#Digital Printing on Fabric Price

Explore tagged Tumblr posts

Text

Digital Printed Fabric Manufacturers India

Digital Printed Fabric Manufacturers India

Response Fabrics is leading, exporter, manufacturer, distributor, supplier, wholesaler for Digital Printed Fabric Manufacturers in India. With their extensive experience of supplying & trading, RESPONSE FABRICS has made a reputed name for themselves in the market with high quality etc.

Digital Printed Cotton Fabric

Response Fabrics brings high-quality digital printing on fabrics. We have gained vast demand in this field of digital printing fabric. Our elegant & eye-catching designs are just perfect for almost any kind of garment, we can also help you to design samples as per the requirements. We are known in the market for top quality, and form of unmatched styles, and styling of the product.

Digital Printing on Fabric Online

Response Printing offers the best online Digital Printed Fabric that can be prepared by the highly qualified designers who can give you almost any kind of design you want. Giving you every reason to adore classic to trendy prints is Response Fabrics through its attractive printed range of fabrics, garments, and home furnishings. We introduce a premium array of Digital Print 100% Digital Fabric, Floral Digital Print, and much more items online.

Digital Printing on Fabric Price

Get the best digital printing on Response Fabrics that produces high quality fabric, and other similar products at a reasonable price.

Printed Fabric Suppliers

Response Fabrics gives the printed fabric suppliers to create, and print your designs on amazing fabrics with love & care that offers solutions from design creation to print fabrics & custom clothing. We are actively engaged in manufacturing, exporting, and supplying superior quality cotton saree, printed fabric, dyed fabric, and much more.

Digital Print Cotton Fabric Wholesale

Response Fabrics offers cotton sarees that are made using the finest quality cotton. These are widely known for their alluring patterns, and beautiful designs. Our printed fabrics are available in different colors, and designs.

Moreover, our expertise in offering dyed fabric & cotton fabric has allowed us to gain a huge clientele all over India. We have maintained an advanced infrastructure facility for us to handle all our operations related to manufacturing, and storing.

Digital Printing On Fabric Near Me

The company produces digital printing fabrics, and apparel manufacturing facilities to serve international orders & orders from India. The concept of teamwork through online display of designs from Independent Designers, Artists, Painters, Photographers, and use their creations for fabric printing, and manufacturing orders. The offered extent is unequivocally outlined, and created utilizing premium quality fundamental material, and advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Digital Printed Garment Fabric Manufacturer from Surat

Response Fabrics comes under the top digital printed garment fabric brands in Surat that brings a range of solutions for Digital Printed Garment Fabric, leather, synthetics, interior textiles, and wood. This offers a wide range of Digital Printed Garment Fabric. You will get high in quality products, and all kinds of furnishing fabrics that are used by furnishing industries. This also provides quality fabrics, and the best service.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

READ MORE...Home - Response Fabrics

#Digital Printed Fabric Manufacturers India#Digital Printed Cotton Fabric#Digital Printing on Fabric Online#Digital Printing on Fabric Price

0 notes

Text

Foil Printing Machine

Mohindra is recognized as one of the leading manufacturers in India. Based in Delhi, we distribute our extensive range of products across the country. All our machines are crafted from high-quality raw materials. The demand for Rotogavurve Machines is increasing, paralleling the growing use of paper bags in India. The Foil Producing Machine from Mohindra Mechanical Works is specifically designed for the production of blister and medication foils with exceptional precision. Utilizing modern technology, this machine ensures consistent and high-quality printing, which is essential for pharmaceutical packaging where clarity and accuracy are crucial. Foil Printing Machine The foil printing machine from Mohindra Mechanical Works is a specialized device that prints blister and medication foils with remarkable precision. Engineered with advanced technology, it delivers consistent and high-quality printing, which is vital for pharmaceutical packaging where clarity and accuracy are paramount. Constructed with a robust steel frame, it is built to withstand prolonged use in demanding environments, ensuring long-term reliability and minimal vibration during the printing process. Featuring innovative roller systems and high-resolution print heads, the machine produces sharp, clear text and images that meet the stringent requirements of pharmaceutical packaging.

#Foil Printing Machine price in India#Foil printing machine price#Gold foil Printing Machine price#Foil printing machine near me#Foil printing machine For Fabric#Digital foil printing machine#Foil printing machine for sale#Hot foil Printing Machine

0 notes

Text

If you're a fan of elegant and delicate fabrics, you need to check out georgette. This versatile fabric is perfect for creating stunning dresses, blouses, and other garments that are both comfortable and stylish. Our comprehensive guide covers everything you need to know about georgette fabrics, including their history, types, care, and uses.

