#Diesel Engine Disadvantages

Explore tagged Tumblr posts

Note

Hi author...

For MC that have engineering background, can they create something like steam engine? It's probably too advanced to build gasoline or diesel engine because maybe there is no oil or not yet discovered in this world.

Not sure about the level of technology in this world, are they in early Renaissance where field cannon already exist or still in medieval era where rock throwing siege engine still staple of warfare.

However they still doesn't have Roman era crane yet so maybe it's way more primitive.

No, they can't. That's more mechanical engineering, whereas our Champion is more experienced in Civil Engineering! I did this choice to make sure we don't advance science and civilization too far too quickly since I wanna stick to the current time period for the time being.

As of right now, we are in the early Renaissance period when it comes to the Belthean Empire and the Kingdom of Jelaytha.

Everyone else is in the Late Middle Ages.

It's honestly a mishmash of time periods in KaE working at once, and this is due to the inspirations at play here. The eastern half of Nareth is Imperial China inspired, and Imperial China has always been, until historically recent, ahead of the west in terms of civilization, technology, organization, logistics, etc. This gap in Civilization levels will of course showcase in KaE, and Argent has been trailing behind... that is of course until we are born.

There's also Adelina, our mother, who took her studies seriously and learned all the things her half-siblings learned and took that with her to Argent. While we're growing up, our mother will be speed-running Argent to a level where Argent doesnt have such a disparity in all the things I listed above. We'll also be nudging things here and there to influence how the kingdom turns out by the time we enter the academy as well, as some of you who read the progress reports may know (such as the Proto-Portuguese Empire, Colonialism in the Sankri Continent, Building a Larger Navy, etc).

All that will show up later in our life as they'll have plenty of time to realistically build up. Childhood sucks tbh. Writing about it sucks too. But it's awesome if I can pull it off how I envision. I want our choices in childhood to give us advantages and disadvantages once we're finally grown, and you the player can see what choices has impacted what or changed what later down the line.

Anyways, thank you for sending your question!!!

#interactive fiction#choice of games#hosted games#interactive novel#kingdomsandempires#cogdemos#if wip#choicescript

22 notes

·

View notes

Note

Gordon X Boco Ship meme

Love this ship because not only was Gordon completely at the disadvantage when they met, but it continues to be a struggle for him because he has to come to terms with the idea that he, Gordon who is biggest and best and pulls the Express, is infatuated with a diesel. In a time when people will tease you for it. Love that for him.

It kinda ties into a concept I mighta talked about before (or maybe I just told Ray?) that Gordon's natural state is winning. We almost always see Gordon in a state of dismay and disgrace because it's funny that way and it's narratively what we need out his character, but it only truly works if the audience understands that Gordon is winning all day erry day offscreen. That's what makes it satisfying when he's busted down a peg.

Excepting engines from Tidmouth Shed who know him and smarter engines from elsewhere who just know better, Gordon could probably pull any engine he likes on his status and size alone. Falling for a diesel engine who met him in a moment of deep - and as we know, false - alarm is fantastic for him. It's what he deserves!

And I mean, it could be worse. Of all the diesels you could fall for, BoCo wouldn't rub it in or even make a thing of it. He's a good boy.

Now whether Gordon can actually land BoCo is another question. And how embarrassing to even have to ask that of yourself when you're a big grand Express engine? Are you good enough for that diesel? And will he recognize it if you are?

33 notes

·

View notes

Text

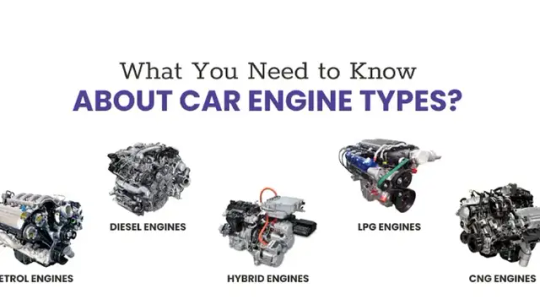

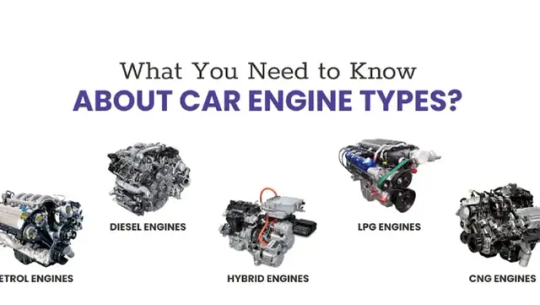

Understanding the Basics of Car Engine Types

Understanding the Basics of Car Engine Types When buying a car, one of the most critical aspects to understand is the type of engine it uses. The engine is the heart of any vehicle, and knowing how different car engine types work can help you make an informed decision. Whether you're considering fuel efficiency, power, or environmental impact, each engine type offers unique advantages. In this blog, we’ll break down the basics of car engine types, including petrol, diesel, hybrid, and electric engines, to help you choose the one that fits your needs.

1. Petrol Engines Petrol engines, also known as gasoline engines, are among the most common types found in passenger vehicles. These engines use a spark-ignition system to ignite the air-fuel mixture inside the combustion chamber. Advantages of Petrol Engines: Smoother and Quieter: Petrol engines tend to run smoother and quieter compared to diesel engines. Lower Initial Cost: Cars with petrol engines are generally cheaper than diesel variants. Lower Maintenance: Maintenance costs are typically lower due to simpler engine design and fewer emissions control components. Disadvantages of Petrol Engines: Lower Fuel Efficiency: Petrol engines usually consume more fuel than diesel engines. Higher Emissions: They emit more carbon dioxide, contributing more to environmental pollution.

