#Dynamometer Market

Explore tagged Tumblr posts

Text

Dynamometer Market - Forecast(2024 - 2030)

Dynamometer Market Overview

The Dynamometer market size in 2021 is estimated to be $928.1 Million and is projected to reach $1161.5m in 2027 at a CAGR of 30.25% during the forecast period 2022-2027. A dynamometer is a tool for determining the mechanical force or power transmitted by a rotating shaft. All power-measuring dynamometers are essentially torque-measuring devices because power is the product of torque (turning force) and angular speed. The ever-increasing demand for clean energy sources, particularly wind, necessitates the use of massive turbines and generators to efficiently produce power on a large scale. To build such infrastructure, there is an increasing demand for development facilities with dynamometers to calculate torque and power output regularly. Thus, the primary driver of the global dynamometer market is an increase in demand for energy sources. Also, stringent laws are being formulated for vehicle noise and emission control (such as Regulation (EU) No 540/2014, 40 CFR 205.52, and more), in which the design of a vehicle's engine and powertrain is continuously modified and upgraded. And since dynamometer is the only device that can measure and analyze the exterior noise and internal noise, the dynamometer market is being further accelerated with these stringent regulations.

Dynamometer Market Report Coverage

The report: “Dynamometer Market – Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the Dynamometer market.

.By Category: Absorption, Transmission and Motoring

By Type: Rope Brake Dynamometer, Hydraulic Dynamometer, Torsion Dynamometer, AC Dynamometer, Eddy Current Dynamometer, Hysteresis Dynamometer, Powder Dynamometer, Engine Dynamometer, Transmission Dynamometer, Chassis Dynamometer, Medical Dynamometer and Others

By Measurement Range: Up to 100kW, 100.1kW to 500kW, 500.1kW to 1MW, Above 1.1MW

By Application: Automotive, Aerospace & Defense, Railways, Manufacturing (Pump, Compressor & Blower, Motor & Generator, Machine Tools and Others), Power Generation, Marine, Medical and Others

By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa)

Request Sample

Key Takeaways

Moreover, other factors that stimulate market demand include rising demand from the automotive and aerospace industry, as well as increased investments in the marine industry around the world.

In 2020, the global COVID-19 pandemic enforced lockdown globally which led to factory closures. The complete lockdown and partial lockdowns had both demand-side and supply-side impacts on the dynamometer industry. However, the manufacturing of dynamometers picked up its pace in the second quarter of 2021 after core end-use industries swiftly began their production process.

Dynamometer Market Segment Analysis – By Type

The absorption segment held the largest share in the dynamometer market in 2021 and is anticipated to grow at a CAGR of 3.5% by revenue through the forecast period 2021-2027. Absorption dynamometers such as prony brake dynamometer, rope brake dynamometer, and Hydraulic dynamometer measure and absorb the power output of the engine to which they are coupled, the absorbed energy is usually dissipated as heat, which generally dissipates into the ambient air or transfers to cooling water that dissipates into the air. Various patents activities have been noted in the last few years related to absorption dynamometer which determines that companies are focusing on innovative absorption products advancement and product launches. For illustration, hydraulic dynamometer patents such as Hydraulic dynamometer control system and method (CN112612240A), Multi-unit combined hydraulic dynamometer (CN212133947U), Novel high-power-density hydraulic dynamometer (CN201922000124U) Double-station hydraulic dynamometer (CN209055258U) have been filed in the period 2019-2021.

Inquiry Before Buying

Dynamometer Market Segment Analysis – By End Use Industry

The automotive segment held the largest share in the dynamometer market in 2021 and is anticipated to grow at a CAGR of 3.5% by revenue through the forecast period 2021-2027, owing to the increasing demand for dynamometer from the automotive industry to meet the testing criteria set by the government such as the Federal Test Procedure (FTP). Dynamometer are often used in the automotive industry test engines, electric motors and various drivetrain components. And to verify performance after rebuild, ensuring a higher level of product quality that helps reduce warranty claims and satisfy customers. To meet the growing need for testing and certification of hybrid, electric and alternative-fuel cell vehicle components, the demand for dynamometers is increasing from the automotive manufacturing companies. For instance, Meidensha Corporation provided Hitachi Automotive Systems, Ltd. Chassis Dynamometer for the FF and the FR vehicle, Superflow provided Ford with a dynamometer. In September 2021, Ford Motor Company announced plans to develop the next generation of electric F-Series trucks at two new massive, environmentally and technologically advanced facilities in Tennessee and Kentucky, bringing electric vehicles to American customers on a large scale. Such projects are also accelerating the demand for dynamometers as new facilities require installation of new dynamometer for testing purpose.

