#Electro Hydraulic Servo Valve industry

Explore tagged Tumblr posts

Text

Electro Hydraulic Servo Valve Market - Forecast(2024 - 2030)

Electro-Hydraulic Servo Valve Market Overview:

Electro-Hydraulic Servo Valve Market size is forecast to reach $1.42 Billion by 2030, after growing at a CAGR of 3.35% during 2024-2030. This growth is driven by the Electro Hydraulic Servo Valve market is experiencing a trend toward intelligent and interconnected valves. These valves integrate advanced sensors, data analytics, and communication features, enabling real-time monitoring, predictive maintenance, and remote control. This shift towards smart valves enhances operational efficiency and minimizes downtime for industries. With increasing automation and connectivity demands, the demand for intelligent Electro Hydraulic Servo Valves is on the rise, reflecting a significant market trend.

Additionally, material science advancements and miniaturization are pivotal trends shaping the Electro Hydraulic Servo Valve (EHSV) market. Manufacturers are leveraging innovations to enhance the durability, corrosion resistance, and thermal stability of EHSVs. Moreover, there's a growing emphasis on miniaturization to cater to compact, lightweight systems demanded by portable devices, robotics, and space-constrained environments. This trend towards optimized materials and smaller sizes reflects the evolving landscape of EHSVs, driving market progression. As technology continues to evolve, these developments underscore the industry's commitment to innovation and efficiency.

Electro-Hydraulic Servo Valve Market - Report Coverage:

The “Electro Hydraulic Servo Valve Market Report - Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Electro Hydraulic Servo Valve Market.

By Product Stage: Single Stage, Double Stage and Others.

By Type: Nozzle Flapper Valve, Jet Action Valve, Dynamic Valve, Deflector jet valve, and Others.

By End-Use Industry: Industrial, Marine, Aerospace & Defense, Construction Sector, Oil & Gas and Others

By Geography: North America, South America, Europe, APAC, and RoW.

Request Sample

COVID-19 / Ukraine Crisis - Impact Analysis:

• The COVID-19 pandemic had a significant impact on the electro-hydraulic servo valve market, affecting both supply and demand. Disruptions in manufacturing and supply chains led to delays in production and delivery of these critical components, causing ripple effects across industries reliant on hydraulic systems. Reduced demand from sectors like aerospace, automotive, and industrial machinery further compounded the challenges faced by servo valve manufacturers. However, the pandemic also spurred innovation, with companies exploring remote monitoring and control solutions to address operational challenges. Additionally, the increased focus on automation and efficiency in response to the pandemic could drive long-term growth in the adoption of electro-hydraulic servo valves, particularly in industries prioritizing safety, reliability, and precision in their hydraulic systems.

• The Russia-Ukraine crisis has impacted the electro-hydraulic servo valve market due to disruptions in the supply chain and geopolitical tensions affecting trade relations. Ukraine is a significant producer of precision engineering components, including parts used in electro-hydraulic servo valves. Any disturbance in the region can lead to delays or shortages in raw materials and components crucial for manufacturing these valves. Moreover, increased uncertainty and instability can dampen investor confidence, affecting investment decisions in industries that heavily rely on electro-hydraulic servo valves, such as aerospace, defense, and industrial sectors. Furthermore, sanctions or trade restrictions imposed as a result of the crisis may exacerbate supply chain disruptions, leading to price volatility and increased production costs for manufacturers, thereby impacting the overall market dynamics.

Key Takeaways:

• North America is witnessing remarkable growth in the electro-hydraulic servo valve market due to its flourishing aerospace, defense, and industrial sectors. The region's stringent quality standards and technological advancements drive the demand for precise control systems, where electro-hydraulic servo valves excel. Moreover, the presence of key market players and ongoing research and development initiatives contribute to innovation and product enhancements, further fueling market expansion. Additionally, supportive government policies and investments in defense and infrastructure bolster the region's position as the highest-growing market for electro-hydraulic servo valves.

• The single-stage electro-hydraulic servo valve segment is witnessing the highest growth in the market due to several factors. Single-stage valves offer simplified design, cost-effectiveness, and ease of integration compared to multi-stage counterparts. Technological advancements have enhanced their precision and reliability, meeting stringent industry requirements. Additionally, the demand for compact, lightweight solutions in industries like aerospace, defense, and industrial automation favors single-stage valves. Moreover, applications requiring rapid response and precise control, such as robotics, further drive the growth of this segment, making it a key driver in the market's expansion.

• The nozzle flapper valve is emerging as the fastest-growing type in the electro-hydraulic servo valve market due to its exceptional precision and responsiveness. Leveraging a nozzle and flapper mechanism, these valves offer superior fluid flow control, ensuring accurate positioning in critical applications like aerospace, defense, and industrial sectors. Their rapid response times, enhanced accuracy, and compact design make them increasingly favored over traditional valves. With rising demand for precise motion control systems, particularly in automated industries, the market for nozzle flapper valves is poised for significant growth, presenting lucrative opportunities for manufacturers and suppliers.

Inquiry Before Buying

Electro-Hydraulic Servo Valve Market Segment Analysis – By Product

In the electro-hydraulic servo valve market, the single-stage valve is experiencing the highest growth trajectory with a CAGR of 4.5% during the forecast period 2024-2030. This surge can be attributed to several factors. Firstly, single-stage valves offer simplified design and operation compared to multi-stage valves, making them more cost-effective and easier to integrate into various systems. Secondly, advancements in technology have enabled single-stage valves to achieve high levels of precision and reliability, meeting the stringent requirements of industries such as aerospace, defense, and industrial automation. Thirdly, the increasing demand for compact and lightweight solutions across industries has favored the adoption of single-stage valves, which typically have a smaller footprint and lower weight compared to multi-stage counterparts. Additionally, the rise of applications requiring rapid response times and precise control, such as in robotics and autonomous vehicles, has further propelled the growth of single-stage electro-hydraulic servo valves. Overall, the combination of technological advancements, cost-effectiveness, and growing application areas positions single-stage valves as a key driver of growth in the electro-hydraulic servo valve market.

Electro-Hydraulic Servo Valve Market Segment Analysis – By Type

Nozzle flapper valves are experiencing rapid growth in the electro-hydraulic servo valve market with a CAGR of 4.9% during the forecast period 2024-2030 due to their superior performance and efficiency in various applications. These valves offer precise control over fluid flow by utilizing a nozzle and a flapper mechanism, allowing for highly responsive and accurate operation. Compared to traditional valves, nozzle flapper valves boast faster response times, enhanced accuracy, and improved reliability, making them ideal for applications requiring precise positioning and control, such as aerospace, defense, and industrial sectors. Additionally, advancements in manufacturing technologies have enabled the production of nozzle flapper valves with higher efficiency and reduced maintenance requirements, further driving their adoption. Moreover, increasing demand for automation and robotics across industries has fueled the need for advanced motion control systems, thereby propelling the growth of nozzle flapper valves. Their compact size, lightweight design, and compatibility with digital control systems make them well-suited for integration into modern machinery and equipment. As a result, the market for nozzle flapper valves is expected to continue its upward trajectory, offering lucrative opportunities for manufacturers and suppliers in the electro-hydraulic servo valve industry.

