#Durable zinc steel tank

Explore tagged Tumblr posts

Text

Zinc Aluminium Steel Tanks in India by Mizutanks: A Reliable Solution for Industrial and Commercial Water Storage

In the realm of water storage, durability, and reliability are crucial factors that determine the effectiveness of a storage solution. Mizutanks excels in providing top-notch zinc aluminium steel tanks in India that cater to both industrial and commercial needs. Our tanks are engineered to withstand the harshest conditions while ensuring the safe storage of water and other liquids.

Why Choose Zinc Aluminium Steel Tanks?

Zinc aluminium steel tanks are renowned for their exceptional strength and corrosion resistance, making them ideal for long-term water storage. The combination of zinc and aluminium provides a protective coating that extends the lifespan of the steel, making it highly durable even in challenging environments. This makes these tanks an excellent choice for both industrial and commercial steel tanks.

Mizutanks: Leading Provider of Zinc Aluminium Steel Tanks in India

At Mizutanks, we specialize in delivering high-quality zinc aluminium steel tanks that are built to last. Whether you need a tank for industrial use or for commercial purposes, our tanks offer the perfect balance of strength, durability, and reliability.

Features of Mizutanks’ Zinc Aluminium Steel Tanks

Durable Zinc Steel Tanks: Our zinc aluminium steel tanks are designed to provide long-lasting performance. The zinc-aluminium coating enhances the tank's resistance to corrosion, ensuring that it can withstand the rigors of both industrial and commercial applications.

Zinc Aluminium Steel Tanks in Pune: We serve customers across India, including Pune, offering zinc aluminium steel tanks that are tailored to meet the specific needs of the region. Our tanks are designed to perform well in Pune's diverse climate, providing reliable water storage solutions for local businesses.

Industrial and Commercial Steel Tanks: Mizutanks offers a wide range of industrial and commercial steel tanks that are suitable for various applications. Whether you need to store water, chemicals, or other liquids, our tanks provide a robust and secure storage solution that meets all industry standards.

Customizable Zinc Water Tanks: Understanding that different industries have different requirements, Mizutanks offers customizable zinc water tanks. We work closely with our clients to ensure that our tanks meet their specific needs, whether it’s for capacity, shape, or installation location.

Advantages of Choosing Mizutanks for Your Storage Needs

Exceptional Durability: The zinc-aluminium alloy used in our tanks provides outstanding protection against rust and corrosion, ensuring that your investment lasts for many years.

High-Quality Manufacturing: At Mizutanks, we use advanced manufacturing techniques and high-grade materials to produce zinc aluminium steel tanks that meet the highest standards of quality.

Versatile Applications: Our tanks are suitable for a wide range of uses, including industrial water storage, commercial applications, and more. Whatever your storage needs, Mizutanks has a solution that fits.

Expert Support: Our team of experts is always available to assist you with selecting the right tank for your needs. From consultation to installation, Mizutanks provides full support to ensure your satisfaction.

Conclusion

When it comes to zinc aluminium steel tanks in India, Mizutanks is a name you can trust for durable, reliable, and high-quality water storage solutions. Our industrial and commercial steel tanks are designed to meet the specific needs of various industries, providing long-term protection and efficiency.

Whether you are located in Pune or anywhere else in India, Mizutanks offers the best zinc aluminium steel tanks that are built to last. Visit our website at Mizutanks to learn more about our products and to find the perfect storage solution for your business.

#Zinc aluminium steel tank in India#Mizutanks#Industrial and commercial steel tanks#Zinc aluminium steel tank in Pune#Zinc aluminium steel tank#Durable zinc steel tank#zinc water tanks

0 notes

Text

For two decades, researchers worked to solve a mystery in West Coast streams. Why, when it rained, were large numbers of spawning coho salmon dying? As part of an effort to find out, scientists placed fish in water that contained particles of new and old tires. The salmon died, and the researchers then began testing the hundreds of chemicals that had leached into the water.

A 2020 paper revealed the cause of mortality: a chemical called 6PPD that is added to tires to prevent their cracking and degradation. When 6PPD, which occurs in tire dust, is exposed to ground-level ozone, it’s transformed into multiple other chemicals, including 6PPD-quinone, or 6PPD-q. The compound is acutely toxic to four of 11 tested fish species, including coho salmon.

Mystery solved, but not the problem, for the chemical continues to be used by all major tire manufacturers and is found on roads and in waterways around the world. Though no one has studied the impact of 6PPD-q on human health, it’s also been detected in the urine of children, adults, and pregnant women in South China. The pathways and significance of that contamination are, so far, unknown.

Still, there are now calls for regulatory action. Last month, the legal nonprofit Earthjustice, on behalf of the fishing industry, filed a notice of intent to sue tire manufacturers for violating the Endangered Species Act by using 6PPD. And a coalition of Indian tribes recently called on the EPA to ban use of the chemical. “We have witnessed firsthand the devastation to the salmon species we have always relied upon to nourish our people,” the Puyallup Tribal Council said in a statement. “We have watched as the species have declined to the point of almost certain extinction if nothing is done to protect them.”

The painstaking parsing of 6PPD and 6PPD-q was just the beginning of a global campaign to understand the toxic cocktail of organic chemicals, tiny particles, and heavy metals hiding in tires and, to a lesser extent, brakes. While the acute toxicity of 6PPD-q and its source have strong scientific consensus, tire rubber contains more than 400 chemicals and compounds, many of them carcinogenic, and research is only beginning to show how widespread the problems from tire dust may be.

While the rubber rings beneath your car may seem benign — one advertising campaign used to feature babies cradled in tires — they are, experts say, a significant source of air, soil, and water pollution that may affect humans as well as fish, wildlife, and other organisms. That’s a problem because some 2 billion tires globally are sold each year — enough to reach the moon if stacked on their sides — with the market expected to reach 3.4 billion a year by 2030.

(Researchers weigh a salmon that died after four hours in a tank filled with road runoff.)