Dynamometer Market Segment Analysis – By Geography

Asia-Pacific held the largest share in the dynamometer market in 2021 and is anticipated to grow at a CAGR of 4.5% by revenue through the forecast period 2021-2027, owing to an upsurge in the automotive and aerospace manufacturing facilities in the region, which is facilitating the testing procedure in the region. The increasing number of new automotive and aerospace manufacturing units, is driving the demand for dynamometer in the country as dynamometers are established in new facility for setting up testing space of the facility. For instance, in November 2021, Autoliv a global leader in automotive safety part manufacturing announced the establishment of two new manufacturing plants in Central Japan, and the construction is estimated to be completed by 2023. In April 2021, Volkswagen Group China has started work on a brand-new modular electric drive matrix (MEB) plant in Anhui, China. It is expected to be completed in mid-2022, with production beginning in the second half of 2023. In March 2021, Plexus, a manufacturer of aerospace & defense equipment, has announced the construction of a manufacturing plant in Bangkok, Thailand, which will be completed by 2022. In addition, other end-user of dynamometers such as marine, power generation, medical, and more is also flourishing in the region, which is further propelling the market growth.

Schedule a Call

Dynamometer Market Drivers

Rising Demand from Medical Sector

The medical dynamometer is used to calculate the strength of bones and nerves along with various muscle groups in the human body. The extending awareness among the physicians and patients regarding the benefits of medical dynamometer is driving the dynamometer market growth. Medical dynamometers estimate the intensity of different groups of muscles, nerves, and joints in the body. Monitoring muscle strength is one of the ways physical therapists and other healthcare practitioners can objectively assess overall health. The best tool for accurately evaluating muscle strength is dynamometers.

There has been constant development in the medical field using dynamometers as they are the only way to consistently measure muscle strength in patients. For instance, in 2021, Astellas Pharma developed adeno-associated virus (AAV) vectors for gene therapies targeting skeletal and cardiac muscle using Dyno Therapeutics’ CapsidMap platform, which could generate more than US$2 billion. One of the major factors attributing the dynamometer market growth is the growing incidence of sports injuries, growing cases of arthritis, and osteoporosis with the growing time. For instance, in the United States about 63 million adults has been reported by doctors to be diagnosed by arthritis in 2021 and is projected to rise by 20% by the year 2040. Thus, the rise in arthritis will further grow the demand for the medical dynamometer market. Furthermore, according to the Office of Disease Prevention and Health Promotion, in 2021 in the United States, an estimated 5.3 million people aged 50 years and older have osteoporosis which is an increase of 4% compared to the previous year. Thus, the above-mentioned growing health issue is undoubtedly driving the demand for dynamometer in the medical sector and thus impacting its market growth.

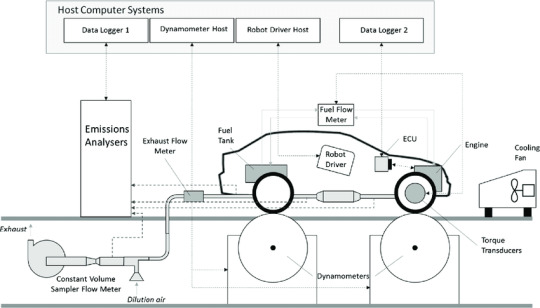

Growing Applications in Automotive Sector

The dynamometer market is predominantly driven by rising demand from the automotive industry. In standard emissions testing cycles such as those defined by the US Environmental Protection Agency (US EPA), dynamometers are used to provide simulated road loading of either the engine (using an engine dynamometer) or full powertrain (using a chassis dynamometer). A thriving automotive industry and its increasing manufacturing plants is one of the key factors driving the market growth as it is used to measure power or torque and is precisely associated with motor or motor automobile testing. This, coupled with the growing demand for automobile restoration, contributes significantly to the sales of the automotive dynamometer.

