#Electrical testing and verification

Explore tagged Tumblr posts

Text

Inversion: Ch. 5 - Stumbling around the dark

Prologue ←Previous Next→ On Ao3.

Relationships: Ramattra/Genji Shimada, Cole Cassidy/Hanzo Shimada

[Processes cleared. Initializing.]

[Booting BIOS…]

[Power-on-self test passed.]

[AnpuOS loading…]

[☐☐☐☐☐☐ l☐☐ded.]

To coast along the void of nonexistence; an ephemeral reprieve. Faint sensations trickled in, trudged through the electric system and sharpened the shapeless edges of reality with the whetstone of awareness.

[☐np☐☐S l☐☐ded.]

[Syste☐ c☐nfig☐☐☐ti☐n in p☐☐g☐☐☐☐...]

Feeling. A pull, uncomfortable and heavy.

Hearing. A low humming, continuous and incessant.

Sight. Darkness, a different void altogether, broken up by flickering dots and shapes of faint colors.

Everything was singular up until each sensation combined, consolidating into the being he understood as himself. But he was not whole yet.

A piece was missing.

[System configuration complete.]

...Peace was missing.

Sentience always found him in the end. Wrenched him back into the turgid hellscape of a gift.

[Verifying files...]

Core memory files replayed in order and in the span of a few seconds, Ramattra relived it all. Scenes and words he knew he understood were disconnected, within his grasp, so close, touchable, yet simultaneously so far away and intangible. Faces and names, all vague recollections in the drifting psyche. None would wait for him; the memories passed him by, turned sepia before vanishing altogether, and though they started vague, they became stronger, heavier, more present and real.

At the threshold of comprehension, so close to enlightenment, everything fizzled.

[Verification complete.]

[Loading system utilities…]

[System utilities loaded.]

[Awaiting user authentication.]

Ramattra returned in a flash, a shock of information surging through his unit. The apertures of his optics snapped open only to close shut again with a sharp hiss. Too bright—everything was too bright and loud, battered his head until he swore it would split from pressure.

Rebooting is the absolute worst.

With sluggish, near-drunk movements, he turned off his side and onto his stomach, waiting for the spinning to stop. Dizziness and dull throbs were the brunt of his world at that moment, floundering through the fog of reset to understand what had transpired to leave him in such a state. He decided he had enough intimacy with the cold floor, pushing himself onto his knees with the help of his one functional arm. Mulling on why his right was unresponsive would have to wait; the surroundings rolled and he slammed his side against the wall.

Curse this stupor...

When was the last time he endured the effects of rebooting? Through a wave of nausea, courtesy of his recalibrating inertial measurement unit, he remembered. Right before leaving to wander in search of answers. Which was...

Ramattra pulled up his internal clock.

…12 years, 324 days, 22 hours and a handful of minutes ago.

No wonder.

Slipping down the wall, he turned over onto his back and sunk into a seated position, head lolling onto his shoulder like a discarded mannequin. Something was amiss. As if a persistent whisper was alerting him to hidden danger. But could he afford to care right now? Weary and ill, he wanted nothing more than to rest, allow this torment to pass.

And then, like a sucker punch out of nowhere, it hit him and he started awake.

Betrayal!

Zenyatta, his brother. Talon had taken him. Twisted him. And more still had they stolen; they held the keystone and now the fate of every omnic tumbled out of Ramattra's hands and into theirs.

Careless. He had been so very careless to trust them. To trust humans.

Overwatch...!

Now, for all his efforts, he found himself in a cell, their cell, a tall rectangle of modest size, nigh barren. In front of him were two metal doors, one of which sported a smaller hatch in its lower half. Attempting to pry them apart would be useless, if the electric humming was anything to go by; even in the scenario he had been able to utilize his nemesis form, he would be outmatched by the strength of the magnetic locks gluing the doors together.

His baffled incredulity morphed into mild surprise and disappointment. This was what Overwatch chose for him? An offense not to be treated with the fear and respect he deserved. In his mind, he should have been handed the same fate as every omnic criminal in high security prisons: Mounted to a hanging suspension system, connected to a console forcibly overriding his hydraulics, left to rot with nothing but his mind intact. A cruel, but not unusual, punishment.

With such a dark thought, he considered the source of his earlier paranoia, and quickly felt at the back of his neck, nearly wrenched away the wire plugged to his port by mortified instinct. He still had his wits and his awareness, but for how long? Ramattra's core choked, panic rousing at the mere thought of a Trojan slipping past his firewalls. While his scanners worked to analyze his system, he personally sifted through the history of data packet transfers.

Nothing. Not a comfort. The wall-mounted computer Ramattra was plugged into continued droning along, ignorant to his plight, its small screen updating his diagnostics in real-time. Possibly a red herring, but bereft of other options, it was the sole lead to investigate. His fingers were barely hovering over the keypad when a voice spoke.

“You are not alone,” a feminine voice warned, radiating off the walls, everywhere and nowhere at once, turning the narrow room all the smaller.

“Who are you?” Ramattra pressed, turning around in search of the voice's source. Perhaps an overlooked element to be exploited. A usual thought to pass over the mind, what once burned him with anger and lingered disgust, now nothing more than tired sentiment.

“I am not a physical being; I am an AI. Athena, they call me. I have been tasked with overseeing you.”

Ramattra was aware of the advanced AI Overwatch utilized, though none were certain what became of the artificial being following the organization's downfall. Hardly a surprise she still existed, though Ramattra had expected her to have been transferred to a different project altogether. Her kind were one of a select few, considering the global ban on advanced AI development, and thus a commodity highly coveted by every perceivable industry in existence. Including his own.

“Then surely you must be sympathetic toward my plight, of ensuring I was neither hacked nor infected,” Ramattra said, punctuating his appeal to reason with a puff of hot air from his auxiliary vents, barely denting the anxiety slithering around his internals.

“You are more than welcome to. Be aware I have direct insight over your interactions with the console. For what it is worth, I can personally attest to command declining the opportunity to attempt a direct interface.”

Not content with Athena's word alone, Ramattra engaged with the computer and entered a few inputs. The slight delay before the submitted commands took effect confirmed to him the AI was quarantining his actions to pore over them. An entire minute passed for the display swap to a detailed feed of his internal and external systems, wires constantly prickling with buzz all the while.

Optics passed over the overview, a stream of the word nothing repeating in his head, each successive echo calming the overactive electricity pulsing from within his core. No records of transfers or intrusions. Only a burned-out integrated circuit. With such a confirmation, the wires were detached to a click, discarded on the floor and his hand rubbed at his neck in appreciation of the heft leaving him.

“Command is willing to speak with you,” Athena proposed suddenly. Ramattra was neither in the shape nor in the position to act so inflammatory against his digital warden, yet he still met her offering with a condescending scoff.

