#Drill Pipe Market Size

Explore tagged Tumblr posts

Text

2 notes

·

View notes

Text

#Drill Pipe Market#Drill Pipe Market Size#Drill Pipe Market Growth#Drill Pipe Market Trends#Drill Pipe Market Opportunities#Drill Pipe Market Analysis

0 notes

Text

#Global Drill Pipe Market Overview#Size#Share#Trends#Top Companies#Segments#Regions#Growth Will Expand at a CAGR of 5.4% by 2031 | IMIR#intellectualmarketinsights

1 note

·

View note

Quote

Drill Pipe Market

Drill Pipe Market-In-Depth Analysis by Size | IMR

1 note

·

View note

Text

Drill Pipe Market : Size, Share, Emerging Trends and Future Outlook

Drill pipes are essential components of a drilling rig used in the exploration and extraction of natural resources such as oil and gas. They are an essential component of any drilling rig and are used to transfer drilling fluids, such as mud, downhole to the drill bit. The drill pipe also provides a conduit for the cuttings to return to the surface. These pipes are typically made of high-strength steel and are designed to withstand the high pressures and torque of the drilling process. The length of a drill pipe can vary depending on the depth of the well being drilled, with typical lengths ranging from 30 to 45 feet. The pipes are connected end-to-end using threaded connections called tool joints, which provide a secure and tight seal. Additionally, drill pipes can be equipped with a variety of specialized tools, such as stabilizers and shock absorbers, to help optimize the drilling process and increase efficiency. Without drill pipes, drilling for oil and gas would not be possible, making them an indispensable tool for the energy industry.

One of the key trends in the market was the increasing demand for horizontal drilling, which requires longer drill pipes that can reach greater depths. This has led to the development of high-strength drill pipe materials, such as grade S135 steel, which can withstand the high pressures and torque of horizontal drilling. Another trend was the focus on sustainability and reducing the environmental impact of drilling operations. This has led to the development of eco-friendly drill pipe coatings and the use of recycled materials in their manufacturing. Furthermore, there has been a rise in the use of digital technologies such as artificial intelligence and machine learning in the drilling process. This has enabled companies to better predict drilling outcomes, optimize drilling operations, and improve safety. As new technologies and sustainable practices are developed to improve efficiency and reduce environmental impact.

Gain deeper insights on the market and receive your free copy with TOC now @: http://www.grandviewresearch.com/industry-analysis/drill-pipe-market

The global drill pipes market is expected to reach USD 1.31 billion by 2025, according to a new report by Grand View Research, Inc. Increasing innovation regarding improving product strength is a major trend in the industry. Industry players are focused on developing new technologies and raw materials for better performance in all types of drilling conditions including onshore and offshore remote oil and gas fields.

#Drill Pipe Market Size & Share#Global Drill Pipe Market#Drill Pipe Market Latest Trends#Drill Pipe Market Growth Forecast#COVID-19 Impacts On Drill Pipe Market#Drill Pipe Market Revenue Value

0 notes

Text

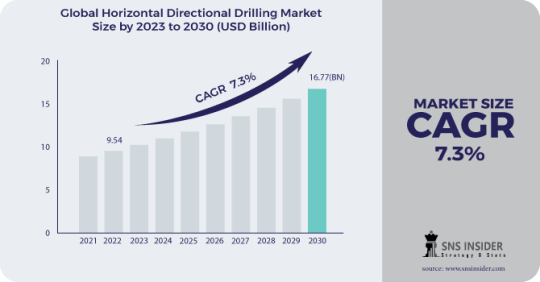

Horizontal Directional Drilling Market Analysis and Forecast 2031: Exploring Size, Share, and Scope Trends

The��Horizontal Directional Drilling research report provides a quick analysis of market value, volume, return, factors, opportunity, competition, and current strategic behaviour. This includes forecasting demand, detailed explanations of assumptions and methodologies, as well as historical data and forecasts. This study examines the financial market environment to assess competition in local and global markets. The survey highlights the growth potential of the Horizontal Directional Drillingindustry over the forecast period.

