#Electrical Insulating Film Price

Explore tagged Tumblr posts

Text

Vietnam Importer of PVCVietnam is one of the biggest manufacturing and trading countries in South East Asia due to increased economic growth and industrialization in the country in the 21st century. As for such industries, PVC utilization has especially been realized. This versatile material is used in constructing buildings, packing, automotive and electric industries, among others, is gradually being imported to serve a fast-growing economy of Vietnam.

This blog will let you know the importance of PVC in Vietnam industries, the key market players of Vietnam and the major exporters and importers of PVC. Key Highlights:- The total value of PVC imported by Vietnam between Sep 2023 - Aug 2024 is approx $46 billion. - PVC’s major exporters include the People’s Republic of China, Japan, Taiwan and Indonesia.

- PVC has the HSN code 39041092.

- PVC is widely applied in many sectors for construction purposes, packing industries and automotive industries and many more.

Properties of PVC and Their Uses

PVC is majorly used for construction, packaging and automotive in Vietnam. It is used majorly in applications such as:

Construction Materials: The most common application of PVC is in the fabrication of pipes; window frames; floor tile and roofing sheets etc.

Packaging: In packaging, it functions as a flexible film or a rigid container and so qualifies as a useful material in packaging.

Automotive: Automotive application of PVC includes interiors, wire insulation and underbody coatings.

Electrical and Electronics: PVC provides great insulation characteristics thus it is most commonly used in electrical cables and fittings.

Healthcare: PVC is also used in the manufacturing of medical products like IV bags, tubing, and gloves.

According to Vietnam PVC import data, PVC has many uses and, thus, it is vital to many of Vietnam’s rapidly advancing industries. The Demand for PVC in VietnamAccording to Vietnam import export data, the reason behind the import of PVC in such a large quantity is mentioned below:

1. Construction Industry Boom

The construction industry in Vietnam has been rapidly growing primarily due to the expansion of infrastructure brought by urbanization. The government has set up extensive infrastructure requirements in the form of roads, bridges, housing structures which has led to utilization of PVC material like pipes, profiles and sheets etc.

2. Growing Manufacturing Sector

In today’s time, Vietnam is one of the leading manufacturing power houses in the world especially in electronics, textiles and automobiles. These sectors need PVC for different parts including electrical wiring and synthetic leather.

3. Packaging Industry Expansion

The food and beverage industry has benefited from this by extending their packaging life and reduced weight. Making PVC as the material at the center of cost-efficient packaging makes PVC an indispensable resource in the sector.

4. Export-Oriented Economy

Vietnam’s economy is dependent on industries in the agriculture and seafood sectors that require premium quality PVC for safe packaging in accordance with global standards.

Market Players of PVC Imports in Vietnam

As per Vietnam import data, several entities play an essential role in Vietnam’s PVC import industry, few are:

Importers and Distributors: Some of the local firms that supply and distribute PVC to other businesses users across different sectors.

Global Suppliers: Purchasers have focused on preserving the technological forefront and reasonable pricing in the supply chain which is controlled mainly by Asian nations including China, South Korea, and Japan.

Industry Associations: Vietnam plastics associations help in trade and market connection among interest groups.

Government Entities: Importation standards, tariff and certification is controlled and regulated by various bodies to make sure that PVC products in the market are safe to use. Major Exporters of PVC to Vietnam. According to Vietnam trade data, there are a total of 26 countries that supply or export PVC to Vietnam. The major countries list is mentioned below: 1. China 2. Taiwan 3. Indonesia 4. USA 5. South Korea 6. Thailand 7. Malaysia 8. Japan 9. Singapore

Difficulties Encountered in PVC Import Business

Despite its promising growth, the PVC import sector in Vietnam faces several challenges. Few of the challenges are:

1. Fluctuating Global Prices

Costs such as the raw materials and productive abilities depend on the market forces and other geopolitical factors whereby the prices of PVCs are not exempted. Such fluctuation can be of great concern to the profit margin of importers and distributors of the products.

2. Regulatory Compliance

Vietnam fixes very serious quality and health check points to standardise quality PVC products to discourage importation.

3. Supply Chain Disruptions

Issues such as global outbreaks of COVID-I9 and other conflicts have exposed weaknesses in supply chain management. On the other hand, there are issues like, delay in shipment/transport, shortage of containers, and high transport fare are issues that bother PVC importers.

4. Environmental Concerns

PVC production and disposal have become a major issue, so they have received much attention from consumers and authorities. That is why it is necessary for the importers to consider that the products they import are environmentally friendly and meet the main eco requirements.

How to begin the Importation of PVC Plastic products in Vietnam?

For global suppliers and new entrants looking to capitalize on Vietnam’s growing demand for PVC, the following steps can guide their market entry:

Market Research: Take your time to find out the potential from demand and supply side and key players in the market as well as legal requirements for the emerging market. For accurate and precise data, you can hire Vietnam Trade Data. Our platform is a Vietnam import export data provider who enables you to access data from across 200+ countries.

Regulatory Compliance: To avoid any hindrances when dealing with imports it is important to familiarize with the regulations, certifications and standards in relation to importing.

Building Partnerships: Maintain good relations with suppliers in the country, manufacturers, and relevant associations.

Investing in Marketing: Advertise your products as being affordable, of high quality, and from sustainable sources to be able to lure customers.

Leveraging Technology: Avail and apply digital technologies in supply chain operations, and improve customer interactions. Conclusion:Finally, Vietnam has become a large market for Polyvinyl Chloride (PVC) due to its increasing industrialisation and diverse economy. It can’t be unnoticed that PVC is now greatly involved in construction and packaging, automotive and many other industries that are quickly growing in the country. Vietnam is still an attractive market for PVC importation, with the challenge of having been decorated by among other factors, fluctuating global prices, including regulatory challenges and environmental factors. Through good alliance and cooperation, compliance with the set rules and regulations, and promotion of innovation, the market holds greater opportunities for civil and commercial businesses. Vietnam presents the proper approach to demand for PVC as a highly profitable opportunity for both international sellers and local dealers.

0 notes

Text

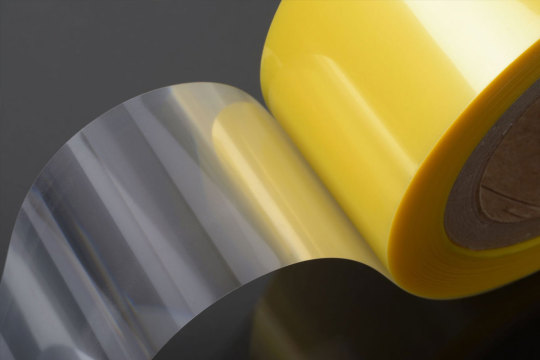

BOPET and BOPP Films Manufacturer

Introduction

BOPET (Biaxially Oriented Polyethylene Terephthalate) and BOPP (Biaxially Oriented Polypropylene) films are two of the most widely used flexible packaging materials in various industries, from food to electronics. Their unique properties, such as durability, transparency, and barrier performance, make them essential in packaging solutions. This article delves into the manufacturing processes of BOPET and BOPP films, the key players in the market, and the future of these vital materials.