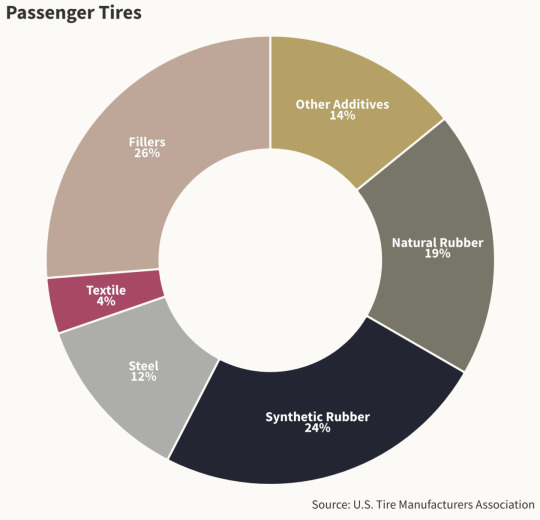

Tires are made from about 20 percent natural rubber and 24 percent synthetic rubber, which requires five gallons of petroleum per tire. Hundreds of other ingredients, including steel, fillers, and heavy metals — including copper, cadmium, lead, and zinc — make up the rest, many of them added to enhance performance, improve durability, and reduce the possibility of fires.

Both natural and synthetic rubber break down in the environment, but synthetic fragments last a lot longer. Seventy-eight percent of ocean microplastics are synthetic tire rubber, according to a report by the Pew Charitable Trust. These fragments are ingested by marine animals — particles have been found in gills and stomachs — and can cause a range of effects, from neurotoxicity to growth retardation and behavioral abnormalities.

“We found extremely high levels of microplastics in our stormwater,” said Rebecca Sutton, an environmental scientist with the San Francisco Estuary Institute who studied runoff. “Our estimated annual discharge of microplastics into San Francisco Bay from stormwater was 7 trillion particles, and half of that was suspected tire particles.”

Tire wear particles, or TWP as they are sometimes known, are emitted continually as vehicles travel. They range in size from visible pieces of rubber or plastic to microparticles, and they comprise one of the products’ most significant environmental impacts, according to the British firm Emissions Analytics, which has spent three years studying tire emissions. The company found that a car’s four tires collectively emit 1 trillion ultrafine particles — of less than 100 nanometers — per kilometer driven. These particles, a growing number of experts say, pose a unique health risk: They are so small they can pass through lung tissue into the bloodstream and cross the blood-brain barrier or be breathed in and travel directly to the brain, causing a range of problems.

According to a recent report issued by researchers at Imperial College London, “There is emerging evidence that tyre wear particles and other particulate matter may contribute to a range of negative health impacts including heart, lung, developmental, reproductive, and cancer outcomes.”

The report says that tires generate 6 million tons of particles a year, globally, of which 200,000 tons end up in oceans. According to Emissions Analytics, cars in the U.S. emit, on average, 5 pounds of tire particles a year, while cars in Europe, where fewer miles are driven, shed 2.5 pounds per year. Moreover, tire emissions from electric vehicles are 20 percent higher than those from fossil-fuel vehicles. EVs weigh more and have greater torque, which wears out tires faster.

Unlike tailpipe exhaust, which has long been studied and regulated, emissions from tires and brakes — which emit significant amounts of metallic particles in addition to organic chemicals — are far harder to measure and control and have therefore escaped regulation. It’s only in the last several years, with the development of new technologies capable of measuring tire emissions and the alarming discovery of 6PPD-q, that the subject is receiving much needed scrutiny.

Recent studies show that the mass of PM 2.5 and PM 10 emissions — which are, along with ozone and ultrafine particles, the world’s primary air pollutants — from tires and brakes far exceeds the mass of emissions from tailpipes, at least in places that have significantly reduced those emissions.

The problem isn’t just rubber in its synthetic and natural form. Government and academic researchers are investigating the transformations produced by tires’ many other ingredients, which could — like 6PPD — form substances more toxic than their parent chemicals as they break down with exposure to sunlight and rain.

“You’ve got a chemical cocktail in these tires that no one really understands and is kept highly confidential by the tire manufacturers,” said Nick Molden, the CEO of Emissions Analytics. “We struggle to think of another consumer product that is so prevalent in the world, and used by virtually everyone, where there is so little known of what is in them.”

“We have known that tires contribute significantly to environmental pollution, but only recently have we begun to uncover the extent of that,” said Cassandra Johannessen, a researcher at Montreal’s Concordia University who is quantifying levels of tire chemicals in urban watersheds and studying how they transform in the environment. The discovery of 6PPD-q has surprised a lot of researchers, she said, because they have learned that “it’s one of the most toxic substances known, and it seems to be everywhere in the world.”

Regulators are playing catch up. In Europe, a standard to be implemented in 2025, known as Euro 7, will regulate not only tailpipe emissions but also emissions from tires and brakes. The California Environmental Protection Agency has passed a rule requiring tire makers to declare an alternative to 6PPD-q by 2024.

(A worker takes apart a tire at a recycling shop in Mit al-Harun, Egypt.)

Tire companies are conducting their own studies of 6PPD, which they have long considered critical for tire safety, and seeking alternatives. In response to new regulations and the emerging research on tire emissions, 10 of the world’s large tire manufacturers have formed the Tire Industry Project to “develop a holistic approach to better understand and promote action on the mitigation” of tire pollution, according to a statement by the project. The group has committed to search for ways to redesign tires to reduce or eliminate emissions.

One critical area of research is how long tire waste, and its breakdown products, persist in the environment. “A five-micron piece of rubber shears off the tire and settles on the soil and sits there a while,” said Molden. “What, over time, is the release of those chemicals, how quickly do they make their way into the water, and are they diluted? At the system level, how big of a problem is this? It is the single biggest knowledge gap.”

Another area of research centers on the impacts of aromatic hydrocarbons — including benzene and naphthalene — off-gassed by synthetic rubber or emitted when discarded tires are burned in incinerators for energy recovery. Even at low concentrations, these compounds are toxic to humans. They also react with sunlight to form ozone, or ground-level smog, which causes respiratory harm. “We have shown that the amount of off-gassing volatile organic compounds is 100 times greater than that coming out of a modern tailpipe,” said Molden. “This is from the tire just sitting there.”

When tires reach their end of life, they’re either sent to landfills, incinerated, burned in an energy-intensive process called pyrolysis, or shredded and repurposed for use in artificial turf or in playgrounds or for other surfaces. But as concern about tire pollutants grows, so do concerns about these recycled products and the hydrocarbons they may off-gas. There is ongoing debate over whether crumb rubber, made from tire scraps, poses a health threat when used to fill gaps in artificial turf. Based on several peer-reviewed studies, the European Union is instituting stricter limits on the use of this material. Other studies, however, have shown no health impact.

Besides California’s requirement to study alternatives to 6PPD, there are a number of efforts worldwide to redesign tires to counter the problems they pose. More than a decade ago, tire makers hoped that dandelions, which produce a form of rubber, and soy oil could provide a steady and sustainable supply of rubber. But tires made from those alternatives didn’t live up to expectations: they still required additives. The Continental Tire Company, based in Hanover, Germany, markets a bicycle tire made of dandelion roots. Tested by Emission Analytics, it emitted 25 percent fewer carcinogenic aromatics than conventionally made bike tires, but the plant-powered tire still contained ingredients of concern.