For instance, in 2021, China’s automotive manufacturer, Great Wall Motor, acquired US-based General Motors manufacturing plant in India and invested US$1 billion. The company looks to establish two brands in India – Haval and GWM EV. While the former will cater to all SUVs, the EV brand will house non-SUV electric vehicles. Ford Motor Co. on Monday invested US$11 billion to build several new plants to produce parts for electric vehicles. Ford had already announced an investment over the past two years of $950 million in the Rouge Complex in Dearborn, Michigan, to build the all-electric 2022 F-150 Lightning. Furthermore, escalating technological innovations such as the introduction of ETPS (engine torque pulsation simulation) dynamometer and accessibility of automation processes such as engine mounting testbed and crank angle position recognition are also anticipated to catalyze the market growth. The dynamometer market owing to the establishment of manufacturing and production units of automotive coupled with the growth of e-vehicles, is expected to drive the growth of the market in the forecast period. Additionally, the automotive vehicle industry is undergoing various advances owing to new technologies and upgrades. One significant example is the rise in electrical content per vehicle. Therefore, testing for vehicle and engine performance has become an essential addition in the vehicle offered by the new technologies.

Buy Now

Dynamometer Market Challenges

High Cost of the Devices might Hinder the Market Growth

High cost associated with the usage of devices and the lack of advanced and improved healthcare infrastructure in developing economies is likely to act as a restraint for the dynamometer market growth. Dynamometers are typically expensive pieces of equipment and generally are used only in specific fields that rely on them for a particular purpose. Manufacturers are functioning hard to maintain challenging market position and the maintenance of customers by executing low-cost strategy for dynamometer, hence compromising on their profit margins. The dynamometer used in the automotive industry has become crucial for engine testing is significantly high in cost.

Automotive dynamometer is an expensive piece of equipment that offers greater control and options for the user looking for the ideal real-world tune. For instance, the Dynomax companies dynamometers price varies from US$12,309- US$19,424 for electromagnetic brake and US$42,913 – US$46,301 for electromagnetic retarders. However, the prices have increased with the rising demand of the product and also, price may vary on the complexity and the vehicles engine. According to Engine Builder, typical rates for dynamometer testing an engine range from US$500-US$1,000. Several top dyno manufacturers offer a starter package for 1,500 hp and 1,000 ft.lbs. for around US$25,000. Thus, the price figure of various dynamometers is very high, which is one of the primary reasons for the downfall of the market growth.

Dynamometer Market Landscape

The Dynamometer market is moderately consolidated with key players are adopting strategies such as acquisition, product launches and others with the players and companies prevalent in the market. The top companies present in the market include the below.

Horiba

AVL List GmbH

Meidensha Corporation

Phoenix Dynamometer Technologies

Power Test LLC

Dynomerk Controls

Froude

Mustang Dynamometer

Burke E. Porter Machinery Company

Biodex Medical Systems

Acquisitions

In June 2020, Power Test Incorporated and Taylor Dynamometer completed the merger of their two heavy-duty dynamometer and test stand businesses

In April 2020, Power Test Inc. a Sussex, Wis. manufacturer has acquired the assets of DynoMite Dynamometer in New Hampshire, a manufacturer of engine and chassis dynamometers.

#Dynamometer Market#Dynamometer Market Share#Dynamometer Market Size#Dynamometer Market Forecast#Dynamometer Market Report#Dynamometer Market Growth

0 notes

Text

Automotive Chassis Dynamometer Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Chassis Dynamometer Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Chassis Dynamometer Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Chassis Dynamometer Market is experiencing robust growth driven by the expanding globally. The Automotive Chassis Dynamometer Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Chassis Dynamometer Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Chassis Dynamometer Market Size, Share & Industry Analysis, By Product Type (Single Roller, Multi Roller), By Vehicle Type (Passenger Cars, Commercial Vehicles) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103618

Key Strategies

Key strategies in the Automotive Chassis Dynamometer Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Chassis Dynamometer Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Chassis Dynamometer Market.

