#Demand for Polymer Emulsion

Text

Polymer Emulsion Market: Uncovering the Potential of High-Performance Coatings

The polymer emulsion market refers to the global industry involved in the production, distribution, and application of polymer emulsions. Polymer emulsions are colloidal dispersions of polymers in water or other solvents, stabilized by surfactants. They find extensive utilization in various industries, including paints and coatings, adhesives, textiles, paper, and healthcare, owing to their versatility, cost-effectiveness, and eco-friendly nature. This article provides a comprehensive overview of the polymer emulsion market, including its current state, key drivers and challenges, major applications, regional analysis, and future growth prospects.

Market Overview:

The global polymer emulsion market has witnessed significant growth over the years, driven by increasing demand from end-use industries and technological advancements in emulsion polymerization processes. The market size was valued at USD XX billion in 2021, and it is expected to reach USD XX billion by 2028, growing at a CAGR of XX% during the forecast period (2021-2028).

Key Drivers:

Growing Demand from Paints and Coatings Industry: Polymer emulsions are widely used as binders in the paints and coatings industry due to their superior properties such as excellent adhesion, flexibility, and water resistance. The booming construction and automotive sectors are fueling the demand for paints and coatings, thereby driving the polymer emulsion market.

Shift towards Water-based Formulations: Stringent environmental regulations and increasing consumer preference for eco-friendly products have led to a shift from solvent-based formulations to water-based formulations. Polymer emulsions serve as ideal substitutes for solvent-based systems, contributing to market growth.

Increasing Demand for Adhesives and Sealants: The construction, packaging, and automotive industries are witnessing a surge in demand for high-performance adhesives and sealants. Polymer emulsions provide excellent bonding properties, moisture resistance, and improved workability, making them an essential component in adhesives and sealants production.

Advancements in Emulsion Polymerization Techniques: Ongoing research and development activities in emulsion polymerization processes have led to the development of novel and more efficient polymer emulsions. These advancements, such as controlled particle size distribution and improved stability, are driving market growth.

Challenges:

Volatile Raw Material Prices: The prices of raw materials used in the production of polymer emulsions, such as monomers and surfactants, are subject to fluctuations. This volatility poses a challenge to manufacturers in terms of cost management and profitability.

Intense Market Competition: The polymer emulsion market is highly competitive, with numerous global and regional players vying for market share. Intensified competition poses challenges in terms of pricing, product differentiation, and market penetration.

Major Applications:

Paints and Coatings: Polymer emulsions are extensively used in architectural paints, decorative coatings, wood coatings, and industrial coatings for their excellent film-forming properties, color stability, and durability.

Adhesives and Sealants: Polymer emulsions serve as key ingredients in the production of water-based adhesives and sealants, providing excellent bonding strength, flexibility, and adhesion to various substrates.

Textiles: Polymer emulsions find application in the textile industry for coating and finishing operations, imparting properties such as wrinkle resistance, flame retardancy, and water repellency.

Paper: Polymer emulsions are used in paper and paperboard manufacturing to improve surface smoothness, printability, and strength of the final product.

Regional Analysis:

The polymer emulsion market is segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Asia Pacific holds the largest market share due to rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also contribute significantly to the market growth, driven by the demand from end-use industries and increasing environmental awareness.

Future Outlook:

The polymer emulsion market is poised for substantial growth in the coming years. Factors such as rising environmental concerns, stringent regulations, and the need for sustainable solutions will continue to drive the market. Additionally, advancements in technology, research and development, and expanding application areas are expected to create new opportunities for market players. However, the market may face challenges such as raw material price volatility and intense competition, which need to be effectively managed to ensure sustained growth.

Conclusion:

The polymer emulsion market is witnessing significant growth, driven by the increasing demand from various end-use industries. With its wide range of applications, eco-friendly nature, and technological advancements, polymer emulsions are expected to continue playing a crucial role in diverse sectors. Market players need to focus on innovation, product differentiation, and strategic partnerships to capitalize on the market opportunities and maintain a competitive edge in this dynamic industry.

0 notes

Text

Static Mixer Market - Forecast(2024 - 2030)

Static Mixer Market Overview:

The static mixers are market has been growing rapidly mainly due to used extensively for extensively use of static mixer in the process of homogenization various hominization process in various the industrial operations such as food processing, heat transfer, chemical reactions, polymer blending, and cosmetics and pharmaceutics, but also for in water treatment of waste water. The global Static Mixer Market size is estimated to grow at a CAGR of 5.1% during the forecast period i.e. 2018—-2023. The APAC region is estimated calculated to be as the largest segment for market for Static Mixers, with holding a share of 35.28% of the overall market in by 2023, and itsthe value is estimated to grow toreach $965.28mM by 2023. The rising market in China and India, particularly for disposable static mixers will drive the market.

