPs). Improper disposal of EAP products could harm the environment and ultimately impact the food chain. Manufacturers of EAPs may experience increased costs associated with the disposal of certain electroactive polymers (EAPs) that cannot be disposed of by biodegradation. The government has, therefore, enforced strict regulations on the use of such polymers. Besides, the environmental regulations on the use of petroleum products restrict the growth of the EAPs market. These factors are hampering the electroactive polymer market growth.

Electroactive Polymers Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Electroactive Polymers Market. Major players in the Electroactive Polymers Market are Solvay, Parker Hannifin, Agfa-Gevaert, 3M, Merck, Lubrizol, Novasentis, Premix, PolyOne Corporation, Celanese Corporation, and KEMET Corporation.

Key Market Players:

The Top 5 companies in the Electroactive Polymers Market are:

Merck

3M

Solvay

Parker Hannifin

Agfa-Gevaert

For more Chemicals and Materials Market reports, Please click here

#ElectroactivePolymers#SmartMaterials#ConductivePolymers#FlexibleElectronics#ShapeMemoryAlloys#PolymersInElectronics#SoftRobotics

0 notes

Text

0 notes

Quote

In electromagnetism, Brillouin scattering (also known as Brillouin light scattering or BLS), named after Léon Brillouin, refers to the interaction of light with the material waves in a medium (e.g. electrostriction and magnetostriction). It is mediated by the refractive index dependence on the material properties of the medium; as described in optics, the index of refraction of a transparent material changes under deformation (compression-distension or shear-skewing).

Brillouin scattering - Wikipedia

0 notes

Text

Smart Materials Market Growth Dynamics 2023 Emerging Technologies and Supply Chain Analysis

Smart materials refer to those materials that have the ability to change their properties in response to an external stimulus. These stimuli can be temperature, pressure, light, or any other physical or chemical change. The properties of smart materials can change reversibly or irreversibly, depending on the type of material and the stimulus applied.

The global smart materials market is expected to grow significantly in the coming years, driven by the increasing demand for smart materials in various end-use industries such as aerospace, automotive, healthcare, and construction.

Some of the major types of smart materials are:

Shape memory alloys (SMAs): These are metallic alloys that can return to their original shape when heated after being deformed.

Piezoelectric materials: These are materials that generate an electric charge when subjected to mechanical stress or pressure.

Electrostrictive materials: These are materials that change shape when an electric field is applied.

Magnetostrictive materials: These are materials that change shape when subjected to a magnetic field.

Thermoelectric materials: These are materials that generate an electric voltage when there is a temperature difference between two points.

Phase change materials: These are materials that can change their phase from solid to liquid or vice versa, in response to changes in temperature.

Some of the major applications of smart materials are:

Actuators and motors

Sensors and transducers

Structural materials

Energy harvesting

Medical devices

Consumer electronics

The smart materials market is also segmented by geography, with North America, Europe, Asia Pacific, and Rest of the World being the major regions. Some of the key players in the global smart materials market are:

BASF SE

Carpenter Technology Corporation

Kyocera Corporation

TDK Corporation

Noliac A/S

CeramTec GmbH

Smart Material Corporation

Wright Medical Group N.V.

Harris Corporation

CTS Corporation

In conclusion, the smart materials market is expected to witness significant growth in the coming years, driven by the increasing demand for smart materials in various end-use industries. With advancements in technology, the development of new and innovative smart materials is expected to further boost the growth of this market.

0 notes

Text

Inventions | Free Full-Text | Robust Control and Active Vibration Suppression in Dynamics of Smart Systems

1. Introduction A piezoelectric structure with a control strategy has the potential to adapt to both a changing internal environment and a changing external environment, such as stresses or form changes. It includes intelligent actuators that enable controlled modification of system parameters and reactions. Piezoelectric materials (PZT), shape memory alloys, electrostrictive materials,…

View On WordPress

0 notes

Text

Who are the Active Players in Electrostrictive Materials Market ?