Major Automotive Chassis Dynamometer Market Manufacturers covered in the market report include:

Major players operating in the global automotive chassis dynamometers market include Mustang Dynamometer, ONO SOKKI CO.,LTD, Sierra Instruments, Inc., Rototest, Saj Test Plant Pvt. Ltd., AVL List GmbH, Dynapack, KRATZER AUTOMATION AG, Horiba, and MEIDENSHA CORPORATION among others.

Moreover, the increasing number of sales and production of automobiles owing to the rapid development such as high performance, fuel efficient, light weight as well as integration of technologically advanced systems. All these factors are creating high demand for automotive chassis dynamometers in the global market.

Trends Analysis

The Automotive Chassis Dynamometer Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Chassis Dynamometer Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Chassis Dynamometer Market Solutions.

Regions Included in this Automotive Chassis Dynamometer Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Chassis Dynamometer Market.

- Changing the Automotive Chassis Dynamometer Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Chassis Dynamometer Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Chassis Dynamometer Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Chassis Dynamometer Market?

► Who are the prominent players in the Global Automotive Chassis Dynamometer Market?

► What is the consumer perspective in the Global Automotive Chassis Dynamometer Market?

► What are the key demand-side and supply-side trends in the Global Automotive Chassis Dynamometer Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Chassis Dynamometer Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Chassis Dynamometer Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Chassis Dynamometer Market#Automotive Chassis Dynamometer Market Share#Automotive Chassis Dynamometer Market Size#Automotive Chassis Dynamometer Market Trends

0 notes

Text

#Dynamometer Product & Services Market size#Dynamometer Product & Services Market share#Dynamometer Product & Services Market Trends

0 notes

Text

Global Test Automation Systems for Powertrain Dynamometer Market Size, Share & Trends Analysis Report by 2027

The global test automation systems for powertrain dynamometer market is expected to reach USD 1.07 billion by 2027, growing at a CAGR of 5.78% from 2021 to 2027.

The growth of the market is being driven by the increasing demand for powertrain testing in the automotive industry. Test automation systems help to improve the efficiency and accuracy of powertrain testing, which is essential for ensuring the quality and performance of vehicles.

Get a free sample copy of the research report: https://www.vynzresearch.com/automotive-transportation/automation-systems-for-powertrain-dynamometer-market/request-sample

The market is segmented by type, communication, vehicle type, propulsion, testing type, and region.

By type, the market is segmented into hardware and software. The hardware segment is expected to account for the largest share of the market during the forecast period. This is due to the increasing demand for high-performance test automation systems that can handle the complex testing requirements of modern vehicles.

By communication, the market is segmented into mobile, FlexRay, web, embedded software, CAN bus, and others. The mobile segment is expected to grow at the fastest CAGR during the forecast period. This is due to the increasing adoption of mobile devices for test automation.

By vehicle type, the market is segmented into passenger vehicles, light commercial vehicles, heavy-duty trucks, buses & coaches, motorcycles, power generation sets, motorsports, Powersports, agricultural vehicles, and others. The passenger vehicle segment is expected to account for the largest share of the market during the forecast period. This is due to the increasing demand for test automation systems for passenger vehicles in the global automotive market.

By propulsion, the market is segmented into internal combustion engines (ICE) and electric. The ICE segment is expected to account for the largest share of the market during the forecast period. This is due to the increasing demand for ICE vehicles in the global automotive market.

By testing type, the market is segmented into durability tests, performance tests, vehicle simulations, and others. The durability test segment is expected to account for the largest share of the market during the forecast period. This is due to the increasing demand for durability testing of vehicles in the global automotive market.

By region, the market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. North America is expected to account for the largest share of the market during the forecast period. This is due to the presence of a large number of automotive manufacturers and suppliers in the region.

The key players operating in the global test automation systems for the powertrain dynamometer market include:

SAKOR Technologies

Rototest

Horiba Automotive

Power Test, Inc.

