#Dental 3D Printing Material

Explore tagged Tumblr posts

Text

A Market Research and Competitive Intelligence Provider: The global dental 3dimensional (3D) printing market is estimated to reach US$ 3 billion in 2023 and accelerate at an astonishing 22% CAGR from 2023 to 2033. The revenue generated from the market is expected to result in a valuation of US$ 21.9 billion by 2033.

#advanced 3D dental printers#dental 3D printing Companies#tooth 3D printing materials#ceramic dental 3D printing

1 note

·

View note

Text

Dental 3D Printing Material Market Outlook from 2023 to 2033

The dental 3D printing materials market size is projected to grow to a value of US$117.02 million by 2023. Over the course of the forecast period, a 3.9% CAGR is projected for it. The estimated overall market size by 2033 is around US$ 171.81 million..As per the latest report, the metal segment will likely hold a prominent market share of 38.5% in 2033. However, ceramic materials are anticipated to witness higher demand, rising at 6.0% CAGR through 2033.Several factors are expected to stimulate growth in the global dental 3D printing material market. These include the rising prevalence of dental diseases, increasing demand for cosmetic dentistry, and innovation in 3D printing materials.Get a Sample Copy of the Report:https://www.futuremarketinsights.com/reports/sample/rep-gb-18050

0 notes

Text

New solvent-free 3D printing material could enable biodegradable implants

Additive manufacturing (AM) has revolutionized many industries and holds the promise to affect many more in the not too distant future. While people are most familiar with the 3D printers that function much like inkjet printers, another type of AM offers advantages using a different approach: building objects with light one layer at a time. One such technology is digital light processing (DLP). Widely used in both industrial and dental applications, DLP works by converting a liquid resin into a solid part using light, essentially pulling solid objects out of a shallow pool of resin one layer at a time. A major challenge to using this 3D printing method, however, is that the resins need to have a low viscosity, almost like water, to function properly at high resolution. Plenty of polymers that would otherwise be useful in DLP printing are solids or too viscous, requiring solvents to dilute them to an appropriate consistency.

Read more.

8 notes

·

View notes

Text

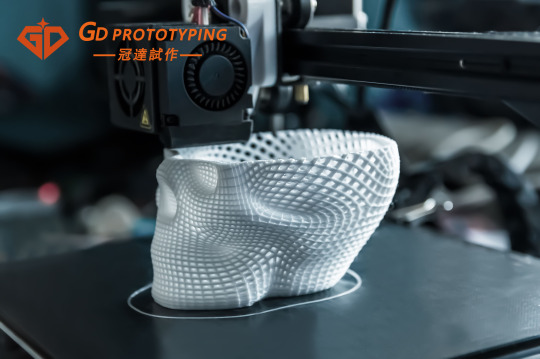

Top 8 Applications of 3D Printing in Medical Industry

3D printing technology, with its highly customizable, responsive and material-saving features, is triggering profound changes in the medical field. Especially in the application of medical models, 3D printing technology shows unparalleled advantages and potential.

Furthermore, 3D printing technology, as an emerging additive manufacturing technology, has made breakthroughs in its application in the medical field in recent years. The application of 3D printing technology in the medical field is becoming more and more widespread. Through the layer-by-layer stacking of digital models, a variety of medical devices, prosthetics, orthotics and other aids, and even human organs, can be accurately printed.

1.Surgical preview model

With 3D printing technology, doctors can create surgical preview models to help them simulate operations before surgery, improving accuracy and safety.

It is important for medical workers to conduct preoperative planning for risky and difficult procedures. In the previous surgical preview process, medical workers often need to obtain the patient's data through CT, magnetic resonance imaging (MRI) and other imaging equipment, and then the two-dimensional medical image using software to convert into realistic three-dimensional data. Today, medical workers can use devices such as 3D printers to print 3D models directly. In this way, it not only can assist the doctor to carry out accurate surgical planning, improve the success rate of surgery, but also to facilitate the communication and exchange between medical workers and patients on the surgical program plan.

2.Surgical guide

Surgical guides can help the surgeon to accurately position and operate during surgery, reducing surgical errors and improving surgical outcomes.

As an auxiliary surgical tool during surgery, surgical guides can help medical workers to accurately implement surgical programmes. Currently, the types of surgical guides have included joint guides, spinal guides, oral implant guides, etc. With the help of 3D printed surgical guides, firstly, the 3D scanning technology can produce three-dimensional data on the patient's affected area, which allows the doctor to obtain the most realistic information, so as to better plan the surgery. Secondly, while making up for the shortcomings of the traditional surgical guide manufacturing process, the size and shape of the guide can also be adjusted as needed.In this way, different patients can have a guide plate that meets their real needs.

3.Dental applications

3D printing technology is also widely used in the field of dentistry to print personalized trays, moulds, etc., to help patients have better dental treatment.

The application of 3D printing in the dental field mainly focuses on the design and production of metal teeth, invisible braces, etc. The emergence of cutting-edge technology of 3D printing creates more possibilities for those who need orthodontic treatment to achieve personalized and customized braces. At different stages of orthodontic treatment, orthodontists need different sets of braces. With the help of 3D printing to create multiple sets of braces needed for orthodontic treatment, it not only helps the healthy development of teeth, but also reduces the cost of braces production. The significance of these digital technologies is that they are gradually making it less necessary for doctors to make models, dentures, etc. by hand, and returning more of their efforts to the diagnosis of oral diseases and the performance of oral surgery itself.

4.Rehabilitation medical equipment

Through 3D printing technology, a variety of rehabilitation medical devices, such as prosthetics and orthotics, can be created to help patients regain function.

The real value of 3D printing for orthopaedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only to achieve accurate customization, but also to allow accurate and efficient digital manufacturing technology to replace the traditional production methods, reducing the cost of individual customized rehabilitation medical devices and shortening the production cycle. 3D printing process is diversified, and there is a wide range of 3D printing materials. SLA light-curing 3D printing technology has the advantage of being able to provide the most efficient and cost-effective 3D printing technology. SLA light-curing 3D printing technology is widely used in rapid prototyping by the medical device industry due to its advantages of fast processing speed, high precision, good surface quality of photosensitive resin material moulding and moderate cost.

5.Medical Equipment Cases

3D printing technology can also be used to create a variety of medical devices, such as surgical instruments and medical equipment, to improve the personalization and accuracy of medical devices.

Take the example of 3D printing for mass customized production in the hearing aid shell industry. In the traditional way, injection moulds need to be made from a model of the patient's ear canal. The final shape of the hearing aid is obtained by drilling sound holes and manually processing the plastic product. If a mistake is made during the process, the mould needs to be recreated. The process of making a hearing aid using a 3D printer, on the other hand, begins with the design of a silicone mould or impression of the patient's ear canal, a step that is done using a 3D scanner. CAD software is then used to convert the scanned data into a design file that can be read by the 3D printer. The designer can then use the software to modify the 3D image and create the final product shape.

6.Precision replication and personalization

3D printing technology is able to accurately restore a patient's anatomy and produce full-size, high-fidelity medical models based on the patient's CT, MRI and other imaging data. These models not only have extremely high geometric accuracy and surface quality, but also reflect the unique physiological characteristics of the patient, providing doctors with real and reliable references.

