#Elastomer Coated Fabrics Market

Explore tagged Tumblr posts

Text

Tetrahydrofuran Market Supply Chain Challenges and Future Strategies to 2033

Tetrahydrofuran (THF) is a versatile, colorless, and water-miscible organic solvent with the chemical formula (CH₂)₄O. As a heterocyclic ether, it plays a pivotal role in various industrial applications, notably in the production of polymers, solvents, and as a precursor in chemical syntheses. The global THF market has witnessed significant growth over the past decade, driven by its expanding applications across multiple industries. This article delves into the current industry trends and provides a comprehensive forecast of the THF market up to 2032.

Market Overview

As of 2024, the global THF market size was valued at approximately USD XX billion. Projections indicate that by 2032, the market is expected to reach nearly USD XX billion, exhibiting a compound annual growth rate (CAGR) of XX% during the forecast period from 2025 to 2032.

Download a Free Sample Report:-https://tinyurl.com/kx7b6uwn

Key Drivers of Market Growth

Rising Demand for Polytetramethylene Ether Glycol (PTMEG): THF is primarily utilized in the production of PTMEG, which serves as a precursor for manufacturing spandex fibers and polyurethane elastomers. The burgeoning textile industry, coupled with the increasing demand for stretchable fabrics, has significantly bolstered the consumption of PTMEG, thereby driving the THF market.

Expansion of the Automotive and Transportation Sectors: The automotive industry's shift towards lightweight materials to enhance fuel efficiency has led to increased use of polyurethane products derived from THF. These materials contribute to weight reduction in vehicles, aligning with global sustainability goals.

Growth in the Pharmaceutical Industry: THF's efficacy as a solvent in Grignard reactions and other pharmaceutical syntheses has made it indispensable in drug manufacturing. The continuous growth of the pharmaceutical sector, driven by rising healthcare needs, has consequently escalated the demand for THF.

Advancements in Polymer Production: THF is extensively used as a solvent in the production of polyvinyl chloride (PVC) and other polymers. The increasing application of PVC in packaging, construction, and electrical industries has further propelled the THF market.

Market Restraints

Health and Environmental Concerns: The use of THF poses health risks, including respiratory issues and potential carcinogenic effects. Stringent regulations by environmental and health agencies have led to increased scrutiny and operational costs for manufacturers.

Volatility in Raw Material Prices: Fluctuations in the prices of raw materials, such as butadiene, used in THF production can impact profit margins and pose challenges for market stability.

Regional Market Insights

Asia-Pacific: This region dominates the global THF market, attributed to rapid industrialization, a robust textile industry, and expanding automotive and pharmaceutical sectors. China, in particular, stands as the largest market, owing to its vast manufacturing capabilities and consumption rates.

North America: The presence of major THF producers and high demand across various industries position North America as a significant market. The region's advanced industrial infrastructure and chemical production capacity contribute to its leading position.

Europe: With a well-established automotive industry and growing emphasis on sustainable materials, Europe exhibits steady growth in THF consumption.

Application Segmentation

PTMEG Production: Accounting for the largest revenue share, the demand for PTMEG is driven by its application in spandex fibers and polyurethane elastomers.

Solvents: THF's excellent solvency properties make it a preferred choice in various applications, including coatings, adhesives, and chemical syntheses. The market for THF used as solvents is projected to grow at a CAGR of 6.8% during the forecast period from 2024 to 2032.

Chemical Intermediates: THF serves as a precursor in producing various chemicals, enhancing its demand in the chemical industry.

Technological Advancements

Innovations in THF production processes, such as the Reppe process, have improved efficiency and reduced environmental impact. The Reppe process is preferred over the furfural process because it is entirely synthetic and does not depend on agricultural conditions for raw material availability.

Future Outlook

The global THF market is poised for substantial growth, driven by its versatile applications and the expansion of end-use industries. However, addressing environmental concerns and adhering to regulatory standards will be crucial for sustainable development. Investments in research and development to discover safer and more efficient production methods are anticipated to shape the market's future landscape.

Conclusion

Tetrahydrofuran's unique properties and wide-ranging applications have cemented its position as a vital industrial solvent. The projected growth of the THF market underscores its significance in various sectors. Balancing industrial growth with environmental and health considerations will be essential to ensure the THF market's sustainable expansion in the coming years.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/chemicals-materials/tetrahydrofuran.html

0 notes

Link

0 notes

Text

Electroactive Polymers Market — By Type , By Application , By Geography — Global Opportunity Analysis & Industry Forecast, 2024–2030

Electroactive Polymers Market Overview

Request Sample :

Electroactive Polymers Market COVID-19 Pandemic

The outbreak of Covid-19 is having a huge impact on the economy of electronic devices. The COVID-19 pandemic caused an unprecedented increased demand for some medical devices, as well as significant disruptions in the manufacturing and supply chain operations of global medical devices. The FDA monitors the supply chain of medical products and works closely with producers and other stakeholders to assess the risk of disruption and to prevent or reduce its impact on patients, health care providers, and the general public’s health. In addition, there is a delay in imports and exports of medical devices due to the import-export restriction by the governments in various regions. All these factors are having a major impact on the Electroactive Polymers Market during the pandemic.

