#EO gas sterilizers

Explore tagged Tumblr posts

Text

Cath Lab ETO Sterilizer

Cath lab ethylene oxide sterilizer is one of the key machines commonly used in pharmaceutical, textile, healthcare and food industries among others. Adinath International is a leading cath lab hospital EO sterilizer manufacturer in India offering cath lab sterilizer equipped with plethora of features.

Cath lab ETO sterilizer is also known as hospital ETO sterilizer and is uses to sterilize medical and pharmaceutical products which cannot be sterilized using conventional high temperature steam sterilization methods. Such products include devices which are made of electronic components or plastic packaging containers. As a leading manufacturer and supplier of cath lab ETO sterilizer in India, Adinath International offers EO gas sterilizers of the following two types:

Fully Automatic EO sterilizer

Semi-Automatic EO sterilizer

Cath lab ETO sterilizer is an ultra-modern sterilizer that is vastly used in the sterilization of medical, surgical and pharmaceutical products. Ethylene oxide sterilization is an advanced method to sterilize medical devices and other heat sensitive devices. As a pioneering cath lab ethylene oxide supplier in India, we provide advanced hospital EO sterilizer that is not only safe to use but eco-friendly as well. A vast array of delicate devices which are otherwise impossible to sterilize by deploying conventional methods can be seamlessly sterilized using this ultra-modern sterilizer.

#ETO Sterilizer#Cath lab ethylene oxide sterilizer#cath lab hospital EO sterilizer#EO gas sterilizers

0 notes

Text

Tappi per inchiostro sterili : innalza i tuoi standard di tatuaggio

Mantenere un ambiente sterile è fondamentale per i tatuatori. I cappucci per inchiostro sterili sono uno strumento essenziale, che garantisce igiene e precisione durante ogni sessione. Ecco perché questi piccoli accessori svolgono un ruolo importante nella configurazione del tuo tatuaggio.

Cosa sono i cappucci sterili per inchiostro?

I tappi per inchiostro sterili sono contenitori monouso progettati per contenere l'inchiostro per tatuaggi. Realizzati in plastica resistente, sono confezionati singolarmente e sterilizzati con gas EO. Questi tappi sono disponibili in varie dimensioni, in genere 9 mm o 16 mm, per soddisfare le diverse esigenze di volume di inchiostro.

Vantaggi dell'utilizzo di tappi di inchiostro sterili

1. Garantisce igiene e sicurezza I tappi di inchiostro sterili riducono il rischio di contaminazione, proteggendo sia l'artista che il cliente. Ogni tappo è pre-sterilizzato, offrendo uno spazio di lavoro pulito e mantenendo la purezza dell'inchiostro.

2. Comodi e facili da usare Grazie alla confezione monouso, i tappi per inchiostro sterili consentono di risparmiare tempo durante l'installazione. Apri, posiziona e riempi: semplice. Una volta terminata la sessione, smaltiscili per mantenere ordinato lo spazio di lavoro.

3. Materiale durevole per la stabilità Realizzati in plastica di alta qualità, questi tappi sono progettati per resistere alla pressione e prevenire le fuoriuscite, garantendo un flusso di lavoro regolare.

4. Versatili per tutti gli stili di tatuaggio Che tu stia lavorando su linee complesse o ombreggiature, i cappucci per inchiostro sterili contengono diverse quantità di pigmento, rendendoli ideali per diverse tecniche di tatuaggio.

Come usare efficacemente i tappi di inchiostro sterili

Preparazione: aprire la confezione sterile e posizionare i tappi su una superficie pulita o su un porta tappi per inchiostro.

Riempimento: versare l'inchiostro richiesto in ogni tappo. Evitare di riempire eccessivamente per evitare fuoriuscite.

Dopo la sessione: smaltire responsabilmente i tappi usati per preservare l'igiene.

Perché scegliere i nostri cappucci per inchiostro sterili?

A In MaxShop , diamo priorità alla qualità e alla sicurezza. I nostri tappi per inchiostro sterili sono rigorosamente testati e sono conformi agli standard del settore. Disponibili in comode confezioni da 200 (9 mm) o 150 (16 mm), questi tappi offrono un ottimo rapporto qualità-prezzo per i professionisti. Inoltre, gli ordini all'ingrosso sono accompagnati da sconti interessanti, il che li rende convenienti per un utilizzo su larga scala.

Domande frequenti

D1: Questi cappucci per inchiostro sono adatti a tutti i tipi di pelle? Sì, i nostri cappucci per inchiostro sono sterili e sicuri, garantendo la compatibilità con tutti i tipi di pelle.

D2: Posso riutilizzare questi tappi dopo averli sterilizzati? No, questi tappi sono progettati per essere monouso per garantire un'igiene e una sicurezza ottimali.

D3: Quali sono le dimensioni disponibili? Offriamo tappi da 9 mm e 16 mm, perfetti per diverse esigenze di inchiostro.

Ordini all'ingrosso e sconti

Fai scorta di tappi di inchiostro sterili per non rimanere mai senza durante le sessioni di punta. Offriamo sconti per ordini di cinque unità o più, aiutandoti a risparmiare fino al 30%. Consegna rapida e una politica di reso di 14 giorni assicurano un'esperienza di acquisto senza intoppi.

Perché affidarsi a I MAX International?

Con oltre 30 anni di esperienza, I MAX International è un nome affidabile nel settore delle forniture per tatuaggi. Il nostro vasto catalogo include più di 10.000 prodotti di qualità, assicurandoti di trovare tutto ciò di cui hai bisogno sotto lo stesso tetto. Dall'inchiostro per tatuaggi agli accessori, ci impegniamo a supportare gli artisti in tutto il mondo.

Rimani aggiornato sulle ultime offerte

Iscriviti alla nostra newsletter per ricevere aggiornamenti su nuovi prodotti, sconti e novità del settore. Unisciti a una community di artisti che danno priorità alla qualità e all'innovazione.