Electro-Hydraulic Servo Valve Market Segment Analysis – By End-Use Industry

The aerospace and defense industry stands out as one of the highest-growing end-use sectors in the electro-hydraulic servo valve market with a CAGR of 5.3% during the forecast period 2024-2030. Electro-hydraulic servo valves play a critical role in flight control systems, missile guidance systems, and other aerospace and defense applications, where precision, reliability, and rapid response are paramount. With the increasing demand for military aircraft, unmanned aerial vehicles (UAVs), and commercial airliners equipped with advanced flight control systems, the need for high-performance electro-hydraulic servo valves is escalating. Furthermore, the development of next-generation fighter jets, space exploration vehicles, and sophisticated missile defense systems necessitates cutting-edge hydraulic control technologies, thereby driving the demand for electro-hydraulic servo valves. Additionally, ongoing modernization initiatives by defense agencies worldwide, coupled with the growing investments in commercial aviation infrastructure, contribute to the robust growth of this market segment. As aerospace and defense applications continue to evolve, the electro-hydraulic servo valve market is poised to witness sustained growth, with manufacturers focusing on innovation and technological advancements to meet the stringent performance requirements of this industry.

Schedule a Call

Electro-Hydraulic Servo Valve Market Segment Analysis – By Geography

North America stands out as one of the dominant markets in the electro-hydraulic servo valve sector with a market share of 34% in 2023 due to several factors. Firstly, the region's robust aerospace and defense industries, driven by technological advancements and military modernization programs, demand highly precise and reliable control systems, where electro-hydraulic servo valves play a vital role. Secondly, the increasing adoption of automation and robotics in various industrial applications across sectors like automotive, manufacturing, and healthcare further fuels the demand for electro-hydraulic servo valves. Thirdly, the presence of major market players and technological innovators in North America fosters continuous research and development, leading to the introduction of advanced valve solutions catering to diverse industry needs. Additionally, favorable government initiatives supporting infrastructure development and investments in defense and aerospace sectors contribute to the region's growth. With these factors combined, North America emerges as a dynamic and rapidly expanding market for electro-hydraulic servo valves, poised for sustained growth in the foreseeable future.

Electro-Hydraulic Servo Valve Market Drivers

Increasing adoption of industrial robots globally

The increasing adoption of industrial robots globally is driving growth in the electro-hydraulic servo valve market. Industrial robots rely on precise hydraulic control systems to execute tasks with accuracy and efficiency across various industries. With the rise of automation and Industry 4.0 initiatives, industries such as automotive manufacturing, metalworking, and electronics assembly are increasingly integrating robots into their production processes to improve productivity and flexibility. Electro-hydraulic servo valves play a crucial role in controlling the movement and force of these robots, enabling precise and smooth operations. According to the International Federation of Robotics (IFR), global sales of industrial robots reached a record high in recent years, indicating a growing demand for automation solutions. This trend is expected to continue, further fuelling the demand for electro-hydraulic servo valves in the market.

High acceptance of smart control which uses an electro-hydraulic servo valve

The growing acceptance of smart control systems is emerging as a significant market driver for electro-hydraulic servo valves. Smart control technologies, integrating advanced sensors, actuators, and feedback mechanisms, enhance the precision, efficiency, and performance of hydraulic systems. Electro-hydraulic servo valves play a pivotal role in these systems, providing precise and dynamic control over fluid flow and pressure. Industries such as aerospace, automotive, and manufacturing are increasingly adopting smart control solutions to optimize operations, reduce energy consumption, and improve productivity. For instance, in aerospace applications, smart control systems utilizing electro-hydraulic servo valves enable aircraft to achieve greater manoeuvrability and fuel efficiency. Moreover, the rise of industry 4.0 initiatives and the Internet of Things (IoT) is driving the demand for intelligent hydraulic systems, further bolstering the growth of the electro-hydraulic servo valve market.

Buy Now

Electro-Hydraulic Servo Valve Market Challenges

High costs associated with electro-hydraulic servo valves

High costs associated with electro-hydraulic servo valves present a significant market challenge. These valves incorporate precision engineering, advanced materials, and complex manufacturing processes, leading to inherently high production costs. Additionally, stringent quality standards and regulatory requirements further escalate expenses for manufacturers. The aerospace, defense, and industrial sectors, major consumers of electro-hydraulic servo valves, are often cost-sensitive industries, necessitating competitive pricing. Moreover, customers increasingly demand cost-effective solutions without compromising performance or reliability, adding pressure on manufacturers to optimize production processes and reduce costs. Furthermore, the emergence of alternative technologies, such as electromechanical actuators, poses a threat to the market dominance of electro-hydraulic servo valves. To address this challenge, manufacturers are investing in research and development to innovate cost-effective solutions while maintaining quality standards to remain competitive in the market.

Market Landscape

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Electro Hydraulic Servo Valve Market. The top 10 companies in this industry are: Moog, Inc., Eaton Corporation, Honeywell International, Inc, Parker Hannifin Corp, Woodward, Inc, Voith GmbH & Co. KGaA, Bosch Rexroth AG, Schneider Servohydraulics GmbH, HAEW Hydraulik SE, Oligear Co.

Developments:

Moog Inc. in September 2022, launched their new X700 Series servo cartridge valves aimed at the high-end segment of the Electro Hydraulic Servo Valve Market. The key feature of this new series is a robust design that allows for a maximum main-stage operating pressure of 420 bar. This increased pressure capability potentially expands Moog's offerings in the market for high-performance applications.

In February 2022, HAEW Hydraulik introduced its latest innovation, the OSCA load-holding screw-in valve. Designed to resist dirt and debris, this valve boasts a remarkable pressure tolerance of up to 500 bar. HAEW's cutting-edge technology ensures enhanced durability and reliability, catering to demanding industrial applications. This launch underscores HAEW's commitment to delivering high-performance hydraulic solutions, addressing industry needs for robust and efficient components.

#Electro Hydraulic Servo Valve Market#Electro Hydraulic Servo Valve Market size#Electro Hydraulic Servo Valve industry#Electro Hydraulic Servo Valve Market share#Electro Hydraulic Servo Valve top 10 companies#Electro Hydraulic Servo Valve Market report#Electro Hydraulic Servo Valve industry outlook

0 notes

Text

0 notes

Text

Carbon Credits Market Size, Share, Volume, Trends, Demand, Growth and Forecast Report 2024-2032

Carbon Credits Market provides in-depth analysis of the market state of Carbon Credits manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Carbon Credits in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Carbon Credits Market Report:

The report offers a comprehensive and broad perspective on the global Carbon Credits Market.

The market statistics represented in different Carbon Credits segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Carbon Credits are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Carbon Credits.

Major stakeholders, key companies Carbon Credits, investment feasibility and new market entrants study is offered.