The Significance of BOPET and BOPP Films

BOPET Films: BOPET films are known for their excellent mechanical properties, high tensile strength, and resistance to moisture, chemicals, and UV radiation. These attributes make BOPET ideal for applications in food packaging, electrical insulation, and medical supplies. The film is also appreciated for its clarity and gloss, enhancing product visibility on retail shelves.

BOPP Films: BOPP films are recognized for their lightweight nature, excellent barrier properties, and thermal stability. They are commonly used in packaging snacks, confectionery, and personal care products. BOPP films are also widely used in labeling and as a substrate for printing, thanks to their good surface properties.

Manufacturing Processes

The production of BOPET and BOPP films involves several steps:

Resin Production: BOPET is made from polyethylene terephthalate (PET) resin, while BOPP is produced from polypropylene resin. Both types of resin undergo polymerization to create the base material.

Film Extrusion: The resin is melted and extruded into a film. This initial film is typically thick and requires further processing.

Biaxial Orientation: The film is stretched in both the machine direction and the transverse direction. This biaxial orientation enhances the film’s strength, clarity, and barrier properties.

Heat Setting: After orientation, the films undergo heat setting to stabilize their dimensions and improve thermal properties.

Surface Treatment: Many manufacturers apply surface treatments to improve adhesion for printing or lamination, making the films suitable for a variety of applications.

Challenges in the Industry

The BOPET and BOPP film manufacturing sector faces several challenges:

Environmental Concerns: The production and disposal of plastic films contribute to environmental pollution. Manufacturers are increasingly focusing on developing recyclable and biodegradable alternatives.

Raw Material Costs: Fluctuations in the prices of petrochemical-based raw materials can impact production costs and profitability.

Competition: The global market for flexible packaging is competitive, with manufacturers needing to continuously innovate to maintain market share.

Future Outlook

The future of BOPET and BOPP films looks promising, driven by several trends:

Sustainability: As consumer awareness of environmental issues grows, manufacturers are investing in sustainable practices, including recycling initiatives and the development of bio-based films.

Technological Advancements: Innovations in production technology are expected to improve the performance of BOPET and BOPP films, making them suitable for even more specialized applications.

Market Growth: The demand for flexible packaging is expected to rise, particularly in emerging markets, driven by the growth of e-commerce and the need for convenient, ready-to-eat food products.

Conclusion

BOPET and BOPP films are indispensable components of modern packaging solutions, offering a unique combination of properties that cater to a wide range of industries. With a robust manufacturing base and a commitment to innovation, Indian manufacturers are well-positioned to meet the growing global demand for these films. As the industry navigates challenges and embraces sustainable practices, the future of BOPET and BOPP films appears bright, promising new opportunities for manufacturers and consumers alike.

0 notes

Text

Polyvinylidene Fluoride (PVDF) Prices | Pricing | Trend | News | Database | Chart | Forecast

Polyvinylidene Fluoride (PVDF) is a high-performance thermoplastic polymer known for its exceptional chemical resistance, mechanical strength, and thermal stability. Due to its versatile applications in industries such as chemical processing, electrical insulation, and photovoltaic panels, the demand for PVDF has seen a steady increase over recent years. However, PVDF prices are subject to various market factors, making them fluctuate over time. Understanding these price determinants is crucial for manufacturers, suppliers, and consumers who rely on PVDF for their operations.

The pricing of PVDF is closely linked to the cost of raw materials, primarily fluorspar, a key component used in the production of fluoropolymers. Fluorspar prices have been volatile due to fluctuations in global supply and demand. China is the largest producer of fluorspar, and any changes in its mining policies or export restrictions can significantly impact the availability of raw materials for PVDF production, thereby influencing its prices. Additionally, environmental regulations imposed by various governments on fluorine-based products can affect production costs, subsequently leading to higher PVDF prices.

Get Real Time Prices for Polyvinylidene Fluoride (PVDF): https://www.chemanalyst.com/Pricing-data/polyvinylidene-fluoride-1523Another critical factor influencing PVDF prices is energy costs. The production of PVDF requires significant amounts of energy, particularly in the electrochemical processes used to synthesize the polymer. As energy prices rise, particularly in regions dependent on fossil fuels, the cost of producing PVDF increases, pushing up market prices. In recent years, the global push towards renewable energy sources has also introduced variability in energy costs, which can further affect PVDF pricing. Manufacturers must therefore constantly monitor energy market trends to anticipate changes in PVDF prices.

Demand for PVDF has also grown considerably, especially in emerging sectors such as electric vehicles (EVs) and renewable energy. PVDF is widely used in the production of lithium-ion batteries, where it serves as a binder material. With the rapid growth of the EV market, the demand for lithium-ion batteries has surged, driving up the demand for PVDF. Similarly, the increasing installation of photovoltaic solar panels, where PVDF is used as a protective film, has further contributed to the rise in demand. This heightened demand from expanding industries has led to upward pressure on PVDF prices, as suppliers strive to meet the needs of a growing market.

Technological advancements in PVDF production have also impacted pricing trends. Innovations in manufacturing processes have allowed producers to improve efficiency and reduce production costs, which can, in turn, lead to lower PVDF prices. However, the introduction of new technology often requires significant investment, and producers may initially raise prices to offset these costs. Over time, as technology becomes more widespread and production becomes more streamlined, these costs can decrease, making PVDF more affordable.

Environmental regulations and sustainability initiatives are also influencing PVDF prices. The production of PVDF involves the use of hazardous chemicals, and stringent environmental regulations can lead to increased production costs due to the need for waste management and emissions control. Manufacturers must invest in cleaner, more sustainable production methods, which can drive up the cost of PVDF in the short term. However, as the global market increasingly prioritizes environmentally friendly products, the demand for sustainable PVDF alternatives may rise, potentially stabilizing or even lowering prices in the future.

Geopolitical factors also contribute to the price volatility of PVDF. Trade policies, tariffs, and sanctions can affect the import and export of fluorspar and PVDF, altering the global supply and demand balance. For example, tariffs imposed on Chinese exports can lead to higher costs for PVDF in international markets. Additionally, any geopolitical tensions in key producing regions can disrupt the supply chain, creating scarcity and driving up prices. Businesses that rely on PVDF must stay informed about global political events to anticipate potential price shifts.

Another influencing factor is the competition within the PVDF market. As more manufacturers enter the market, there is a greater supply of PVDF, which can help stabilize prices. However, as competition intensifies, especially from low-cost producers, established manufacturers may face pressure to lower their prices to remain competitive. This can result in a more dynamic pricing environment, where market conditions fluctuate based on the entry of new players and the pricing strategies they adopt.

Market speculation can also lead to changes in PVDF prices. Investors and traders who anticipate changes in demand for PVDF, particularly in emerging industries, may influence prices through their buying and selling activities. If speculation drives demand beyond what is immediately available, PVDF prices can temporarily increase. Conversely, if market sentiment shifts, and there is an expectation of decreased demand or oversupply, prices can fall as investors adjust their positions.