Report Coverage

The report: “Electroactive Polymers Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the electroactive polymers Industry.

By Type: Ionic Electroactive Polymers (Ionic Polymer Gels (IPG), Ionic Polymer Metal Composites (IPMC), Conductive Polymers (CP), and Carbon Nanotubes (CNT)), Electronic Electroactive Polymers (Ferroelectric Polymers, Electrostrictive Graft Elastomers, Dielectric Elastomers, Electro VIscoelastic Elastomers, Liquid Crystal Elastomer (LCE), and Others), and Others.

By Application: Actuators, Sensors, Plastic, Aviation Technology, Energy Generation, Automotive Devices, Prosthetics, Robotics, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the Electroactive Polymers Market owing to the increasing demand for the electroactive polymers industry in the region. The increasing urbanization coupled with the rising population in APAC is the major factor driving the demand for electroactive polymers.

Electroactive polymers are extensively used for corrosion-preventing coatings in ferrous and non-ferrous alloys, actuators, damped harmonic oscillator, metamorphic biomaterials, and protective fabrics points. These properties of electroactive polymers are projected to increase market growth.

Electroactive polymers due to its unique properties find application in different end-use industries. These are lighter in weight, more durable, and have better conductive properties, unlike conventional materials (metals). During the forecast period, this factor is anticipated to drive the market.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which the projects and operations of various industries such as energy generation and automotive are disruptively stopped, which is hampering the Electroactive Polymers Market growth.

Electroactive Polymers Market Segment Analysis — By Type

The conductive polymers segment held the largest share in the Electroactive Polymers Market in 2020 and is growing at a CAGR 8.10% over 2024–2030. The significant class of functional materials that have certain useful properties of both organic polymers (such as strength, plasticity, flexibility, strength, elasticity) and semiconductors (such as electric conductivity) are conducting polymers (CPs). The conductive polymers are often used in miniature boxes that have the ability to open and close, micro-robots, surgical tools, surgical robots that assemble other micro-devices. In addition, conductive polymers (CPs) are extensively used as an alternative to metallic interfaces within biomedical devices as a way of imparting electroactivity to normally passive devices such as tissue scaffolds. Thus, all these extensive characteristics of conductive polymers are the key factor anticipated to boost the demand for conductive polymers in various regions during the forecast period.

Schedule A Call :

Electroactive Polymers Market Segment Analysis — By Application

The actuator segment held the largest share in the Electroactive Polymers Market in 2020 and is expected to grow with a CAGR of 7.2% for forecast period. To maximize the actuation capability and durability, effective fabrication, shaping, and electrode techniques are being developed. Many engineers and scientists from many different disciplines are attracting attention with the impressive advances in improving their actuation strain. Due to their inherent piezoelectric effect, ferroelectric polymers, such as polyvinylidene fluoride (PVDF), are largely used in manufacturing electromechanical actuators. For biomimetic applications, these materials are especially attractive, as they can be used to make intelligent robots and other biologically inspired mechanisms. To form part of mass-produced products, many EAP actuators are still emerging and need further advancements. This requires the use of models of computational chemistry, comprehensive science of materials, electro-mechanical analytical tools, and research into material processing. Which will eventually drive is the Electroactive Polymers Market during the forecast period.

Electroactive Polymers Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the Electroactive Polymers Market in 2020 up to 38%, owing to the escalating medical device industry in the region. A key factor behind the growth of the region’s electroactive polymer market is the large demand for electroactive polymers for the manufacture of advanced implant devices for medical conditions. According to Invest India, the Indian medical device sector is projected to register a CAGR of 14.8% and is expected to reach $11.9 billion in 2021–22, and the sector is projected to reach $ 65 bn industry by 2024. According to the most recent official figures from the Ministry of Health, Labour and Welfare (MHLW), the Japanese medical devices market in 2018 was roughly $29.3 billion, up about 6.9 percent from 2017 in yen terms. And from 2018 to 2023, the medical device market in Japan is estimated to show an increment of 4.5% CAGR in yen terms. Furthermore, North America also holds a prominent market share of the Electroactive Polymers Market due to the escalating medical device industry. According to the Select USA, the United States medical device market is anticipated to rise to $208 billion by the year 2023. Thus, with the expanding medical device industry, the demand for electroactive polymers will also subsequently increase, which is anticipated to drive the Electroactive Polymers Market in the Asia Pacific and North America during the forecast period.

Electroactive Polymers Market Drivers

Increasing Automotive Production

In the automotive industry, electroactive polymers are used as actuators and sensors. For materials that are light in weight but strong and durable such as an electroactive polymer, there is high demand. By using modern electroactive polymers in numerous automotive electronic components, such as multiple sensors, accelerometers, and accelerator pedal modules, car manufacturers are attempting to achieve lightweight properties. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects the production of cars to reach 35 million by 2025. According to the International Trade Administration (ITA), in 2019 the Mexican market for electric, plug-in vehicles, and hybrid vehicles reached 25,608 units, representing a 43.8% growth over 2018. Thus, increasing automation production will require more electroactive polymers for manufacturing various automotive components, which will act as a driver for the Electroactive Polymers Market during the forecast period.