Electrostrictive Materials Market 2021

All the dielectric materials are electrostrictive materials, which cause electrostriction when the displacement of ions occurs in the crystal lattice during exposure to an external electric field. Cation moves towards the direction of the electric field, while anion moves away from the electric field. Electrostriction is similar to piezoelectricity; the main difference is that electrostriction is a quadratic effect, while piezoelectricity is a linear effect. Therelaxor ferroelectrics are considered electrostrictive material as they have extraordinarily high electrostrictive constants. The most commonly used electrostrictive include lead magnesium niobate (PMN), lead magnesium niobate lead titanate (PMN-PT), and lead lanthanum zirconate titanate (PLZT).

Get a Sample copy of this report : https://straitsresearch.com/report/Electrostrictive Materials-Market/request-sample

The Major Manufacturers Covered in this Report:

APC International Harris Corporation PI Ceramic Morgan Technical Ceramics Mad City Labs Noliac A/S and more...

0 notes

Photo

Atomically engineered interfaces improve electrostriction in an oxide material

An international team of researchers has found a way to improve electrostriction in an oxide material by atomically engineering the interfaces of the layers of which it is made. In their paper published in the journal Nature, the group shows that electrostriction in oxides can be enhanced through the use of artificial interfaces. David Egger with the Technical University of Munich, has published a News & Views piece in the same journal issue outlining the work done by the group on this new effort.

Prior research has shown that applying an electric field to a material can sometimes result in desired modifications to the shape of the material—a phenomenon known as electrostriction. It has been used to great effect in creating motors and actuators. Formally, it is described as the process of generating strain in a material through application of an electric field. Unfortunately, most such applications involve the use of lead, which is toxic, so researchers have been looking for other materials.

One such promising possibility involves the use of tailored oxides, though the tailoring has not yet been worked out. In this new effort, the researchers report a big step toward that goal. They found a material made by layering different oxides in particular ways can improve the degree of electrostriction that results.

Read more.

21 notes

·

View notes

Link

0 notes

Text

Smart Materials Market to Reach USD 115.08 Billion by 2030 | Growth Rate (CAGR of 14%)

The global smart materials market is expected to exhibit a strong 14% CAGR over the forecast period from 2022 to 2030, according to the latest research report from Market Research Future (MRFR). The global smart materials market is thoroughly analyzed in the report, which takes into account all the major factors enabling the growth of the smart materials market and presents a detailed analysis of the key factors driving and restraining the global market. The major economic and regulatory factors affecting the market’s growth are also profiled in the report to provide readers with a comprehensive overview of the market.

Smart materials have become increasingly important in recent years due to the growing commercial interest in the Internet of Things (IoT) and smart connectivity. Smart materials are materials that can alter their response to environmental variables. This makes them highly valued in several consumer electronics, automotive, and IT products. Electric fields, magnetic fields, temperature, moisture, and pressure are just some of the stimuli that can trigger a change in smart materials. The growing demand for smart, responsive skins on mobile phones, tablets, and other consumer electronics is likely to be a major driver for the smart materials market over the forecast period. The growing demand for smart fabrics and smart clothing is also likely to be a major driver for the global smart materials market. Smart clothing can be made to react to a wide range of stimuli, making it capable of reacting to heat gain, heat loss, moisture gain or loss, and other factors. This allows smart clothing to provide a valuable service to the wearers.

The growing demand for piezoelectric devices in a number of healthcare applications is likely to be a key driver for the global smart materials market. Medical devices, medical and other robotic tools, and automotive are some of the key applications for piezoelectric devices and are likely to exhibit robust demand over the forecast period. This is likely to lead to steady growth of the smart materials market over the forecast period. Increasing demand for artificial organs made from smart materials is also likely to be a major driver for the global smart materials market. Artificial organs made from smart materials are likely to take on an important role in the smart materials market over the forecast period, as an increasing number of patients requiring artificial organs has driven the demand at a strong rate over the last few years.