#georgette#floral georgette fabric#georgette ke kapde#silk georgette fabric price#georgette chiffon dress material#ombre georgette fabric#premium georgette fabric#tie and dye georgette fabric#georgette digital print fabric#pure georgette printed fabric#bandhani fabric georgette#georgette flower print fabric#georgette chikankari material#white georgette dress material#georgette net fabric#georgette foil print fabric

0 notes

Text

Fastdtftransfer - Devasa+

Digital Direct-to-Film, dtf printing is a popular method used in the custom printing industry. This technique involves printing designs directly onto a film, which is then transferred onto various surfaces such as t-shirts, hoodies, and other fabric materials. DTF printing allows for vivid, full-color transfer printing using eco-friendly water-based ink. With DTF printing, custom designs can be created with high quality and vibrant colors, resulting in visually appealing products. The process involves using a gang sheet, which is a practical tool that enables multiple designs to be printed on a gang sheet, optimizing resources and reducing material waste. This method is widely used in the custom printing industry due to its efficiency and ability to produce detailed and vibrant prints. Custom printing services offer a wide range of applications for businesses and individuals. These services allow customers to personalize their products by printing custom designs, logos, or messages on various items such as t-shirts, mugs, bags, and more. Custom tshirt is commonly used for promotional purposes, creating branded merchandise, or simply expressing personal style. With advancements in printing technology, custom printing services can produce high-quality prints with sharp details and vibrant colors, ensuring that the final product meets the customer's expectations. Whether it's for personal use or business needs, custom printing services provide a convenient and effective way to create unique and customized products. Direct to Film Transfer (DTF) is a technique used in the custom printing industry that offers several benefits. This method involves transferring designs from a film directly onto the desired surface, such as fabric or other materials. DTF transfers allow for high-quality, full-color prints with excellent durability and washability. This technique is particularly useful for creating custom t-shirts, as it provides a smooth and vibrant print that can withstand regular wear and washing. DTF transfers are also eco-friendly, as they use water-based inks instead of traditional plastisol inks. Additionally, dtf price calculator can be produced as gang sheets, which are multiple designs printed on a single sheet. This allows for efficient production and reduces material waste. Overall, the direct to film transfer technique offers versatility, durability, and eco-friendliness, making it a popular choice in the custom printing industry. You can visit our website for more information.

1K notes

·

View notes

Text

A statement on ficbinding (according to me)

I've joined the book/ficbinding tag on tumblr a couple of weeks ago, and in that time I've seen some confusion and concern about what ficbinding is, so I thought I'd post a statement of how I see ficbinding and why I do it. (If you're an author and I redirected you to this post because I want to bind your fic, hiiii) (Fellow ficbinders, if you find this post a useful ressource, don't hesitate to use it yourselves)

What's ficbinding?

Ficbinding (also called fanbinding) means a reader is going to print your fic and make a book out of it. It goes from the simple single booklet stapled together to leatherbound gold-foiled volumes.

Are you gonna make money off of my writing?!

I wouldn't dream of it. Ficbinding is just another fandom practice: you can't monetize your fic writing because you don't own the universe you're writing about, and I can't monetize your fic because it doesn't belong to me. I believe there are professionals who bind fics for a price (on Etsy, maybe?) but I'm ethically opposed to it.

Why do you do it, then?

Love of the craft. I'm a craftsman, I love choosing the best fabrics, fonts and embellishments for a project and making something with my hands.

Love of your fic. I liked it so much I want it in my house! I'm not fond of reading on a screen, it drastically reduces the chances I'll re-read the fic (even if I want to). Printing your fic ensures I'll enjoy it for years to come. It's the best compliment I can pay you.

As a gift to a friend who doesn't have the skills.

And what, it happens whether I want it or not?

As you can imagine, this is kind of a gray area legally. Nothing forces a ficbinder to reach out and tell you they're binding your fic. But this is fandom, and I personally view it as a community and consider that it's only courteous to let authors know I'm doing this. If I post pictures of my binding here, I want to be able to give credit where it's due, and since most authors are very happy to see their work bound, tagging them means they'll get a nice surprise when they open tumblr. I'll always do my best to find a way to contact you (ao3 comment, tumblr if you've put it on your ao3 profile).

I don't like strangers messaging me, is there a way to let people know I agree/don't allow this without talking to someone?

Valid, and there is! The simplest way is to write it in your ao3 bio, it's called a blanket permission or a transformative works statement. For example, mine says that I allow all transformative works (ficbinding is one, like fanart) based on my fics but that I like to be notified so I can gush about it and reblog/link to it, and I put my tumblr there to make it easy to contact me.