“Speak of what? The weather? Such a droll proposition. Do I really have to state out loud that I refuse to comply with Overwatch?” Entities like them served only to spread their own agendas, acting unhindered under the obfuscating guise of altruism—Ramattra was convinced humans were incapable of such acts. Assistance and goodwill for the sake of it were a farce, and his presence there, in that damned cell, was undeniable proof, his captors sparing no time to try and turn him into an asset.

“I understand your reluctance. Command only wishes to share a few words. A transmission will begin shortly.”

The small screen flashed. Replacing the diagnostics was a gorilla peering into the camera, rearing back when he realized he was all too close, nearly throwing the glasses off his broad nose. With a cough into a hand to try and play off his blunder, he composed himself.

“Hello Ramattra. My name is Winston,” he greeted, carefully securing the skewed glasses back into place. Ramattra's shoulders squared, offended to have his refusal so deftly ignored and he briefly juggled the idea of smashing the screen, end the unsolicited meeting then and there. No, he decided he would not let them have the satisfaction to see him lash out, to have their perception of him confirmed.

“I know who you are. You are a traitor,” Ramattra hissed, his synth sharp despite withheld furor. “A traitor to all non-humans gifted with sapience. You should have championed our cause, yet you chose to side with our oppressors!”

Winston's brow furrowed, turning his head away from the scathing barrage, nostrils flaring and lips twitching in distaste. A sore point, Ramattra duly noted.

“You're angry. I get that. But we're not your enemy. Neither Overwatch nor humans. As a species, they—”

“Save your breath and spare me from your propaganda, agent. Your intention is more than evident.” Ramattra punctuated his feelings by folding an arm over his chest, the defensive stance emboldening.

Winston's expression morphed into bewilderment. “What? No, that's not—”

“Join me in a thought exercise, would you? You're imprisoned by your enemy. They offer to hold a dialogue. Are they going to chit chat? I don't think so. There's an ulterior motive behind everything, and by your clumsy approach I can tell you carry one as well. Frankly, I'm insulted that you thought mere words would suffice.” Holding the conversation hostage, Ramattra leaned close to the screen, uncertain if Winston could see him at all. Not that it mattered; the Ravager would fight not with force but with words, and his tongue was sharper than any sword, laced with corrosive venom. “Or do you think I am so easily swayed, beast?” A direct hit, the sudden sheen overcoming Winston's widened eyes telling. “Yes. That is how the humans refer to you, isn't it? Beast. That is all you will ever be to them. What we will ever be to them.”

Straightening his slumped posture—conceivably in an attempt to appear less bestial, Ramattra figured, wishing to bark out a contemptuous laugh—Winston exhaled with the same resignation that told he had been through this kind of agonizing exchange more than once.

“Right. Well, I can see this is going nowhere,” he bemoaned, sullen, pawing close a container of sorts. Ramattra narrowed his apertures. Was that peanut butter? “I will contact you later, with details surrounding your handling.”

“Winston, if I may?” Athena cut in, her voice lighting up the sour expression on the great ape's face.

“Of course, Athena. Your input is always valued. Please, go ahead.”

Such a trite exchange. It proved nothing to Ramattra, wholly convinced of its grandstanding function. Still, he listened, combed through the AI's words for any hint of defiance or dissatisfaction with her superiors.

“Thank you, Winston. Ramattra, you did work well with Genji earlier. Perhaps you would be more comfortable speaking with him?”

Ramattra paused, attention stolen away from his plotting. He had been so preoccupied with ensuring the integrity of his system and hassling his captors, he had barely had time to fret over the events preceding his capture. He stepped away from the computer, as if physical distance would spare him from the turmoil brewing inside.

It did not escape him just how close he came to dying, had it not been for an intervention in the nick of time. The image in his mind was clear, of a moment frozen in time: Stood before him in that poise, trailing green light, not faltering to the shattered bullet flinging debris every which way, not only thwarting the fate that Talon had concocted for him but also somehow succeeding in escaping the confines of the failing ship, clutching said Ravager three times his weight.

His analysis of the snapshot was cut off, covered with the results of his internal scanners. He lightly shook his head, trying to scatter the many possibilities and scenarios vying for his attention. What was important was that in the span of twenty four hours, everything had changed, and again, he told himself, he needed to focus. Complacency led him into this situation. It would not help him escape it.

He had but one question. “How do you know this?”

“I was overseeing the initial infiltration of your vessel and I witnessed the clash with Talon and Zenyatta.”

Ramattra continued his retreat, up until his back pressed against the wall, staring at the static text overlaying his vision.

[No viruses or unauthorized access detected.]

Slowly, he slid down onto the floor, weighed down by a dangerous mixture of anguish, defeat and—worst of all—the faintest glimmer of hope. Emotions had to wait, for when they could be properly weaponized.

His tone was flat as he spoke.

“…So be it.”

3 notes

·

View notes

Text

Suspended from an overhead crane in the Vehicle Assembly Building at NASA’s Kennedy Space Center, the orbiter Discovery is lowered toward the Solid Rocket Booster and External Tank (seen below) already stacked on the top of the Mobile Launcher Platform (MLP). After Discovery has been mated to the External Tank/Solid Rocket Booster assembly on the MLP and all umbilicals have been connected, workers will perform an electrical and mechanical verification of the mated interfaces to verify all critical vehicle connections. A Shuttle interface test is performed using the launch processing system to verify Space Shuttle vehicle interfaces and Space Shuttle vehicle-to-ground interfaces. In approximately one week, Space Shuttle Discovery will be ready for rollout to Launch Pad 39B for Return to Flight mission STS-114. The launch window for STS-114 is May 15 to June 3.

Date: March 29, 2005

NASA ID: KSC-05PD-0515

#STS-114#Space Shuttle#Space Shuttle Discovery#Discovery#OV-103#Orbiter#NASA#Space Shuttle Program#March#2005#VAB#Kennedy Space Center#Florida#my post

17 notes

·

View notes

Text

G53U finished repairing the window projector 54 seconds past the deadline indicated in the ticket. It was understandable why the SecUnit's dark visor, turned towards him, seemed tense. The Unit should have detected the potential delay in advance and taken measures to ensure that junior technician G53U wasn’t slacking off. But neither the Unit nor G53U could have predicted that, after replacing the window control module (which burned out after Supervisor Bethane threw a chair at the SecUnit and missed), it would turn out that all the image files were hopelessly corrupted. And now they had to be urgently acquired from somewhere.

G53U didn’t have a single service token to purchase a new set of landscape images. And with what he usually received, he could only afford a picture for the public halls, and even then, only in low resolution. So, G53U resorted to extreme measures.

Permission to contact block 87-76-554, - he sent to the SecUnit, hastily assembling a code that vaguely resembled a supervisor-level access key. To be sure, he displayed the code for less than 0.001 seconds, so the SecUnit wouldn’t have time to record it and verify it. G53U wouldn’t have been able to. As for the SecUnit—who knows? G53U hadn’t tested that before, only speculated.