Looking to the future, PVDF prices are likely to remain dynamic as a result of ongoing developments in the global economy, energy markets, and technological innovations. The transition towards greener energy solutions, such as electric vehicles and renewable energy systems, will likely continue to drive demand for PVDF. However, advancements in alternative materials and recycling technologies may also create downward pressure on prices as industries seek more cost-effective and sustainable solutions. Furthermore, geopolitical tensions and environmental regulations will continue to influence production costs, contributing to the overall volatility of PVDF prices.

In conclusion, the pricing of polyvinylidene fluoride is influenced by a wide range of factors, including raw material costs, energy prices, supply chain dynamics, technological advancements, and environmental regulations. As global industries continue to evolve and demand for PVDF grows, its prices are expected to remain subject to fluctuations. Businesses that rely on PVDF must closely monitor these factors to anticipate market trends and make informed decisions regarding procurement and pricing strategies. By staying informed about the key drivers of PVDF prices, stakeholders can better navigate the complexities of the market and minimize the impact of price volatility on their operations.

Get Real Time Prices for Polyvinylidene Fluoride (PVDF): https://www.chemanalyst.com/Pricing-data/polyvinylidene-fluoride-1523

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Polyvinylidene Fluoride#Polyvinylidene Fluoride Price#Polyvinylidene Fluoride Prices#Polyvinylidene Fluoride News

0 notes

Text

Top Insulating Varnish Manufacturer in Ahmedabad, India

Insulating Varnish Manufacturer in Ahmedabad, India. Get Insulating Varnish at the best price from Angel Coating in Ahmedabad, India. Offering high quality & wide range of solvent-based “Insulating Varnish” in Ahmedabad, India.

Angel Coating Pvt. Ltd. is offering high quality & wide product range in solvent-based “Insulating Varnish” in Ahmedabad, Gujarat, India. It is based on alkyd, phenolic, and hard resins.

It is versatile, economical, fast-drying, and excellent glossy. Golden air-drying Insulating Varnish, Low viscous, having good bonding strength and electrical properties.

The cured Varnish fills are characterized by a hard and tough film, Moisture, and chemical resistance to dilute, alkalis, and transformer oils. We have a wide range of products from B class, F class, and

Read more: https://angelcoating.com/products/special-finish/insulating-varnish/

0 notes

Text

Global Market Trends for Colorless Polyimide Films: Forecasts and Predictions

Introduction to Colorless Polyimide Films Market

Colorless polyimide films are high-performance materials known for their excellent thermal stability, electrical insulation, and optical clarity. Used in various applications such as electronics, aerospace, and automotive industries, these films offer superior performance in demanding environments. The market for colorless polyimide films is driven by the increasing demand for advanced materials in technology sectors. As electronics become more compact and complex, the need for efficient, reliable insulation materials grows. Additionally, the aerospace industry’s focus on lightweight, durable materials further fuels market expansion. Key players in this market are investing in innovations to enhance film properties and applications.

Market overview

The Colorless Polyimide Films Market is Valued USD 152.8 billion by 2024 and projected to reach USD 10,037.2 Million by 2030, growing at a CAGR of CAGR of 59.20% During the Forecast period of 2024–2032.This growth is fueled by the expanding use of these films in flexible electronics, advanced packaging, and other high-tech applications.

Access Full Report : https://www.marketdigits.com/checkout/3504?lic=s

Major Classifications are as follows:

By Type:

50 m

31–50 m

21–30 m

20 m

By application:

Flexible Displays

Flexible Solar Cells

Flexible Printed Circuit Boards

Lighting Equipment

Others

By end-use industry:

Data Security

Electronics

Solar Energy

Medical

Others

Key Region/Countries are Classified as Follows: ◘ North America (United States, Canada, and Mexico) ◘ Europe (Germany, France, UK, Russia, and Italy) ◘ Asia-Pacific (China, Japan, Korea, India, and Southeast Asia) ◘ South America (Brazil, Argentina, Colombia, etc.) ◘ The Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria, and South Africa)

Major players in Colorless Polyimide Films Market:

DuPont, Kaneka Corporation, Kolon Industries Inc., SK Innovation Co., Ltd., Sumitomo Chemical Company Ltd., Wuhan Imide New Materials Technology Co., Ltd., Industrial Summit Technology Corporation, NeXolve Holding Company, Wuxi Shunxuan New Materials Co., Ltd., Suzhou Kinyu Electronics Co., Ltd., Changchun Gao Qi Polyimide Material Co., Ltd., Zymergen Inc., Dr. Dietrich Muller GmbH and Others.

Market Drivers in Colorless Polyimide Films Market:

Technological Advancements: Continuous innovation in electronics, including flexible displays and wearable technology, requires materials with high thermal stability and electrical insulation, driving demand for colorless polyimide films markets.

Miniaturization of Electronics: The trend toward smaller, more compact electronic devices increases the need for efficient, thin, and durable insulating materials, boosting the demand for polyimide films.

Aerospace Industry Growth: The aerospace sector’s need for lightweight and high-strength materials for components and insulation supports the growth of polyimide films.

Market challenges in Colorless Polyimide Films Market:

High Production Costs: The manufacturing of polyimide films involves complex processes and high-quality raw materials, leading to elevated production costs. This can limit market growth, especially in cost-sensitive applications.

Raw Material Prices: Fluctuations in the prices of raw materials used in polyimide film production can impact overall costs and profitability.

Competition from Alternative Materials: The development of alternative materials with comparable or superior properties, such as other high-performance polymers, can pose a threat to the market for polyimide films.

Regulatory Compliance: Adherence to stringent environmental and safety regulations can increase operational costs and affect market dynamics.

Market opportunities in Colorless Polyimide Films Market:

Growth in Flexible Electronics: The increasing use of flexible and wearable electronics creates a demand for colorless polyimide films market due to their excellent flexibility, thermal stability, and clarity.

Advancements in Aerospace Applications: Expanding aerospace and defense sectors require lightweight, durable materials for advanced applications, creating opportunities for polyimide films.

Expansion of Electric Vehicles (EVs): The rise of EVs and their need for high-performance insulation materials for batteries and electronic systems presents a growing market for colorless polyimide films.

Future trends in Colorless Polyimide Films Market:

Integration with Flexible Electronics: As flexible electronics and wearables continue toevolve, the demand for colorless polyimide films market with enhanced flexibility and durability is expected to grow. Innovations in film technology will likely cater to these advanced applications.

Advancements in Manufacturing Techniques: Improved manufacturing processes and technologies, such as roll-to-roll processing and advanced coating techniques, may reduce production costs and enhance film properties.

Increased Adoption in Automotive Sector: With the rise of electric and autonomous vehicles, there will be a growing need for high-performance insulation materials for batteries and electronic components, driving demand for polyimide films.

Conclusion:

In conclusion, the colorless polyimide films market is poised for significant growth driven by technological advancements, increasing demand for high-performance materials, and expanding applications across industries such as electronics, aerospace, and automotive. Despite facing challenges such as high production costs and competition from alternative materials, the market presents numerous opportunities through innovations in manufacturing, sustainability trends, and the development of new applications. Future trends indicate a continued evolution towards more flexible, durable, and eco-friendly films, which will further fuel market expansion. Overall, the colorless polyimide films market is set to thrive as industries seek advanced materials to meet the demands of modern technology and applications.