Per maggiori informazioni visita ora: IMaxShop

0 notes

Text

eo sterilizer manufacturers

Introduction to ETO Sterilizers

Definition and Purpose

ETO sterilizers utilize Ethylene Oxide gas to achieve high-level disinfection and sterilization of medical equipment, pharmaceuticals, and other sensitive materials. This method is crucial for industries where heat or moisture-sensitive items need to be sterilized effectively.

Applications of ETO Sterilizers

Healthcare Facilities

Hospitals, clinics, ASCs, and nursing homes rely on ETO sterilizers for sterilizing surgical instruments, implantable devices, and other critical medical equipment that cannot withstand traditional autoclave methods.

Pharmaceutical Industry

Pharmaceutical manufacturing plants and R&D laboratories use ETO sterilization to ensure sterility of medications, drug packaging, and equipment before distribution to maintain product integrity and patient safety.

Medical Device Manufacturers

Manufacturers use ETO sterilization to comply with regulatory requirements and ensure medical devices are safe for use, particularly those with complex designs or made of heat-sensitive materials.

Laboratories

Research and testing laboratories utilize ETO sterilization for sterilizing glassware, instruments, and sensitive lab equipment to prevent cross-contamination and maintain the integrity of experiments and research.

Veterinary Clinics and Hospitals

ETO sterilizers are employed in veterinary practices to sterilize surgical instruments and equipment used in animal care, ensuring safety and preventing infections among animals.

Food Industry

Food processing plants use ETO sterilization to sterilize packaging materials, food containers, and processing equipment to eliminate pathogens and ensure food safety before products reach consumers.

Cosmetics Industry

ETO sterilizers are used in the cosmetics industry to sterilize equipment and containers used in the production and packaging of cosmetics to prevent contamination and ensure product safety.

Government Agencies

Public health departments and regulatory bodies require ETO sterilization for ensuring compliance with stringent sterilization standards and regulations to protect public health and safety.

Contract Sterilization Service Providers

Companies specializing in contract sterilization offer ETO sterilization services to various industries, providing cost-effective solutions for businesses that do not have in-house sterilization capabilities.

Features of ETO Sterilizers

Sterilization Process

ETO gas penetrates packaging materials and intricate devices, ensuring thorough sterilization without causing damage to sensitive components.

The sterilization cycle includes stages for gas exposure, aeration, and off-gassing to ensure safety before items can be used.

Safety Features

ETO sterilizers are equipped with advanced safety features such as gas monitoring systems to maintain safe levels of ETO gas during sterilization cycles.

Ventilation and aeration systems are crucial to ensure the removal of residual ETO gas from sterilized items before they can be handled safely.

Material Compatibility

ETO sterilization is suitable for a wide range of materials, including plastics, rubber, electronics, and certain metals, making it versatile for various industry applications.

Manufacturers conduct compatibility testing to ensure materials can withstand ETO sterilization without compromising their structural integrity or performance.

Considerations When Choosing ETO Sterilizer Manufacturers

Regulatory Compliance

ETO sterilizer manufacturers must adhere to FDA and international regulatory standards for medical device sterilization and ensure their equipment meets stringent safety and efficacy requirements.

Certifications such as ISO 13485 and CE marking indicate compliance with quality management systems and product safety standards.

Customization Options

Manufacturers offer customized ETO sterilizer solutions tailored to specific industry needs, including modular designs that accommodate different sterilization volumes and throughput requirements.

Scalable options allow businesses to expand their sterilization capacity as needed without compromising operational efficiency.

Technical Support and Service

Choosing a reliable ETO sterilizer manufacturer involves evaluating their technical support capabilities, including availability of service technicians, spare parts availability, and maintenance contracts to minimize downtime and ensure equipment reliability.

Leading ETO Sterilizer Manufacturers

Cistron Systems

Cistron systems ,We are certified EO Sterilizer Manufacturers we design, supply and qualify Ethylene Oxide Sterilizers (EO) for the sterilization of thermo sensitive products (sensitive to heat and humidity) like sutures, syringes, plastic dressings, catheters, dialysis cartridges, etc.

Future Trends in ETO Sterilization Technology

Advancements in Sterilization Techniques

Ongoing research aims to enhance ETO sterilization efficiency and reduce cycle times through innovative technologies and automation.

Integration of IoT and data analytics could improve sterilization process monitoring and equipment performance.

Environmental Considerations

Future trends focus on developing eco-friendly ETO sterilization methods that minimize environmental impact, such as reducing ETO emissions and optimizing gas consumption.

Sustainable practices in sterilization aim to meet regulatory requirements while promoting environmental stewardship in healthcare and industrial sectors.

Conclusion

Summary of Key Points

ETO sterilizers play a critical role in ensuring sterility and safety across various industries, from healthcare to food processing.

Choosing the right ETO sterilizer manufacturer involves considering regulatory compliance, customization options, and technical support to meet specific industry needs.

Final Thoughts on Choosing ETO Sterilizer Manufacturers

As industries evolve, the demand for reliable ETO sterilization solutions will continue to grow, emphasizing the importance of partnering with reputable manufacturers committed to innovation and quality.

0 notes

Text

Unlocking the Power of Ethylene Oxide: From Production to Practical Applications

Hello and welcome to our blog about Ethylene Oxide – a unique and indispensable substance in different areas of our life. Ethylene Oxide is one of the most important organic compounds as it has many uses and chemical properties. In this blog, we explore the use of Ethylene Oxide in various industries ranging from pharmaceuticals to agriculture and textiles among others. So, lets drive into it!

