#Electrical Insulating Film Market Analysis

Explore tagged Tumblr posts

Text

Global Polytetrafluoroethylene (PTFE) Market Report: Projected Growth and Key Insights

Global Polytetrafluoroethylene (PTFE) Market Report: Projected Growth and Key Insights

Straits Research is pleased to announce the release of its comprehensive report on the global Polytetrafluoroethylene (PTFE) market. The global polytetrafluoroethylene (PTFE) market was valued at USD 2.54 Billion in 2024. It is expected to reach USD 2.66 Billion in 2025 to USD 3.87 Billion in 2033, growing at a CAGR of 4.8% over the forecast period (2025-2033).

Industry Overview

Polytetrafluoroethylene (PTFE), commonly known as Teflon, is a synthetic fluoropolymer known for its high resistance to heat and chemical reactions. Its unique properties make it an essential material in various applications, including automotive components, electrical insulation, and non-stick cookware. As industries increasingly seek durable and efficient materials, the demand for PTFE continues to rise.

Key Drivers in the PTFE Market

The growth of the PTFE market is driven by several factors:

Increasing Demand in Automotive and Aerospace Industries: The automotive sector's need for high-performance materials that can withstand extreme conditions is propelling PTFE adoption in gaskets, seals, and bearings.

Growth in Chemical Processing: PTFE’s exceptional chemical resistance makes it indispensable for lining vessels and piping in chemical processing applications.

Healthcare Applications: The healthcare industry’s growing reliance on PTFE for medical devices and equipment is contributing to market expansion.

Consumer Products: The popularity of non-stick cookware continues to drive demand for PTFE coatings.

Request a Sample Report of Polytetrafluoroethylene (PTFE) Market

Key Developments in the PTFE Market

Recent developments indicate a dynamic shift within the PTFE market:

Technological Innovations: Advancements in manufacturing processes are enhancing the efficiency and safety of PTFE production.

Sustainability Initiatives: Manufacturers are increasingly focusing on developing eco-friendly alternatives to traditional PTFE products.

Rising Competition: The market is witnessing intense competition from manufacturers aiming to capture larger market shares through innovation and cost-effective solutions.

Market Segmentation Analysis

The global PTFE market can be segmented into various categories:

By Form:

Granular

Fine Powder

Dispersion

By Applications:

Sheets

Coatings

Pipes

Films

Others

By End-User Industry:

Automotive and Transportation

Chemical and Industrial Processing

Healthcare

Construction

Cookware

Electrical and Electronics

Others

Buy Polytetrafluoroethylene (PTFE) Market Report here!

Regional Trends

The PTFE market exhibits diverse trends across different regions:

North America:

The United States remains a significant player due to its robust automotive and aerospace industries. The demand for high-performance materials is driving growth in this region.

Asia-Pacific (APAC):

Dominated by countries like China and Japan, this region is experiencing rapid industrialization. China’s extensive use of PTFE in electronics and automotive applications significantly contributes to market growth.

Europe:

Countries such as Germany and France are leading the European market due to increasing requirements for improved materials in industries like chemical processing and electrical engineering.

Latin America, Middle East, and Africa (LAMEA):

This region is gradually adopting PTFE products, driven by infrastructure development and rising industrial activities.

Top Players in the PTFE Market

Straits Research identifies several key players driving innovation within the PTFE market:

AGC Inc.

BEMU Fluorkunststoffe GmbH

Aidmer (JiangXi Aidmer Seal & Packing Co. Ltd)

Daikin Industries Ltd.

Gujarat Fluorochemicals Limited

Dyneon GmbH & Co. KG (3M)

HaloPolymer

Freudenberg FST GmbH

Jiangsu Meilan Chemical Co. Ltd.

These companies are actively investing in research and development to enhance product offerings and meet evolving customer demands.

Conclusion

The global Polytetrafluoroethylene (PTFE) market is poised for steady growth driven by increasing demand across various industries, particularly automotive, healthcare, and consumer products. As stakeholders navigate this evolving landscape, opportunities abound for innovation and collaboration aimed at enhancing the efficiency and sustainability of PTFE applications.For more detailed insights into the Polytetrafluoroethylene (PTFE) Market trends and forecasts, please refer to our full report or contact Straits Research directly.

Browse Full Report and TOC of Polytetrafluoroethylene (PTFE) Market

About Straits Research

Straits Research is a premier provider of business intelligence specializing in research, analytics, and advisory services aimed at delivering comprehensive insights through detailed reports. For further information or inquiries regarding this press release or our research services, please contact us at [email protected] or call +1 646 905 0080.

Contact:

Straits Research Email: [email protected] Phone: +1 646 905 0080 Address: 825 3rd Avenue, New York, NY, USA, 10022

#Polytetrafluoroethylene (PTFE) Market Share#Polytetrafluoroethylene (PTFE) Market Size#Polytetrafluoroethylene (PTFE) Market Growth#Polytetrafluoroethylene (PTFE) Market Insights#Polytetrafluoroethylene (PTFE) Market Trends#Polytetrafluoroethylene (PTFE) Market Analysis#Polytetrafluoroethylene (PTFE) Market Industry#Polytetrafluoroethylene (PTFE) Market Forecast

0 notes

Text

Adhesive Tape Films Market Size, Share, Forecast Report by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Adhesive Tape Films Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Adhesive Tape Films Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Adhesive Tape Films Market?

The global adhesive tape films market was valued at US$ 14.7 Billion in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 21.1 Bn in 2032.

What are Adhesive Tape Films?

Adhesive tape films are multifunctional materials widely utilized across various industries, from manufacturing to everyday consumer products. These films comprise a thin layer of adhesive-coated material that adheres securely to numerous surfaces while remaining flexible and durable. Typically crafted from polymers such as polyethylene, polypropylene, or polyester, adhesive tape films can be tailored to possess specific characteristics, including moisture resistance, UV stability, and heat resistance, making them ideal for applications like packaging, insulation, electrical work, and automotive uses. Their easy application and ability to conform to irregular shapes make them crucial in both professional and DIY projects, enhancing efficiency and reliability across multiple sectors.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2466

What are the growth prospects and trends in the Adhesive Tape Films industry?

The adhesive tape films market growth is driven by various factors and trends. The adhesive tape films market is experiencing substantial growth, driven by rising demand for versatile bonding solutions across diverse industries such as automotive, electronics, packaging, and construction. These films provide unique features, including moisture resistance, heat resistance, and electrical insulation, making them suitable for various applications. The surge in e-commerce and the need for effective packaging solutions further stimulate market expansion, as businesses seek reliable products to ensure safe delivery. Moreover, advancements in manufacturing technologies and the introduction of innovative adhesive formulations are enhancing product performance and broadening their applications. With a growing emphasis on sustainability, the market is also shifting toward eco-friendly and recyclable adhesive tape films, aligning with global initiatives to reduce environmental impact. Overall, the adhesive tape films market is well-positioned for continued growth, driven by changing consumer preferences and technological innovations. Hence, all these factors contribute to adhesive tape films market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Transparent

Colored

By Backing Material Type

Polyethylene (PE) Films

Polypropylene (PP) Films

Polyvinyl Chloride (PVC) Films

Polyester (PET) Films

Others

By Adhesive Type

Rubber-Based Adhesives

Acrylic Adhesives

Silicone Adhesives

Others

By End Use

Packaging

Automotive

Electronics

Construction

Healthcare

Paper & Printing

Others

North America

United States

Canada

Europe

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

Benelux

Nordic

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America

Brazil

Mexico

Argentina

Middle East & Africa

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Taghleef Industries

Nitto Denko Corporation

PAC Adhesive Products (Suzhou) Co., Ltd.