Ask For Sample Report Here @ https://www.snsinsider.com/sample-request/1099

The report includes data on strategic alliances, new product launches, projects, transactions, collaborations, key market players, and drivers, constraints and opportunities. It provides the tools you need to assess the Horizontal Directional Drilling market for companies, customers, buyers, sellers, service providers, and distributors.

Market Segmentation

By Technique

Conventional

Rotary Steerable System

By Parts

Rigs

Pipes

Bits

Reamers

Others

By Application

On-shore

Off-shore

By End User

Oil and Gas Excavation

Utility

Telecommunication

By Company

American Augers, Inc.

Ditch Witch

Ellingson Companies

Vermeer Corporation

The Toro Company

Baker Hughes Incorporate

Halliburton Company

Schlumberger Limited

Weatherford International National Oilwell Varco, Inc.

Nabors Industries, Ltd.

The Application Management Services (AMS) market is divided into three categories: type, provider and application, allowing you to more accurately assess the size, climate, growth and development of the market. Charts, diagrams and records are used to represent the segments. Horizontal Directional Drillingmarket research also provides insights into the target market's product category and is based on a variety of organizational objectives such as product segmentation, production volume, product definition, and requirements, etc.

The market study thoroughly investigates the scope of the target market. Market innovation that has been stable in the past and is expected to stabilize again in the future is the subject of this study. Industry structure, definition, product characteristics, market penetration and maturity analysis are all included in the Horizontal Directional Drilling market report. Market size and growth rate are also analysed for forecast periods.

Regional Analysis

The report covers industry rankings and reported interpretations using regional surveys. Use of both primary and secondary sources to calculate market revenue for large industry organizations. Therefore, this study contains several important features. This Horizontal Directional Drillingmarket study explores the many factors that influence the growth of a region, including the financial, cultural, social, technical and political conditions of the region. This chapter describes the regional and global globalization of various term exchanges. Similarly, this study provides a reliable amount of country-by-country research and analysis of regional market share.

Buy This Report Here @ https://www.snsinsider.com/checkout/1099

Competitive Outlook

The size of the sector is also determined by the characteristics of the major players in the sector, according to the report. Major capabilities of major industry players are studied using secondary as well as primary sources and their revenue in the market is calculated in this study. This market research examines the top-down tactics of large companies. This section of the report provides contact details for the major vendors in the Horizontal Directional Drillingindustry. The survey also explores the market competition, market prices and channel characteristics among the major players.

2 notes

·

View notes

Text

Steel Pipes & Tubes Market Forecast: Strengthening Global Infrastructure

The global steel pipes & tubes market size is expected to reach USD 192.60 billion by 2030, according to a new report by Grand View Research, Inc., expanding at a CAGR of 6.1% from 2024 to 2030. Increasing investment by governments across the world to improve the water system is expected to propel the demand for steel pipes & tubes over the forecast period.

In March 2022, in view of the increasing concern over drinking water contamination in certain parts of the country, the U.S. EPA announced that it would release a USD 50 billion fund to be used for the development of clean water infrastructures. Such investments are expected to fuel the market growth in water treatment applications over the forecast period.

In the oil & gas industry, steel pipes & tubes are used for a wide range of applications, such as concrete pilings, conveyor belt roller bearings, or wall thickness. This application segment is expected to maintain its dominance across the forecast period, as increasing investment in offshore exploration & production is further aiding the product demand.

For instance, in June 2022, the Netherlands and Germany jointly announced that they would drill a new gas field in the North Sea. The first gas from the field is anticipated to be generated by the end of 2024. This is expected to positively impact the market growth over the forecast period.