Introduction

Ethylene Oxide serves as a versatile chemical primarily utilized as an intermediate in the production of various industrial chemicals, notably Ethylene Glycol. Additionally, it functions as a surface disinfectant, particularly prevalent in the healthcare and medical equipment sectors, where it substitutes steam in sterilizing heat-sensitive tools such as disposable plastic syringes. Moreover, Ethylene Oxide finds extensive application in diverse sectors, including non-contact infrared thermometers, thermal imaging systems, liquid chemical sterilization, patient lifts, surgical staplers, household and industrial cleaners, cosmetics, shampoos, polyurethanes, heat transfer liquids, plasticizers, ointments, and various fabric applications.

Manufacturing Process

This blog unveils a process for manufacturing Ethylene Oxide which has several steps. The operations fall into four main stages:

Stage 1 involves EO reaction, EO recovery, and carbon dioxide removal

Stage 2 focuses on removing non-condensables and purifying EO

Stage 3 centers on glycols reaction and dewatering

Stage 4 deals with glycols purification.

Stage 1: EO Reaction, EO Recovery, and Carbon Dioxide Removal

Feedstock ethylene is commonly delivered via pipeline from a steam cracker. While air can supply oxygen in an air-based process, modern methods rely on pure oxygen from an air separation unit.

The reaction between ethylene and oxygen occurs in a fixed-bed reactor with a silver catalyst in the tubes and a coolant on the shell side. Heat from the exothermic reactions is managed by the coolant, which produces steam for heating various parts of the plant.

A substantial gas flow continuously circulates through the EO reactors. Reaction byproducts (EO, carbon dioxide, and water) are removed, while unreacted oxygen and ethylene are recycled. To mitigate fire and explosion risks, a diluent is added to the recycle gas, typically methane, enabling safe operation with higher oxygen levels.

A small amount of organic chlorinated compound is introduced to control catalyst performance, with resulting chlorine distributed across product and effluent streams. A vent stream, known as inerts purge, reduces the accumulation of inerts and impurities in the recycle gas. This vent gas is often used as fuel.

Additional ethylene, oxygen, and diluent are introduced into the recycle gas loop as needed.

To manage the significant influx of inert nitrogen from the air feed, a portion of the recycle gas was redirected to a secondary EO reactor, referred to as the purge-reactor, where the majority of the ethylene was converted. EO was extracted from the purge-reactor product gas through absorption in water, while the remaining gases (such as unreacted ethylene, nitrogen, and carbon dioxide) were released into the atmosphere.

EO mixes completely with water. At normal temperatures and without catalysts, EO's reactivity with H2O (leading to glycol formation) remains minimal across a broad pH spectrum, making water an effective medium for scrubbing EO for removal or recovery. The gas exiting the reactor is treated to recover EO by absorbing it into water. The resulting aqueous EO solution undergoes concentration in a stripper. From the top of the stripper, a concentrated EO-water mixture is directed to a stage for removing non-condensable substances and purifying EO (Stage 2). The bottom stream of the stripper consists of EO-free water, which is cooled and returned to the EO absorber.

Typically, one or more bleed streams are extracted from the EO recovery process to prevent the buildup of glycols and/or salts. These substances undergo further processing to reclaim EO and/or glycols.

A portion of the recycle gas exiting the EO absorber is directed through a column where carbon dioxide, produced during the oxidation process, is absorbed under pressure. It forms hydrogen carbonate in a heated potassium carbonate solution.

The carbon dioxide is then separated from the carbonate solution in an atmospheric stripper through a reverse reaction. The carbon dioxide released from the top of the stripper can be released into the atmosphere or reclaimed for other purposes, such as in carbonated drinks, following treatment to eliminate volatile organic compounds (VOCs). The regenerated carbonate solution from the bottom of the stripper is cooled and reused in the carbon dioxide absorber. The overhead stream from the absorber, now depleted of carbon dioxide, is combined again with the recycle gas stream and directed back to the EO reactor(s).

Step 2: Non-condensables removal and EO purification

After the initial separation process, the Ethylene Oxide (EO) and steam mixture is cleaned up. This purification step removes unwanted elements like carbon dioxide and excess ethylene. The unusable gases get sent back for recycling, while the cleaned-up EO-water mix gets separated. In most European plants, this mix gets distilled to extract high-purity EO. Leftover water might be reused or sent for further processing. The final EO product is chilled and stored. Since EO is a gas at normal temperatures, special storage methods are needed. It's typically kept under nitrogen and cooled, though pressurized storage is also an option. Any leftover EO gas from storage or other processes gets captured and recycled back into the system. Finally, for transport, EO is loaded onto pressurized railcars under a nitrogen blanket.

Step 3: Glycols reaction and dewatering

Glycols are produced by introducing a mixture of EO and water into a reactor operating at elevated temperatures, usually ranging between 150 and 250 °C. Under these conditions, reactions occur rapidly, requiring no catalyst. Sufficient residence time is provided to ensure complete conversion of EO. A reactor pressure typically between 10 and 40 barg is maintained to prevent EO vaporization. The feed to the reactor contains an excess of water to control the adiabatic temperature rise and enhance MEG selectivity. Generally, glycol products consist of 75 to 92 wt-% MEG, with the remaining portion comprising DEG and some TEG. All of the EO feed is converted into glycols, including MEG, DEG, TEG, or heavier glycols.

The output from the glycols reactor comprises different glycol products along with surplus water. This excess water is eliminated through multiple-effect evaporation followed by vacuum distillation. After heat exchange, the purified water is returned to the glycols reactor for reuse. A portion of the recycled water is extracted to prevent impurity buildup. Low-pressure steam produced in this process serves as a heat source in various sections of the plant.

Step 4 - Glycols purification

The glycol stream, now depleted of water, undergoes fractionation in several vacuum columns to separate and recover the different glycol products at high purity. The co-products in the MEG manufacturing process, in decreasing quantities, are diethylene glycol (DEG), triethylene glycol (TEG), and heavier glycols. These individual glycol products are then further purified through subsequent fractionation. After cooling, the glycol products are directed to storage. The residual stream from the final vacuum column contains the heavier glycols, which can either be sold for additional glycol recovery or disposed of, such as through incineration.

