#Digital Twin Market Demand

Explore tagged Tumblr posts

Text

Digital Twin Market to Witness High Growth Owing to Increasing Adoption of IoT and AI Technologies

The global Digital Twin Market is estimated to be valued at US$ 8.60 billion in 2023 and is expected to exhibit a CAGR of 42.6% over the forecast period 2023-2030, as highlighted in a new report published by Coherent Market Insights.

A) Market Overview:

Digital twin is a virtual representation of a physical object or system that enables the analysis and optimization of its performance. It captures real-time data from sensors and uses advanced analytics and artificial intelligence (AI) algorithms to simulate the behavior and predict future outcomes. Digital twins find applications in various industries, including manufacturing, healthcare, smart cities, transportation, and agriculture, among others.

B) Market Dynamics:

The digital twin market is primarily driven by the increasing adoption of Internet of Things (IoT) and AI technologies. The integration of IoT with digital twins allows the collection of data from sensors embedded in physical objects, enhancing operational efficiency and enabling predictive maintenance. AI algorithms analyze this data to provide insights and optimize processes, leading to cost savings and improved performance.

Another driver for the market is the rising demand for remote monitoring and simulation capabilities. Digital twins enable businesses to remotely monitor and control their assets, reducing downtime and maximizing productivity. They also facilitate simulation and testing of new products or processes before implementation, reducing time-to-market and minimizing risks.

C) Market Key Trends:

One key trend in the Digital Twin Market is the use of digital twins in the healthcare industry. Medical professionals can create virtual models of patients based on their individual characteristics and medical history. These digital twins can be used to simulate disease progression, predict treatment outcomes, and plan personalized interventions. For example, surgeons can use digital twins to practice complex procedures before performing them on actual patients, improving surgical precision and patient outcomes.

D) SWOT Analysis:

Strengths:

1. Real-time data monitoring

2. Improved operational efficiency

Weaknesses:

1. High implementation costs

2. Limited awareness and understanding of the technology

Opportunities:

1. Integration of digital twins with blockchain for enhanced security

2. Rising adoption of digital twins in small and medium-sized enterprises (SMEs)

Threats:

1. Privacy and data security concerns

2. Lack of interoperability among different digital twin platforms

E) Key Takeaways:

- The global digital twin market is expected to witness high growth, exhibiting a CAGR of 42.6% over the forecast period. The increasing adoption of IoT and AI technologies is driving this growth.

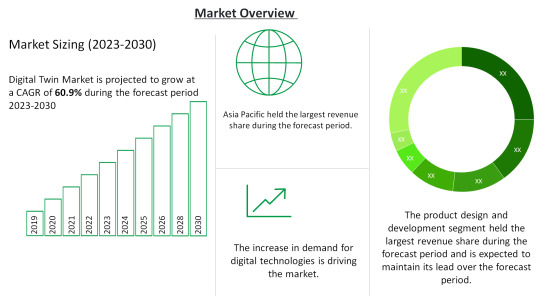

- The Asia-Pacific region is expected to be the fastest-growing and dominating region in the market, driven by the rapid industrialization and the increasing adoption of digital technologies in countries like China and India.

- Key players operating in the global digital twin market include General Electric, IBM Corporation, PTC Inc., Siemens AG, SAP SE, Microsoft Corporation, Alphabet Inc., Dell, Oracle Corporation, Robert Bosch GmbH, and AT&T.

In conclusion, the digital twin market is poised for significant growth in the coming years due to the increasing adoption of IoT and AI technologies. The ability of digital twins to enhance operational efficiency, enable predictive maintenance, and facilitate remote monitoring and simulation makes them valuable assets for businesses across various industries. However, challenges related to implementation costs and data security need to be addressed to unlock the full potential of this technology.

#Digital Twin#Digital Twin Market#Digital Twin Market Trends#Digital Twin Market Scope#Digital Twin Market Demand#Smart Technologies

0 notes

Text

Chifuyu nearly lost his best friend at 13 years old.

They fought a lot. The neighborhood they grew up in wasn't the best - if he's honest with himself it was a slum. A dump. His mother, bless her heart, tried her best to steer her son on the right path but their circumstances weren't easily ignored. Without a father in the picture Chifuyu found himself in the company of little boys who were in similar predicaments to him, all susceptible to the same fates, and all banded together to face the world as one stronger entity rather than what they really were, a bunch of misguided little kids.

It was through this group that he met Keisuke. It was also through this group that he nearly lost Keisuke.

The day still demands occasional attention through his memories. Sometimes it's like he's living it over again, seeing Keisuke's body hunched over, blade of a rusty knife with a dirty handle lodged deep into his stomach. It was that day when he realized what he was, what they all were. Kids running around like makeshift Yakuza members. Kids way above their heads. Young, dumb, and in need of help.

His love for his friends grew that day.

It wasn't easy, but eventually, they decided unanimously to become better. To strive for different. Whilst Keisuke dropped out of school, Chifuyu pushed for his diploma and later encouraged his friend to do the same. In turn, when Keisuke enrolled at the local community college to pursue his aspirations of learning mechanics, he afforded Chifuyu the same encouragement.

"Why don't you study photography?"

It's not like the thought hadn't been in his mind for years. Chifuyu hoarded dozens of disposable cameras in an old Nike shoebox beneath his bed, film developed with the pictures neatly packed into envelopes. He's carried one with him ever since the incident, a camera tucked into the front of his bookbag with new rolls of film sat next to it. He's become the group photographer - eager to catch memories of everything. He's snapped pictures of Mikey trying and failing to ask girls out. Of the twins making ramen for the entire gang at once. Of Keisuke and Kazutora, engine oil smeared on their cheeks as they proudly display the first bike they've refurbished together. Of Draken when he finally got his first apartment. Of the day he found Peke J. Everything. Every moment is too precious of a memory after you've nearly watched everything slip away. By the time he was out of high school, with smart phones on the rise and digital media at his fingertips, Chifuyu still stubbornly carried around a disposable camera, fingers itching to capture a fleeting moment.

He, nineteen, with mousy dark hair and wide eyes, swallowed hard. "You think I should do it?"

Keisuke shrugs. "I don't see why not."

Keisuke gifted Chifuyu his first real camera that day. A Canon 6D, fresh and new on the market with a Sigma lens to match. The very camera that Chifuyu had been eyeing in secret for months.

Keisuke holds it awkwardly in an overgrown hand. "They say it's really good for capturing pictures in low light," he explains. "You do that a lot. We uh, we usually get together at night or at sunset or something and you would bring flashlights because you say your cameras don't do well at night. It took me a couple months to save up for this but then I did that job with Ken on that truck and it paid out really well so...managed to snag this early."

Chifuyu still remembers Keisuke's face that day. His long, curly black and blonde hair. His crooked smile and thrice dimpled cheeks. The way his nose tinged pink - a sign of uncharacteristic timidity. Amber eyes that looked at him in earnest.

"I think you should study photography."

Chifuyu, today, toys with the camera in his hands. He's since gotten equipment leagues better, and has since phased out of using that in favor of cameras with clearer qualities and specification designed for different scenarios. He's no longer confined to hunching over in his childhood bedroom with a doctored version of Photoshop on his broken down laptop. He's sat in his photography studio, decorated with lights and hoods, with custom backdrops and furniture all neatly arranged. He's sat in his dream.

He flips the camera on its underside. A sliver of paper is taped to it, a little dingy and torn in corners, though the scratchy ink is still readable.

Make more memories. - Keisuke.