Segmentation:

The global smart materials market is segmented by product, application, and region.

By product, the global smart materials market is segmented into piezoelectric materials, shape memory materials, electrostrictive materials, magnetostrictive materials, phase change materials, electrochromic materials, and others.

By application, the global smart materials market is segmented into actuators and motors, transducers, sensors, structural materials, and others.

Regional Analysis:

North America is the leading revenue generator in the global smart materials market, followed by Europe and Asia Pacific. The growing demand for smart actuators and motors in automotive, aerospace, and consumer goods industries in North America is likely to be a major driver for the smart materials market in the region.

Competitive Analysis:

Leading players in the global smart materials market include LORD Corporation, Channel Technologies Group, Wright Medical Group Inc., Noliac A/S, TDK Corporation, Kyocera Corporation, CeramTec, Harris Corporation, and APC International.

In October 2019, a research team from the University of Iowa and the University of Illinois at Urbana-Champaign launched a project to develop smart skin based on the skin of cephalopods. Twisted and coiled polymer fibers were used to produce the musculature of the artificial skin, making the skin capable of fine motion and smooth modulation of the shape. The skin is expected to see application in interfaces in 3D displays for the blind as well as in marine vehicles, where the skin can be used to reduce the drag and make the vehicle more aerodynamic.

Read More Report Summary: https://www.marketresearchfuture.com/reports/smart-materials-market-5333

#Smart Materials Market#Global Smart Materials Market#Smart Materials Industry#Smart Materials Market Analysis#Smart Materials Market Types

0 notes

Text

Smart Materials Market - Industry Analysis, Market Size, Share, Trends, Application Analysis, Growth And Forecast 2022 - 2027

The Smart Materials market size is forecast to reach US$110.7 billion by 2027 after growing at a CAGR of 12.8% during 2022-2027. Smart materials have inherent and extrinsic qualities that are adaptable and clever in operation. Technological advancements in material science have enabled the growth of this market for the production of smart materials like photovoltaic-integrated electrochromic devices for smart applications, having specific required purposes that were earlier hard to manufacture using conventional materials like polymers, plastics, metals, glass, and ceramics. Smart materials are more often being utilized as dielectric elastomers in microelectronic component energy supply systems. Smart materials hold some special properties that allow them to get back to their original state after removal of the external stimuli, like electric and magnetic fields, temperature, pressure, mechanical stress, hydrostatic pressure, and others. Piezoelectric materials (PZT), shape memory alloy materials (SMA), electrostrictive materials (PMN), magnetostrictive materials, and phase change materials have gained wide industrial acceptance in recent times. Moreover, ferromagnetic shape memory alloys, conductive polymers, nanotube actuators, and electroactive polymers are a couple of emerging smart materials used within the market, with strong application potential. Increasing use of smart transducers, actuators, sensors, and structural materials, is expected to drive the demand of the smart materials market during the forecast period.

COVID-19 Impact

Currently, due to the COVID-19 pandemic, the core end-use industries such as aerospace, automotive, industrial, electrical, and electronics industries were highly impacted. Due to social distancing policy, most of the manufacturing plants of aircraft and automobiles were shut down, which declined the regular production of commercial aircraft and vehicles. With aerospace and defense being the major end-use industry, according to the Welsh Government services and information, the global demand for production of short-haul sized aircraft is most probably going to drop by 15% and by 30 - 65% for long haul sized craft, by the end of 2025, as an extended-term impact of the covid-19. Also, due to supply chain disruptions like delay in reaching of raw materials or non-arrival, disrupted financial flows, and rising absenteeism among production line staff and employees, OEMs have been forced to function at zero or partial capacity, resulting in lower demand and consumption for Smart Materials in 2020.