Berry Global Inc.

YANGFENG TAPE AND ADHESIVE PRODUCTS, LTD.

LINTEC Corporation

Shurtape Technologies, LLC

FROMM Holding GmbH Co. KG

USG Corporation

Henkel AG Co. KGaA

Tes tape group

Avery Dennison Corporation

View Full Report: https://www.reportsandinsights.com/report/Adhesive Tape Films-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Aerogel Market Size, Trends, Statistics and Analysis Report, 2030

The global aerogel market size was estimated at USD 1.04 billion in 2022 and is expected to register a growth of 16.3% over the forecast period.

In terms of properties, it offers superior thermal resistance, lightweight, very low density, fire-resistance, and excellent thermal insulation wherein it is widely used across varied applications. In accordance with the properties, aerogels are manufactured in several forms such as blankets, particles, panels, and monolith.

Aerogels can be molded into thin films or monoliths and used in thermal insulation, acoustic, thin-film coatings, vibration damping, or any place where structural foam is required in case of automotive purposes. The automotive industry is shifting from internal combustion engines (ICEs) to fully electric and automatic moving machines earlier the companies focused on one of the specified parameters in a vehicle, including efficiency, comfort, performance, or safety however, with the help of aerogels all these requirements can be clubbed together in a vehicle, thus, making them an ideal raw material for automotive use.

The U.S. holds a strong dominance in the market owing to the increased awareness among manufacturers regarding the benefits of aerogels as compared to other insulating materials. The key players are constantly working on research and development for improving the products with support from the government for funding the research. With the well-established aerospace, marine, automobiles, building and construction, performance coating, oil and natural gas industry in the U.S., the use of aerogels for these applications prevails in high volume.

Gather more insights about the market drivers, restrains and growth of the Aerogel Market

Detailed Segmentation:

Product Insights

Silica segment led the market and accounted for more than 66% share of the global revenue in 2022. Silica aerogels have attracted increased traction worldwide owing to their efficient chemical properties and their existing and potential applications in a wide variety of technological areas. These gels are nanostructured materials, with high specific surface areas, increased porosity, low density, reduced dielectric constant, and excellent heat insulation properties.

The demand for polymer aerogels is anticipated to witness the fastest growth worldwide during the forecast period owing to their higher chemical and physical benefits compared with silica aerogels. Polymer aerogels are used in defense applications, electronic substrates, building and construction applications, vehicle interiors, and antennas. Polymer when developed in a monolithic form, are mechanically robust and thus, tend to drop a few advantages provided by silica including transparency and low thermal conductivity.

Technology Insights

Supercritical drying segment led the market and accounted for more than 72.8% share of the global revenue in 2022 since it enables preservation of their three-dimensional pore structures. This leads to unique properties such as high porosity, low density, and large surface area of aerogels. Supercritical drying is defined as the extraction of solvents from pores of aerogels using supercritical fluids, is a popular method for drying wet gels.

The process of supercritical drying is important for scaling up laboratory drying units to pilot and industrial scales and assessing the production economics of aerogels on an industrial scale. High-temperature supercritical drying using organic solvents is also the best way to minimize shrinkage, allowing for supercritical drying to have a density lower than carbon dioxide.

Form Insights

Blanket aerogels segment led the market and accounted for USD 696.7 million of the global revenue in 2022 as they offer thermal insulation in buildings as well as apparel owing to their well-suited properties required in insulation such as high-breathability, water repellency, low-dusting & low-powdering, and light diffusion. The presence of such characteristics is expected to boost the demand for blanket aerogel market.

Particle aerogel segment is anticipated to witness substantial growth over the forecast period owing to its efficient chemical and physical properties over blankets aerogels. These products have a variety of applications in defense, electronic substrates, building and construction, transport interiors, and antennas.

End-use Insights

In 2022 oil & gas end-use segment exhibited to be the largest market which accounted for more than 62% of the global revenue. Aerogel blankets are mostly used to improve the insulation of deep-sea pipes and oil & gas pipelines to reduce the production cost, improve pipeline compression resistance, and reduce the amount of steel used in construction. Moreover, hydrophobicity, mechanical strength, and exceptional thermal performance is further expected to fuel the application industry growth over the forecast period.

Regional Insights

North America dominated the market and accounted for a 45.2% share of global revenue in 2022 owing to increasing demand from end-use industries including aerospace, building & construction, automotive, and oil & gas. The market in North America exhibits a huge growth potential in terms of application development, quality, and product innovation for the aerogel market, whereas the demand is driven by its superior insulation and low thermal conductivity properties.

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global fast curing Nitrile Butadiene Rubber (NBR) market size was valued at USD 757.7 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.7% from 2024 to 2030.

• The global aerosol actuators market size was valued at USD 1.31 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030.

Key Companies & Market Share Insights

The market is moderately competitive in nature owing to the presence of a few manufacturers with strong networks across the globe. It is highly influenced by North America and the Middle East and Africa due to the presence of companies with huge investing power for continuous development. Aerogels will remain high in demand across the globe due to their chemical and physical benefits.

The high switching cost of buyers is a prominent factor contributing to the high bargaining power of the suppliers. The less number of players with their strong foothold along with their ability to provide cost-effective use of aerogels is another major factor contributing to the high supplier power.

Some prominent players in the global aerogel market include:

• Aspen Aerogels, Inc.

• Cabot Corporation

• Aerogel Technologies, LLC

• Active Aerogels, LDA

• BASF SE

• JIOS Aerogel Corporation

• Nano Technology Co., Ltd.

• Dow, Inc.

• Enersens

Aerogel Market Segmentation

Grand View Research has segmented the global aerogel market report based on product, form, technology, end-use, and region:

• Product Outlook (Revenue, USD Million, 2018 - 2030)

• Silica

• Polymers

• Carbon

• Others

• Technology Outlook (Revenue, USD Million, 2018 - 2030)

• Supercritical Drying

• Others

• Form Outlook (Revenue, USD Million, 2018 - 2030)

• Blanket

• Particle

• Panel

• Monolith

• End-use Outlook (Revenue, USD Million, 2018 - 2030)

• Oil & Gas

• Building & Construction

• Automotive, Aerospace & Marine

• Performance Coatings

• Others

• Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

• Europe

o Germany

o U.K.

• Asia Pacific

o China

o Japan

• Central & South America

o Brazil

• Middle East & Africa

Order a free sample PDF of the Aerogel Market Intelligence Study, published by Grand View Research.

0 notes

Text

India CPP Packaging Market: Current Analysis and Forecast (2024-2032)

According to the UnivDatos Market Insights analysis, growing demand for flexible packaging with increased efficiency will drive the growth scenario of CPP Packaging and as per their “India CPP Packaging Market” report, the Indian market was growing at a CAGR of 6.15% during the forecast period from 2024 – 2032.