#ooc: i'll tag this later but anyway. lore day!#edit: I FORGOT TO SAY BUT LIKE#THIS IS SET IN 2013#cause i think in canon they were in seventh grade in 2008#but anyway. dates technically don't mean much i just wanted to write it like this#carry on

13 notes

·

View notes

Text

Industry 4.0 and the Demand for Smart Manufacturing in Pharma: A New Era for CMOs

The pharmaceutical industry is experiencing a paradigm shift with the advent of Industry 4.0 and smart manufacturing technologies. For contract manufacturing organizations (CMOs), these improvements are not just optional but necessary to remain competitive in a rapidly evolving marketplace. By leveraging cutting-edge technology, CMOs can increase productivity, reduce costs, and deliver better results for their customers. Let’s explore how Industry 4.0 is transforming medicine and the critical role CMOs play in this new era

What is Industry 4.0 in Pharma?

Industry 4.0 refers to the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), robotics, data analytics, etc. In medicine, these technologies enable real-time monitoring, predictive maintenance and automated quality control for smarter and more efficient production

For CMOs, adopting Industry 4.0 means embracing these innovations to streamline operations and meet the stringent demands of pharmaceutical procurement. With an increased focus on quality and speed, smart manufacturing gives CMOs a competitive advantage by ensuring accuracy and compliance.

Key benefits of Industry 4.0 for CMOs

1. Improved productivity

Industry 4.0 technology empowers CMOs to optimize production processes. Using IoT-enabled devices and sensors, production lines can be monitored in real-time, in order to instantly identify bottlenecks and malfunctions. This ensures minimal downtime and increases productivity.

2. Quality control

AI-powered quality assurance systems help CMOs identify deficiencies early in the process.

Real-time data collection and analysis ensures that each batch meets the highest standards, reducing the risk of recalls and compliance issues.

3. Debt reduction

Smart design reduces waste, energy consumption and labor costs. Predictive maintenance enabled by the IoT reduces device failures and extends device life, saving CMOs operating costs.

4. Quick time to market

With automated processes and flexible workflows, CMOs can reduce development cycles. This is especially important in the pharmaceutical industry, where time to market can determine the success of a product.

Projects 4.0 Technologies for CMO transformation

1. Internet of Things (IoT) .

IoT devices provide seamless communication between devices, systems and people. For CMOs, IoT ensures real-time visibility into production, inventory levels, and supply chain management.

2. Artificial Intelligence (AI) .

AI-driven analytics provide CMOs with actionable insights, enabling them to streamline their processes and improve decision-making. Machine learning algorithms can predict demand, optimize resource allocation, and improve process efficiency.

3. Robotics and Automation

Automation technologies are transforming medicine. Robots perform tasks with repeatedly increasing accuracy, freeing up humans for more subtle activities to improve stability.

4. Digital twins

Digital twins are virtual replicas of physical objects or systems. CMOs can use these to simulate and optimize processes, reduce trial-and-error methodologies, and accelerate innovation.

Challenges for CMOs to adopt Industry 4.0

While the benefits are undeniable, CMOs face several challenges in implementing Industry 4.0 technologies:

Significant initial investment: Implementing smart manufacturing processes requires significant upfront costs, which can be a barrier for smaller CMOs.

Skills Gap: The transition to Industry 4.0 requires a workforce with advanced technology skills, which may require significant training and recruitment efforts.

Data Security Issues: As manufacturing becomes increasingly digital, ensuring data security and protecting intellectual property becomes increasingly important.

The future of CMOs is in the industry 4.0 era

Adopting Industry 4.0 technologies is not a luxury but a necessity for CMOs to remain competitive. As pharmaceutical companies demand faster, superior solutions and lower costs, CMOs need to invest in smarter manufacturing processes to meet these expectations

The future of pharmaceuticals is collaboration and innovation. By partnering with technology providers and taking advantage of advanced systems, CMOs can position themselves as leaders in the industry. As Industry 4.0 continues to evolve, CMOs that embrace this shift will not only survive but thrive in this time of change

conclusion

Industry 4.0 and smart manufacturing are reshaping the medical landscape, creating unparalleled opportunities for CMOs to advance their capabilities. From real-time analytics to AI-driven analytics, these technologies empower CMOs to deliver exceptional value to their clients. By overcoming challenges and investing in innovation, CMOs can play a key role in shaping the future of medicine.

2 notes

·

View notes

Text

Digital Twin Market Size 2023-2030: ABB, AVEVA Group plc, Dassault Systemes

Digital Twin Market by Power Source (Battery-Powered, hardwired with battery backup, Hardwired without battery backup), Type (Photoelectric Smoke Detectors, Ionization Smoke Detectors), Service, Distribution Channel, and region (North America, Europe, Asia-Pacific, Middle East, and Africa and South America). The global Digital Twin Market size is 11.12 billion USD in 2022 and is projected to reach a CAGR of 60.9% from 2023-2030.

Click Here For a Free Sample + Related Graphs of the Report at: https://www.delvens.com/get-free-sample/digital-twin-market-trends-forecast-till-2030

Digital twin technology has allowed businesses in end-use industries to generate digital equivalents of objects and systems across the product lifecycle. The potential use cases of digital twin technology have expanded rapidly over the years, anchored in the increasing trend of integration with internet-of-things (IoT) sensors. Coupled with AI and analytics, the capabilities of digital twins are enabling engineers to carry out simulations before a physical product is developed. As a result, digital twins are being deployed by manufacturing companies to shorten time-to-market. Additionally, digital twin technology is also showing its potential in optimizing maintenance costs and timelines, thus has attracted colossal interest among manufacturing stalwarts, notably in discrete manufacturing.

The shift to interconnected environments across industries is driving the demand for digital twin solutions across the world. Massive adoption of IoT is being witnessed, with over 41 billion connected IoT devices expected to be in use by 2030. For the successful implementation and functioning of IoT, increasing the throughput for every part or “thing” is necessary, which is made possible by digital twin technology. Since the behavior and performance of a system over its lifetime depend on its components, the demand for digital twin technology is increasing across the world for system improvement. The emergence of digitalization in manufacturing is driving the global digital twin market. Manufacturing units across the globe are investing in digitalization strategies to increase their operational efficiency, productivity, and accuracy. These digitalization solutions including digital twin are contributing to an increase in manufacturer responsiveness and agility through changing customer demands and market conditions.

On the other hand, there has been a wide implementation of digital technologies like artificial intelligence, IoT, clog, and big data which is increasing across the business units. The market solutions help in the integration of IoT sensors and technologies that help in the virtualization of the physical twin. The connectivity is growing and so are the associated risks like security, data protection, and regulations, alongside compliance.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Delvens Industry Expert’s Standpoint

The use of solutions like digital twins is predicted to be fueled by the rapid uptake of 3D printing technology, rising demand for digital twins in the healthcare and pharmaceutical sectors, and the growing tendency for IoT solution adoption across multiple industries. With pre-analysis of the actual product, while it is still in the creation stage, digital twins technology helps to improve physical product design across the full product lifetime. Technology like digital twins can be of huge help to doctors and surgeons in the near future and hence, the market is expected to grow.

Market Portfolio

Key Findings

The enterprise segment is further segmented into Large Enterprises and Small & Medium Enterprises. Small & Medium Enterprises are expected to dominate the market during the forecast period. It is further expected to grow at the highest CAGR from 2023 to 2030.

The industry segment is further segmented into Automotive & Transportation, Energy & Utilities, Infrastructure, Healthcare, Aerospace, Oil & Gas, Telecommunications, Agriculture, Retail, and Other Industries. The automotive & transportation industry is expected to account for the largest share of the digital twin market during the forecast period. The growth can be attributed to the increasing usage of digital twins for designing, simulation, MRO (maintenance, repair, and overhaul), production, and after-service.