You can build a statement with this excellent tool. Answer the questions at the bottom of the page and you'll get a clearly-worded short statement to copy-paste into your bio (you can edit it, of course). The blanket permission is the thing ficbinders look for and as a digitally socially anxious person, let me tell you, it's a life-changer.

(Now, can I bind your fic, pretty please 🥺?)

96 notes

·

View notes

Text

Depending on our budget, I may be attending the Portland Quilt Show this week*. It's a little over two hours away, and will be the first quilt show I've attended since childhood. It simply depends on the budget. Fuel, tickets, and food aren't an issue, but attending with no shopping just isn't gonna work for me. Fabric, tools, books, patterns, and a few other fun things are gonna be there. A four hour round trip is gonna require coming how with good things.

I have items in my shop, prices start at $0 USD, and I have quilt tops available with the option to have me handquilt them before shipping. Everything has a base price, some starting at $0, and the option to pay more.

I asked my mom, who has been to dozens of such shows, what I should bring woth me for shopping, she laughed. Why? Because she has a large budget. She told me a minimum of $400 to cover fuel, food, tickets, and goodies.

Yes, I flinched when she told me that.

She takes a lot of classes at shows, and leaves with many quilt kits. I have only purchased a couple kits, and one was about $100 at 50% off. They include fabric and the pattern. The most expensive already have the fabric cut and include thread, needles, templates, and rulers. Personally, I'm fine with a pattern, but that's not always an option.

Books and fabric will be what grab my attention. I'm low on red and yellow yardage, and need to restock those prints. Books are my weakness. Multiple patterns in a single unit? Less expensive than individual patterns. I especially love foundation paper piecing books with CDs included because those have the patterns ready to print. Then there's the other goodies, like threads, to consider.

Please consider making a purchase from my shop, even just a digital download. If I don't hit the minimum $400 my mom suggested, all funds will be applied to the goal on my ko-fi page.

*There will be other quilt shows I might be able to attend this year. My husband will likely be relieved about not attending seeing as he's gonna be bored. 😅

9 notes

·

View notes

Text

DIY Duvet Cover

Project by Brett Bara:

I don’t know about you, but I never cease to be shocked at the price of bedding. And nothing sets off my “I could make that myself so much cheaper and better” instincts like duvet covers. It’s just a big flat case of fabric, yet even the simplest options easily soar into the three digits—but all it takes to make your own is a bunch of fabric, a few straight seams, and a spare afternoon.

Not only will going DIY with your duvet cover save you some cash, it’ll also allow you to custom-make exactly what you are looking for. What’s better than that? Let’s go! –Brett Bara

What You’ll Need

Approximately 10 yards fabric (see below to calculate exact amount; I suggest buying extra just in case)

Yard stick, long quilter’s ruler or tape measure

Sharp scissors

Straight pins

Sewing machine

Iron and ironing board

Selecting and Preparing Fabric

I recommend machine-washable cottons or cotton-linen blends for duvet covers. Quilting shops are a great place to look for fabrics, as there are tons of choices there for cottons in tiny prints, large prints, solids and everything in between.

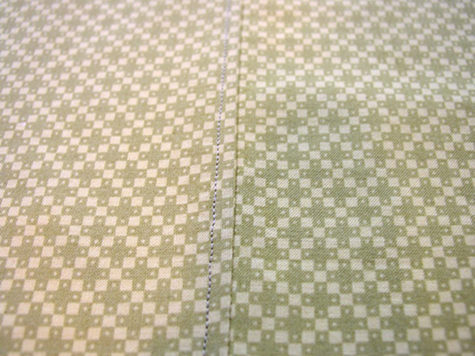

Here I’m working with Denise Schmidt Hope Valley Piney Woods from Free Spirit Fabrics.

Be sure to wash, dry and iron your fabric before beginning to pre-shrink it.

Fabric Tips

*If you find yourself head over heels for designer bedding, check to see if you can buy two flat sheets from the line, and use these to sew your own duvet cover. This can be much less expensive than buying the duvet cover itself, and sometimes the manufacturer uses the very same fabric for the sheets as for the duvets, so you’re really working with the exact same material.

*Consider using a different fabric for the front and back of the duvet so that the piece is reversible—two looks for the price of one, and a special bonus for the décor commitment-phobes among us.

Planning and Cutting

There aren’t strict standards for bedding sizes in the US (comforter sizes tend to vary among manufacturers), so I recommend measuring the comforter you plan to cover and using those numbers to plan your duvet cover.

Since fabric generally isn’t sold in widths wide enough for a full duvet, you’ll need to seam a few panels of fabric together to make the front and back. I suggest placing one full panel down the center of the duvet with two smaller panels to each side of it; this is generally nicer-looking than making one seam down the middle of the duvet.