Increasing Application of Electroactive Polymers

Textiles called sensing and actuating microfibers can be directly woven into electromechanical systems such as sensors, actuators, electronics, and power sources. They can be used as smart fabrics because of the flexibility and low cost of electroactive polymers. In developing intelligent fabrics, polypyrrole and polyaniline are used. In addition, using electroactive polymers in robotics for muscle development is better, as it is more cost-effective than the semiconductor and metal materials. And robotics is widely used; hence the demand for electroactive polymers will also positively affect the market growth. Furthermore, Electroactive Polymers Market growth is increasing owing to its wide usage in areas such as medical devices, damped harmonic oscillator, electric displacement field, electrostatic discharge/electromagnetic interference, high-strain sensors, and biomimetic. Hence, the increasing application of electroactive polymers acts as a driver for the Electroactive Polymers Market.

Buy Now :

Electroactive Polymers Market Challenges

Environmental Hazards Related to the Electroactive Polymers

Raw materials which are used to produce electroactive polymers (EAPs) are difficult to extract and often harmful to the environment. The disposal of waste generated by electroactive polymers is one of the major concerns (EAPs). Improper disposal of EAP products could harm the environment and ultimately impact the food chain. Manufacturers of EAPs may experience increased costs associated with the disposal of certain electroactive polymers (EAPs) that cannot be disposed of by biodegradation. The government has, therefore, enforced strict regulations on the use of such polymers. Besides, the environmental regulations on the use of petroleum products restrict the growth of the EAPs market. These factors are hampering the electroactive polymer market growth.

Electroactive Polymers Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Electroactive Polymers Market. Major players in the Electroactive Polymers Market are Solvay, Parker Hannifin, Agfa-Gevaert, 3M, Merck, Lubrizol, Novasentis, Premix, PolyOne Corporation, Celanese Corporation, and KEMET Corporation.

Key Market Players:

The Top 5 companies in the Electroactive Polymers Market are:

Merck

3M

Solvay

Parker Hannifin

Agfa-Gevaert

For more Chemicals and Materials Market reports, Please click here

#ElectroactivePolymers#SmartMaterials#ConductivePolymers#FlexibleElectronics#ShapeMemoryAlloys#PolymersInElectronics#SoftRobotics

0 notes

Text

Quality TPU Film and Protective Solutions in India

In today's fast-paced world, quality TPU film and protective solutions in India have become essential for various industries. Thermoplastic polyurethane (TPU) is renowned for its versatility and durability, making it an ideal choice for a wide range of applications, from automotive and electronics to textiles and packaging. As TPU film manufacturers in India continue to innovate and improve their products, businesses are increasingly recognizing the value of integrating TPU solutions into their operations.

Understanding TPU Film

Quality TPU film and protective solutions in India stem from a deep understanding of thermoplastic polyurethane. TPU is a type of elastomer that exhibits excellent elasticity, transparency, and resistance to abrasion, oil, and grease. These properties make TPU film a preferred material for applications requiring durability and flexibility. By utilizing TPU protective film, industries can enhance the longevity and performance of their products while ensuring superior protection against environmental factors.

Applications of TPU Film

Quality TPU film and protective solutions in India find extensive applications across various sectors. In the automotive industry, TPU film is used for protective coatings, ensuring that vehicle surfaces remain scratch-free and visually appealing. The electronics sector also benefits from TPU film as it provides a protective layer for devices, shielding them from impacts and environmental damage. Additionally, the textile industry leverages TPU film to create water-resistant and breathable fabrics, enhancing the functionality and comfort of apparel.

Advantages of TPU Film

The quality TPU film and protective solutions in India offer numerous advantages that make them highly sought after. One of the key benefits of TPU film is its exceptional flexibility, allowing it to conform to various shapes and surfaces. This adaptability is crucial for applications requiring precise fit and coverage. Furthermore, TPU film is lightweight yet durable, making it an ideal choice for applications where weight reduction is essential without compromising strength.

Another significant advantage of TPU film is its chemical resistance. This property ensures that products protected by TPU can withstand exposure to various substances without degrading. As a result, industries can maintain the integrity of their products, leading to reduced maintenance costs and improved longevity.

The Role of Film Manufacturers in India

Quality TPU film and protective solutions in India are driven by the efforts of dedicated TPU film manufacturers. These manufacturers are committed to producing high-quality TPU films that meet international standards and cater to the diverse needs of their customers. By investing in advanced manufacturing technologies and rigorous quality control processes, TPU film manufacturers in India ensure that their products deliver consistent performance and reliability.

Moreover, these manufacturers actively engage with their clients to understand their unique requirements, enabling them to develop tailored solutions that address specific challenges. This collaborative approach fosters innovation and helps businesses stay competitive in an ever-evolving market.