Step 5 - Crystallization Step

The crystallization step follows the barium removal process to precipitate Ethylene Oxide from the solution, yielding pure Ethylene Oxide. This ensures the removal of impurities, particularly barium ions, resulting in high-purity Ethylene Oxide suitable for various applications.

Crystallization techniques such as heat concentration or vacuum distillation are employed to precipitate Ethylene Oxide. Higher temperatures during crystallization expedite the process; however, subsequent drying at temperatures below 60°C prevents the release of water of crystallization, maintaining the product as hydrated Ethylene Oxide, which is easier to handle. Additional treatments like pulverization may be performed to adjust the physical properties of Ethylene Oxide as needed.

Applications of Ethylene Oxide

Chemical Industry

Ethylene Oxide is used majorly for the production of Ethylene Glycol. Ethylene Glycol is a multi-functional chemical. It serves as an antifreeze which is used in automotive coolant systems to prevent freezing and protect the engines from cold. It also plays a vital role as a raw material for the synthesis of polyester fibers and resins in the textile and plastic industries. Ethylene Glycol is used as a deicing fluid for planes and runways to enable them to operate even during the winter season. It is also a humectant in cosmetics, a heat transfer medium in industrial processes, and a solvent for paints and coatings. It is used as a chemical intermediate for the manufacture of several industrial chemicals that are essential in various industries hence can be considered as the most important industrial chemical. Additional derivatives of Ethylene Oxide find application in household cleaning products and personal care items like cosmetics and shampoos. These derivatives are also utilized in industrial cleaning solutions, heat transfer fluids, polyurethanes, and plasticizers.

2. Medical

Ethylene Oxide sterilization processes can sanitize medical and pharmaceutical products that cannot support conventional, high-temperature steam sterilization procedures. Medical devices that require Ethylene Oxide sterilization include heart valves, pacemakers, surgical kits, gowns, drapes, ventilators, syringes, and catheters.

3. Agriculture

Ethylene Oxide and its derivatives play a crucial role in producing a wide array of active and inactive components utilized in insecticides, pesticides, and herbicides, tailored to meet the specific needs of the agricultural sector, thereby safeguarding crops and enhancing agricultural productivity. In agricultural crop processing, Ethylene Oxide-based demulsifiers enhance the separation of oil from water, particularly in corn oil extraction within the bioethanol production process. The extracted oil finds applications in the food industry, animal feed production, or biodiesel manufacturing. Ethylene Oxide is also instrumental in producing industrial starches from agricultural sources, known as hydroxyethyl starches, which serve as versatile inputs in various industries such as adhesives, papermaking, and laundry starch. Additionally, in veterinary and animal surgical settings, Ethylene Oxide is utilized to sterilize medical equipment, surgical instruments, and procedure kits, ensuring optimal hygiene and safety standards.

4. Oil & Gas

Ethylene Oxide derivatives play a surprising role in making oil and gas production cleaner and more efficient. These compounds help purify natural gas, prevent pipeline corrosion, and even capture carbon emissions. They also speed up oil well operations and extend equipment life, ultimately lowering the cost of petroleum products. A key family of these derivatives – ethanolamines – even contributes to cleaner burning fuels by removing impurities.

Market Outlook

The primary use of Ethylene Oxide lies in its role as a chemical intermediate for synthesizing glycol ethers, acrylonitrile, ethoxylates, ethylene glycol, and polyether polyols, all of which find extensive applications across various downstream industries. The escalating demand for these derivatives from end-user sectors is a key driver propelling the global market forward. Among these derivatives, the Ethylene Glycol segment holds dominance globally, particularly due to its widespread utilization in automotive, packaging, and pharmaceutical industries. Ethylene Glycol serves as a crucial component in the production of polyester fibers, polyethylene terephthalate (PET) resins, and automotive antifreeze. Furthermore, the increasing global population, particularly in emerging economies, is fueling demand for personal and healthcare products, further augmenting the need for Ethylene Oxide.

Ethylene Oxide Major Global Producers

Major companies in the Global Ethylene Oxide market are Sinopec, BASF, Shell, Dow Chemical, Ningbo Henyuan, Nippon Shokubai Co., Ltd., Reliance Industries Limited, SINOPEC SABIC (TIANJIN) Petrochemical Company Limited, Maruzen Petrochemical Co., Ltd., PTT Global Chemical, Sasol Limited, Saudi Kayan Petrochemical Company, Nizhnekamskneftekhim, Indorama Ventures Public Company Limited, and Others.

Conclusion:

Ethylene Oxide serves primarily as a chemical precursor for the synthesis of glycol ethers, acrylonitrile, ethoxylates, ethylene glycol, and polyether polyols, essential components utilized across diverse industries. The rising demand from the chemical sector, particularly for chemicals like Ethylene Glycol is expected to propel the global Ethylene Oxide market in the foreseeable future. Furthermore, the increasing need within the medical industry for Ethylene Oxide to sterilize medical instruments and equipment is also contributing to the growth of the Ethylene Oxide market.

#ethyleneoxide#ethyleneoxideprices#ethyleneoxidemarket#ethyleneoxidenews#ethyleneoxidepricetrend#ethyleneoxidepriceforecast#ethyleneoxidedemand#ethyleneoxidesupply#ethyleneoxidemarketprice#priceofethyleneoxide

1 note

·

View note

Text

Ethylene Oxide (EO) Market Review: Trends and Future Prospects

Ethylene oxide (EO), a crucial chemical compound, serves as a cornerstone in various industries, owing to its versatile properties and wide-ranging applications. This blog aims to explore the dynamics of the global EO market, highlighting its demand drivers, key applications, emerging trends, and future prospects.

