#Drilling Services in India

Explore tagged Tumblr posts

Text

Get a Quote Call Now..!

How Does the Choice of Drilling Equipment Impact the Outcome of a Drilling Project?

In the realm of drilling services, the choice of drilling equipment plays a pivotal role in determining the success and efficiency of a drilling project. Two common types of drilling equipment, rotary and percussion drills, offer distinct advantages and disadvantages. In this blog, we'll delve into the impact these choices have on the outcome of drilling projects, with a specific focus on Drilling Services in Pune, highlighting the expertise of Sanas Engineering.

Understanding Rotary Drills

Rotary drills are versatile machines that use a rotating motion to bore through various surfaces, including soil, rocks, and concrete. The key advantage of rotary drills lies in their ability to handle a wide range of materials efficiently. This versatility makes them suitable for diverse drilling projects, from foundation construction to geotechnical exploration.

Advantages of Rotary Drills

1. Versatility: Rotary drills can adapt to different drilling conditions and materials, making them a preferred choice for projects with varying geological compositions.

2. Speed and Efficiency: The rotational motion of these drills allows for faster penetration, leading to increased project efficiency.

3. Precision: Rotary drills provide greater control and precision, ensuring that the desired depth and diameter are achieved with accuracy.

Challenges with Rotary Drills:

1. Cost: The initial investment and maintenance costs for rotary drills can be higher compared to other drilling methods.

2. Limited in Hard Rock: While versatile, rotary drills may face challenges when encountering extremely hard rock formations.

Percussion Drills: A Different Approach:

Percussion drills, on the other hand, use a hammering or pounding motion to break through surfaces. This type of drill is particularly effective in penetrating hard materials like rocks and concrete.

Advantages of Percussion Drills:

1. Suitability for Hard Materials: Percussion drills excel in projects where the drilling surface is tough and resistant, making them ideal for certain geological conditions.

2. Cost-Effectiveness: Percussion drills can be a more cost-effective option for specific projects, especially those involving hard rock.

Challenges with Percussion Drills :

1. Limited Versatility: Percussion drills may not be as adaptable to different materials as rotary drills, restricting their use in certain projects.

2. Slower Drilling Speed: In comparison to rotary drills, percussion drills may have a slower drilling speed, potentially impacting project timelines.

Sanas Engineering's Expertise in Drilling Services in Pune:

When it comes to Drilling Services in Pune, Sanas Engineering stands out for its commitment to providing tailored solutions for diverse drilling needs. Leveraging their expertise, Sanas Engineering carefully assesses project requirements to determine the most suitable drilling equipment.

Conclusion

the choice between rotary and percussion drills significantly influences the outcome of a drilling project. Understanding the advantages and limitations of each type is crucial for making informed decisions. In the context of Drilling Services in Pune, partnering with experienced professionals like Sanas Engineering ensures that the right equipment is employed, leading to successful and efficient drilling projects.

3 notes

·

View notes

Photo

Raise Boring Machine for Raise and Shaft Drilling

Laxyo trusted raise and shaft drilling Contractor. Get the top best results with the right RBM equipment & driller can make or break. Call us now! Our raise boring machine used in underground mining. Our experienced professional teams regularly deliver raise drilling in combination with shaft development services.

For more Info please visit our website: http://www.laxyo.com/raise-boring-contractors.php

Contact us at: +91-9425103444, +91-731-4043798

Email: [email protected]

#Raise and Shaft Drilling#Raise Boring Machine#Vertical Shaft contractors#Tunnel Boring Service in India#Raise boring equipment#raise bore shaft#raise bore shaft construction#raise bore shaft mining#underground boring contractors#raise bore job#raise bore drilling jobs#raise bore equipment#Mining Raise Bore Drilling#raise boring reaming

2 notes

·

View notes

Text

Brazed Carbide, HSS Cutting Tools, Milling Cutters, Manufacturer

Ball nose End Mill, Ball Nose End Mills, Boring Bar, Boring Bars, Boring Tool, Boring Tools, Brazed Carbides, Brazed Carbide, Burnishing Drill, Burnishing Drills, Burnishing Reamers, Center Drill, Center Drills, Champer Tool, Champer Tools, Circular Form Tools, Corner Radious Cutters, Corner Radius Cutter, Counter Bores, Counter Sink, Counter Sinks, Dia Sinking Cutter, Die Sinking Cutters, Drill, Drills, End Mill, End Mills, End mill with corner radius, End Mills with Corner Radius, Extra Long Drills, Extra long End Mill, Extra Long End Mills, Extra long tools, Face Mill Cutter, Form Cutters, Form Tools, Grooving Cutter, Grooving Cutters, Gun Drills, Gun Reamers, High helix End Mill, High Helix End Mills, Hole Mill, Hole Mills, HSS Tools, Indexable Tools, Inserts, Large dia cutter, Large Dia Cutters, Lugged Tools, Micro Drills, Milling Cutter, Milling Cutters, Milling Tools, Multi dia Cutter, Multi Dia Cutters, Multi Dia Reamers, PCD, CBN Tools, Profile Cutter, Profile Cutters, Profile Tools, Radius Cutter, Radius Cutters, Reamer, Reamers, Roughing End Mill, Roughing End Mills, SC End Mills, SC Tools with taper shank, Sliting Cutter, Slitting Cutter, Slitting Cutters