#colorless polyimide films market demand#colorless polyimide films market share#colorless polyimide films market size#colorless polyimide films market trend

0 notes

Text

The global demand for polyethylene naphthalate (PEN) was valued at USD 1124.5 Million in 2022 and is expected to reach USD 2081.4 Million in 2030, growing at a CAGR of 8% between 2023 and 2030.Polyethylene Naphthalate (PEN) is an advanced polymer known for its superior properties compared to conventional plastics like polyethylene terephthalate (PET). Its unique characteristics make it an attractive material for a variety of high-performance applications, driving growth in the global PEN market. This article explores the current trends, market drivers, and future outlook for the PEN market.

Browse the full report at https://www.credenceresearch.com/report/polyethylene-naphthalate-market

Overview of Polyethylene Naphthalate

PEN is a high-performance thermoplastic resin derived from the polymerization of naphthalene and ethylene glycol. It boasts a range of beneficial properties, including high thermal stability, chemical resistance, and superior mechanical strength. These attributes make PEN suitable for applications in demanding environments where traditional polymers might fail.

Market Drivers

1. Growing Demand in Electronics and Electrical Industries: The electronics and electrical sectors are major consumers of PEN due to its excellent dielectric properties and thermal stability. PEN is used in manufacturing components like insulating films, connectors, and substrates for circuit boards. As electronics become more advanced and miniaturized, the demand for high-performance materials like PEN is expected to rise.

2. Advancements in Packaging: PEN’s high barrier properties against gases and moisture make it a valuable material for packaging applications. It is increasingly used in food and beverage packaging to extend shelf life and maintain product quality. As the demand for high-quality and durable packaging materials grows, so will the need for PEN.

3. Automotive Industry Growth: The automotive industry’s shift towards lightweight and high-strength materials is driving the adoption of PEN. The polymer’s strength and durability make it suitable for use in various automotive components, from interior parts to under-the-hood applications. With the automotive industry’s focus on improving fuel efficiency and vehicle performance, PEN’s role is expected to expand.

4. Sustainable Alternatives: As sustainability becomes a critical focus across industries, PEN offers an advantage due to its recyclability and lower environmental impact compared to some traditional plastics. This shift towards more sustainable materials is likely to bolster PEN’s market growth.

Challenges Facing the PEN Market

Despite its advantages, the PEN market faces several challenges:

1. High Production Costs: PEN production involves complex processes and higher costs compared to other polymers. These costs can impact its adoption in price-sensitive applications. Manufacturers are continually working on improving production techniques and reducing costs to make PEN more competitive.

2. Limited Awareness and Application: PEN is still relatively niche compared to more widely used polymers. Limited awareness and understanding of its benefits may restrict its adoption across various industries. Increasing educational efforts and demonstrating PEN’s advantages could help expand its market presence.

3. Competition from Alternatives: Other high-performance polymers and materials, such as polyimides and PEEK, also offer similar benefits and may compete with PEN in certain applications. The PEN market must continuously innovate to maintain its competitive edge.

Market Trends

1. Technological Innovations: Ongoing research and development in polymer technology are leading to innovations in PEN production and applications. Advances in processing techniques, such as improved polymerization methods, are expected to enhance PEN’s performance and reduce production costs.

2. Emerging Applications: New and emerging applications for PEN, including advanced medical devices, aerospace components, and renewable energy technologies, are driving market growth. As industries continue to seek materials with superior properties, PEN is likely to find new and expanding applications.

3. Regional Insights: The PEN market is experiencing growth in various regions, with significant developments in North America, Europe, and Asia-Pacific. The expanding electronics and automotive industries in these regions are contributing to the increased demand for PEN.

Future Outlook

The future of the Polyethylene Naphthalate (PEN) market looks promising, driven by technological advancements and increasing demand across various sectors. While challenges remain, ongoing innovations and a growing emphasis on sustainability are expected to enhance PEN’s market position. As industries continue to seek high-performance materials, PEN’s unique properties will likely play a crucial role in shaping the future of advanced polymer applications.

Key Players

Teijin DuPont Films

Toray Monofilament Co. Ltd

Sumitomo Chemical Co. Ltd

DuraFiber Technologies Inc

SKC Inc

SASA Polyester Sanayi A.S.

DuPont

Seiwa Inc

Others

Segmentation

By Applications

Films

Bottles and Containers

Automotive Parts

Electrical and Electronic Parts

Textiles

Other Industrial Applications

By End-Use Industry

Packaging Industry

Automotive Industry

Electrical and Electronics Industry

Textile Industry

Aerospace Industry

Healthcare and Medical Industry

Other Industries

By Processing Methods

Extrusion

Injection Molding

By Grade Types

Standard PEN

Modified PEN

Reinforced PEN

By Environmental and Sustainability Aspects

Recycled PEN (r-PEN)

Biodegradable PEN

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/polyethylene-naphthalate-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

PP Sheets: The Versatile Workhorses of Plastic

Plastic sheets are ubiquitous in our world, from the clear packaging film protecting your groceries to the sturdy signs lining the streets. But have you ever stopped to wonder about the different types of plastic sheets and their uses? Today, we'll delve into the world of P p sheet manufacturers india, also known as polypropylene sheets!

What are PP Sheets?

PP stands for Polypropylene, a type of thermoplastic polymer known for its:

Strength: Offers good resistance to tearing, impact, and chemicals.

Lightweight: Makes it easy to handle and transport.

Versatility: Can be molded, cut, and shaped into various forms.

Cost-effectiveness: An affordable option compared to other plastics.

Recyclability: Can be recycled into new products, reducing waste.

The manufacturing process for PP sheets involves melting polypropylene pellets and extruding them through a die into a thin, continuous sheet. The sheet is then cooled and solidified to create the final product. Pp sheet price india come in a variety of thicknesses, ranging from thin films to thick, rigid plates, catering to diverse applications.

Properties of PP Sheets

Here's what makes PP sheets a popular choice for various projects:

Chemical resistance: Stands up well to exposure to many chemicals, acids, and bases.

Water resistance: Repels moisture, making it suitable for outdoor applications.

Heat resistance: Withstands moderate heat without warping or melting.

Electrical insulation: Provides good electrical insulating properties.

Food-grade options: Certain types of PP sheets are food-safe, ideal for food packaging.

Easy to work with: Can be easily cut, drilled, and welded using common tools.

Translucency or opacity: Available in both clear and opaque varieties for different needs.

Applications of PP Sheets

The versatility of PP sheets shines through their diverse applications across various industries:

Packaging: Food trays, blister packs, shrink wrap, and industrial packaging materials.

Stationery and Signage: Binders, folders, presentation covers, and signage boards.

Construction: Roofing underlayment, vapor barriers, and waterproofing membranes.

Automotive: Interior trim panels, trunk liners, and mud flaps.

Industrial Applications: Machine parts, gaskets, and chemical containment.