Request Sample

Static Mixer Market Outlook:

The static mixer is also known as a motionless mixer, this device is basically inserted into housing or pipelines with the objective to handle or control the fluid streams. Insertion of a static mixer significantly accelerates inline mixing or reaction. This market includes the technique essentially desirable for inexpensive, fast and continuous operation. According to IndustryARC findings, iIndustrial static mixers will hold the largest market share during the forecast period. In the industrial static mixer, there is a very broad range of applications are incorporated in fluid processing industries such as Chemical Industry, Oil, Gas & Petrochemicals, Plastics Injection Molding & Extrusion, Polymer Production, and other industries. The Industrial segment of the static mixer market was valued at $459.28m in 2017 and by type is estimated to reach $581.29m by 2023, M growing at a CAGR of 4.5% during the forecast period of 2018—-2023 by 2023 from $459.28m M in 2017 and is forecast to grow at a CAGR of 4.5% during the forecast period of 2018-2023.

The average selling price of disposable static mixer was estimated to be $0.75 per unit in 2017 and is anticipated to reach $0.59 per unit. This decline in ASP is more compared to non-disposable static mixer due to the decline in the plastic prices and the increasing number of Chinese players in disposable static mixer market that provides the less priced products.The decline in average selling price of disposable static mixers is higher as compared tothan that of non-disposable static mixers because of the increasing number of Chinese players in the disposable static mixer market offering that offer low-cost products; and also, due to the drop in plastic prices.

Static Mixer Market Growth Drivers:

According to the Organisation for Economic Co-operation and DevelopmentOrganization For Corporation and Development (OECD), in manufacturing sector, countries such as Estonia, Lithuania, the Czech Republic, Brazil, and Slovenia are anticipated to witness a have significant increase of SMEs in the manufacturing sectorin SME’s. The growing number of SMEs coupled with the growing demand for the static mixers in various end- user industries such as water treatment, oil & gas, pulp and paper, and food & beverage for mixing, blending, dispersion, heat transfer, mass transfer, solids suspension, dosing, emulsion formation, dissolution, pH adjustment, and dilution is expected to strengthen the static mixers market growth. The rising market for disposable static mixers in China and India, particularly for disposable static mixers will also act as a growth driver.drive the market.

Inquiry Before Buying

Static Mixer Market Challenges:

Though the helical static mixers market has continued to be in matured over stage the since past 15 recent years, . The customers are still viewing the helical static mixers as a commodity, and are ignoring the difference between the offerings andor performance. This view of customers towards helical static mixers is anticipated to give rise provide prospects to the new entrants in the market offeringthat offer which offers the helical static mixers for at huge price variations. This price variation is anticipated to further result in decreased margins for major players and lessen the number of distribution channels, thereby affecting the overall profitability of the manufacturers of helical static mixers. Thus, the increasing number of new players in the manufacturing of helical static mixers with huge price variation is anticipated to hampering the revenue growth of helical static mixers;, which in turn and consequently, affectings the entire Sstatic Mmixer market growth.

Number of SMEs and Large Enterprises in Brazil, 2012—-2017

Schedule a Call

Static Mixer Market Research Scope:

The base year of the study is 2017, with forecast done up to 2023. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the plastics in electric vehicleStatic Mixer market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of static mixer market, and itstheir specific applications in different end user industries in different types of vehicles.

Static Mixer Market Report: Industry Coverage

Types of Static Mixer Market — By Type: Industrial, Laboratory

Structure of Static Mixer Market — By Structure: Helical, Square, Plate

Usage of Static Mixer Market — By Usages: Disposable, Non Disposable

Flow of Static Mixer Market — By Flow: Laminar flow, Turbulent flow, Transitional fFlow

End Users of Static Mixer Market — By End Users: Water Treatment, Oil & Gas, Pulp and Paper, Food and Bbeverages, Pharmaceuticals, Construction, Chemicals, HealthCare and Cosmetics, Mining and Metal, Transportation, and Power Generation.

The Static Mixer market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Chile, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

Static Mixer Market Key Players Perspective:

Nordson Xaloy, SPX Corporation, and Sulzer Ltd. were analyzed to be the dominant players ofin the Static Mixer market in 2017, with a share of 12.7%, 11.4% and 8.8% respectively. EThe extensive product portfolio, along with well- diversified sales and distribution network, provides avail significant exposure and visibility to these players in the market.

Some of the other key players mentioned in this report are DuPont, BASF SE, Solvay SA, Covestro (Bayer), DSM NV, Toray Industries, Celanese Corporation, RTP Company, and Mitsui Chemicals America among others.