2. Diesel Engines Diesel engines work on the principle of compression ignition. Instead of using a spark, the air is compressed to a high temperature, and fuel is injected into the chamber, causing it to ignite. Advantages of Diesel Engines: Better Fuel Economy: Diesel engines are more fuel-efficient, especially on long drives and highways. Higher Torque: Ideal for towing and heavy-duty vehicles due to strong torque output. Longer Engine Life: Diesel engines are robust and generally last longer. Disadvantages of Diesel Engines: Higher Maintenance Costs: More complex systems can lead to expensive repairs. Noisier Operation: Diesel engines are louder and produce more vibrations. Pollution: Though fuel-efficient, diesel engines can emit more NOx and particulates.

to know more, visit..https://themotorpedia.com/blog/understanding-the-basics-of-car-engine-types/f6601a84a208d9a28434a384fc3d529d

0 notes

Text

Understanding the Basics of Car Engine Types

When buying a car, one of the most critical aspects to understand is the type of engine it uses. The engine is the heart of any vehicle, and knowing how different car engine types work can help you make an informed decision. Whether you’re considering fuel efficiency, power, or environmental impact, each engine type offers unique advantages. In this blog, we’ll break down the basics of car engine types, including petrol, diesel, hybrid, and electric engines, to help you choose the one that fits your needs.

1. Petrol Engines

Petrol engines, also known as gasoline engines, are among the most common types found in passenger vehicles. These engines use a spark-ignition system to ignite the air-fuel mixture inside the combustion chamber.

Advantages of Petrol Engines:

Smoother and Quieter: Petrol engines tend to run smoother and quieter compared to diesel engines.

Lower Initial Cost: Cars with petrol engines are generally cheaper than diesel variants.

Lower Maintenance: Maintenance costs are typically lower due to simpler engine design and fewer emissions control components.

Disadvantages of Petrol Engines:

Lower Fuel Efficiency: Petrol engines usually consume more fuel than diesel engines.

Higher Emissions: They emit more carbon dioxide, contributing more to environmental pollution.

2. Diesel Engines

Diesel engines work on the principle of compression ignition. Instead of using a spark, the air is compressed to a high temperature, and fuel is injected into the chamber, causing it to ignite.

Advantages of Diesel Engines:

Better Fuel Economy: Diesel engines are more fuel-efficient, especially on long drives and highways.

Higher Torque: Ideal for towing and heavy-duty vehicles due to strong torque output.

Longer Engine Life: Diesel engines are robust and generally last longer.

READ MORE:

#Car engine types#Boxer engine#Rotary engine#Car engine comparison#Engine configuration explained#Types of car engines#Car performance engines#Fuel-efficient engines#Car engine basics#How car engines work#Car engine guide#Beginner's guide to engines

0 notes

Text

The Benefits and Features of Owning a Diesel Car

When it comes to choosing the right car, fuel efficiency and long-term cost savings are two key factors that often influence decisions. A diesel car is a popular choice for many drivers due to its efficiency and reliability. In this blog post, we will explore the various benefits and features that make a diesel car a great option for your next vehicle purchase.

Key Features of Diesel Cars

Fuel Efficiency: Diesel cars are known for their exceptional fuel efficiency. Diesel engines provide more miles per gallon compared to gasoline engines, which can save you money at the pump in the long run.

High Torque Output: One of the main features of a diesel car is its ability to produce high torque. This makes diesel engines ideal for tasks that require heavy lifting, such as towing and carrying heavy loads.

Longevity and Durability: Diesel engines are designed to last longer than their gasoline counterparts. With proper maintenance, a diesel car can easily surpass 300,000 miles, making it a great option for drivers looking for a long-term investment.

Better for Highway Driving: Diesel engines perform exceptionally well on highways, providing great power for long-distance driving while maintaining fuel economy. If you often find yourself on the open road, a diesel car might be your best choice.

Lower CO2 Emissions: Diesel engines tend to produce less carbon dioxide (CO2) than gasoline engines, making them a more eco-friendly option for those who want to reduce their carbon footprint.

Advantages of Diesel Cars

Cost-Effective: While the initial cost of a diesel car might be higher than a gasoline car, the long-term savings in fuel and maintenance make it a cost-effective option over time.

Resale Value: Diesel cars tend to hold their value better than gasoline cars, especially in regions where diesel fuel is more widely available and used.

Efficiency in Commercial Use: Diesel engines are commonly used in trucks, vans, and other commercial vehicles due to their durability and fuel economy. If you're considering a vehicle for business purposes, a diesel car could be a wise investment.

Disadvantages to Consider

Initial Purchase Price: As mentioned earlier, diesel cars tend to have a higher initial price tag than their gasoline counterparts. However, the price difference often pays off over time.

Higher Maintenance Costs: Diesel engines can sometimes require more expensive maintenance and repairs, although they are generally more durable.

Noise and Vibration: Diesel engines are typically noisier and have more vibrations compared to gasoline engines, which might not appeal to every driver.

In conclusion, owning a diesel car can be an excellent choice for those looking for long-term fuel efficiency, durability, and strong performance, especially for long-distance or commercial use. Before making your decision, it's essential to weigh both the benefits and drawbacks based on your personal driving habits and needs.

0 notes

Text

What are the Functions of Piston Rings and Piston Pins in a Diesel Generator

In a diesel generator, the piston ring groove is surrounded by a certain elastic metal open ring. This metal ring is called the piston ring. Piston ring is one of the key components of the diesel generator, its performance directly affects the quality and reliability of the diesel generator.

According to the different uses of piston rings, piston rings are categorized into gas rings and oil rings.

The main role of the gas rings is to form a sealed combustion chamber space with the piston, cylinder head and cylinder liner to prevent the high temperature and high pressure gases in the combustion chamber from flowing into the crankcase from the piston gap, as well as the cylinder wall.