(Rubber made from dandelions.)

Other companies are searching for ways to address the problem of tire emissions. The Tyre Collective, a clean-tech startup based in the U.K., has developed an electrostatic plate that affixes to each of a car’s tires: The plates remove up to 60 percent of particles emitted by both tires and brakes, storing them in a cartridge attached to the device. The particles can be reused in numerous other applications, including in new tires.

In San Francisco, scientists studying the pollutants in storm runoff found a potential solution: Rain gardens, installed in yards to capture stormwater, were also trapping 96 percent of street litter and 100 percent of black rubbery fragments. In Vancouver, B.C. researchers found that rain gardens could prevent more than 90 percent of 6PPD-q from running off roads and entering salmon-bearing streams.

Tire waste particles, says Molden, of Emissions Analytics, are finally getting the attention they deserve, thanks in part to California’s rule requiring a search for alternatives to 6PPD. The legislation “is groundbreaking,” he says, “because it puts the chemical composition [of tires] on the regulatory agenda.” For the first time, he adds, “Tire manufacturers are being exposed to the same regulatory scrutiny that car manufacturers have been for 50 years.”

8 notes

·

View notes

Text

Cost-effective galvanized steel tanks as fish aquaculture tanks

At Shijiazhuang Zhengzhong Technology Co., Ltd, we are dedicated to providing innovative storage solutions that meet the diverse needs of various industries. Our cost-effective galvanized steel tanks are an ideal choice for fish aquaculture, offering a robust and reliable option for sustainable fish farming. With over 30 years of experience in the storage industry, we understand the unique requirements of aquaculture and are committed to delivering high-quality products.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Galvanized Steel Tanks for Aquaculture?

Durability and Corrosion Resistance

Our galvanized steel tanks are constructed from high-quality steel, coated with a layer of zinc to provide excellent corrosion resistance. This ensures that the tanks can withstand harsh environmental conditions and the corrosive nature of water and aquatic life. The durability of galvanized steel tanks makes them a long-lasting investment, minimizing the need for frequent replacements.

Cost-Effectiveness

One of the key advantages of galvanized steel tanks is their cost-effectiveness. Compared to other materials, galvanized steel offers a lower initial investment while still providing exceptional durability and performance. This makes our tanks an ideal choice for fish farmers looking to maximize their return on investment without compromising quality.

Lightweight and Easy to Install

Galvanized steel tanks are lightweight and designed for easy transportation and installation. This feature is particularly beneficial for aquaculture operations in remote locations, where quick setup is essential. The tanks can be assembled on-site with minimal disruption, allowing for efficient deployment of aquaculture systems.

Customization Options

At Center Enamel, we understand that each aquaculture project has unique requirements. Our galvanized steel tanks can be customized to fit specific dimensions and capacities, ensuring they meet the needs of your fish farming operation. Additionally, we offer a range of accessories, including aeration systems and filtration options, to enhance the functionality of the tanks.

Environmental Sustainability

Fish aquaculture is a growing industry focused on sustainability and environmental responsibility. Our galvanized steel tanks are designed to promote efficient water use and reduce waste, contributing to sustainable aquaculture practices. The robust construction of our tanks minimizes leaks and ensures a stable environment for fish, supporting healthy growth and productivity.

Applications in Fish Aquaculture

Freshwater and Saltwater Species

Our galvanized steel tanks are suitable for both freshwater and saltwater aquaculture. They provide a controlled environment that supports the growth of various fish species, from tilapia to shrimp, ensuring optimal conditions for breeding and farming.

Recirculating Aquaculture Systems (RAS)

For operations utilizing recirculating aquaculture systems, our galvanized steel tanks can be seamlessly integrated into existing setups. The tanks’ durability and corrosion resistance make them ideal for maintaining the water quality necessary for RAS, allowing for efficient filtration and oxygenation processes.

Quality Assurance and Standards

Shijiazhuang Zhengzhong Technology Co., Ltd is an ISO 9001 certified company, adhering to international quality management standards. Our galvanized steel tanks are produced using state-of-the-art manufacturing processes, ensuring consistency and reliability in every product. We also comply with relevant industry standards, providing you with peace of mind regarding the quality of our tanks.

Comprehensive Support and Service

From the initial design phase to installation and ongoing support, our team is dedicated to providing exceptional service. We collaborate closely with our clients to ensure that our galvanized steel tanks meet their specific aquaculture needs. Our experienced engineers and technicians are available to assist with any questions or challenges that may arise during the implementation of your aquaculture system.

Shijiazhuang Zhengzhong Technology Co., Ltd is your trusted partner for cost-effective galvanized steel tanks in fish aquaculture. Our commitment to quality, innovation, and customer satisfaction sets us apart in the industry. By choosing our galvanized steel tanks, you are investing in a durable, efficient, and sustainable solution for your aquaculture needs. Contact us today to learn more about our products and how we can support your fish farming operations. Let us help you achieve success in your aquaculture endeavors with our superior storage solutions.

0 notes

Text

Commercial Protective Coatings - Valence coatings

What materials are used in protective coatings?

Protective coatings are used to safeguard surfaces from corrosion, wear, chemicals, and other environmental factors. The materials used in protective coatings depend on the specific application and the type of protection required. Common materials include:

1. Epoxy Resins

Properties: Excellent adhesion, chemical resistance, and durability.

Applications: Industrial environments, marine coatings, and pipelines.

2. Polyurethane

Properties: High flexibility, impact resistance, and UV stability.

Applications: Automotive finishes, floors, and exterior building surfaces.

3. Zinc

Properties: Sacrificial corrosion protection, preventing rust by corroding in place of the base metal.

Applications: Galvanizing steel, bridges, and marine structures.

4. Acrylics

Properties: Quick drying, good weather resistance, and gloss retention.

Applications: Architectural coatings, automotive topcoats, and decorative finishes.

5. Silicones

Properties: High heat resistance and water repellency.

Applications: High-temperature equipment, chimneys, and exhaust systems.

6. Alkyds

Properties: Good weather resistance, flexibility, and ease of application.

Applications: General-purpose metal protection, structural steel, and machinery.

7. Polyurea

Properties: Rapid curing, abrasion resistance, and waterproofing.

Applications: Bridges, roofing, and tanks.