NOTE: Remember that you should trim off the selvedge edges of your fabric (these are the finished edges on both sides of the fabric which are a little different in texture and/or color from the rest of the fabric) before sewing. Remember to subtract the selvedge edge from any measurements as you plan your piece.

Measure the width of your fabric without selvedge; plan to place one full panel of fabric down the center of the duvet and two smaller panels to each side of it. Simply make the side panels as large as they need to be to reach the desired width of your duvet cover, adding 1” to the width of each panel to allow for seam allowance.

So, if your center panel needs to be 40” wide and each side panel needs to be 20” wide, cut the panels 41” wide and 21” wide. Those extra inches will be consumed by the seams.

The length of your duvet is simply the desired finished length plus 2 ½” for hem and seam allowance.

*Remember that you need a front and a back, so plan all your measurements and double them to calculate the total amount of fabric you’ll need.

Here’s what your panels will look like when they’re ready to go. (Note: I’m making a mini duvet here to make it easier to see the big picture of shape and construction.)

Sewing: French Seams

To begin, you’ll sew each side panel to its corresponding center panel, to make the front and back of the cover.

For a really nice professional-looking finished result, I recommend using French seams in this project. These seams are finished on both the inside and outside, so that no raw edges of fabric will be visible anywhere.

French seams may sound fancy, but they’re really easy! Here’s how:

Place two pieces of fabric WRONG SIDES TOGETHER. (This is the opposite of normal; usually you sew most seams right sides together.)

Sew the seam with a ¼” seam allowance.

Trim away about ½ of the seam allowance, being careful not to get too close to the stitches.

Iron the seam to one side, then fold at the seam so that right sides of the fabric are facing together, and iron the seam closed.

Pin the seam closed to avoid shifting, and sew it again with a ¼” seam allowance. Iron this seam to one side, and your French seam is done.

From the outside it looks like a regular seam, but on the inside all you see is this nice finished flap. Nice, right?!

For a nice finishing touch, you can top stitch to tack down the flap. All you do is top stitch on the right side of the duvet alongside the French seam, stitching over the folded-over flap in the back.

Iron the seam once again after top stitching to smooth and relax it.

Repeat for all center/side panels so that you have a complete front and back.

Attaching the Front and Back Together

Place the front and back together with wrong sides facing, pinning each side seam in place. Sew each side with French seams as described above (but skip the top-stitching for the sides). After sewing the sides, sew the top closed with a french seam as well.

The inside of the duvet is now fully finished, with no raw edges visible at all. Isn’t that nice? Here is what the corners will look like on the inside.

To hem the bottom of the duvet, fold 1” of fabric to the inside and press. Fold up another 1” and press again; pin folds in place.

Stitch hem close to the exterior fold line and again close to the interior fold line.

Getting Closure

You have many options for closing up the bottom of the duvet (in each of these cases, I suggest placing a button/snap/ribbon about every 8” along the bottom):

*Buttons and buttonholes: easy to do with the buttonhole attachment that comes with most sewing machines.

*Sew-on snaps: very easy to sew on by hand, and quick to snap/unsnap when you change the duvet.

*Snap fastener kit: All you need is a hammer and the special tool that comes in this set to attach snaps without sewing for a very professional-looking result. (Check the instructions on the package.)

*Ribbon or twill tape: even easier to install. I suggest tucking 10” lengths of ribbon or tape under the folds of the hem before sewing it.

*Zippers: long zippers can be purchased online; you might consider a zipper closure along the bottom, using the same zipper-installation method as the zippered pillow cover.

That’s all there is to it! Don’t you feel so wonderfully nice and cozy with your new handmade duvet cover?!

14 notes

·

View notes

Text

Ex-Designer Project Bar in Barcelona

via e-flux

Martí Guixé’s Ex-Designer Project Bar, an exceptional project that turns a digitally designed interior, produced entirely using full-size 3D printing techniques into a standalone object, will be on display at the Disseny Hub Barcelona (DHub) from May 23 to August 25.

The project was born in November 2015, when Martí Guixé, one of Barcelona’s most internationally influential 21st century designers, set out to design and 3D-print, independently and without help, all the components of a bar on Barcelona’s C/ Entença in collaboration with architect Pau Badia. The bar, an empty commercial unit with minimal structure, was gradually redesigned and built over a period of almost five years, using three on-site printers while still in operation. Thus, all the bar’s components were gradually printed: everything from the tiles on the walls and the furniture down to the smallest utensils, such as glasses of different types, plates and cutlery.

According to Martí Guixé, the process itself is what matters, so the project became something performative, incorporating coincidence in a natural way.