Development scope of Carbon Credits in each market segment is covered in this report. The macro and micro-economic factors affecting the Carbon Credits Market

Advancement is elaborated in this report. The upstream and downstream components of Carbon Credits and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/carbon-credits-market-100582

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket MarketMarket Analysis

Segmented Ball Valves MarketMarket Size

Global Massive Multiplayer Online (MMO) Games MarketMarket Share

Global Residential Interior Door MarketMarket Growth

Boron Doped Diamond Electrode (BDD) MarketMarket

Optical Character Recognition MarketMarket Share

Retail Banking MarketMarket Growth Rate

Rare Disease Treatment MarketMarket Forecast

Global MEMS Microphone MarketMarket Size

Electronic Logging Device MarketMarket Growth

Real Time Payments MarketMarket Analysis

Ion Exchange Resins MarketMarket Size

Global E-Learning Services MarketMarket Share

Global Enterprise Social Networking (ESN) MarketMarket Growth

Iron and Steel MarketMarket

Direct Drive (Gearless) Wind Turbine MarketMarket Share

LVT Flooring MarketMarket Growth Rate

AI in Education MarketMarket Forecast

Global Note Taking App MarketMarket Size

Aluminum Powder in Additive Manufacturing MarketMarket Growth

Free Space Optics Communication Technology MarketMarket Analysis

Curved Televisions MarketMarket Size

Global Laser Communication Terminal MarketMarket Share

Global Unified Communication as a Service (UCaaS) MarketMarket Growth

Produce Wash MarketMarket

Biaxially Oriented Polyamide (Nylon) Film (BOPA) MarketMarket Share

Transaction Monitoring MarketMarket Growth Rate

Wedding Dress MarketMarket Forecast

Global Dry Construction Material MarketMarket Size

Voltage Controlled Crystal Oscillator (VCXO) MarketMarket Growth

Electro Hydraulic Servo Valve MarketMarket Analysis

B2B Publishing MarketMarket Size

Global Rubber Shoe Sole MarketMarket Share

Global Intelligent Virtual Assistant MarketMarket Growth

D-Luciferin Substrate Market Market

Pendant Stations MarketMarket Share

Curved Guide Rail MarketMarket Growth Rate

Insulin Injection Related Product MarketMarket Forecast

Global Selective Wave Solder Pallet MarketMarket Size

Medical Grade Silicone Rubber MarketMarket Growth

0 notes

Text

Ram Automations: Your Premier Destination for Industrial Automation & Marine Spare Parts

In the dynamic landscape of industrial automation and marine spare parts, finding a reliable partner is critical. Look no more than Ram Automations, your trusted source for advanced options and top-tier brands. With a commitment to excellence and a large selection of offerings, Ram Automations stands as a beacon of quality and reliability in the industry.

At Ram Automations, we comprehend the value of efficiency, reliability, and accuracy in every element of your operations. That's why we've curated a comprehensive portfolio of brands renowned for their innovation and quality. Whether you're in requirement of industrial automation components or marine spare parts, we have you covered with products from leading manufacturers across the globe.

Our comprehensive series of brands consists of household names like Siemens, Bosch, Allen Bradley, and Schneider, alongside specialized manufacturers such as Alfa Laval, Furuno, and Yokogawa. You'll also discover relied on brands like Aastra, ABB, Agastat, Amot Controls, Arnold Magnetics, Autonics, Autronica, Azbil, Azimuth, Baylor, BBC, Bemac, Bodotherm, BQT Solutions, Brannstrom, BW, Carlo Gavazzi, Carrier Controller, Compaq Computer, Consilium, Converter Concepts, Crouzet, Danfoss, Deif, Desautel, Drager, E. Dold & Shone, Electro Matic, Emerson, Endress+Hauser, Enraf Nonius, Ericsson, Fanuc, Fellow Kogyo, Fischer, Fuji Electric, Gai-Tronics, George Kelk, Gestra, Gordian Group, Gresen, Gutor Electronics, H.M. Stein Sohn, Hawe, Hawke, Hewlett Packard, Honeywell, Hydropa Hydrostar, Hyundai, IBM, Idec, Invensys, Johnson Controls, Jrc, JRCS, Jumo, Kaneko Sangyo, Kessler-Ellis Products, Kidde, Klockner Moeller, Kokosha, Kone, Kongsberg, Koyo, Lamarche, Liaanen Helitron, Liebherr, Lilley & Gillie, Lyngso Marine, Maiyo Electric, Man B&W, Marioff, Masibus, Mean Well, Mitsubishi, Mizar, Moeller, Moog Servo Valve, MSA, MTL, Mutec Instruments, Nagano Keiki, Nakakita Seisakusho, Newage Engineers, Nor Control, Norgren, Noris, Northrop Grumman Sperry Marine, Noshok, Notifier, Omron, Opsis, Parker, Pellerin Milnor, Pepperl Fuchs, Phoenix Contact, Pr Electronics, Ram Automations, Rexroth, Riken Keiki, Robertshaw, Ross Hill, SAAB, Sabroe, Saginomiya, Sauer Danfoss, Sauter, Schaffner, Schmersal, Seiko Electric, Shinybow, SMC, Smiths Heimann, Squared, Stahl, Stromberg, Sun Hydraulics, Tamagawa, TDK, TDK Lambda, Teamtec, Telemecanique, Terasaki, TRACO POWER, Trafag, Ueda Seisakusho, Ultra Electronics, VAF Instrument, Van Air, Vingtor Stentofon, Wabco, Weidmuller, Westfalia Separator Systems, Wieland, Yamatake, Yokogawa, and York.

0 notes

Text

China Yoyik Globe valve A156.33.01.01 for Electric Company Is a spare part for power plants

"China Yoyik Globe valve A156.33.01.01 for Electric Company Is a spare part for power plants. Deyang YOYIK specializes in producing all kinds of generating units supporting the processing of power plants, power plants, metallurgical systems, chemical systems, color systems, steel mills, chemical fertilizer plants, colored copper and aluminum processing plants, coking plants, oxygen plants and other industrial and mining enterprises , Including: rolling mill, compressor, circulating compressor, air compressor, steam turbine, high pressure pump ice machine, ball mill, coal mill, motor and other bearings, cross head, slide and other products. YOYIK strict promises, timely supply, in order to sincerity, refinement, durability, and trustworthy for the quality policy, only low-profit, user satisfaction, welcomed the new and old customers come to our factory.