7.Teaching and training

3D printed medical models also play an important role in medical education and training. By printing out models of various typical cases, medical students can perform practical operations in a simulated surgical environment to enhance their surgical skills and resilience. At the same time, these models can also be used as teaching tools to help students better understand human anatomy and disease principles.

8.Scientific research and experimentation

In the field of medical research, 3D printed medical models also have important applications. Researchers can use these models to conduct experimental studies such as drug screening and biomechanical testing to explore new treatment methods and technologies. In addition, by printing tissue or organ models with specific physiological functions, they can also provide strong support for research in cutting-edge fields such as organ transplantation and regenerative medicine.

In summary, 3D printing technology has a wide and far-reaching significance in the application of medical models. It not only improves the accuracy and efficiency of medical services, but also promotes the innovative development of medical education, research and clinical practice. With the continuous progress of technology and the expansion of application scope, we have reason to believe that 3D printing will play a more important role in the future medical field.

#3d printing#3d printing services#3d printed#additive manufacturing#3d print#medical device machining#medical 3d printing#3d printed parts#3d printing materials market#3d printing market share

4 notes

·

View notes

Text

How Israeli Tech is Shaping the Future of Additive Manufacturing Worldwide

Overview of Israel’s Strategic Position in Additive Manufacturing

Israel has rapidly emerged as a global force in additive manufacturing (AM), fortified by a powerful high-tech ecosystem, robust government support, and a legacy of innovation in defense, aerospace, and medical technologies. With the Israel additive manufacturing market valued at USD 221.4 billion in 2024 and forecasted to exceed USD 280.3 billion by 2032, the nation is positioned to lead transformative advances in 3D printing technologies. The Israel additive manufacturing market compound annual growth rate (CAGR) of approximately 7% reflects both escalating domestic demand and global interest in Israeli AM innovation.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40589-israel-additive-manufacturing-market-research

Driving Forces of Growth in Israel's Additive Manufacturing Market

Innovation Across Key Industrial Verticals

Israel additive manufacturing market sector is evolving as a backbone for modernization in:

Aerospace and Defense: Lightweight components, complex geometries, and high-performance materials enable operational efficiency and reduced lead times.

Healthcare: Customized prosthetics, implants, bioprinting, and surgical models offer patient-centric care and improved clinical outcomes.

Automotive and Industrial Manufacturing: Rapid prototyping, tooling, and small-batch production optimize supply chains and cut production timelines.

These sectors benefit from the convergence of additive technologies with AI, machine learning, and advanced robotics, all core competencies of Israel's high-tech sector.

Rising Demand for Customization and Sustainability

The shift toward sustainable manufacturing and personalized solutions is fueling AM adoption. Israeli startups and research institutions are developing biocompatible, recyclable, and multi-material printing solutions that meet stringent regulatory and industry-specific standards.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40589-israel-additive-manufacturing-market-research

Technological Landscape of the Israeli Additive Manufacturing Ecosystem

Polymer-Based Additive Manufacturing

Valued at USD 306.31 million in 2024, this segment dominates due to its cost-effectiveness, versatility, and compatibility with lightweight, complex part production. With an expected CAGR of 17.3%, applications in consumer goods, automotive interiors, and medical devices continue to surge.

Metal-Based Additive Manufacturing

Growing at a robust 20.1% CAGR, metal AM is the cornerstone of defense and aerospace advancements. In 2024, it accounted for USD 180.86 million, projected to exceed USD 775.48 million by 2032. Israel’s focus on titanium, aluminum alloys, and nickel-based superalloys supports structural applications with high thermal and mechanical stability.

Hybrid Additive Manufacturing

By blending subtractive and additive processes, hybrid AM enhances surface finish and dimensional accuracy, critical in precision tooling, aerospace, and dental prosthetics. This segment is rapidly gaining traction due to its versatility and integration into smart manufacturing systems.

Segmental Breakdown of the Israel Additive Manufacturing Market

By Component

Hardware: Represents the largest share, valued at USD 1,137.28 million in 2024, supporting high-throughput production and industrial-scale fabrication.

Software: Fueled by AI-powered design, generative modeling, and process simulation, this segment is experiencing 19.9% CAGR, revolutionizing digital twin applications and real-time process monitoring.

Services: The on-demand printing ecosystem is expanding, empowering SMEs to access advanced AM capabilities with minimal capital expenditure.

By Deployment Model

In-House Manufacturing: With a Israel additive manufacturing market valuation of USD 317.09 million in 2024, large enterprises prefer internal AM operations for confidentiality and operational control.

Service-Based Models: Growing at 19.4% CAGR, third-party service bureaus are crucial in democratizing access to advanced AM technologies for startups and research institutions.

By Functionality

Prototyping: Dominates with USD 340.60 million in 2024, essential for R&D, iterative design, and proof-of-concept validation.

Production: The rising shift to end-use part manufacturing is catalyzing growth in this segment, valued at USD 197.73 million in 2024.

Tooling: Customized, high-durability tooling supports faster transitions from design to production across various industrial sectors.

By Printer Size

Small/Compact Printers: Most accessible and dominant segment, valued at USD 253.09 million in 2024, ideal for labs, healthcare, and educational institutions.

Medium and Large Printers: Increasingly adopted in industrial manufacturing, these enable batch production and larger component fabrication.

End-Use Industries Driving Adoption

Aerospace & Defense

USD 159.32 million in 2024, this sector prioritizes weight reduction, material performance, and supply chain agility. With Israel’s defense sector being R&D intensive, 3D printing significantly enhances manufacturing autonomy and mission-readiness.

Healthcare & Medical

USD 131.40 million in 2024, growing due to demand for patient-specific devices, bioprinted tissues, and anatomical models. With innovations in regenerative medicine, Israel is at the forefront of personalized healthcare.

Industrial & Automotive

Israel’s industrial ecosystem leverages AM for lightweighting, thermal management, and low-volume production, especially in EV components and robotics enclosures.

Strategic Movements and Competitive Intelligence

Leading Israel Additive Manufacturing Market Participants

Stratasys: A global pioneer, deeply rooted in Israel, with continuous development in multi-material, high-resolution systems.

XJet: Revolutionizing ceramic and metal printing with NanoParticle Jetting™ technology.

Nano Dimension: Innovator in multi-layer electronics and PCB printing, driving miniaturization and functional integration.

Recent Developments

XJet (June 2024): Launched new ceramic printers with applications in automotive and aerospace, enhancing resolution and mechanical strength.

Nano Dimension (Sept 2024): Acquired startups to advance multi-material electronics printing, expanding their capabilities in embedded sensor systems.

Challenges and Strategic Opportunities

Major Israel Additive Manufacturing Market Challenges

Capital Intensity: High upfront costs limit adoption, especially among SMEs.

Talent Gap: Scarcity of AM-trained professionals hampers rapid scaling.

Scaling Complexity: Transitioning from prototype to full production requires new QA methodologies and workflow optimization.

Strategic Israel Additive Manufacturing Market Opportunities

Workforce Development: Partnerships with universities and technical institutes to offer AM-centric curricula.