The main role of the oil ring is to ensure that the oil is evenly distributed on the inner wall of the cylinder liner, preventing the oil from entering the combustion chamber. If the oil enters the combustion chamber, the diesel generator will burn the oil, and blue smoke will come out of the exhaust pipe, and it will also increase the carbon deposits in the exhaust valve and combustion chamber and increase the amount of oil.

Piston rings are prone to severe wear, diminished elasticity, internal gumming and damage during long-term use.

The structure of a piston ring is mainly based on the shape and cross-section of the opening. The shapes of the openings are usually straight, slanted and trapezoidal. These three kinds of opening piston rings have their own advantages and disadvantages, but currently the most commonly used are straight and oblique piston rings. According to the cross-section state of the rings, they are generally categorized into rectangular, twisted, conical, barrel-faced and trapezoidal rings. Rectangular rings are easy to process, have good thermal conductivity, and are widely used in various piston rings.

According to the different structure of the oil ring, it can be generally divided into ordinary oil ring, spring expansion ring and combined steel plate oil ring. Spring-expanded oil rings and ordinary oil rings are widely used among these three types of oil rings.

Piston pins are usually made of low carbon steel or low carbon alloy steel. The surface is carburized and quenched for high hardness and improved wear resistance. Maintaining internal toughness is favorable to withstand and impact loads.

Piston pins are generally made into hollow short round tubes. The outer circle has high machining accuracy and finish, and grooves and gaps are not allowed. The inner hole is usually cylindrical. According to the bearing capacity of the piston pin, part of the bore is formed into a conical structure.

The main function of the piston pin is to connect the piston and the connecting rod, and transfer the gas pressure at the top of the piston and the inertia force of the reciprocating motion of the piston group to the connecting rod.

At present, there are two combinations of piston pins, piston pin seats, and connecting rod small end bushing holes. One is a semi floating piston pin, and the other is a fully floating piston pin, which is the piston pin and pin. The seat hole is a transition (or gap), and there is a gap with the small end bushing hole of the connecting rod. At present, high-speed diesel engines mostly use fully floating piston pins, as this type of matching piston pin rotates slowly, which can ensure uniform wear along the circumference.

We hope the above content is helpful to you. If you are interested in diesel generator sets, please feel free to contact us via email at: [email protected] .

0 notes

Text

How to Buy a New Generator for Your Office Building

When choosing a new generator for an office building, it becomes paramount to ensure that the particular generator selected will, in fact, meet the needs of the business should there be an outage. Power cuts can stop productivity, paralyse essential business operations and may lead to considerable losses in resources and time. This blog explores tips on buying the right new generator for your office building.

Know Your Power Requirements Right

Determining the specific needs of an office and the amount of power needed is the most crucial procedure in the process of choosing a generator. The first step would be to check your workspace and list all electrical loads in fine detail. Determine the combined wattage required to power core electrical appliances while being run, such as the IT equipment, computers, servers, network tools, lighting, and crucial office equipment. Think about not only the necessity in the present but often their capacity to expand in the future. A comprehensive power analysis avoids under or over-procurement of a generator while providing exactly the right power and efficiency at the optimal price.

Different Generator Types

The generator marketplace has different types of new generators, all of which have varying features depending on the environments they will be used in. For very large commercial office structures, automatic permanently installed standby generators used in conjunction with automatic transfer switches deliver a continuous source of electricity. Standby generators can be an excellent idea for small places or as backups. Inverter generators provide electricity that is clean, steady and good for devices such as laptops, etc. Be very careful about each type, which has certain advantages and disadvantages that need to be judged depending on the following criteria: noise level, fuel, consumption, maintenance, and installation.

Consider Fuel Efficiency and Environmental Impact

Modern-day generator selection goes beyond just the provision of power to capture other aspects of the environment and the economy. Assess different fuel types, which include diesel, natural gas, propane or hybrid systems, where the assessment focuses on the efficiency, cost and environmental impact. Diesel generators are generally reliable and long-lasting, while natural gas engines are environmentally friendly. Think of a local source of fuel, the need for storage, and the costs that are likely to be incurred in the long run. EPA directly relates to your generator’s sustainability and operating costs, which is why this criterion is critical for organisations wishing to make environmentally sound and cost-effective decisions.

Installation by professionals and compliance

Installation of generators is a technical task that needs mark and subtle technical competence and provision of applying safety procedures. Hire certified personnel familiar with regulations governing construction, electrical engineering, and safety in your region. Installation considerations include ventilation, noise and sound absorption, fuel line connections and light fixtures, among others. These service providers guarantee your office that your generator complies fully with the local municipality and national set safety measures, is efficient and is a subsection to the insurance compliance laws.

Conclusion

Choosing the right generator is not just a matter of procurement – it is an investment in your organisation’s continuity and organisational stability. When the selection process is done this way, it offers efficiency and reliability in the power supply and professional installation, giving an exemplary power management program. A suitable generator is not just a standby power supply but rather a must-use business continuity power that shields your output, preserves your infrastructure and offers assurance.

Source URL By:https://mygroundbiz.co.uk/how-to-buy-a-new-generator-for-your-office-building/

1 note

·

View note

Text

Where can you find high quality fuel tank parts?

Mining, construction, and other industrial sectors always want ways to reduce the costs of their operations. One way they try to achieve this is by using fuel tank partsfor storage, which can reduce fuel costs for your equipment and reduce wait times for fuel delivery, but not only does it improve the overall productivity and efficiency of your workers. It can even save you money.

What is a fuel tank?

The fuel tank for flammable and hazardous liquids like diesel, gasoline, petrol, and more is a safe storage solution. Some are transportable or highly portable, so they are made to transport and provide fuel to work sites when needed. They can also store fuel in large quantities in a correct state of preservation and optimal performance.