8. Ceramic Coatings

Properties: High thermal resistance, wear resistance, and chemical stability.

Applications: High-temperature machinery, aerospace components, and exhaust systems.

9. Fluoropolymers

Properties: Excellent chemical resistance, low friction, and high durability.

Applications: Chemical tanks, pipelines, and exterior architectural coatings.

10. Powder Coatings

Properties: Environmentally friendly (no solvents), durable, and resistant to chipping.

Applications: Appliances, furniture, and automotive parts.

Each material provides specific benefits, making them suitable for different environments and protective requirements.

#Garage Floor Coatings Mn#Protective Coating For Concrete#Protective Coating Solutions#Epoxy Flooring Companies#Commercial Protective Coatings#Branded Concrete Coatings#Polyurea Coatings Suppliers#Concrete Coatings Mn#Concrete Coatings Minnesota

0 notes

Text

High-Quality Zinc-Aluminium Steel Tanks in Dubai and UAE

For businesses and industries in need of durable, long-lasting water storage solutions, Zinc-Aluminium Steel Tanks are the perfect choice. At Prefabtanks in Dubai, we offer top-tier zinc-aluminium steel tanks designed for optimal performance and longevity. These tanks are ideal for storing potable water, domestic water, and a variety of other liquids, making them an essential solution for residential, commercial, and industrial applications in Dubai and across the UAE.

The unique combination of zinc and aluminium gives these tanks superior corrosion resistance and strength, ensuring that they can withstand the harsh environmental conditions in Dubai, including extreme heat and UV exposure. Our zinc-aluminium steel tanks are designed to offer robust protection against rust and wear, making them a reliable and cost-effective solution for long-term water storage.

At Prefabtanks, we specialize in providing customizable solutions to meet your specific water storage needs. Whether you need a small tank for household use or a large-scale tank for an industrial facility, our zinc-aluminium steel tanks deliver exceptional durability and performance. In addition to their strength, these tanks are lightweight, making installation easy and efficient.

For reliable water storage that stands the test of time, choose Prefabtanks in Dubai. Our zinc-aluminium steel tanks are engineered to provide safe, long-term storage for potable and domestic water. Visit Zinc-Aluminium Steel Tanks in Dubai for more information and to explore our range of durable, high-performance tanks.

#Potable & domestic water storage tanks in Dubai#Potable & domestic water storage tanks#Potable & domestic water storage tanks in UAE#potable & domestic water storage tanks in Dubai-UAE#Prefabtanks in Dubai

0 notes

Text

Ensuring Durability and Strength: Why MKV Tech Solutions is Your Trusted Water Storage Tank Partner

In today’s rapidly evolving industrial landscape, businesses demand innovative and reliable solutions for their water storage needs. MKV Tech Solutions stands at the forefront, offering top-notch water storage tanks that combine durability, strength, and advanced technology. Whether you’re in need of a Zincalume water storage tank or an industrial-grade demineralized water tank, We delivers unparalleled quality and service.

Zincalume Water Storage Tank Manufacturers

When it comes to water storage, Zincalume tanks have become a popular choice due to their excellent corrosion resistance and long-lasting durability. As leading Zincalume Water Storage Tank Manufacturers, We ensures that each tank is engineered with precision, utilizing cutting-edge Zincalume steel technology. These tanks are ideal for industrial use, providing longevity and reliable performance in a variety of challenging environments.

Zinc Aluminium Water Storage Tank Manufacturers

We also recognized as a premier Zinc Aluminium Water Storage Tank Manufacturers, offering tanks that leverage the unique properties of zinc and aluminum alloys. The combination of these metals enhances the tank’s strength and corrosion resistance, making them a perfect fit for both industrial and commercial applications. With our expert craftsmanship, each tank meets the highest industry standards, ensuring safety and efficiency for our clients.

Industrial Water Storage Tank Service Provider

At MKV Tech Solutions, we take pride in being a leading Industrial Water Storage Tank Service Provider. Our commitment goes beyond just manufacturing; we provide comprehensive services that include consultation, installation, and maintenance. Our expert team is equipped to handle the most complex storage needs, ensuring that your industrial water systems operate smoothly and efficiently, no matter the scale of your project.

Demineralized Water Tank Suppliers

For industries that require ultra-pure water, such as pharmaceuticals, power generation, and food processing, we are trusted Demineralized Water Tank Suppliers. Our demineralized water tanks are designed to prevent contamination and preserve water purity. These tanks are built to withstand rigorous industrial environments while maintaining the high standards required for demineralized water storage.

Zincalume Steel Storage Tank Suppliers

As reputable Zincalume Steel Storage Tank Suppliers, we ensure that all our storage solutions meet the evolving needs of modern industries. The Zincalume steel we use combines the best properties of zinc and aluminum, resulting in tanks that are not only robust but also offer superior corrosion protection. These tanks are perfect for long-term use, ensuring that your investment is safeguarded for years to come.

Why Choose MKV Tech Solutions?

MKV Tech Solutions is dedicated to providing reliable, cost-effective, and innovative water storage solutions to clients across various industries. Our products, backed by exceptional customer service, stand as a testament to our commitment to quality. Whether you’re looking for Zincalume water storage tanks or demineralized water tanks, we deliver customized solutions tailored to meet your unique needs.

By choosing us you’re investing in superior water storage systems that are built to last. Trust us to deliver the quality and performance your business deserves.

#Zincalume Water Storage Tank Manufacturers#Zinc Aluminium Water Storage Tank Manufacturers#Industrial Water Storage Tank Service Provider#Demineralized Water Tank Suppliers#Zincalume Steel Storage Tank Suppliers

0 notes

Text

4WD Bash Plates: Essential Protection for Extreme Off-Roading

When it comes to off-road adventures, a four-wheel drive vehicle needs 4WD bash plates that offer the best protection to handle rough terrains and unpredictable obstacles. A bash plate is one of the most critical components for safeguarding a vehicle since the underneath of the vehicle actually has many components that are vulnerable. When one is going for an off-road drive then various obstacles like rocks, boulders, etc can damage equipment like the radiator, steering, sump, and transmission. Generally, these bash plates are add-ons and there are many other items that are add-ons but essential for four-wheel drive vehicles when one needs to go for a trip.

For off-road enthusiasts, fridge slides are essential for keeping provisions both accessible and secure. People do need a tilt fridge slide, a drop-down fridge slide, or an easy slide fridge slide as this equipment helps in getting the food out of the fridge easily and makes things easily accessible. One can also choose other options like Waeco fridge slides and MSA drop slides accommodate a range of fridge sizes, from 40 litres to 95 litres. These slides make sure your fridge is always within reach, even when your vehicle is fully loaded, boosting both convenience and practicality during your adventures.