The market is also divided into various regions such as North America, Europe, Asia-Pacific, South America, and Middle East and Africa. North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

During the COVID-19 pandemic, the use of digital twin technologies to manage industrial and manufacturing assets increased significantly across production facilities to mitigate the risks associated with the outbreak. Amid the lockdown, the U.S. implemented a National Digital Twin Program, which was expected to leverage the digital twin blueprint of major cities of the U.S. to improve smart city infrastructure and service delivery. The COVID-19 pandemic positively impacted the digital twin market demand for twin technology.

Regional Analysis

North America to Dominate the Market

North America is expected to hold the largest share of the digital twin market throughout the forecast period. North America is a major hub for technological innovations and an early adopter of digital twins and related technologies.

North America has an established ecosystem for digital twin practices and the presence of large automotive & transportation, aerospace, chemical, energy & utilities, and food & beverage companies in the US. These industries are replacing legacy systems with advanced solutions to improve performance efficiency and reduce overall operational costs, resulting in the growth of the digital twin technology market in this region.

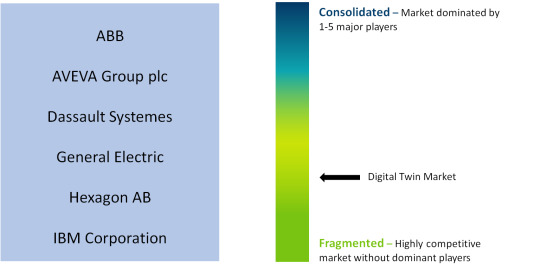

Competitive Landscape

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

Microsoft

Siemens

ANSYS

PTC

IBM

Recent Developments

In April 2022, GE Research (US) and GE Renewable Energy (France), subsidiaries of GE, collaborated and developed a cutting-edge artificial intelligence (AI)/machine learning (ML) technology that has the potential to save the worldwide wind industry billions of dollars in logistical expenses over the next decade. GE’s AI/ML tool uses a digital twin of the wind turbine logistics process to accurately predict and streamline logistics costs. Based on the current industry growth forecasts, AI/ML might enable a 10% decrease in logistics costs, representing a global cost saving to the wind sector of up to USD 2.6 billion annually by 2030.

In March 2022, Microsoft announced a strategic partnership with Newcrest. The mining business of Newcrest would adopt Azure as its preferred cloud provider globally, as well as work on digital twins and a sustainability data model. Both organizations are working together on projects, including the use of digital twins to improve operational performance and developing a high-impact sustainability data model.

Reasons to Acquire

Increase your understanding of the market for identifying the best and most suitable strategies and decisions on the basis of sales or revenue fluctuations in terms of volume and value, distribution chain analysis, market trends, and factors

Gain authentic and granular data access for Digital Twin Market so as to understand the trends and the factors involved in changing market situations

Qualitative and quantitative data utilization to discover arrays of future growth from the market trends of leaders to market visionaries and then recognize the significant areas to compete in the future

In-depth analysis of the changing trends of the market by visualizing the historic and forecast year growth patterns

Direct Purchase of Digital Twin Market Research Report at: https://www.delvens.com/checkout/digital-twin-market-trends-forecast-till-2030

Report Scope

Report FeatureDescriptionsGrowth RateCAGR of 60.9% during the forecasting period, 2023-2030Historical Data2019-2021Forecast Years2023-2030Base Year2022Units ConsideredRevenue in USD million and CAGR from 2023 to 2030Report Segmentationenterprise, platform, application, and region.Report AttributeMarket Revenue Sizing (Global, Regional and Country Level) Company Share Analysis, Market Dynamics, Company ProfilingRegional Level ScopeNorth America, Europe, Asia-Pacific, South America, and Middle East, and AfricaCountry Level ScopeU.S., Japan, Germany, U.K., China, India, Brazil, UAE, and South Africa (50+ Countries Across the Globe)Companies ProfiledABB; AVEVA Group plc; Dassault Systems; General Electric; Hexagon AB; IBM Corp.; SAP.Available CustomizationIn addition to the market data for Digital Twin Market, Delvens offers client-centric reports and customized according to the company’s specific demand and requirement.

TABLE OF CONTENTS

Large Enterprises

Small & Medium Enterprises

Product Design & Development

Predictive Maintenance

Business Optimization

Performance Monitoring

Inventory Management

Other Applications

Automotive & Transportation

Energy & Utilities

Infrastructure

Healthcare

Aerospace

Oil & Gas

Telecommunications

Agriculture

Retail

Other Industries.

Asia Pacific

North America

Europe

South America

Middle East & Africa

ABB

AVEVA Group plc

Dassault Systemes

General Electric

Hexagon AB

IBM Corporation

SAP

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B, 21ST FLOOR ALPHATHUM SECTOR 90 NOIDA 201305, IN +44-20-8638-5055 [email protected] WEBSITE: https://delvens.com/

#Digital Twin Market#Digital Twin#Digital Twin Market Size#Digital Twin Market Share#Semiconductors & Electronics

2 notes

·

View notes

Text

The Role of Technology in Operational Excellence Consulting

In today’s fast-paced business environment, operational excellence is crucial for organizations striving for efficiency, productivity, and sustainable growth.

Consulting firms specializing in operational excellence help businesses streamline processes, reduce costs, and improve overall performance. However, with the advent of digital transformation, technology plays an increasingly significant role in operational excellence consulting. From data analytics and automation to artificial intelligence and cloud computing, technology enables consultants to offer more precise insights, implement faster solutions, and drive continuous improvements.

The Evolution of Operational Excellence Consulting

Traditionally, operational excellence consulting focused on Lean Six Sigma, process optimization, and change management methodologies. While these principles remain relevant, the digital era has introduced new tools and approaches that enhance their effectiveness. The shift towards Industry 4.0, which integrates smart technologies into operations, has redefined the way consultants approach process improvements.

Key Technologies Driving Operational Excellence Consulting

1. Data Analytics and Business Intelligence

Data analytics is a cornerstone of operational excellence consulting. By leveraging big data and business intelligence tools, consultants can:

Identify inefficiencies and bottlenecks within an organization.

Provide real-time performance metrics and predictive analytics.

Improve decision-making through actionable insights.

Advanced analytics platforms, such as Power BI, Tableau, and Google Analytics, allow consultants to visualize data effectively and drive data-driven strategies.

2. Automation and Robotic Process Automation (RPA)

Automation plays a vital role in reducing manual tasks and increasing efficiency. Robotic Process Automation (RPA) enables businesses to automate repetitive processes, such as data entry, report generation, and compliance tracking. Benefits of RPA include:

Enhanced accuracy and reduced human errors.

Faster processing times and increased productivity.

Cost savings through workforce optimization.

Operational excellence consultants integrate RPA solutions to help organizations optimize workflows and achieve higher efficiency levels.

3. Artificial Intelligence and Machine Learning

AI and machine learning are transforming how businesses approach problem-solving and decision-making. Consultants utilize AI-powered tools to:

Predict market trends and customer behaviors.

Optimize supply chain operations through demand forecasting.

Enhance customer experience with chatbots and AI-driven insights.

AI-driven technologies enable businesses to achieve operational excellence by improving efficiency, reducing waste, and personalizing customer interactions.

4. Cloud Computing and Digital Collaboration

The adoption of cloud computing has revolutionized operational excellence consulting by providing scalable, flexible, and cost-effective solutions. Cloud-based platforms offer:

Real-time data access and collaboration across global teams.

Secure and centralized storage for seamless information sharing.

Scalable infrastructure that supports business growth.

Tools like Microsoft Azure, Google Cloud, and AWS empower consultants to implement cloud-based solutions that enhance operational efficiency.

5. Internet of Things (IoT) and Smart Manufacturing

IoT technology enables businesses to collect and analyze data from connected devices, leading to smarter decision-making. In operational excellence consulting, IoT applications include:

Monitoring equipment performance and predictive maintenance.