Agriculture: Greenhouse panels, seed trays, and crop protection sheets.

DIY and Crafts: Project boards, stencils, and creative projects.

Choosing the Right PP Sheet

With so many options available, selecting the right PP sheet for your project requires considering a few factors:

Thickness: Choose a thickness that provides the desired rigidity and strength.

Surface finish: Options include smooth, textured, or embossed finishes for specific applications.

Color: Clear, translucent, or opaque sheets are available depending on visibility needs.

Food-grade rating: If the sheet will come into contact with food, ensure it's food-grade certified.

Benefits of Using PP Sheets

Here's why PP sheets might be the perfect fit for your next project:

Cost-effective: Compared to other plastic sheets like PVC or PETG, PP sheets offer a budget-friendly option.

Durable: They offer good resistance to wear and tear, ensuring long-lasting performance.

Lightweight: Their light weight makes them easy to handle and transport, reducing labor costs.

Versatile: PP sheets can be used in countless applications due to their diverse properties.

Recyclable: When their useful life is over, PP sheets can be recycled into new products, promoting sustainability.

Environmental Considerations

While PP sheets offer many advantages, responsible use and disposal are crucial:

Reduce: Minimize the use of PP sheets whenever possible and opt for reusable alternatives.

Reuse: Find ways to reuse PP sheets for different projects before discarding them.

Recycle: Check with local recycling programs to see if they accept PP sheets.

The Future of PP Sheets

The future of PP sheets lies in innovation:

Biodegradable alternatives: Research is ongoing to develop PP sheets with biodegradable properties, minimizing plastic waste.

Improved functionalities: Developments in additives and processes can enhance properties like fire resistance and UV protection.

Recycled content: Increasing the use of recycled PP in manufacturing can further reduce reliance on virgin plastic.

Conclusion

PP sheets are a valuable addition to the plastic sheet world. Their affordability, versatility, and durability make them a popular choice for countless applications. By promoting responsible use, encouraging recycling, and fostering innovation, Pp sheets manufacturer in india can continue to serve various industries for years to come.

Frequently Asked Questions (FAQs):

1. What are the advantages of using PP sheets for my project?

PP sheets offer several benefits for various projects:

Versatility: They can be used for a wide range of applications due to their strength, water resistance, and ease of fabrication.

Durability: PP sheets are built to last, offering good resistance to wear and tear, chemicals, and moisture.

2. How do I choose the right PP sheet for my needs?

Selecting the right PP sheet involves considering a few key factors:

Thickness: The thickness should provide the necessary rigidity and strength for your project.

Application: Consider the specific use – food packaging requires food-grade certification, while signage might need a specific color or finish.

3. Are PP sheets eco-friendly?

While PP itself is not biodegradable, responsible use and disposal can minimize environmental impact:

Reduce: Minimize PP sheet usage and explore reusable alternatives when possible.

Reuse: Find ways to reuse PP sheets for different projects before discarding them.

0 notes

Text

Dee Five Shrink Insulations Pvt. Ltd.: Your Trusted Partner for LDPE Shrink Films and PVC Heat Shrinkable Sleeves

Businesses need dependable and superior packaging solutions in today's cutthroat market to guarantee the protection, safety, and appearance of their goods. At Dee Five Shrink Insulations Pvt. Ltd., we take pride in being the best LDPE shrink film manufacturer and a leading PVC heat shrinkable sleeves supplier. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry.

Why Choose Dee Five Shrink Insulations Pvt. Ltd.? Dee Five Shrink Insulations Pvt. Ltd. distinguishes itself as a business committed to offering superior shrink packaging solutions for a number of reasons.

Quality Assurance: To guarantee that our products meet international standards, we employ the best raw materials and follow strict quality control procedures. Innovative Solutions: Our team is always coming up with new ideas to provide cutting edge and effective packaging solutions that meet the changing demands of different sectors. Customer-Centric Approach: Our goal is to establish enduring connections with our clients through individualized assistance and services. Competitive Pricing: We make sure that, even though we provide high-quality goods, our prices are reasonable and offer great value. Our Products Being the top producer of LDPE shrink film, we provide an extensive selection of shrink films and sleeves to satisfy various packaging requirements.

LDPE Shrink Films Our shrink films made of Low-Density Polyethylene (LDPE) are renowned for their exceptional shrinkage qualities, flexibility, and longevity. They are perfect for protecting and improving the look of a wide range of products when they are packaged.

High Clarity: Because of their great transparency, our LDPE shrink films are ideal for protecting products while showing them. Excellent Shrinkage: Our films efficiently secure articles by wrapping around them firmly because to their outstanding shrinking qualities. Adaptable: Our LDPE shrink films come in a range of thicknesses, widths, and lengths, and can be tailored to meet certain packaging needs.

PVC Heat Shrinkable Sleeves As a prominent PVC heat shrinkable sleeves supplier, we offer high-quality sleeves that are widely used in industries such as electronics, automotive, and consumer goods.

High Insulation: Our PVC heat-shrinkable sleeves are perfect for shielding wires and cables because they offer superior electrical insulation. Sturdy and Flexible: These sleeves fit people of all shapes and sizes snugly since they are both sturdy and flexible. Wide Range of Sizes: We offer a variety of sizes to meet the specific needs of different applications. Applications of Our Products Several industries use our PVC heat-shrinkable sleeves and LDPE shrink films, including Several industries use our best PVC heat-shrinkable sleeves and LDPE shrink films, including:

Food and Beverage: Securely wrapping food products, ensuring freshness, and enhancing shelf appeal. Consumer Goods: packaging and safeguarding consumer goods, including household goods, stationery, and cosmetics. Electronics: Providing insulation and protection for electronic components and devices. Automotive: Ensuring the safety and protection of automotive parts and accessories. Case Studies

Leading Beverage Manufacturer A well-known beverage producer came to us looking for advice on how to make their product packaging better. Using our high-clarity LDPE shrink films, they guaranteed safe and tamper-evident packaging in addition to improving the product's look. Their sales consequently rose by 25% in a span of six months.

Electronics Company A corporation that specialized in electronics needed dependable insulation for their wire systems. Our PVC heat-shrinkable sleeves, which offer excellent insulation and protection, were the ideal answer. As a result, there were significantly fewer product failures, and the company's reputation for quality was improved.

Client Testimonials Manager at Fresh Foods Pvt. Ltd. "Dee Five Shrink Insulations Pvt. Ltd. has been a game-changer for our packaging needs. Their LDPE shrink films are of top-notch quality, and their customer service is exceptional. Truly the best LDPE shrink film manufacturer!"

Procurement Head at Tech Innovators Ltd. "For our electronic items, we have been using PVC heat shrinkable sleeves from Dee Five, and their quality and dependability have surpassed our expectations. I heartily endorse them as a reliable source of PVC heat-shrinkable sleeves!"

Get in Touch If you're in search of the best LDPE shrink film manufacturer or a reliable PVC heat shrinkable sleeves supplier, look no further than Dee Five Shrink Insulations Pvt. Ltd. Our team is dedicated to providing you with the highest quality products and exceptional service. Contact us today to learn more about our offerings and how we can assist with your packaging needs.