Understanding Ethylene Oxide (EO):

Ethylene oxide the chemical formula C2H4O, is a colorless and flammable gas at room temperature. It is primarily used as a precursor in the production of ethylene glycol, a vital ingredient in antifreeze, polyester fibers, and polyethylene terephthalate (PET) resins. EO also finds applications as a sterilant in the healthcare industry and as a chemical intermediate in various manufacturing processes.

Market Dynamics:

Polymer Industry Growth: The polymer industry is a major consumer of EO, primarily for the production of ethylene glycol, which serves as a raw material for PET resins used in beverage bottles, polyester fibers for textiles, and antifreeze in automotive applications.

Healthcare Sector Demand: EO is widely used in the healthcare industry for sterilization of medical devices and equipment due to its high efficacy in killing microorganisms and its compatibility with heat-sensitive materials.

Surfactant and Detergent Production: EO is a key ingredient in the production of surfactants and detergents, utilized in household cleaning products, personal care items, and industrial applications due to its ability to reduce surface tension and enhance cleaning properties.

Chemical Intermediates: EO serves as a versatile chemical intermediate in the synthesis of various organic compounds, including ethanolamines, glycol ethers, and polyols, which find applications in diverse industries such as textiles, coatings, and pharmaceuticals.

Applications Across Industries:

Polymer Industry: Ethylene glycol production for PET resins and polyester fibers.

Healthcare Sector: Sterilization of medical devices and equipment.

Surfactants and Detergents: Household cleaning products, personal care items.

Chemical Intermediates: Ethanolamines, glycol ethers, polyols for various industries.

Market Trends:

Sustainability Initiatives: The EO market is witnessing a growing demand for bio-based ethylene oxide and eco-friendly derivatives to address environmental concerns and meet regulatory requirements.

Technological Advancements: Ongoing research and development efforts focus on improving EO production processes, developing new applications, and enhancing product purity and safety standards.

Healthcare Sector Expansion: The healthcare industry's emphasis on infection control and sterilization drives the demand for EO as a sterilant, especially in emerging markets with growing healthcare infrastructure.

Future Prospects:

The global Ethylene Oxide market is poised for significant growth, driven by its diverse applications, expanding end-user industries, and technological advancements. As industries continue to prioritize sustainability, safety, and efficiency, EO remains a critical component in the chemical landscape, offering solutions to meet the evolving demands of modern applications.

Conclusion:

Ethylene Oxide's versatile applications and pivotal role in various industries underscore its significance in the global market. Navigating the EO market requires a deep understanding of market dynamics, emerging trends, and the evolving needs of industries. With a promising future shaped by sustainability initiatives and technological advancements, EO stands poised to continue as a key player in the chemical industry, driving innovation and progress in diverse applications worldwide.

0 notes

Text

0 notes

Text

Ethylene Oxide

Ethylene Oxide

called oxirane by IUPAC CAS#: 75-21-8 Used to sterilize medical equipment and supplies. Sterilization of medical devices. It is an organic compound with the formula C2H4O. It is a cyclic ether and the simplest epoxide. It is a basic chemical primarily produced by the catalytic oxidation of ethylene.

Categories: Ethylene Oxide Gas, Specialty GasesTags: C ₂H ₄O gas, Ethylene oxide, Ethylene oxide supplier

Description

Ethylene Oxide Cylinders

DSW industry offers Ethylene Oxide in various purity, packaged perfectly in multiple cylinder sizes and volumes, to ensure quality. C2H4O is available in 5 PPM-50 PPM concentrations in Nitrogen available in 12L, 34L, 58L or 110L cylinders. It is a flammable, colorless gas used to make other chemicals used in making a range of products, including antifreeze, textiles, plastics, detergents, and adhesives.

Ethylene Oxide specifications

raw materialC2H4OoriginSinopec2#-2019-02-350quantity3 tonwayBottle samplinginspection standardGB/T 13098-2008itemindexmeasured valueconclusionC2H4O %≧99.9599.99up to standardappearanceColorless transparent, no mechanical impuritiesColorless transparent, no mechanical impuritiesup to standardTotal aldehydes (in acetaldehyde) %≦0.003Check-in COAup to standardAcid (in acetic acid)≦0.002Check-in COAup to standardCO2 %≦0.001˂0.0005up to standardH2O %≦0.010.0062up to standardHazen≦5Check-in COAup to standardInspector; date:2019.02.25

Ethylene oxide – Wikipedia

Ethylene oxide is a colorless gas at 25 °C (77 °F) and is a mobile liquid at 0 °C (32 °F) – the viscosity of liquid ethylene oxide at 0 °C is about 5.5 times lower than that of water. The gas has a characteristic sweet odor of ether, noticeable when its concentration in the air exceeds 500 ppm. C2H4O is readily soluble in water, ethanol, diethyl ether, and many organic solvents.

Ethylene Oxide Uses

EtO is capable of sterilizing at low temperatures, enabling the sterilization of many plastic, composite, and other temperature-sensitive devices. Additionally, it penetrates packaging materials and diffuses into the channels and crevices of complicated medical devices, including entire palletized loads of devices, destroying pathogens and assuring sterility of the product. Ethylene Oxide is also utilized to sterilize, fumigate, and reduce the microbial load for a variety of other products, including spices and seasonings, cosmetics, aseptic packaging, laboratory materials, pharmaceuticals, artifacts, archival materials, and library objects.

Manufacturers use EO primarily in producing other chemicals used in consumer and industrial applications. The main chemical created from EO is ethylene glycol, a chemical used in products from brake fluid to industrial solvents. Some studies have found it in e-cigarette liquids.

EO is also used to create healthcare products and sterilize medical devices.