Cast Polypropylene Packaging (CPP) is a well-known and versatile packaging material. The segment has gained extensive popularity because it is more appealing than propylene due to its clearer appearance and better heat resistance. CPP also hold multiple qualities that has paved its way to the rapidly increased adoption among the packaging manufacturers such as being fit to be customized as per the packaging type, greater tear and impact resistance, completely recyclable properties, etc.

Rising Trend of CPP Packaging from the Food & Beverages Industry:

The Food & Beverages industry has exhibited rapid growth in the recent year. Some of the factors that have contributed to the growth of the food & beverages industry are rising disposable income, rapid urbanization, expanding urban retail infrastructure, and the hospitality and tourism sector. The packaged convenience food industry in India was INR 3,194 Bn in 2020, which is further anticipated to grow to INR 4,883 Bn by 2026. Of all the categories, snacks, Indian sweets, non-alcoholic beverages, and biscuits have grabbed the major market share. These segments are anticipated to hold the dominant share in the coming period as well. Some of the leading companies in the Indian packaged convenience food industry were Nestle, Britannia, Parle, ITC, Hindustan Unilever, Tata Consumer Products, Mondelez India, etc.

Considering the rising domestic demand for food & beverages as well as the enhanced export focus of the food & beverages companies, the demand for the packaging in the respective segment will further grow in the coming years, i.e., 2024-2032.

Rising Demand for CPP Packaging from the Automotive Sector:

The demand for CPP packaging is further supported by the rise of the automotive sector in India. CPP Packaging is used for manufacturing the internal parts of a vehicle such as a door panel, instrument panel, and trim parts. The CPP film offers a smooth and abrasion-resistant surface to the internal panels, enhancing both the aesthetic appeal and robustness of the components.

Recently, the usage of CPP packaging for exterior protection of vehicles has increased extensively. With the applications of withstanding UV, weather changes, rain, dust, and temperature shifts, the film has been used by customers to provide an additional layer of safety to the vehicle.

Access sample report (including graphs, charts, and figures): https://univdatos.com/get-a-free-sample-form-php/?product_id=62006

According to the Society of India Automotive Manufacturers (SIAM) the total sales of automotive the total sales of automobiles in India reached 2,38,53,463 in 2023 from 1,76,17,606 in 2021. This is around a 35% increase, which is further anticipated to rise in the coming years.

The Electric Vehicle category has also enhanced the need for CPP packaging as the CPP films are used for battery pack insulation and protection. As films provide protection from electrical charge and temperature changes, the increasing sales of electric vehicles is further anticipated to assist the market growth of the CPP Packaging market.

These updates, along with technological updates, would be further conducive to the adoption of CPP Packaging in the coming period, i.e., 2024-2032.

Conclusion:

The India CPP Packaging market is experiencing a transformative phase driven by technological advancements, sustainability packaging operations, digitalization, market dynamics, and implementation of government policies. Stakeholders across the industry are embracing these trends to enhance operational efficiency, flexible packaging, sustainable packaging alternatives, etc. As robust protection needs in veneering continue to play a strategic role in improving packaging solutions, staying abreast of these trends and embracing innovation will be crucial for the India CPP Packaging market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Glass Wafer for Semiconductor Devices Market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

Within the Glass Wafer for Semiconductor Devices market, the industry dynamics are driven by the demand for increasingly smaller and more powerful electronic components. As technological innovation propels the semiconductor sector forward, glass wafers become pivotal in enabling the production of smaller and more efficient semiconductor devices. This market thrives on the perpetual quest for miniaturization and enhanced performance in electronic applications. Glass wafers are an integral component in the production of semiconductor devices like integrated circuits, transistors, and diodes. The silicon semiconductor industry relies heavily on high-quality glass wafers to provide a stable base for manufacturing chips and circuits.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2580

Top Companies

Corning Inc.

Asahi Glass Co., Ltd

Plan Optik

Tecnisco Ltd

Nippon Electric Glass Co., Ltd.

Samtec

Dsk Technologies Pte Ltd

Swift Glass Inc.

Nano Quarz Wafer

SCHOTT AG

WaferPro LLC

The glass wafer begins as a cylindrical boule made from materials like quartz, borosilicate glass, or aluminosilicate glass. These glass formulations possess high uniformity and chemical stability needed for fabricating electronic components. The boule is sliced into thin discs using specialized saws, then polished down to an optically flat and scratch-free surface. These glass wafers serve as the foundational substrate onto which the active layers of a semiconductor device are deposited.

Access Full Report @https://www.metastatinsight.com/report/glass-wafer-for-semiconductor-devices-market

Before device fabrication, glass wafers undergo extremely thorough cleaning and surface preparation. Steps like solvent cleaning, wet chemical etching, and high temperature annealing remove contaminants and enhance the molecular bonding between the glass and deposited films. The purity and integrity of the glass wafer surface is paramount for enabling proper electrical performance and reliability.

The semiconductor layers such as dielectric insulators, conductors, and photoresist are laid down on the wafer through techniques like molecular beam epitaxy, chemical vapor deposition, sputtering, and lithography. The glass provides mechanical support while these overlying materials are patterned and etched into integrated circuits or discrete components. The flatness and stability of the wafer surface facilitates precision patterning down to nanometer dimensions.

Glass offers key advantages over other wafer materials for electronics manufacturing. It is inexpensive, nonconductive, and optically transparent. The thermal expansion coefficient and melting point of glass pairs well with silicon. Glass allows inspection and metrology of circuits using optical transmission. And glass wafers are easily scaled up to accommodate larger generation chip sizes and increased production volumes.

As semiconductor technology advances into smaller feature sizes and innovative device architectures, glass wafers must keep pace. Manufacturers continually refine glass composition, surface quality, and mechanical strength to meet industry demands. Investment in glass wafer engineering aims to bolster chip yields, processing capabilities, and end-product performance.

With its unique set of chemicals, optical, thermal, and mechanical attributes, glass remains an indispensable material at the heart of modern semiconductor fabrication. As the foundational substrate for microelectronics, the humble glass wafer enables our interconnected digital world of computers, appliances, mobile devices, and cutting-edge electronics.

Global Glass Wafer for Semiconductor Devices market is estimated to reach $470.6 Million by 2031; growing at a CAGR of 5.5% from 2024 to 2031.

Contact Us:

+1 214 613 5758

#GlassWaferforSemiconductorDevices#GlassWaferforSemiconductorDevicesMarket#GlassWaferforSemiconductorDevicesindustry#marketsize#marketgrowth#marketforecast#marketanalysis#marketdemand#marketreport#marketresearch

0 notes

Text

Vehicle Maintenance Trends Fuel Growth in Paint Protection Film Market Amidst High Installation Costs

Overview :

Paint Protection Film Market size is expected to be worth around USD 971.5 Million by 2033, from USD 537.4 Million in 2023, growing at a CAGR of 6.1% during the forecast period from 2023 to 2033.