Affirmative? - the SecUnit responded uncertainly. It might have managed to check the code but hadn’t reported the verification to SecSystem and its governor module.

Without wasting another second, G53U dove into block 87-76-554, the facility’s public data repository, partially using the permission just issued by the SecUnit. He quickly found the needed images and videos, filtering out the popular and free content while marking the exclusive ones—those created or filmed by artists on corporate commission or auctioned for senior executive use. The quality of the previews was truly impressive, but each file was incredibly expensive, and some came as premium or holiday tokens for management. So G53U assigned the SecUnit the task of trying to defragment the corrupted files from the old window module. And while the Unit flooded the feed with information about why SecUnits shouldn’t be doing this, G53U was breaking the file protection, using access codes he'd stolen from the SecUnit itself during the joint window repair (the SecUnit had tried to set up walls and protest against overly close contact, but 057-G insisted that full modules integration was needed to extract information from the burnt-out block and to perform a complete replacement).

G53U also negotiated with the Unit's governor module, rather crudely, creating a loop for its commands and overrides that triggered thermal and electrical shocks. This, too, was justified because when the tech and construct systems were integrated, the nasty program would hit not only the construct’s brain but augmented human's too. Now, the program believed everything was correct, and everyone received deserved suffering in time, the SecUnit thought all of G53U’s actions were justified and legal, and G53U could work calmly amidst the madness.

The file protection resisted as much as it could, but G53U was persistent and patient—by a whole +50 seconds, during which he successfully raided the elite section of the repository. The SecUnit still didn’t object to his actions but did object to defragmenting the corrupted files. So, G53U threw the new images at it and said, "Upload."

Which it did. Then, for another two seconds, they fiddled with settings and checked the compatibility of the images with the new window module, flipping through one stunning landscape after another. The SecUnit admired them next to G53U, tilting its head back and aiming all its drones at the window. After all, now it had copies of all these files. It could enjoy the illusions of exotic places and masterpieces of the past as much as it wanted.

And then both noticed the flashing red overdue ticket signal.

54 seconds. That was serious.

Timer malfunction,- the SecUnit suggested, already correcting the exact start time of the repair.

Affirmative - G53U replied.

5 notes

·

View notes

Text

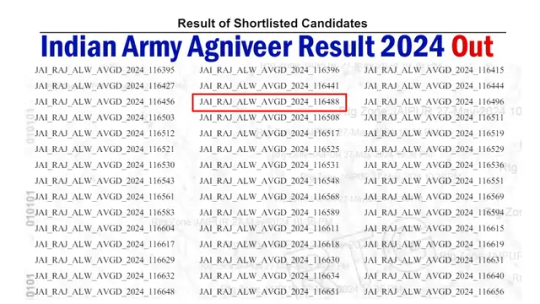

Army Recruitment Result: Understanding the Process, Checking Results, and Next Steps

The announcement of the Army Recruitment Result is a important moment for hundreds of aspiring candidates. This result determines the selection of individuals who have correctly met the rigorous criteria set via the military, along with bodily fitness, written examinations, and scientific checks. Understanding the system, how to test the end result, and what to do next is important for applicants who wish to pursue a career inside the army.

Where to check my army recruitment result

Understanding the Army Recruitment Process

The army recruitment procedure is established to assess candidates primarily based on numerous criteria. Here is a breakdown of the key degrees:

Notification and Application: The recruitment manner begins with the discharge of an reputable notification, detailing eligibility standards, utility methods, and essential dates.

Physical Fitness Test (PFT): Candidates need to undergo a bodily fitness check that includes strolling, push-ups, pull-ups, and other patience exams.

Written Examination: Those who clean the PFT continue to a written exam, which tests their knowledge in topics like widespread cognizance, arithmetic, and reasoning.

Medical Examination: Candidates who skip the written take a look at undergo an intensive clinical test-up to ensure they meet the desired health requirements.

Document Verification: Finally, a hit applicants should present authentic files for verification before the very last selection list is posted.

How to Check the Army Recruitment Result

After completing all levels of the recruitment technique, candidates eagerly await their effects. Here are the commonplace approaches to test the navy recruitment end result:

Regional Army Recruitment Offices:

Candidates can visit their respective local recruitment offices to check the merit list and get in addition facts.

Newspapers and Employment News:

Some recruitment results are also posted in leading newspapers or employment bulletins.

SMS/Email Notifications:

Candidates who've registered with their cellular numbers and email IDs can also get hold of end result notifications via SMS or e-mail.

What to Do After Checking the Result

Once the result is asserted, selected applicants want to comply with precise steps to continue further:

Download the Call Letter:

If selected, applicants have to down load their name letter, which incorporates details about their schooling agenda and joining commands.

Prepare for Training:

Selected applicants need to undergo training at specified military schooling facilities.

It is recommended to stay bodily healthy and mentally prepared for the rigorous education beforehand.

Verify Documents:

Ensure that every one required files (instructional certificate, identity proof, scientific certificate, and so forth.) are in order earlier than reporting for schooling.

Stay Updated:

Regularly check legit web sites or recruitment offices for any updates or changes in the becoming a member of system.

Common Reasons for Disqualification

Not all applicants clean the recruitment technique. Here are a few common reasons for disqualification:

Medical Unfitness:

Candidates who do no longer meet the clinical requirements set by using the army can be disqualified.

Failure in Physical Test:

Inability to complete the specified bodily endurance tests might also cause disqualification.

Document Discrepancy:

Any mismatch or falsification of documents can result in rejection.

Failure in Written Examination:

Candidates who fail to steady the minimal qualifying marks within the written take a look at aren't decided on.

How to Improve Your Chances of Selection

Candidates who do no longer make it of their first strive can prepare better for destiny recruitments by following those hints:

Improve Physical Fitness:

Regular exercising, running, and electricity training can decorate physical performance.

Prepare Well for the Written Exam:

Study from relevant books, clear up previous yr’s query papers, and take mock assessments.

Stay Medically Fit:

Maintain a healthy lifestyle and go through regular scientific take a look at-united states of americato satisfy the specified requirements.

Ensure Proper Documentation:

Keep all required documents up to date and demonstrated earlier than applying.

Official Website:

Visit the legit recruitment internet site of the respective military branch.

Enter your registration variety and date of start to view your result.

2 notes

·

View notes

Text

How to kill a company.

February 22, 2023

Followers of Elon Musk's career understand that, while he is most assuredly obscenely wealthy, a business genius he ain't. Stock in his electric car company, Tesla, has dropped a stunning 26% thus far in 2024. And the year has only begun. His SpaceX venture isn't faring much better, either. Its attempt at a rocket launch last November ended with the spacecraft exploding minutes into the test flight. It was the sixth such failure for the space technology company.

So when Musk bought the social media platform known as Twitter in October 2022 for the announced price of $44 billion (after considerable legal wrangling as Musk tried to wriggle out of the deal), many wondered how long it would take him to destroy the company. Turns out not that long.