Yoyik can offer many spare parts for power plants as below:

DF-Globe valve A156.33.01.01-DF

stator cooling water pump coupling cushion 65-250A dc vane pump F3-V10-1S6S-1C-20 Rod end bearing SIB12F/K stainless steel globe valve (welded) J20F1.6P transfer pump vane F3-SDV10-1B7B-1A vickers vane pump F3V101S6S1C20 impeller pump IHF80-50-200 centrifugal water pump DFB80-80-240 SEAL KIT NXQ-A-10/20 LEH centrifugal pump suction DFB80-80-220-03 EH circulating oil pump F3-V10-1S6S vacuum cleaner 30-WS-32 globe valve J965Y-32 DN20 JB/T308 AST solenoid valve DF2051-1MPa pressure hose SMS-20/N1/4-2438mm-B solenoid valve RV5-10-S-0-35 vacuum pump parts 30-WS-32 seal kit YGM-233 servo valve MOOG761-003 ball valve RKH20S-445-DN16PN400 screw pump stainless ACF090N41RBP screw pump diagram NM031BY01L06B vaccum pump ACG070K7 NVBP EH oil pump F3-V10-IS6S-IC-20 centrifugal pumps SLQ-63 sealing ring HB4-56J8-156 AST/OPC solenoid valve 0508.919T0301.AW027 radial piston pump PVH131Q1C.RSF.10.C25 transfer pump fuel 80AY50X6 vacuum pump ac P-1931A screw pump diagram HSNH440-46 CV valve (solenoid valve) 4WE6Y60-SG24M9K4-V manual vacuum pump ROTARYPUMP NO.30-WS SEARIAL pressure hose S110-AC-FC-0040 globe valve 40FWJ1.6P O-type seal ring φ25*1.8 Globe valve A156.33.01.01

rotary piston pump PVH074R01AB10A250000002001AE010A pump screw HSNH210-46A vacuum pump P1825B hydraulic oil pumps 150LY-32-B vacuum pump valve spring P-540 vacuum pump oil P-540 sealing ring HB4-56J8-152 Electro hydraulic servo valve DEC21NF58N S22KDFB5VAMN solenoid valveJ-110VDC-DN10-DOF/20D/2Nsealing ring HB4-56J8-142 electric oil transfer pump SDH65-50-160 dc motor coupling PVH074R01AB10A2500000001E010A EH oil pump sealing set PVH098R01AD30A manual vacuum pump HSNH440Q2-46NZ pressure hose SMS-20-3048mm-B HP starting oil pump 100LY-215-2 hydraulic jack pump 125LY-31-6 Mechanical seal of seal oil recirculation pump HSNH280-43NZ piston vacuum pump MOOG0514 7005 37 piston pump parts PVH074R01AA10A250000002001AB piston pump PV29-2L-5D-C00 pump screw ACF-090N5-ITBP bladder 32L EHV-32-330/90 Directional control valve DG4V-32AL-MU-P7-60 centrifugal pump impeller YCZ65-250C vacuum pump oil 30-WS-COML rotary vacuum pump P-1762 radial piston pump hydraulic PVH141R13AF30A230000002001AB01A screw pump working NM063BT01L06V non-return valve M-SR20KE15-1X vacum pump air vacuum PVH74(QI)C-RM-IS-10-C14 transfer pump oil YW-32-160 solenoid valve 34EH-H6B-T axial piston variable pump 25MCY14-1B accumulator bladder NXQAB-10/31.5-2-A Circulating pump 26SH-28 600S42 Globe valve A156.33.01.01

DFYLSYC-2024-7-15-A

"

0 notes

Text

Electro Hydraulic Servo Valve Market - Forecast (2024 - 2030)

Electro Hydraulic Servo Valve Market Overview

The market size for Electro Hydraulic Servo Valve is analyzed to be USD $1,42 Billion in 2021. It is further projected to grow at a CAGR of 3.35% during the forecast period 2022-2027. A hydraulic servo valve is a device that controls position, velocity, pressure or force in a machine or device by maneuvering the flow of fluid (oils) in response to an electrical input signal or command (usually through a piston or cylinder). Closed-loop control devices, servo valves can be single-stage, two-stage or three-stage designs. Moreover, the growth in the aerospace and defense industry would eventually boost the demand for Electro-Hydraulic Servo Valve. EHSVs have a range of applications in the aerospace and defense industry vertical including three-and four-way flow and pressure control, fuel monitoring, actuator position control, flight critical applications, thermal management, over-speed protection, thrust vector nozzle actuation and more. According to a report by the IBEF, Indian aviation markets have witnessed a growing demand for large aircraft from key players including Spicejet, Indigo and more. Additionally, the increasing military and defense expenditure by governments are analyzed to positively aid the underlying market. India’s defense budget for 2020-2021 stood at $67.4 Billion, which is 9.3% higher than 2019-2020. Factors like these are driving the growth of the Electro Hydraulic Servo Valve market.

Report Coverage

The report: “Electro Hydraulic Servo Valve Market – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Electro Hydraulic Servo Valve market.

By Product: Single Stage, Double Stage and Others.

By Type: Nozzle Flapper Valve,Jet Action Valve, Dynamic Valve, Deflector jet valve and Others.

By Application: Industrial, Marine, Aerospace & Defense, Construction Sector, Oil and Others.

By Geography: North America (the U.S., Canada and Mexico), South America (Argentina, Brazil, Chile, Colombia and the Rest of South America), Europe (Belgium, Denmark, France, Germany, Italy, the Netherlands, Spain, the UK and the Rest of Europe), Asia Pacific (Australia, China, India, Japan, Malaysia, South Korea, Taiwan and the Rest of Asia Pacific) and the RoW (Israel, Nigeria, Saudi Arabia, South Africa, the UAE, the Rest of Africa and the Rest of the Middle East).

#Electro Hydraulic Servo Valve Market price#Electro Hydraulic Servo Valve Market size#Electro Hydraulic Servo Valve Market share

0 notes

Text

Global Electro Hydraulic Servo Valve Market Size, Trends and Growth Opportunity By Region and forecast till 2030. Global Electro Hydraulic Servo Valve Market was valued at USD 1,669.82 million in 2022 and is slated to reach USD 2661.64 million by 2030 at a CAGR of 5.2% from 2023-2030.

Overview

The report contains a thorough study of the global ELECTRO HYDRAULIC SERVO VALVE market. It has successfully pointed out the key factors that have substantial impact on the ELECTRO HYDRAULIC SERVO VALVE market. This report is based on result of a well-planned research methodology. The methodology employed both primary and secondary research tools. These tools aid the researchers to collect authentic data and arrive at a definite conclusion. The prevailing competitors in the global ELECTRO HYDRAULIC SERVO VALVE market has also been portrayed in the report, offering an opportunity to the market players to gauge their performance. The report has been prepared after studying the different parameters ruling the global ELECTRO HYDRAULIC SERVO VALVE market and the forecast period has been estimated from ELECTRO HYDRAULIC SERVO VALVE-ELECTRO HYDRAULIC SERVO VALVE. The forecast period is the time period when the key driving factors and parameters will help the market to flourish significantly. The estimated value of the market has been represented through a Compound Annual Growth Rate percentage (CAGR %). In addition to that, the report represents the approximate revenue which can be generated over the forecast period. However, the report has also outlined the factors that can slowdown the growth of the global ELECTRO HYDRAULIC SERVO VALVE market.

Key Drivers

The report includes the key driving forces prevailing in the global ELECTRO HYDRAULIC SERVO VALVE market. This part of the report has been studied keeping in mind the political, economic, social, technological, geographical, and cultural scenario of the global ELECTRO HYDRAULIC SERVO VALVE market. These factors can be projected to have their effects on the market, or they can have interconnected impacts. Besides, subtle change in the timeframe within which these factors are functioning might have ripple effects on the global ELECTRO HYDRAULIC SERVO VALVE market.