The use of the establishment as a bar—where concerts, presentations, talks and other events were also held—was just as important as its role as a laboratory for experimenting on the possibilities of additive printing, and the utopia of digital autonomy. The project explores the true potential of digital fabrication technologies to achieve the dream of self-sufficiency for local production, without having to rely on large global manufacturing systems.

Just as the bar was finished, with the grand opening scheduled for February 2020, the pandemic and subsequent lockdown forced it to close. It then underwent a process of “deconstruction”, which was carried out behind closed doors and in an orderly manner, like a work of archaeology, in order to preserve it in full. The Ex-Designer Project Bar thus ceased to be a bar or a work of interior design to become a standalone “object” adapted for other possible uses.

Martí Guixé’s Ex-Designer Bar is a reflection on the potential for democratising industrial production and the industrial process: “The use of 3D technology makes artisans redundant and unifies materials. The world is made up of ideas, not of people’s energy”. He also said that “bringing the Ex-Designer Bar to a museum turns it into an object, a ruin and an archaeological site of the future”.

The first full-size reconstruction of the bar With Ex-Designer Project Bar, the DHub is exhibiting this monumental object in its original format, after assembling the walls and other various components: A total of 30 wooden panels measuring 122 cm x 150 cm, plus over six thousand 14 cm x 14 cm tiles. The result is an installation that measures 8.75 x 3.56 m and is 5.02 m high, whose component parts have been 3D-printed in full size using polylactic acid (PLA), a biodegradable polymer made from 100% renewable resources, such as corn or plant starch.

The interior walls include the front of the bar, which features figurative motifs from other projects by Martí Guixé, the side bars with experiments with bas-reliefs and pseudo-geometric figures in various sizes and thicknesses, and unsuccessful attempts to create a series of bag and coat hooks. There is also a notice board with backlit tiles for posting information about events and food and drink prices, as well as a front panel in which the main figure represents Artificial Intelligence, a representation of all the 3D printers used, including the one for printing food.

5 notes

·

View notes

Text

diy shirt design inspo

tried out cyanotype print the other day on 2 knit fabrics, currently waiting for a sunny day for the dye to develop some more. in the mean time, i've been wanting some clothes that have nice, original designs; typically something you don't see at your average retail store.

on pinterest, i found some designs that i think i could take inspiration from and hand-dye/paint on plain t-shirts. simultaneously, i'll need to find a t-shirt that has a nice pattern/fit as a base.

in this design above, i like the contrast between the red and blue, and the hierarchy between the blue, red, and yellow that descends in amount respectively. one thing i learnt from doing digital art is that an equal balance between colours is not very pleasing to the eye. although i've never used it before, i could create this design using fabric paint and handmade stencils.

this design is pretty simple. could bleach a dark shirt with a paintbrush to create the fine lines. a 100% cotton content would help avoid the t-shirt from stretching and distorting the image while i paint.

i've been highly interested in designs that stretch beyond the front panel of the t-shirt and extend to the arms/back. this design reminds me of droplets of water or fingerprints.

this design mostly intrigues me because of how loose it is. almost like the ashes rising out of a campfire, the exterior of the design stretches freely. the crown on top of the person's head is also a key feature that i want to incorporate. like the first design, i could use fabric paints to make this.

diy-ing shirts lets me have a one-of-a-kind design that is exactly how i want it for only a fraction of a store-bought price.

2 notes

·

View notes

Link

Digital Printed Fabric Manufacturers India - Response Fabrics

Digital Printed Fabric Manufacturers India

Response Fabrics is leading, exporter, manufacturer, distributor, supplier, wholesaler for Digital Printed Fabric Manufacturers in India. With their extensive experience of supplying & trading, RESPONSE FABRICS has made a reputed name for themselves in the market with high quality etc.

Digital Printed Cotton Fabric

Response Fabrics brings high-quality digital printing on fabrics. We have gained vast demand in this field of digital printing fabric. Our elegant & eye-catching designs are just perfect for almost any kind of garment, we can also help you to design samples as per the requirements. We are known in the market for top quality, and form of unmatched styles, and styling of the product.

Digital Printing on Fabric Online

Response Printing offers the best online Digital Printed Fabric that can be prepared by the highly qualified designers who can give you almost any kind of design you want. Giving you every reason to adore classic to trendy prints is Response Fabrics through its attractive printed range of fabrics, garments, and home furnishings. We introduce a premium array of Digital Print 100% Digital Fabric, Floral Digital Print, and much more items online.

Digital Printing on Fabric Price

Get the best digital printing on Response Fabrics that produces high quality fabric, and other similar products at a reasonable price.