FEV Europe GmbH

Sierra Instruments, Inc

A&D Technology

Dyne Systems

Integral Powertrain Ltd

AIP GmbH & Co. KG

These companies are focusing on developing innovative test automation solutions to meet the growing demand for powertrain testing in the automotive industry.

The global test automation systems for powertrain dynamometer market is a highly competitive market. The key players are competing on the basis of product offerings, features, and pricing. The market is expected to witness new product launches and partnerships in the coming years.

About Us:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities.

Source: VynZ Research

#Test Automation Systems for Powertrain Dynamometer#Test Automation Systems for Powertrain Dynamometer Market#Test Automation Systems for Powertrain Dynamometer Market Size#Test Automation Systems for Powertrain Dynamometer Market Share#Test Automation Systems for Powertrain Dynamometer Market Analysis#Test Automation Systems for Powertrain Dynamometer Market Growth#Test Automation Systems for Powertrain Dynamometer Market Value

0 notes

Text

Test Automation Systems for Powertrain Dynamometer Market Size, Top Players and Forecast by 2027

VynZ Research has predicted that the Global Test Automation Systems for Powertrain Dynamometer Market Size will reach USD 1.07 billion by 2027, with a projected CAGR of 5.78% during the forecast period from 2021-2027.

Get a sample copy: https://www.vynzresearch.com/automotive-transportation/automation-systems-for-powertrain-dynamometer-market/request-sample

The research report offers an in-depth analysis of the market, including segmentation, dynamics, competition, and regional growth, with the latest trends and strategies for vendors in the Global Test Automation Systems for Powertrain Dynamometer Market.

The report also provides answers to key questions such as which geographical areas will be most lucrative, what factors will shift the demand for Test Automation Systems for Powertrain Dynamometer market Growth, and how evolving trends will impact the market.

Source: VynZ Research

#Test Automation Systems for Powertrain Dynamometer#Test Automation Systems for Powertrain Dynamometer Market#Test Automation Systems for Powertrain Dynamometer Market Size#Test Automation Systems for Powertrain Dynamometer Market Share#Test Automation Systems for Powertrain Dynamometer Market Analysis

0 notes

Text

0 notes

Text

0 notes

Link

0 notes

Text

Diesel Engines: Powering the World with Efficiency and Reliability

Established in 1979, Engines, Inc. is a fourth-generation, family-owned business with roots tracing back to 1935 in the John Deere implement sector. Specializing in diesel and spark-ignited power products, we proudly serve the OEM, Marine, Agriculture, and Industrial markets. Our commitment to quality is reflected in our partnerships with top-tier brands such as John Deere, Yanmar, Kohler, and Ford.

Our Facilities

Our main production facility in Jonesboro, Arkansas, spans 117,000 square feet of climate-controlled space dedicated to parts, shipping, receiving, production, and offices. Complementing this is our 54,000-square-foot ei Technology Center, where our engineering team designs, tests, and prototypes engine packages. Additionally, we maintain a 120,000-square-foot warehouse housing our extensive engine inventory.

Our Products

At Engines, Inc., we offer a comprehensive range of products tailored to meet diverse power needs:

Industrial Diesel Engines: We provide engines with varying levels of efficiency, capability, and affordability to suit your specific applications. Engines, Inc.

DriveTrain Components: Our John Deere and Funk™ drivetrain components are designed with a modular approach, ensuring versatility and prompt delivery. Engines, Inc.

Generator Drive Engines: Our engines deliver both prime and standby power, catering to a wide array of critical applications. Engines, Inc.

Marine Engines: We offer marine propulsion systems, generators, and auxiliary engines renowned for their endurance and performance, tailored to fit your operations. Engines, Inc.

Agricultural Power Solutions: Our solutions are designed to keep your agricultural operations running smoothly, even during peak times. Engines, Inc.

Repower Options: Choosing a repower engine is an excellent way to extend the lifespan of your equipment without overextending your budget. Engines, Inc.

Export Solutions: We offer engines compliant with Tier 1, 2, and 3 emissions standards for Marine, Agriculture, Generator, and Industrial industries, providing power solutions beyond U.S. borders. Engines, Inc.

Rental Options: Our rental fleet comprises compact yet powerful units, ready to provide reliable power wherever you need it. Engines, Inc.