Ideally, the fuel system contains a fuel tank, pump, filter, and injectors or carburetor, which supply fuel to the engine as needed. If you want to maintain optimal performance and reliability of your vehicle, all components must work properly.

Fuel tank parts and accessories are very important for any vehicle, which includes some vital parts like the fuel tank cap, fuel tank sending unit, fuel tank pressure sensor, fuel tank vent valve, and the petcock valve. Each of these parts plays a vital role in allowing the fuel system of a car to function as no vehicle can run without fuel. Taking good care of this crucial component becomes important because the gas tank has the space to store and carry fuel for trips.

Is it possible to protect the fuel tank part of your car at a lower cost instead of paying an exorbitant amount to replace it? Ideally, there is no good material for fuel tanks as both steel and plastic tanks have their advantages and disadvantages. However, polyethylene fuel tanks are the best choice because they are lightweight, sleek, clean, have less condensation, and are durable.

Fuel tank caps also serve different functions. It acts as a valve that helps control the pressure of the fuel tank as it controls the pressure by producing fuel vapors. Fuel filler necks are the main point where fuel enters the vehicle. It is important to buy a high-quality filler neck because the main cap prevents fuel from leaking or dripping during filling.

If you are looking for quality fuel tank parts and accessories, Caps Necks are your best options. They are excellent suppliers of filler neck fuel tanks and caps, all of which are available on their website. Order high-quality filler neck and fuel tank parts at a reasonable price from Caps Necks website. https://www.capsnecks.com

0 notes

Text

What is Electrolysis Hydrogen Production? A Beginner’s Guide

As the world transitions toward cleaner energy solutions, hydrogen has emerged as a promising alternative to traditional fossil fuels. One of the most sustainable methods of producing hydrogen is through electrolysis. But what exactly is electrolysis hydrogen production, and why is it important? This beginner’s guide aims to answer these questions and shed light on its potential to revolutionize the energy landscape.

Understanding Electrolysis Hydrogen Production

Electrolysis is a process that uses electricity to split water ( H₂O ) into its basic components: hydrogen ( H₂ ) and oxygen ( O₂ ). When the electricity used comes from renewable energy sources like wind or solar, the hydrogen produced is often referred to as “green hydrogen” due to its minimal environmental impact.

The Basic Process

Electrolyzer: The device used for electrolysis consists of an anode and a cathode submerged in water, separated by an electrolyte.

Electric Current: A direct current (DC) is passed through the water.

Separation: Hydrogen gas collects at the cathode, while oxygen is released at the anode.

This simple yet effective process is at the heart of electrolysis hydrogen production, offering a clean and efficient way to generate hydrogen for various applications.

Why is Electrolysis Hydrogen Production Important?

1. A Cleaner Energy Source

Hydrogen produced via electrolysis emits no greenhouse gases during its use, making it an excellent substitute for fossil fuels in sectors like transportation, manufacturing, and power generation.

2. Energy Storage

Hydrogen acts as a powerful energy carrier, enabling the storage of excess energy generated by renewable sources. This addresses the intermittency issues of solar and wind power.

3. Industrial Applications

Industries like steel production, ammonia manufacturing, and chemical refining benefit from the high purity hydrogen generated through electrolysis.

Types of Electrolyzers Used in Hydrogen Production

1. Alkaline Electrolyzers

How It Works: Uses a liquid alkaline electrolyte, such as potassium hydroxide, to conduct electricity.

Advantages: Proven technology, cost-effective, and scalable.

Disadvantages: Lower efficiency compared to advanced systems.

2. Proton Exchange Membrane (PEM) Electrolyzers

How It Works: Utilizes a solid polymer electrolyte to separate hydrogen and oxygen.

Advantages: Higher efficiency and compact design.

Disadvantages: More expensive due to the use of precious metals like platinum.

3. Solid Oxide Electrolyzers

How It Works: Operates at high temperatures to split water molecules.

Advantages: Extremely efficient, especially when integrated with industrial heat sources.

Disadvantages: Still under development and requires further cost reductions.

Applications of Hydrogen from Electrolysis

1. Clean Transportation

Hydrogen-powered fuel cells are being increasingly used in vehicles, providing a zero-emission alternative to gasoline and diesel engines.

2. Power Generation

Hydrogen can be burned or used in fuel cells to generate electricity, making it a flexible energy source for both grid and off-grid applications.

3. Industrial Uses

In industries requiring high temperatures, such as steelmaking, hydrogen offers a cleaner fuel alternative to coal.

4. Export Potential

Countries investing in electrolysis hydrogen production can export green hydrogen to nations seeking to decarbonize their energy systems.

Challenges in Electrolysis Hydrogen Production

1. High Energy Requirements

Electrolysis requires significant amounts of electricity, making its efficiency directly dependent on the energy source used.

2. Cost Factors

The cost of electrolyzers and renewable energy infrastructure is still relatively high, which impacts the overall affordability of green hydrogen.

3. Scaling Up

While the technology is promising, scaling up to meet global energy demands requires further innovation and investment.

The Future of Electrolysis Hydrogen Production

The global push toward sustainability has positioned electrolysis hydrogen production as a cornerstone of the energy transition. Governments and organizations worldwide are investing in research, infrastructure, and policies to support the adoption of green hydrogen. With advancements in electrolyzer technology and renewable energy integration, the cost of hydrogen production is expected to decrease, making it more accessible across industries.

Why Choose TryIn Solution for Hydrogen Solutions?

At TryIn Solution, we understand the transformative potential of green hydrogen and are dedicated to supporting businesses in adopting sustainable energy practices. From providing cutting-edge technology to offering expert guidance, we help you harness the benefits of electrolysis hydrogen production effectively and efficiently.