Regional Description

Global ELECTRO HYDRAULIC SERVO VALVE market has been segmented into Europe, the Americas, Asia Pacific, and the Middle East & Africa. This part of the report provides an exhaustive view of the regional scope existing in the global ELECTRO HYDRAULIC SERVO VALVE market. The recent market trends and preferences dominating each region have a direct impact on the industries. The report tries to exploit the recent trends and preferences prevailing in a region to provide the users with a clear picture of the business potential existing in that region.

Research Methodology

The primary research procedure is based on results of face to face interviews with industry experts and consumers. The secondary research process includes an intricate study of the scholarly journals and reports available online.

Request A Free Sample: https://qualiketresearch.com/reports-details/Global-Electro-Hydraulic-Servo-Valve-Market

Market Segmentation

Global Electro Hydraulic Servo Valve Market is segmented into Stage Types, Valve Types, LPM Types, and Applications. By Stage Types such as Single Stage Servo Valve, Two Stage Servo Valve, Three Stage Servo Valve. By Valve Types such as Nozzle Flapper Valve, Jet Pipe Servo Valve, Deflector Jet, and Others. By LPM Types such as Less Than 20 LPM, and More Than 20 LPM. By Applications such as Aerospace, Power Industry, Steel Industry, Chemical Industry, Oil & Gas, Marine Industry, Construction Industry, Healthcare, and Others.

Regional Analysis

Global Electro Hydraulic Servo Valve Market is segmented into five regions Americas, Europe, Asia-Pacific, and the Middle East & Africa. In light of the increasing usage of electro-hydraulic drive control systems in the aerospace and marine industries, North America dominates the electro-hydraulic servo valve market. In the market for electro-hydraulic servo valves, the United States is a market leader since it is home to several significant market participants. Due to growing activity in hydraulic control system R&D and technological advancements, Germany currently dominates the European continent. Because of the growing adoption of automation in manufacturing and industrial robotics, China leads the Asia-Pacific area.

Key Players

This report includes a list of numerous Key Players, namely YUKEN KOGYO CO., LTD, MTS Systems, Moog Inc., Atos Spa, PARKER HANNIFIN CORP, Aviation industry AVIC Nanjing Servo Control System Co., Ltd., Continental Hydraulics Inc., JASC, Bosch Rexroth AG, Woodward, Inc.,

About Us:

QualiKet Research is a leading Market Research and Competitive Intelligence partner helping leaders across the world to develop robust strategy and stay ahead for evolution by providing actionable insights about ever changing market scenario, competition and customers.

QualiKet Research is dedicated to enhancing the ability of faster decision making by providing timely and scalable intelligence.

QualiKet Research strive hard to simplify strategic decisions enabling you to make right choice. We use different intelligence tools to come up with evidence that showcases the threats and opportunities which helps our clients outperform their competition. Our experts provide deep insights which is not available publicly that enables you to take bold steps.

Contact Us:

6060 N Central Expy #500 TX 75204, U.S.A

+1 214 660 5449

1201, City Avenue, Shankar Kalat Nagar,

Wakad, Pune 411057, Maharashtra, India

+91 9284752585

Sharjah Media City , Al Messaned, Sharjah, UAE.

+91 9284752585

0 notes

Text

The Electro Hydraulic Servo Valve Market Report aims to provide a comprehensive analysis of the global electro hydraulic servo valve industry.

0 notes

Text

0 notes

Text

Global Electro Hydraulic Servo Valve Market Is Estimated To Witness High Growth Owing To Increasing Demand for Precise and Efficient Control Systems

The global Electro Hydraulic Servo Valve Market is estimated to be valued at US$ 1,898.2 Mn in 2022 and is expected to exhibit a CAGR of 3.3% over the forecast period, as highlighted in a new report published by Coherent Market Insights. Market Overview: Electro Hydraulic Servo Valve is a type of valve that combines electrical and hydraulic control techniques to provide precise and efficient control systems in various industries. These valves are widely used in aerospace, defense, automotive, and industrial applications due to their ability to respond quickly and accurately to control signals. They offer advantages such as high positioning accuracy, fast response time, and enhanced system performance. The increasing demand for automation and the need for improved control systems are driving the growth of the Electro Hydraulic Servo Valve market. Market key trends: One key trend in the Electro Hydraulic Servo Valve market is the integration of Internet of Things (IoT) technology. IoT enables connectivity between devices and systems, allowing real-time monitoring and control. The integration of IoT in Electro Hydraulic Servo Valves enables remote monitoring, predictive maintenance, and data analytics, thereby enhancing operational efficiency and reducing downtime. For example, companies are developing smart Electro Hydraulic Servo Valves that can communicate with other systems to optimize performance and minimize energy consumption. PEST Analysis: - Political: The political stability in major economies is favorable for the growth of the Electro Hydraulic Servo Valve market. The governments are also promoting digitization and automation, which is driving the adoption of advanced control systems. - Economic: The growing industrialization and infrastructural development worldwide are creating a demand for efficient control systems, thereby boosting the Electro Hydraulic Servo Valve market. - Social: The increasing focus on improving productivity and reducing manual labor in industries is driving the adoption of Electro Hydraulic Servo Valves. Additionally, the need for precise control in critical applications such as aerospace and defense is fueling the market growth. - Technological: Technological advancements in control systems, such as sensor integration and IoT connectivity, are propelling the growth of the Electro Hydraulic Servo Valve market. The development of smart valves that can communicate and optimize performance is a major technological trend. Key Takeaways: - Market size related content: The global Electro Hydraulic Servo Valve Market is expected to witness high growth, exhibiting a CAGR of 3.3% over the forecast period, due to increasing demand for precise and efficient control systems. The need for automation and improved control in various industries is driving the adoption of Electro Hydraulic Servo Valves. - Regional analysis related content: North America is expected to be the fastest growing and dominating region in the Electro Hydraulic Servo Valve market. The presence of major aerospace and defense companies, along with increasing automation in industries, is fueling market growth in this region. - Key players related content: Key players operating in the global Electro Hydraulic Servo Valve market include Matrox Imaging Ltd., Omron Adept Technology, Inc., Toshiba Teli Corporation, Ltd., Cognex Corporation, ISRA VISION AG, Panasonic Corporation, Omron Microscan Systems Inc., Perceptron, Inc., Sharp Corporation, Edmund Optics, AMETEK, Inc., Teledyne Technologies, Keyence Corporation, Datalogic S.p.A., Sony Corporation, Basler AG, Vitronic GmbH, SICK AG, IMS Messsysteme GmbH, Industrial Vision Systems Ltd., Allied Vision Technologies, Baumer Group, and Dark Field Technologies.

0 notes

Text

Mastering the Power of Hydraulics: A Comprehensive Training Guide

Introduction:

Hydraulics is a fascinating field that harnesses the power of fluid mechanics to generate force and transmit energy. It plays a crucial role in various industries, including manufacturing, construction, and transportation. Whether you're a hydraulic technician, engineer, or simply interested in expanding your knowledge, a comprehensive hydraulic training program can be an invaluable resource. In this blog, we'll explore the key aspects of hydraulic training and how it can help you master this powerful technology.