Having extravagantly overpaid for Twitter, Musk set about trying to recoup by extracting every dime he could from the business. His first act was to cut costs by firing over 80% of Twitter's staff, reducing it from just under 8,000 to around 1500 employees. In particular, this included content moderators whose job it was to battle disinformation on the site. As a result, the platform became flooded with phony bot accounts, conspiracy theorists and previously banned users (i.e., right-wing trolls, anti-Semites and other hate-mongers). In response, hundreds of major advertisers reduced or halted their ad spending on the site by January 2023.

Twitter’s original verification system was based on the premise that it had evidence the accounts it identified with blue check marks belonged to the actual people claiming them and that those were people or organizations of some importance. Musk did away with all that by selling blue checks to anyone willing to shell out $8 a month — an offer taken up by less than 1% of the app's actual users.

Finally, in what was possibly the worst re-branding decision ever, Musk decided to ditch the globally known Twitter name and relabel the app X (a letter he seems obsessed with). As the technology news site Engadget reported,

Musk killed Twitter by slowly making it useless for those who relied on it for real-time information, by choking off conversations from those not willing to pay, by flooding users’ timelines with spammy blue-check sycophants and renaming the company X.

Recently, a Pew Research study asked current and recent X users how likely they are to use the platform a year from now. A quarter of the respondents said not very or not at all. So congrats, Elon. You've euthanized your enterprise.

13 notes

·

View notes

Text

So without getting into what a garbage bag of a human Elon Musk is, and also how he isn't smart, doesn't have an engineering degree, isn't an inventor, etc etc...

i see the headline that his neuralink brain chip has been implanted into the first human brain. (NPR) (Al Jazeera)

OK and without getting into the dodgy ethics of this even apart from all the dead monkeys, like a LOT of dead monkeys... (like holy shit it's at least 12 monkeys and over 1,500 animals including sheep, pigs, and monkeys) (like OMG HOLY SHIT they don't even keep precise records on the numbers of animals tested and killed?? this is monstrously immoral) (source)

left unchecked i worry this is going to end like Dollhouse. (a 15 year old TV series you should watch, which doesn't have any monkeys) and why is Musk doing all this? that answer is in The Fall of the House of Usher (a recent streaming series you should watch, although there are definitely monkeys in it).

(semi related on the recommendation of my dentist i bought an electric toothbrush. damn thing wants to be bluetooth paired to its app. an app!! it's a fucking toothbrush it doesn't need to be connected to jack shit.)

anyways, everything Musk touches goes to shit (or goes up in flames) so even if there was some timeline where this is a good use of technology and it helps people - he's going to run the company poorly and it will hurt people. just like it's already hurt a ton of animals. where is the independent verification of their claims that the human is "recovering well?" where is the oversight? JFC

#rant#anti elon musk#fuck musk#fuck neuralink#randomly this also includes#show recos#i get that research will sometimes entail experimentation on animals but the only way that has a chance of not being immoral#is if the animals are super tracked and you're learning from every injury and doing all you can to prevent actual deaths#not even keeping precise records? like to me that right there means shut them down

12 notes

·

View notes

Text

By Nick Miller Jul 18, 2022

Barbra Banda is a woman.

It’s important to start from that point for a couple of reasons.

The first is that nothing in what follows here should suggest she is not a woman. The second reason is that this is ultimately an extremely sad human story — one about a footballer who is potentially about to be denied her career — not an “issue” to be jumped on by anyone with malign intent.

You might be familiar with Banda if you watched the women’s football tournament at the Olympics last summer. Zambia only gained a point from their three games in Japan, comprehensively outmatched in a 10-3 opening defeat by the Netherlands, although they did draw 4-4 with China and performed credibly in only losing 1-0 to Brazil.

Banda dazzled, though.

The forward scored hat-tricks against the Dutch and the Chinese — the first woman to ever score back-to-back trebles at the Olympics — a combination of pace, wily movement and slick finishing earmarking the then 21-year-old as arguably the breakout star from the women’s football.

Banda moved from Dux Logrono in northern Spain to the slightly more lucrative environs of Shanghai Shengli at the start of 2020. In her first season in Shanghai, she was top scorer in the Chinese Women’s Super League with 18 goals from 13 games.

Her performances have been such that she has been heavily linked with a move back to Spanish football with Real Madrid this summer, although neither the club nor a source close to the player could confirm how advanced that potential transfer is.

She was thus expected to be one of the key players at the Women’s Africa Cup of Nations, currently taking place in Morocco.

FIFA was using her image to promote the tournament only a week or so before it started. The tournament’s Twitter feed hyped her as one of the players to watch at WAFCON. Zambia have never made it beyond the group stage on the other two occasions they qualified for WAFCON in its current format in 2014 and 2018. But with Banda as their captain, supported by brilliant No 10 Grace Chanda and electric winger Xiomara Mapepa, they had a real shot at making a significant impact this time.

Then, just before the tournament started, Zambia announced a squad that did not have Banda, along with two other players who were expected to be named, in it.

Initially, the official line was that Banda was not present for slightly vague-sounding “medical reasons”. Ultimately it emerged that she had not met the criteria put forward in the gender verification tests laid down by the Confederation of African Football (CAF), African football’s governing body.

Banda’s tests revealed elevated levels of testosterone — naturally occurring, but higher than the levels permitted by CAF (which maintains it is simply applying standards put forward by FIFA, football’s global rulers).

Testosterone level is not the only criterion, but neither CAF nor officials from the Football Association of Zambia (FAZ) would confirm what those other criteria were.

It was an echo of the previous edition of the tournament four years ago, when Banda was initially named in the Zambia squad but was ultimately prevented from competing for similar reasons. But it left a star on the sidelines, opened a debate that could easily stray into desperately toxic areas, and perhaps most importantly denied a young woman the chance to play on one of the biggest stages of her career.

The whole business is, to be frank, an absolute mess. There has been claim and counter-claim throughout, but the situation as The Athletic understands it is as follows.

Before the tournament, FAZ medical staff conducted tests to, in their view, comply with gender recognition regulations set forward by CAF and FIFA. After those tests, Banda and three players were not named in their WAFCON squad. Zambia did not call up any replacements: a maximum of 26 players are allowed in each squad, and they named 22.

The players were offered hormone suppression medication that could bring their testosterone down to “acceptable” levels, but — setting aside the moral issues of whether that is acceptable — due to side effects reported by athletes who have taken them in the past, such as South African middle-distance runner Caster Semenya, they declined.

“These are personal issues, and she refused,” former FAZ official Blackwell Siwale told ESPN. “Someone should first counsel (them), and tell that how it would affect them, or that it might affect their energy levels et cetera.”

It was reported that CAF had “banned” the players from competing, but the African federation’s position was that Zambia simply named a squad as they saw fit, rather than the players in question being included and CAF rejecting them.