Material Innovation Hubs: Support from government and private sectors to develop high-strength composites, bioresorbable materials, and nanostructured alloys.

Sustainability Mandates: Incentives for closed-loop manufacturing systems, energy-efficient printers, and recyclable materials.

Future Outlook: Israel’s Role in Global Additive Manufacturing Leadership

Israel is poised to lead the next frontier of digital manufacturing, where data-driven fabrication, machine learning-enhanced design, and autonomous production lines define industry 4.0. With unmatched cross-sector collaboration between startups, research centers, and government agencies, the nation’s AM sector is evolving from rapid prototyping to full-fledged production infrastructure.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40589-israel-additive-manufacturing-market-research

Conclusion

Israel additive manufacturing market is entering a golden era, driven by its technological prowess, strategic policy initiatives, and vibrant innovation culture. As the global demand for agile, sustainable, and customized manufacturing solutions intensifies, Israel is uniquely equipped to lead the charge. Enterprises, investors, and policy makers must align to fully harness this momentum and establish Israel as a global additive manufacturing powerhouse.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Israel#Additive Manufacturing#3D Printing#Israeli Tech#Advanced Manufacturing#Industrial 3D Printing#Aerospace#Medical Devices#Defense Technology#Innovation#Startups#Tel Aviv#Prototyping#Manufacturing Industry#AM Materials#Digital Manufacturing#Smart Manufacturing#High-Tech Industry#Metal 3D Printing#Polymer Printing#R&D#Technology Trends#Engineering#Robotics#Supply Chain#Product Development

1 note

·

View note

Text

The History and Development of Grillz Jewelry

Grillz, also known as dental jewelry or dental bling, is a unique form of decorative dental coverings, typically made of precious metals and may be adorned with gemstones. These ornaments are not only for aesthetics but also symbolize fashion and social status. The origins of grillz can be traced back to ancient civilizations, but the popularity of modern grillz is a phenomenon of the last few decades.

The earliest grillz appeared during the ancient Egyptian period, where the nobility used gold and gemstones to decorate their teeth to display their wealth and status. Over time, these decorations appeared in different cultures in various forms, such as in the Mayan and Aztec civilizations, where grillz also symbolized social status.

Entering the 20th century, grillz began to gain popularity in Western countries, especially in hip-hop culture, where it became a way to express individuality and identity. Dentists and jewelers started to collaborate to create grillz that were both practical and aesthetically pleasing, ranging from simple metal bars to complex designs embedded with diamonds and other gemstones.

With the advancement of technology, modern grillz have become more diverse and personalized. The application of 3D printing technology has made the customization of grillz easier and more precise. People can choose different designs and materials according to their preferences, creating one-of-a-kind grillz.

Grillz are not just decorative; they also reflect the changes in social culture and the pursuit of beauty. As society evolves, grillz jewelry may continue to transform into a more diverse and innovative fashion element.

#grillz#jewelry#jewellery#ring#earrings#fashionsonder#fashionsonderjewelry#sonderjewelry#grillz jewelry

2 notes

·

View notes

Text

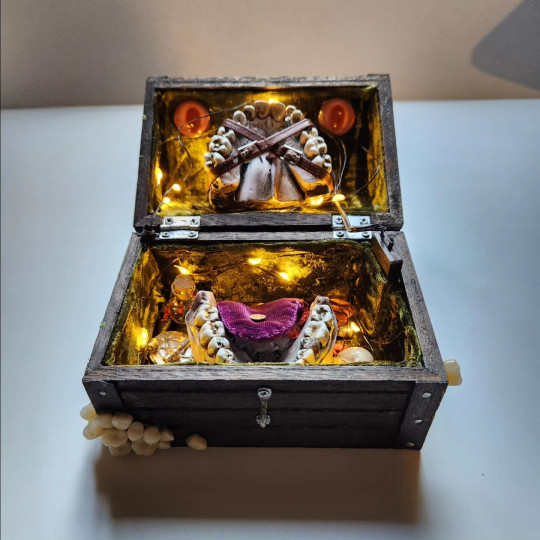

I am delighted to present, at long last, my latest commission: Julya's Teeth. Materials include wood, stain, leather, velvet, silver miniatures, LED lights, nail polish, acrylic paint, synthetic teeth, a deer bone skull, artificial rabbit eyes, and 3d printed dental casts.

2 notes

·

View notes

Text

Glycidyl Methacrylate and the Rise of Smart Materials

Glycidyl Methacrylate (GMA) is a reactive, dual-functional monomer known for its unique combination of methacrylate and epoxy groups. These properties make it an essential chemical intermediate in a wide range of applications, including adhesives, coatings, resins, and high-performance plastics.

With industries increasingly demanding materials that are strong, durable, and chemically resistant, GMA has emerged as a versatile solution. The growing use of lightweight and high-performance materials across sectors like automotive, construction, electronics, and packaging is fueling the global glycidyl methacrylate market.

Market Overview

The glycidyl methacrylate market is witnessing consistent growth, driven by its broad application potential and increasing investments in advanced polymer manufacturing. GMA enhances the chemical resistance, adhesion, heat tolerance, and mechanical properties of end products, making it a preferred choice in performance-critical applications.

Asia-Pacific dominates the market due to its thriving automotive, electronics, and packaging industries, followed by North America and Europe, where environmental regulations are also driving demand for low-VOC and high-performance coatings.

Key Market Drivers

Rising demand for advanced coatings and adhesives in automotive and electronics

Growth in lightweight composites and engineered plastics

Increasing use of GMA-modified polymers in packaging and healthcare industries

Shift toward low-VOC and water-based formulations in paints and coatings

Expanding applications in electrical insulation and circuit board laminates

Applications Across Industries

1. Automotive

Used in manufacturing coatings, adhesives, and composite parts that require high mechanical strength and resistance to heat and chemicals.

2. Electronics

GMA-modified polymers offer excellent electrical insulation and adhesion for circuit boards, cables, and encapsulating compounds.

3. Paints & Coatings

Its reactive structure enables strong adhesion to metal, plastic, and glass surfaces, making it valuable in corrosion-resistant and industrial coatings.

4. Packaging

Improves the adhesion and durability of flexible and rigid packaging materials, especially for food-safe and chemically inert containers.

5. Healthcare & Medical Devices

Used in bio-compatible materials and specialty coatings where durability, clarity, and sterilization compatibility are essential.

Key Benefits of Glycidyl Methacrylate

Dual Reactivity: Combines epoxy and methacrylate chemistry for versatile bonding and polymerization

Enhanced Adhesion: Strong chemical bonding to various substrates including metals, plastics, and ceramics

Thermal and Chemical Resistance: Maintains integrity in harsh environments

Improved Mechanical Properties: Boosts tensile strength, elasticity, and impact resistance in polymers

Compatibility: Easily copolymerized with acrylics, styrene, or vinyl monomers for tailored formulations

Key Market Players

Leading chemical companies are actively investing in R&D to optimize GMA production and create new polymer technologies. Major players include:

Dow Inc.

Mitsubishi Chemical Group

Estron Chemical Inc.

Evonik Industries AG

Kowa American Corporation

Perstorp Holding AB

Nippon Shokubai Co., Ltd.