Innovations in TPU Film Technology

The quality TPU film and protective solutions in India are continually evolving, thanks to ongoing research and development efforts. Manufacturers are exploring new formulations and processing techniques to enhance the performance characteristics of TPU films. Innovations such as self-healing TPU films and antimicrobial TPU coatings are gaining traction, further expanding the potential applications of this versatile material.

These advancements not only improve the functional properties of TPU film but also contribute to sustainability. By developing eco-friendly TPU formulations and recycling processes, manufacturers are working towards reducing the environmental impact of their products while meeting the growing demand for sustainable solutions.

Market Trends and Future Prospects

The quality TPU film and protective solutions in India are witnessing significant growth, driven by increasing demand across various industries. As businesses seek to enhance product durability and performance, the adoption of TPU solutions is expected to rise. The automotive and electronics sectors, in particular, are poised for substantial growth, creating opportunities for TPU film manufacturers to expand their offerings.

Additionally, the growing emphasis on sustainability is influencing the TPU film market. Manufacturers are exploring biodegradable TPU alternatives and recycling initiatives, aligning their products with global sustainability goals. This trend presents an exciting opportunity for businesses to leverage eco-friendly solutions while meeting consumer expectations for responsible manufacturing.

Conclusion

In conclusion, quality TPU film and protective solutions in India are integral to various industries seeking durable, flexible, and protective materials. With the commitment of TPU film manufacturers in India to deliver high-quality products and the continuous innovations in TPU technology, businesses can expect enhanced performance and reliability from their protective solutions. As the market for TPU film continues to grow, industries are well-positioned to benefit from the advantages of Thermoplastic polyurethane in india, paving the way for a more sustainable and efficient future.

Frequently Asked Questions (FAQs) Related to TPU Film

Q1: What is TPU film, and what are its main properties? A1: TPU film is made from thermoplastic polyurethane, known for its exceptional flexibility, durability, and resistance to abrasion, oil, and grease. These properties make it suitable for various applications, including automotive, electronics, and textiles.

Q2: How does TPU protective film differ from other protective films? A2: TPU protective film offers superior flexibility and resistance to environmental factors compared to traditional protective films. Its self-healing properties and chemical resistance also make it more durable and reliable.

Q3: What industries commonly use TPU film in India? A3: TPU film is widely used in industries such as automotive, electronics, textiles, and packaging. Its versatility allows it to meet the unique demands of various applications across these sectors.

Q4: Are there eco-friendly TPU film options available? A4: Yes, many TPU film manufacturers are exploring biodegradable TPU formulations and recycling processes to reduce the environmental impact of their products, aligning with global sustainability initiatives.

0 notes

Text

Global Top 15 Companies Accounted for 39% of total Waterproof Fabrics market (QYResearch, 2021)

Waterproof fabrics are fabrics that are inherently, or have been treated to become, resistant to penetration by water and wetting. They are usually natural or synthetic fabrics that are laminated to or coated with a waterproofing material such as rubber, polyvinyl chloride (PVC), polyurethane (PU), silicone elastomer, fluoropolymers, and wax.

In this report we focus on raw membrane material.

According to the new market research report “Global Waterproof Fabrics Market Report 2023-2029”, published by QYResearch, the global Waterproof Fabrics market size is projected to reach USD 2.12 billion by 2029, at a CAGR of 3.9% during the forecast period.

Figure. Global Waterproof Fabrics Market Size (US$ Million), 2018-2029

Figure. Global Waterproof Fabrics Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Waterproof Fabrics include Gore, Performax, Toray Industries, Polartec Neoshell, Swmintl, Sympatex, DSM, Carrington Textiles, Derekduck, Porelle Membranes, etc. In 2021, the global top five players had a share approximately 39.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

0 notes

Text

Rubber Coated Fabric Market Size, Opportunities, Share, Industry Analysis, Top Suppliers, Growth, Regional Trends, Key Segments, Graph and Forecast

Rubber-coated fabric is a material composed of a flexible fabric substrate coated with a layer of rubber or elastomer. This coating provides the fabric with enhanced properties such as waterproofing, durability, and resistance to abrasion, chemicals, and UV rays. Rubber-coated fabrics find applications in various industries including automotive, marine, aerospace, and outdoor gear for…

View On WordPress

0 notes

Text

Natural Rubber or Neoprene - How To Choose the Best?

Two materials that are frequently utilized to create various components are neoprene and natural rubber. Selecting the appropriate material for the task is crucial to optimizing the lifespan, robustness, and effectiveness of every component. You must understand the distinction between rubber and neoprene if you want to make sure your parts withstand abrasion and wear.

Natural rubber and neoprene both have special qualities that enable them to be used for a variety of purposes. You'll be able to choose the ideal rubber products online in Netherlands for your needs after you know what each material is and how it's created. To assist you in choosing the best medium for your operation, let's compare these materials.