Our Services

Customer service is at the core of Engines, Inc. We offer an extensive support system, including a 24-hour support line and a vast global network, to ensure your operations run smoothly.

ei Technologies

Our ei Technology Center is equipped with the latest software and technology, enabling our engineers to customize engines specifically for your operations. Our services include:

Designing & Prototyping: Utilizing Solidworks software, we facilitate rapid and efficient design and inspection of complex packages, reducing costs and enhancing quality. Operating in a 3D design environment allows for better visualization of the end product. Engines, Inc.

Testing & Validation: With three Taylor dynamometers and two load banks, we validate every custom power unit package and generator, accurately testing horsepower from 17 to 1500 and eKW up to 1250. Engines, Inc.

Service & Rebuild Department: Our skilled team services engines from all manufacturers we represent, whether at our location or yours. We offer complete engine rebuilds, overhauls, equipment refurbishment, and maintenance contracts to minimize downtime. Engines, Inc.

Diesel engines have been a cornerstone of industrial and commercial applications for over a century, offering unparalleled efficiency, durability, and power. From powering heavy machinery in construction and agriculture to propelling marine vessels and generating electricity, diesel engines are integral to various sectors. This comprehensive article delves into the intricacies of diesel engines, their applications, advantages, and the innovative solutions provided by industry leaders like Engines, Inc.

Understanding Diesel Engines

A diesel engine is an internal combustion engine in which fuel ignition occurs due to the high temperature of air compressed in the cylinder, a process known as compression ignition. This contrasts with petrol engines, which use spark plugs for ignition. The efficiency of diesel engines stems from their high compression ratios and lean air-fuel mixtures, leading to better fuel economy and torque characteristics.

Key Components and Operation

Cylinder Block and Head: The main structure housing the cylinders where combustion occurs.

Pistons and Crankshaft: Convert the energy from combustion into mechanical motion.

Fuel Injection System: Precisely injects fuel into the combustion chamber at high pressure.

Turbocharger: Many modern diesel engines are equipped with turbochargers to increase air intake, enhancing power and efficiency.

Exhaust Aftertreatment Systems: Components like Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR) systems reduce emissions to meet environmental standards.

Advantages of Diesel Engines

Fuel Efficiency: Diesel engines typically offer higher fuel efficiency compared to petrol engines, making them cost-effective for long-term use.

Durability and Longevity: Built to withstand high compression, diesel engines often have longer lifespans.

High Torque Output: Diesel engines provide substantial torque at low RPMs, ideal for heavy-duty applications.

Safety: Diesel fuel is less flammable than petrol, reducing the risk of fire hazards.

Applications of Diesel Engines

Diesel engines are versatile and find applications across various industries:

Automotive: Used in trucks, buses, and some passenger vehicles for their fuel efficiency and torque.

Industrial Machinery: Powering equipment like excavators, loaders, and cranes.

Agriculture: Driving tractors, harvesters, and irrigation pumps.

Marine: Propelling ships, boats, and submarines.

Power Generation: Serving as generators for electricity in remote locations or as backup power sources.

Engines, Inc.: A Leader in Diesel Engine Solutions

Established in 1979, Engines, Inc. is a fourth-generation, family-owned business with a rich history dating back to 1935 in the John Deere implement sector. Specializing in diesel and spark-ignited power products, Engines, Inc. serves the OEM, Marine, Agriculture, and Industrial markets. Their commitment to quality is reflected in partnerships with top-tier brands such as John Deere, Yanmar, Kohler, and Ford.

Product Offerings

Engines, Inc. provides a comprehensive range of products tailored to meet diverse power needs:

Industrial Diesel Engines: Offering engines with varying levels of efficiency, capability, and affordability to suit specific applications.

DriveTrain Components: John Deere and Funk™ drivetrain components designed with a modular approach, ensuring versatility and prompt delivery.

Generator Drive Engines: Engines that provide prime and standby power for a wide variety of critical applications.

Marine Engines: Marine propulsion systems, generators, and auxiliary engines with unmatched endurance and performance to fit various operations.