Lianyungang Ningkang Chem-Tech Co., Ltd.

Shanghai Tianyue Chemicals Co., Ltd.

Future Outlook & Trends

Sustainability Focus: Increasing demand for eco-friendly coatings and adhesives will drive innovation in GMA-based formulations

3D Printing and Additive Manufacturing: GMA’s adaptability in resins makes it ideal for precision printing applications, especially when combined with specialized 3D printing gases that enhance material flow, printing accuracy, and surface finish in high-performance additive manufacturing environments.

Emerging Biomedical Applications: Use in dental resins, implants, and drug delivery materials is gaining traction

Hybrid Polymer Systems: GMA is playing a vital role in blending epoxy and acrylic technologies for high-performance hybrid materials

Asia-Pacific Growth: Surge in electronics manufacturing and infrastructure will keep regional demand high

Conclusion

The Glycidyl Methacrylate market is poised for sustained expansion, backed by its critical role in creating stronger, lighter, and more durable materials. As global industries innovate toward performance, sustainability, and versatility, GMA will remain a cornerstone chemical for advanced polymer development.

Whether it's improving coatings on a car, ensuring insulation on a circuit board, or enhancing the strength of packaging films, glycidyl methacrylate is shaping the future of materials science.

0 notes

Text

3D Printers in Bangalore: Best Models, Local Stores & Printing Services [2025 Guide]

Introduction

The tech capital of India, Bangalore, is fast becoming a hub for 3D printing innovation. With a strong startup ecosystem, engineering talent pool, and growing industrial base, the city is embracing 3D printers for rapid prototyping, design, education, and manufacturing. Whether you're a student, entrepreneur, product designer, or business owner, exploring the best 3D printers in Bangalore can unlock new possibilities for creation and customization.

This comprehensive 2025 guide will help you understand the 3D printer landscape in Bangalore, including top models, local stores, print services, and what to consider before buying.

Why Bangalore Is a Hotspot for 3D Printing

Bangalore's ecosystem is ideal for 3D printing growth because:

It hosts hundreds of tech startups and R&D labs.

Leading engineering colleges and design schools integrate 3D printing into their curriculum.

The city has dozens of 3D printing service bureaus, hardware stores, and industrial suppliers.

Demand is high across sectors like aerospace, electronics, consumer products, and healthcare.

Whether you’re in Koramangala, Whitefield, Electronic City, or Yelahanka, you’ll find 3D printers and support services nearby.

Best 3D Printers Available in Bangalore (2025)

Here are the most popular and recommended 3D printers you can buy in Bangalore today:

1. Creality Ender 3 V3 KE

Type: FDM

Build Volume: 220 x 220 x 250 mm

Price in Bangalore: ₹20,000 – ₹25,000

Ideal For: Beginners, hobbyists, student projects

Where to Buy: Robu.in, WOL3D Indiranagar, Amazon India

2. Anycubic Kobra 2 Max

Type: FDM

Build Volume: 420 x 420 x 500 mm

Price: ₹60,000 – ₹70,000

Ideal For: Large format prints, makerspaces

Available At: WOL3D Bangalore, 3D Bazaar

3. Elegoo Mars 4 Ultra

Type: Resin (MSLA)

Resolution: 9K

Price: ₹22,000 – ₹26,000

Use Cases: Jewelry design, miniature modeling, dental

Available At: Local stores and Amazon India

4. Bambu Lab X1-Carbon

Type: FDM

Build Volume: 256 x 256 x 256 mm

Price: ₹1,10,000 – ₹1,30,000

Known For: Speed, multi-material capability, AI-assisted leveling

Where to Find: Import resellers, WOL3D, 3D Bazaar

5. Raise3D Pro3 Plus

Type: Professional FDM

Build Volume: 300 x 300 x 605 mm

Price: ₹6,50,000+

Best For: Industrial design, manufacturing, batch production

Where to Buy: think3D Bangalore, Exxjet Systems

Where to Buy 3D Printers in Bangalore

Bangalore has several reliable retailers and distributors. Some offer demo units, training, and after-sales support.

🔹 Top 3D Printer Dealers in Bangalore

WOL3D Bangalore – Indiranagar & Yelahanka

Wide range of FDM and resin printers

Official distributor of Creality, Anycubic, Elegoo

Offers filament, resin, accessories

Website: wol3d.com

Exxjet Systems – Yelahanka

Offers 3D scanning, printing, and reverse engineering services

Sells Einscan, FreeScan, and industrial printers

Great for businesses and engineering applications

Website: exxjet.com

think3D Bangalore

Focused on enterprise-grade solutions

Offers Raise3D, FlashForge, Ultimaker, and metal 3D printers

Onsite installation and training included

Website: think3d.in

3D Bazaar & 3Ding Resellers

Active online with quick shipping to Bangalore

Offer Bambu Lab, Prusa, and DIY kits

Custom printer builds also available

3D Printing Services in Bangalore

Not ready to invest in your own printer? Use local 3D printing services in Bangalore for one-off projects or batch jobs.

🔸 Popular 3D Printing Bureaus in Bangalore

Exxjet Systems

Specializes in high-precision industrial 3D printing

Materials: PLA, ABS, PETG, TPU, resin, nylon

Offers reverse engineering and 3D scanning

Ideal for startups and prototyping firms

Fabulyst 3D Printing Studio – Koramangala

Fast-turnaround jobs for consumer goods, fashion, and art

Custom designs, file assistance, and model finishing

3Ding Bangalore

Offers print-on-demand via online upload

Ships anywhere in the city within 2–4 days

Materials: PLA, resin, nylon, carbon fiber

Makerspaces & Labs

Several colleges and coworking spaces offer public access to 3D printers

Example: Workbench Projects, RV College Makerspace

Cost of 3D Printing Services in Bangalore

Service Type

Price Range

FDM Print (per gram)

₹20 – ₹40

Resin Print (per cc)

₹40 – ₹100

3D Scanning

₹1,000 – ₹5,000

Reverse Engineering

₹2,500 – ₹20,000

CAD Modeling

₹1,500 – ₹10,000

Prices vary by material, complexity, and delivery timeline. Local print shops often offer same-day or next-day service for standard jobs.

Industries Using 3D Printers in Bangalore

🏭 Startups & Product Development

Rapid prototyping and iteration

Functional testing before mass manufacturing

🦷 Healthcare & Dental

Customized implants, surgical guides, dental aligners

🛠️ Engineering & Manufacturing

Jigs, fixtures, lightweight parts, and test models

🧠 Education & Design

Architecture, mechanical engineering, STEM learning tools

💎 Jewelry & Art

High-precision casting models and sculptural pieces

Tips for Buying the Right 3D Printer in Bangalore

Define Your Use Case

Resin for details, FDM for strength, and SLS/DMLS for industrial parts

Evaluate Support & Warranty

Choose sellers that offer onsite support in Bangalore

Compare Build Volume & Print Speed

Larger printers cost more but enable big or batch prints

Material Compatibility

Check filament or resin types available locally

Check Community Support

Bangalore has active maker communities and forums (e.g., Reddit, Discord)

Future of 3D Printing in Bangalore

The city is likely to see growth in:

Bioprinting and medical R&D

Construction 3D printing

Metal 3D printing for aerospace/automotive

Integration with AI, CAD, and robotics

With institutions like IISc, NID, and IITs collaborating with startups, Bangalore is leading India’s 3D printing revolution.