About Natural Rubber

Rubber is frequently used to make a variety of goods, including silly putty, gaskets, and tractor tires. Although the latex used to make natural rubber is produced by approximately 200 plants, including dandelion, this material was traditionally solely available from natural sources, such as the rubber tree. Neoprene, the first synthetic rubber, was created in 1930, however. Today's market offers a vast array of synthetic rubber products online in Netherlands, including the original, made from petrochemicals.

About Neoprene

Neoprene, sometimes referred to as polychloroprene, is a particular kind of synthetic rubber composed of polymers containing carbon, hydrogen, and chlorine. Neoprene's resistance to water, oil, temperature changes, and solvents is derived from the cross-linking of these polymers, which also gives it its chemical inertness. Neoprene finds its application in automotive and industrial applications, as well as in corrosion-resistant coatings, electrical insulators, and materials subjected to severe weather and wear and tear. Its softness, wearability, and flexibility make it a favourite in the packaging, safety, and medical sectors. It is also helpful in building because of its resilience to weather and compression. Because of its insulating and waterproof properties, it is also utilized for maritime gear such as wetsuits and as a replacement for latex in gloves.

Neoprene Vs Rubber

Neoprene and natural rubber are similar to several other rubber compounds in a few ways. When you require rubber products online in Netherlands for your purposes, there are a few significant distinctions that will significantly influence which material you should pick.

Resistance to Various Material: Neoprene is designed to flourish in conditions where other fabrics cannot. Neoprene is very helpful for any parts that may come into contact with petroleum and oil. Neoprene components have a high level of resistance to ozone, UV, and other ageing agents.

Although natural rubber has additional benefits, it may not work well in applications that call for certain resistances. When it comes to light, oil, chemicals, and other obstacles, natural rubber is not particularly resilient. It shouldn't be the default option in these kinds of situations.

Reaction to Temperature: Neoprene is often a preferable choice if high temperatures are a concern, depending on your precise temperature needs. While natural rubber is certified for temperatures as low as 175 degrees, neoprene can withstand temperatures as high as 250 degrees Fahrenheit. In comparison to other elastomers, neoprene has superior flame-retardant properties.

Durability: In applications requiring a lot of physical exertion, natural rubber is especially resilient and resilient. High tensile strength and superior resistance to abrasion and tearing are two qualities of natural rubber. It is a great option for shock absorbers that deal with frequent contact and other problems because of these features.

Neoprene is incredibly durable, while not being as robust as natural rubber. It is not insignificant for demanding applications because of its tensile elongation, tear resistance, strength, and which are comparable to those of natural rubber.

Cost: Neoprene costs far more than other rubbers because of its increased resilience to temperature changes, enhanced durability, and superior material resistance. Neoprene's high strength and manufacturing process will drive up the cost of any project in which it is used. But in exchange, you get a rubber that can more easily withstand harsh circumstances. Hopefully, the information is helpful. If you still are a little confused, consult a professional to get the best rubber products online in Netherlands before choosing any one of the two.

0 notes

Text

Pipeline Thermal Insulation Materials Market Share, Trends, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global pipeline thermal insulation materials market size at USD 2.64 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects global pipeline thermal insulation materials market size is projected to grow at an impressive CAGR of 5.96% reaching a value of USD 3.94 billion by 2029. Pipe insulation materials are regarded as necessary because of their capacity to maintain pipes and any substance that travels through them at an acceptable or desired temperature, including steam, hot air, and thermic fluid. Due to demand from several industries, including chemical and petrochemicals, food processing, and oil & gas sectors, the global market for pipe insulation materials is expanding.

Global Pipeline Thermal Insulation Materials Market - Overview

Pipeline thermal insulation is a pipe covering that not only prevents heat loss but also reduces operating expenses and energy consumption. Moreover, it helps prevent corrosion caused by sudden temperature swings and pipeline leaks. Pipelines can be built using a variety of materials, depending on their intended application. Thermoplastic elastomers like polyethylene, PVC, and other plastic resins are used to make the item. In other cases, fiberglass- or kevlar-based nonwoven fabric is used. Nonstick coatings are applied to metal alloys including stainless steel and nickel alloys.

Sample Request @ https://www.blueweaveconsulting.com/report/pipeline-thermal-insulation-materials-market/report-sample

Global Pipeline Thermal Insulation Materials Market – By End Use Industry

The global pipeline thermal insulation materials market is segmented into Chemicals, Pharmaceuticals, Food & Beverages, Power Plant, Oil & Gas, Mining & Metallurgy, and others based on end use. The pharmaceuticals segment commands the highest market share. Some applications for pipeline thermal insulation in the pharmaceutical sector include the ones listed below: to reduce heat transmission through pipes. To stop condensation from forming on cold surfaces inside insulated pipe systems, which causes corrosion. Pipeline thermal insulation is a reliable technique for avoiding corrosion-causing condensation from developing on chilly walls inside insulated piping systems. Thermal insulation for pipelines is advantageous for chemical businesses, as it helps reduce heat loss (hot or cold) and corrosion brought on by contact with water.