Ergo, in CAF’s view, this was all essentially nothing to do with it as the governing body.

Zambia, clearly, took a different view.

“Everybody at home has been made to believe that FAZ did nothing and decided on their own to exclude the player,” FAZ president Andrew Kamanga told the BBC. “We the federations are compelled to undertake the tests and then we pass on the information to CAF, and CAF, equally, test the players if needs be in the tournament. So it will be unfair to turn around and say CAF is not part and parcel of whatever has transpired.”

FAZ made representations to a meeting on July 7 that involved officials from FIFA, the CAF medical department and others. It “appealed” Banda’s omission from the tournament.

Meanwhile, Zambia’s campaign on the pitch was underway. Banda was still with the squad in Morocco, supporting the team from the stands.

Rumours circulated on social media in the following days that FIFA had intervened and Banda would be allowed to play in the remainder of the tournament, but these turned out to be false.

FIFA did not respond when asked by The Athletic for comment.

Then, on July 12, CAF wrote to Adrian Kashala, the general secretary of FAZ — a rather brusque letter that has been seen by The Athletic. In so many words, the letter tells Zambia to get lost. The letter reiterates the position that there was “no decision taken by any CAF body” so, officially and technically speaking, there is nothing to appeal against.

A FAZ spokesman suggested that it will work in the future to change the regulations in the long term, but as things stand Banda and the other players will not be allowed to compete in the ongoing WAFCON, where Zambia face South Africa in the semi-finals today (Monday).

And that, at the time of writing, is that.

A situation that is, at best, deeply unsatisfactory, whereby a player is being prevented from representing their country and nobody seems to be taking responsibility for the decision to prevent her from doing so.

The FAZ says it is complying with CAF rules. CAF says it had nothing to do with the decision.

When asked to supply more details about its medical processes, CAF declined to do so. FIFA is, at present, saying nothing.

It is worth pausing for a minute to look at exactly why increased levels of testosterone are considered to provide an athletic advantage.

“Testosterone is an anabolic hormone,” says professor Anthony Hackney from the exercise and sports science department of the University of North Carolina in the US. “One of the major things that anabolisms do is build protein.

“One of the largest tissues of your body that contains the most protein is skeletal muscle, and when skeletal muscle is asked to do its job — to contract and produce force, strength, endurance — it has to use those proteins.

“One of the reasons testosterone is viewed as a possible enhancement to sports performance is to allow you to have more muscle, which means you have more force-generating capacity, more strength and greater endurance.

“The other aspect of this anabolism is that one of the proteins that it helps to synthesise is haemoglobin, which is found in your red blood cells, and haemoglobin’s job is to carry oxygen. Any highly aerobic sporting activity is potentially going to be benefitted by more haemoglobin, which could be due to more testosterone.”

So, in short, testosterone could potentially make you stronger and faster for longer. Which is why artificial enhancements, such as anabolic steroids, are banned in sport.

But there is no suggestion the testosterone levels found in Banda are anything but naturally occurring.

The most prominent and obvious case that will come to the mind of most people when hearing about Banda’s situation is that of Semenya, who has been barred from competing in her favoured 800m event (the event she has two Olympic and three World Championship gold medals in) since 2019, unless she first takes medication that lowers her testosterone levels, which she has refused to do. Recently, Semenya called leading figures in African athletics “cowards” for not fighting harder for competitors in her situation.

However, directly comparing Banda and Semenya is tricky, simply because not enough is publicly known about Banda’s condition to put them both in the same category. Their issues are both related to “differences in sexual development” tests and regulations but they could be different, so at this stage, it is probably wise not to make a direct comparison.

From its perspective, CAF will argue that it is simply trying to be fair, and trying to avoid a situation similar to the one that came to a head after the 2010 WAFCON when complaints were lodged against two Equatorial Guinea players who took part in that tournament.

After that, CAF introduced the regulations at the centre of this case.

The whole situation seems deeply unsatisfying, partly because it is so opaque, but also from a distance at least, it is inconsistent. A FAZ official, when contacted by The Athletic, bemoaned a situation where Banda and other athletes in her position could appear in some international competitions but not in others.

“The points we touch upon in our position is the inconsistency in these rules,” says Tim Harper, executive director of Equity Sport, a group that aims to advance equality in global sport and does much of its work in sub-Saharan Africa. “Banda was allowed to play in the Olympics and was celebrated throughout as a superstar, and now, a year later, she’s suddenly not allowed to even be on the pitch.”

Olympic rules in this area only apply to a select few sports, including the 400-metre, 800-metre and hammer throw. Football isn’t included, so Banda was allowed to play at the Games last summer, and did so brilliantly.

Equity Sport also points out that this is an issue which seems to disproportionately impact Black, sub-Saharan African women.

In addition to Banda and Semenya, recent examples include Christine Mboma and Beatrice Masilingi, two Namibian 400-metre runners who were banned from those same Tokyo Olympics.

“What we want to understand is whether this is a biological matter,” Harper says.

The short answer to which is: It might be.

Professor Hackney is at pains to point out that the vast majority of research into whether higher levels of testosterone naturally occur in Black athletes has been conducted on men, but: “If you look at just the male research, there is evidence to suggest very definitely that testosterone happens to be higher in African Americans, than in matched Caucasian white populations.

“The difference is consistent, it seems to be across age ranges, but it’s not a large magnitude of difference. It’s in the range of five per cent, maybe 10 per cent, so it’s not as if it’s astronomically higher. I would suspect it would also be true in women, but again, without the same body of evidence and literature, I couldn’t say Black women are always going to have higher testosterone levels.”

“It should concern all of us,” Harper says. “If it was happening to the England team, there would be even more of a global media storm about it.

“The question we have to ask ourselves is: Is this what we want sport to be?”

Again, it should be repeated that testosterone is not the sole marker in this case, although FAZ seems to think it forms a disproportionate part of the regulations.

“Many players can be affected by these regulations, and football is their livelihood,” FAZ communications director Sydney Mungala told ESPN. “I think the CAF regulations are a lot more stringent (than Olympic regulations), and they put too much stress on testosterone levels.”

But what of the woman at the centre of this latest episode?

It’s easy to forget that, although Banda has been part of the Zambia team for some time and was their captain, she is still just 22.

Banda grew up playing on the streets of capital city Lusaka, and her talent meant she became the first female Zambian footballer to play for a European club. She is a wildly popular member of the squad, and not just because she is their best player. A source close to Banda described her as “jovial” but also “a warrior”.

The source suggested she was coping as well as can be expected with her omission from the WAFCON squad, although there were concerns that the debate around her could adversely impact her mental state.

Even if she is unable to play for Zambia in Morocco, she has been present at their games and has posted her encouragement to the team on social media as they have progressed to the final four.

After each victory, she has tweeted messages of congratulations, all of which include a variant of “I am with you all the way”.