Based on region, Asia Pacific is expected to register the fastest growth of CAGR 7.2% in terms of revenue across the forecast period. Rising investment in chemicals & petrochemicals and the power industry is expected to drive the market growth. For instance, in September 2023, China-based Dushanzi Petrochemical Corp commenced construction of a ~USD 3 billion petrochemical complex in Xinjiang. The operations at this new plant are anticipated to begin in 2026.

Capacity expansion is one of the key strategic initiatives that is adopted by market players to keep pace with competitors. For instance, Rama Steel Tube Ltd. completed a capacity expansion in February 2023 at its plant in Khopoli, India. It is a 30,000 MT expansion for special-grade structural steel and high-thickness tubes.

Steel Pipes & Tubes Market Report Highlights

Based on technology, ERW is anticipated to register a growth rate of 6.3% across the forecast period. The growth is attributed to its cost-efficient manufacturing process

Based on application, the chemicals & petrochemicals is anticipated to grow at a CAGR of 6.1% from 2024 to 2030. Steel pipes & tubes find use in petrochemical processing plants for refining processes owing to their characteristics such as high oxidation and corrosion resistance

Based on region, North America held the second-largest revenue share in 2023 of the global market. The growth is anticipated to be driven by increasing investment in offshore oil & gas production

Increasing investment in the construction of pipeline networks to supply oil and gas is expected to propel the demand for steel pipes in the coming years. For instance, as of January 2024, ~41,999 miles of pipeline are under construction, and 80,557 miles are in planning stage, as per the Pipeline & Gas Journal

Steel Pipes & Tubes Market Segmentation

Grand View Research has segmented the global steel pipes & tubes market based on technology, application, and region:

Steel Pipes & Tubes Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Seamless

Electric Resistance Welded

Submerged Arc Welded

Steel Pipes & Tubes Application Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Oil & Gas

Chemicals & Petrochemicals

Automotive & Transportation

Mechanical Engineering

Power Plant

Construction

Others

Steel Pipes & Tubes Regional Outlook (Volume, Kil0tons; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

Russia

France

Italy

Asia Pacific

China

India

Japan

Indonesia

Philippines

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

List of Key Players

ArcelorMittal

United States Steel

Nippon Steel Corporation

Tata Steel

Jindal Steel & Power Ltd.

Rama Steel Tubes Limited

Steel Authority of India Limited (SAIL)

Hyundai Steel

AM/NS INDIA

VALLOUREC

EVRAZ plc

ThyssenKrupp AG

JFE Steel Corporation

Order a free sample PDF of the Steel Pipes & Tubes Market Intelligence Study, published by Grand View Research.

0 notes

Text

0 notes

Text

Saudi Arabia Steel Pipes and Steel Tubes Market Trends, Insight, Forecast 2023-2030

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated Saudi Arabia Steel Pipes and Steel Tubes Market size by value at USD 435.90 million in 2023.During the forecast period between 2024 and 2030, BlueWeave expects Saudi Arabia Steel Pipes and Steel Tubes Market size to expand at a CAGR of 5.11% reaching a value of USD 587.12million by 2030. Saudi Arabia Steel Pipes and Steel Tubes Market is driven by expanding construction, oil & gas, and petrochemical sectors due to rising infrastructure projects and energy demand. Increasing investments in desalination and water distribution infrastructure boost the demand for steel pipes. Additionally, government initiatives like Vision 2030, emphasizing industrial diversification and local manufacturing, support market growth. Rising urbanization, population growth, and demand for durable materials in diverse applications could further fuel the growth of Saudi Arabia Steel Pipes and Steel Tubes.

Sample: https://www.blueweaveconsulting.com/report/saudi-arabia-steel-pipes-and-steel-tubes-market/report-sample

Opportunity – Demand from Large Infrastructure Development Projects

The growth of Saudi Arabia Steel Pipes and Tubes Market is propelled by a surge in construction and infrastructure projects under Vision 2030. Mega-projects like NEOM and the Red Sea Project are driving the demand for steel materials, including pipes and tubes, essential for utilities, transportation, and structural frameworks. Additionally, increasing investments in the oil & gas sector are fueling pipeline installations, further boosting the expansion of Saudi Arabia Steel Pipes and Steel Tubes Market.