#Brazed Carbide Cutting Tools#Cutters#HSS Tools#Milling Cutter#Counter Sinks#Center Drill#End Mill#Reamer#Drill#Form Tools#Manufacturer#Supplier#Exporter#Services#Pune#Maharashtra#India

1 note

·

View note

Note

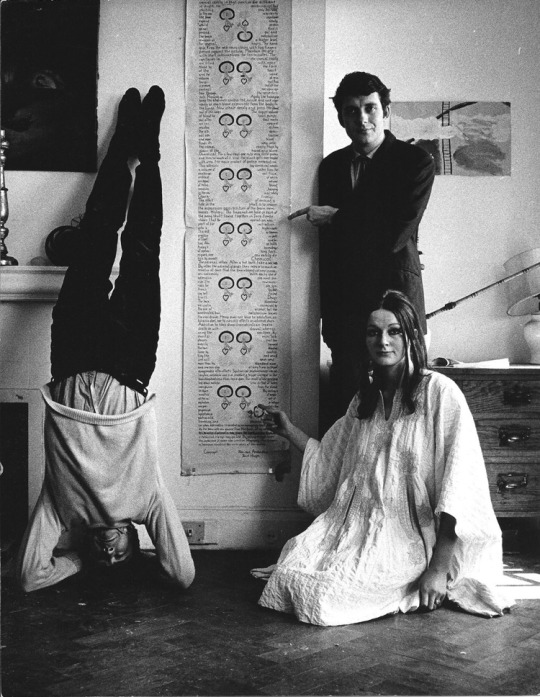

joey mellen wrote bore hole, hughes wrote mechanism of brainbloodvolume (i did not know there were two of these guys lol)

i know! those photos are alternately attributed to either of them, i still dont know who actually is in the photo because they were all white englishmen the same age.

and there were THREE. these guys were their own little trepanation cult polycule for a while in the 60s and 70s. as usual the woman, (Countess) Amanda Feilding (sic), is the one who gets forgotten, even though shes the one who made the actual gore movie of herself drilling a hole in her head for real: Heartbeat in the Brain (1970), which is considered "lost media" by that kind of person but i dont think it's actually lost, it was screened in 2011 and i think the fact that its about someone drilling a hole in their face is lending the footage more mystique than it actually possesses. looking for citations for this post is the first time ive heard it referred to as "lost", i dont think media is "lost media" just because it isnt on youtube but whatever

anyway Feilding ran for parliament several times. "Feilding ran for British Parliament twice, in 1979 and 1983, on the platform 'Trepanation for the National Health' with the intention of advocating research into its potential benefits; she advocated the provision of the procedure by the National Health Service.[3]" her parents were second cousins btw the english peerage is so fucked up it is unbelievable

she has spent her post-trepanation life advocating for drug policy reform, which is based, but unfortunately her son is also in politics and is a tory piece of shit

i have a Special Interest in trepanation and will probably eventually get it done somehow, i just have a feeling of fate about it or maybe dysmorphia. reading about idiopathic intermittent intercranial hypertension and hypoperfusion recently sounded real familiar. doctors dont like to talk about this stuff though, to them everything inside your skull is a schroedinger's cat that is assumed to be completely fine and normal until you prove to them via feats of strength that you have a Brain Problem of some kind, which heretofore is forbidden from mention

edit: trepanation doesnt actually do anything to your brain unless you have a pressure issue and the hole will just heal over anyway and reseal your brain, none of the Bore Hole claims or beliefs are anything except placebo

to people other than wumblr, who i assume has already read it: Bore Hole is an EXCELLENT book and will act as a fast and easy history lesson on how the counterculture boomers actually lived. their economy was unbelievable, americans and english used to be able to just "go to india" and hang out, things just did not cost a lot of money for a while there and this has permanently altered the part of their brain that makes cost calculations

63 notes

·

View notes

Text

Coiled Tubing Insights: A Deep Dive into Services, Operations, and Applications

Coiled Tubing Market Overview:

Request Sample

Inquiry Before Buying

Coiled Tubing Market Report Coverage

The “Coiled Tubing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Coiled Tubing Industry. By Service: Well Intervention & Production, Drilling, Perforating, Fracturing, Engineering Services, Milling Services, Nitrogen services and others. By Operations: Circulation, Pumping, Logging, Perforation, Milling and Others. By Technology/Services: Software Solutions, Hardware By Location: On-Shore, Off-Shore By Application: Wellbore Cleanouts, Electrical Submersible Pump Cable Conduit, Fracturing, Pipeline Cleanout, Fishing, Cementing, Nitrogen Jetting and others. By End Use Industry: Oil and gas Industry, Engineering Procurement and Construction Industry, Others By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina, and others), Europe (Germany, UK, France, Italy, Spain, and Others), APAC (China, Japan India, SK, Australia and Others), and RoW (Middle East and Africa)

Schedule a Call

Key Takeaways

North America dominates the Coiled Tubing Market share of 46.6% in 2023, owing to its advanced oil and gas industry, technological innovation, and substantial investments in exploration and production activities.

The development of unconventional resources, such as shale oil and gas, has increased the demand for coiled tubing services. Coiled tubing is often employed in hydraulic fracturing (fracking) operations in these unconventional reservoirs.

Well intervention services, including well cleaning, stimulation, and logging, are major applications of coiled tubing. As older wells require maintenance and newer wells require optimization, as a result growing the Demand for Well Intervention Services using coiled tubing continues to increase.

Buy Now

Coiled Tubing Market Drivers

Increased Exploration and Production Activities

The surge in oil and gas exploration, notably in unconventional resources such as shale, tight gas, and heavy oil, is fueling the demand for coiled tubing services. Integral to well intervention and stimulation procedures, coiled tubing plays a pivotal role in sustaining and augmenting production rates. This heightened exploration and production activity underscores the significance of coiled tubing services in maintaining operational efficiency and maximizing output in the energy sector.

Increasing Energy Demand

The escalating global energy demand propels the coiled tubing market forward. With an ever-growing need for energy resources, particularly in oil and gas sectors, there’s a heightened requirement for efficient extraction methods. Coiled tubing technology offers a versatile and cost-effective solution for various well intervention and drilling operations, catering to the increasing complexities of resource extraction. Its flexibility, mobility, and ability to access challenging environments make it indispensable in meeting the surging energy demands worldwide. As industries strive to optimize production and enhance operational efficiency, coiled tubing emerges as a crucial component in the quest for sustainable energy solutions.

3 notes

·

View notes

Text

Top Applications of Friction Reducers in the Oil and Gas Industry

The oil and gas industry is a cornerstone of global energy production, relying heavily on advanced technologies to optimize operations and enhance efficiency. Among these technologies, friction reducers play a critical role in hydraulic fracturing and other processes, enabling operators to maximize well productivity while minimizing environmental impact.

India, with its growing energy demands and a thriving oilfield services sector, has emerged as a key hub for high-quality friction reducers. As a leading friction reducer manufacturer in India, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) provides advanced solutions tailored to meet the industry's diverse requirements. This blog delves into the top applications of friction reducers in the oil and gas industry and highlights their indispensable role in modern-day energy exploration.

What Are Friction Reducers?

Friction reducers are specialized chemical additives, primarily used in hydraulic fracturing operations. These compounds are designed to reduce the frictional pressure within fluid systems, allowing for efficient pumping at lower energy consumption levels.

They typically function by modifying the fluid's rheological properties, ensuring smooth flow through pipelines and wellbores. This enhancement is vital for optimizing operational costs and improving overall productivity.

Importance of Friction Reducers in Hydraulic Fracturing

Hydraulic fracturing, commonly referred to as "fracking," is a widely adopted technique for extracting oil and natural gas from underground reservoirs. The process involves injecting a high-pressure fluid mixture into rock formations to create fractures, facilitating the flow of hydrocarbons.

However, this process generates significant frictional forces that can hinder fluid movement and elevate operational costs. Friction reducers mitigate these challenges by lowering the resistance within the fluid system.

For operators seeking reliable products, partnering with a friction reducer supplier in India like ICPL ensures access to high-performance solutions tailored to specific geological and operational conditions.

Top Applications of Friction Reducers

1. Hydraulic Fracturing Operations

The most prominent application of friction reducers is in hydraulic fracturing. By minimizing fluid resistance, these additives enhance the efficiency of the fracking process. Key benefits include:

Increased Pumping Efficiency: Lower friction allows higher fluid volumes to be pumped into the wellbore without additional energy expenditure.

Reduced Wear and Tear: Equipment experiences less stress due to lower operating pressures, leading to extended service life.

Cost Savings: Optimized fluid dynamics result in reduced fuel consumption and lower operational costs.

ICPL, a trusted friction reducer supplier in Gujarat, provides customized solutions that cater to the specific needs of shale formations, tight sandstones, and other reservoir types.