Feel free to adjust any part of this blog to better fit your company’s tone and additional details!

0 notes

Text

POE (polyether ether ketone) is a thermoplastic elastomer with good wear resistance, oil resistance, low-temperature resistance, and chemical corrosion resistance.

Types of POE Resin

POE (Polyolefin Elastomer) is a versatile material known for its exceptional elasticity, durability, and chemical resistance. With its wide range of applications in automotive, electronics, and packaging industries, POE resin offers superior performance and reliability. Whether it’s for gaskets, seals, or flexible components, POE is the go-to choice provided by the leading plastic resin suppliers for high-quality elastomeric solutions.

Application of POE (Polyolefin Elastomer)

POE (Polyolefin Elastomer) finds extensive application in various industries due to its unique properties. Some common applications include:

Automotive: Used for sealing systems, gaskets, weatherstripping, and vibration-dampening components due to its excellent resistance to oils, fuels, and automotive fluids.

Electronics: Utilized in cable insulation, connectors, and electronic components due to its electrical insulation properties and resistance to heat and chemicals.

Packaging: Used for flexible packaging films, closures, and seals due to its excellent sealing properties, puncture resistance, and flexibility.

Consumer Goods: Used in the production of soft-touch grips, handles, and over-molded parts for appliances, tools, and sporting goods due to its softness, durability, and chemical resistance.

Medical: Used in medical tubing, seals, and gaskets due to its biocompatibility, flexibility, and resistance to sterilization methods.

Industrial: Used for conveyor belts, hoses, and seals in industrial applications due to its abrasion resistance, flexibility, and resistance to chemicals and oils.

Overall, POE offers a wide range of applications across industries where flexibility, durability, chemical resistance, and electrical insulation properties are required.

1 note

·

View note

Text

A Homeowner’s Guide to AC Repair in McKinney: What You Need to Know

Living in McKinney means relying heavily on your air conditioning system to keep your home comfortable during the hot Texas summers. Ensuring that your AC system is in top working condition is not just about comfort but also about efficiency and preventing costly breakdowns. Here’s a comprehensive guide to help homeowners understand and manage their AC repair needs effectively.

1. Recognizing Common AC Problems

The first step to effective AC maintenance is recognizing the signs of trouble. Common issues include unusual noises, ice formation on the coils, frequent cycling, and warm air blowing from the vents. Each of these symptoms could indicate different problems ranging from simple fixes like changing a dirty filter to more complex issues such as a refrigerant leak. Early detection and repair can save you from more significant expenses later on.

2. Importance of Professional Annual Inspections

Scheduling annual inspections with a reputable HVAC service can prevent many of the most common AC issues. A professional technician can check your system’s components, such as the compressor, evaporator unit, and thermostat, to ensure they are all working correctly. These inspections can also extend the lifespan of your unit by ensuring that all parts are lubricated, connections are tight, and pressures are correct. In McKinney, where AC systems work harder than in cooler climates, regular professional maintenance is crucial.

3. Choosing the Right HVAC Service in McKinney

Not all HVAC services are created equal. When choosing a service provider in McKinney, look for licensed, insured, and experienced professionals. Check online reviews and ask for recommendations from neighbors to find a reliable service. A good service provider will offer transparent pricing, detailed quotes, and warranties on their work. This ensures that you can trust the repairs and the people performing them.

4. DIY Maintenance Tips for Homeowners

While professional maintenance is important, there are several things that homeowners can do to keep their AC running smoothly. Regularly replacing or cleaning air filters can prevent a host of problems and improve air quality in your home. Keeping the area around outdoor units clear of debris and foliage ensures adequate airflow, which is essential for efficiency. Additionally, checking thermostat settings and replacing batteries annually can save you from unnecessary AC repair calls.

5. Understanding When to Repair vs. Replace

Knowing whether to repair or replace your AC unit in McKinney can be a tough decision. A good rule of thumb is to consider replacing any system that is over 10 years old, particularly if it requires frequent repairs or has become inefficient. Newer systems offer improved technology and better energy efficiency, which can significantly lower your electricity bills, especially important in the hot Texas summers.

6. Preparing for McKinney’s Seasonal Weather

McKinney’s climate demands a lot from air conditioning systems. Preparing for the intense summer heat involves more than just regular maintenance. Consider upgrading insulation in your home to reduce the workload on your AC unit. Installing window films, using blinds during the hottest part of the day, and sealing leaks around doors and windows can also help maintain cooler temperatures indoors without overworking your system.

7. The Benefits of Smart Thermostats

Installing a smart thermostat can greatly enhance the efficiency of your home’s cooling system. These devices allow for more precise control of indoor temperatures and can be adjusted remotely via smartphones. Many smart thermostats also learn your schedule and temperature preferences to optimize cooling and energy use. This technology not only makes life more convenient but can also reduce the strain on your AC system by avoiding unnecessary cooling when no one is home.

By following these guidelines, homeowners in McKinney can ensure that their air conditioning systems are well-maintained and ready to handle the challenges of the local climate. Remember, taking proactive steps towards maintenance and being informed about your AC system’s needs can lead to significant savings and a more comfortable home environment.

0 notes

Text

Unlocking the Versatility of Nylon Film: A Modern Marvel in Manufacturing

In the realm of modern manufacturing, Nylon film stands out as a versatile and indispensable material, finding applications across a myriad of industries. From packaging to electronics, its unique properties have made it a staple in various production processes. Let's delve into the world of Nylon film, exploring its characteristics, uses, and the prominent role played by China Nylon film manufacturers in meeting global demands.

Understanding Nylon Film:

Nylon film, derived from polyamide resins, boasts a remarkable combination of strength, durability, and flexibility. Its molecular structure imbues it with excellent barrier properties, making it resistant to moisture, chemicals, and punctures. This inherent toughness, coupled with its lightweight nature, renders Nylon film an ideal choice for a multitude of applications.

Applications Across Industries:

Packaging: One of the primary uses of Nylon film is in packaging materials. Its ability to form strong, tear-resistant barriers makes it perfect for protecting goods during storage and transit. Whether it's food products, pharmaceuticals, or industrial equipment, Nylon film ensures that items remain safe from external elements.

Electronics: In the electronics industry, Nylon film finds applications in circuit board protection, insulation, and component packaging. Its dielectric properties make it an excellent electrical insulator, safeguarding delicate electronic components from static discharge and environmental contaminants.

Textiles: Nylon film is also utilized in textile manufacturing, where its lightweight yet robust nature enhances the durability and performance of fabrics. From sportswear to industrial textiles, Nylon film adds strength and resilience to a wide range of materials.

Agriculture: In agriculture, Nylon film is employed in greenhouse coverings and mulch films. Its ability to regulate temperature and moisture levels creates optimal growing conditions, improving crop yields and protecting plants from adverse weather conditions.

The Role of China Nylon Film Manufacturers:

China Nylon film manufacturers play a pivotal role in meeting global demand for this essential material. With advanced production facilities and a focus on innovation, these manufacturers ensure a steady supply of high-quality Nylon film to industries worldwide. Leveraging state-of-the-art technology and stringent quality control measures, they uphold international standards while offering competitive pricing and tailored solutions to meet diverse customer needs.