Conclusion

If you're searching for 3D printers in Bangalore, you're in the right place. Whether you want to buy a 3D printer, explore on-demand printing services, or join the local maker ecosystem, the city offers everything you need to get started or scale.

From budget-friendly machines to high-end industrial models, Bangalore has the stores, support, and services to make your 3D printing journey smooth and successful. Embrace the future of manufacturing—locally, creatively, and efficiently.

0 notes

Text

Transforming Dental Practices with Advanced 3D Printing Resin

Explore how modern 3D printing resin can cut costs and improve your dental treatments. Take the next step in dental tech now.

The digital age we live in, dentistry is undergoing a technological transformation. From diagnostic imaging to prosthetic creation, modern tools are helping dental professionals work with greater speed, precision, and confidence. Among these innovations, 3D Printing resin and Dental resin have emerged as game changers bringing efficiency and cost-effectiveness to dental laboratories and clinics alike.

These advanced jyoticeramic resins are revolutionizing the dental industry, empowering professionals to deliver higher-quality treatments, faster turnaround times, and better patient experiences.

3D Printing Resin

This is a liquid photopolymer that hardens under UV light, used in stereolithography, digital light processing, and LCD 3D printers. It offers high resolution detail and superior surface finish, making it ideal for intricate models and precision-based components.

In dental applications, this resin allows for accurate printing of surgical guides, dental models, crowns, dentures, and aligners. It reduces material wastage, speeds up production, and allows for repeatable accuracy factors that were challenging to achieve using traditional methods like milling or manual modeling.

Using resin into their workflow, dental professionals and technicians can save time, lower costs, and improve design freedom.

Understanding This Resin and Its Clinical Importance

It is a specialized class of resin formulated for intraoral and extraoral use. It is engineered to meet biocompatibility standards, ensuring safety and comfort for patients.

This resin is used for:

Temporary crowns and bridges

Surgical and diagnostic guides

Orthodontic aligners

Custom impression trays

Permanent dental prosthetics (in some cases)

The precision and biocompatibility of Dental resin make it indispensable in modern restorative and prosthodontic dentistry. It enables the fabrication of appliances and restorations that fit seamlessly and require minimal post-processing adjustments.

Benefits of Using Advanced Resins in Dentistry

Unmatched Accuracy The resin-based 3D printing process allows for micrometer-level precision, which is essential for dental applications where even minor deviations can affect fit and function.

Reduced Production Time With traditional workflows, producing crowns or aligners might take several days. With in-house 3D printers and high-quality resins, this process can be completed in hours.

Cost Savings By eliminating outsourcing and reducing material waste, practices and labs can significantly cut their production costs.

Customization Made Simple Every patient’s anatomy is unique. These resins support fully personalized dental appliances, tailored for fit, performance, and aesthetics.

Enhanced Patient Experience Faster service, better-fitting restorations, and high-quality results lead to greater patient satisfaction and loyalty.

The Role of jyoticeramic in Advancing Resin Technology

It has emerged as a trusted name in the field of technical ceramics and advanced resin solutions. With decades of expertise and a strong commitment to research and innovation, they offer materials that meet the highest standards of safety and performance.

It includes a selection of resin for professional dental and industrial applications. These products are designed for use in high precision SLA/DLP printers and have been rigorously tested for dimensional stability, strength, and biocompatibility.

Dental Practice Use

1. Surgical Guides

Used to assist implant placements with millimeter precision, guides printed with resin help improve surgical outcomes and reduce operative time.

2. Orthodontic Appliances

Aligners and retainers made using resin offer a snug fit and superior clarity perfect for discreet treatment.

3. Prototyping and Restoration

Temporary crowns and bridges can be printed chairside, allowing same-day service and eliminating the wait associated with outsourced labs.

4. Educational Models

Dental schools and training centers use printed models to educate students and explain procedures to patients.

Industrial and Non-Dental Applications

dentistry is a major area of application, but these resin also caters to:

Medical device prototyping

Consumer product design

Jewelry molds and castable models

Precision industrial parts

high resolution and mechanical integrity make it suitable for demanding use cases where accuracy and durability are essential.

The Future of Resin in Dentistry

As dental practices continue to adopt digital tools, the demand for advanced materials will grow. Future innovations are likely to include:

Longer-lasting permanent resins

Resins with antimicrobial properties

Faster-curing and eco-friendly options

Increased color matching for aesthetics

Modern dental techniques are changing as a result of advanced resin. Clinical and commercial benefits include increased efficiency, precision, and patient satisfaction. Dental practitioners can maintain their competitive edge in a market that is changing quickly by adopting these materials and technology.

Using better, reliable solutions like Jyoticeramic's lab or practice may reach new heights of performance. Because work and patients deserve the finest.

Visit: https://www.jyoticeramic.com/jyocure.php

Contact: +91 253 6918111

0 notes

Text

The worldwide dental 3D printing market size boasts a value of $3 billion in 2023, and it is anticipated to undergo remarkable growth at a staggering compound annual growth rate (CAGR) of 22% in the coming decade, culminating in a market worth $21.9 billion by the close of 2033.

#dental 3D printing market#global dental 3D printing market#demand for advanced 3D dental printers#dental 3D printing manufacturers#3D dental printer manufacturers#tooth-shaded 3D printing materials#dental 3D printing technology

1 note

·

View note

Text

Unlocking the Future of Fabrication: How 3DPrintService.in is Powering Innovation in India

The rise of 3D printing has been nothing short of revolutionary. It has transformed how prototypes are built, how ideas are tested, and how customized products come to life — all without the need for traditional large-scale manufacturing setups. In India, one name that stands out in delivering this cutting-edge service is 3DPrintService.in.

Whether you’re an engineer, architect, product designer, entrepreneur, or hobbyist, this platform has become a one-stop solution for high-quality, affordable, and fast 3D printing services.

🧩 What Is 3DPrintService.in?

3DPrintService.in is a specialized online platform that offers on-demand 3D printing for individuals, startups, educational institutions, and industries across India. From rapid prototyping and mechanical part fabrication to architectural models and art installations — the platform turns your digital designs into precise, functional physical objects.

With a combination of advanced printing technologies (FDM, SLA, SLS, etc.) and expert handling, they cater to a wide range of industries including:

Mechanical & Industrial Design

Education & STEM Projects

Consumer Products

Robotics & Drones

Architecture

Healthcare Models

Jewelry Prototyping

🔧 Why Choose 3DPrintService.in?

1. Custom Fabrication at Your Fingertips

At its core, 3DPrintService.in democratizes manufacturing. All you need is a 3D file (like STL or OBJ), and you can get your model printed and shipped right to your doorstep. This is ideal for creators who don’t have access to industrial machinery but still want professional-grade outputs.

2. Affordable Pricing

Unlike many high-end 3D print providers, this service is tailored to the Indian market, offering budget-friendly pricing without compromising on quality. Whether you’re a student working on a capstone project or a startup needing iterative prototypes, they offer pricing that scales to your needs.