Conclusion

Electrolysis hydrogen production is a game-changing technology that promises to redefine how we produce and use energy. By offering a clean, sustainable, and versatile energy source, it addresses some of the most pressing challenges of our time, from reducing carbon emissions to ensuring energy security. As we move toward a greener future, investing in this innovative solution will be pivotal for industries and governments alike.

Explore how TryIn Solution can help you integrate hydrogen solutions into your operations. Contact us today to learn more!

0 notes

Text

Buy a New Car: Petrol or Diesel? Choose the Best Option

When buy a new Car, one of the most significant decisions you'll face is choosing between a petrol or diesel car. This choice can have a substantial impact on your driving experience, long-term costs, and even your carbon footprint. While both types of engines have their own advantages and disadvantages, the right option for you will depend on your specific needs and driving habits.

https://www.epnlocal.com/

0 notes

Text

Portable Diesel Heaters vs. Electric Heaters: Which One Best Suits Your Needs?

When it comes to choosing the right heating solution for your space, you’re faced with numerous options. Two popular choices are Portable Diesel Heaters and Electric Heaters, each offering unique benefits depending on your needs. Whether you’re heating a workshop, an outdoor event, or an industrial site, understanding the advantages and disadvantages of each option will help you make an informed decision. In this article, we’ll compare Portable Diesel Heaters and Electric Heaters to help you determine which one is the best fit for your situation. Let’s dive into the key differences between these two types of heaters and explore their respective strengths.

1. Power Source and Efficiency

Portable Diesel Heaters are powered by diesel fuel, making them a great option for remote or outdoor locations where electricity may not be readily available. Diesel heaters are generally more fuel-efficient than electric models because diesel has a higher energy content per gallon. This means you can heat a larger area or use the heater for longer periods without needing to refuel as often. On the other hand, Electric Heaters run on electricity and require an accessible power source. While they may be easier to use in indoor settings, their efficiency is directly tied to the cost of electricity. For larger spaces or extended heating needs, Electric Heaters can become costly over time due to higher electricity consumption, especially in areas with high energy rates.

2. Heating Power and Area Coverage

When it comes to heating large spaces, Portable Diesel Heaters generally outperform electric models in terms of heating power. Diesel heaters can generate much higher levels of heat, making them suitable for larger, more open areas. They are commonly used on construction sites, warehouses, and outdoor events where quick and intense heat is required. Electric Heaters, in comparison, tend to be better suited for smaller spaces. They provide steady heat but may struggle to keep larger areas warm efficiently. However, they can still work well in smaller rooms or enclosed spaces where they don’t need to compete with cold drafts or large volumes of air. If you need to heat a large workshop or an outdoor area, a Diesel Portable Heater may be the more appropriate choice. However, if you’re dealing with a small, well-insulated space, an Electric Heater might be more than sufficient.

3. Mobility and Ease of Use

Electric Heaters are typically lighter and more compact than Diesel Portable Heaters, making them easier to move around and set up. They are perfect for indoor environments where ease of installation is a priority. Plugging them into a standard electrical outlet is quick and hassle-free. Portable Diesel Heaters, while still mobile, tend to be bulkier due to the additional components required for fuel storage and combustion. They are designed for more rugged applications, and moving them may require additional effort, especially if the space has limited access or power sources. However, their portability is still one of their standout features, especially when a fuel-powered solution is needed in remote locations.

4. Maintenance and Running Costs

In terms of maintenance, Diesel Portable Heaters generally require more upkeep. Diesel engines have moving parts that need regular inspection and service to ensure efficient operation. Fuel storage and management also need to be considered, as diesel fuel can degrade over time, especially if the heater is not used frequently. Electric Heaters, by contrast, are much easier to maintain. They have fewer parts that wear out, and they don’t require fuel storage or constant refueling. However, their long-term operating costs may increase depending on how often they’re used and the price of electricity in your area.

5. Environmental Impact

Electric Heaters are considered a cleaner option in terms of emissions since they don’t burn fossil fuels. If you are focused on reducing your environmental impact, electric heaters can be a more eco-friendly choice, especially if you power them with renewable energy sources. Diesel Portable Heaters, while highly efficient, produce emissions from the combustion of diesel fuel. If you’re operating in an environmentally sensitive area, this may be a consideration. However, modern diesel heaters are designed to be more efficient and reduce emissions compared to older models.

Conclusion: Which One Is Right for You?

Ultimately, the choice between Portable Diesel Heaters and Electric Heaters depends on your specific needs. If you require a heater for a large outdoor area, a construction site, or an event where access to electricity is limited, Diesel Portable Heaters provide reliable, high-powered heat. Their ability to run on fuel makes them ideal for demanding situations, and their cost-effectiveness for larger areas is a key advantage. On the other hand, if you’re heating a smaller indoor space, an Electric Heater may be more convenient and cost-effective. It’s easier to use, requires less maintenance, and is a cleaner option for reducing emissions. At Cantherm, we offer a range of Portable Diesel Heaters and other heating solutions to meet your needs. If you need help deciding between a Diesel Generator or Portable Diesel Heater, feel free to contact us for expert advice and product recommendations.

0 notes

Text

Reach Trucks vs. Forklifts: Which is Better for Your Warehouse?

Reach Trucks vs. Forklifts: Which is Better for Your Warehouse?

When it comes to warehouse operations, choosing the right equipment is crucial for efficiency and safety. Two common pieces of equipment are reach trucks and forklifts, each with its own set of advantages and disadvantages. Here's a detailed comparison to help you make an informed decision for your warehouse needs.

1. Design and Maneuverability Reach Trucks: Designed for narrow aisles and high stacking, reach trucks have an extendable mast that allows them to reach into racks. Their compact design makes them ideal for tight spaces and high-density storage. Forklift Forklifts: Traditional forklifts have a larger footprint and are better suited for open spaces. They excel in moving heavy loads over long distances and can operate in outdoor environments as well.