Enhancing supply chain transparency through real-time tracking.

Improving workplace safety through sensor-based monitoring.

IoT-driven insights help businesses minimize downtime, reduce operational costs, and optimize resource allocation.

6. Process Mining and Digital Twins

Process mining tools analyze business processes in real time to identify inefficiencies and recommend optimizations. Digital twins, on the other hand, create virtual models of physical assets, allowing businesses to simulate and test improvements before implementation. These technologies:

Enhance process transparency and eliminate bottlenecks.

Reduce risks associated with process changes.

Enable continuous improvement through real-time insights.

Consultants use process mining and digital twins to enhance operational workflows and drive excellence across industries.

Benefits of Integrating Technology in Operational Excellence Consulting

Embracing technology in operational excellence consulting provides numerous benefits, including:

Increased Efficiency: Automation and AI-driven tools enhance productivity and reduce manual intervention.

Cost Reduction: Technology-driven process improvements lower operational costs and optimize resource utilization.

Enhanced Decision-Making: Data analytics and AI provide real-time insights for better strategic decisions.

Scalability and Flexibility: Cloud computing enables businesses to scale operations seamlessly.

Competitive Advantage: Companies leveraging technology gain a strategic edge in the market.

Challenges and Considerations

Despite its advantages, technology integration in operational excellence consulting comes with challenges such as:

Implementation Costs: Initial investments in technology can be high.

Change Resistance: Employees may resist digital transformation due to unfamiliarity.

Data Security Risks: Increased reliance on digital tools raises cybersecurity concerns.

Skill Gaps: Organizations may require upskilling programs to maximize technology benefits.

Consultants must develop tailored strategies to address these challenges and ensure smooth digital transformation.

Conclusion

Technology has become a game-changer in Operational Excellence Consulting Firms, enabling businesses to optimize processes, enhance efficiency, and drive innovation. By leveraging data analytics, automation, AI, IoT, and cloud computing, consultants can offer actionable insights and sustainable improvements. However, successful implementation requires careful planning, addressing challenges, and fostering a culture of continuous improvement. As technology continues to evolve, its role in operational excellence consulting will only grow, shaping the future of business optimization and performance excellence.

0 notes

Text

Comprehensive Market Assessment: Data Center Support Infrastructure Trends & Innovations

The global data center support infrastructure market size was valued at USD 57.94 billion in 2024 and is anticipated to grow at a CAGR of 8.2% from 2025 to 2030. The industry encompasses critical components such as power systems (UPS, generators), cooling systems, racks, monitoring systems, and Racks and Enclosures solutions. These elements ensure the operational reliability, efficiency, and Racks and Enclosures of data centers.

The rapid adoption of cloud services, big data analytics, internet of things (IoT), and AI-driven Tier Levels is transforming the technology landscape. Organizations across industries are migrating their workloads to the cloud, leveraging its scalability, cost efficiency, and flexibility. This surge in demand for cloud computing fuels the need for robust data centers capable of handling massive volumes of data and ensuring uninterrupted services. To support these operations, data centers require advanced support infrastructure, including efficient cooling systems to manage heat from high-density servers, reliable power backup systems to prevent downtime, and intelligent management solutions for optimal performance and energy utilization. This trend drives continuous innovation and investment in Tier 3, enabling businesses to meet growing digital demands and ensure seamless operations in an increasingly data-driven world.

Hyperscale data centers cater to large-scale cloud operations, offering extensive Power Distribution Systems and computational capabilities, while edge data centers provide localized, low-latency services for real-time Tier Levels like IoT and 5G. The rise of these facilities has created a need for scalable and modular infrastructure to accommodate rapid growth and evolving technology demands. Hyperscale data centers require optimized cooling and power systems to manage high-density workloads, ensuring efficiency and reliability. Edge data centers, on the other hand, emphasize compact and flexible solutions to support deployment in remote or distributed locations. Together, these developments are transforming the data center landscape, driving innovation in infrastructure to meet the diverse and growing demands of modern digital ecosystems.

Key Data Center Support Infrastructure Company Insights

Key players operating in the industry include Corning, Schneider Electric, Leviton, Legrand, Eaton, ABB, Motivair, Panduit, Rittal, Chatsworth Products, APC by Schneider Electric, Raritan, Hubbell, Vertiv, and Emerson Network Power. The companies are focusing on various strategic initiatives, including new product development, partnerships & collaborations, and agreements to gain a competitive advantage over their rivals. The following are some instances of such initiatives.

In January 2025, Panduit partnered with Hyperview to offer modern Data Center Infrastructure Management (DCIM) software tools to enhance clients' capabilities in security, environment responsiveness, and operational efficiency. By integrating Hyperview’s cloud-based platform with Panduit's critical power solutions, the collaboration aims to provide comprehensive insights, optimize operations, and promote sustainability. This move ensures seamless service continuity for existing clients while leveraging the advanced capabilities of Azure-based infrastructure for scalability and privacy

In April 2024, Eaton partnered with Red Dot Analytics (RDA) to enhance data center operations with AI-focused solutions. This collaboration aims to improve predictive maintenance, anomaly detection, and energy optimization in data centers. By integrating RDA’s Cognitive Digital Twin technology with Eaton’s expertise in power management, the partnership seeks to boost sustainability, resilience, and efficiency in handling the growing demand for AI and high-density computing workloads.

Data Center Support Infrastructure Market Report Segmentation

Grand View Research has segmented the global data center support infrastructure market report based on Infrastructure, tier level, enterprise size, end use and region.

Infrastructure Outlook (Revenue, USD Million, 2018 - 2030)

Power Distribution Systems

Cooling Systems

Racks and Enclosures

Site and Facility Infrastructure

Security Systems

Tier Level Outlook (Revenue, USD Million, 2018 - 2030)

Tier 1

Tier 2

Tier 3

Tier 4

Enterprise Size Outlook (Revenue, USD Million, 2018 - 2030)

Large Enterprise

Small & Medium Sized Enterprises

End Use Outlook (Revenue, USD Million, 2018 - 2030)

Cloud Service Provider

Technology Provider

Telecom

Healthcare

BFSI

Retail & E-commerce

Entertainment & Media

Energy

Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia Pacific

China

India

Japan

South Korea

Australia

Latin America

Brazil

Middle East & Africa

A.E

Saudi Arabia

South Africa

Order a free sample PDF of the Data Center Support Infrastructure Market Intelligence Study, published by Grand View Research.

0 notes

Text

Digital Twin Market,Size, Share, Key Players | BIS Research

A Digital Twin is a virtual representation or simulation of a physical object, system, or process, typically in real-time. It is created using data collected from sensors, devices, or other sources embedded in the physical counterpart. The digital twin mirrors the characteristics, behavior, and performance of the real-world entity, allowing for analysis, monitoring, and optimization.

The Global Digital Twin Market size was valued at $10.3 billion in 2023, and it is expected to grow with a CAGR of 58.52%

Digital Twin Overview

A digital twin is a virtual model designed to accurately reflect a physical object, process, system, or service. This innovative concept leverages the convergence of the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and big data analytics to create a dynamic and real-time simulation of a physical entity or system. Digital twins are used across various industries, including manufacturing, healthcare, urban planning, and more, enabling professionals to simulate, predict, and optimize systems before they are built and throughout their lifecycle.