2. Wellbore Cleaning

Friction reducers are crucial for cleaning wellbores during drilling and completion operations. In this application, friction reducers:

Facilitate the removal of debris, drill cuttings, and other obstructions.

Ensure smooth fluid flow, preventing blockages and operational delays.

Enhance the effectiveness of other cleaning agents used in the process.

Collaborating with a friction reducer supplier in India ensures wellbore cleaning solutions that maintain operational continuity and minimize downtime.

3. Water Management in Oilfields

Water management is a significant concern in oilfield operations, particularly in regions with limited freshwater availability. Friction reducers help optimize water usage by:

Reducing the energy required to pump water into the well.

Enhancing the recyclability of produced water, reducing freshwater consumption.

Lowering environmental impact through sustainable water management practices.

As an environmentally conscious friction reducer manufacturer in India, ICPL offers products that support greener and more efficient oilfield operations.

4. Pipeline Transport

Transporting crude oil, natural gas, or water through pipelines often involves significant frictional losses, which can impede flow and increase pumping costs. Friction reducers address these challenges by:

Enhancing the flow of fluids through pipelines.

Reducing the risk of pressure surges and system failures.

Ensuring the safe and efficient delivery of resources over long distances.

By sourcing products from a reliable friction reducer supplier in Gujarat, oilfield operators can ensure smooth pipeline operations even in challenging conditions.

5. Enhanced Oil Recovery (EOR)

Friction reducers also play a role in Enhanced Oil Recovery (EOR) techniques, where they improve the injection efficiency of water or gas into the reservoir. This application includes:

Enhancing the penetration of injection fluids.

Reducing the pressure drop across the reservoir, ensuring uniform fluid distribution.

Improving overall hydrocarbon recovery rates.

India's leading friction reducer manufacturers provide high-quality products that maximize the effectiveness of EOR techniques.

6. Drilling and Cementing Operations

Friction reducers are essential for drilling and cementing operations in the oil and gas industry. Their benefits include:

Reducing torque and drag during drilling, ensuring smoother operations.

Enhancing the placement of cement slurry, which is critical for well integrity.

Lowering the risk of stuck pipe incidents, saving valuable time and resources.

With an established presence as a friction reducer supplier in India, ICPL delivers innovative solutions that streamline drilling and cementing processes.

7. Minimizing Scale and Corrosion

Friction reducers are often used in combination with scale and corrosion inhibitors to maintain the integrity of equipment and pipelines. These chemicals help by:

Reducing deposition rates of scale-forming minerals.

Lowering the corrosive effects of high-pressure fluids.

Enhancing the lifespan of oilfield infrastructure.

ICPL offers friction reducers designed to work synergistically with other oilfield chemicals, ensuring comprehensive protection and performance.

Why Choose a Reliable Friction Reducer Supplier in India?

India's oilfield chemical industry is renowned for its commitment to quality and innovation. Partnering with a reputable friction reducer supplier in Gujarat like ICPL offers several advantages:

High-Quality Products: ICPL’s friction reducers are formulated to meet international standards, ensuring reliability and effectiveness.

Customized Solutions: Every oilfield is unique, and ICPL provides tailored products to address specific challenges.

Competitive Pricing: By leveraging India’s cost-efficient manufacturing ecosystem, ICPL offers premium products at competitive rates.

Sustainability: ICPL emphasizes eco-friendly formulations that align with global sustainability goals.

ICPL: Your Trusted Friction Reducer Manufacturer in India

As a leading friction reducer manufacturer in India, ICPL takes pride in delivering cutting-edge solutions for the oil and gas industry. Our products are designed to:

Enhance operational efficiency.

Minimize environmental impact.

Reduce overall costs for our clients.

With a state-of-the-art manufacturing facility in Gujarat and a team of experienced professionals, ICPL has established itself as a preferred friction reducer supplier in Gujarat and beyond.

Conclusion

The oil and gas industry continues to evolve, driven by advancements in technology and the need for sustainable practices. Friction reducers are a vital component in this transformation, enabling operators to achieve higher efficiency, lower costs, and reduced environmental footprints.

For companies seeking high-performance friction reducers, partnering with a trusted friction reducer supplier in India like ICPL ensures access to top-tier products backed by technical expertise. Whether you are optimizing hydraulic fracturing, improving pipeline transport, or enhancing oil recovery, friction reducers are indispensable in achieving operational excellence.

Explore ICPL’s range of friction reducers today and experience the difference they can make in your oilfield operations. Contact us to learn more about how we can support your business goals.