3. Diverse Material Options

You can print in materials like:

PLA (eco-friendly)

ABS (durable)

PETG (semi-flexible)

Resin (high detail)

TPU (rubbery/flexible)

Nylon, and more

This flexibility allows clients to match the right material with their project — whether it requires strength, precision, elasticity, or visual appeal.

4. Fast Turnaround Times

3DPrintService.in is known for its quick delivery. Urgent prototyping or last-minute school projects? They’re equipped to get your prints done in hours, not weeks — depending on complexity and size.

5. Pan-India Reach

Based online, the platform accepts orders from anywhere in India. Whether you’re in Delhi, Mumbai, Pune, Bangalore, or a tier-3 town, you can access world-class 3D printing services with just an upload.

🤖 Popular Use Cases

- Robotics & Drones

3DPrintService.in prints lightweight yet strong frames, joints, and custom components for robotic and drone applications. Builders can create modular, repairable, and upgradeable systems easily.

- Educational Models

STEM educators and students use 3D printing to bring learning to life — from working gears and molecules to replicas of historical architecture.

- Mechanical & Automotive

Engineers can prototype parts like gears, enclosures, housings, and fixtures before committing to final manufacturing. This cuts costs and development time drastically.

- Medical & Dental

Anatomical models for training, patient-specific devices, and ergonomic tools are made with precision.

🌐 Easy-to-Use Platform

The website 3DPrintService.in is user-friendly and streamlined:

Upload your design files

Select material, size, and print quality

Receive a quote

Confirm your order

Get your parts delivered quickly

There’s also an option to consult the team directly if you’re unsure about materials, scale, or feasibility.

💡 Beyond Printing: Support & Community

What sets this platform apart is not just the service, but the community support and transparency. Their social channels often showcase completed projects, DIY guides, and customer success stories — encouraging a culture of creativity and open innovation.

They also offer:

Design feedback

File fixing

Batch production

Workshops for schools and startups

✨ Final Thoughts

As India embraces Industry 4.0, platforms like 3DPrintService.in are playing a vital role in making high-tech fabrication accessible to everyone — from college students to SMEs and artists. It breaks down the barriers to manufacturing and empowers users to turn ideas into physical reality with unmatched ease.

If you’re looking for a trusted, flexible, and fast 3D printing partner, look no further than 3DPrintService.in. Upload your design today and see your imagination take shape — layer by layer

0 notes

Text

Applications & Precautions of CNC Machining Acrylic(PMMA)

Acrylic (PMMA) is a highly desirable material due to its strength, toughness and transparency. However, it may not be practical to rely on conventional processing to cut acrylic as the material is very fragile and any excessive force can lead to unwanted breakage.

Nevertheless, CNC machining offers a reliable method of manufacturing acrylic parts safely, with high precision and minimal waste of trim. CNC machining produces very few errors, allowing the manufacture of high quality acrylic parts and prototypes such as headlamps, housings, jewellery and more.

Advantages of Acrylic CNC Machining

As a CNC machined plastic, acrylic has many inherent advantages. Excellent transparency comparable to glass, Lighter weight than glass, Excellent dimensional stability, Good tensile and flexural strength, Good insulation level, Anti-wear, Anti-UV & sunlight, Good biocompatibility, Relatively low cost, Can be solvent bonded, Easy to polish, Available in a wide range of colours, Recyclable.

Choosing CNC machined acrylic over molding or 3D printing can bring additional benefits, some of the main advantages of machined acrylic include:

1.Material compatibility Acrylic is a thermoplastic that is malleable when heated, making it ideal for CNC machining. This inherent property makes it easy to fabricate and shape acrylic using this precise and efficient process.

2.Manufacture of High-Precision parts CNC machines offer extremely high cutting accuracy with tolerances down to thousandths of an inch. This level of high accuracy is particularly important when working with materials such as acrylic, where the need for neat edges and dimensional accuracy is critical.

3.Increasing productivity CNC machining is one of the most efficient ways to manufacture acrylic materials, especially when producing small batches of acrylic parts. The process allows for faster production speeds compared to manual methods, resulting in increased efficiency and productivity in acrylic manufacturing.

4.Reducing waste Thanks to its precise manufacturing method, the CNC machining is able to cut acrylics with optimum force, avoiding irreversible damage. This enables fast and efficient production of acrylic components with precise shapes and sizes. Using CNC machining increases accuracy and minimises waste in the manufacturing process.

5.Achieve high repeatability The automated CNC process ensures consistency across multiple parts or batches, thus ensuring consistent reproduction accuracy for each part. This reliability is a key benefit of CNC machining, especially in maintaining uniformity and accuracy in the production of acrylic parts.

6.Saving on manufacturing costs CNC machining can provide significant manufacturing cost savings due to reduced material waste, increased efficiency and lower labour costs. The precision and automation of CNC helps to achieve a leaner, more cost-effective production process.

Applications of Acrylic CNC Machining

CNC machined acrylic has many industrial uses, with the material being most widely used in the optical and automotive industries.

Alternatives to Glass

Due to its excellent transparency and clarity, acrylic is used as a replacement for shatterproof glass in many industries, including automotive, aerospace and optical.

Acrylic is commonly used as a glass replacement for window structures in aquariums, submarines, and hockey arenas. It is also used in the manufacture of lighting components such as headlights in the automotive industry. However, lights used in optical and automotive applications often have complex shapes and may also require very tight tolerances to provide optimal performance.

Medical and Dental

Due to its good biocompatibility, acrylic can be used in a variety of medical applications, including cosmetic surgery, where it can be used as a dermal filler. Acrylic can also be used as a bone cement in orthopaedic surgery (often used in fracture repair, joint replacement surgery or in vertebroplasty to fix the vertebrae, stabilize the spine and alleviate pain), as well as in dentistry for a variety of purposes (e.g. dentures).

Consumer goods

The aesthetics of acrylic make it suitable for a wide range of consumer products from furniture to consumer electronics to musical instruments.

Precautions When Machining Acrylic

Acrylic is a useful and versatile material, but it usually fails when subjected to compressive and tensile forces. This means that machining the desired shapes and cavities into acrylic panels requires care and attention.

However, the digital precision of CNC machining greatly simplifies this task. It also greatly increases the speed of acrylic machining and allows input parameters to be programmed to meet a wide range of needs.

Workpiece clamping

Plastics and metals have different workpiece clamping requirements, and acrylic is no exception in this regard. All areas of the material must be clamped using jigs and vises (smaller parts) or using adhesives to secure the entire part to the table (larger parts). If budget allows, a vacuum table is best suited for acrylic machining because it can effectively clamp and unclamp the material without damaging it.

Machining

CNC machining of acrylic typically requires a steady feed rate. Feed rates that are too low can lead to heat build-up and chips sticking back to the part, which can greatly reduce the quality of the surface finish. Another way to prevent heat build-up is to pre-cool the acrylic material before machining begins to allow for better chip removal. During machining, it is best to use oil-free coolants as they do not react with the plastic.