Impact of Escalating Geopolitical Tensions on Saudi Arabia Steel Pipes and Steel Tubes Market

Escalating geopolitical tensions could impact Saudi Arabia Steel Pipes and Steel Tubes Market by increasing uncertainties in supply chains, especially for raw materials like iron ore. Rising energy costs and potential trade restrictions add to production expenses, potentially affecting export competitiveness. Additionally, heightened security concerns may lead to fluctuating demand in the oil and gas sector, which are key consumers of steel pipes and tubes in Saudi Arabia. These factors drive both market volatility and a push toward localizing production for resilience.

Oil & Gas Application Segment Holds Largest Market Share

The oil & gas sector is the largest application segment in Saudi Arabia Steel Pipes and Steel Tubes Market. The segment’s dominance is driven by the country's extensive oil and gas industry, which requires a substantial volume of steel pipes and tubes for exploration, drilling, and transportation infrastructure. The demand is further amplified by Saudi Arabia's ongoing efforts to expand its oil and gas production capacities. Additionally, government-backed initiatives and investments in energy infrastructure contribute significantly to the segment’s growth, cementing its position as the key consumer within the steel pipes and tubes market in Saudi Arabia

Competitive Landscape

Saudi Arabia Steel Pipes and Steel Tubes Market is fiercely competitive, with numerous companies vying for a larger market share. Major companies in the market include Saudi Steel Pipe Bending Factory, Alazzaz Steel and Pipes, Al-Jazera Factories for Steel Products (JASCO), Tirox Steel Pipes and Tubes, Alkafaa Limited Company, Gulf Pipe Supply and Services, Tenaris Saudi Arabia, Santok Steel Corporation, Al Ashrak Group, Victor Steel Corporation, and Metline Industries. These companies use various strategies, including increasing investments in their R&D activities, mergers and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in Saudi Arabia Steel Pipes and Steel Tubes Market.

Contact Us:

BlueWeave Consulting & Research Pvt Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Being called a Russian misinformation bot is totally wild but apparently I need to show my working on this hellsite or people think I have no idea what's going on.

1) It doesn't matter if the US (stated) intention is to give the gas to the Palestinians. Israel has a long history of stealing resources from Palestinians (including the offshore drills currently standing).

2) Who's going to kick in the rig and exploration money? Israel? The USA? A private company? Whoever does is going to take a share of the oil and gas profits and given the Palestinians have little negotiations power and don't appear to have been consulted on this decision, they'll probably get pennies in the dollar for it.

3) this is definitely eyeing the European gas market that currently has a giant Russian-sized hole in it, so it's not really about Palestinians at all, but filling the approaching Russian void because of pipe destruction and sanctions.

4) Big Oil is a shorthand that refers to the big players in the oil and gas game. It's not a sign that I don't know the difference between oil and gas FFS

5) This is all assuming Israel will actually ever give Gaza back to the Palestinians because they're currently shooting Palestinians in the legs for trying to return to their homes in the north DURING A CEASEFIRE

[source]

guess who's sucking Big Oil's dick hard enough to actively allow a genocide

1K notes

·

View notes

Text

Subsea Well Access System Market: Enhancing Productivity in Subsea Operations

The Subsea Well Access System Market size was valued at USD 3.61 billion in 2022 and is expected to grow to USD 5.24 billion by 2030 and grow at a CAGR of 4.78 % over the forecast period of 2023–2030.

Key Market Drivers

Increasing Offshore E&P Activities: As onshore reserves dwindle, companies are investing heavily in offshore oil and gas fields, particularly in deepwater and ultra-deepwater locations, driving the demand for advanced subsea well access systems.