#Friction reducer manufacturer in India#Friction reducer supplier in India#Friction reducer supplier in Gujarat#Friction reducer

5 notes

·

View notes

Text

For almost seven decades, India and Israel have maintained a close political and military partnership, which has flourished under the rhetoric of “civilizational ties” and “shared ideals.”

However, it’s the last 30 years that have significantly accelerated India’s rise among the top markets for Israeli arms, and the two states have been investing in joint weapons production, army and intelligence services training, military drills, and circulation of carceral technologies.

This military-industrial complex has been further cemented by a parallel partnership in the sphere of education, entertainment, tourism, and art, producing a mass consciousness that accepts and extols the logic of ethnic cleansing and settler-colonialism practiced by India and Israel.

— Shivangi Mariam Raj

24 notes

·

View notes

Text

Exploring Top notch M2 Steel Supplier in India!

Heat Up Your Production! 🔥 Discover the power of M2 Steel the high-speed tool steel that belongs to the tungsten–molybdenum series for cutting tools industries. Let's delve into the details of M2 Steel, also known as AISI M2 or DIN 1.3343, particularly as offered by Virat Special Steels.

M2 Steel Overview: M2 Steel is a high-speed tool steel that belongs to the tungsten–molybdenum series, known for its exceptional properties that make it ideal for cutting tools and high-speed applications. It combines a good balance of toughness, wear resistance, and red hardness, making it a preferred choice in the industry.

Key Characteristics: High Red Hardness, M2 steel maintains its hardness at elevated temperatures, which is crucial for high-speed cutting tools. Good Wear Resistance, This steel grade offers excellent resistance to wear and abrasion.

Applications M2 steel is widely used in: - Cutting Tools: Such as drill bits, end mills, reamers, and saw blades. - Punches and Dies: For stamping and forming operations. - Industrial Knives: Used in various cutting applications. - Forming Rolls: For forming and shaping materials.

Virat Special Steels Offerings: Virat Special Steels offers high-quality M2 steel that meets the strict industry standards. Their M2 steel is processed with precision to ensure optimal performance in demanding applications. They provide detailed technical support and advice on the best practices for using their steel grades

Contact us today to learn more about our products and services! 🌐https://www.viratsteels.com/m2.html 📬[email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#toolsteelsupplier#viratspecialsteels#pune#ToolSteel#DieSteels#MetalIndustry#SpecialSteel#M2Steel#din3343#T1Steel#delhi#India

2 notes

·

View notes

Text

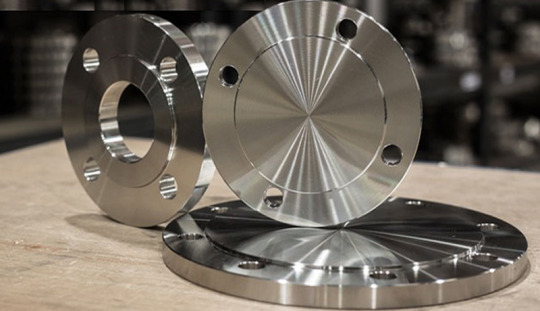

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Ground Water Engineers & Borewell Drilling Contractors in Chennai,Tamilnadu India. incorporated in 1990, a leading Ground Water firm in Chennai,Tamilnadu India.

2 notes

·

View notes

Photo

At Laxyo Group, We strive to bring the great result to our customer’s tunnel boring service projects in India. Our professional team cares about giving you the extraordinary construction at the great value. Our raise bore drilling division is an integral part of our underground mining capability, servicing some of India's largest projects. Our tunnel boring machine contractors with an extensive track record drilling shafts and raises for the mining and heavy civil industries.

For more Info please visit our website: http://www.laxyo.com/raise-boring-contractors.php

#Underground Mining Consultants#Vertical Shaft contractors#Tunnel Boring Service in India#Raise boring equipment#raise bore shaft construction#raise bore shaft mining#drilling and boring contractors#tunnel boring machine contractors#underground boring contractors#raise bore operation#raise bore job

3 notes

·

View notes

Text

Our company is a well-established and reputable Oilfield chemicals manufacturer and exporter in India. With years of experience in the industry, we have become the go-to supplier for high-quality and reliable oilfield chemicals. Our products are trusted by leading companies in the oil and gas industry for their superior quality and effectiveness. We are based in Vadodara, Gujarat and are known as the best oilfield chemicals company in Vadodara, Gujarat. Our state-of-the-art manufacturing facilities and cutting-edge technology ensure that our products meet the highest standards of quality and consistency. Our product range includes drilling fluids, cementing additives, stimulation chemicals, and production chemicals, among others. We use only the best raw materials and adhere to strict quality control measures to ensure that our products deliver optimal performance in the field. As an Oilfield chemicals exporter in India, we have a wide network of clients across the globe. We pride ourselves on our timely delivery and exceptional customer service, ensuring that our clients always receive the best products and support.