Report Coverage

The report: “Smart Materials Market – Forecast (2022-2027)”, by IndustryARC, covers an in-depth analysis of the following segments of the Smart Materials Market.

By Product Type: Piezoelectric Materials (PZT), Shape Memory Alloy Materials (SMA), Electrostrictive Materials (PMN), Magnetostrictive Materials (Terfenol-D), Electrochromic Materials, Phase Change Materials, Others. By Application: Transducers, Actuators and Motors, Sensors, Structural and Building Materials, Smart Textile, Packaging, and Others. By End-Use Industry: Industrial, Aerospace and Defense, Automotive, Electrical and Electronics, Healthcare, Food and Beverages, and Others. By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (the Middle East, and Africa).

Key Takeaways

North America was the leading region for the smart materials market, thanks to the rising demand for smart actuators and motors in end-use industries like automotive, electrical and electronics, and aerospace.

Europe accounted for the second-largest share of the market, followed by the Asia Pacific, and is anticipated to be the fastest-growing region of the market during the forecast period.

Growing consumption of piezoelectric devices in numerous end-use industries has accelerated the demand in the smart materials market, thereby being the most important shareholder within the product type segment.

The dominance of the piezoelectric product segment care is often primarily attributed to the rising demand in applications such as hydrophones, sonar, speakers, buzzers, gas igniters, and sporting equipment.

The use of smart materials within the aerospace and defense segment has increased and is predicted to grow at a rapid rate as compared to other industries during the forecast period.

Figure: North America Smart Materials Market Revenue, 2021-2027 (US$ Billion)

For More Details on This Report - Request for Sample

Smart Materials Market Segment Analysis – By Product Type

The Piezoelectric Materials (PZT) segment held the largest share of 36% in the Smart Materials market in 2021. Piezoelectric smart materials have the ability to transduce the mechanical pressure acting on them into the electrical signals called the direct piezoelectric effect, and electrical signals to mechanical signals called the converse piezoelectric effect. For the material to possess piezoelectricity, it should have a lack of center of symmetry and also depends on its crystal lattice structure. Piezoelectric smart materials are applied in a wide range of applications in the electrical and electronics industry which includes transducers, actuators, motors, and sensors. Piezoelectric smart materials are also utilized as electroactive scaffolds for tissue repair and regeneration in tissue engineering. They have the capacity to deliver variable electrical stimuli without an external power source involved. Globally increasing research and development investments by research universities & companies for the development of advanced technology for piezoelectric smart materials in aerospace and defense applications, electrical, and other major industries, are driving the market growth. Additionally, the rise in demand for piezoelectric smart sensors for fluid measurements like compositions, density, viscosity, and impact force is expected to bring new opportunities and demand during the forecast period for the smart materials market. As a result, the demand for piezoelectric smart materials can be seen and will increase significantly, which contributes to increased business growth.

Smart Materials Market Segment Analysis – By Application

The sensors segment held the largest share of 34% in the Smart Materials market in 2021. A piezoelectric sensor is a smart device that helps to convert changes in strain, pressure, acceleration, temperature, or force into an electric charge using the piezoelectric effect. These sensors offer a variety of advantages like good frequency response, availability in the desired shape, negligible phase shift, and is of small size. The industrial segment employs piezoelectric sensors for a number of uses such as pressure sensors and sonar equipment. Moreover, the increasing use of piezoelectric sensors in industries like aerospace and defense, automotive, healthcare for medical applications, as pressure sensors in the touchpads of mobile phones, and as tilt sensors in electrical and electronic devices, is expected to accelerate the global smart materials market. Furthermore, the actuators segment is projected to be the fastest-growing segment during the forecast period of the global smart materials market, as they are highly employed in the aerospace and defense industry. Hence, a positive growth curve for the smart materials market in various applications is expected during the forecast period.