Agricultural Power Solutions: Solutions designed to keep agricultural operations running smoothly, even during peak times.

Repower Options: Reliable repower options to extend the lifespan of equipment without overextending budgets.

Export Solutions: Engines compliant with Tier 1, 2, and 3 emissions standards for Marine, Agriculture, Generator, and Industrial industries, providing power solutions beyond U.S. borders.

Rental Options: A rental fleet comprising compact yet powerful units, ready to provide reliable power wherever needed.

Services and Support

Customer service is at the core of Engines, Inc. They offer an extensive support system, including a 24-hour support line and a vast global network, to ensure operations run smoothly.

#diesel engine solutions#diesel engine services in odessa#diesel parts#diesel engine solution#diesel engine#kohler engine#new orleans#baton rouge#san antonio tx#Diesel engine houston TX#Diesel engine dallas TX#Diesel engine odessa TX

0 notes

Text

https://github.com/anushka224473/InMarket-Insights/blob/main/North America Car Dynamometer Market Drivers And Trends.md

0 notes

Text

Automotive Chassis Dynamometer Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Chassis Dynamometer Market and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Chassis Dynamometer Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Chassis Dynamometer Market is experiencing robust growth driven by the expanding globally. The Automotive Chassis Dynamometer Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Chassis Dynamometer Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Chassis Dynamometer Market Size, Share & Industry Analysis, By Product Type (Single Roller, Multi Roller), By Vehicle Type (Passenger Cars, Commercial Vehicles) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103618

Key Strategies

Key strategies in the Automotive Chassis Dynamometer Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Chassis Dynamometer Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Chassis Dynamometer Market.

Major Automotive Chassis Dynamometer Market Manufacturers covered in the market report include:

Major players operating in the global automotive chassis dynamometers market include Mustang Dynamometer, ONO SOKKI CO.,LTD, Sierra Instruments, Inc., Rototest, Saj Test Plant Pvt. Ltd., AVL List GmbH, Dynapack, KRATZER AUTOMATION AG, Horiba, and MEIDENSHA CORPORATION among others.

Moreover, the increasing number of sales and production of automobiles owing to the rapid development such as high performance, fuel efficient, light weight as well as integration of technologically advanced systems. All these factors are creating high demand for automotive chassis dynamometers in the global market.

Trends Analysis

The Automotive Chassis Dynamometer Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Chassis Dynamometer Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Chassis Dynamometer Market Solutions.

Regions Included in this Automotive Chassis Dynamometer Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Chassis Dynamometer Market.

- Changing the Automotive Chassis Dynamometer Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Chassis Dynamometer Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Chassis Dynamometer Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2024 to 2030?

► What are the key market dynamics influencing growth in the Global Automotive Chassis Dynamometer Market?

► Who are the prominent players in the Global Automotive Chassis Dynamometer Market?

► What is the consumer perspective in the Global Automotive Chassis Dynamometer Market?

► What are the key demand-side and supply-side trends in the Global Automotive Chassis Dynamometer Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Chassis Dynamometer Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Chassis Dynamometer Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

308, Supreme Headquarters,

Survey No. 36, Baner,

Pune-Bangalore Highway,

Pune - 411045, Maharashtra, India.

Phone:

US:+1 424 253 0390

UK: +44 2071 939123

APAC: +91 744 740 1245

#Automotive Chassis Dynamometer Market#Automotive Chassis Dynamometer Market Share#Automotive Chassis Dynamometer Market Size#Automotive Chassis Dynamometer Market Trends

0 notes

Text

Applications of Direct Drive Machines Across Industries

Direct drive machines are transforming industries with their ability to deliver high efficiency, precision, and reliability. Unlike traditional systems that rely on belts or gears, direct drive technology connects the motor directly to the load, eliminating the need for intermediary components. This streamlined design not only reduces maintenance but also enhances performance, making it a preferred choice in diverse applications.

Here’s an in-depth look at the applications of direct drive machine across industries and how they are revolutionizing operations worldwide.

1. Manufacturing and Industrial Automation

Direct drive machines have become a cornerstone in manufacturing and industrial automation due to their precise motion control and high torque capabilities.