Download a sample report in MINUTES@ https://market.us/report/paint-protection-film-market/request-sample/

The paint protection film (PPF) market refers to the industry involved in the production and distribution of films designed to protect the paint on vehicles and other surfaces. These films are applied to surfaces to shield them from damage caused by scratches, stains, and environmental factors such as UV rays and road debris. Over the next few years, the market is anticipated to experience growth driven by increasing applications across various sectors, including automotive, aerospace, and consumer electronics. The rise in demand is partly due to technological advancements leading to the development of high-performance films that offer better durability and protection.

Technological progress is expected to further enhance the market by introducing more sustainable and environmentally friendly products. Innovations in paint protection films aim to provide better resistance to stains and scratches while maintaining a low environmental impact. As consumers and industries seek products that combine performance with eco-friendliness, the market will likely see a surge in demand. The performance of these films and their ability to deliver long-lasting protection will play a crucial role in driving growth and determining market trends.

Key Market Segments :

Material:

TPU (Thermoplastic Polyurethane)

Polyester

PVC (Polyvinyl Chloride)

Polyethylene

PET(Polyethylene Terephthalate)

Others

Application:

Automotive & Transportation

Aerospace & Defense

Electrical & Electronics

Others

Material Analysis:

In superior properties, including transparency, elasticity, and abrasion resistance, make it a top choice for high-performance applications.

Polyvinyl Chloride (PVC) held a 25.4% share of the market. PVC films are favored in the electronics industry for their hardness and mechanical strength. Their excellent insulation properties contribute significantly to their demand, driving growth in this segment.

Application Analysis:

The Automotive and Transport sector led the paint protection film market in 2023, accounting for over 68.4% of the revenue. This dominance is driven by rapid industrialization and increasing vehicle maintenance awareness, with continued growth expected in the automotive industry.

Key Market Players

3M Company

Saint-Gobain

AVERY DENNISON CORPORATION

Eastman Chemical Company

XPEL, Inc.

Hexis S.A.

PremiumShield Limited

STEK-USA

Reflek Technologies Corporation

GRAFITYP Selfadhesive Products NV

ORAFOL Europe GmbH

OPTICSHIELD

SCHWEITZER-MAUDUIT INTERNATIONAL, INC.

Dow

Drivers :

The increasing demand for Paint Protection Films (PPFs) from various end-use industries, particularly automotive and electronics, is driving market growth. PPFs offer essential protection against scratches, chips, and environmental damage, crucial for maintaining vehicle aesthetics and value. The booming automotive sector, contributing significantly to global GDP, along with the rising use of PPFs in luxury vehicles to preserve resale value, is a key factor.

Restraining Factors :

High installation costs and the temporary lifespan of Paint Protection Films present significant challenges. Installation requires skilled professionals, leading to substantial costs, which may deter short-term vehicle owners. PPFs can degrade and yellow with UV exposure, despite advancements in urethane films that offer extended warranties. This degradation, combined with the labor-intensive application process, can lead to high replacement costs and affect market growth.

Opportunities:

Growing innovations in recyclable materials and production technologies present lucrative opportunities for market expansion from 2023 to 2033. Increased consumer awareness about the benefits of PPFs, such as protecting vehicles from damage and enhancing resale value, is expected to drive demand. The appeal of maintaining a vehicle’s appearance and longevity continues to attract customers, leading to increased adoption of PPFs.

Challenges :

Despite their benefits, Paint Protection Films face challenges such as potential dulling of vehicle color and limited water repellency. Skilled installers often use additional treatments like ceramic coatings to address these issues, but these limitations can hinder market growth. Addressing these drawbacks while ensuring effective protection remains a challenge for the industry.

0 notes

Text

Perfluoroalkoxy (PFA) Market Report: Trends, Analysis, and Projections

Perfluoroalkoxy (PFA) is a high-performance fluoropolymer known for its exceptional thermal stability, chemical resistance, and electrical insulation properties. This blog delves into the dynamics of the global PFA market, exploring key drivers, diverse applications across industries, emerging trends, and future growth prospects.

Understanding the PFA Market:

Perfluoroalkoxy (PFA) Is a fluoropolymer closely related to polytetrafluoroethylene (PTFE) and offers similar advantageous properties. PFA exhibits excellent non-stick characteristics, resistance to high temperatures, chemicals, and UV radiation, making it indispensable in critical applications across various sectors.

Market Dynamics:

Semiconductor Industry: PFA is widely used in the semiconductor industry for manufacturing critical components such as wafer carriers, tubing, seals, and gaskets due to its purity, non-contaminating nature, and resistance to corrosive chemicals used in semiconductor processes.

Chemical Processing: PFA's exceptional chemical resistance makes it ideal for use in chemical processing equipment, valves, pumps, linings, and gaskets, where exposure to corrosive chemicals, acids, and solvents is common.

Medical and Pharmaceutical: PFA is utilized in medical and pharmaceutical applications for tubing, catheters, fluid handling systems, and components requiring biocompatibility, sterilizability, and resistance to chemicals used in healthcare settings.

Automotive and Aerospace: PFA coatings, tapes, and films find applications in automotive and aerospace industries for wire and cable insulation, thermal protection, and anti-corrosion coatings in harsh environments.

Applications Across Industries:

Semiconductor: Wafer carriers, tubing, seals.

Chemical Processing: Equipment linings, gaskets, valves.

Medical and Pharmaceutical: Tubing, catheters, fluid handling.

Automotive and Aerospace: Wire insulation, coatings, thermal protection.

Market Trends:

Miniaturization and High Purity Demands: Increasing demand for miniaturized semiconductor components and high-purity materials in semiconductor manufacturing processes drive the adoption of PFA due to its cleanliness, non-contaminating properties, and precise fabrication capabilities.

Focus on Healthcare Innovations: Growing healthcare innovations, including minimally invasive procedures, drug delivery systems, and medical device advancements, fuel the demand for biocompatible and chemically resistant materials like PFA in medical and pharmaceutical applications.

Rapid Prototyping and Additive Manufacturing: Advances in additive manufacturing techniques and 3D printing technologies enable the fabrication of complex PFA parts and components, supporting rapid prototyping and customized solutions across industries.

Future Prospects:

The global PFA market is poised for significant growth, driven by technological advancements, expanding applications in critical industries, and increasing emphasis on material performance, purity, and sustainability. Investments in R&D, manufacturing capabilities, and regulatory compliance will shape the market's evolution and competitiveness.

Conclusion:

Perfluoroalkoxy (PFA) emerges as a versatile and indispensable fluoropolymer with diverse applications ranging from semiconductor manufacturing to healthcare and aerospace industries. Understanding market trends, technological innovations, and industry demands is crucial for stakeholders in the PFA market to capitalize on growth opportunities effectively. With a focus on purity, performance, and application versatility, the PFA market presents promising prospects for continued growth and innovation in the global polymer and materials landscape.