Smart Materials Market Segment Analysis – By End Use Industry

The Aerospace and Defense segment held the largest share of 44% in the Smart Materials market in 2021. The increasing aircraft fleet and the rising defense expenditure have increased the production of aircraft across the world, creating immense demand for smart materials, as it helps in maintaining and guiding the airflow across the aircraft wings and while take-off and landing. Also, these smart materials are applied to solve some common complications associated with aircraft engine vibration, flow separation due to turbulence, ice formation on wings, and high cabin noise levels. Every year, countries allocate a specific amount of budget for their defense sector, especially in developed and developing countries like the United States, China, and India, the governments have been increasing the national defense budget regularly, which is predicted to boost the smart materials market. These smart materials are widely used as nanorobots, sensors, combat suits, and others in the military and defense sectors extensively. For instance, China’s military spending is increasing every year, with around a 25% rise in almost every following year over the past two decades, which was around USD 10 billion in 1999 and has increased to over USD 250 billion in 2020. Furthermore, due to the covid impact, there was a temporary dip in the revenue graph of Boeing, a leading manufacturer of aircraft and defense crafts in the world, which had a revenue of USD 58.16 billion in the year 2020, which has comparatively fallen from 2019 revenue of USD 76.56 billion. Overall, the market for smart materials in the aerospace and defense industry is expected to recover gradually through the forecast period and grow consistently.

Smart Materials Market Segment Analysis – By Geography

North America region held the largest share in the Smart Materials market in 2021 up to 40%, owing to the increasing demand from the aerospace and defense industry, which has increased at a rapid rate, due to the rise in the exports and consumer base of the region. The United States accounts for the most important manufacturers of the aerospace and defense industry in the world. According to the Federal Aviation Administration (FAA), “the entire commercial aircraft fleet is predicted to reach 8,270 by 2037, due to the expansion in air cargo.” Also, the US mainliner carrier fleet is predicted to grow at a rate of 54 aircraft per annum, thanks to the prevailing fleet getting older. According to the International trade association, “Canada ranks first in civil flight simulation, third in civil engine production, and fourth in civil aircraft production”. It is the sole nationally ranked within the top five of all the key categories. The aerospace industry led the Canadian manufacturing sector in innovation-related investment such as R&D activities with an expenditure of over USD 1.4 billion annually (nearly a quarter of all manufacturing R&D). Hence, all the aforementioned factors driving the aerospace and defense segment are expected to cause a significant impact on the demand for smart materials market within the region over the forecast period.

Secondly, Asia Pacific is predicted to be the fastest-growing region over the forecast period. Europe is the second major exporting region for Smart Materials due to its capacity. Hence, with all such applications and robust demand within all the regions, the Smart Materials market is predicted to witness healthy growth globally during the forecast period.

Smart Materials Market Drivers

Increasing demand for smart materials by a growing global economy

The smart materials market is growing and thanks to the rapidly rising demand in various applications like the industrial, automotive, and aerospace industries. Also, the rapid growth within automotive and automobile production on account of the rapidly growing demand from emerging economies is additionally highly impacting the expansion of smart materials. In spite of the coronavirus crisis, between march and may 2020, global automotive sales contracted by around 15% globally. But within a few months, the market recovered by 5% showing a positive sign of growth. Thus, increasing automation production will require more automotive smart materials, which will act as a driver for the smart materials market. Additionally, the rising importance of air cargo delivery alongside the growing number of air passengers is also anticipated to flourish the demand of the smart materials market due to the above-mentioned reasons and is additionally projected to grow substantially during the forecast period.

Demand from the Healthcare industry

Smart materials are consistently gaining attention in the healthcare industry owing to their benefits and properties. These materials are utilized in biomedical devices mainly for their biocompatibility and biodegradability. The increasing consumption of smart materials like sensors and actuators to develop smart medical devices and supply a greater understanding of piezoelectricity within the medical industry is driving the expansion of the market. Also, the rising investments in medical devices in the healthcare sector are another major factor driving the growth of the market. For instance, according to the India Brand Equity Foundation (IBEF), in May 2020, the government of India announced incentivization plans of at least USD 4.9 billion over a five-year period to further facilitate investments in manufacturing medical devices, which will involve the use of smart materials. Thus, all the aforementioned factors are therefore expected to drive the smart materials market growth in the healthcare industry during the forecast period.