Greater Insights About the Importance of Bash Plates and Battery Trays

Designed to shield the undercarriage from rocks, debris, and other hazards, high-quality 4WD bash plates are essential for preventing damage to vital components such as the engine, transmission, and fuel tank. Investing in durable bash plates ensures that the vehicle remains in top condition, ready to tackle any trail with confidence and reliability.

Battery trays are similarly very important for vehicles and essential for keeping the vehicle's auxiliary battery secure, especially when navigating off-road trails. These top-notch trays, crafted from 2mm mild steel, are precision laser cut and folded to fit perfectly. The leading manufacturers boast a zinc-plated finish to ward off corrosion and are strategically welded to ensure maximum strength. The leading manufacturers understand the design of all major models of 4WDs and are designed to hold batteries up to N70 or 12 inches.

Contact the leading companies selling these products and one can purchase these products online as well by browsing the catalogue.

Source: https://hiluxbashplates.blogspot.com/2024/08/4wd-bash-plates-essential-protection.html

0 notes

Text

Zincalume Water Storage Tank

A Zincalume water storage tank offers durable and reliable water storage solutions that are ideal for residential and commercial use. Made from high-strength steel coated with zinc, aluminum, and silicon, it resists corrosion and withstands harsh weather conditions. These tanks are long-lasting, low-maintenance, and eco-friendly, providing a cost-effective and efficient way to store water for various needs. Bhupati Engineering is a leading manufacturer and exporter of Zincalume water storage tanks, offering durable, corrosion-resistant tanks designed for reliable water storage solutions across various industries.

#Zincalume Water Storage Tank#Zincalume Water Storage Tank Manufacturers#Zincalume Water Tank#Zincalume Water Tank Manufacturers#Zincalume Water Storage Tanks Exporters#Zincalume Water Storage Tanks Exporters in India#Zincalume Water Storage Tanks Exporter

0 notes

Text

What are the Applications of Zinc Aluminium Tanks in Industries?

Applications of Zinc Aluminium Tank:

Zinc-aluminum Tanks are used in a variety of industries and applications due to their excellent corrosion resistance:

Construction: In the construction industry, zinc-aluminum coated steel is used for roofing sheets, structural beams, and cladding. The coating provides long-term protection against weathering and exposure to the elements.

Automotive: The automotive industry uses zinc-aluminum Tanks for parts that are exposed to harsh conditions, such as chassis components and undercarriages. The coating helps to extend the service life of these parts and improve vehicle durability.

Infrastructure: For infrastructure projects such as bridges, railways, and pipelines, zinc-aluminum Tanks are applied to steel components to protect against corrosion and ensure the structural integrity of these critical assets.

Agricultural Equipment: In agriculture, equipment such as irrigation systems and storage tanks benefit from the corrosion resistance of zinc-aluminum coatings, which helps to reduce maintenance and increase longevity.

What is Zinc Aluminum Tank?

A “Zinc-Aluminium Tank” refers to a tank that is either made of steel coated with a zinc-aluminum alloy or constructed entirely from a zinc-aluminum alloy. These tanks benefit from the corrosion-resistant properties of the zinc-aluminum coating, making them suitable for storing a variety of substances in challenging environments.

How Does Zinc Aluminium Tank Work?

The zinc-aluminum tanks provides a dual-layered protection system:

Barrier Protection: The coating acts as a physical barrier between the steel and environmental factors such as moisture, oxygen, and pollutants. This prevents direct contact of these corrosive agents with the steel surface.

Galvanic Protection: Zinc is more reactive than steel and will corrode preferentially, protecting the underlying steel. Aluminum further enhances this protective effect by forming a stable oxide layer that further shields the zinc and steel from corrosion.

Key Benefits of Zinc Aluminium Tank:

Enhanced Corrosion Resistance: The primary advantage of zinc-aluminum Tanks is their superior resistance to corrosion compared to standard zinc coatings. The combination of zinc and aluminum provides a more durable and long-lasting barrier.

Improved Durability: Zinc-aluminum coatings are known for their durability and ability to withstand harsh environmental conditions, including exposure to high humidity and saline environments. This makes them ideal for applications in coastal or industrial areas.

Self-Healing Properties: Zinc-aluminum coatings have a self-healing property. When the coating is scratched or damaged, the zinc and aluminum react with the environment to form a protective layer over the exposed area, mitigating further corrosion.

Cost-Effectiveness: While the initial cost of zinc-aluminum coatings may be higher than standard zinc coatings, their extended lifespan and reduced maintenance needs can result in lower overall costs.

Conclusion

Zinc-aluminum Tanks represent a significant advancement in corrosion protection technology. By combining the best properties of zinc and aluminum, these coatings provide enhanced durability, improved resistance to harsh environments, and cost-effective solutions for a wide range of applications. Whether in construction, automotive, infrastructure, or agriculture, zinc-aluminum coatings play a crucial role in extending the lifespan and performance of steel products.

For more details, please contact us!

Website :- www.orisonindustries.in

Contact No. :- +91���8860602980

Email :- [email protected]

#Zinc Aluminium Tanks#Zinc Aluminium Tanks manfuacturer#Zinc Aluminium Tanks supplier in India#Zinc Aluminium Tanks manufacturer in India#Orison Industries

1 note

·

View note

Text

Zinc-Aluminium Steel Tanks: Durable Potable Water Storage Solutions by Mizutanks

Water storage solutions are essential for ensuring access to clean and safe water in both domestic and industrial settings. Mizutanks offers high-quality zinc-aluminium steel tanks designed specifically for potable water storage in India. These tanks are engineered to provide reliable and long-lasting storage solutions for a variety of needs, from domestic water tanks to large-scale industrial water storage.

Potable Water Storage Tanks in India

Mizutanks is a leader in providing potable water storage tanks in India. Our zinc-aluminium steel tanks are crafted to meet the highest standards of safety and durability. These tanks are ideal for storing drinking water, ensuring that it remains pure and uncontaminated. The use of zinc-aluminium steel provides additional protection against corrosion, making these tanks a smart choice for long-term water storage.

Domestic Water Tanks for Reliable Supply

For households across India, Mizutanks offers durable domestic water tanks that are perfect for ensuring a steady supply of potable water. Our tanks are available in various capacities, allowing you to choose the right size for your household’s needs. With Mizutanks, you can be confident that your domestic water storage is secure, and that your family has access to safe drinking water at all times.