Technological Advancements: Innovations in rig-based and rig-less well access systems have enhanced operational efficiency and safety, reducing costs and improving productivity.

Focus on Safety and Environmental Compliance: Stringent safety and environmental regulations are pushing operators to adopt reliable subsea well access systems to minimize risks and ensure compliance.

Rising Energy Demand: The growing global energy demand is prompting exploration in more challenging offshore environments, necessitating advanced well access solutions.

Read Complete Report Details of ubsea Well Access System Market 2023–2030@ https://www.snsinsider.com/reports/subsea-well-access-system-market-3266

Market Segmentation

By Technology:

Rig-Based: These systems are integrated with drilling rigs and provide robust solutions for well control, particularly in deepwater and ultra-deepwater operations. Rig-based systems offer greater control and safety features, making them a preferred choice for complex offshore projects.

Rig-Less: Rig-less well access systems enable maintenance and intervention without the need for a drilling rig, significantly reducing costs and operational downtime. They are increasingly used in well intervention and workover operations.

By Product:

Annular Blowout Preventer (BOP): Annular BOPs are critical for sealing around different sizes of drill pipes and casings, ensuring well control during drilling operations.

Ram Blowout Preventer (BOP): Ram BOPs provide a more rigid seal and are designed to close off the wellbore entirely, offering enhanced safety and control in high-pressure scenarios.

By Location:

Shallow Water: Subsea well access systems in shallow waters are primarily used in conventional offshore fields, which are easier to access but still require advanced safety and control measures.

Deepwater: Deepwater operations are more complex and demand high-performance well access systems to handle extreme pressures and temperatures.

Ultra-Deepwater: Ultra-deepwater projects present unique challenges, requiring cutting-edge technologies to ensure the safety and efficiency of drilling and production operations.

By Region:

North America: The U.S. Gulf of Mexico leads the market in North America, driven by significant investments in deepwater and ultra-deepwater E&P projects.

Europe: The North Sea is a major hub for offshore oil and gas activities in Europe, where companies are adopting advanced subsea well access technologies to enhance operational efficiency.

Asia-Pacific: Growing offshore exploration activities in countries such as China, India, and Australia are expected to drive the demand for subsea well access systems in the Asia-Pacific region.

Latin America: Brazil’s pre-salt reserves are a key growth driver for the market in Latin America, with increasing investments in deepwater and ultra-deepwater fields.

Middle East & Africa: The region’s offshore fields, particularly in Africa, are gaining attention as operators explore new frontiers to meet rising energy demands.

Key Players:

Drill-Quip Inc.

GE Oil & Gas

Aker Solutions

FMC Technologies Inc.

OneSubsea

Halliburton

Weatherford International Ltd.

Dril-Quip

Oceaneering International

Proserv Group

Kongsberg Oil and Gas Technologies

Market Trends and Opportunities

Adoption of Digital Solutions: Digitalization and the integration of Internet of Things (IoT) technologies in subsea well access systems are enabling real-time monitoring, predictive maintenance, and improved decision-making.

Focus on Cost Optimization: With fluctuating oil prices, operators are increasingly looking for cost-effective solutions such as rig-less well access systems to improve the economics of offshore projects.

Growth in Deepwater and Ultra-Deepwater Projects: As companies explore deeper waters for new reserves, the demand for advanced well access systems designed to operate in extreme conditions is expected to surge.

Sustainability Initiatives: The industry is adopting greener technologies to minimize the environmental impact of offshore operations, creating opportunities for innovation in subsea well access systems.

Challenges

High Capital Investment: The high costs associated with deploying advanced subsea well access systems can be a barrier for smaller operators.

Technical Complexity: Offshore operations, particularly in deepwater and ultra-deepwater, present significant technical challenges, requiring continuous innovation and expertise.

Regulatory Hurdles: Stricter regulations on offshore drilling and environmental protection may slow down project approvals and increase compliance costs.