Request a free sample report of the Digital Twin Market Trends

Drivers and Trends

IoT Interrogation

Industry 4.0

Predictive Maintenance

Customization and Personalization

AI and Machine Learning Integration

5G Connectivity

Sustainability Focus

Increased Adoption and Emerging Markets

Applications of Digital Twin Market

Manufacturing

Healthcare

Automotive

Smart Cities

Market Segmentation

1 By Application

• Product Design Development

• Performance Monitoring

• Predictive Maintenance

• Inventory Management

• Others

2 By End Users

• Manufacturing

• Automotive

• Aviation

• Energy and Utilities

• Healthcare

• Logistics and Retail

• Others

3 By Type

• Asset Digital Twin

• Process Digital Twin

• System Digital Twin

• Digital Twin of an Organization (DTO)

4 By Product Offering

• Platforms

• Hardware

• Support Services

5 By Region

• North America — U.S. and Canada

• Europe — U.K., Germany, France, Russia, and Rest-of-the-Europe

• Asia-Pacific — China, India, Japan, and Rest-of-Asia-Pacific

• Rest-of-the-World — Latin America and Middle East and Africa

Key Components for Digital Twin Market

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

IBM

I Health Lab, Inc.

Download Complete TOC of the Digital Twin Market Trends

The global Digital Twin market, encompassing telemedicine, remote patient monitoring, mobile health applications, and electronic health records, is witnessing substantial growth due to increasing demand for accessible, cost-effective, and outcome-focused healthcare solutions. Digital Twin refers to the integration of digital technologies into healthcare systems to enhance the delivery of medical services, improve patient engagement, and promote proactive healthcare management.

Digital Twin Market Segmentation

1 By Application

2 By Offering

3 By Technology

4 By Region

Get more market insights on Advanced materials and chemicals

Key Market Players

Allscripts Healthcare Solutions Inc.

AMD Global Telemedicine Inc.

Apple, Inc.

AT & T, Inc.

Biotricity

GE Healthcare

Recent Developments

•In December 2023, Siemens signed a collaboration with Intel on advanced semiconductor manufacturing, which aimed to improve production efficiency and sustainability throughout the value chain. The collaboration explored initiatives such as optimizing energy management and mitigating carbon footprints throughout the value chain. A notable aspect involved investigating the use of digital twins for complex manufacturing facilities, aiming to standardize solutions and enhance efficiency in every aspect of the process.

• In September 2023, GE Vernova launched a new product, an AI-powered carbon emissions management software for the energy sector. Utilization of this new software would enable precise measurement, management, and operationalization of insights aimed at lowering carbon emissions. With the use of a reconciliation algorithm and digital twin technology driven by machine learning (ML) and data analytics, the software aimed to increase the accuracy of greenhouse gas (GHG) calculations on scope one gas turbines by as much as 33%.

• In April 2023, Siemens signed a partnership with IBM to create an integrated software solution for systems engineering, service lifecycle management, and asset management. The collaboration aimed to support traceability and sustainable product development across mechanical, electronics, electrical, and software engineering domains. The new suite, based on SysML v1 standards, would utilize a digital thread to link design, manufacturing, operations, maintenance, updates, and end-of-life management throughout the product lifecycle

Conclusion

The digital twin market represents a paradigm shift in how industries approach problem-solving and optimization. With its ability to simulate, predict, and enhance, digital twin technology is set to become an indispensable tool across various sectors.

0 notes

Text

Industrial Control System(ICS) Market : The Future Of Smart Factrories And Industries

Introduction

The Industrial Control Systems (ICS) Market is expanding rapidly due to the increasing demand for automation, cybersecurity, and digital transformation across industries. ICS includes various control systems such as Supervisory Control and Data Acquisition (SCADA), Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC) that enable efficient monitoring, management, and operation of industrial processes. With advancements in Industry 4.0, IoT, AI, and cybersecurity, ICS plays a crucial role in optimizing productivity, reducing operational costs, and ensuring system security.

Market Growth and Trends

Increasing Adoption of Industry 4.0 and Smart Manufacturing The shift towards smart factories and industrial automation is driving the adoption of ICS for real-time monitoring, predictive maintenance, and data-driven decision-making.

Rising Demand for Cybersecurity in Industrial Control Systems As cyber threats to industrial infrastructure grow, ICS cybersecurity solutions are becoming essential to protect critical systems from attacks and unauthorized access.

Growth in Energy and Utility Sector ICS is widely used in power plants, water treatment facilities, and oil & gas refineries to enhance process control, improve efficiency, and ensure safety in energy distribution networks.

Expansion of IoT and Cloud-Based Control Systems The integration of IoT sensors, edge computing, and cloud-based ICS platforms enables real-time data analytics, remote monitoring, and improved system efficiency.

Adoption in Transportation and Infrastructure ICS is increasingly used in railways, traffic management, and smart city infrastructure to enhance operational efficiency and automate critical processes.

Market Challenges

Despite its growth potential, the ICS market faces several challenges:

Cybersecurity Risks: As ICS becomes more connected, vulnerabilities to cyber threats increase, necessitating robust security measures.

Integration Complexity: Many industries still rely on legacy systems, making it challenging to integrate new ICS technologies.

High Implementation Costs: Setting up and maintaining industrial control systems requires significant investment, which can be a barrier for small and medium enterprises (SMEs).

Future Outlook

The future of the Industrial Control Systems market is promising, with increasing investments in AI-powered automation, blockchain for security, and digital twins for real-time system modeling. As industries move towards sustainable and energy-efficient operations, ICS will play a vital role in optimizing resource utilization and enhancing productivity. Governments and organizations worldwide are also focusing on improving ICS security standards, further driving market growth.

Conclusion

The Industrial Control Systems Market is witnessing significant expansion due to technological advancements, increased cybersecurity needs, and growing industrial automation trends. While challenges such as cybersecurity risks and high implementation costs exist, continuous innovation and strategic investments will drive the adoption of ICS across multiple industries, ensuring a smarter and more efficient future.

Read More Insights @ https://www.snsinsider.com/reports/industrial-control-systems-market-5514

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes

Text

Enterprise Asset Management Market Size And Share Report, 2030

Enterprise Asset Management Market Growth & Trends

The global enterprise asset management market size is estimated to reach a market size of USD 19.68 billion by 2030 and expand at a CAGR of 16.9% from 2023 to 2030, according to a new study by Grand View Research, Inc. The significant market growth can be attributed to the rising technical advancements, the growing acceptance of advanced technologies for developing asset lifecycles, and the advent of innovative digital technologies across industrial verticals, such as cloud-based EAM. For instance, in April 2023, Ernst & Young LLP, a consulting company, announced a partnership with Asset Lifecycle Intelligence, a division of Hexagon AB, to offer asset performance management and enterprise asset management (EAM) technologies. Through the partnership, EY would help its customers track, monitor, and extract value from assets while mitigating risks such as unplanned costs and operational downtime.

To provide EAM and Asset Performance Management (APM) technologies as part of digital transformation and cloud migration initiatives through innovation and solution expertise. For clients aiming to address business challenges and issues regarding assets, this alliance employs EAM and APM service offerings. To promote the sustainability of digital realities and promote autonomous futures, this partnership draws together technological expertise in sustainability, digital twin, cyber, supply chain, and manufacturing execution systems, along with installation and upgrade assistance.

Cloud EAM deployment eliminates the need for extensive on-premises hardware and reduces IT infrastructure costs, allowing organizations to allocate resources more efficiently. Furthermore, cloud deployment offloads maintenance tasks, such as software updates and security patches, to the service provider, allowing the organization's IT team to focus on core business activities. For instance, in November 2022, as global's an IT services provider, announced a partnership with Dynaway, a provider of Microsoft Dynamics platform-based enterprise asset management. Through the partnership, the former company will add Dynaway’s EAM solution to its offering portfolio. The new solution would help sa.global’s clients to improve asset performance with predictive maintenance and create connected ecosystems that boost productivity, efficiency, and quality.