Printed Fabric Suppliers

Response Fabrics gives the printed fabric suppliers to create, and print your designs on amazing fabrics with love & care that offers solutions from design creation to print fabrics & custom clothing. We are actively engaged in manufacturing, exporting, and supplying superior quality cotton saree, printed fabric, dyed fabric, and much more.

Digital Print Cotton Fabric Wholesale

Response Fabrics offers cotton sarees that are made using the finest quality cotton. These are widely known for their alluring patterns, and beautiful designs. Our printed fabrics are available in different colors, and designs.

Moreover, our expertise in offering dyed fabric & cotton fabric has allowed us to gain a huge clientele all over India. We have maintained an advanced infrastructure facility for us to handle all our operations related to manufacturing, and storing.

Digital Printing On Fabric Near Me

The company produces digital printing fabrics, and apparel manufacturing facilities to serve international orders & orders from India. The concept of teamwork through online display of designs from Independent Designers, Artists, Painters, Photographers, and use their creations for fabric printing, and manufacturing orders. The offered extent is unequivocally outlined, and created utilizing premium quality fundamental material, and advanced innovation. Additionally, we offer manufactured leather in various hues, and outlines according to the necessity of the customer at sensible costs.

Digital Printed Garment Fabric Manufacturer from Surat

Response Fabrics comes under the top digital printed garment fabric brands in Surat that brings a range of solutions for Digital Printed Garment Fabric, leather, synthetics, interior textiles, and wood. This offers a wide range of Digital Printed Garment Fabric. You will get high in quality products, and all kinds of furnishing fabrics that are used by furnishing industries. This also provides quality fabrics, and the best service.

Response Fabric feels love to bring your satisfied products as per your requirement! If you have made up your mind, it is time to start browning the pictures, and pick the best alternative that suits your choice, and need.

READ MORE...Fabric Manufacturers In India - Response Fabrics

#Digital Printed Fabric Manufacturers India#Digital Printed Cotton Fabric#Digital Printing on Fabric Online#Digital Printing on Fabric Price

0 notes

Note

I'm pretty clueless to fashion production; is there no way you can produce a "decent" facsimile of that camo by taking a digital pattern and sort of printing it onto a similar match of fabrics? I actually have some stake in something like this existing, because there's a lot of discontinued aloha shirt patterns I wanna claim for myself.

you can, technically, and for reproductions that’s usually the easiest solution. if you look up “michell pattern camo for sale” you’ll find a variety of shops selling cheap dropshipped commodities, usually outsourced, in every pattern under the sun from the emblematic, like M81 woodland, to the esoteric, like 1945 German Leibermuster. all of these are polyester shein-esque clothes tho, with all the quality of a halloween costume and made at the cheapest price possible. to truly recreate a pattern as authentic to the originals as possible, one not only needs quality fabrics to print on but a similar machine to those that existed in the factories 40, 60, or 80+ years ago, and to replicate the printing process. camouflage is typically printed in layers, similar to silkscreening though at an industrial scale, and to a discerning eye this can produce distinctions in the final product. as one might expect, none of these factories still exist, their tooling has disappeared into time, and the manufacture process was likely either never recorded or kept secret. that said, some modern companies do seek out old tools, of which Buzz Rickson’s became famous with their bomber jacket repros, and it’s not like it’s impossible to make something that looks nice with new methods. however, even if a cunning tailor finds a solution or negotiates with a textile mill to produce a pattern, such manufacturing steps are often time consuming and expensive, and the commodity itself is only appealing to a very niche market. thus, old camo patterns are either not worth it to businesses to try and recreate, or have a dizzying price tag when they do.

Aloha shirts are actually a very apt comparison, not only are the patterns themselves somewhat of a civilian equivalent of camouflage, but the trends in production and reproduction are similar. Companies like Sugar Cane are well renowned for their Hawaiian shirts, but, like with military apparel, because the tooling doesn’t exist anymore many of the best new-made garments are made with vintage dead-stock fabric.

all that said tho, i’m not an expert on such things so all of the above is more or less what i’ve learned or intuited through exposure, there are likely more erudite articles on the subject.

6 notes

·

View notes

Text

Crafting and Selling in the hobby.

I think there’s some important differences in expectations about crafting in the hobby. One is on crafting for our dolls and encouraging others to do the same and then the second is our expectation of quality or skill level when we buy a handcrafted item or doll. I think most of us feel it’s great when people want to learn (or even just try) any or every interesting aspect of customizing and crafting for their own dolls. Personally I think that’s one of the best parts of this hobby, the creative potential to customize so many aspects of our own dolls. I try to really encourage people to create for their dolls if they want to.