C2H4O uses include: Adhesives Agricultural insecticide Antifreeze Chemicals used to create fabrics for clothes, pillows and carpets Cosmetics Detergents Fiberglass used in jet skis, bowling balls, and other products Herbicide Household cleaners Industrial cleaners Medicines Polyethylene terephthalate (PET) plastic resin used to make packaging and beverage containers. Shampoos Sterilizing medical devices that are too delicate or sensitive for high-heat sterilizing, such as knee implants, bandages, electronics, and devices containing plastic Sterilizing spices

0 notes

Text

Ethylene Market Size, Incredible Growth Possibilities, Industry Trends, Global Opportunities by 2030

Ethylene is a simple hydrocarbon gas with the chemical formula C2H4. It is a colorless and flammable gas with a faintly sweet odor. Ethylene is an important industrial chemical and is widely used in various applications.

Production: Ethylene is primarily produced through the cracking of hydrocarbons, such as ethane and naphtha, in a process called steam cracking. This process breaks down larger hydrocarbon molecules into smaller ones, resulting in the formation of ethylene.

Uses: Ethylene has numerous applications in various industries, including:

Petrochemical industry: Ethylene is a key building block for the production of a wide range of chemicals, including polyethylene (the most widely used plastic), ethylene oxide, ethylene glycol, vinyl chloride, and many others.

Agriculture: Ethylene is used to regulate the ripening of fruits and vegetables. It can be used to trigger the ripening process in fruits, such as bananas, avocados, and tomatoes.

Polymer industry: Ethylene is used to produce various polymers, including polyethylene, which is used in packaging materials, plastic bags, bottles, and containers.

Medical applications: Ethylene oxide, a derivative of ethylene, is used as a sterilizing agent for medical equipment and supplies due to its ability to kill microorganisms.

Welding: Ethylene is used as a fuel gas in oxyfuel welding and cutting processes.

Health and safety: Ethylene is a flammable gas and should be handled with caution. It can cause asphyxiation in high concentrations and is also an asphyxiant in the presence of inadequate oxygen levels. Ethylene is also an asphyxiant fire hazard, and appropriate safety measures should be followed when handling or storing it.

Environmental impact: Ethylene is a greenhouse gas and contributes to the greenhouse effect and global warming. It is produced naturally by plants as part of their normal metabolic processes and is also released through various industrial activities. Efforts are being made to reduce ethylene emissions and develop more sustainable production methods.

Here is a complete overview of the ethylene market:

Production: Ethylene is predominantly produced through the steam cracking process, where hydrocarbon feedstocks such as ethane, propane, and naphtha are heated at high temperatures to break down the molecules and produce ethylene. The largest producers of ethylene are the United States, China, and the Middle East countries, such as Saudi Arabia.

Consumption: The demand for ethylene is driven by its versatile applications across various industries. The major consumer sectors include packaging, construction, automotive, textiles, chemicals, and agriculture. Ethylene is used to manufacture products such as polyethylene (PE), ethylene oxide (EO), ethylene glycol (EG), polyvinyl chloride (PVC), and many others.

Market Size: The ethylene market has experienced steady growth over the years. According to industry reports, the global ethylene market size was valued at approximately USD 190 billion in 2020. Factors contributing to market growth include increasing population, urbanization, industrialization, and rising demand for plastics and other ethylene-based products.

Trade: Ethylene is a highly traded commodity, with significant international trade flows. Major exporting countries include the United States, Saudi Arabia, Russia, Qatar, and Belgium. Key importing countries are China, the United States, Germany, Japan, and South Korea. Ethylene is transported in various forms, including pipelines, ships, and trucks.

Major players in the global ethylene market includes Saudi Basic Industries Corporation (SABIC), Exxon Mobil Corporation, The Dow Chemical Company, Royal Dutch Shell plc, China Petroleum & Chemical Corporation (Sinopec Corporation), Chevron Phillips Chemical Company LLC, Total S.A., LyondellBasell Industries, National Petrochemical Company (NPC), and INEOS Group AG.

Price Trends: Ethylene prices are influenced by several factors, including feedstock prices (such as crude oil and natural gas), supply and demand dynamics, and market conditions. Price fluctuations can impact the profitability of ethylene producers and downstream industries.

Sustainability and Environmental Impact: The ethylene industry is increasingly focusing on sustainability and reducing its environmental footprint. Efforts are being made to improve energy efficiency, develop alternative feedstocks, and implement technologies for carbon capture and utilization.

Future Outlook: The ethylene market is projected to witness continued growth in the coming years, driven by factors such as population growth, urbanization, and the demand for lightweight materials and energy-efficient products. However, the industry also faces challenges related to environmental concerns, regulatory pressures, and the development of sustainable alternatives.

The ethylene market offers several benefits for various stakeholders, including producers, consumers, and the overall economy. Here are some key benefits of the ethylene market:

Versatile Applications: Ethylene is a fundamental building block for the production of a wide range of products. Its derivatives, such as polyethylene, ethylene oxide, ethylene glycol, and vinyl chloride, are used in various industries, including packaging, automotive, construction, textiles, healthcare, and more. The versatility of ethylene and its derivatives enables the creation of diverse products to meet consumer and industrial needs.

Economic Growth: The ethylene industry plays a significant role in driving economic growth. It provides employment opportunities, both directly in the production facilities and indirectly in associated industries. The ethylene value chain includes raw material suppliers, producers, distributors, and end-users, contributing to the overall economic development of regions where these activities are concentrated.

Industrial Advancements: Ethylene and its derivatives are essential for the advancement of several industries. For example, polyethylene, which is derived from ethylene, is a widely used plastic that has revolutionized packaging, enabling the creation of lightweight, durable, and cost-effective materials. Ethylene oxide and ethylene glycol are crucial for the production of various products, including solvents, antifreeze, polyester fibers, and plastics.

Agricultural Benefits: Ethylene has applications in the agricultural sector. It is used to regulate the ripening process of fruits and vegetables, allowing for efficient supply chain management and extending the shelf life of produce. This benefit helps reduce food waste and enhances the availability of fresh produce for consumers.

Technological Innovation: The ethylene market drives research and development efforts to enhance production efficiency, develop new derivatives, and improve process technologies. This continuous innovation fosters technological advancements and supports the growth of related industries, leading to improved product performance, sustainability, and cost-effectiveness.