And “all the way” might not just be a turn of phrase, because Zambia — nicknamed The Copper Queens (copper mining is big business there) — have been exceptional so far. They were arguably the most eye-catching team in the group stage, easing into things with a 0-0 draw against Cameroon, then squeezing past Tunisia 1-0 with a stoppage-time winner before really cutting loose to defeat Togo 4-1.

With her direct, rapid running, Mapepa won a penalty after 47 seconds against Togo. That was missed by defender Lushomo Mweemba, but from that point Chanda took over, dictating the game from the No 10 position and helping herself to two goals. Another came from Ireen Lungu, architect of some remarkable passes elsewhere in the game (some have nicknamed her “Xavi”), who skimmed a 35-yard effort over the goalkeeper after the ball had broken to her.

Mapepa, who has described Banda as her “idol” and is wearing her No 11 shirt at the tournament, scored the pick of the goals late in the first half, shortly after Togo had made it 2-1; driving down the left flank, leaving defenders in her wake, she thrashed a finish into the roof of the net from an implausible angle. Then came their quarter-final against Senegal on Wednesday. It was a nervy affair, the tension raised by the fact that the teams knew victory would also earn them a World Cup spot (WAFCON doubles as African qualification for next summer’s global tournament in Australia and New Zealand), something neither side had previously achieved.

It went to penalties, and in what can only be described as “quite the flex”, goalkeeper Hazel Nali stepped up to take Zambia’s fifth kick. Into the top corner it went and Zambia were through — to the semis, and to their first ever World Cup. Whether Banda will be there with them is another question entirely.

Even given her absence on the field, Banda was with the team off it. She was there in the dressing room after that shootout victory in Casablanca, wearing a team tracksuit and a shirt with the number 23 (remember, Zambia only named 22 players in their squad when 26 are permitted) on it, leading her team-mates in celebratory song.

“This was for Barbra Bandaaaaaaaaaa!!!!” yelled Nali as the whole squad celebrated.

“We still missed them,” said Zambia coach Bruce Mwape after the Togo game, when asked about the missing players. “They are part of our team.”

Zambia could be on the verge of doing something extraordinary.

It’s just profoundly sad that Banda won’t be on the pitch to do it with them.

https://www.nytimes.com/athletic/3426458/2022/07/18/barbra-banda-womens-football/

#rmsoccer

2 notes

·

View notes

Text

GF312B2 PORTABLE THREE PHASE REFERENCE METER WITH CLAMP ON CT

GF312B2 portable three phase reference meter high accuracy 0.02%, with all kinds of optional clamp on ct and smart optical sampler. It can be applied in electrical laboratory or on site. it will be ensured by a combination of measures such as the use of 24bit A/D converter, DSP+32 bit ARM technology, a widely measuring range 600V/120A, adapted to typical test points of most recognized national metrological institutes. It can be as high precision three phase reference energy meter, also three phase portable meter calibrator, test ct pt ratio, burden etc.

FEATURES ■ Vector diagram function; ■ Data download by U disk; ■ With PC control software; ■ Waveform display function; ■ High accuracy up to 0.02%; ■ 7 inch TFT touch color LCD; ■ DSP+32 bit ARM technology; ■ Energy accumulating function; ■ Metal body, strong and reliable; ■ Measurement 2~63 times harmonics; ■ Suit for testing in the field or in the lab; ■ Verification of comprehensive metering device;

APPLICATION ■ Power plant; ■ Electrical laboratory; ■ Energy meter R & D; ■ Watt-hour meter factory; ■ Metrological service center; ■ Electricity power bureau & power company; ■ National Metrology and testing department; ■ Electrical Department of industrial and mining enterprises;

3 notes

·

View notes

Text

NASA completes spacecraft to transport, support Roman Space Telescope

The spacecraft bus that will deliver NASA’s Nancy Grace Roman Space Telescope to its orbit and enable it to function once there is now complete after years of construction, installation, and testing.

Now that the spacecraft is assembled, engineers will begin working to integrate the observatory’s other major components, including the science instruments and the telescope itself.

“They call it a spacecraft bus for a reason — it gets the telescope to where it needs to be in space,” said Jackie Townsend, the Roman deputy project manager at NASA’s Goddard Space Flight Center in Greenbelt, Maryland. “But it’s really more like an RV because it has a whole assortment of functions that enable Roman to accomplish its scientific goals while out there too.”

Those goals include surveying wide swaths of the universe to study things like: dark energy, a mysterious cosmic pressure thought to accelerate the universe’s expansion; dark matter, invisible matter seen only via its gravitational influence; and exoplanets, worlds beyond our solar system.

The mission’s science wouldn’t be possible without a spacecraft to transport the telescope, point the observatory toward different cosmic targets, provide power, communicate with Earth, control and store instrument data, and regulate Roman’s temperature. Nearly 50 miles of electrical cabling are laced throughout the assembly to enable different parts of the observatory to communicate with each other.

The spacecraft will also deploy several major elements that will be stowed for launch, including the solar panels, deployable aperture cover, lower instrument Sun shade, and high-gain antenna. It’s also responsible for collecting and beaming down data, which is no small task for a space observatory that will survey the cosmos like Roman will.

“Roman will send back 1.4 terabytes of data per day, compared to about 50 to 60 gigabytes from the James Webb Space Telescope and three gigabytes from the Hubble Space Telescope,” said Jason Hylan, the Roman observatory manager at NASA Goddard. “Webb’s daily downlink is roughly comparable to 13 hours of YouTube video at the highest quality while Roman’s would amount to about 2 weeks.”

A Goddard Grand Slam

This milestone is the culmination of eight years of spacecraft design work, building, and testing by hundreds of people at Goddard.

“Goddard employees were the brains, designers, and executors. And they worked with vendors who supplied all the right parts,” Townsend said. “We leaned on generations of expertise in the spacecraft arena to work around cost and schedule challenges that arose from supply chain issues and the pandemic.”

One time- and money-saving technique the team came up with was building a spacecraft mockup, called the structural verification unit. That allowed them to do two things at once: complete strength testing on the mockup, designed specifically for that purpose, while also assembling the actual spacecraft.

The spacecraft’s clever layout also allowed the team to adapt to changing schedules. It’s designed to be modular, “more like Trivial Pursuit pie pieces than a nesting egg, where interior components are buried inside,” Townsend said. “That’s been a game-changer because you can’t always count on things arriving in the order you planned or working perfectly right away with no tweaks.” It also increased efficiency because people could work on different portions of the bus at the same time without interfering with each other.

The slightly asymmetrical and hexagonal spacecraft bus is about 13 feet (4 meters) wide by 6.5 feet (2 meters) tall and weighs in at 8,400 pounds (3,800 kilograms).