Market Outlook

The Subsea Well Access System Market is set for steady growth through 2030 as offshore exploration intensifies and technology continues to advance. Deepwater and ultra-deepwater projects will play a crucial role in shaping the future of the market, with operators focusing on improving safety, efficiency, and sustainability. As the industry embraces digitalization and cost-effective solutions, subsea well access systems will remain a cornerstone of offshore oil and gas operations.

About the Report

This comprehensive report provides an in-depth analysis of the Subsea Well Access System Market, covering key trends, market segmentation, regional insights, and growth forecasts. It serves as a valuable resource for industry stakeholders, investors, and policymakers seeking to navigate the evolving offshore oil and gas landscape.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

SS Seamless Pipe Supplier at Lowest Price

When it comes to sourcing SS Seamless Pipes at the lowest price, Udhhyog stands out as a reliable supplier in India. Our focus is on providing high-quality stainless steel pipes for industrial applications, all while ensuring affordability. Whether you're looking for a reliable piping solution for your construction, manufacturing, or other industrial needs, we offer SS Seamless Pipes that combine strength, durability, and the best value for your money.

Why Udhhyog is Your Best Choice for SS Seamless Pipes

Lowest Prices Guaranteed: Udhhyog understands the importance of cost-effectiveness in procurement. We offer the lowest prices for SS Seamless Pipes without compromising on quality, ensuring that businesses, especially MSMEs, can access the best products at affordable rates.

Top-Quality Assurance: Our SS Seamless Pipes are sourced from the most trusted manufacturers, such as Jindal and Tata, ensuring that you get pipes with superior strength, corrosion resistance, and excellent durability. These pipes meet international standards, making them suitable for a wide range of industrial uses.

Wide Range of Sizes and Grades: Udhhyog offers SS Seamless Pipes in various sizes and grades to meet your specific needs. Whether it's for high-pressure systems, low-pressure pipelines, or corrosive environments, we provide a range of options to fit your requirements.

Fast and Reliable Delivery: We understand the urgency of industrial projects. With Udhhyog, you can expect fast delivery of SS Seamless Pipes anywhere in India. We ensure that your order reaches you on time, minimizing any delays to your operations.

Bulk Discounts Available: For large orders, we offer attractive bulk discounts. This helps you save even more on your industrial piping needs, making Udhhyog your go-to supplier for SS Seamless Pipes at the lowest price.

Advantages of SS Seamless Pipes

Corrosion Resistance: SS Seamless Pipes are highly resistant to corrosion, making them perfect for harsh environments like chemical plants, offshore drilling rigs, and other industries that deal with aggressive substances.

High Strength: These pipes have superior tensile strength, making them suitable for high-pressure applications where durability is a key factor.

Long Lifespan: The seamless construction provides greater durability and prevents leaks or failures, ensuring that your investment lasts longer.

Smooth Flow: The seamless design eliminates joints, which means smoother internal surfaces, allowing fluids and gases to flow with less resistance.

Applications of SS Seamless Pipes

Oil and Gas Industry: Ideal for transporting fluids like oil, gas, and water in pipelines where corrosion resistance and durability are critical.

Chemical Processing: For conveying chemicals and aggressive liquids where standard pipes might fail due to corrosion or wear.

Pharmaceuticals and Food: Stainless steel pipes are crucial in industries where hygiene and contamination-free transport of liquids are vital.

Construction and Infrastructure: Used in high-stress applications such as structural piping, plumbing, and heating systems in large-scale construction projects.

Why Choose Udhhyog for Your SS Seamless Pipe Needs?

Udhhyog is a trusted name in the Indian market for SS Seamless Pipes. Our commitment to quality, affordability, and reliable service makes us a preferred supplier for industries across India. We strive to help businesses access the best products at competitive prices, empowering them to complete their projects without compromising on quality.

Order Your SS Seamless Pipe Today

At Udhhyog, we make ordering SS Seamless Pipes hassle-free. With easy online ordering, quick delivery, and customer support for large or customized orders, you can rely on us for all your piping needs.