Buy Now

Static Mixer Market Trends:

The U.A.E. has planned to establish a comprehensive hub for international pharmaceutical companies, and the country is planning to double its drug manufacturing factories by 2021. As of now, the country has 54 pharmaceutical firms in the region. These i The iIncreasinge in the number of pharmaceutical firms coupled with the deployment of static mixers for various applications such as penicillin production, syrup dilution, and others is anticipated to provide offer prospects for the Static Mixer market.

The manufacturers of static mixers are actively investing in R&D, research and the development of static mixers. These increasing the chances of investments in R&D is primarily responsible for the launching of new products with advanced technology. One such instance is was the launch of PerfectPeak™ 3D Printed Static Mixer by Motto Corp. This product has incorporated incorporates 3D printing technology to reduce the baseline noise significantly. Thus, the increasing investments in R&D is anticipated to provide ample amount of opportunities for Static Mixer market in near future

Water is a critical global resource now and for the future. With the world population expected to reach 9.8 bBillion by 2050 coupled with extensive industrial growth, there is tremendous a pressing need for recycling and reusing of the water. Growing industrialization coupled with erratic rain fall patterns due to climate change in developing countries has resulted in lowering and depletion of water resources. At this juncture, governments around the world have started focusing on setting upthe water treatment plants. This is set to drive the market for the Static Mixers.

DThe dental implants, where the static mixers have direct applications, is one market that is set to witness tremendous growth in the future due to the increased increasing number of dental clinics in developed countries and the growing awareness about dental hygiene in emerging economies. The rising demand for better oral hygiene services coupled with the growing disposable incomes is set to boost the market for dental services.

#static mixer market#static mixer market size#static mixer market shape#static mixer market forecast#static mixer market analysis#static mixer market report#static mixer market growth#motionless mixer#food processing#Water And Wastewater Treatment Technologies#chemical reactions#polymer blending

0 notes

Text

Opaque Polymers Market Position, Trends, Size, Vendors, and Applications by 2024-2031

The "Opaque Polymers Market" is a dynamic and rapidly evolving sector, with significant advancements and growth anticipated by 2031. Comprehensive market research reveals a detailed analysis of market size, share, and trends, providing valuable insights into its expansion. This report delves into segmentation and definition, offering a clear understanding of market components and drivers. Employing SWOT and PESTEL analyses, the study evaluates the market's strengths, weaknesses, opportunities, and threats, alongside political, economic, social, technological, environmental, and legal factors. Expert opinions and recent developments highlight the geographical distribution and forecast the market's trajectory, ensuring a robust foundation for strategic planning and investment.

What is the projected market size & growth rate of the Opaque Polymers Market?

Market Analysis and Insights

Global Opaque Polymers Market

Data Bridge Market Research analyses that the opaque polymers market will witness a CAGR of 10.50% for the forecast period of 2022 to 2029. The rapid rise of the opaque polymers market is being fuelled by rising TIO2 pricing.

Opaque polymer is a styrene acrylic copolymer emulsion that gives emulsion paint its opacity. The emulsion particle is a styrene-acrylic copolymer bead, a sophisticated polymeric opacifier designed to boost TiO2 efficiency. The opaque polymer can help minimize raw material costs and increase concealment in various items.

Rust remover is becoming more popular in paints and coatings, personal care, and detergents and is predicted to be one of the market's primary drivers during the forecast period of 2022-2029. Increased demand for architectural paints in the building industry and the rising need for rust remover in paints and coatings, personal care, and detergent activates are all driving market expansion. In the projected period, modernization and diversity in the end-user industry will generate new opportunities for the opaque polymers market in the forecast period of 2022- 2029.

However, worse hiding performance than TIO2 and fluctuation in raw material prices are the key reasons acting as barriers, which will continue to hamper the growth of the opaque polymers market throughout the forecast period.

This opaque polymers market report provides details of new recent developments, trade regulations, import export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographical expansions, technological innovations in the market. To gain more info on opaque polymers market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

Browse Detailed TOC, Tables and Figures with Charts which is spread across 350 Pages that provides exclusive data, information, vital statistics, trends, and competitive landscape details in this niche sector.

This research report is the result of an extensive primary and secondary research effort into the Opaque Polymers market. It provides a thorough overview of the market's current and future objectives, along with a competitive analysis of the industry, broken down by application, type and regional trends. It also provides a dashboard overview of the past and present performance of leading companies. A variety of methodologies and analyses are used in the research to ensure accurate and comprehensive information about the Opaque Polymers Market.

Get a Sample PDF of Report - https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-opaque-polymers-market

Which are the driving factors of the Opaque Polymers market?