One reason it doesn’t weigh more is that some components have been partially hollowed out. If you could peel back some of the spacecraft’s panels, you’d find superthin metallic honeycomb sandwiched between two slim layers of metal. And many of the components, such as the antenna dish, are made of strong yet lightweight composite materials.

When the spacecraft bus was fully assembled, engineers conducted a comprehensive performance test. Prior to this, each component had been tested individually, but just like with a sports team, the whole unit has to perform well together.

“The spacecraft passed the test, and now we’re getting ready to install the payload –– Roman’s instruments and the telescope itself,” said Missie Vess, a spacecraft systems engineer for Roman at NASA Goddard. “Next year, we’ll test these systems together and begin integrating the final components of the observatory, including the deployable aperture cover, outer barrel assembly, and solar panels. Then we’ll finally have ourselves a complete observatory, on track for launch by May 2027.”

TOP IMAGE: This enormous piece of space hardware is NASA's Nancy Grace Roman Space Telescope's spacecraft bus, which will maneuver the observatory to its place in space and enable it to function while there. It is photographed here in the largest clean room at NASA’s Goddard Space Flight Center, where engineers are inspecting it upon delivery. The bus rests atop an aluminum ring that will temporarily protect its underside. The two copper-colored flaps are Roman's Lower Instrument Sun Shade –– deployable panels designed to help shield the observatory from sunlight. Credit NASA/Chris Gunn

CENTRE IMAGE: This top-down view shows NASA’s Nancy Grace Roman Space Telescope’s spacecraft bus from another angle. It rests atop an aluminum ring that will not be part of the observatory and is surrounded by an enclosure used in testing to ensure electromagnetic interference will not affect the bus's sensitive electronics. The bus is covered in gray bagging material to prevent contamination –– even tiny stray particles could affect its performance. Credit NASA/Chris Gunn

LOWER IMAGE: While it may look small in this photo, the spacecraft bus for NASA's Nancy Grace Roman Space Telescope is 8 feet (2.5 meters) wide by 6.5 feet (2 meters) tall and weighs in at 8,400 pounds (3,800 kilograms). In this photo, it rests atop an aluminum ring that will not be part of the observatory. The bundles of wires on top are part of more than 50 miles of cabling laced throughout the assembly to enable different parts of the observatory to communicate with each other. Credit NASA/Chris Gunn

3 notes

·

View notes

Text

How to Do a Load Bank Test on a Generator?|EMAX Load Bank

Generators are critical assets for businesses and homes, providing essential backup power during outages. To ensure that a generator will perform as needed during an emergency, it is crucial to conduct regular maintenance and testing. One of the most effective ways to test a generator's performance is through a load bank test. This comprehensive guide will walk you through the steps of performing a load bank test on a generator, ensuring optimal performance and reliability.

What is a Load Bank Test?

A load bank test involves using a device known as a load bank to simulate electrical loads that the generator might encounter during operation. The test ensures the generator can handle its full rated capacity and helps identify any issues that could affect performance. Load bank tests are essential for maintaining the health of standby generators, ensuring they can provide reliable power when needed.

Why Perform a Load Bank Test?

Performing a load bank test has several benefits:

Verification of Performance: Ensures the generator can handle its maximum load without issues.

Identifying Potential Problems: Helps detect issues like wet stacking in diesel generators, which occurs when the engine doesn't reach optimal temperature.

Improved Reliability: Regular testing ensures the generator is reliable and ready for emergencies.

Compliance with Regulations: Some industries require regular load testing to comply with safety and operational regulations.

Types of Load Bank Tests

There are three primary types of load bank tests:

Resistive Load Bank Test: Simulates real-world loads such as lighting and heating. It is the most common type of test.

Reactive Load Bank Test: Simulates loads that include inductive (motors, transformers) and capacitive (capacitors) components.

Combined Load Bank Test: Uses both resistive and reactive loads to simulate the most realistic operating conditions.

Preparation for Load Bank Testing

Before performing a load bank test, follow these preparatory steps:

1. Review Manufacturer Guidelines

Consult the generator’s manual for specific instructions and safety precautions related to load bank testing. Adhering to manufacturer guidelines is crucial to avoid voiding warranties or causing damage.

2. Inspect the Generator

Conduct a thorough visual inspection of the generator. Look for any signs of wear, leaks, or damage. Ensure that the fuel, oil, and coolant levels are adequate and that all connections are secure.

3. Ensure Adequate Ventilation

Load testing generates a significant amount of heat. Ensure that the testing area is well-ventilated to dissipate heat and prevent overheating.

4. Gather Necessary Equipment

Ensure you have the following equipment ready:

Load bank unit

Load cables

Personal protective equipment (PPE)

Monitoring devices (e.g., multimeters, temperature sensors)

Step-by-Step Guide to Performing a Load Bank Test

Step 1: Connect the Load Bank to the Generator

Safety First: Wear appropriate PPE, including gloves and safety glasses.

Shut Down the Generator: Ensure the generator is turned off before making any connections.

Connect Cables: Attach the load bank cables to the generator’s output terminals. Ensure that the connections are secure to prevent arcing or loose connections.

Verify Connections: Double-check all connections to ensure they are tight and correctly aligned.

Step 2: Start the Generator

Start-Up: Follow the standard procedure to start the generator.

Warm-Up Period: Allow the generator to run for a few minutes to reach its normal operating temperature. This helps in accurate load testing.

Step 3: Gradually Apply Load

Incremental Load: Begin by applying a small load incrementally using the load bank. This gradual increase helps prevent sudden surges that could damage the generator.

Monitor Parameters: As you increase the load, continuously monitor the generator’s parameters, such as voltage, current, frequency, and temperature.

Stabilize Each Load Level: Allow the generator to stabilize at each load level for a few minutes. This helps in identifying any potential issues early.

Step 4: Apply Full Load

Full Load Application: Once the generator has stabilized at incremental loads, apply the full rated load. This step is crucial as it tests the generator’s ability to handle its maximum capacity.

Continuous Monitoring: Keep monitoring all critical parameters. Look for any signs of overheating, abnormal vibrations, or unusual noises.

Step 5: Maintain Full Load

Duration: Maintain the full load for a specified duration, typically around 30 minutes to an hour. This duration helps in identifying any long-term issues.

Document Readings: Record all readings and observations during the test. This documentation is valuable for future reference and maintenance planning.

Step 6: Gradually Reduce Load

Incremental Reduction: Gradually reduce the load in small increments until the generator is running without any load.

Cooldown Period: Allow the generator to run without load for a few minutes to cool down gradually.

Step 7: Shut Down and Disconnect

Shutdown Procedure: Follow the standard shutdown procedure for the generator.

Disconnect Cables: Safely disconnect the load bank cables from the generator. Ensure that all connections are secure and the generator is back to its standby mode.

Post-Test Analysis and Maintenance

Review Test Data

Analyze the data collected during the test. Look for any anomalies or deviations from normal operating parameters. Identifying trends or issues early can prevent major problems later.