Smart Materials Market Challenges

High cost of smart materials

Smart materials are very efficient materials and have high performance, however, it comes with high costs associated with the high level of investments made in the research and development of the product. End-use industries usually prefer and are searching for products that have greater efficiency with lower costs. Due to which, the industrial sector is cost-intensive and manufacturers are still searching for both effective and low-cost alternatives of smart materials. Additionally, in the automotive industry, active smart materials are gaining attention, but the growth might get hampered due to the high costs involved and would become a barrier to penetrate into the majority class of middle-stream background and would be seen upon as a futile investment, therefore, limiting the market only to high-end users. Hence, the high cost of smart materials will remain a restraint for the smart materials market growth during the forecast period.

Smart Materials Industry Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in this market. Smart Materials top 10 companies include:

APC International Ltd.

Harris Corporation

CeramTech GmbH

Kyocera Corporation

TDK Corporation

Noliac A/S

Ametek Inc.

CTS Corporation

LORD Corporation

Arkema

Recent Developments

In February 2021, CTS Corporation, along with Entekno Materials of Turkey, announced that they have secured funding from Eurostars to develop environmentally-friendly lead-free piezoelectric ceramic smart material. This material is developed in consideration to replace lead-based materials.

In April 2021, Evonik launched a new product line of photopolymers for 3D printing, where the product incorporates color phase change materials. This new line of photopolymers is ready-to-use, high-performance formulations, which is bundling Evonik’s expertise in 3D printing using smart materials and its innovation growth field.

In February 2020, Hexagon announced the launch of a new smart material, where its release of Intergraph Smart® Materials 10 marked a major milestone in its product’s history. This latest update to Hexagon’s market-leading materials and contract management system marks the largest update in Smart Materials history.

0 notes

Text

Smart Materials Market CAGR Status, Emerging Trends and Forecast till 2030

Smart materials refer to a class of advanced materials that are capable of changing their properties based on external stimuli such as temperature, stress, pH, magnetic or electric fields, and other environmental factors. The market for smart materials is driven by their growing application across a wide range of industries including aerospace, automotive, healthcare, consumer electronics, and construction.

Market Size:

The global smart materials market size was valued at USD 50.38 billion in 2020 and is expected to grow at a CAGR of 14.9% from 2021 to 2028 to reach USD 152.27 billion by 2028.

Key Drivers:

The growth of the smart materials market is driven by factors such as the increasing demand for smart materials in the automotive and aerospace industries, the rising use of smart materials in consumer electronics and wearable devices, and the growing focus on energy efficiency and sustainability.

Smart Materials Types:

Piezoelectric materials

Shape memory alloys

Electrostrictive materials

Magnetostrictive materials

Thermoresponsive materials

Photoresponsive materials

Hydrogels

Others

Applications:

Aerospace & Defense

Automotive

Consumer Electronics

Healthcare

Construction

Others

Regional Analysis:

North America

Europe

Asia Pacific

Middle East and Africa

Latin America

Key Players:

Honeywell International Inc.

3M

BASF SE

Covestro AG

Wacker Chemie AG

KYOCERA Corporation

Noliac A/S

CTS Corporation

TDK Corporation

CeramTec GmbH

Conclusion:

The smart materials market is expected to witness significant growth in the coming years due to the increasing demand for these materials across various industries. The rising adoption of smart materials in the automotive, aerospace, and healthcare sectors is expected to drive the market growth. However, the high cost of smart materials and the lack of skilled professionals may hinder market growth to some extent.

0 notes