The driving factors of the Opaque Polymers market include technological advancements that enhance product efficiency and user experience, increasing consumer demand driven by changing lifestyle preferences, and favorable government regulations and policies that support market growth. Additionally, rising investment in research and development and the expanding application scope of Opaque Polymers across various industries further propel market expansion.

Opaque Polymers Market - Competitive and Segmentation Analysis:

Global Opaque Polymers Market, By Type (Solid Content 30%, Solid Content 40%), Application (Paints and Coatings, Personal Care, Detergents), Country (U.S., Canada, Mexico, Germany, France, U.K., Italy, Spain, Russia, Turkey, Belgium, Netherlands, Switzerland, Luxemburg, Rest of Europe, Japan, China, South Korea, India, Australia And New Zealand, Singapore, Thailand, Malaysia, Indonesia, Philippines, Rest of Asia-Pacific, Brazil, Argentina, Rest of South America UAE, Saudi Arabia, Egypt, Israel, South Africa, And Rest Of Middle East and Africa) Industry Trends and Forecast to 2031.

How do you determine the list of the key players included in the report?

With the aim of clearly revealing the competitive situation of the industry, we concretely analyze not only the leading enterprises that have a voice on a global scale, but also the regional small and medium-sized companies that play key roles and have plenty of potential growth.

Which are the top companies operating in the Opaque Polymers market?

Some of the major players operating in the opaque polymers market report are Ashland, Croda International Plc, En-Tech Polymer. Co., Ltd, EC21 Inc., GUANGZHOU JUNNENG CHEMICALS CO., LTD., Organik Kimya., Dow, and Visen Industries Limited among others.

Short Description About Opaque Polymers Market:

The Global Opaque Polymers market is anticipated to rise at a considerable rate during the forecast period, between 2024 and 2031. In 2023, the market is growing at a steady rate and with the rising adoption of strategies by key players, the market is expected to rise over the projected horizon.

North America, especially The United States, will still play an important role which can not be ignored. Any changes from United States might affect the development trend of Opaque Polymers. The market in North America is expected to grow considerably during the forecast period. The high adoption of advanced technology and the presence of large players in this region are likely to create ample growth opportunities for the market.

Europe also play important roles in global market, with a magnificent growth in CAGR During the Forecast period 2024-2031.

Opaque Polymers Market size is projected to reach Multimillion USD by 2031, In comparison to 2024, at unexpected CAGR during 2024-2031.

Despite the presence of intense competition, due to the global recovery trend is clear, investors are still optimistic about this area, and it will still be more new investments entering the field in the future.

This report focuses on the Opaque Polymers in global market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report categorizes the market based on manufacturers, regions, type and application.

Get a Sample Copy of the Opaque Polymers Report 2024

What are your main data sources?

Both Primary and Secondary data sources are being used while compiling the report. Primary sources include extensive interviews of key opinion leaders and industry experts (such as experienced front-line staff, directors, CEOs, and marketing executives), downstream distributors, as well as end-users. Secondary sources include the research of the annual and financial reports of the top companies, public files, new journals, etc. We also cooperate with some third-party databases.

Geographically, the detailed analysis of consumption, revenue, market share and growth rate, historical data and forecast (2024-2031) of the following regions are covered in Chapters

What are the key regions in the global Opaque Polymers market?

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia and Vietnam)

South America (Brazil, Argentina, Columbia etc.)

Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa)

This Opaque Polymers Market Research/Analysis Report Contains Answers to your following Questions

What are the global trends in the Opaque Polymers market?

Would the market witness an increase or decline in the demand in the coming years?

What is the estimated demand for different types of products in Opaque Polymers?

What are the upcoming industry applications and trends for Opaque Polymers market?

What Are Projections of Global Opaque Polymers Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

Where will the strategic developments take the industry in the mid to long-term?

What are the factors contributing to the final price of Opaque Polymers?

What are the raw materials used for Opaque Polymers manufacturing?

How big is the opportunity for the Opaque Polymers market?

How will the increasing adoption of Opaque Polymers for mining impact the growth rate of the overall market?

How much is the global Opaque Polymers market worth? What was the value of the market In 2020?

Who are the major players operating in the Opaque Polymers market? Which companies are the front runners?

Which are the recent industry trends that can be implemented to generate additional revenue streams?

What Should Be Entry Strategies, Countermeasures to Economic Impact, and Marketing Channels for Opaque Polymers Industry?

Customization of the Report

Can I modify the scope of the report and customize it to suit my requirements? Yes. Customized requirements of multi-dimensional, deep-level and high-quality can help our customers precisely grasp market opportunities, effortlessly confront market challenges, properly formulate market strategies and act promptly, thus to win them sufficient time and space for market competition.