Industrial Water Storage in India

In addition to domestic applications, Mizutanks also specializes in industrial water storage in India. Our zinc-aluminium steel tanks are designed to handle the rigorous demands of industrial environments. Whether you need to store large volumes of water for processing, cooling, or any other industrial purpose, Mizutanks provides robust solutions that ensure the integrity and safety of your water supply.

Comprehensive Water Tank Solutions

Mizutanks offers a full range of water tank solutions to meet diverse needs. Our tanks are designed to be versatile and reliable, whether you need potable water tanks for drinking water or industrial tanks for large-scale water storage. The zinc-aluminium steel construction of our tanks ensures they are resistant to harsh environmental conditions, providing long-lasting service.

Choosing the Right Domestic Water Tank Capacity

Selecting the appropriate domestic water tank capacity is crucial for meeting your household’s water needs. Mizutanks provides a variety of sizes to choose from, ensuring you can find the perfect fit. Whether you need a small tank for a single home or a larger one for a residential complex, our tanks are designed to provide efficient and reliable water storage.

Why Mizutanks?

Mizutanks is committed to delivering high-quality water storage solutions that cater to both domestic and industrial needs. Our zinc-aluminium steel tanks are engineered to offer durability, reliability, and safety, making them the ideal choice for potable water storage in India. By choosing Mizutanks, you are investing in a solution that ensures your water is stored safely and efficiently, whether for domestic or industrial use.

#Zinc aluminium steel tank in India#Mizutanks#Industrial and commercial steel tanks#Zinc aluminium steel tank in Pune#Zinc aluminium steel tank#Durable zinc steel tank#zinc water tanks

0 notes

Text

Step-by-Step: What Does a Roof Plumber Do?

Roof plumbing is a specialised field within the broader construction industry that focuses on ensuring effective water management and protection from the elements for buildings.

A roof plumber Hampton plays a crucial role in installing, repairing, and maintaining the intricate systems that safeguard homes and commercial structures from water damage. This blog explores the responsibilities of a roof plumber in detail, breaking down their tasks step-by-step.

More Info: www.titanplumbingservices.com.au/plumber-hampton

Understanding the Role of a Roof Plumber

Roof plumbers are trained professionals responsible for the installation and maintenance of roofs' plumbing systems. Unlike traditional plumbers, who work primarily with indoor plumbing, roof plumbers deal with systems that manage rainwater, ensuring it is directed away from the building effectively.

Their expertise lies in preventing leaks, ensuring proper drainage, and integrating gutters, downpipes, and rainwater tanks seamlessly into the overall building structure.

Installation of Roof Plumbing Systems

The first major task of a roof plumber is the installation of new roof plumbing systems. This process involves several key steps:

Assessment and Planning: Before any work begins, roof plumbers assess the building plans or existing structure to determine the most efficient placement of gutters, downpipes, and other components. They consider factors such as roof pitch, local weather patterns, and building codes.

Material Selection: Roof plumbers select appropriate materials such as copper, zinc, Colorbond steel, or PVC for gutters and downpipes based on durability, aesthetic appeal, and budget constraints.

Installation: Once the planning and material selection is complete, roof plumbers proceed with the installation. This includes accurately measuring and cutting materials, securely attaching them to the roof and walls, and ensuring proper alignment for effective water flow.

Maintenance and Repair Work

Beyond installation, roof plumber Hampton are also responsible for ongoing maintenance and repairs to ensure the longevity and functionality of the plumbing system. This includes:

Clearing Debris: Regularly cleaning gutters or blocked drains Hampton to prevent blockages caused by leaves, twigs, and other debris. Blockages can lead to overflow and water damage to the building.

Inspecting for Damage: Conducting routine inspections to identify signs of wear, corrosion, or damage to gutters, downpipes, and other components. Early detection allows for timely repairs, preventing more extensive issues.

Repairing Leaks: Addressing leaks promptly by sealing joints, replacing damaged sections of guttering or downpipes, and ensuring all connections are watertight.

Compliance with Building Codes and Safety Standards

A critical aspect of a roof plumber's job is ensuring all work complies with local building codes and safety standards. This includes:

Knowledge of Regulations: Staying informed about the latest building codes and regulations pertaining to roof plumbing in their region. This ensures installations meet minimum requirements for structural integrity and water management.

Safety Practices: Adhering to strict safety protocols when working at heights, using ladders, and handling tools and materials. Roof plumbers are trained to minimise risks of falls, injuries, and other hazards associated with their work environment.

Collaboration and Communication

Effective communication and collaboration are essential skills for roof plumbers. They often work closely with other tradespeople, architects, and builders to coordinate projects and ensure seamless integration of plumbing systems with the overall construction or renovation plans.

This collaborative approach helps in delivering high-quality results that meet the client's expectations and regulatory requirements.

Conclusion

A roof plumber's role is indispensable in safeguarding buildings against water damage by installing and maintaining efficient roof plumbing systems. From meticulous planning and installation to ongoing maintenance and repairs, roof plumber Hampton plays a vital role in ensuring structures remain watertight and functional.

Their expertise, attention to detail, and commitment to safety contribute significantly to the longevity and reliability of residential and commercial buildings alike. Whether it's a new construction project or a renovation, the services of a skilled roof plumber are crucial for the overall integrity and durability of any building.

Source: Step-by-Step: What Does a Roof Plumber Do?

0 notes

Text

Lower Maintenance Hot-Dipped Galvanized Steel Tanks for Fire Suppression: Reliable, Cost-Effective Solutions by Shijiazhuang Zhengzhong Technology Co., Ltd

As fire safety requirements and regulations continue to evolve, fire suppression systems are essential in protecting both lives and properties. Shijiazhuang Zhengzhong Technology Co., Ltd., a leading manufacturer of bolted storage tanks, offers hot-dipped galvanized steel tanks specifically designed to meet the stringent demands of fire suppression. Our galvanized tanks are built for durability, requiring minimal maintenance, and provide a cost-effective solution for industrial, commercial, and municipal fire suppression systems.

The Advantage of Hot-Dipped Galvanized Steel Tanks for Fire Suppression

Galvanized steel is widely recognized for its corrosion resistance and durability, making it an ideal material for fire suppression tanks. The hot-dip galvanizing process involves coating steel with a protective layer of zinc, ensuring a highly durable tank that can withstand harsh environmental conditions and resist corrosion over time.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Benefits of Center Enamel’s Hot-Dipped Galvanized Steel Tanks

Exceptional Durability and Corrosion Resistance

The hot-dip galvanizing process forms a durable zinc layer over the steel tank, providing robust corrosion resistance. This layer serves as a shield against oxidation and environmental exposure, ensuring the tank’s longevity even in challenging conditions, such as coastal or industrial environments.