Choose us as your trusted partner for all your oilfield chemical needs and experience the difference in quality and service.

#Oilfield chemicals manufacturer in India#Oilfield chemicals exporter in India#Best Oilfield chemicals company in vadodara#Best Oilfield chemicals company in Gujarat#Leading Oilfield Chemicals Manufacturer and Exporter in India#business#manfacturer#supplier#exporter

4 notes

·

View notes

Link

0 notes

Text

Best PCB Manufacturers for Innovative, Durable, and Efficient Circuit Boards

The world of electronics is powered by Printed Circuit Boards (PCBs). These tiny but crucial components are found in nearly every electronic device, providing the foundation for various electronic elements to interact. As technology advances and the demand for smaller, faster, and more efficient electronics grows, the need for high-quality, innovative, and durable PCBs has become paramount.

Finding the Best PCB Manufacturer is vital for ensuring that your products are not only functional but also reliable. A reliable PCB manufacturer must offer advanced technology, exceptional quality control, and efficiency. In this blog, we will explore the factors that define the Best PCB Manufacturer, the leading PCB Manufacturers in India, and highlight the importance of Saasin Electro, a key player in the PCB manufacturing industry.

What Makes a PCB Manufacturer the Best?

When choosing a PCB Manufacturer, it’s essential to evaluate several critical factors to ensure they can meet your specific requirements. Let's look at what defines a top-tier PCB manufacturer:

1. Innovative Manufacturing Processes

Innovation is crucial in the world of PCB manufacturing, as electronics continue to become more compact and complex. The Best PCB Manufacturers leverage the latest technology and manufacturing techniques, such as automated assembly, laser drilling, and 3D modeling, to ensure that they can produce high-quality, custom-made PCBs.

Manufacturers who embrace cutting-edge innovations allow for the creation of PCBs that can handle complex designs, high-frequency signals, and greater power densities, all while ensuring minimal space usage and enhanced performance.

2. Durability and Reliability

Durability is a non-negotiable quality for PCBs. After all, a PCB is a backbone for any electronic device, and its failure can render the entire system useless. The Best PCB Manufacturer uses high-quality materials and advanced processes that ensure longevity and reliability.

Manufacturers must also conduct thorough testing to ensure that their PCBs meet the required mechanical, electrical, and thermal stress tolerance. Reliability can be ensured through strict quality assurance processes, such as burn-in tests, automated visual inspections, and environmental testing.

3. Efficiency and Timeliness

In today’s competitive market, speed is essential. The Best PCB Manufacturer must have a streamlined production process that ensures on-time delivery without compromising on quality. Quick prototyping and rapid manufacturing are vital for industries such as consumer electronics and automotive, where product cycles are tight, and time-to-market is critical.

4. Customization Capabilities

Every project is unique, and the Best PCB Manufacturers offer customization to meet specific customer needs. Whether you need single-layer, double-layer, multi-layer, or flexible PCBs, the best manufacturers have the ability to tailor their designs to suit your particular requirements.

Customization can also involve unique materials, specific manufacturing processes, or specialized features like high-frequency or high-voltage handling.

5. Global Standards Compliance

The Best PCB Manufacturers operate under stringent international quality standards to ensure that their PCBs are reliable and meet industry regulations. Certifications such as ISO 9001, UL certification, and RoHS compliance are a good indicator of a manufacturer’s commitment to delivering quality products.

Leading PCB Manufacturers You Should Know

Now, let’s dive into some of the top PCB manufacturers known for their innovative, durable, and efficient circuit boards. These manufacturers are renowned in the industry for their expertise and quality of service.

1. Saasin Electro: A Leader in Innovation and Durability

When it comes to Best PCB Manufacturers, Saasin Electro stands out. Based in India, Saasin Electro is a leading name in the PCB manufacturing industry, recognized for its high-quality products, innovative designs, and exceptional customer service.

Saasin Electro specializes in a wide range of PCB types, including single-sided, double-sided, multi-layer, and flexible PCBs. Their commitment to using state-of-the-art technology ensures they meet the needs of industries ranging from telecommunications to automotive and medical devices.

Why Saasin Electro is Important:

Advanced Technology: Saasin Electro uses cutting-edge manufacturing techniques to create precise and durable PCBs.

Customization: Whether you need specialized designs, materials, or high-frequency PCBs, Saasin Electro offers a range of customizations to meet your needs.

Efficient Production: With streamlined processes, Saasin Electro ensures timely delivery of products without sacrificing quality. Their global customer base benefits from fast turnarounds, even for large orders.

Quality Control: Saasin Electro follows stringent quality assurance protocols and adheres to international standards to ensure that all PCBs are free of defects and function reliably over time.