Surface finishing

For an aesthetically pleasing product, acrylic needs to be polished after CNC machining to produce optimum clarity and light transmission in the part. This is usually done by using progressively finer grit sandpaper followed by hand polishing with a linen towel and polishing paste. For high-quality prototypes, such as automotive headlight lenses or taillight lenses, or windows for electronics, polishing must be done by hand, a job done by the most experienced and skilled employees.

To create a diffusion effect on acrylic parts, the surface can be sandblasted and textured, while milky white paint offers another aesthetic option. Or to colour the part while maintaining transparency, it can be painted and coloured after hand polishing.

Conclusion

Acrylic is widely used for its strength, toughness and transparency, and CNC machining provides a reliable method for manufacturing high-quality acrylic parts. Acrylic machining has a variety of industrial applications, such as optical, automotive, and medical, but requires care and attention to post-processing such as clamping and polishing. Benefits include good material compatibility, manufacturing high precision parts, increasing productivity, reducing waste, achieving high repeatability and saving manufacturing costs.

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#cnc machining service#cnc machining services#cnc machining plastic parts#cnc machining parts#plastic cnc#cnc plastic part#cnc plastic#cnc plastic machining#plastic cnc machining#acrylic machining#pmma cnc machining#acrylic

2 notes

·

View notes

Text

Why Europe is Leading the Veterinary 3D Printing Revolution

Introduction

The Europe Veterinary 3D Printing Market is undergoing a transformative phase, driven by technological advancements in additive manufacturing and increasing demand for customized medical solutions in veterinary medicine. This market, valued at $41.42 million in 2024, is projected to expand at a compound annual growth rate (CAGR) of 11.1% over the forecast period. The integration of artificial intelligence (AI), bioprinting, and cloud-based 3D printing platforms is revolutionizing veterinary healthcare by enabling personalized treatments, reducing surgical risks, and enhancing rehabilitation solutions. With growing investments from veterinary tech firms, research institutions, and biotech companies, the sector is poised for significant expansion, minimizing dependency on traditional treatment methods and enhancing precision in veterinary procedures.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40639-europe-veterinary-3d-printing-market

Europe Veterinary 3D Printing Market Analysis

Key Growth Drivers

Advancements in Additive Manufacturing The continuous evolution of 3D printing technologies, including selective laser sintering (SLS) and stereolithography (SLA), is enabling the creation of highly precise prosthetics, implants, and anatomical models. This has led to improved treatment outcomes and greater efficiency in veterinary surgical procedures.

Rising Demand for Personalized Veterinary Treatments The shift toward customized treatment approaches, such as patient-specific implants and prosthetic solutions, is driving the adoption of 3D printing in veterinary hospitals and clinics across Europe.

Increased Adoption in Veterinary Research and Education Research institutions and academic centers are leveraging 3D printing to create anatomical models for surgical training, enhancing veterinary education and research capabilities.

Integration of AI and CAD for Precision Printing The use of AI-powered modeling and computer-aided design (CAD) software is refining the accuracy of 3D-printed veterinary models, minimizing surgical errors and improving pre-surgical planning.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40639-europe-veterinary-3d-printing-market

Challenges Hindering Market Expansion

High Initial Costs: The procurement and maintenance of advanced 3D printing equipment require substantial investment, which may limit adoption among smaller veterinary clinics.

Material Constraints: Limited availability of biocompatible materials suitable for veterinary applications is a key barrier to market expansion.

Regulatory Challenges: The absence of standardized protocols for veterinary 3D printing, especially for implantable devices, poses commercialization hurdles.

Key Europe Veterinary 3D Printing Market Trends

Emerging Technologies in Veterinary 3D Printing

Bioresorbable Implants: These implants facilitate natural tissue regeneration, reducing the need for secondary surgeries.

3D-Printed Dental Solutions: Veterinary dentistry is experiencing a surge in 3D-printed dental implants, enabling precise and durable solutions for oral health issues.

Cloud-Based 3D Printing Platforms: These platforms are improving accessibility to customized prosthetics and implants, enabling veterinary professionals across Europe to leverage advanced printing solutions remotely.

Investment in Bioprinting and Regenerative Medicine

The increasing focus on bioprinting technologies aims to develop tissue-engineered grafts and regenerative solutions for veterinary applications. This segment is expected to drive significant market growth as researchers explore bioengineered tissues and 3D-printed organoids for treating complex veterinary conditions.

Europe Veterinary 3D Printing Market Segmental Analysis

Europe Veterinary 3D Printing Market By Component

Hardware: Leading segment due to the growing adoption of advanced 3D printers.

Software: Fastest-growing segment driven by increasing demand for AI-powered modeling tools.

Services: Includes consulting, maintenance, and custom printing solutions.

Europe Veterinary 3D Printing Market By Material

Polymers: Most widely used due to affordability, flexibility, and biocompatibility.

Metals: Titanium-based implants gaining traction for orthopedic applications.

Ceramics: Used in dental prosthetics for durability and precision.

Biomaterials: Increasingly utilized in regenerative medicine and tissue engineering.

Europe Veterinary 3D Printing Market By Technology

Stereolithography (SLA): Dominant segment due to high precision in anatomical modeling.

Selective Laser Sintering (SLS): Rapidly growing, enabling complex implant structures with high mechanical strength.

Fused Deposition Modeling (FDM): Popular for cost-effective prosthetic manufacturing.

Digital Light Processing (DLP): Offers high-resolution printing for veterinary applications.

Europe Veterinary 3D Printing Market By Application

Prosthetics & Orthotics: Largest segment, accounting for nearly 47% of the market.

Surgical Guides & Models: Essential for pre-surgical planning and veterinary education.

Dental Implants: Rising demand for customized dental solutions in companion animals.

Tissue Engineering: Fastest-growing segment with potential in regenerative veterinary medicine.

Drug Delivery: Expanding with the development of 3D-printed drug-eluting implants.

Europe Veterinary 3D Printing Market By End-User

Veterinary Hospitals & Clinics: Dominating segment, driven by increasing adoption of 3D printing for surgical planning and prosthetic development.

Veterinary Research Institutes: Rapid growth due to rising investment in bioprinting research and regenerative medicine.

Europe Veterinary 3D Printing Market By Country

Germany: Market leader due to strong research initiatives and advanced veterinary infrastructure.

U.K.: Rapidly expanding, fueled by increasing investments in veterinary 3D printing technologies.

France: Significant market presence with growing adoption of precision veterinary medicine.

Spain: Emerging market with rising integration of 3D printing in veterinary clinics.

Rest of Europe: Includes key markets such as Switzerland, Belgium, and the Netherlands, contributing to overall market expansion.

Competitive Landscape & Recent Developments

Key Players in the Europe Veterinary 3D Printing Market

WIMBA

Vet3D

Bio3Dvet

Novus Life Sciences

r3volutionD

3D-Side

RTsafe

Invent Medical

Axial3D

Supercraft3D

Cella Medical Solutions

Metamason

Vimian

CABIOMEDE Vet

Materialise

Recent Innovations & Developments

February 2025: r3volutionD AG launched a new range of 3D-printed titanium implants and dental prosthetics for equine healthcare.

January 2025: Materialise NV partnered with veterinary clinics to implement its Mimics Innovation Suite for patient-specific anatomical modeling.