2. Load Capacity and Lifting Height Reach Trucks: Generally, reach trucks have a lower load capacity, typically ranging from 2,000 to 5,500 pounds. However, they can lift loads to significant heights, often up to 30 feet or more, making them ideal for high-bay warehouses.

Forklifts: Forklifts usually have a higher load capacity, often exceeding 5,500 pounds. They can also lift loads to considerable heights but are more versatile in handling heavier items at lower heights.

3. Operational Efficiency Reach Trucks: Due to their design, reach trucks are highly efficient in narrow aisle operations and high racking systems. They optimize vertical space usage and improve picking and stacking efficiency.

Forklifts: Forklifts are more versatile and can handle a variety of tasks, including loading and unloading trucks, transporting materials over long distances, and operating on uneven surfaces.

4. Battery Life and Maintenance Reach Trucks: These are typically electric-powered, which means they require regular charging and maintenance of batteries. They are quieter and produce zero emissions, making them suitable for indoor use.

Forklifts: Forklifts can be either electric or powered by internal combustion engines. While electric models share similar maintenance needs to reach trucks, gas or diesel forklifts require engine maintenance and fuel management but offer the advantage of extended operation times without needing frequent recharging.

5. Cost Considerations Reach Trucks: Generally, reach trucks can be more expensive than standard forklifts due to their specialized design. However, their efficiency in space utilization can lead to long-term cost savings.

Forklifts: Forklifts tend to have a lower upfront cost but might incur higher long-term expenses if they are internal combustion models, due to fuel and maintenance costs.

6. Safety Features Reach Trucks: Advanced reach trucks come with features like stability control, height sensors, and ergonomic controls, enhancing operator safety and comfort in high-bay storage operations.

Forklifts: Modern forklifts are equipped with a variety of safety features including load weight indicators, seat belts, and improved visibility, making them safe for diverse applications.

Conclusion Choosing between reach trucks and forklifts depends on your specific warehouse needs. Reach trucks are ideal for narrow aisles and high-density storage, offering superior vertical space utilization. Forklifts provide greater versatility and higher load capacities, suitable for various indoor and outdoor tasks. Assess your operational requirements, space constraints, and budget to determine the best fit for your warehouse.

0 notes

Text

Understanding the Basics of Car Engine Types

When buying a car, one of the most critical aspects to understand is the type of engine it uses. The engine is the heart of any vehicle, and knowing how different car engine types work can help you make an informed decision. Whether you're considering fuel efficiency, power, or environmental impact, each engine type offers unique advantages. In this blog, we’ll break down the basics of car engine types, including petrol, diesel, hybrid, and electric engines, to help you choose the one that fits your needs.

1. Petrol Engines

Petrol engines, also known as gasoline engines, are among the most common types found in passenger vehicles. These engines use a spark-ignition system to ignite the air-fuel mixture inside the combustion chamber.

Advantages of Petrol Engines:

Smoother and Quieter: Petrol engines tend to run smoother and quieter compared to diesel engines.

Lower Initial Cost: Cars with petrol engines are generally cheaper than diesel variants.

Lower Maintenance: Maintenance costs are typically lower due to simpler engine design and fewer emissions control components.

Disadvantages of Petrol Engines:

Lower Fuel Efficiency: Petrol engines usually consume more fuel than diesel engines.

Higher Emissions: They emit more carbon dioxide, contributing more to environmental pollution.

2. Diesel Engines

Diesel engines work on the principle of compression ignition. Instead of using a spark, the air is compressed to a high temperature, and fuel is injected into the chamber, causing it to ignite.

to know more, visit.. https://themotorpedia.com/blog/understanding-the-basics-of-car-engine-types/f6601a84a208d9a28434a384fc3d529d

0 notes

Text

Internal Combustion Engines: A Comprehensive Guide

Internal combustion engines (ICEs) have been the driving force behind technological advancements for over a century. The Indian Internal Combustion Engines Market is projected to reach USD 8.3 billion by 2026, growing at a CAGR of 7.6% during the forecast period (2020–2026). This growth is primarily driven by the increasing demand for vehicles, construction equipment, and power generation solutions in the country that uses ICEs.

Basic Components of an Internal Combustion Engine

An ICE consists of several interconnected components that work together to produce power:

Combustion Chamber: The space where the fuel-air mixture is ignited and combustion occurs.

Piston: A movable component that reciprocates within the cylinder, converting the combustion energy into mechanical energy.

Connecting Rod: A component that connects the piston to the crankshaft, transmitting the mechanical energy.

Crankshaft: A rotating shaft that converts the reciprocating motion of the piston into rotary motion.

Valves: Devices that control the flow of fuel-air mixture into and out of the combustion chamber.

Fuel System: Delivers fuel to the engine for combustion.

Ignition System: Ignites the fuel-air mixture in the combustion chamber.

Cooling System: Removes excess heat from the engine to prevent overheating.

Exhaust System: Directs the exhaust gases from the engine to the atmosphere.

How an Internal Combustion Engine Works

ICEs typically operate on either a four-stroke or a two-stroke cycle.

Four-Stroke Cycle:

Intake Stroke: The intake valve opens, allowing a mixture of fuel and air to enter the cylinder.

Compression Stroke: The intake valve closes, and the piston compresses the fuel-air mixture.

Power Stroke: The spark plug ignites the compressed mixture, causing a power stroke that pushes the piston downward.

Exhaust Stroke: The exhaust valve opens, and the piston pushes the exhaust gases out of the cylinder.

Two-Stroke Cycle:

Intake and Compression Stroke: The piston moves downward, creating a vacuum that draws in a fresh charge of fuel and air.

Power and Exhaust Stroke: As the piston moves upward, the compressed mixture is ignited, generating power and forcing the exhaust gases out through the exhaust port.