But when I shop, buy or commission something I have a different expectation about skill level. If you are sewing items for sale, I expect well designed items, proper fit, evenly sewn stitching, appropriate fabric weights, reasonably scale of prints and trimmings, etc. If it’s a faceup, I want to see at minimum, several different well photographed examples of your work on several different resin bjd sculpts, a materials/sealants list, a published price list and an estimate of your average turn around times. I don’t think I would commission a faceup artist that had fewer than about a dozen good examples of their work to view.

If as a doll hobbyist, you make your own bjd that suits your vision, I’m happy to see that as part of your hobby activity and I like to follow the progress of these projects. But if you expect me to be interested in buying it myself, at minimum it needs to be a strong and unique concept, a well sculpted head or doll with a professional level of casting and finishing and properly engineered joints - priced competitively to other artist-made dolls. I want to see multiple photos, head examples in each resin tone offered and to see at least 1 finished example, painted and styled. Honestly, I feel that well over half of the artist dolls I’ve seen for sale in the last 2 years haven’t been developed or refined enough yet to be offered for sale. Regarding unfinished 3d printed dolls or files to DIY print, I would want to see several completely finished, assembled and painted examples, not just an example of the digital mock-ups. I expect these items to be priced accordingly too if it’s basically a bare-bones garage kit or if it is just a set of instructions and a file, which has no further time, replication or materials costs required beyond the initial development.

Is any of this required? Of course not. Everyone’s free to do just as they like. But I’ve also heard a certain amount of complaining among doll crafters who say that people like their items and give them positive and encouraging feedback but they are frustrated when people don’t actually buy their stuff. If they hang out in groups that are mainly based on mutual encouragement and overall hobby enjoyment, especially if they don’t really offer an area for direct, honest and straightforward constructive critique, people may be mistaking a general feel-good encouragement and approval commentary of their crafting activities for an accurate quality assessment of their items.

I am just one voice on these topics. I’m a person who crafts in another hobby, I know how to judge the skill level of my own work, price it accordingly and I sell it successfully. I’m also a person who likes handcrafted items, buys them regularly from others and would like to see more skill in the handcrafted items for sale within doll hobby - so my post is my opinion based on that. Hopefully the comments will also offer several additional opinions in this discussion.

~Anonymous

21 notes

·

View notes

Text

Digital Print Kurta for Men in Borivali:

Digital print kurtas for men in Borivali represent a modern and innovative approach to traditional Indian attire. These kurtas feature designs digitally printed directly onto the fabric, offering a departure from conventional handcrafted techniques. Unlike the time-consuming processes of block printing or embroidery, digital print kurtas in Borivali allow for intricate and customizable patterns that cater to contemporary fashion preferences.

The emergence of digital print kurtas has transformed the world of men’s ethnic wear in Borivali. These garments present a plethora of advantages, such as access to a diverse range of vibrant and unique designs, quick availability, and the option for customization to match individual style and special occasions.

When seeking the perfect digital print kurta for men in Borivali, it’s crucial to consider factors like the quality of the digital prints, the choice of materials (cotton, silk, and more), pricing, and the provider’s ability to cater to specific design preferences. Borivali, a bustling city within Mumbai, offers a thriving marketplace for digital print kurtas, providing a fusion of tradition and contemporary style in men’s fashion.

2 notes

·

View notes

Text

There isn’t a perfect crafting material and one isn’t strictly “better” than the other: a blog post styled rant on why people need to stop asking which material is the best and why 3D printing pieces for cosplay is not ‘cheating’ or easier than any other method

I have seen waaaaay too many people lately (especially on the clock app) claiming that 3D printing is cheating or somehow easier than the low tech, older methods like foam work and thermoplastic crafting. This absolutely drives me crazy.

I am a fabrication girlie at heart. I am a foam gremlin to the core but started out with Worbla (a delightful classic). I have recently picked up sculpting/mold making/resin casting. I am teaching myself how to 3D model. I have put hundreds of hours into finishing the dozens of 3D printed props and bits & baubles I have for various cosplays. I have worked with air drying clays, apoxie sculpt, paper mache, and chainmail. I work both in the digital and physical spaces for patterning. I have won several major craftsmanship awards with my fabrication skills. With all that as my credentials, let me say that 3D printing is not any easier, faster, or somehow better than all the other things I mentioned.

There is no such thing as a perfect crafting material. Anyone that tells you that is trying to sell you something. Every material and it’s corresponding techniques have pro and cons- the things that it excels at the and the things that it doesn’t work so well for. Wether it is a high-tech and automated process or a low-tech process done mostly by hand, every material can be utilized poorly or expertly. What makes the difference in the quality of the finished product or what wins awards in craftsmanship contests is how the material/technique was executed. A low budget cosplay can beat one that used tools that cost upwards of $1,000. It’s all about HOW the materials and tools were used.