Inquire more and share questions if any before the purchase on this report at - https://www.databridgemarketresearch.com/inquire-before-buying/?dbmr=global-opaque-polymers-market

Detailed TOC of Global Opaque Polymers Market Insights and Forecast to 2031

Introduction

Market Segmentation

Executive Summary

Premium Insights

Market Overview

Opaque Polymers Market By Type

Opaque Polymers Market By Function

Opaque Polymers Market By Material

Opaque Polymers Market By End User

Opaque Polymers Market By Region

Opaque Polymers Market: Company Landscape

SWOT Analysis

Company Profiles

Continued...

Purchase this report – https://www.databridgemarketresearch.com/checkout/buy/singleuser/global-opaque-polymers-market

Data Bridge Market Research:

Today's trends are a great way to predict future events!

Data Bridge Market Research is a market research and consulting company that stands out for its innovative and distinctive approach, as well as its unmatched resilience and integrated methods. We are dedicated to identifying the best market opportunities, and providing insightful information that will help your business thrive in the marketplace. Data Bridge offers tailored solutions to complex business challenges. This facilitates a smooth decision-making process. Data Bridge was founded in Pune in 2015. It is the product of deep wisdom and experience.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 975

Email:- [email protected]

Browse More Reports:

Global Arthroscopic Shavers Market – Industry Trends and Forecast to 2028

Global Opaque Polymers Market – Industry Trends and Forecast to 2029

Global Commercial Aviation Crew Management Systems Market – Industry Trends and Forecast to 2029

Global Elbow Lesion Treatment Market – Industry Trends and Forecast to 2029

Global Automotive Intelligence Park Assist System Market – Industry Trends and Forecast to 2028

#Opaque Polymers Market#Opaque Polymers Market Size#Opaque Polymers Market Share#Opaque Polymers Market Trends#Opaque Polymers Market Growth#Opaque Polymers Market Analysis#Opaque Polymers Market Scope & Opportunity#Opaque Polymers Market Challenges#Opaque Polymers Market Dynamics & Opportunities

0 notes

Text

Exploring the Booming Waterborne Polyurethane Market

Overview and Scope

Waterborne polyurethane refers to a polyurethane polymer resin that can be dispersed in water. It has good adherence to numerous surfaces, including glass and polymeric fibres, and can be formed into coatings and adhesives.

Sizing and Forecast

The waterborne polyurethane market size has grown strongly in recent years. It will grow from $5.07 billion in 2023 to $5.41 billion in 2024 at a compound annual growth rate (CAGR) of 6.6%. The growth in the historic period can be attributed to government investments in research and development, environmental regulations, market demand shift, advancements in formulation, industry adoption..

The waterborne polyurethane market size is expected to see strong growth in the next few years. It will grow to $6.98 billion in 2028 at a compound annual growth rate (CAGR) of 6.6%. The growth in the forecast period can be attributed to consumer preferences for eco-friendly products, collaboration with industries, customization, impact of covid-19 pandemic, supply chain restrictions, manpower & equipment shortage.. Major trends in the forecast period include brand reputation and consumer awareness, energy efficiency, market penetration strategies, global economic trends, focus on health & safety..

To access more details regarding this report, visit the link:

https://www.thebusinessresearchcompany.com/report/waterborne-polyurethane-global-market-report

Segmentation & Regional Insights

The waterborne polyurethane market covered in this report is segmented –

1) By Type: Polyurethane Emulsion, Polyurethane Dispersion, Polyurethane Aqueous Solution

2) By Application: Coating, Sealant, Adhesive, Elastomer

3) By End-use industry: Building and construction, Automotive and transportation, Bedding and furniture, Electronics, Other End Users

Asia-Pacific was the largest region in the waterborne polyurethane market share in 2023. The regions covered in the waterborne polyurethane market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, Africa.

Intrigued to explore the contents? Secure your hands-on sample copy of the report:

https://www.thebusinessresearchcompany.com/sample.aspx?id=8316&type=smp

Major Driver Impacting Market Growth

The growth of the construction industry is expected to propel the growth of the waterborne polyurethane market going forward. The construction sector is involved in building infrastructure such as houses, buildings, bridges, and so on. Waterborne polyurethane coatings are used for both floor and wall coatings in various newly constructed buildings as a protective layer for abrasion resistance, weathering resistance, and chemical resistance, thereby increasing the demand for the waterborne polyurethane market. For instance, according to data by The Construction Index, a UK-based publisher of construction sector information, construction output increased by 1.7% in volume terms in March 2022 in comparison with February data in the UK. The rise in repair and maintenance (3.0%) and new work (1.0%) activity drove the increase in monthly construction production in March 2022. Therefore, the growth of the construction industry is driving demand for the waterborne polyurethane market.