Environmental Considerations: While the production and use of ethylene have some environmental impact, advancements in technology and sustainable practices are helping to minimize the industry's footprint. Efforts are being made to reduce emissions, enhance energy efficiency, and explore alternative feedstocks and production methods. Additionally, the recycling and circular economy initiatives in the plastics industry contribute to the sustainable management of ethylene-derived products.

It's important to note that while this information provides a general overview of the ethylene market, specific market conditions, trends, and forecasts may vary over time. It's recommended to refer to up-to-date industry reports and consult market experts for the most accurate and current information.

0 notes

Text

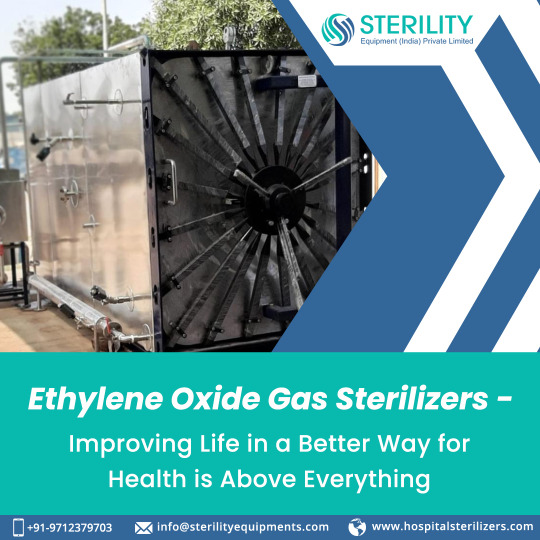

EO Sterilizers for Hospitals and Medical Colleges. The company is located in Ahmedabad, Gujarat - a leading business hub in India. Ethylene Oxide Gas Sterilizers which are used in hospitals and medical schools to sterilise a variety of items, are manufactured of the highest grade stainless steel, and other materials.

For more details, visit us at https://www.hospitalsterilizers.com/product/industrial-eto-sterilizer-machine/

#sterilityequipmentindia#etosterilizer#hospitalityindustry#ethyleneoxidegas#medicalcollege#hospitals

0 notes

Text

IV Infusion Set

It is suitable for the quantitative delivery of liquid medicine for infants, children, and patients with special diseases, especially for infants and young children or patients with heart and kidney failure, and patients who need small doses, multiple drugs, and infusions at short time intervals.

***Specifications:

Type:100ml,150ml bottle size, 60 drops/ml

Tube length:150cm

Product Structure: air-filter, soft tube, drip chamber, a flow regulator, fluid filter, clamp, stop valve and "Y"injection site for adding fluid drug, without needle

Product Instruction: medical polymer materials

Sterillized by EO gas

Buy now https://www.alibaba.com/product-detail/IV-Infusion-set-with-Burette-100ml_60843249852.html

---------------------------

���https://medhave.com/

#medical#medicalsupplies#infusion#infusionset#ivinfusionset#infants#children#heartdisease#kidneyfailure#hospital#patients

0 notes

Text

Ethylene Oxide Sterilization Unit

Ethylene Oxide Sterilization Unit (Eo gas sterilizer) including Eto gas sterilization chamber has been specially designed for sterilization of products sensitive to high temperature and to humidity (Syringes, DE fluxers, Catheters, Cartridges for Dialysis, Plastic articles, Bandages, Sutures etc.). Sterilizer can be uses even for sterilization of powders which deteriorate by heating exposure. For the wide range of product that can be treated, such sterilizer find application in Disposable Surgical Products, Para Pharmaceutical and Pharmaceutical Industry, Laboratories, Hospital and Food Processing Industries.

Adinath EO Gas Sterilization Unit Manufacturer can be realized in to satisfy different requirements working under pressure (1.5 kg/cm² + vacuum) with mixtures of Ethylene Oxide and Carbon Oxide (usual composition 10% ETO + 90% CO₂, 20% ETO + 80% CO₂)

Ethylene Oxide gas infiltrates packages as well as products themselves to kill microorganisms that are left during production or packaging processes. This gas, mixed with air at a ratio of at least 3% ETO gas, forms an explosive mixture. Pure ETO gas boiling point is 10.73 ºC at atmospheric pressure. Most of the time, it is mixed with Nitrogen or CO2. EO Gas Sterilizers uses to sterilize ot surgical instruments and medical disposables.

The system has been designed to operate on eto+co2 combination gas cylinders. The chamber and all contact parts shall be made from S.S 304. The chamber has been provided with a single door, easy locking arrangement and silicon gasket for leak proof operation. Electronically controlled heating system to ensure uniform heating of the chamber at 50 degrees centigrade. The chamber is provided with a adequate capacity rotary vacuum pump enclosed in sturdy cabinet duly powder coated for durability. We provide four of control switches with built in indicator light to regulate evacuation, feeding of gas, fresh air inlet through filter and aeration facility. Ethylene Oxide Gas Sterilization Unit manufacturer provide compact stand-alone sterilizer chamber.

0 notes

Text

Auto Ethylene Oxide Gas Sterilizer Manufacturers: Pioneering Sterilization Solutions - Cistron Systems

In the ever-evolving landscape of medical technology, where precision and safety are paramount, Cistron Systems stands at the forefront as a beacon of innovation. As prominent Auto Ethylene Oxide (EO) Gas Sterilizer Manufacturers, Cistron Systems has harnessed cutting-edge engineering and meticulous design to revolutionize the field of sterilization, ensuring the highest standards of hygiene and patient care.

The Essence of Ethylene Oxide Gas Sterilization

Ethylene Oxide Gas Sterilization has emerged as a cornerstone in the realm of medical equipment sterilization. Its efficacy in eradicating a wide spectrum of microorganisms, including spores, makes it an indispensable process for devices that cannot withstand the heat of traditional steam sterilization methods. Auto Ethylene Oxide Gas Sterilizers, such as those engineered by Cistron Systems, bring automation and precision to this crucial sterilization technique.