For every 3D printed piece, there are lots of steps. You don’t just press a button and magically have a beautifully finished sword or geometric little Genshin Impact accessory piece. No, not all.

It has to be modeled first, then run through a slicer program to be printed. There’s lot of behind the scenes calibration that has to be done on the printer and adjustments of the model to get it in the optimal position to minimize seams and support material. There’s adjusting settings on the printer, like infill, to balance strength of the finished print vs amount of filament used (and therefore the final weight of the print). After printing, you have to remove support material and clean up the raw print. Next up is the eternal limbo of filling and sanding (god, it takes forever). Depending on your seams, you may be stuck in Bondo hell for a while too. Finally there’s painting, which can range from a quick blast of spray paint but could turn into the exceedingly complicated process I like to do that ends up using about six different paints. Then there’s the clear coat to protect the finished product.

A 3D printed prop does not magically appear from the ether. Much like any other material, there is a long list of steps and so much work put into a single piece. By the nature of how 3D printing works, pieces will come out very exact and crisp with a precision that human hands can’t quite achieve. But that comes at the price of expensive equipment, a steep learning curve for 3D modeling, and countless hours invested into the entire process from beginning to end. Even with purchasing models as I often do, it’s still not easy, cheap, or fast to make 3D printed pieces for cosplay.

Foam can win over 3D printing and sewing can beat out any fabrication build. It’s not a matter of WHAT was used. It’s a matter of HOW WELL it was used. Craftsmanship is not determined necessarily by the material but by the skill of the person using it. 3D printing is just a different set of skills than what is needed for Worbla or EVA foam.

2 notes

·

View notes

Text

Catalog code - 50886

*👉❤️PRESERNTING NEW FANCY DIGITAL PRINTED WITH EMBROIDERY SEQUENCE WORK GOWN WITH DUPATTA 👍*

*💃CODE :- DHK-1129💃*

*🧵🧶FABRIC DETAILS🧵🧶*

*👗GOWN👗*

👉*FABRICE* :- Heavy Faux Georgette

👉*WORK* :- Fancy Digital Print With Heavy Embroidery Sequence Work

👉*SLEEVE* :- Full Sleeve With Fancy Digital Print and Embroidery Sequence Work

👉*INNER* :- Heavy Micro Cotton

*👗BOTTOM👗*

👉*FABRICE* :- No

*👗DUPATTA 👗*

👉*FABRICE* :- Heavy Fox Georgette

👉*WORK* :- Fancy Digital Print With Embroidery Sequence Work Lace Border

*👉PRICE :- 1650 p /- Only👈*

*🚨BASIC DETAILS🚨*

*✨Gown* :- Fully Stitched

*✨Gown Length* :- 54- 56 Inc

*✨Gown Flair* :- 3 MTR

*✨Gown Size* :- XL Stitched With XXL

2 notes

·

View notes

Text

Get Top-quality Fabrics and Wholesale Dress Materials from Reputable Suppliers in Melbourne

The fashion industry in Australia has traditionally relied on the acquisition of Wholesale Dress Materials to provide a range of styles using high-quality materials. Some companies specialise in sourcing vintage fabrics and offer a full range of services, from manufacturing to selling to delivering to customers' doorsteps. This allows them to offer exclusive and unique fashion options to their customers.

Fashion industries often search for reliable Linen Fabric Supplier for summer day outfits and all-time casual wear as linen is one of the most demanded and eco-friendly fabrics. As we know, sustainability has also become a major concern for many fashion businesses, and as a result, there is a growing trend towards using eco-friendly materials and processes. This includes the use of recycled or sustainable fabrics, as well as manufacturing techniques that minimize waste and environmental impact.

Advantages of Purchasing from Reputable Wholesale Fabric Suppliers:

These well-known garment manufacturing companies offer on-demand services at competitive prices, with the ability to create bespoke patterns or use unique materials. These companies often have their own online showrooms featuring a wide range of fashion and corporate outfits in a variety of styles and trends for both men and women.

There are many different ways for businesses to source materials and create fashion products. Many reputable companies now use cotton, silk, viscose, wool, polyester, faux fur, and even recycled materials with a mix of traditional and modern techniques, such as digital printing and 3D knitting, to create unique and innovative fashion items.

In addition, they are providing the finest quality protecting fabric materials for facial mask, made of several layers of and enables unobstructed breathing. These masks are washable and do not change their shape after wash.

Overall, fashion businesses should continue purchasing materials and fabrics from reliable suppliers while also striving to maintain high standards of quality and sustainability.

Source: https://australiantextileindustry.blogspot.com/2023/01/get-top-quality-fabrics-and-wholesale.html

2 notes

·

View notes