Impact of COVID-19 on Global Pipeline Thermal Insulation Materials Market

COVID-19's rapid spread affected industries worldwide. As a result, economic conditions deteriorated significantly, and the government was forced to shut down the business and educational sectors for an extended period. During the COVID-19 epidemic, most countries-imposed lockdown, which is now being phased out industry by industry. The manufacturing industry has suffered significantly as a result of temporary facility closures. Labor and raw material shortages caused by the lockdown have an impact on the pipeline thermal insulation materials industry.

Competitive Landscape

Global pipeline thermal insulation materials market is fiercely competitive. Prominent players in the market include Rockwool International, Owenscorning, DowDuPont, Lfhuaneng, Murugappa Morgan, Shanghai ABM Rock Wool, NGP Industries, Goenka Rockwool, Dhanbad Rockwool Insulation, U.P. Twiga Fiberglass, Thermocare Rockwool, Aspen Aerogels, Shree Ceramic Fibers, and Montex Glass Fibre Industries. These companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in the global pipeline thermal insulation materials market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Thermoplastic Polyurethane (TPU) Films Market Size, Growth Perspectives, Development Technology, SWOT Analysis, and Forecast by 2030

Thermoplastic polyurethane (TPU) films are a type of plastic film made from thermoplastic polyurethane material. TPU is a versatile polymer that exhibits properties of both thermoplastics and elastomers, making it suitable for a wide range of applications. TPU films are known for their excellent flexibility, durability, and mechanical properties, which make them highly desirable for various industrial and consumer applications.

Some key characteristics of TPU films include:

Flexibility: TPU films are highly flexible, allowing them to be used in applications that require bending, stretching, or conforming to complex shapes. They are resistant to cracking and splitting even when subjected to repeated flexing or bending, making them suitable for use in products that require durability and flexibility, such as sportswear, footwear, and inflatable products.

Transparency: TPU films are typically transparent or translucent, allowing for visual clarity and enabling them to be used in applications that require transparency, such as protective covers for electronic devices, medical products, and packaging films.

Chemical resistance: TPU films exhibit good resistance to various chemicals, oils, and solvents, making them suitable for use in applications that require exposure to harsh chemicals, such as automotive components, industrial seals, and membranes for filtration.

Moisture resistance: TPU films have low moisture absorption and excellent moisture barrier properties, making them suitable for use in applications that require protection against moisture or water, such as outdoor gear, rainwear, and protective covers.

UV resistance: TPU films are typically UV resistant, which makes them suitable for outdoor applications where exposure to sunlight and weathering is a concern, such as automotive interiors, outdoor signage, and awnings.

Breathability: TPU films can be engineered to be breathable, allowing for air and moisture vapor transmission while maintaining water resistance. This makes them suitable for applications such as breathable fabrics, medical dressings, and hygiene products.

Processability: TPU films can be easily processed using various techniques such as extrusion, lamination, and coating, making them versatile and adaptable to different manufacturing processes.

Some common applications of TPU films include automotive components, footwear, apparel, inflatable products, protective covers for electronic devices, medical products, outdoor gear, sports equipment, industrial seals, and membranes for filtration, among others.

The thermoplastic polyurethane (TPU) films market refers to the global industry that involves the production, distribution, and use of films made from thermoplastic polyurethane materials. TPU films are a type of polymer film that are known for their unique combination of properties, including flexibility, transparency, durability, and resistance to abrasion, chemicals, and UV radiation. These films are widely used in various applications across industries such as automotive, aerospace, electronics, packaging, medical, and textile, among others.

The TPU films market has been experiencing steady growth due to increasing demand from various end-use industries. The automotive industry, in particular, has been a major driver for the TPU films market, as TPU films are used in automotive interiors, exteriors, and under-the-hood applications, providing excellent performance characteristics such as scratch resistance, moisture resistance, and flexibility. Additionally, the growing demand for TPU films in the medical industry for applications such as wound dressings, surgical drapes, and inflatable medical devices, has also contributed to the market's growth.

The packaging industry has also been a significant contributor to the TPU films market, with TPU films being used in flexible packaging applications due to their excellent barrier properties, puncture resistance, and flexibility. TPU films are also used in sports and leisure applications, such as protective gear, inflatable toys, and sportswear, due to their durability, flexibility, and comfort.

Geographically, the TPU films market is global in nature, with Asia-Pacific being a prominent region in terms of production and consumption. The region's growing automotive, electronics, and packaging industries, along with the availability of low-cost raw materials and labor, have fueled the demand for TPU films. Other regions such as North America, Europe, Latin America, and the Middle East and Africa also contribute to the TPU films market, driven by various end-use industries and applications.