Inspect Generator

Conduct a post-test inspection of the generator. Look for any signs of stress or damage caused by the load test. Check for leaks, unusual wear, or any other abnormalities.

Perform Necessary Maintenance

Based on the test results and inspection, perform any necessary maintenance. This may include changing filters, topping off fluids, tightening connections, or addressing any identified issues.

Update Maintenance Records

Keep detailed records of the load bank test, including all readings, observations, and maintenance actions taken. This information is crucial for tracking the generator’s performance over time and planning future maintenance.

Safety Considerations

Safety is paramount when performing a load bank test. Here are some key safety considerations:

Follow Manufacturer Guidelines: Always adhere to the generator and load bank manufacturer’s safety instructions.

Use PPE: Wear appropriate personal protective equipment, such as gloves, safety glasses, and hearing protection.

Secure Connections: Ensure all electrical connections are secure and correctly made to prevent electrical hazards.

Monitor Continuously: Never leave the generator unattended during the test. Continuous monitoring is essential to identify and address issues promptly.

Adequate Ventilation: Ensure the testing area is well-ventilated to dissipate heat generated during the test.

Conclusion

A load bank test is an essential part of generator maintenance, ensuring that your generator is capable of handling its full rated capacity and ready to provide reliable backup power during emergencies. By following the steps outlined in this guide, you can perform a load bank test safely and effectively. Regular testing, combined with routine maintenance, will help extend the life of your generator and ensure its reliability when you need it most.

Maintaining detailed records of each load bank test, addressing any identified issues promptly, and adhering to safety protocols will contribute to the long-term performance and reliability of your generator. By investing time and effort into regular load bank testing, you can have peace of mind knowing that your generator is ready to perform at its best when it matters most.

2 notes

·

View notes

Text

A Step-by-Step Guide to Setting Up a Micro ATM in Your Community

Micro ATMs are instrumental in enhancing financial inclusion by providing basic banking services in underserved areas. Setting up a Micro ATM in your community can significantly improve access to financial services and empower local businesses. Here’s a comprehensive guide on how to establish a Micro ATM:

1. Research and Planning

Before setting up a Micro ATM, conduct thorough research to understand the regulatory requirements, market demand, and infrastructure needs in your community. Identify potential locations where the demand for banking services is high but access to traditional banks is limited.

Key Considerations:

Regulatory Compliance: Ensure compliance with local regulations and licensing requirements for operating a Micro ATM.

Market Demand: Assess the demand for banking services and potential customer base in your community.

Infrastructure: Evaluate the availability of electricity, internet connectivity, and mobile network coverage in the chosen location.

2. Selecting a Micro ATM Provider

Choose a reputable Micro ATM provider that offers reliable devices, secure transaction processing, and technical support. Consider factors such as cost-effectiveness, ease of integration with existing banking networks, and customer service quality.

Criteria for Selecting a Provider:

Device Reliability: Ensure the Micro ATM device is robust, durable, and equipped with necessary security features (biometric authentication, PIN protection).

Transaction Fees: Compare transaction fees and operational costs associated with different providers to choose the most cost-effective option.

Technical Support: Opt for a provider that offers responsive technical support and maintenance services to minimize downtime.

3. Acquiring Necessary Permissions and Licenses

Obtain the required permissions and licenses from regulatory authorities to operate a Micro ATM in your community. This may include approvals from banking regulators, local authorities, and relevant government agencies.

Steps Involved:

Banking Partner: Establish a partnership with a licensed bank or financial institution that can provide backend support for transaction processing and settlement.

Local Authorities: Obtain permits or clearances from local authorities for installing and operating the Micro ATM at the chosen location.

4. Installation and Setup

Once you have selected a provider and secured necessary permissions, proceed with the installation and setup of the Micro ATM. Ensure proper installation to optimize functionality and security.

Installation Steps:

Location Selection: Choose a secure and accessible location with adequate foot traffic, such as near markets, community centers, or local shops.

Power Supply: Ensure continuous power supply for the Micro ATM through mains electricity or alternative power sources (e.g., solar panels in remote areas).

Connectivity: Establish reliable internet connectivity or mobile network coverage for seamless transaction processing.

5. Testing and Calibration

After installation, conduct thorough testing and calibration of the Micro ATM to ensure all functions are working correctly. Test transaction processing, biometric authentication (if applicable), receipt printing, and connectivity.

Testing Procedures:

Transaction Tests: Perform test transactions using different payment methods (cash withdrawal, deposit, fund transfer) to verify system reliability.

Security Checks: Test security features such as PIN protection, biometric verification, and data encryption to safeguard customer transactions.

User Interface: Evaluate the user interface for ease of use and clarity of instructions for customers conducting transactions.

6. Training and Awareness

Train local operators and users on how to use the Micro ATM effectively and securely. Conduct awareness campaigns to educate the community about the benefits of using the Micro ATM for banking transactions.

Training Components:

Operational Training: Train operators on operating procedures, troubleshooting common issues, and maintaining the Micro ATM.

Customer Education: Educate customers on how to use the Micro ATM for various transactions, security best practices, and the importance of banking formalization.

7. Launching and Promoting the Micro ATM

Officially launch the Micro ATM and promote its availability to the community. Use local channels such as community meetings, posters, and word-of-mouth to inform residents about the new banking service.

Promotional Strategies:

Community Outreach: Engage with local community leaders, businesses, and organizations to promote the benefits of using the Micro ATM.

Demonstrations: Conduct live demonstrations of the Micro ATM’s features and functionality to attract potential users and build trust.

Incentives: Offer promotional incentives such as reduced transaction fees or rewards for early adopters to encourage initial usage.

8. Monitoring and Maintenance

Regularly monitor the performance of the Micro ATM and address any technical or operational issues promptly. Implement routine maintenance and security updates to ensure optimal performance and reliability.

Monitoring Activities:

Transaction Monitoring: Track transaction volumes, types, and frequency to gauge usage patterns and customer preferences.

Maintenance Schedule: Schedule regular maintenance checks and software updates to keep the Micro ATM operating smoothly and securely.

Customer Feedback: Gather feedback from users to identify areas for improvement and enhance customer satisfaction.

Conclusion

Setting up a Micro ATM in your community can significantly enhance financial inclusion by providing accessible and affordable banking services to underserved populations. By following this step-by-step guide—from initial research and planning to installation, testing, training, and promotion—you can contribute to empowering local businesses and individuals through improved access to financial services. As Micro ATMs continue to evolve, their role in fostering economic development and financial empowerment in developing countries becomes increasingly pivotal.

2 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes

Text

CONSULTATION SERVICES – TMCS

National Instruments software has been a technical pioneer and leader in virtual instrumentation for than four decades, a groundbreaking notion that has altered the way engineers and scientists in business, government, and academia approach measurement and automation. Everything from prototyping and probability analysis to project management and the integration of third-party software and hardware may be done quickly.