Understanding the Basics:

To start your Hydraulic training journey, it's essential to grasp the fundamental concepts. Hydraulics relies on Pascal's law, which states that a change in pressure applied to an enclosed fluid is transmitted undiminished to all portions of the fluid and to the walls of its container. Training programs often begin with an overview of fluid properties, hydraulic components, and their functions. This foundational knowledge forms the basis for further exploration.

Hands-on Experience:

A hands-on approach is crucial to mastering hydraulics. Training programs typically provide practical exercises and simulations to give participants a chance to work with hydraulic systems firsthand. These activities may involve assembling and disassembling hydraulic components, troubleshooting common issues, and performing maintenance tasks. By actively engaging in these exercises, trainees gain the necessary skills and confidence to work with hydraulic systems effectively.

Safety Protocols:

Safety should always be a top priority when working with hydraulic systems. Hydraulic training programs emphasize the importance of following proper safety protocols. Trainees learn about potential hazards, such as high-pressure leaks, and how to prevent accidents. They also acquire knowledge about the appropriate personal protective equipment (PPE) and safety procedures to ensure a safe working environment.

System Design and Analysis:

Hydraulic systems can be complex, requiring careful design and analysis. A comprehensive training program delves into the principles of system design, including selecting appropriate components, calculating flow rates, and sizing hydraulic lines. Trainees learn to interpret hydraulic schematics and understand the interconnections between various components. Additionally, they gain insight into system optimization and efficiency enhancement techniques.

Maintenance and Troubleshooting:

Regular maintenance is vital for the longevity and performance of hydraulic systems. Hydraulic training equips participants with the skills to perform routine maintenance tasks, such as fluid changes, filter replacements, and seal inspections. Moreover, trainees learn troubleshooting techniques to identify and resolve common issues, such as leaks, erratic operation, or insufficient pressure. This knowledge allows them to keep hydraulic systems running smoothly and minimize costly downtime.

Advanced Topics:

As trainees progress in their hydraulic training, they may explore advanced topics tailored to their specific interests or industry needs. These may include proportional and servo hydraulics, electro-hydraulic systems, hydraulic power units, or hydraulic control valves. Advanced training helps participants develop a deeper understanding of specialized applications and opens up opportunities for more complex hydraulic projects.

Certifications and Continuing Education:

Hydraulic training programs often offer certifications upon successful completion. These certifications validate the trainee's knowledge and skills, enhancing their professional credibility. Additionally, the field of hydraulics is constantly evolving with new technologies and innovations. Continuing education programs and seminars allow hydraulic professionals to stay updated with the latest advancements and broaden their expertise.

Conclusion:

Hydraulic training is a transformative experience for individuals seeking to master the power of fluid mechanics. It provides a solid foundation in hydraulic principles, hands-on experience with system components, and the ability to analyze and troubleshoot hydraulic systems effectively. Whether you're a hydraulic technician or an engineer, investing in a comprehensive hydraulic training program can significantly enhance your career prospects and contribute to your professional growth. So, embark on this educational journey and unlock the full potential of hydraulic power!

0 notes

Text

Electro Hydraulic Servo Valve Market - Forecast (2023 - 2028)

View More @ https://tinyurl.com/4fvzs6w4

The electrohydraulic servo valve (EHSV) is a core component of servo control systems. Due to its advantages such as high level of control precision, quick response, light weight, small volume and high immunity to load variations, EHSV has been applied in many fields, such as astronavigation, aviation, navigation, and military equipment. EHSV is one of the most failure prone components, and has a direct and significant impact on the performance and reliability of the entire servo control system. Thus, it is very important to analyze the failure mode, failure effects, failure mechanism and failure rate of EHSV.

The key driving factors for the electro hydraulic servo valves are growing demand for quality and smart control. There have been many design innovations as it has been implied across the sectors to control air/fluid flow. The aerospace industry was the driver in earlier times but growing industrial use has been on the higher side in the recent times.

What are Electro Hydraulic Servo Valves?

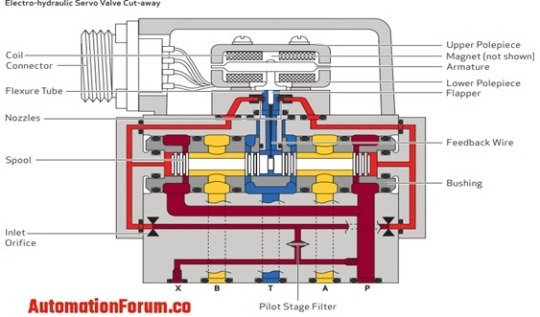

The term servo valve traditionally refers to mechanical feedback valves, where a spring element (feedback wire) connects a torque motor to the main-stage spool. Servo valve has come to mean a valve whose main spool is positioned in proportion to the electrical input to the valve, where the spool movement is achieved through internal hydraulic actuation. The size of metering orifices is controlled by the spool movement thus enabling the valve to control flow; however this flow is dependent on the pressure difference across the orifice unless some form of pressure compensation is used. Spool displacement causes the wire to impart a torque onto the pilot-stage motor. The spool keeps position when the torque from an electromagnetic field induced by the current through the motor coil equals torque from the feedback wire's deflection. These two-stage valves contain a pilot stage or torque motor, and a main or second stage. Sometimes the main stage is referred to as the power stage and there may be more than two stages also involved in regulation.

A Hydraulic Servo Valves is a device that maneuvers the flow of fluid (oils) in response to an electrical input signal or command to control position, velocity, pressure or force in some type of machine or device (usually through a piston or cylinder). Servo Valves are closed-loop control devices that can be single stage, two-stage or three stage designs.

Flow control servo valves produce hydraulic flow output proportional to electrical current input. p/Q valves control flow and regulate pressure (upper or lower limiting pressure) and can be used for both pressure regulation as well as applying a pressure-limit. They are used to regulate emissions, increase productivity and reliability at the same time. More and more functionalities are controlled by software that reduces complexity and enables regional design, manufacturing and customer specific variants.

What are the major applications for Electro Hydraulic Servo Valves?

Embryonic electro hydraulic servo valves where developed for military applications in the Second World War, such as for automatic fire control (gun aiming).Such servo valves typically consisted of a solenoid driven spool with spring return. These were able to modulate flow, but with poor accuracy and a slow response.

Servo valve development in the 1950’s, was largely driven by the needs of the aerospace industry (particularly missiles). The technical status and available products at that time are well documented in a series of reports commission by the US Air Force.

The electro hydraulic servo valve finds applications in wide range of industries such as steel industry, power industry, chemical industry, construction sector and still more.

Market Research and Market Trends of Electro Hydraulic Servo Valves Ecosystem

There has been a thorough research on alternative valve designs for the improved response, reducing leakage from the valves by various manufacturers and also to achieve ease in manufacturability process.

Most investigations have involved new ways of actuating the spool, often using active materials such as piezoelectric crystals have been used on certain experimental models to achieve better dynamic response. It is difficult to use them because of high susceptibility to vibration, temperature changes, and electrical noise and because of the difficulty in obtaining sufficiently large displacements from the crystals.