Low Maintenance Requirements

Hot-dipped galvanized tanks require minimal maintenance compared to traditional steel tanks. The zinc coating provides an extended lifespan, reducing the frequency of repairs and touch-ups. This lower maintenance demand translates to long-term cost savings, making it an economical choice for fire suppression storage.

Rapid Assembly and Installation

Our bolted galvanized tanks are designed for fast and efficient assembly. The modular construction allows for quick installation, minimizing on-site labor costs and reducing setup time. This rapid installation is particularly beneficial for remote or urgent projects that require reliable fire suppression solutions.

Long-Term Cost Efficiency

The durability and low maintenance of galvanized steel reduce the tank’s life cycle costs. These tanks are designed for decades of use, providing value through extended service life and reduced operational costs.

Comprehensive Compliance with Fire Protection Standards

Our galvanized steel fire suppression tanks are engineered to comply with NFPA 22 standards for water tanks used in fire protection and other relevant international codes. By meeting these standards, our tanks ensure that your fire suppression system remains compliant and reliable.

Galvanizing Expertise and Quality Assurance

Center Enamel’s galvanized steel tanks are crafted with advanced galvanizing technology and undergo rigorous quality control measures to ensure that each tank meets our high standards. As one of Asia’s most experienced bolted tank manufacturers, we bring over 30 years of expertise to every product we create. Our quality control system aligns with international standards, such as ISO 9001 for quality management, guaranteeing reliable performance and durability.

Ideal Applications for Hot-Dipped Galvanized Fire Suppression Tanks

Our galvanized steel tanks are suitable for a wide range of applications, including:

Commercial Facilities: Reliable fire suppression storage for office buildings, retail spaces, and mixed-use properties.

Industrial Sites: Fire protection for factories, manufacturing plants, and warehouses.

Municipal Firefighting Systems: Robust water storage solutions for city fire suppression systems, ensuring readiness in case of emergency.

Remote and Rural Areas: Rapid deployment and installation in areas without direct water supply access, ensuring fire safety compliance.

Why Choose Center Enamel for Hot-Dipped Galvanized Fire Suppression Tanks?

Proven Industry Experience: With over three decades of expertise in bolted tank manufacturing, Center Enamel is a trusted name in the industry.

Customized Solutions: Our engineering team collaborates closely with clients to design fire suppression tanks that meet their specific site requirements and regulatory needs.

Global Reach and Recognition: Center Enamel’s tanks are used in over 100 countries, providing reliable storage solutions for diverse fire suppression applications worldwide.

Extensive Client List: We are proud to partner with industry leaders, including well-known corporations across sectors, who trust Center Enamel for their storage needs.

Partner with Center Enamel for Reliable Fire Suppression Solutions

With Center Enamel’s hot-dipped galvanized steel tanks, you gain a durable, low-maintenance, and cost-effective solution for your fire suppression water storage needs. Our dedication to quality and compliance ensures that each tank offers the reliability and peace of mind necessary for effective fire protection.

For more information about our hot-dipped galvanized steel fire suppression tanks, please contact our team. We are ready to provide you with a custom solution to meet your fire safety requirements and ensure comprehensive fire protection for your facility.

0 notes

Text

SMOK MORPH 2 230W STARTER KIT The SMOK Morph 2 Kit built with zinc alloy to improve the durability and the leather for comfort. Equipped with the IQ-S chipset and has outstanding performance., and the 0.001S instant fire. Powered by dual 18650 batteries (Not Included) and max output up to 230W, with USB type-c charging port and the max 2A balance charging to shorten the charging time. The SMOK Morph 2 230W Starter Kit supports Power Mode and Temp Control Mode. The 0.96-inch OLED screen will show you vaping data, such as working mode, battery life, resistance, wattage, puff counting and vape time. The SMOK Morph 2 comes with the latest TFV18 Tank, which can hold 7.5ml of e-juice, with 3 large adjustable airflow slots allows for Direct Lung (DL) or tight Mouth To Lung (MTL) vaping. SMOK MORPH 2 230W BOX MOD FEATURES: IQ-S Chipset Dimensions - 88mm by 47.5mm by 31.7mm Dual 18650 Batteries - Not Included Wattage Output Range: 1-230W Voltage Output Range: 1.2-8.2V Resistance Range - VW Mode: 0.1-2.5ohm Resistance Range - TC Mode: 0.05-2.0ohm Temperature Range: 200°F-600°F /100°C-315°C Nickel, Titanium, and Stainless Steel Wire Compatibility Firing Speed: 0.001s Zinc-Alloy Chassis Construction Intuitive Firing Button 0.96" OLED Display Screen Two Adjustment Buttons 8s Cut-Off Protection Atomizer Detection Over-Heating Protection Short Circuit Protection Low Battery Warning Reverse Polarity Over-Discharge Protection Type-C Port SMOK TFV18 TANK FEATURES: 32mm Diameter 7.5mL Capacity Optional 6.5mL Capacity Pyrex Glass Construction Superior 304 Stainless Steel Tank Construction Top Filling System - Press and Slide TFV18 Mesh Coil Series 0.33ohm TFV18 Meshed Coils 0.15ohm TFV18 Dual Meshed Coils Press-Fit Coil Installation Dual Slotted Bottom Airflow Control Ring Threaded 510 Connection PACKAGE INCLUDES: 1 Morph 2 Mod 1 TFV18 Tank 1 0.33ohm TFV18 Meshed Coil 1 0.15ohm TFV18 Dual Meshed Coil 1 Replacement Bulb Glass Tube 1 Type-C Cable 1 User Manual

0 notes

Text

The Complete Guide to Zinc Plating: All You Need To Know

Zinc plating is a process widely used in various industries to enhance the corrosion resistance of steel and iron. This guide will provide you with a comprehensive understanding of zinc plating, its benefits, and its applications, particularly in the context of rust removal from steel Cincinnati and metal cleaning services Cincinnati.

What is Zinc Plating?

Zinc plating, also known as galvanization, involves the application of a thin layer of zinc to the surface of metal parts. The primary goal is to prevent rust and corrosion, which can significantly extend the life of metal components.

The Zinc Plating Process

Cleaning: The metal surface is cleaned thoroughly to remove any dirt, oil, or existing corrosion. This step is crucial for ensuring a strong bond between the zinc and the metal.