0 notes

Text

Sulfone Polymer Market: Impact Analysis of COVID-19 on the Market

Sulfone Polymers: A Versatile Class of Thermoplastics Sulfone polymers are a class of high-performance engineering thermoplastics known for their exceptional heat resistance, chemical resistance and electrical properties. They have been used in diverse applications ranging from electrical and electronic components to medical devices. In this article, we will discuss the key characteristics of sulfone polymers along with their various uses and future potential. Chemical Structure and Properties

Sulfone polymers are characterized by the sulfone group (O=S=O) in their main chain. The most common commercial sulfone polymer is polysulfone (PSU) which was first developed by Union Carbide in the late 1960s. PSU has an aromatic backbone containing bisphenol units linked together by sulfone groups. This linear structure gives PSU its robust thermomechanical properties. PSU exhibits excellent thermal stability with a glass transition temperature around 185°C and a continuous use limit of 125-150°C. It also demonstrates outstanding chemical resistance to acids, alkalis and aliphatic hydrocarbons. Sulfone polymers are highly resistant to oxidation, hydrolysis and radiation damage as well. Their dimensional stability, rigidity and melting point of around 270°C makes them useful for high-temperature applications. In addition, sulfone polymers also have good dielectric properties with a dielectric constant of around 3.0 and very low dielectric losses. Uses in Electrical & Electronics industries

Due to their superior electrical properties, sulfone polymers find major use in electrical and electronics applications. PSU is commonly used to produce printed circuit boards (PCBs), capacitors, connectors and switches as insulating materials that can handle high voltages and temperatures. Its ability to survive lead-free soldering processes further adds to its attractiveness for printed electronics. Sulfone polymer are also used to manufacture housings and parts for industrial equipment operating in harsh conditions like metering devices, semiconductor fabrication equipment, high voltage switchgears etc. Their resistance to corona discharge and hydrolysis makes them well-suited for outdoor insulators. New derivatives of sulfone polymers are being evaluated as gate insulators in photovoltaics and thin film devices owing to their favorable insulating properties. Medical Applications

In the medical industry, sulfone polymers find extensive applications owing to their biocompatibility and processing versatility. PSU is commonly used to make blood dialysis equipment including hemodialyzers, blood lines and dialysis cartridges. It provides an excellent thromboresistant surface and can be steam sterilized repeatedly. Sulfone polymers are also gaining popularity for manufacturing contact lenses as they can be easily fabricated into thin structures and impart significant oxygen permeability to the cornea. Their moldable nature allows producing complex contact lens geometries for orthokeratology and vision correction. Other medical uses include catheter tubing, drug delivery components, implantable devices and cartridges for insulin pens or syringes. New Developments

Continuous research efforts are being made to develop sulfone polymers with advanced properties. Copolymerization with other stabilizing units has enabled engineering higher glass transition temperatures over 250°C in new sulfone polymers. Grafting with siloxane side chains has also produced modified sulfone polymers with better hydrolytic stability and microporosity. Combining sulfone groups with biphenyl groups led to the development of polymers with extremely high modulus and strength, making them potential candidates for ballistic shielding and armor applications. New sulfone polymers based on polyamides, polyimides and polysulfides have also emerged with enhanced properties such as permeation resistance and bioerodibility. Future Outlook

Going forward, sulfone polymers are expected to gain further acceptance in niche applications that demand robust performance under extreme conditions of heat, chemicals and high voltages. New advanced materials from this family can facilitate greater penetration in developing technologies like water purification membranes, fuel cells, electrical energy storage, implantable medical devices and aerospace structural components. Continuous innovations in polymer chemistry are likely to birth novel sulfone polymers catering to emerging application spaces. Conclusion In conclusion, with their excellent thermal and chemical stability along with good processability, sulfone polymers have established themselves as premium engineering thermoplastics. They fulfill critical requirements in strategic industries from electronics and electrical equipment to medical technologies. Constant advancement in sulfone polymer chemistry is further expanding their application potential. Undoubtedly, sulfone polymers have a bright future ahead as high-performance materials for demanding environments.

0 notes

Text

Market Analysis: Adhesive Tapes Market Expected to Reach $110.6 Billion by 2028

Adhesive tapes, often viewed as an everyday convenience, play a crucial role in diverse industries, from construction and manufacturing to healthcare and electronics. This seemingly simple product boasts a complex global market worth billions, and its story is far from ordinary. Let's explore the Adhesive Tapes Market, examining its size, trends, growth, and exciting predictions for the future.

Industry Size: Sticking to Impressive Numbers

As of 2024, the global Adhesive Tapes Market was valued at USD 80.2 billion, and according to MarketsandMarkets, it's projected to reach USD 110.6 billion by 2028, witnessing a healthy CAGR of 5.6%. This impressive growth signifies the increasing reliance on these versatile bonding solutions across numerous sectors.

Market Trends: Innovation Takes Center Stage

Several key trends are shaping the Adhesive Tapes Market:

Technological Advancements: Continuous innovations are leading to tapes with enhanced functionalities, like higher temperature resistance, improved conductivity, and eco-friendly materials.

Sustainability Focus: Environmental concerns are driving the development of biodegradable and recyclable tapes, minimizing environmental impact.

Specialty Applications: Tapes are catering to niche applications in industries like medical devices, electronics, and aerospace, demanding high-performance characteristics.

E-commerce Boom: Growing online retail is fueling the demand for packaging tapes, creating opportunities for manufacturers.

Market Analysis: A Tapestry of Players and Products

The market comprises diverse players ranging from established global giants like 3M, Nitto Denko, and Avery Dennison to regional players and niche specialists. Tapes are segmented by:

Type: Single-sided, double-sided, transfer tapes, masking tapes, etc.

Material: Acrylic, rubber, silicone, paper, film, etc.

Application: Packaging, construction, automotive, healthcare, electronics, etc.

Market Demand: Where's the Stickiness Coming From?

Several factors are driving the demand for adhesive tapes:

Urbanization and Infrastructure Development: Growing infrastructure projects require high-performance tapes for construction and bonding.

Advancements in Healthcare: The healthcare industry utilizes specialized tapes for medical devices, wound care, and diagnostics, increasing demand.

Rise of Electronics: Miniaturization and complexity in electronics require sophisticated tapes for precise bonding and insulation.

Sustainability Concerns: Eco-friendly tapes cater to environmental awareness, creating a new market segment.

Market Growth: A Future Held Together by Innovation

With rising demand and continuous innovation, the Adhesive Tapes Market is poised for significant growth. Industry experts predict:

Expansion into Emerging Markets: Developing economies will witness increased demand for tapes due to infrastructure development and industrialization.

Growing Adoption in Specialty Applications: Tapes will cater to niche applications in areas like renewable energy and electric vehicles.

Focus on Smart Tapes: Tapes integrated with sensors and electronics will offer real-time monitoring and data collection capabilities.

Download PDF Brochure :

The Adhesive Tapes Market transcends its simplistic image, showcasing a dynamic and innovative landscape. With its diverse applications, constant advancements, and promising future, the market is poised to stick around for years to come, playing a vital role in various industries and shaping our everyday lives in ways we might not even realise.