Key Industry Players

Major companies operating in the waterborne polyurethane market report are Covestro AG, Koninklijke DSM NV, BASF SE, Allnex Belgium SA, Dow Inc., H.B. Fuller Company, Wanhua Chemical Group Co. Ltd., SNP Inc., Kamsons Chemicals Pvt. Ltd., Axalta Coating Systems Ltd., The Sherwin-Williams Company, Perstorp AB, C.L Hauthaway & Son Corporation, Lamberti S.p.A., Sun Polymers International Inc., R. STAHL GmbH, Chemtura Corporation, Lanxess AG, Lubrizol Corporation, Bayer MaterialScience AG, PPG Industries Inc., Capital Resin Corporation, Walter Wurdack Inc., Palmer Holland Inc., SIWO US Inc., Brilliant Group Inc., Aditya Birla Chemicals Ltd., Hauthaway Corporation, Henkel AG & Co. KGaA, Huntsman Corporation, Nippon Polyurethane Industry Co. Ltd.

The waterborne polyurethane market report table of contents includes:

1. Executive Summary

2. Market Characteristics

3. Market Trends And Strategies

4. Impact Of COVID-19

5. Market Size And Growth

6. Segmentation

7. Regional And Country Analysis

.

.

.

27. Competitive Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Vinyl Acetate Monomer Market Report: Trends, Analysis, and Projections

Vinyl Acetate Monomer (VAM) is a key chemical intermediate used in the production of various polymers and resins, offering versatility in applications across industries. This blog explores the dynamics of the global VAM market, analyzing key drivers, applications, emerging trends, and future growth prospects.

Understanding the VAM Market:

Vinyl Acetate Monomer (VAM) Is an organic compound produced by the reaction of acetylene and acetic acid. It serves as a crucial building block in the synthesis of polyvinyl acetate (PVAc), ethylene-vinyl acetate (EVA) copolymers, and other vinyl acetate-based polymers and resins.

Market Dynamics:

Polymer Production: VAM is primarily used in the production of PVAc, a versatile polymer used in adhesives, paints, coatings, textiles, and packaging materials due to its adhesive properties, flexibility, and film-forming capabilities.

Adhesives and Sealants: PVAc-based adhesives and sealants find applications in woodworking, paper packaging, construction, and consumer goods industries, offering strong bonding, versatility, and ease of use.

Coatings and Emulsions: VAM-based polymers are used in paints, coatings, and emulsions for architectural, automotive, and industrial coatings, providing adhesion, durability, and weather resistance properties.

Textile and Nonwoven Applications: VAM polymers are utilized in textile finishes, nonwoven binders, and fiber treatments, enhancing fabric properties such as softness, water repellency, and strength.

Applications Across Industries:

Adhesives: Woodworking, paper packaging, construction.

Coatings: Paints, architectural coatings, industrial coatings.

Textiles: Finishes, nonwoven binders, fiber treatments.

Packaging: PVAc films, adhesives for flexible packaging.

Market Trends:

Green and Sustainable Solutions: Increasing demand for eco-friendly adhesives, coatings, and polymers drives the development of bio-based VAM and sustainable formulations using recycled materials, aligning with environmental regulations and market preferences.

High-Performance Applications: Innovations in VAM-based copolymers such as EVA copolymers and VAM-acrylic copolymers cater to specialized applications in automotive, electronics, and medical sectors requiring enhanced properties such as heat resistance, flexibility, and chemical resistance.

Technological Advancements: Advances in VAM production processes, catalyst technologies, and polymerization techniques improve efficiency, product quality, and cost-effectiveness, driving market competitiveness.

Future Prospects:

The global VAM market is poised for significant growth, driven by the expanding demand for polymers, adhesives, coatings, and specialty materials across industries. Investments in R&D, sustainability initiatives, and market diversification strategies will shape the market's evolution and unlock new opportunities for stakeholders.

Conclusion:

Vinyl Acetate Monomer (VAM) plays a vital role in the production of polymers, adhesives, coatings, and specialty materials essential for diverse industries. Understanding market trends, technological advancements, and sustainability imperatives is crucial for stakeholders in the VAM market to leverage growth opportunities and address evolving industry needs effectively. With a focus on innovation, sustainability, and customized solutions, the VAM market presents promising prospects for continued growth and development in the global chemical and materials industry landscape.

0 notes

Text

Waterproof Coatings Market Trends: Riding the Tide of Innovation

Waterproof Coatings: A Barrier Against Moisture To Prevent Water And Moisture

The Evolution of Waterproof Coatings

Waterproof coats serve as a protective barrier that prevents water and moisture from penetrating surfaces like fabrics, concrete, wood, and more. The development of modern waterproofing techniques and materials allows us to keep everything from phones to buildings dry even in wet conditions. Let's take a deeper look at how waterproof coats work and the technologies behind them.