Through continuous research and development efforts, China Nylon film manufacturers strive to enhance the performance and sustainability of their products. By adopting eco-friendly production processes and exploring recyclable materials, they contribute to the drive for a more sustainable future.

Conclusion:

In conclusion, Nylon film emerges as a modern marvel in manufacturing, offering unparalleled versatility and performance across a spectrum of applications. From its role in packaging and electronics to textiles and agriculture, its impact is felt in diverse industries worldwide. China Nylon film manufacturers stand at the forefront of this dynamic market, driving innovation and delivering quality products to meet the evolving needs of global consumers. As the demand for resilient and reliable materials continues to rise, Nylon film remains an indispensable asset, shaping the landscape of modern manufacturing for years to come.

0 notes

Text

Aluminum CNC Machining

AL is one of the most common materials used in CNC machining. Aluminum is highly machinable and relatively inexpensive, making it ideal for CNC machining.

Xintao usually machine it three or even four times faster than other commonly machined materials, such as steel and titanium. Because CNC machining of aluminum can reduce many tools and we only need to change the machining process flow for parts with more complex machining styles.

The Advantages of Using Aluminum For CNC Machining

1. The density of aluminum is very small, only 2.7g/cm³, although it is relatively soft, it can be made into various aluminum alloys, such as hard aluminum, super hard aluminum, rust-proof aluminum, cast aluminum, etc.. These aluminum alloys are widely used in aircraft, automobile, train, ship and other manufacturing industries.

2. Aluminum is second only to silver, copper and gold in terms of electrical conductivity, and the oxide film on the surface of aluminum not only has the ability to resist corrosion, but also has a certain degree of insulation.

3, aluminum surface oxide film not only has the ability to resist corrosion, but also has a certain degree of insulation.

4. Aluminum has good ductility

5. Aluminum has a silver-white luster, which is more beautiful than other materials.

6. The reflection performance of aluminum sheet is also very good, and has the function of sound absorption.

What Are Some Common Applications of Aluminum CNC Machining?

The density of aluminum parts is very small, so it is often used in space rockets, space shuttles, artificial satellites, airplanes, ships and other above.

Aluminum parts have good electrical conductivity, so in the electrical manufacturing industry, wire and cable industry and radio industry has a wide range of uses.

Aluminum parts have good thermal conductivity, commonly used in radiators, exchangers and other precision parts

Aluminum parts are more beautiful, often used in consumer products, such as laser swords, cell phone parts, etc.

0 notes

Text

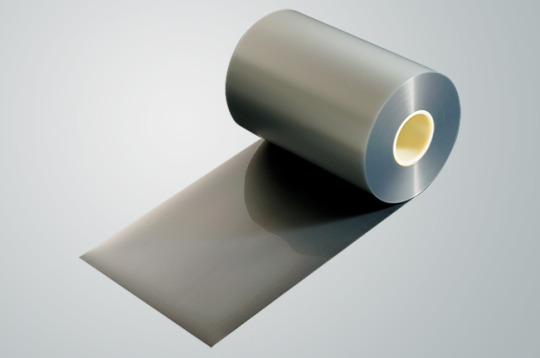

Polyester Film Manufacturers in India

Introduction

Polyester film, a versatile and widely used material, is essential in various industries, including packaging, electrical, and automotive. In India, the demand for polyester films has surged, driven by rapid industrialization and an expanding consumer market. This article explores the landscape of polyester film manufacturers in India, highlighting key players, production processes, and future prospects.

The Polyester Film Market in India

The Indian polyester film market is characterized by a diverse range of products, including biaxially oriented polyester (BOPET) films, which are known for their strength, clarity, and resistance to moisture and chemicals. These properties make BOPET films suitable for applications such as food packaging, insulation, and graphics.

According to industry reports, the Indian polyester film market is projected to grow significantly, driven by increasing demand from the packaging sector, especially with the rise of e-commerce and food delivery services. The government's push for 'Make in India' has also encouraged local production, reducing dependence on imports.

Production Processes

The production of polyester films involves several key steps:

Polymerization: The process begins with the polymerization of terephthalic acid and ethylene glycol to produce polyethylene terephthalate (PET) resin.

Film Extrusion: The PET resin is then melted and extruded into a thin sheet, which is subsequently cooled and solidified.

Biaxial Orientation: The film is stretched in both the machine direction and the transverse direction to enhance its mechanical properties, clarity, and barrier characteristics.

Surface Treatment: Many manufacturers apply surface treatments to improve adhesion for printing and lamination processes.

Challenges Facing the Industry

Despite the growth prospects, the polyester film industry in India faces several challenges:

Environmental Concerns: The production and disposal of polyester films raise environmental issues. Manufacturers are increasingly focusing on recycling and developing biodegradable alternatives.

Competition from Imports: While local production is growing, competition from imported films can put pressure on domestic manufacturers. The industry must innovate to compete effectively.

Raw Material Prices: Fluctuations in the prices of raw materials, particularly petrochemicals, can impact production costs and profitability.

Future Prospects

The future of polyester film manufacturing in India looks promising. With the increasing focus on sustainable packaging solutions, manufacturers are exploring eco-friendly alternatives and recycling technologies. Furthermore, the rise of industries such as solar energy and electric vehicles presents new opportunities for specialty polyester films.

Government initiatives aimed at boosting manufacturing and infrastructure development will also play a crucial role in shaping the industry. As consumer preferences evolve, the ability to adapt to new trends and technologies will be vital for the success of polyester film manufacturers in India.

Conclusion

The polyester film manufacturing sector in India is on a path of robust growth, driven by innovation, sustainability, and a burgeoning market. With key players focusing on quality and eco-friendly practices, the industry is poised to meet the challenges ahead while catering to the diverse needs of various sectors. As India continues to establish itself as a manufacturing hub, polyester films will undoubtedly play a significant role in its industrial landscape.

0 notes

Text

Polyimide Prices Trend, Database, Index, News, Chart, Forecast

Polyimide prices have been subject to fluctuations in recent years due to various factors impacting the supply chain and market dynamics. Polyimides are high-performance polymers known for their exceptional thermal stability, mechanical strength, and chemical resistance, making them indispensable in industries such as electronics, aerospace, automotive, and healthcare. The cost of polyimides is influenced by several key factors, including raw material prices, manufacturing processes, demand-supply dynamics, and technological advancements.

One significant factor affecting polyimide prices is the cost of raw materials. Polyimides are typically derived from aromatic dianhydrides and aromatic diamines, which are themselves derived from petroleum or other chemical feedstocks. Fluctuations in crude oil prices, geopolitical tensions, and supply chain disruptions can all impact the cost of these raw materials, thereby affecting the overall price of polyimides. Additionally, the availability of raw materials can be influenced by factors such as natural disasters, regulatory changes, and shifts in global trade patterns, further contributing to price volatility.