0 notes

Text

Functional Films Market Growth Drivers: Unveiling Key Catalysts

Functional films are multi-layer thin film coatings that provide functional properties beyond basic optical properties. They help enhance the performance of various products by imparting properties such as anti-reflection, anti-scratch, anti-fog, anti-microbial, and energy-saving. The growing need for energy conservation and advantages of functional films in saving energy of buildings is driving the demand of these films. The global Functional Films Market is estimated to be valued at US$ 9.02 Mn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The opportunity in energy saving through the use of functional films is driving the growth of the market. Functional films help reduce energy consumption and CO2 emissions of buildings by controlling heat and light transmission. They provide insulation properties and prevent heat loss during winters and heat gain during summers. This results in savings on energy costs required for heating, ventilation, and air conditioning (HVAC). As energy efficiency becomes a focus area globally to reduce carbon footprint, the demand for functional films is increasing from the construction industry. Their energy saving features make buildings more sustainable and help lower operating costs in the long run. Growing emphasis on green buildings will continue contributing to the increased adoption of functional films. Porter's Analysis Threat of new entrants: Low capital requirement however established brands enjoy recognition and economies of scale. Bargaining power of buyers: High as buyers can negotiate on price and choose from various global and regional functional film manufacturers. Bargaining power of suppliers: Moderate as raw material suppliers have established supply networks however functional films manufacturers can switch suppliers. Threat of new substitutes: Low as functional films have applications across industries however new materials pose threat. Competitive rivalry: High as the market is fragmented with global and regional players competing on price and quality. SWOT Analysis Strength: Wide applications in electronics, automotive and construction industries. Additional functional properties enhance product performance. Weakness: High R&D and production costs. Stringent quality standards and certification processes. Opportunity: Growing end-use industries in emerging markets. Development of bio-based and environment-friendly films. Threats: Fluctuating raw material prices and availability. Strong competition from alternative materials. Key Takeaways The global functional films market is expected to witness high growth during the forecast period of 2023 to 2030. The market size is projected to reach US$ 9.02 Mn in 2024.

Regional analysis: Asia Pacific as the fastest growing region due to growth in electronics and automotive industries in China, India, Japan and Southeast Asian countries. North America and Europe hold major shares of the global market currently.

Key players operating in the functional films market are 3M, Toray Industries, Inc., Nagase & Co. Ltd., Eastman Chemical Company, and Tatsuta Electric Wire & Cable Co., Ltd. 3M enjoys leading position with wide product portfolio for various applications. Toray Industries commercializes protection and insulation films targeting electronics and energy industries.

#Functional Films Market Share#Functional Films Market Growth#Functional Films Market Demand#Functional Films Market Trend#Functional Films Market Analysis

0 notes

Text

Global Gas Mixtures Market Analysis 2024 – Estimated Market Size And Key Drivers

The Gas Mixtures by The Business Research Company provides market overview across 60+ geographies in the seven regions - Asia-Pacific, Western Europe, Eastern Europe, North America, South America, the Middle East, and Africa, encompassing 27 major global industries. The report presents a comprehensive analysis over a ten-year historic period (2010-2021) and extends its insights into a ten-year forecast period (2023-2033).

Learn More On The Gas Mixtures Market: https://www.thebusinessresearchcompany.com/report/gas-mixtures-global-market-report

According to The Business Research Company’s Gas Mixtures , The gas mixtures market size has grown strongly in recent years. It will grow from $39 billion in 2023 to $42.37 billion in 2024 at a compound annual growth rate (CAGR) of 8.7%. The growth in the historic period can be attributed to industrial growth, healthcare applications, electronics manufacturing, environmental regulations.

The gas mixtures market size is expected to see strong growth in the next few years. It will grow to $58.62 billion in 2028 at a compound annual growth rate (CAGR) of 8.5%. The growth in the forecast period can be attributed to renewable energy, emerging technologies, global expansion. Major trends in the forecast period include customized gas mixtures, r&d and innovation, hybrid and electric vehicles, collaborative initiatives.

Increased demand for electronics products is expected to propel the growth of the gas mixtures market going forward. Electronic products refer to software products made available through electronic media. The gaseous mixtures are used for microelectric manufacturing and semiconductor processing applications such as thin film deposition and also for insulation purposes. For instance, according to the United Nations Comtrade database on international trade, a US-based repository of official international trade statistics and relevant analytical tables, the United Kingdom's imports of electrical and electronic equipment increased to $61.76 billion in 2021, which was approximately $57 billion in 2020. Therefore, the increased demand for electronic products is driving the growth of the gas mixtures market.

Get A Free Sample Of The Report (Includes Graphs And Tables): https://www.thebusinessresearchcompany.com/sample.aspx?id=7658&type=smp

The gas mixtures market covered in this report is segmented –

1) By Mixture: Oxygen Mixtures, Nitrogen Mixtures, Carbon Dioxide Mixtures, Argon Mixtures, Hydrogen Mixtures, Specialty Gas Mixtures, Other Mixtures (Rare Gas Mixtures) 2) By Manufacturing Process: Air Separation Technology, Hydrogen ProductionTechnology, Other Manufacturing Process (Pressure Swing Adsorption) 3) By Storage, Distribution, And Transportation: Cylinder and Packaged Distribution, Merchant Liquid Distribution, Tonnage Distribution 4) By End-Use Industry: Metal Manufacturing and Fabrication, Chemicals, Medical and Healthcare, Electronics, Food and Beverage, Other End-Users Industries (Glass, Energy, and Oil and Gas)

Product innovation is a key trend gaining popularity in the gas mixture market. Major companies operating in the gas mixtures market are focused on developing new products to strengthen their position. For instance, in January 2022, SuperFlash LLC, a US-based company operating in gas mixtures, launched its new mobile and compact gas analyzer, the GA300. The GA300 would allow for the analysis of gas mixtures for systems that do not have an integrated analyzer. Gas analysis is critical in various processes that include food, beverages, and a myriad of industrial manufacturing applications. The unique features of this product include mobility; ae light, sturdy, and low-maintenance product that is easy to use through clear menu option; and a digital LCD display that continuously monitors gas mixtures which is capable of monitoring up to 10 binary gas mixtures.

The gas mixtures market report table of contents includes:

Executive Summary

Market Characteristics

Market Trends And Strategies

Impact Of COVID-19

Market Size And Growth

Segmentation

Regional And Country Analysis . . .

Competitive Landscape And Company Profiles

Key Mergers And Acquisitions

Future Outlook and Potential Analysis

Contact Us: The Business Research Company Europe: +44 207 1930 708 Asia: +91 88972 63534 Americas: +1 315 623 0293 Email: [email protected]

Follow Us On: LinkedIn: https://in.linkedin.com/company/the-business-research-company Twitter: https://twitter.com/tbrc_info Facebook: https://www.facebook.com/TheBusinessResearchCompany YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ Blog: https://blog.tbrc.info/ Healthcare Blog: https://healthcareresearchreports.com/ Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Europe Magnesium Oxide Market Share, Upcoming Trends, Size, Key Segments 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Magnesium Oxide Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Magnesium Oxide Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Magnesium Oxide Market?

The Europe magnesium oxide market was valued at US$ 1,349.2 Million in 2023 and is expected to register a CAGR of 3.0% over the forecast period and reach US$ 1,752.7 Mn in 2032.

What are Europe Magnesium Oxide?

Magnesium Oxide in Europe encompasses the diverse applications and uses of MgO within the region. This versatile compound is integral to several industries for its thermal stability, electrical insulation properties, and refractory capabilities. It serves as a critical component in construction, ceramics, and agriculture, found in products ranging from refractory bricks to fertilizers. Moreover, magnesium oxide plays a vital role in environmental applications such as wastewater treatment and soil remediation, underscoring its multifaceted significance in both industrial processes and environmental management across Europe.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2353

What are the growth prospects and trends in the Europe Magnesium Oxide industry?