Some of the key players in the global thermoplastic polyurethane (TPU) films market are 3M, American Polyfilm Inc., Avery Dennison Corporation, Covestro AG, Ding Zing Advanced Materials Inc., Gerlinger Industries GmbH, Huntsman International LLC, Okura Industrial Co. Ltd, Permali Gloucester Ltd, Schweitzer-Mauduit International Inc., Wiman Corporation, and The Lubrizol Corporation

The demand for thermoplastic polyurethane (TPU) films has been steadily increasing over the years, driven by various factors across different end-use industries. Some of the key factors influencing the demand for TPU films in the market include:

✦ Automotive Industry: The automotive industry is a major consumer of TPU films, with applications in automotive interiors, exteriors, and under-the-hood components. The demand for TPU films in the automotive sector is driven by their properties such as scratch resistance, moisture resistance, and flexibility, which make them ideal for use in automotive applications such as instrument panels, airbags, and door panels.

✦ Packaging Industry: TPU films are extensively used in the packaging industry due to their excellent barrier properties, puncture resistance, and flexibility. They are used in flexible packaging applications, including food packaging, medical packaging, and industrial packaging, where they provide protection to the contents, extend shelf life, and enhance aesthetics.

✦ Medical Industry: TPU films find extensive applications in the medical industry, including wound dressings, surgical drapes, and inflatable medical devices. The demand for TPU films in the medical sector is driven by their biocompatibility, flexibility, and resistance to chemicals and moisture, which make them suitable for medical applications requiring high performance and safety standards.

✦ Textile Industry: TPU films are used in the textile industry for various applications such as laminates, membranes, and coatings in sportswear, footwear, and other textile products. The demand for TPU films in the textile industry is driven by their properties such as breathability, flexibility, and durability, which enhance the performance and comfort of textile products.

✦ Electronics Industry: TPU films are used in the electronics industry for applications such as protective films for displays, keypads, and touchscreens, as well as for cable coatings and insulations. The demand for TPU films in the electronics industry is driven by their transparency, flexibility, and resistance to chemicals and UV radiation, which make them suitable for electronic applications that require high performance and durability.

✦ Sports and Leisure Industry: TPU films are used in the sports and leisure industry for applications such as protective gear, inflatable toys, and sportswear. The demand for TPU films in this industry is driven by their properties such as durability, flexibility, and comfort, which enhance the performance and safety of sports and leisure products.

The thermoplastic polyurethane (TPU) films market offers several benefits to various stakeholders, including manufacturers, end-users, and the overall industry. Some of the key benefits of the TPU films market are:

◘ Versatility: TPU films are known for their versatility, as they can be produced in a wide range of thicknesses, widths, and colors, and can be used in a diverse array of applications across various industries. This versatility allows for customization and adaptation to different requirements, making TPU films suitable for a wide range of end-use applications.

◘ Excellent Properties: TPU films exhibit a unique combination of properties, including flexibility, transparency, durability, and resistance to abrasion, chemicals, and UV radiation. These properties make TPU films ideal for demanding applications where performance, reliability, and durability are crucial, such as automotive interiors and exteriors, medical applications, and protective gear, among others.

◘ High Performance: TPU films are known for their high-performance characteristics, such as excellent mechanical properties, good chemical resistance, and high abrasion resistance. They also have good thermal stability and can withstand extreme temperatures, making them suitable for a wide range of challenging environments and applications.

◘ Enhanced Product Performance: TPU films can enhance the performance of end-products in various industries. For example, in the automotive industry, TPU films can provide scratch resistance, moisture resistance, and flexibility to automotive interiors, improving the overall aesthetics and durability of the vehicle. In the medical industry, TPU films can provide biocompatibility, flexibility, and resistance to chemicals, enhancing the safety and reliability of medical devices.

◘ Sustainability: TPU films can offer sustainability benefits as well. Some TPU films are available in bio-based formulations, which are derived from renewable sources and can help reduce the environmental footprint of the end-products. Additionally, TPU films are recyclable and can be processed into new products or used as energy sources, contributing to the circular economy and reducing waste.

◘ Wide Range of Applications: TPU films find applications across a wide range of industries, including automotive, packaging, medical, textile, electronics, sports and leisure, and more. This diverse range of applications provides opportunities for manufacturers to cater to different markets and industries, expanding their customer base and business opportunities.

◘ Cost-Effective: TPU films can offer cost-effective solutions due to their excellent performance characteristics, which can result in longer product lifespan, reduced maintenance costs, and improved product reliability. Additionally, TPU films can be processed using conventional techniques, such as extrusion and lamination, which can help optimize manufacturing processes and reduce production costs.

In summary, the thermoplastic polyurethane (TPU) films market offers several benefits, including versatility, excellent properties, high performance, enhanced product performance, sustainability, wide range of applications, and cost-effectiveness. These benefits make TPU films a preferred choice for many industries and applications, driving the growth of the TPU films market.

0 notes

Text

The coated fabrics market is estimated to reach a value of USD 36.96 billion by 2028 and is expected to grow at a compound annual growth rate of 4.65% for the forecast period of 2021 to 2028.

#coated fabrics market#coated fabrics market size#elastomer coated fabrics market#global polymer coated fabrics market size

0 notes

Text

Elastomer Coated Fabrics Market 2022 Development Status, Industry Insights and Forecast Research Report 2030

Elastomer Coated Fabrics Products Market is projected to be worth USD 13.4 Billion by 2030, registering a CAGR of 5% during the forecast period (2021 - 2030).