Repelling Water Through Chemistry

At the molecular level, waterproof coats use specific chemical formulations to repel water. Many coatings contain polymers that are hydrophobic, meaning they do not attract water molecules. Silicones are a commonly used hydrophobic polymer in waterproofing products. The large silicone molecules form a tight, flexible barrier that prevents water from passing through but still allows surfaces to breathe. Other chemicals like fluoropolymers also exhibit exceptional water-repellent properties due to the structure of their molecules. These water-repellent chemicals are integral components of modern waterproof coats.

Advanced Barrier Technologies

Beyond chemical composition, modern waterproofing technologies create physical barriers against moisture as well. Many coatings deposit ultra-thin, crack-free films only a few nanometers thick using plasma or other deposition processes. These barrier layers are completely non-porous so no water can penetrate no matter how small the pores might be. Additional barrier methods employ multiple coating layers that self-heal any small defects. Self-healing polymers can replenish damaged areas of a waterproof barrier on their own over time. Networked barrier coatings also work to repel moisture even if microscopic cracks or holes occur.

Applications in Daily Life

Waterproof coats enable all kinds of applications we rely on every day. They protect our phones, watches, sports gear and more from water damage. Specialist coats and boots with waterproof membranes keep outdoor enthusiasts dry in rain or snow. Waterproof fabrics allow us to enjoy activities like kayaking without worrying about getting soaked. Waterproof construction materials like sealants form barriers around buildings, ensuring interiors stay protected. Even paper and cardboard products like packaging can be coated to withstand moisture. Thanks to advanced waterproofing technologies, we can now go about our daily lives with confidence in nearly any conditions.

Endurance Testing for Real-World Performance

Guaranteeing a coating's waterproof performance requires stringent testing methods. Standard tests involve controlled exposure to water sprinkling or submersion over extended periods. Testing evaluates factors like barrier integrity, adhesion strength after water contact and flexibility at low temperatures where coatings may crack. Some testing regimes involve over 5000 hours of water exposure to simulate 15+ years of real-world conditions. Advanced testing uses specialized equipment like pressure cookers and weathering chambers that can accelerate corrosion and wear equivalents. Xenon arc light exposure reproduces years of natural weathering in only weeks. Combined environmental testing helps develop coatings proven to withstand demanding outdoor applications for many years.

Eco-Friendly Formulations for Sustainability

As waterproofing technologies evolve, the demand grows for greener, more sustainable coating options. Researchers strive to replace harmful volatile organic compounds (VOCs) with eco-friendly alternatives. Some new bio-based hydrophobic polymers come from plant oils rather than petrochemical sources. Silicone replacements using renewable plant-based components are also under development. Water-based polymer emulsions eliminate solvents for reduced toxicity. Self-curing coatings use ultraviolet light or moisture itself to cure rather than heat sources. Nano-additives allow thinner, more efficient coatings to achieve the necessary performance. Continued innovation will drive the industry towards providing high performance without compromising environmental sustainability.

0 notes

Text

The ABCs of ABS: Unraveling the Characteristics and Uses of Acrylonitrile Butadiene Styrene (2023-2034)

This blog will focus on Acrylonitrile Butadiene Styrene (ABS). ABS is comprised of three monomers: Acrylonitrile, Butadiene, and Styrene. In this article, we'll look at how the polymer's unique properties work together to give ABS its exceptional strength, toughness, as well as the manufacturing process. The global Acrylonitrile Butadiene Styrene (ABS) market is likely to flourish at a moderate CAGR of 5.90% by the year 2034.

Introduction

Styrene Acrylonitrile has existed since the 1940s. While they improved toughness over pure styrene, their limits necessitated the addition of rubber (butadiene) as a third monomer. ABS consists of three major monomers: acrylonitrile, butadiene, and styrene.

Acrylonitrile contributes to ABS's chemical resistance and heat stability.

Butadiene enhances the toughness and impact strength of ABS.

Styrene provides ABS with rigidity and facilitates its processability.

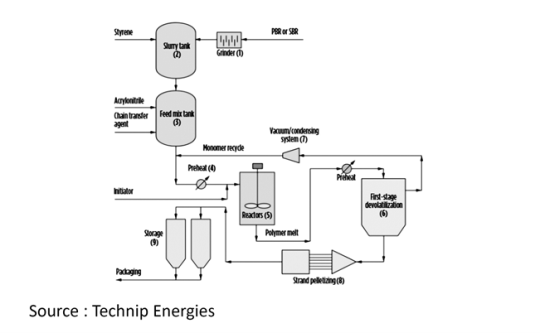

Manufacturing Process

ABS copolymers exhibit notable toughness, superior thermal resistance, and properties that surpass those of polystyrene plastics. ABS is produced through three distinct polymerization techniques: emulsion, suspension, and mass processes.