The Europe magnesium oxide market growth is driven by various factors and trends. The European market for magnesium oxide (MgO) is thriving, propelled by its broad applications across various industries. Renowned for its thermal resilience, electrical insulation properties, and refractory capabilities, MgO is indispensable in sectors such as construction, ceramics, agriculture, and environmental remediation. In construction, it is crucial for fire-resistant materials and cement additives, while in agriculture, it enriches soil as a magnesium source in fertilizers. Market expansion is bolstered by advancements in manufacturing technologies and growing demand for sustainable, high-performance materials throughout Europe. Hence, all these factors contribute to Europe magnesium oxide market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Typе

Caustic Calcined Magnesia (CCM)

Dead Burned Magnesia (DBM)/ Sintered Magnesia

Fused MgO

By Form

Pellets

Powder

Sputtering Targets

Tablets

Nanopowder

By Purity

85-95%

99%

By Application

Cements

Refractories

Crucibles

Heating Elements

Thermocouple Tubes

Brake Linings

Plasma Display Screens

Thin Film Semiconductors

Fuel additives

Fertilizers

Waste Water Treatment

Rubber Processing

Cattle Feed Supplement

Adhesive

Others

By End-Usе Industry

Steel

Glass & Cement

Chemical

Electricals & Electronics

Agriculture

Pharmaceutical

Plastics & Rubber

Water Treatment

Environmental

Nuclear

Others

Who are the key players operating in the industry?

The report covers the major market players including:

Linde plc

Air Liquide

Air Products and Chemicals, Inc.

Messer Group GmbH

Yara International ASA

Gasum Oy

SOL Group

RWE AG

SIAD Group

Orlen

View Full Report: https://www.reportsandinsights.com/report/Europe Magnesium Oxide-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Magnesium Oxide Market share#Europe Magnesium Oxide Market size#Europe Magnesium Oxide Market trends

0 notes

Text

Ethylene Tetrafluoroethylene (ETFE) Market[R1] Size by Research Nester Reveals the Market to Grow with a CAGR of ~7% During 2024-2036

Research Nester’s recent market research analysis on “Ethylene Tetrafluoroethylene (ETFE) Market: Global Demand Analysis & Opportunity Outlook 2036” delivers a detailed competitors analysis and a detailed overview of the global ethylene tetrafluoroethylene (ETFE) market in terms of market segmentation by technology, product type, application, end-use industry, and by region.

Prospering Architectural Sector to Promote Global Market Share of Ethylene Tetrafluoroethylene (ETFE)

The growing employment prospects in the field may attest to the boom in the architecture industry. For instance, the U.S. Bureau of Labour Statistics (BLS) projects that employment opportunities for architects and designers will increase by 3% between 2022 and 2030. As a result of its affordability and durability, ETFE is increasingly being used in contemporary architectural projects to construct stadiums, polytunnels, and other similar structures, which is expected to drive the worldwide ethylene tetrafluoroethylene market in the years to come. For instance, research has shown that ETFE has tremendous strength and can support 400 times its own weight in weight.

Request Report Sample@

Some of the major growth factors and challenges that are associated with the growth of the global ethylene tetrafluoroethylene (ETFE) market are:

Growth Drivers:

Increasing Investment in Clean Energy

Growing Demand from the Aviation and Aerospace Industries

Challenges:

ETFE claimed, due to the fact that its widespread use has been doubted and hindered market growth, "natural" building materials are actually plastic. The demand for ETFE is expected to decrease over the forecast period, as pollution of plastics becomes one of the world's major threats.

By product type, the global ethylene tetrafluoroethylene (ETFE) market is segmented into granule, powder and others. Granule segment is expected to garner a significant share of around ~45% in the year 2036. In addition, the increasing demand for corrosion resistant parts, insulation components, wire and cable housings, insulated steel jackets, construction films, valve casing etc. is also a factor that contributes to segment growth in global electronics as well as building industry. In fact, the US construction sector was estimated to contribute around 4 % of United States GDP in 2021.

By region, the Asia Pacific ethylene tetrafluoroethylene (ETFE) market is to generate the highest revenue by the end of 2036. The market share of ethylene tetrafluoroethylene in Asia Pacific is projected to be the largest with a share of about 36% by the end of 2036. The increase in demand for fluoropolymers which include PVDF, PTFE, ETFB, and others from the car industry due to their widespread use in lithium-ion batteries, brake systems as well as braking wear sensors is a major factor driving market growth. According to these findings, the main consumer of fluoropolymers worldwide was mainland China in 2022, accounting for 37% of PTFE consumption and around 48% of others. Thus, the market for ethylene tetrafluoroethylene is expected to also grow with other types of fluoropolymers as giant car manufacturers expand their presence in the region and vehicle production increases.

This report also provides the existing competitive scenario of some of the key players of the global thylene tetrafluoroethylene (ETFE) market which includes company profiling of Daikin Industries, Ltd., Saint-Gobain S.A., DuPont Teijin Films, Chemours Company, Foiltec, Taiyo Kogyo Co., Ltd., AGC Inc., Nitto Denko Corporation, Nippon Electric Glass Co., Ltd., Daikin Industries Ltd, MakMax Group and others.

0 notes

Text

Ultra-High Molecular Polyethylene Market Grow with a CAGR of 11.7% During 2023-2035 and Attain USD 7.9 Billion by 2035

Research Nester’s recent market research analysis on “Ultra-High Molecular Polyethylene Market: Global Demand Analysis & Opportunity Outlook 2035” delivers a detailed competitors analysis and a detailed overview of the global ultra-high molecular polyethylene market in terms of market segmentation by form type, application, end user industry, and by region.

Need for Compatible Medical Devices to Promote Global Market Share of Ultra-High Molecular Polyethylene

The medical device market has traditionally relied on innovation, and in recent years, the desire to minimize the size of devices and implants has encouraged innovation. UHMWPE (Ultra-High Molecular Weight Polyethylene) fiber development is projected to be a major contributor to the development of unique and exciting developments that will assist in driving growth in the medical devices market. The rising shift of trend toward minimally invasive implants and procedures such as laparoscopic or robotic surgery is expected to drive the market growth. The adoption of minimally invasive procedures results in shorter hospital stays, reduced trauma, and reduced overall cost of care for the patient.

Get a Sample PDF Brochure: https://www.researchnester.com/sample-request-3081

Some of the major growth factors and challenges that are associated with the growth of the global ultra-high molecular polyethylene market are:

Growth Drivers:

Surging Development in Medical Equipment

Rising Need for Electric Vehicles

Challenges:

Changing raw material prices for Ultra High Molecular Weight Polyethylene (UHMWPE) might be a substantial impediment to the UHMWPE market. The price of raw materials required in the polymerization process, such as ethylene gas, influences the cost of making UHMWPE. Whenever the costs of these raw materials fluctuate frequently or significantly, it can have an impact on the entire cost of UHMWPE manufacture. On the other hand, when subjected to temperature fluctuations, UHMWPE exhibits a significant coefficient of thermal expansion, resulting in dimension changes. Because of its thermal instability, it is less suitable for precision parts. There are some of the major factors anticipated to hamper the global market size of ultra-high molecular polyethylene.