Several enterprises worldwide were impacted by the pandemic's breakout and the following lockdowns, travel bans, limits on people's liberty of movement, and company closures. Numerous businesses worldwide have adopted enterprise asset management solutions to manage assets, equipment, IT systems, and other resources efficiently and effectively, avoid potential hardware or machine failures, cut downtime, and maintain continuous operations. Several companies allowed remote working as part of their efforts to preserve and defend their employees' well-being following the pandemic outbreak, which resulted in a persistent demand for EAM solutions. Due to this factor, demand for enterprise asset management solutions is expected to increase notably in the forecast period.

Organizations across the world are increasingly concerned about data security at the time of implementation of an advanced IT or cloud-based EAM solution. Several manufacturing organizations wanting to improve business efficiency, asset management, and industrial operations believe security and compliance as the main barriers restricting the deployment of EAM solutions. For instance, in October 2022, Oracle launched an asset-based customer service for Oracle Fusion Cloud Applications Package to assist organizations in improving service effectiveness and customer experience.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

Enterprise Asset Management Market Report Highlights

The cloud service segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Organizations that want to control customer and company information security tend to prefer the on-premises version of EAM. A company's internal IT team is responsible for setting up, hosting, and managing this deployment

The small & medium enterprise segment is anticipated to emerge as the fastest-growing solution segment from 2023-2030. SMEs are starting to invest in cloud-based EAM software and transition to upgraded solutions. It has a low initial investment requirement, enables users to manage assets remotely, and allows for mobile usage, giving workers more freedom in their jobs

The government segment is anticipated to emerge as the fastest-growing solution segment over the forecast period. Government organizations can boost accountability and transparency throughout the entire organization and extend the life of their most valuable assets by implementing EAM software

The APAC market is estimated to be the fastest-growing segment, offering lucrative growth opportunities for the industry players. Businesses in APAC countries such as India still in the development stage are focusing on globalization to build a regional economic outlook and get traction in the local EAM market

Enterprise Asset Management Market Segmentation

Grand View Research has segmented the global enterprise asset management market based on deployment, enterprise size, end use, and region.

Enterprise Asset Management (EAM) Deployment Outlook (Revenue, USD Million; 2018 - 2030)

Cloud

On-premise

Enterprise Asset Management (EAM) Enterprise Size Outlook (Revenue, USD Million; 2018 - 2030)

Large Enterprise

Small & Medium Enterprise

Enterprise Asset Management (EAM) End Use Outlook (Revenue, USD Million; 2018 - 2030)

Manufacturing

Facility Management

Healthcare

Education

Government

Others

Enterprise Asset Management (EAM) Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of The Key Player in the Enterprise Asset Management Market

Aptean

AssetWorks, LLC

CGI, Inc.

IFS AB

Infor

International Business Machines (IBM) Corporation

Oracle Corporation

PcsInfinity (Asset Infinity)

Sage Group PLC

SAP SE

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/enterprise-asset-management-market-report

#Enterprise Asset Management Market Size#Enterprise Asset Management Market Share#Enterprise Asset Management Market Trends

0 notes

Text

The Future of Wire Machinery: Cutting-Edge Innovations You Need to Know

The wire machinery industry is undergoing a remarkable transformation, driven by technological advancements that enhance efficiency, precision, and sustainability. As industries demand higher-quality wire products and faster production cycles, manufacturers are embracing cutting-edge innovations to stay ahead of the curve. In this blog, we explore the latest breakthroughs shaping the future of wire machinery.

Wire Machine Manufacturers

1. Automation and Smart Manufacturing

Automation is revolutionizing wire machinery, reducing manual intervention, and increasing production speed. Advanced robotics and AI-powered systems are streamlining processes such as wire drawing, stranding, and coating. Smart sensors and IoT-enabled devices provide real-time monitoring, ensuring precise control over quality and minimizing downtime.

2. Artificial Intelligence and Predictive Maintenance

AI and machine learning are playing a crucial role in predictive maintenance. By analyzing machine performance data, AI can detect potential failures before they occur, reducing costly breakdowns and unplanned stoppages. This not only enhances efficiency but also extends the lifespan of machinery, optimizing overall operational costs.

3. 3D Printing in Wire Manufacturing

Additive manufacturing, or 3D printing, is emerging as a game-changer in the wire industry. From designing customized wire components to producing intricate dies and tools, 3D printing enables rapid prototyping and reduces material waste. This innovation enhances flexibility in production and accelerates product development cycles.

Cable Machinery Manufacturers

4. Energy-Efficient and Eco-Friendly Solutions

Sustainability is a growing focus in wire manufacturing. Companies are adopting energy-efficient machines that consume less power while maintaining high output. Innovations in eco-friendly coatings, recyclable materials, and low-emission production processes are helping reduce the industry's carbon footprint. These advancements align with global sustainability goals and regulatory requirements.

5. High-Speed and Precision Engineering

Modern wire machinery is designed for ultra-fast operations without compromising accuracy. Innovations such as laser-guided cutting, precision wire straightening, and automated tension control ensure flawless output. These technologies enable manufacturers to meet the increasing demand for high-quality wire products across various industries, from automotive to telecommunications.

6. Advanced Materials and Coating Technologies

The development of new wire materials, including superalloys and composites, is expanding the possibilities in various applications. Enhanced coating techniques, such as nano-coatings and corrosion-resistant treatments, are improving wire durability and performance in harsh environments. These innovations are particularly beneficial in aerospace, medical, and energy sectors.

7. Digital Twins and Virtual Prototyping

The concept of digital twins—virtual models of wire machinery—allows manufacturers to simulate production processes before implementing changes in real-time. This reduces trial-and-error costs, optimizes machine settings, and ensures smoother transitions when upgrading machinery or introducing new products.

Wire Machine Manufacturers

Final Thoughts

The future of wire machinery is being shaped by automation, AI, sustainability, and precision engineering. As these innovations continue to evolve, manufacturers must embrace digital transformation to remain competitive in a fast-changing landscape. Investing in cutting-edge technology will not only enhance efficiency and product quality but also open new opportunities for growth in the global market.

Are you ready to embrace the future of wire machinery? Stay ahead by integrating these innovations into your manufacturing process today!

#Wire Machine Manufacturers#Wire Machinery Manufacturers#Cable Machinery Manufacturers#Cable Making Machine Manufacturers#Wire Making Machine Manufacturers

0 notes

Text

Smart Hospital Infrastructure Market to Boom from $45.2B in 2024 to $150.3B by 2034

Smart Hospital Infrastructure Market is on a rapid growth trajectory, projected to expand from $45.2 billion in 2024 to $150.3 billion by 2034, at a CAGR of 12.8%. This market is revolutionizing healthcare by integrating IoT, AI, big data, blockchain, and cloud computing to create intelligent, connected, and efficient hospital ecosystems. From real-time patient monitoring to automated hospital operations, smart hospital infrastructure is driving the future of healthcare through data-driven decision-making, resource optimization, and improved patient outcomes.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS11102 &utm_source=SnehaPatil&utm_medium=Article

Key Market Drivers & Regional Insights

The demand for smart hospital solutions is increasing due to rising healthcare costs, digital transformation, and the need for sustainable infrastructure. The hardware segment, particularly in medical devices, sensors, and networking equipment, dominates the market, while AI-driven software solutions for predictive analytics and patient management are rapidly gaining traction. North America leads the market, fueled by robust digital healthcare adoption and government-backed initiatives. Europe follows closely, with Germany and the UK at the forefront of hospital modernization and smart infrastructure investments. Meanwhile, Asia-Pacific is emerging as a high-growth region, with China and India investing heavily in healthcare IT and smart hospitals to cater to a growing population.