Types of Internal Combustion Engines

ICEs can be classified based on several factors:

Fuel Type:

Gasoline engines

Diesel engines

Natural gas engines

Number of Cylinders:

Single-cylinder engines

Multi-cylinder engines (V-engines, inline engines, etc.)

Cooling System:

Air-cooled engines

Liquid-cooled engines

Ignition System:

Spark-ignition engines (gasoline engines)

Compression-ignition engines (diesel engines)

Applications of Internal Combustion Engines

ICEs are used in a wide range of applications, including:

Automobiles Passenger & Commercial Vehicles: Cars, trucks, and SUVs

Motorcycles Two & Three Wheelers: Bikes, scooters, passenger & goods carriers

Construction Equipment: Excavators, bulldozers, and cranes

Marine Engines: Boats and ships

Power Generators: Providing electricity for various purposes

Advantages and Disadvantages of Internal Combustion Engines

ICEs offer several advantages:

Efficiency: They can convert a significant portion of the fuel’s energy into mechanical work.

Power Output: ICEs can produce substantial power, making them suitable for heavy-duty applications.

Versatility: They can be adapted to fit various applications and sizes.

However, ICEs also have some disadvantages:

Pollution: The combustion process produces harmful emissions that contribute to air pollution.

Noise: ICEs can be noisy, especially when operating at high speeds.

Fuel Consumption: The consumption of fossil fuels can contribute to climate change.

The Future of Internal Combustion Engines

With increasing environmental concerns and stringent fuel efficiency regulations, the future of Internal Combustion Engines (ICEs) is evolving. While there is a growing emphasis on alternative power sources like electric vehicles, ICEs are still a dominant force in many industries.

At Greaves Engineering, we are committed to driving innovation in ICE technology to ensure their continued relevance. Our focus on research and development has led to significant advancements in:

Fuel Efficiency: We have developed engines that deliver exceptional fuel economy, reducing carbon emissions and operating costs.

Emission Reduction: Our engineers have implemented cutting-edge technologies to minimise harmful emissions, ensuring compliance with stringent environmental regulations.

Performance Optimization: We continuously strive to enhance the power output and performance of our ICEs, making them suitable for a wide range of applications.

Greaves Engineering’s Role in Shaping the Future of ICEs

Greaves Engineering is actively contributing to the future of ICEs by:

Developing Sustainable Solutions: Our focus on fuel-agnostic engines and alternative fuel options demonstrates our commitment to a sustainable future.

Investing in Research and Development: We invest heavily in research and development to explore new technologies and improve the efficiency and performance of our ICEs.

Collaborating with Industry Partners: We collaborate with industry leaders to develop innovative solutions and drive the adoption of advanced ICE technology.

While the transition to electric vehicles is gaining momentum, ICEs will likely remain a crucial part of the transportation landscape for many years to come. Greaves Engineering is at the forefront of this evolution, ensuring that our ICEs continue to meet the demands of a changing world.

0 notes

Text

Diesel Generator Market Analysis 2024 Forecasts to 2030

Diesel Generator Industry Overview

The global diesel generator market size was estimated at USD 16.36 billion in 2023 and is expected to grow at a CAGR of 9.6% from 2024 to 2030. Increasing energy demand globally far outstrips the supply. Factors, such as continuous population growth, infrastructure development, and rapid industrialization in emerging economies drive power demand.

Diesel generators are favoured for their numerous benefits, including low operating costs and superior fuel efficiency, making them particularly popular in developing areas, notably the Asia Pacific region. Despite these advantages, they also have several disadvantages, such as noise pollution and the emission of harmful gases. The World Nuclear Association has predicted that the electricity demand is likely to double from current levels. In addition, the U.S. Department of Energy forecasts that solar energy will become the most plentiful energy source available.

Gather more insights about the market drivers, restrains and growth of the Diesel Generator Market

Significant growth in the economies of major developing nations, such as India and Brazil, is expected by 2050. India is expected to grow from being the third largest to the second largest economy in the world, only after China in terms of GDP at PPP (purchase power parity). Countries, such as Brazil, India, and South Africa, are already suffering due to a low power supply. Emerging economies are expected to account for 65% of the global economy. The U.S. market is anticipated to witness substantial growth owing to rising costs of power outages across several IT-enabled service firms and data centers and growing consumer awareness of the need for a reliable emergency power supply. In addition, the market is also driven by the rising vulnerability of grid power stations to disasters caused by changing weather conditions across the region.

Solution providers are mainly responsible for manufacturing, installing, maintaining, and repairing generator systems. Dealers or electrical contractors typically enter into supply and maintenance agreements with end-market consumers, which include commercial establishments, residential areas, and small businesses that use generators for emergency power backup. In addition, companies often appoint an in-house monitoring engineer to oversee the operation of numerous generators in industrial-scale settings. Stringent government regulations regarding reducing harmful carbon emissions are expected to boost the penetration of gas-based generators over diesel generators. This trend is anticipated to restrict the demand for diesel generators across all end-use sectors. However, low operating costs and low initial investment are among the key factors sustaining the current requirement for diesel generator sets.

Key Companies profiled:

• AKSA Power Generation Company • Atlas Copco AB • Caterpillar • Cummins Inc. • Doosan Portable Power • Generac Power System Inc. • Honda India Power Products Ltd. • Kohler Co. • Rolls-Royce Plc • Wartsila Corporation

Browse through Grand View Research's Category Power Generation & Storage Industry Research Reports.

• The global offshore pipeline market size was estimated at USD 13.97 billion in 2022 and is anticipated to expand at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. The rising global demand for energy, particularly oil and natural gas, is poised to highlight the necessity for offshore pipelines, as they are vital in transporting such resources from offshore fields to onshore processing facilities, ensuring a stable supply of energy.