Internal Links Explore other related products such as MS Flanges and GI Pipes for a complete piping solution.

#SSSeamlessPipes#LowestPricePipes#AffordablePipes#Udhhyog#IndiaPipes#SeamlessPipes#SteelPipes#IndustrialPipes

1 note

·

View note

Text

#Drill Pipe Market#Drill Pipe Market Size#Drill Pipe Market Growth#Drill Pipe Market Trends#Drill Pipe Market Opportunities#Drill Pipe Market Analysis

0 notes

Text

Find SS ERW Pipes at Lowest Prices

Looking to find SS ERW pipes at the lowest prices? Udhhyog is here to assist you! We specialize in supplying high-quality SS ERW Pipes tailored to meet diverse industrial applications, all while ensuring affordability. With our commitment to excellence, you can trust us to provide reliable solutions without breaking the bank.

What are SS ERW Pipes?

SS ERW Pipes (Electric Resistance Welded Pipes) are made by rolling steel sheets and welding the edges using an electric current. This manufacturing process enhances their durability and strength. Key features of SS ERW Pipes include:

Cost-Effective: Compared to other pipe options, such as seamless pipes, SS ERW Pipes are generally more affordable, making them ideal for budget-conscious projects.

Robustness: Designed to handle high pressures and stresses, these pipes are perfect for demanding applications.

Corrosion Resistance: Constructed from stainless steel, they provide excellent resistance to rust and corrosion, ensuring long-term performance.

Applications of SS ERW Pipes

The versatility of SS ERW Pipes makes them suitable for various industries, including:

Construction: Widely utilized in structural frameworks, providing essential strength and support for buildings and infrastructure.

Automotive: Used in manufacturing exhaust systems and structural components, ensuring vehicles are durable and reliable.

Chemical Processing: Ideal for transporting various chemicals, thanks to their corrosion-resistant properties.

Oil and Gas: Essential for drilling operations and the safe transportation of oil and gas products.

Why Choose Udhhyog for Your SS ERW Pipe Needs?

As a trusted supplier of SS ERW Pipes at the lowest prices, Udhhyog offers numerous benefits:

Extensive Product Range: We provide a wide selection of SS ERW Pipes in different sizes and specifications to meet various industrial requirements.

Quality Assurance: Our pipes undergo rigorous quality checks to ensure compliance with industry standards, giving you confidence in your purchase.

Competitive Pricing: Udhhyog is committed to offering the lowest prices for SS ERW Pipes in the market without compromising quality. You get the best value for your investment.

How to Find and Purchase SS ERW Pipes from Udhhyog

Finding and purchasing SS ERW Pipes from Udhhyog is simple:

Visit Our Website: Explore our extensive product range at SS ERW Pipe. Our user-friendly website makes it easy to browse and find what you need.

Select Your Specifications: Choose the appropriate size, thickness, and quantity based on your project requirements.

Request a Quote: Contact our knowledgeable sales team for personalized assistance and receive a competitive quote tailored to your needs.

Place Your Order: Once you’ve confirmed your specifications, place your order, and our logistics team will ensure prompt delivery to your location.

Customer Satisfaction

Our focus on quality and customer service has earned us positive feedback:

Reliable Supplier: "Udhhyog consistently provides the best prices for SS ERW Pipes. I rely on them for all my piping needs!" - Ravi, Site Supervisor.

Excellent Quality: "The quality of Udhhyog's SS ERW Pipes is exceptional, and their pricing is unbeatable!" - Neha, Procurement Manager.

Get Started with Udhhyog Today

If you're looking to find SS ERW pipes at the lowest prices, Udhhyog is your ideal partner. With our dedication to quality and customer satisfaction, we ensure you receive the best products for your industrial applications.

For more information, visit our SS Pipe page and explore our competitive pricing options.

1 note

·

View note