Magnetostriction is a material phenomenon which can be used to create a ‘smart‘ actuator. Magnetostrictive spool valve is another way to actuate valves action. The challenges for this technology introduction to actuate the valves are similar to piezoelectric actuation, including limited displacement, hysteresis, and temperature sensitivity.

The torque motor still finds applications in providing an alternative, although there have been breakthroughs in piezoelectric actuator technology, including drive electronics and hysteresis compensation methods. There are other reliable options available such as electronic automation controls which pose a tough competition to valve market.

Many manufacturing constraints for e.g. in designing valve bodies and other hydraulic components are not present due to additive manufacturing, particularly where manufacturing volumes are not too large (such as in aerospace). These provides a constraint free environment to innovators to further research and develop new ways to implement these motors and keeps the window open for new manufacturing technologies to be exhibited in future.

A further continuing trend in electro hydraulic servo valve market is increased valve intelligence. Integration of self-tuning functions, condition monitoring, and increased communication capability are continuously being adopted in industrial application side of the valves and are now being incorporated into aerospace field also.

Who are the Major Players in Electro Hydraulic Servo Valves market?

The key companies to the market mentioned in report include Moog Inc., Bosch Rexroth AG, Parker Hannifin Corporation, Honeywell International Inc., Eaton Corporation Plc, Woodward, Inc., Voith GmbH, Schneider Kreuznach, Aviation Industry Corporation of China (AVIC), Oilgear Company

What is our report scope?

The report incorporates in-depth assessment of the competitive landscape, product market sizing, product benchmarking, market trends, product developments, financial analysis, strategic analysis and so on to gauge the impact forces and potential opportunities of the market. Apart from this the report also includes a study of major developments in the market such as product launches, agreements, acquisitions, collaborations, mergers and so on to comprehend the prevailing market dynamics at present and its impact during the forecast period 2018-2024.

All our reports are customizable to your company needs to a certain extent, we do provide 20 free consulting hours along with purchase of each report, and this will allow you to request any additional data to customize the report to your needs.

Key Takeaways from this Report

Evaluate market potential through analyzing growth rates (CAGR %), Volume (Units) and Value ($M) data given at country level – for product types, end use applications and by different industry verticals.

Understand the different dynamics influencing the market – key driving factors, challenges and hidden opportunities.

Get in-depth insights on your competitor performance – market shares, strategies, financial benchmarking, product benchmarking, SWOT and more.

Analyze the sales and distribution channels across key geographies to improve top-line revenues.

Understand the industry supply chain with a deep-dive on the value augmentation at each step, in order to optimize value and bring efficiencies in your processes.

Get a quick outlook on the market entropy – M&A’s, deals, partnerships, product launches of all key players for the past 4 years.

Evaluate the supply-demand gaps, import-export statistics and regulatory landscape for more than top 20 countries globally for the market.

#electro hydraulic servo valve market#electro hydraulic servo valve market size#electro hydraulic servo valve market shape#electro hydraulic servo valve market forecast#electro hydraulic servo valve market analysis#electro hydraulic servo valve market share#electro hydraulic servo valve market price#electro hydraulic servo valve market report#electro hydraulic servo valve market research#Chemical

0 notes

Photo

Moog_631F734F_P10FXFM4VBR_Electro_ Hydraulic_Servo_Valve_editurk.com #moog #631F734F #P10FXFM4VBR #electro #hydraulic #servo #valve #industrial #international #trade #bussiness #import #export #innovation #editurk #editürk #engineering #mechanics #mechanicalengineering #Mühendislik #makina #sparepart #spareparts www.editurk.com (Editürk Mühendislik İthalat ve İhracat) https://www.instagram.com/editurkmuhendislik/p/CZGtuiiNM3n/?utm_medium=tumblr

#moog#631f734f#p10fxfm4vbr#electro#hydraulic#servo#valve#industrial#international#trade#bussiness#import#export#innovation#editurk#editürk#engineering#mechanics#mechanicalengineering#mühendislik#makina#sparepart#spareparts

0 notes

Text

Carbon Credits Market Size, Share, Volume, Trends, Demand, Growth and Forecast Report 2024-2032

Carbon Credits Market provides in-depth analysis of the market state of Carbon Credits manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Carbon Credits in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Carbon Credits Market Report:

The report offers a comprehensive and broad perspective on the global Carbon Credits Market.

The market statistics represented in different Carbon Credits segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Carbon Credits are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Carbon Credits.

Major stakeholders, key companies Carbon Credits, investment feasibility and new market entrants study is offered.

Development scope of Carbon Credits in each market segment is covered in this report. The macro and micro-economic factors affecting the Carbon Credits Market

Advancement is elaborated in this report. The upstream and downstream components of Carbon Credits and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/carbon-credits-market-100582

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Plastic Bucket MarketMarket Analysis

Segmented Ball Valves MarketMarket Size

Global Massive Multiplayer Online (MMO) Games MarketMarket Share

Global Residential Interior Door MarketMarket Growth

Boron Doped Diamond Electrode (BDD) MarketMarket

Optical Character Recognition MarketMarket Share

Retail Banking MarketMarket Growth Rate

Rare Disease Treatment MarketMarket Forecast

Global MEMS Microphone MarketMarket Size

Electronic Logging Device MarketMarket Growth

Real Time Payments MarketMarket Analysis

Ion Exchange Resins MarketMarket Size

Global E-Learning Services MarketMarket Share

Global Enterprise Social Networking (ESN) MarketMarket Growth

Iron and Steel MarketMarket

Direct Drive (Gearless) Wind Turbine MarketMarket Share

LVT Flooring MarketMarket Growth Rate

AI in Education MarketMarket Forecast

Global Note Taking App MarketMarket Size

Aluminum Powder in Additive Manufacturing MarketMarket Growth

Free Space Optics Communication Technology MarketMarket Analysis

Curved Televisions MarketMarket Size

Global Laser Communication Terminal MarketMarket Share

Global Unified Communication as a Service (UCaaS) MarketMarket Growth

Produce Wash MarketMarket

Biaxially Oriented Polyamide (Nylon) Film (BOPA) MarketMarket Share

Transaction Monitoring MarketMarket Growth Rate

Wedding Dress MarketMarket Forecast

Global Dry Construction Material MarketMarket Size

Voltage Controlled Crystal Oscillator (VCXO) MarketMarket Growth

Electro Hydraulic Servo Valve MarketMarket Analysis

B2B Publishing MarketMarket Size

Global Rubber Shoe Sole MarketMarket Share

Global Intelligent Virtual Assistant MarketMarket Growth

D-Luciferin Substrate Market Market

Pendant Stations MarketMarket Share

Curved Guide Rail MarketMarket Growth Rate

Insulin Injection Related Product MarketMarket Forecast

Global Selective Wave Solder Pallet MarketMarket Size

Medical Grade Silicone Rubber MarketMarket Growth

0 notes

Text

Ram Automations : Industrial Automation & Marine Spare Parts

In the dynamic landscape of industrial automation and marine spare parts, finding a reliable partner is critical. Look no more than Ram Automations, your trusted source for advanced options and top-tier brands. With a commitment to excellence and a large selection of offerings, Ram Automations stands as a beacon of quality and reliability in the industry.