• The global battery recycling market size was estimated at USD 1.83 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 37.6% from 2024 to 2030. The industry is expected to grow rapidly during the forecast period owing to increasing popularity of electric vehicles (EVs) and renewable energy storage systems leading to a higher demand for batteries, and, in turn, driving the need for recycling.

Diesel Generator Market Segmentation

Grand View Research has segmented the global diesel generator market based on power rating, application, region:

Diesel Generator Power Rating Outlook (Revenue, USD Million, 2018 - 2030)

• Low Power Generator • Medium Power Generator • High Power Generator

Diesel Generator Application Outlook (Revenue, USD Million, 2018 - 2030)

• Industrial • Commercial • Residential

Diesel Generator Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America o US o Canada o Mexico • Europe o UK o Germany o Russia o France • Asia Pacific o China o Japan o India o South Korea • Central & South America o Brazil o Argentina • Middle East & Africa o Saudi Arabia o UAE

Order a free sample PDF of the Diesel Generator Market Intelligence Study, published by Grand View Research.

0 notes

Text

Diesel Generator Market Segmentation And Applications Across Various Industries

Diesel Generator Industry Overview

The global diesel generator market size was estimated at USD 16.36 billion in 2023 and is expected to grow at a CAGR of 9.6% from 2024 to 2030. Increasing energy demand globally far outstrips the supply. Factors, such as continuous population growth, infrastructure development, and rapid industrialization in emerging economies drive power demand.

Diesel generators are favoured for their numerous benefits, including low operating costs and superior fuel efficiency, making them particularly popular in developing areas, notably the Asia Pacific region. Despite these advantages, they also have several disadvantages, such as noise pollution and the emission of harmful gases. The World Nuclear Association has predicted that the electricity demand is likely to double from current levels. In addition, the U.S. Department of Energy forecasts that solar energy will become the most plentiful energy source available.

Gather more insights about the market drivers, restrains and growth of the Diesel Generator Market

Significant growth in the economies of major developing nations, such as India and Brazil, is expected by 2050. India is expected to grow from being the third largest to the second largest economy in the world, only after China in terms of GDP at PPP (purchase power parity). Countries, such as Brazil, India, and South Africa, are already suffering due to a low power supply. Emerging economies are expected to account for 65% of the global economy. The U.S. market is anticipated to witness substantial growth owing to rising costs of power outages across several IT-enabled service firms and data centers and growing consumer awareness of the need for a reliable emergency power supply. In addition, the market is also driven by the rising vulnerability of grid power stations to disasters caused by changing weather conditions across the region.

Solution providers are mainly responsible for manufacturing, installing, maintaining, and repairing generator systems. Dealers or electrical contractors typically enter into supply and maintenance agreements with end-market consumers, which include commercial establishments, residential areas, and small businesses that use generators for emergency power backup. In addition, companies often appoint an in-house monitoring engineer to oversee the operation of numerous generators in industrial-scale settings. Stringent government regulations regarding reducing harmful carbon emissions are expected to boost the penetration of gas-based generators over diesel generators. This trend is anticipated to restrict the demand for diesel generators across all end-use sectors. However, low operating costs and low initial investment are among the key factors sustaining the current requirement for diesel generator sets.

Key Companies profiled:

• AKSA Power Generation Company • Atlas Copco AB • Caterpillar • Cummins Inc. • Doosan Portable Power • Generac Power System Inc. • Honda India Power Products Ltd. • Kohler Co. • Rolls-Royce Plc • Wartsila Corporation

Browse through Grand View Research's Category Power Generation & Storage Industry Research Reports.

• The global offshore pipeline market size was estimated at USD 13.97 billion in 2022 and is anticipated to expand at a compound annual growth rate (CAGR) of 4.2% from 2023 to 2030. The rising global demand for energy, particularly oil and natural gas, is poised to highlight the necessity for offshore pipelines, as they are vital in transporting such resources from offshore fields to onshore processing facilities, ensuring a stable supply of energy.

• The global battery recycling market size was estimated at USD 1.83 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 37.6% from 2024 to 2030. The industry is expected to grow rapidly during the forecast period owing to increasing popularity of electric vehicles (EVs) and renewable energy storage systems leading to a higher demand for batteries, and, in turn, driving the need for recycling.

Diesel Generator Market Segmentation

Grand View Research has segmented the global diesel generator market based on power rating, application, region:

Diesel Generator Power Rating Outlook (Revenue, USD Million, 2018 - 2030)

• Low Power Generator • Medium Power Generator • High Power Generator

Diesel Generator Application Outlook (Revenue, USD Million, 2018 - 2030)

• Industrial • Commercial • Residential

Diesel Generator Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America o U.S. o Canada o Mexico • Europe o UK o Germany o Russia o France • Asia Pacific o China o Japan o India o South Korea • Central & South America o Brazil o Argentina • Middle East & Africa o Saudi Arabia o UAE

Order a free sample PDF of the Diesel Generator Market Intelligence Study, published by Grand View Research.

Key Diesel Generator Company Insights

Key companies are adopting several organic and inorganic expansion strategies, such as mergers & acquisitions, new product launches, capacity expansion, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

• In May 2023, Cummins, a power generation equipment and engine manufacturer, launched a novel diesel generator set powered by their B45 engine, a 4.5-liter, four-cylinder diesel engine designed for power generation applications. This new generator set is expected to provide reliable power for a variety of industries, including construction, rental, and prime power

• In August 2022, Caterpillar launched three standby diesel generators ranging from 20 to 30 kilowatts (KW) for the North American market. These diesel generator sets, powered by the Cat C2.2 engine, are designed for small industrial, telecommunications, and commercial applications. They meet U.S. EPA emergency emission standards and industry safety certifications and offer features like exceptional performance, compact size, readily available parts, and optional enclosures

0 notes