November 2024: 3D Systems Corporation expanded its veterinary product portfolio with biocompatible 3D printing materials for orthopedic applications.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40639-europe-veterinary-3d-printing-market

Conclusion

The Europe Veterinary 3D Printing Market is poised for sustained growth, driven by technological innovations, increasing adoption in veterinary research, and rising demand for personalized animal healthcare solutions. The integration of AI, cloud-based platforms, and regenerative medicine technologies will continue to shape the future of veterinary 3D printing. As the industry advances, collaboration between veterinary professionals, biotech firms, and additive manufacturing companies will be crucial in enhancing accessibility, affordability, and efficiency in veterinary treatments.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Europe Veterinary 3D Printing Market#Veterinary 3D Printing#3D Printing in Veterinary Medicine#Europe Pet Healthcare#Animal 3D Printing#Veterinary Prosthetics#3D Printed Animal Implants#Veterinary Technology#Europe Veterinary Innovation#3D Printing for Animals#Veterinary Orthopedics#Pet Healthcare 3D Printing#Animal Prosthetics Market#Europe Veterinary Equipment#Advanced Veterinary Solutions#Veterinary 3D Bioprinting#Custom Veterinary Implants#Digital Veterinary Solutions#3D Printing Market Trends#Veterinary Medical Devices

1 note

·

View note

Text

The Future in Layers: Understanding 3D Printing

3D printing, also known as additive manufacturing, is transforming how we design, create, and innovate. What once belonged to the realm of science fiction is now a powerful tool used in industries ranging from healthcare to aerospace. By building objects layer by layer from digital models, 3D printing offers flexibility, customization, and speed that traditional manufacturing often can’t match. 3D Printing

How 3D Printing Works At its core, 3D printing begins with a digital design, usually created using computer-aided design (CAD) software. The model is then sliced into thin horizontal layers. The 3D printer reads these slices and deposits material — usually plastic, resin, metal, or even food — layer by layer until the final object takes shape.

There are several types of 3D printing technologies, including:

Fused Deposition Modeling (FDM) — Melts plastic filament and extrudes it layer by layer.

Stereolithography (SLA) — Uses UV light to cure liquid resin into solid layers.

Selective Laser Sintering (SLS) — Uses lasers to fuse powdered material, often metals or plastics.

Applications of 3D Printing

Healthcare: 3D printers are used to create prosthetics, dental implants, and even bioprinted tissues. Customization is key — no two patients are the same, and 3D printing makes it possible to tailor medical devices to individual needs.

Manufacturing: Prototyping with 3D printing is faster and more cost-effective than traditional methods. Companies can test and modify designs before full-scale production.

Education: Schools and universities use 3D printing to bring concepts to life in science, engineering, and art.

Architecture: Architects can produce detailed models and even explore 3D-printed housing for rapid, affordable construction.

Fashion & Art: Designers use 3D printing to create unique jewelry, clothing, and sculptures, often unachievable by hand.

Advantages of 3D Printing

Customization: Easily adapt designs for specific users or needs.

Speed: Rapid prototyping accelerates product development.

Reduced Waste: Additive processes use only the material needed.

Accessibility: Desktop 3D printers make production possible at home or in small businesses.

Challenges and Limitations Despite its promise, 3D printing faces challenges. Materials can be expensive or limited in strength and durability. Printing large objects can be time-consuming, and the technology still requires skilled operators for optimal results. Regulatory and safety standards are also developing to catch up with rapid innovation.

The Future of 3D Printing Looking ahead, 3D printing is poised to revolutionize supply chains, reduce environmental impact, and even explore new frontiers like space manufacturing. As the technology matures, we may see everyday products — from shoes to electronics — custom-printed just for us.

0 notes

Text

The Future of Dentistry: Modern Dental Materials Making a Difference

The field of dentistry has come a long way from the days of basic fillings and simple tools. Today, the future of dentistry is being shaped by cutting-edge dental materials, advanced dental equipment, and more precise dental instruments and tools than ever before. These modern solutions are not only improving the quality of dental care but also making treatments faster, safer, and more comfortable for both patients and dentists.

Advancements in Dental Materials

New dental materials are changing how treatments are done, how long results last, and how comfortable the process is for patients. From high-strength ceramics to bio-compatible composites, the shift is clear — we are now treating patients with smarter, stronger, and safer materials.

Composite Resins and Smart Materials

One of the most exciting developments in recent years is the evolution of composite resins. These materials are more durable and aesthetically pleasing, often blending perfectly with natural teeth. Smart composites can even respond to changes in the oral environment, offering protection against bacteria and minimizing tooth decay.

3D Printed Dental Components

3D printing is also entering the dental space with force. Using digital designs, clinics can now create crowns, bridges, and dentures with exact precision. This not only reduces waiting time but also ensures a better fit for the patient.

Better Materials, Better Tools

Advanced materials go hand in hand with better tools. As dental implant instruments, operative dentistry instruments, and oral surgery instruments evolve, they are designed specifically to work with modern materials. For example, new dental handpieces are built to operate efficiently with hard ceramic surfaces while keeping the patient comfortable.

If you're setting up a clinic or upgrading your tools, it's essential to match your materials with high-quality dental instruments and tools. (You can learn more about that in our article on How to Choose the Right Dental Equipment for Your Clinic Setup) — a complete guide to building the right foundation for your clinic.)

The Role of Single-Use & Sterile Materials

In today's dental world, safety is as important as treatment results. The use of disposable dental supplies has increased drastically to prevent cross-contamination. From sterile cotton rolls to single-use mirrors and suction tips, clinics are moving toward safer practices using high-quality materials.

The demand for safe materials has also given rise to more eco-friendly options, allowing clinics to be responsible with both patient care and the environment.

Impact on Specialized Dentistry

New dental materials are not only helping general dentists — specialists like periodontists, oral surgeons, and orthodontists are benefiting too.

Periodontal surgical instruments now come with non-stick coatings and ergonomic designs

Perio instruments are lighter, sharper, and better suited for deep-cleaning tasks

Ortho surgical instruments are more precise, improving treatment for braces and aligners

Dental implant instruments now support safer, faster procedures with bio-compatible materials

These improvements directly impact how effective and efficient treatments can be in any dental practice.

Choosing the Right Suppliers for Modern Materials

While modern materials are widely available, not all suppliers offer the same quality. If you're sourcing from dental equipment suppliers in UAE, make sure they offer the latest material-compatible tools and supplies. A reliable dental supply store will also guide you on the best options based on your treatment style.

Whether you're in Dubai, Sharjah, or looking for laboratory equipment suppliers in Abu Dhabi, selecting a supplier who keeps up with trends in materials and tools is key.

Final Thoughts: Materials that Matter

Modern dental materials are not just upgrades — they’re game-changers. They help patients heal faster, reduce the need for repeated treatments, and support longer-lasting results. From dental diagnostic instruments to the most advanced ceramics, everything is moving toward smarter solutions.

If you want to stay competitive in the ever-evolving world of dentistry, it's important to combine new materials with high-quality instruments. And if you haven’t already planned your clinic setup around modern tools and tech, be sure to check out our guide on how to choose the right dental equipment for your clinic setup — it walks you through the essentials of building a future-ready practice.

0 notes