For businesses seeking a PCB manufacturer that combines technology, reliability, and innovation, Saasin Electro offers the ideal solutions.

PCB Manufacturers in India: A Growing Powerhouse

In recent years, PCB Manufacturers in India have gained global recognition for their competitive pricing, high-quality products, and quick delivery. India’s PCB manufacturing industry is growing rapidly, driven by advances in technology and a highly skilled workforce.

Why Choose PCB Manufacturers in India?

PCB Manufacturers in India have increasingly become the go-to choice for companies worldwide. This shift is driven by India’s competitive pricing, the presence of skilled engineers, and high-quality manufacturing standards. With many manufacturers offering cost-effective solutions without compromising on quality, India has become a hub for PCB production.

The rise of companies like Saasin Electro in India is a testament to the growing importance of the country’s PCB manufacturing sector. By offering top-tier manufacturing capabilities, India is becoming a key player in the global electronics market.

Conclusion

Finding the Best PCB Manufacturer is a critical step for ensuring the quality, durability, and efficiency of your electronic products. Whether you’re designing consumer electronics, medical devices, or automotive systems, choosing the right manufacturer will have a significant impact on your product’s success.

Saasin Electro stands out as a leading manufacturer due to its innovative approach, high-quality products, and exceptional customer service. For those seeking PCB manufacturers in India, the country’s growing industry offers a variety of reliable, cost-effective, and high-quality options.

By carefully considering your needs and evaluating potential manufacturers, you can ensure that your PCBs meet the highest standards of performance, durability, and innovation, driving the success of your products.

0 notes

Text

Enhancing Risk Management with Data Visualization Consultants in Banking

In the ever-evolving landscape of banking, managing risks efficiently is not just an option—it's a necessity. As financial institutions face increasing complexities, the role of data visualization consultants becomes pivotal. Augmented Systems, a leading data migration service company in the USA and India, is at the forefront of this transformation, helping banks navigate these challenges.

But how exactly does data visualization enhance risk management? Let's dive into this fascinating intersection of technology and finance.

Introduction to Risk Management in Banking

Risk management in banking involves identifying, assessing, and mitigating potential financial losses. It's a critical component of banking operations, aimed at protecting assets and ensuring regulatory compliance. But traditional methods of risk management often fall short in the face of modern challenges like cybersecurity threats and global economic fluctuations. This is where data visualization steps in as a game-changer.

The Role of Data Visualization in Banking

Imagine trying to navigate a maze blindfolded—that’s what managing risks without clear data insights feels like. Data visualization turns complex data sets into understandable visuals, making it easier for decision-makers to grasp potential risks and opportunities. It’s like lifting the blindfold to see the entire maze at once, allowing for more informed and timely decisions.

Who is a Data Visualization Consultant?

A data visualization consultant is a specialist who helps organizations transform raw data into actionable insights through visual tools like charts, graphs, and dashboards. In the banking sector, these consultants play a crucial role in risk management by:

Analyzing large volumes of financial data.

Identifying patterns and trends.

Creating intuitive visual representations for better understanding.

Key Data Visualization Components

Effective data visualization involves several critical components:

1. Data Collection and Preparation

Gathering accurate and relevant data is the first step. This includes financial transactions, market trends, and customer behavior.

2. Visualization Tools

Using tools like Tableau, Power BI, or custom software solutions to create visuals.

3. Dashboards and Reports

Developing interactive dashboards that provide real-time insights.

4. User Interaction

Ensuring that the end-users can interact with the data, drill down into specifics, and make data-driven decisions.

Emerging Data Visualization Trends in Banking

As technology advances, several trends are reshaping data visualization in banking:

1. AI and Machine Learning

Integrating AI for predictive analytics, helping banks anticipate risks before they occur.

2. Real-Time Data Processing

Real-time data visualization enables immediate response to potential threats, enhancing agility.

3. Mobile Accessibility

Data visualization tools are becoming more mobile-friendly, allowing decision-makers to access insights anytime, anywhere.

How Augmented Systems Helps Banks?

Augmented Systems specializes in data migration services but also offers comprehensive data visualization solutions. By leveraging their expertise, banks can seamlessly transition from outdated systems to modern, visualization-driven platforms. This transformation enables:

Enhanced data accuracy.

Improved risk assessment.

Streamlined decision-making processes.

The Data Visualization Process

The data visualization process typically involves several stages:

1. Data Extraction

Extracting data from various sources such as financial reports, CRM systems, and market data.

2. Data Cleaning

Ensuring the data is clean, consistent, and ready for analysis.

3. Visualization Design

Choosing the right visual formats to represent different types of data.

4. Implementation and Testing

Developing the visualizations, integrating them into dashboards, and testing for accuracy and usability.