Request for customization @ https://www.researchnester.com/customized-reports-3081

By form type the global ultra-high molecular polyethylene market is segmented into flat materials, rods & tubes, and fibers. The flat materials segment is to garner the highest revenue of USD 3.6 billion by the end of 2035 by growing at a significant CAGR over the forecast period. A variety of applications of the film form of UHMWPE is boosting the segment’s growth. It is utilized in packaging, chute and hopper lining, electrical insulation, and as a barrier material. They are also used in the food processing, automotive, and electronics industries. Dotmar Engineering Plastics, for example, provides Polystone 500 high molecular weight polyethylene sheets with superior mechanical properties, such as rigidity and ability to withstand distortion over time, making them acceptable for the food industry.

By region, the market in the Europe, amongst the market in all the other regions, is projected to hold a market revenue of USD 1.9 billion by the end of 2035 by growing at a CAGR of USD 11.8% over the forecast period. The size and power of leading companies in Europe, as well as increased product releases or the establishment of new plants for ultra-high molecular polyethylene, boosts market growth in Europe. Repsol announced that it planned to spend USD 112.5 million in June 2022 to create Spain's first Ultra High Molecular Polyethylene (UHMWPE) manufacturing facility. The facility will be built at Repsol's Industrial Site in Puertollano and will be operational by the end of 2024.

Obtain this Report @ https://www.researchnester.com/reports/ultra-high-molecular-polyethylene-market/3081

This report also provides the existing competitive scenario of some of the key players of the global ultra-high molecular polyethylene market which includes company profiling of Celanese Corporation, Röchling SE & Co. KG, LyondellBasell Industries Holdings B.V., DuPont, Dotmar Engineering Plastics, Honeywell International Inc., TSE Industries, Inc., Korea Petrochemical Ind. Co., LTD, Mitsui Chemicals Inc., Asahi Kasei Corporation, TEIJIN LIMITED, Nitto Denko Corporation, and DSM.

About Us

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision in order to avoid future uncertainties.

Contact for more Info:

AJ Daniel

Email: [email protected]

U.S. Phone: +1 646 586 9123

U.K. Phone: +44 203 608 5919

0 notes

Text

Specialty Tapes Market: Current Analysis and Forecast (2021-2027)

A comprehensive overview of the global specialty tapes market is recently added by UnivDatos Market Insights to its humongous database. The report has been aggregated by collecting informative data from various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the specialty tapes markets globally. This report offers a detailed analysis of the latest industry developments and trending factors that are influencing market growth. Furthermore, this statistical market research repository examines and estimates the global specialty tapes market at regional and country levels. The global specialty tapes market is likely to showcase a growth of around 6% during the forecast period.

Market Overview

Specialty tapes are composed of a carrier film, foil, or other flexible material. These tapes are manufactured with high-performance adhesives using carrier materials and are designed for utilization in industries including electrical & electronics, automotive, building & construction, retail & graphics, and healthcare. Further, the trend toward using flatter and micro-electronic devices continues, increasing the application of specialty tapes in the electrical & electronics industry. In addition, the demand for in-vitro diagnostics, hydrophilic films, transdermal drug delivery patches, and oral dissolvable films are driving the specialty tapes market in the healthcare industry, globally. Furthermore, rising construction activities are rising the demand for specialty tapes for mounting window panels and sealing gaps in the window and door panels.

The global specialty tapes market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

By backing material, the market is primarily divided into:

Polyvinyl Chloride

Woven/Non-Woven

Paper

Foam

Polypropylene

Others

Among these, the paper held a prominent share in the global specialty tapes market. Paper tapes have excellent adhesion, heat insulation, temperature tolerance, and are environmentally safe, and come in various colors. Further, when compared to other adhesive tapes, these tapes offer more comfort. Moreover, they are thin, flexible, and smooth, making them ideal for vehicle and aviation manufacture, as well as appliance manufacturing, HVAC, and paper and printing applications.

By end-user, the market is primarily divided into:

Electrical & Electronics

Healthcare

Automotive

Paper & Printing

Building & Construction

Others

Among these, healthcare held a prominent share in the global specialty tapes market. The specialty tapes market is rising in healthcare due to the aging population, increased chronic illness incidence, and the high demand for in vitro diagnostics, hydrophilic films, transdermal patches, and oral dissolvable films. Also, the development of products such as disposable infant diapers, feminine hygiene products, and adult incontinence products all use specialty tapes.

Global Specialty Tapes Market Geographical Segmentation Includes:

North America (United States, Canada, Rest of North America)

Europe (Germany, France, United Kingdom, Italy, Spain, Rest of Europe)

Asia-Pacific (China, Japan, India, Australia, Rest of APAC)

Rest of the World

Asia-Pacific held a prominent share in the specialty tapes market owing to growing industries such as electric & electronics, healthcare, packaging, building and construction, and others. Also, the market growth can be attributed to the expanding automotive industry, in electric vehicles (Evs), specialty tapes are used for covering the gaps and for bonding purposes in the battery. Other prominent applications of such tapes in Evs are motor assembly, insulation, and wire harnessing. Moreover, increasing disposable income and rapid economic growth in the region are increasing the better-quality products, and improving the lifestyle is also fueling the market for specialty tapes.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=25092

Competitive Landscape

The degree of competition among prominent companies has been elaborated by analyzing several leading key players operating globally. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the global specialty tapes market. The major players have been analyzed by using research methodologies for getting insight views on market competition.

Key questions resolved through this analytical market research report include:

What are the latest trends, new patterns, and technological advancements in the global specialty tapes market?

Which factors are influencing the global specialty tapes market over the forecast period?

What are the global challenges, threats, and risks in the global specialty tapes market?

Which factors are propelling and restraining the global specialty tapes market?

What are the demanding global regions of the global specialty tapes market?

What will be the market size in the upcoming years?

What are the crucial market acquisition strategies and policies applied by the companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature. Please let us know if you have any custom needs.

Browse Related Newsletter from UnivDatos Market Insights

Autonomous Vehicle Sensor Compatible Coating Market: SWOT Analysis [2023-2028]

Glyphosate Market: SWOT Analysis [2023-2028]

About Us:

UnivDatos Market Insights: Your Partner in Data-Driven Market Strategies. Unlock growth opportunities and make smart decisions with our expert research and insights.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

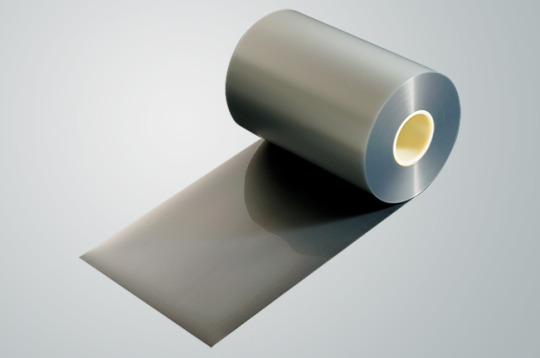

The electrical, thermal, physical, and chemical characteristics of polyimide films are good. These qualities are available in a lightweight package throughout a wide temperature range, making them ideal for electrical insulation applications.

0 notes