Market Segmentation & Emerging Trends

The market is categorized into: ✅ Infrastructure Types: General, IT, Security, Energy, Communication, Automation ✅ Technology: AI, IoT, Blockchain, AR/VR, Cloud Computing ✅ Applications: Patient Monitoring, Medical Imaging, Remote Care, Emergency Assistance ✅ End Users: Hospitals, Clinics, Ambulatory Centers, Specialty Centers

By 2023, the digital infrastructure segment held a 45% market share, followed by energy-efficient infrastructure (30%) and advanced communication systems (25%). The growing emphasis on AI-powered predictive analytics, automation, and blockchain-driven patient data security is expected to shape the market’s future.

Competitive Landscape & Future Outlook

Industry leaders like Siemens Healthineers, Philips Healthcare, and GE Healthcare are shaping the market through strategic partnerships, AI-driven innovations, and energy-efficient hospital solutions. Regulatory frameworks focusing on data security, energy efficiency, and healthcare IT compliance are further accelerating adoption. The next decade will witness an increase in AI-driven automation, 5G-enabled hospital networks, and digital twins for hospital management, unlocking new revenue streams and operational efficiencies in smart hospital infrastructure.

#SmartHospitals #HealthcareAI #IoTHealthcare #DigitalHealth #HospitalInnovation #MedTech #AIinHealthcare #HealthcareAutomation #Interoperability #BigDataHealthcare #Telemedicine #5GHealthcare #PatientMonitoring #BlockchainHealthcare #SustainableHospitals #SmartInfrastructure #HealthcareSecurity #HealthIT #ConnectedCare #PredictiveAnalytics #CloudHealthcare #WearableTech #IoTDevices #RemoteHealthcare #FutureOfHospitals

0 notes

Text

Exploring the Future of Industry: Industrial Metaverse and Its Applications

The industrial metaverse is revolutionizing how industries operate by seamlessly merging the physical and digital worlds. It enables businesses to optimize processes, enhance collaboration, and drive efficiency across sectors such as manufacturing, healthcare, logistics, and more. With an estimated compound annual growth rate (CAGR) of 17.5% from 2023 to 2031, the industrial metaverse market is projected to grow from US$ 22.1 billion in 2022 to US$ 93.5 billion by 2031, signaling a paradigm shift in industrial operations.

What Is the Industrial Metaverse?

The industrial metaverse is a dynamic ecosystem combining digital twins, IoT, AI, augmented reality (AR), and virtual reality (VR) to replicate and optimize physical industrial environments. It offers virtual representations of systems, assets, and spaces, allowing businesses to simulate, monitor, and control operations in real-time. This transformative technology is redefining traditional industrial processes by fostering automation, remote collaboration, and data-driven decision-making.

Market Dynamics and Key Drivers

1. Increasing Adoption of Digital Twin Technology

Digital twins are at the core of the industrial metaverse, enabling businesses to create virtual counterparts of physical systems. This technology facilitates real-time monitoring, predictive maintenance, and performance optimization, driving operational excellence across industries.

For instance, BMW AG is leveraging NVIDIA’s Omniverse platform to build a virtual version of its Debrecen, Hungary manufacturing plant. This digital twin enables BMW to test factory layouts, logistics, and robotics before the facility becomes operational in 2025, showcasing the power of digital twins in industrial planning.

2. Emergence of 5G Technology

5G connectivity plays a pivotal role in advancing the industrial metaverse by enabling real-time data transmission, ultra-low latency, and massive device connectivity. This robust network infrastructure supports applications like remote robotics, AR maintenance, and virtual collaboration, making industrial processes more responsive and efficient.

With 5G, industries can create immersive AR/VR experiences, enhancing employee training, design simulations, and operational oversight, all while reducing downtime and improving productivity.

3. Growing Demand for Industry 4.0 Solutions

The integration of smart technologies and automation through the industrial metaverse aligns with the goals of Industry 4.0. It empowers organizations to:

Optimize supply chains

Enhance production workflows

Minimize operational costs

Achieve sustainable practices

These capabilities make the industrial metaverse a critical tool for businesses looking to stay competitive in a rapidly evolving global economy.

Industry Vertical Applications

The industrial metaverse spans several industry verticals, each benefiting from its transformative potential:

Manufacturing: Streamlined production processes, real-time monitoring, and predictive maintenance.

Healthcare: Enhanced training simulations, telemedicine, and operational efficiency in hospitals.

Energy & Utilities: Monitoring and optimizing power grids, renewable energy operations, and infrastructure management.

Logistics & Transportation: Improved fleet management, supply chain visibility, and warehouse automation.

Retail & E-commerce: AR-powered virtual shopping experiences and efficient inventory management.

Regional Market Insights

North America leads the global industrial metaverse market due to the presence of tech giants like Microsoft, NVIDIA, and Unity Technologies. These companies drive innovation with advanced metaverse platforms and solutions.

Asia Pacific is expected to witness the fastest growth, fueled by rapid digital transformation in major economies such as China, India, Japan, and South Korea. A strong manufacturing base and increasing adoption of smart technologies further accelerate market expansion in the region.

Competitive Landscape

Key players in the industrial metaverse market are focused on R&D and innovation to stay ahead. Major companies include:

Microsoft Corporation

Siemens AG

PTC Inc.

NVIDIA Corporation

Unity Technologies

Dassault Systèmes

These leaders are investing in new technologies to meet the growing demand for industrial metaverse solutions, creating a highly competitive market landscape.

Conclusion: Unlocking the Future of Industry

The industrial metaverse represents a transformative leap for industries worldwide. By integrating advanced digital technologies with physical operations, businesses can achieve unparalleled efficiency, innovation, and sustainability.

As the market continues to expand, companies embracing the industrial metaverse will be better positioned to capitalize on its potential, driving progress in sectors ranging from manufacturing to healthcare.

The journey toward a fully realized industrial metaverse is just beginning, and its impact will undoubtedly shape the future of global industries.

0 notes

Text

Aircraft Wire and Cable Market: Trends, Drivers, and Future Growth

The aviation industry is undergoing a transformative shift driven by the twin forces of digitalization and electrification. These trends are not only enhancing operational efficiency but are also redefining the design and functionality of modern aircraft. Central to this transformation is the Aircraft Wire and Cable Market, which is witnessing substantial growth due to the increasing demand for advanced wiring solutions in aviation systems.

Aircraft wire and cable systems are critical components that facilitate data transmission, power distribution, and communication within an aircraft. From flight control systems to in-flight entertainment, these components are essential for seamless operation in both commercial and military aviation. The rapid adoption of digitalized and electrified systems is driving the demand for high-performance wire and cable solutions, making this market a cornerstone of aviation innovation.

The Impact of Digitalization on the Aircraft Wire and Cable Market

Digitalization has emerged as a key driver of growth in the Aircraft Wire and Cable Market. With advancements in avionics, navigation, and communication systems, modern aircraft rely on sophisticated wiring architectures to handle the increasing complexity of onboard systems.

The integration of digital technologies, such as advanced sensors, data processing units, and real-time communication systems, requires wires and cables capable of transmitting large volumes of data with minimal latency. High-speed data cables, optical fibers, and shielded wires are in high demand to support the seamless operation of these systems.

Digitalization is also driving the need for modular wiring designs that can be easily upgraded or reconfigured to accommodate technological advancements. This trend is particularly evident in commercial aviation, where airlines are constantly seeking to enhance passenger experiences through cutting-edge in-flight entertainment and connectivity systems.

Moreover, digitalization is revolutionizing aircraft maintenance and monitoring processes. With the adoption of predictive maintenance systems and digital twins, aircraft are equipped with advanced wiring systems that enable real-time data collection and analysis. This shift not only reduces downtime but also enhances the safety and reliability of aircraft operations.