Get Real Time Prices of Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Manufacturing processes also play a crucial role in determining polyimide prices. The production of polyimides involves several complex steps, including polymerization, curing, and post-treatment processes. Energy costs, labor expenses, and capital investments required for equipment and infrastructure all factor into the manufacturing cost of polyimides. Innovations in process efficiency, automation, and recycling technologies can help manufacturers optimize their operations and reduce production costs, ultimately influencing the market price of polyimides.

Demand-supply dynamics significantly impact polyimide prices, as these polymers are used in a wide range of high-performance applications. Rapid industrialization, urbanization, and technological advancements drive demand for polyimides in sectors such as electronics (e.g., flexible printed circuits, display films), aerospace (e.g., lightweight composites, thermal insulation), automotive (e.g., engine components, electrical insulation), and healthcare (e.g., medical devices, implants). Fluctuations in end-user demand, market trends, and competitive dynamics can lead to shifts in supply and demand equilibrium, thereby affecting polyimide prices.

Technological advancements and innovation also influence polyimide prices by enabling the development of new grades, formulations, and applications. Research and development efforts focused on enhancing the performance, durability, and sustainability of polyimides can lead to the introduction of advanced materials with superior properties. However, the adoption of novel technologies and materials may initially entail higher production costs, which can impact the pricing of these innovative polyimide products. Over time, economies of scale, process optimization, and market acceptance can help mitigate these cost implications.

In conclusion, polyimide prices are subject to various factors, including raw material prices, manufacturing processes, demand-supply dynamics, and technological advancements. Fluctuations in crude oil prices, manufacturing costs, end-user demand, and innovation all contribute to the volatility and pricing trends observed in the polyimide market. As industries continue to evolve and demand for high-performance materials grows, stakeholders across the value chain must closely monitor these factors to make informed decisions and navigate the complexities of the polyimide market.

Get Real Time Prices of Polyimide: https://www.chemanalyst.com/Pricing-data/polyimide-1579

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Enhancing Product Shelf Life: Functional Films Market Strategies

Functional films are multi-layer thin film coatings that provide functional properties beyond basic optical properties. They help enhance the performance of various products by imparting properties such as anti-reflection, anti-scratch, anti-fog, anti-microbial, and energy-saving. The growing need for energy conservation and advantages of functional films in saving energy of buildings is driving the demand of these films. The global Functional Films Market is estimated to be valued at US$ 9.02 Mn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The opportunity in energy saving through the use of functional films is driving the growth of the market. Functional films help reduce energy consumption and CO2 emissions of buildings by controlling heat and light transmission. They provide insulation properties and prevent heat loss during winters and heat gain during summers. This results in savings on energy costs required for heating, ventilation, and air conditioning (HVAC). As energy efficiency becomes a focus area globally to reduce carbon footprint, the demand for functional films is increasing from the construction industry. Their energy saving features make buildings more sustainable and help lower operating costs in the long run. Growing emphasis on green buildings will continue contributing to the increased adoption of functional films. Porter's Analysis

Threat of new entrants: Low capital requirement however established brands enjoy recognition and economies of scale.

Bargaining power of buyers: High as buyers can negotiate on price and choose from various global and regional functional film manufacturers.

Bargaining power of suppliers: Moderate as raw material suppliers have established supply networks however functional films manufacturers can switch suppliers.

Threat of new substitutes: Low as functional films have applications across industries however new materials pose threat.

Competitive rivalry: High as the market is fragmented with global and regional players competing on price and quality. SWOT Analysis

Strength: Wide applications in electronics, automotive and construction industries. Additional functional properties enhance product performance.

Weakness: High R&D and production costs. Stringent quality standards and certification processes.

Opportunity: Growing end-use industries in emerging markets. Development of bio-based and environment-friendly films.

Threats: Fluctuating raw material prices and availability. Strong competition from alternative materials. Key Takeaways

The global functional films market is expected to witness high growth during the forecast period of 2023 to 2030. The market size is projected to reach US$ 9.02 Mn in 2024.

Regional analysis: Asia Pacific as the fastest growing region due to growth in electronics and automotive industries in China, India, Japan and Southeast Asian countries. North America and Europe hold major shares of the global market currently.

Key players operating in the functional films market are 3M, Toray Industries, Inc., Nagase & Co. Ltd., Eastman Chemical Company, and Tatsuta Electric Wire & Cable Co., Ltd. 3M enjoys leading position with wide product portfolio for various applications. Toray Industries commercializes protection and insulation films targeting electronics and energy industries.

0 notes

Text

Functional Films Market Growth Drivers: Unveiling Key Catalysts

Functional films are multi-layer thin film coatings that provide functional properties beyond basic optical properties. They help enhance the performance of various products by imparting properties such as anti-reflection, anti-scratch, anti-fog, anti-microbial, and energy-saving. The growing need for energy conservation and advantages of functional films in saving energy of buildings is driving the demand of these films. The global Functional Films Market is estimated to be valued at US$ 9.02 Mn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The opportunity in energy saving through the use of functional films is driving the growth of the market. Functional films help reduce energy consumption and CO2 emissions of buildings by controlling heat and light transmission. They provide insulation properties and prevent heat loss during winters and heat gain during summers. This results in savings on energy costs required for heating, ventilation, and air conditioning (HVAC). As energy efficiency becomes a focus area globally to reduce carbon footprint, the demand for functional films is increasing from the construction industry. Their energy saving features make buildings more sustainable and help lower operating costs in the long run. Growing emphasis on green buildings will continue contributing to the increased adoption of functional films. Porter's Analysis Threat of new entrants: Low capital requirement however established brands enjoy recognition and economies of scale. Bargaining power of buyers: High as buyers can negotiate on price and choose from various global and regional functional film manufacturers. Bargaining power of suppliers: Moderate as raw material suppliers have established supply networks however functional films manufacturers can switch suppliers. Threat of new substitutes: Low as functional films have applications across industries however new materials pose threat. Competitive rivalry: High as the market is fragmented with global and regional players competing on price and quality. SWOT Analysis Strength: Wide applications in electronics, automotive and construction industries. Additional functional properties enhance product performance. Weakness: High R&D and production costs. Stringent quality standards and certification processes. Opportunity: Growing end-use industries in emerging markets. Development of bio-based and environment-friendly films. Threats: Fluctuating raw material prices and availability. Strong competition from alternative materials. Key Takeaways The global functional films market is expected to witness high growth during the forecast period of 2023 to 2030. The market size is projected to reach US$ 9.02 Mn in 2024.

Regional analysis: Asia Pacific as the fastest growing region due to growth in electronics and automotive industries in China, India, Japan and Southeast Asian countries. North America and Europe hold major shares of the global market currently.

Key players operating in the functional films market are 3M, Toray Industries, Inc., Nagase & Co. Ltd., Eastman Chemical Company, and Tatsuta Electric Wire & Cable Co., Ltd. 3M enjoys leading position with wide product portfolio for various applications. Toray Industries commercializes protection and insulation films targeting electronics and energy industries.

#Functional Films Market Share#Functional Films Market Growth#Functional Films Market Demand#Functional Films Market Trend#Functional Films Market Analysis

0 notes