Robotics: In robotics, direct drive motors enable smooth and accurate movements, essential for tasks like welding, assembly, and material handling. The absence of backlash improves positioning accuracy, making robots more efficient.

CNC Machines: Direct drive systems in CNC (Computer Numerical Control) machines ensure high-speed, precise cutting and drilling. Their ability to operate without gears reduces vibrations, leading to smoother operations and finer finishes.

Printing and Packaging: Direct drive technology powers high-speed printing presses and packaging machines, enhancing throughput without sacrificing quality.

Benefits in Manufacturing:

Increased productivity

Reduced operational noise

Lower maintenance costs

2. Automotive Industry

The automotive industry leverages direct drive technology for its ability to provide efficient and precise control in critical applications.

Electric Vehicles (EVs): In EVs, direct drive motors eliminate the need for a traditional gearbox, reducing complexity and weight. This enhances energy efficiency and provides smoother acceleration.

Automated Assembly Lines: Direct drive systems ensure precise positioning and consistent performance in robotic arms used for assembling vehicle components.

Testing Equipment: Dynamometers with direct drive motors enable accurate torque and speed measurements, essential for vehicle testing and performance evaluation.

Benefits in Automotive Applications:

Improved energy efficiency

Enhanced driving dynamics

Increased reliability in assembly processes

3. Renewable Energy

Direct drive machines play a pivotal role in renewable energy applications, particularly in wind and solar power generation.

Wind Turbines: Direct drive generators in wind turbines eliminate the need for a gearbox, reducing wear and tear and increasing reliability. This design is particularly beneficial for offshore turbines, where maintenance access is challenging.

Solar Trackers: Direct drive motors in solar tracking systems allow panels to follow the sun’s movement precisely, maximizing energy capture and efficiency.

Benefits in Renewable Energy:

Lower maintenance requirements

Enhanced efficiency and output

Longer operational lifespan

4. Healthcare and Medical Equipment

The healthcare industry demands precision and reliability, making direct drive technology an ideal choice for medical applications.

Imaging Equipment: Direct drive motors are used in MRI machines and CT scanners to provide smooth, precise rotation, resulting in clearer images and faster diagnostics.

Surgical Robots: In robotic-assisted surgery, direct drive systems ensure accurate and stable movements, improving surgical outcomes.

Lab Automation: Direct drive machines in laboratory equipment enable precise handling of samples, enhancing the accuracy of diagnostic tests.

Benefits in Healthcare:

Improved patient outcomes

Higher imaging accuracy

Reduced noise levels for patient comfort

5. Home Appliances

Direct drive technology has made significant inroads into the consumer appliance market, delivering quieter, more efficient, and durable products.

Washing Machines: Direct drive motors eliminate belts, making washing machines quieter, more energy-efficient, and less prone to breakdowns.

Refrigerators: In modern refrigerators, direct drive compressors improve cooling efficiency while reducing power consumption.

Vacuum Cleaners: Direct drive motors enhance suction power and reliability in advanced vacuum cleaners.

Benefits in Home Appliances:

Reduced energy consumption

Increased durability

Enhanced user experience

6. Aerospace and Defense

In aerospace and defense, precision and reliability are non-negotiable, and direct drive systems deliver on both fronts.

Flight Simulators: Direct drive motors provide realistic motion simulation for pilot training.

Radar Systems: These systems benefit from the smooth, accurate rotation offered by direct drive technology.

Weapon Systems: Direct drive motors ensure precise control in targeting and tracking systems.

Benefits in Aerospace and Defense:

Enhanced operational accuracy

Improved system reliability

Lower maintenance requirements

Conclusion

Direct drive machines are revolutionizing industries by offering unmatched efficiency, precision, and durability. From manufacturing to renewable energy, healthcare to aerospace, their applications are vast and varied. By eliminating intermediary components like belts and gears, direct drive systems reduce maintenance needs, enhance performance, and contribute to energy efficiency.

As industries continue to prioritize sustainability and precision, the adoption of direct drive technology will only grow. For businesses seeking to improve reliability and operational efficiency, investing in direct drive machines is not just an upgrade—it’s a strategic advantage.

0 notes

Text

0 notes

Text

0 notes