Leveraging Financial Data Visualization Tools

Financial data visualization tools are designed to handle the unique challenges of the banking sector. These tools offer:

Customizable Dashboards: Tailored views for different stakeholders.

Advanced Analytics: Tools that go beyond basic charts to provide deep insights.

Scalability: The ability to handle increasing amounts of data as the organization grows.

The Future of Risk Management with Data Visualization Specialists

The future of risk management in banking will be increasingly reliant on data visualization specialists. These experts will:

Drive innovation in data analysis.

Ensure banks remain compliant with evolving regulations.

Enhance customer trust through transparent and insightful reporting.

Conclusion

In conclusion, the role of data visualization consultants in banking is indispensable for effective risk management. Augmented Systems exemplifies how leveraging modern data visualization tools and trends can transform the banking sector, making it more resilient and agile.

By embracing these advancements, banks can not only mitigate risks but also seize new opportunities in an ever-changing financial landscape.

#data visualization specialist#data visualization consultant#data visualization trends#data visualization process

0 notes

Text

Top Sectors Hiring Workforce Professionals in India with The Rojgaar.com

Finding reliable job opportunities can be challenging for workforce professionals. The Rojgaar.com bridges this gap by offering tailored solutions across sectors. This article highlights the industries actively hiring and how The Rojgaar.com ensures a seamless job search experience.

Table of Contents

Introduction to Workforce Jobs in India

Top Sectors Actively Hiring Workforce Professionals

Mechanics and Machine Operators

Painters and Maintenance Technicians

Truck Drivers and Drillers

Security Guards and Road Maintenance Workers

Steelworkers and Industrial Laborers

How The Rojgaar.com Facilitates Job Search

Frequently Asked Questions (FAQs)

Introduction to Workforce Jobs in India

India's workforce forms the backbone of its economy, with millions employed in labor jobs, daily wages, and various industries requiring skilled labor and unskilled labor. Accessing secure, well-paying opportunities has been a challenge until the emergence of platforms like The Rojgaar.com.

Statistics on Workforce Jobs

Sector

Employment Rate (Approx.)

Growth Rate (2023-2025)

Construction jobs

22%

6%

Industrial jobs

18%

7%

Factory jobs

15%

5%

Top Sectors Actively Hiring Workforce Professionals

Mechanics and Machine Operators

Mechanics and machine operators are vital across industries like manufacturing and automobile services. Companies prioritize candidates with hands-on experience and technical training.

Roles: Vehicle repair, equipment handling, and factory maintenance.

Skills Needed: Basic mechanics knowledge, operational safety awareness.

Painters and Maintenance Technicians

From residential to industrial projects, painters and maintenance technicians ensure high-quality finishes and infrastructure upkeep.

Roles: Surface preparation, electrical maintenance, and industrial painting.

Safety Measures: PPE compliance, certified workshops, and routine inspections.

Truck Drivers and Drillers

Transportation and energy sectors rely heavily on truck drivers and drillers. These roles demand physical endurance and adherence to safety protocols.

Roles: Long-distance freight hauling, oilfield drilling.

Government Norms: Licensing under the Motor Vehicles Act, adherence to labor laws.

Security Guards and Road Maintenance Workers

Security guards and road maintenance workers ensure public safety and infrastructure quality. These roles require discipline and reliability.

Roles: Asset protection, road repairs, and traffic management.

Training Programs: Emergency response training and road safety courses.

Steelworkers and Industrial Laborers

In sectors like construction and manufacturing, steelworkers and industrial laborers handle complex machinery and heavy-duty tasks.

Roles: Welding, fabrication, and large-scale industrial assembly.

Economic Impact: A 5% annual growth in India's steel industry highlights the demand for these professionals.

How The Rojgaar.com Facilitates Job Search

The Rojgaar.com provides:

Easy Registration: Create a profile in minutes on the job portal.

Verified Job Listings: Authentic listings for worker jobs, factory jobs, and more.

Skill Matching: AI-driven algorithms ensure you find jobs matching your expertise.

Continuous Support: Dedicated support for career advice and legal compliance.

Frequently Asked Questions (FAQs)

1. What makes The Rojgaar.com unique for workforce professionals?

The portal focuses on workforce-centric sectors, offering tailored opportunities and safety compliance for workers.

2. Are job listings on The Rojgaar.com verified?

Yes, all listings are verified to ensure transparency and reliability for job seekers.

3. What safety measures are offered for workers?

Employers listed on The Rojgaar.com comply with safety regulations like PPE guidelines, accident insurance, and training programs.

Discover a world of opportunities with The Rojgaar.com, where workforce professionals meet trusted employers. Start your job search today!

#dailywages#construction workers#india#therojgaar.com#rojgaar#farmers#hotelstaff#job#job in india#miningworkers

0 notes