Cistron Systems: Redefining Sterilization Dynamics

Cistron Systems' Auto Ethylene Oxide Gas Sterilizers embody a fusion of innovation, reliability, and safety. Here's a glimpse into how they are redefining sterilization dynamics:

Advanced Automation: Cistron Systems' sterilizers integrate state-of-the-art automation technology, streamlining the sterilization process while minimizing human intervention. This not only enhances operational efficiency but also reduces the potential for errors.

Exceptional Safety Features: Safety is paramount in the medical field, and Cistron Systems prioritizes it in every aspect of their sterilizers. Comprehensive safety mechanisms, gas monitoring systems, and user-friendly interfaces ensure that sterilization procedures are conducted with utmost precision and adherence to safety protocols.

Customization and Flexibility: Cistron Systems recognizes that different medical facilities have unique needs. Their Auto Ethylene Oxide Gas Sterilizers are designed with modularity and flexibility in mind, allowing for customized cycles that cater to various medical instruments and load sizes.

Environmental Responsibility: Ethylene Oxide Sterilization has historically been associated with environmental concerns. Cistron Systems addresses this challenge by incorporating eco-friendly features and gas recirculation systems that reduce emissions and ensure compliance with environmental regulations.

Comprehensive Support: Cistron Systems' commitment to excellence extends beyond the sale. Their comprehensive support and maintenance services ensure that healthcare professionals can rely on their sterilizers for consistent and reliable performance.

A Path Towards Safer Healthcare

Cistron Systems' Auto Ethylene Oxide Gas Sterilizer Manufacturers have carved a path towards safer and more efficient healthcare practices. By combining technological innovation, meticulous engineering, and a deep understanding of the medical field's requirements, Cistron Systems is redefining the way medical equipment is sterilized. Their unwavering dedication to patient safety, operational excellence, and environmental responsibility cements their role as trailblazers in the realm of medical technology.

In a world where the quality of patient care hinges on the reliability of medical equipment, Cistron Systems emerges as a beacon of trust, offering Auto Ethylene Oxide Gas Sterilizers that pave the way for a healthier, safer future.

0 notes

Text

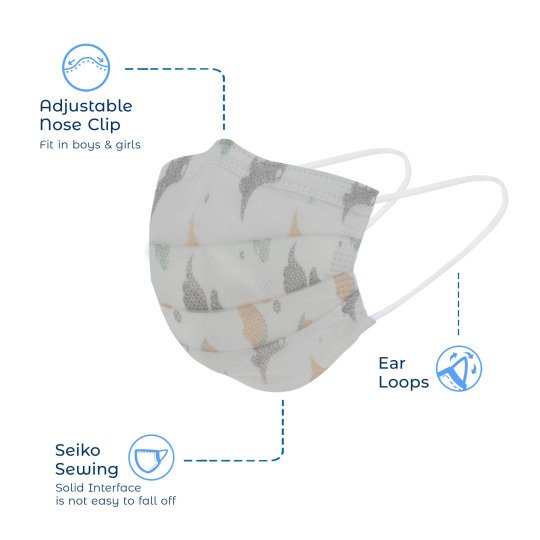

💥 3-Ply Kids Sterile Face Mask

👉 Face mask was designed to use easiler. 👉 The varity pattern 👉 Beutiful color, 3 layers, middle layer have quality antimicrobial layer that fit with kid's face , protect healthy for your kids. 👉 High quality sterilized medical masks, sterilized by EO gas. ✅We have certificate ISO; FSC (Free sales certificate); PPE (personal protective equipment), TUV, mask sold all over the world. ✅ Hidden nose clip: can follow facial contour adjustment, fit the face. ✅ High-elastic, round or flat earloop low pressure, ears more comfortable. For more information please contact us via: 📲 Whatsapp +84 389 799 917 📧 [email protected] 🌐 https://level3surgicalmasks.com/products/3-ply-kids-sterile-face-mask 📌 The price on our website is for customers, for wholesale and large inquiry quotes, we will offer a special price. 📌 FREESHIP in Vietnam ------------------------ 📌 Supplier of Nitrile Gloves, Condom, Surgical Masks, and other Medical Equipment | Sourced from Vietnam’s Leading Manufacturers | Shipping Worldwide

#Safefit_Comdom#Safefit#Condoms#Condom#Level3surgicalmasks#VRT#4LayersFaceMask#3LayersFaceMask#Covid19#coronavirus#SurgicalMask#MedicalDevices#FaceMaskMedical#Facemask

1 note

·

View note

Text

True Rinse Cups are available on every single True Grip and aon our Rogue Cartridge Tubes! "True Rinse Cups" in 50 packs! That's right, True Tubes and True Grips have changed the tattoo product game once again with new and innovative tattoo products! True Rinse Cups are the first EO gas sterilized tattoo rinse cups! * 50 True Rinse Cups per pack / *No more unwanted product waste. / *Multi use for easy tattooing setup. / *The first ever sterilized tattoo rinse cup. / *Rectangular, flat bottom, sturdy rinse cup. / *TrueGrips are two products in one package. / *Unique soft rim edge keeps cup from tipping. / *Convenient for the busy or traveling tattoo artists! Also, all future TrueGrips, TrueGrips II and HexaGrips will now be multi-purpose products by @truetubes accompanied by sturdy, rectangular, flat bottomed "True Rinse Cups"! TrueTubes & TrueGrips have re-designed all the True Grips blister packaging to now be two products in one as these all NEW 50 pack blister package "True Rinse Cups" will also be available individually on all True Grips packaging soon! #truerinsecups #truerinse #truetubes #truegrips #truetattoosupply #truetubes - Grab your #truerinsecups today at www.truetubes.com !

1 note

·

View note

Text

0 notes