Elastomer coated fabrics are manufactured by automated machines that are used for coating. It provides significant properties such as excellent elasticity, visibility along with UV resistance to the finished material. Moreover, they provide versatility and reliability to the product.

The global COVID-19 analysis on Elastomer Coated Fabrics Products Market has been driven by the range of its application in various uses such as transportation, protective clothing, industrial, roofing, awnings & canopies, furniture & seating, and others. Moreover, it is estimated that the transportation segment is set to witness the highest growth in the market due to the growing consumption of coated fabrics to add extraordinary features such as water and dirt repellence to the product.

Elastomer Coated Fabrics Products Market Segmentation

The global market is segregated into product, and application.

On the basis of the elastomer coated fabrics industry product, the market is further categorized into silicones, thermoplastic olefin, thermoplastic polyurethane, and rubber segments.

On the basis of the application, the market is segregated into transportation, protective clothing, industrial, roofing, awnings & canopies, furniture & seating, and others.

Market Scenario

The silicone product is the leading segment of the market on account of its growing consumption in transportation, protective clothing, industrial and other applications. These materials provide enhanced structural properties to the product.

The transportation segment is the leading application in the market and is anticipated to observe a higher CAGR due to extensive use of coated fabrics to add UV along with corrosion resistance features to the product.

Elastomer Coated Fabrics Products Market Regional Analysis

The elastomer coated fabrics industry share is spanned across five key regions: Asia Pacific, North America, Europe, Latin America, and the Middle East & Africa. Among these, Asia Pacific holds the major portion of the global market and is anticipated to continue its dominance due to rising demand for the lightest metal in various applications. Countries such as China, Japan, and India are the major players in this region. The North American region is estimated to witness a higher growth in the U.S., Canada, and Mexico owing to increasing demand for fabrics in automotive, aircraft, marine, railways, and others. The enactment of new rules and regulations set by the European Union has driven the manufacturers to use optimal products in end-use industries. Moreover, it is projected that the advancing research & development of coated fabrics in the market has propelled this region to witness a significant growth in Germany, the U.K, and Italy.

Elastomer Coated Fabrics Products Market Competitive Analysis

Some of the major players functioning in the global Elastomer Coated Fabrics Products Market growth are Continental AG (Germany.), Low & Bonar PLC (Mehler Texnologies) (India), Saint-Gobain S.A. (France), OMNOVA Solutions Inc. (U.S.), Takata Corporation (Japan), Seaman Corporation (U.S.), Serge Ferrari (France), Sioen Industries NV (Belgium), Spradling International, Inc. (U.S.), and SRF Limited (India), among others.

Access Full Report Details and Order this Premium Report @ https://www.marketresearchfuture.com/reports/elastomer-coated-fabrics-market-5070

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans conducts meet with the industry experts and industrial visits for its research analyst members.

#Elastomer Coated Fabrics#Elastomer Coated Fabrics Market#Global Elastomer Coated Fabrics Market#Elastomer Coated Fabrics Industry

0 notes

Link

0 notes

Text

2021-2026 Elastomer Coated Fabrics Market Report | Analysis, Modeling, Risk Factors, Growth Strategies, Drivers, Dynamics, Forecast and more

2021-2026 Elastomer Coated Fabrics Market Report | Analysis, Modeling, Risk Factors, Growth Strategies, Drivers, Dynamics, Forecast and more

A research assessment conducted to provide a thorough analysis of the Elastomer Coated Fabrics Market and different parts of the market mostly envelops the market dynamics stating the complete market segment starting the market size and share worldwide defined and the Elastomer Coated Fabrics market circumstance including the sales and marketing strategies, supply chain and financial status.…

View On WordPress

#Elastomer Coated Fabrics Market#Elastomer Coated Fabrics Market Outlook#Elastomer Coated Fabrics Market Report

0 notes

Photo

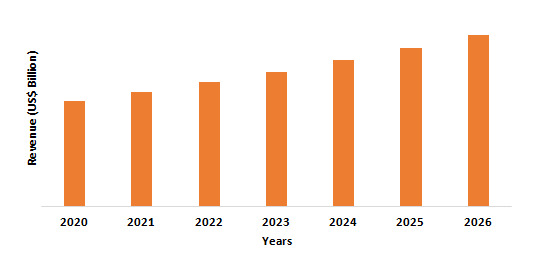

Elastomer coated fabrics market is expected to gain market growth in the forecast period of 2020 to 2027. Data Bridge Market Research analyses that the market is growing at a CAGR of 6.2% in the forecast period of 2020 to 2027and expected to reach USD 9,842.61 million by 2027. High availability of fabric raw material in the region is boosting the market growth.

#Asia-Pacific Elastomer Coated Fabrics Market#Asia-Pacific Elastomer Coated Fabrics Market Size#Asia-Pacific Elastomer Coated Fabrics Market Share#Asia-Pacific Elastomer Coated Fabrics Market Future

0 notes