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=105042386

The Role of Electrification in Shaping the Aircraft Wire and Cable Market

Electrification is another major trend reshaping the aviation industry. As the focus on sustainable aviation intensifies, the adoption of electric and hybrid-electric aircraft is gaining traction. Electrification requires robust wire and cable systems capable of managing high-voltage power distribution while maintaining safety and efficiency.

Electric propulsion systems, which are at the core of electrified aircraft, rely heavily on advanced wiring solutions to transmit power from batteries to motors. These systems demand lightweight yet durable wires and cables that can withstand high electrical loads without compromising performance.

In addition to propulsion, electrification is influencing other aircraft systems, such as environmental control, de-icing, and braking. Electrically driven subsystems are replacing traditional hydraulic and pneumatic systems, leading to an increased demand for specialized wires and cables.

The transition toward more-electric aircraft (MEA) and all-electric aircraft (AEA) is driving innovation in wire and cable materials and designs. Lightweight materials, such as aluminum alloys and advanced composites, are being used to reduce the overall weight of wiring systems, thereby improving fuel efficiency and reducing emissions.

Challenges in the Aircraft Wire and Cable Market

While digitalization and electrification present significant growth opportunities, the Aircraft Wire and Cable Market also faces challenges. One of the primary challenges is the complexity of integrating advanced wiring systems into existing aircraft designs. Retrofitting older aircraft with modern wiring systems requires careful planning and significant investment.

Another challenge is the need for wires and cables that meet stringent safety and performance standards. The aviation industry demands materials that are highly resistant to extreme temperatures, electromagnetic interference, and mechanical stress. Ensuring compliance with these standards while maintaining cost-effectiveness is a critical hurdle for manufacturers.

Furthermore, the growing complexity of aircraft wiring architectures has led to increased weight and space constraints. Addressing these issues requires innovative solutions, such as miniaturized wires, multiplexing technologies, and wireless systems, which can reduce the wiring footprint without compromising functionality.

Opportunities for Growth in the Aircraft Wire and Cable Market

Despite these challenges, the Aircraft Wire and Cable Market presents numerous opportunities for growth. The rising demand for lightweight materials and compact designs is driving innovation in wire and cable manufacturing. Advanced materials, such as high-strength alloys, carbon nanomaterials, and self-healing polymers, are being explored to enhance the durability and performance of wiring systems.

Government and industry initiatives to promote sustainable aviation are also creating opportunities for the market. The electrification of aircraft systems aligns with global efforts to reduce carbon emissions, making it a priority for governments and regulatory bodies. Incentives for the development of electric and hybrid-electric aircraft are encouraging investments in advanced wire and cable technologies.

Emerging markets in Asia-Pacific and the Middle East are witnessing rapid growth in aviation activity, driven by rising air travel demand and expanding airline fleets. These regions offer untapped potential for the Aircraft Wire and Cable Market, particularly in the commercial aviation segment.

Moreover, advancements in automation and digital manufacturing are streamlining the production of wires and cables, enabling manufacturers to meet the growing demand while maintaining quality and cost efficiency.

Competitive Landscape

The Aircraft Wire and Cable Market is highly competitive, with several key players driving innovation and market expansion. Companies are focusing on strategic partnerships, mergers, and acquisitions to strengthen their market presence and enhance their product portfolios.

Investments in research and development are at the forefront of market competition, with manufacturers exploring new materials, designs, and manufacturing techniques to cater to evolving customer requirements. Collaborations with aircraft manufacturers and system integrators are also enabling wire and cable companies to develop customized solutions that address specific needs.

Ask for Sample Report: https://www.marketsandmarkets.com/requestsampleNew.asp?id=105042386

Future Outlook

The Aircraft Wire and Cable Market is poised for significant growth as digitalization and electrification continue to transform the aviation industry. Advanced wiring solutions will play a crucial role in enabling the integration of next-generation technologies, from autonomous flight systems to fully electric aircraft.

As the industry moves toward a more connected and sustainable future, the demand for lightweight, high-performance wires and cables will only intensify. By addressing challenges related to integration, compliance, and complexity, the market can unlock new opportunities and drive the next phase of aviation innovation.

The Aircraft Wire and Cable Market stands at the forefront of aviation's digital and electric transformation. With its critical role in enabling advanced systems and sustainable operations, the market is set to play a pivotal role in shaping the future of air travel.

As manufacturers continue to innovate and adapt to the demands of a rapidly evolving industry, the Aircraft Wire and Cable Market will remain a cornerstone of aviation's journey toward enhanced efficiency, connectivity, and sustainability.

#aircraft wire and cable market#aviation wiring systems#aircraft electrification#aircraft digitalization#wire and cable trends aviation

0 notes

Text

Why NX CAM Dealers in India Are Transforming Smart Manufacturing

NX CAM

In the evolving world of manufacturing, adopting advanced technologies has become essential. NX CAM, a leading Computer-Aided Manufacturing (CAM) software, is paving the way for smarter and more efficient production. This blog explores why NX CAM is the future of smart manufacturing and how authorized NX CAM dealers in India play a crucial role in driving this transformation.

Understanding NX CAM

NX CAM, developed by Siemens, is a powerful tool for automating and optimizing machining processes. It enables manufacturers to create precise and efficient toolpaths for CNC (Computer Numerical Control) machines. This software integrates seamlessly with the broader Siemens Digital Industries Software ecosystem, making it a preferred choice for manufacturers across industries.

The Importance of Smart Manufacturing

Smart manufacturing focuses on using data, automation, and advanced technologies to improve production efficiency, quality, and flexibility. NX CAM supports this approach by offering tools to:

Automate repetitive tasks.

Reduce production errors.

Optimize machining time and material use.

Connect seamlessly with other systems, enhancing collaboration.

These features make NX CAM a vital component for manufacturers seeking to stay competitive in the global market.

Why NX CAM Is the Future of Smart Manufacturing

1. Advanced Automation Features

NX CAM eliminates manual programming by automating toolpath creation. Its advanced algorithms generate optimized machining strategies for complex parts. This saves time and reduces errors.

2. Integration with Digital Twins

NX CAM allows users to create and simulate digital twins of machining processes. These virtual models ensure that machining strategies are tested and optimized before production begins. This reduces downtime and material waste.

3. High Precision and Accuracy

Modern industries demand precision. NX CAM delivers this by enabling manufacturers to create detailed and accurate machining plans. This is especially valuable in industries such as aerospace, automotive, and medical devices.

4. Customizable and Scalable Solutions

NX CAM can adapt to the needs of small workshops and large factories alike. Its modular design allows manufacturers to start with basic features and expand as their requirements grow.

5. Seamless Integration with NX Software

As part of the broader Siemens NX software suite, NX CAM integrates with design and simulation tools. This ensures a smooth flow of data from design to production, enabling manufacturers to innovate faster.

Originally Published Corengg Technologies on December 9, 2024

0 notes

Text

Digital Twin Market,Size, Share, Key Players | BIS Research

A Digital Twin is a virtual representation or simulation of a physical object, system, or process, typically in real-time. It is created using data collected from sensors, devices, or other sources embedded in the physical counterpart. The digital twin mirrors the characteristics, behavior, and performance of the real-world entity, allowing for analysis, monitoring, and optimization.

The Global Digital Twin Market size was valued at $10.3 billion in 2023, and it is expected to grow with a CAGR of 58.52%

Digital Twin Overview

A digital twin is a virtual model designed to accurately reflect a physical object, process, system, or service. This innovative concept leverages the convergence of the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and big data analytics to create a dynamic and real-time simulation of a physical entity or system. Digital twins are used across various industries, including manufacturing, healthcare, urban planning, and more, enabling professionals to simulate, predict, and optimize systems before they are built and throughout their lifecycle.

Request a free sample report of the Digital Twin Market Trends

Drivers and Trends