At Ram Automations, we comprehend the value of efficiency, reliability, and accuracy in every element of your operations. That's why we've curated a comprehensive portfolio of brands renowned for their innovation and quality. Whether you're in requirement of industrial automation components or marine spare parts, we have you covered with products from leading manufacturers across the globe.

Our comprehensive series of brands consists of household names like Siemens, Bosch, Allen Bradley, and Schneider, alongside specialized manufacturers such as Alfa Laval, Furuno, and Yokogawa. You'll also discover relied on brands like Aastra, ABB, Agastat, Amot Controls, Arnold Magnetics, Autonics, Autronica, Azbil, Azimuth, Baylor, BBC, Bemac, Bodotherm, BQT Solutions, Brannstrom, BW, Carlo Gavazzi, Carrier Controller, Compaq Computer, Consilium, Converter Concepts, Crouzet, Danfoss, Deif, Desautel, Drager, E. Dold & Shone, Electro Matic, Emerson, Endress+Hauser, Enraf Nonius, Ericsson, Fanuc, Fellow Kogyo, Fischer, Fuji Electric, Gai-Tronics, George Kelk, Gestra, Gordian Group, Gresen, Gutor Electronics, H.M. Stein Sohn, Hawe, Hawke, Hewlett Packard, Honeywell, Hydropa Hydrostar, Hyundai, IBM, Idec, Invensys, Johnson Controls, Jrc, JRCS, Jumo, Kaneko Sangyo, Kessler-Ellis Products, Kidde, Klockner Moeller, Kokosha, Kone, Kongsberg, Koyo, Lamarche, Liaanen Helitron, Liebherr, Lilley & Gillie, Lyngso Marine, Maiyo Electric, Man B&W, Marioff, Masibus, Mean Well, Mitsubishi, Mizar, Moeller, Moog Servo Valve, MSA, MTL, Mutec Instruments, Nagano Keiki, Nakakita Seisakusho, Newage Engineers, Nor Control, Norgren, Noris, Northrop Grumman Sperry Marine, Noshok, Notifier, Omron, Opsis, Parker, Pellerin Milnor, Pepperl Fuchs, Phoenix Contact, Pr Electronics, Ram Automations, Rexroth, Riken Keiki, Robertshaw, Ross Hill, SAAB, Sabroe, Saginomiya, Sauer Danfoss, Sauter, Schaffner, Schmersal, Seiko Electric, Shinybow, SMC, Smiths Heimann, Squared, Stahl, Stromberg, Sun Hydraulics, Tamagawa, TDK, TDK Lambda, Teamtec, Telemecanique, Terasaki, TRACO POWER, Trafag, Ueda Seisakusho, Ultra Electronics, VAF Instrument, Van Air, Vingtor Stentofon, Wabco, Weidmuller, Westfalia Separator Systems, Wieland, Yamatake, Yokogawa, and York.

0 notes

Text

China made IMO Oil pump KG70/KZ/7.5F4 for power generation

China made IMO Oil pump KG70/KZ/7.5F4 for power generation The use of advanced technology, absolutely first-class service quality, is our constant faith over the years. Production is in strict accordance with national standard, line standard and technical standards. The main technical backbone are retired senior engineer and senior technicians, who has participated in the design, manufacture and installation of Gezhouba, Ertan, Three Gorges and other power plants. We have served hundreds of hydropower stations, thermal power plant overhaul, and technical transformation to provide high quality equipment, construction design, installation, spare parts, and after-sales service.

Yoyik can offer many spare parts for power plants as below:

DF-IMO Oil pump KG70/KZ/7.5F4-DF

Accumulator bladder HY-GNXQ40.1.V.05 Z vacuum pump parts P-2412 Fluoro Rubber O-Ring OR0030039 Temperature control valve PN16, DN25, KVSS.5 EH oil main pump R200L-4 mechanical seal in pump 15F4-IC-20 ac vacuum pump P-1931A screw pump stainless DLZB820-R64 Switching Mode Power Supply MES-150-24 centrifugal pump impeller CZ50-250C twin screw pump HSNH280-54A vacuum pump ac P-2811 key 22*135 oil pump gasket 70LY-3 solenoid valve AM2206A-220VDC-V170N,30W OPC solenoid valve coil Z2804076 cushion 65-250A solenoid valve 4WE6Y6X/EG220NZ4/V balanced vane pump F3-SDV20-1P11P-1A single screw pump ACF080K5IVBP Accumulator blader plus seal NXQ-AB 80/31.5-L-Y fuel pump SDH125-100-200 sealing oil main differential pressure valve 514D098 solenoid valve4WE10D3X/CG110N9K4/Vbalanced vane pump F3-V10-IS6S-1C-20 hydraulic pump motor 40SDZLJ-40B×1.5 centrifugal pump impeller ISG150-160 oil pump 50AYZ-32 solenoid valve dc centrifugal pump DFBII100-80-230 hydraulic oil pumps 70LY-34×2-1 Solenoid valve HQ16.07Z-3 Elastic block of oil pump on hydrogen side GHE004PO cover plate CVCS-32-A-B29-W-10 radial piston pump hydraulic PVH131Q1C.RSF.10.C25 sealing ring HB4-56J8-02 IMO Oil pump KG70/KZ/7.5F4

balance valve (exciter end) 19C1964H01H01 unloading valve CVC-40-N vacuum pump oil P-2037 screw pump diagram HSNS440-46 piston pump hydraulic PVM074ER10GS02AAA28000000A0A hydraulic screw pump DLXB820-R67 solenoid valve VA240LC-6T 220VAC magnetic coupling centrifugal pump DFB80-80-220-03 relief valve DB10-2-30/100 hydraulic screw pump 3Gr70×2 industrial vacuum pump 2S-185 vane pump diagram F320V12A1C22R pipe clamp SP650PADP-AS hydraulic screw pump ACF 090N4 IRBP sealing ring HB4-56J8-184 RSV2 trip solenoid valve 18YV mechanical seal pdf 80AY50*10 rotary vacuum pump 30WS PluginsLC40DB20E-7xSolenoid valve SFZCZP-150Lb piston pumps PVH74(QI)C-RM-10-C14 wet solenoid directional valve 4WE6D6X/OFEW220-50NZ4/V solenoid valve 4WE10M3X/CG24NZ5L/B08 radial piston pump A10VSO100DR/32R-VPB12N00 mechanical seal pump 11-SHF11/135-E9-A3 00 11 centrifugal pump vertical 50-250 HP ball valve HQ14.51Z Electro-hydraulic servo valve J761-004 electric vacuum pump P-1741 solenoid directional valve M-3SE10 oil pump gasket 65AY60A piston vacuum pump PVHD74R01AA10A250000001ABO1OA Accumulator Bladder NXQ-A-25/31.5-L-Y industrial centrifugal pump DFB80-520-240 metering piston pump PVM045ER05CS02AAA28000000A0A solenoid valve B13AXCP00N IMO Oil pump KG70/KZ/7.5F4

DFYLSYC-2024-7-8-A

0 notes