Pickling: The metal is then treated with an acid solution to remove any remaining oxides.

Plating: The cleaned metal is submerged in an electrolyte solution containing zinc ions. An electrical current is passed through the solution, causing the zinc to adhere to the metal surface.

Post-Treatment: The plated metal is rinsed and sometimes treated with a passivation process to enhance corrosion resistance further.

Benefits of Zinc Plating

Zinc plating offers numerous benefits that make it a popular choice in many industries:

Corrosion Resistance: Zinc acts as a sacrificial coating, protecting the underlying metal from rust and corrosion.

Enhanced Appearance: The plated surface has a bright, shiny finish that can improve the aesthetics of the metal parts.

Cost-Effective: Zinc plating is relatively inexpensive compared to other protective coatings.

Versatility: It can be applied to a wide range of metal parts, from small fasteners to large automotive components.

Applications of Zinc Plating

Zinc plating is used in various industries due to its protective properties. Some common applications include:

Automotive Industry: Protecting car parts like brake calipers and fuel tanks from corrosion.

Construction: Ensuring the longevity of metal components in buildings and bridges.

Electronics: Providing a conductive and protective coating for electronic components.

Hardware: Enhancing the durability of fasteners, bolts, and nuts.

Why Choose Zinc Plating for Rust Removal and Metal Cleaning?

If you are looking for rust removal from steel Cincinnati or metal cleaning services Cincinnati, zinc plating is an excellent choice. Here’s why:

Effective Protection: Zinc plating provides superior corrosion resistance, making it ideal for extending the life of metal parts exposed to harsh environments.

Improved Aesthetics: The shiny finish of zinc-plated parts can enhance the visual appeal of products.

Cost-Effectiveness: Zinc plating is an affordable solution that delivers excellent protective benefits.

Versatile Application: It is suitable for a wide range of industries and applications, ensuring your specific needs are met.

Why Choose Mechanical Finishers Inc?

When it comes to rust removal from steel Cincinnati and metal cleaning services Cincinnati, Mechanical Finishers Inc stands out for several reasons:

Expertise: With years of experience in the industry, we have the knowledge and skills to deliver high-quality zinc plating services.

Advanced Technology: We use state-of-the-art equipment and techniques to ensure the best results for our clients.

Customer Satisfaction: Our commitment to excellence means we always strive to exceed customer expectations.

Competitive Pricing: We offer cost-effective solutions without compromising on quality.

Comprehensive Services: From cleaning and pickling to plating and post-treatment, we provide a complete range of services to meet your needs.

Conclusion

Zinc plating is a highly effective method for protecting metal parts from corrosion and enhancing their appearance. For businesses in Cincinnati, Mechanical Finishers Inc offers top-notch rust removal from steel Cincinnati and metal cleaning services Cincinnati. Trust us to deliver exceptional results that meet your requirements and exceed your expectations.

Reference URL: The Complete Guide to Zinc Plating: All You Need To Know

0 notes

Text

Superior Durability with GFS Tank’s Zinc-Aluminium Steel Tanks in Pune

Get robust and reliable storage with zinc-aluminium steel tanks from GFS Tank in Pune. Perfect for industrial and agricultural use, these tanks are built to last. Learn more at GFS Tank.

#Zinc aluminium steel tanks#Zinc aluminium steel tanks in Pune#Zinc aluminium steel tanks in India#Gfs tank#Zincalum Steel Tanks in India#Gfs Tank in India#Steel Tank Manufacturer India#Zincalum Tank Supplier in India#GFS Tank India#Zincalum Tanks Manufacturer in India#gfl tank in india#Steel bolted water tanks"

0 notes

Text

Premier Water Storage Solutions by MKV Tech Solutions

At MKV Tech Solutions, we pride ourselves on delivering exceptional water storage solutions crafted from the finest materials. Our products are designed to meet the highest industry standards, ensuring durability, reliability, and efficiency. Discover why MKV Tech Solutions is the trusted name in water storage across India.

Zincalume Water Storage Tank Manufacturers

MKV Tech Solutions is renowned as one of the leading Zincalume Water Storage Tank Manufacturers. Zincalume is a highly durable material, combining the corrosion resistance of aluminum with the strength of zinc, making it ideal for water storage. Our Zincalume tanks are designed to withstand harsh environmental conditions, ensuring long-lasting performance. Whether for residential, commercial, or industrial use, our Zincalume water storage tanks provide a reliable solution for all your water storage needs.

Zinc Aluminium Steel Tank Service Provider

When it comes to high-quality water storage, MKV Tech Solutions excels as a Zinc Aluminium Steel Tank Service Provider. Our tanks are made from zinc aluminum steel, a material known for its exceptional strength and corrosion resistance. We offer a comprehensive range of services, including installation, maintenance, and repair, ensuring that your water storage system remains in optimal condition. Trust us for expert service and support tailored to your specific requirements.

Zincalume Overhead Water Tank Manufacturers

For robust and reliable overhead water storage solutions, look no further than MKV Tech Solutions, the top Zincalume Overhead Water Tank Manufacturers. Our overhead water tanks made from Zincalume offer superior durability and are designed to resist rust and corrosion. These tanks are ideal for locations where ground space is limited, providing an efficient way to store water while maintaining structural integrity. Choose our Zincalume overhead water tanks for a long-lasting and dependable water storage solution.

Modular Storage Water Tank Manufacturers

Innovation and flexibility define us approach as premier Modular Storage Water Tank Manufacturers. Our modular water tanks are designed for easy assembly and installation, making them perfect for a wide range of applications. These tanks can be customized to fit specific size and capacity requirements, offering a versatile solution for water storage. Whether you need a temporary or permanent water storage solution, our modular tanks provide unmatched convenience and reliability.

Galvanised Steel Water Storage Tank Manufacturers

We stands out as one of the top Galvanised Steel Water Storage Tank Manufacturers. Galvanized steel tanks are known for their superior strength and corrosion resistance, making them ideal for water storage in various environments. Our galvanized steel tanks are designed to meet stringent quality standards, ensuring they provide safe and hygienic water storage. With Us, you can be confident that you are choosing the best in galvanized steel water storage tanks.

Conclusion

MKV Tech Solutions is dedicated to providing high-quality, durable, and efficient water storage solutions tailored to meet your specific needs. Whether you require Zincalume, zinc aluminum steel, modular, or galvanized steel water storage tanks, we have the expertise and products to deliver exceptional results. Contact us today to learn more about our innovative water storage solutions and how we can support your water storage requirements with precision and reliability.

0 notes