In the Mass Process, ABS is produced by the continuous copolymerization of styrene and acrylonitrile monomers with Polybutadiene Rubber (PBR) or Styrene-Butadiene Rubber (SBR) using a series of reactors, aided by organic peroxide. In a sequential process, chopped PBR or SBR is added to a slurry tank containing styrene monomer. The resultant mixture is then transferred to the ABS feed batch tank for complete rubber dissolution. This concentrated rubber solution is diluted with acrylonitrile, recycled monomer, and a chain transfer agent according to product requirements before preheating prior to entering the polymerization reactors.

Polymerization Section

The polymerization section employs a unique combination of plug flow and boiling stirred tank reactors arranged in series. Organic peroxide is introduced to initiate polymerization. This reactor setup allows precise control over various parameters such as rubber grafting, phase inversion, and molecular weight. Monomer conversion increases progressively throughout the reactor system, reaching final levels between 60% to 75%. Devolatilization is achieved through either extrusion or flash chamber methods.

Devolatization

In the extrusion devolatilization approach, the product from the last reactor undergoes stripping of unreacted monomers and byproducts in an extruder devolatilization system. Alternatively, the reactor product is subjected to volatile removal in a multistage flash devolatilization system operating under vacuum. Vapors are condensed, and the resulting mixture is recycled. The devolatilized polymer melts and then pelletizes and then dried.

Applications of Acrylonitrile Butadiene Styrene (ABS):

ABS (Acrylonitrile Butadiene Styrene) finds numerous applications across various industries. High impact grades are utilized in the production of travelling bags, helmets, furniture, sports goods, and automotive components, while medium impact grades are employed in radiator and air conditioner grills, heavy-duty domestic appliances, and control panels. Electroplating grades find their place in TV and radio knobs, bathroom fittings, refrigerator handles, and nameplates. High flow grades are ideal for housing domestic appliances, office equipment, and cabinets of electronic devices. High heat-resistant grades are utilized in automobile components and housing for electrical heaters and dryers. Transparent grades are sought after for areas requiring high transparency and impact strength, while impact modifier grades serve as modifiers for PVC compounding across various formulations. Glass-filled grades cater to applications demanding high flexural strength and stiffness, maintaining impact and tensile properties, while extrusion grades are used in refrigerator linings and luggage production.

Automotive

The automotive industry demands stringent standards from its materials. They must remain dimensionally stable and resist warping even when subjected to extreme stresses and significant temperature fluctuations.

Electronics & Electricals

ABS stands out in this regard due to its outstanding antistatic properties, providing a distinct advantage in meeting these requirements.

Appliances

ABS finds extensive applications in appliances, encompassing appliance control panels, housings for various devices such as shavers, vacuum cleaners, and food processors, as well as refrigerator liners, among others. Household and consumer goods represent the primary domains where ABS is widely utilized. Additionally, ABS is commonly employed in the manufacturing of keyboard keycaps.

Pipes & Fittings

ABS pipes and fittings are highly liked due to their ease of installation and rust resistance, making them a popular choice in a variety of applications.

Market Outlook:

ABS is an invariable thermoplastic polymer made up of three distinct monomers: acrylonitrile, butadiene, and styrene, which can change in proportion. They are also referred to as engineering plastics. Acrylonitrile provides chemical and thermal stability, styrene gives the plastic a glossy sheen, and butadiene provides strength and durability. These materials are widely used in the electronic appliance and automobile industries for vehicle and auto components production. The rapid growth of the medical business has increased demand for medical equipment, which is driving market growth. Furthermore, the growing construction and aerospace industries are predicted to significantly boost the ABS sector during the projection period. The global Acrylonitrile Butadiene Styrene (ABS) market is anticipated to reach approximately 15.7 million tonnes by 2034.

Acrylonitrile Butadiene Styrene (ABS) Major Manufacturers

Significant companies in the Global Acrylonitrile Butadiene Styrene (ABS) market are Formosa Chemicals and Fiber Corporation, LG Chem, LOTTE Chemical Corporation, Jilin Petrochemical Company, Toray Industries, CHIMEI Corporation, Tianjin Dagu Chemical Co., Ltd., and Others.

Challenges and Opportunities

While ABS possesses numerous advantageous properties, there are several restraining factors that could impact its market growth:

Environmental Concerns: ABS is derived from petrochemical sources, and its production and disposal can contribute to environmental pollution. Increasing environmental consciousness, combined with strict laws on plastic waste management and recycling, may present difficulties to the ABS market.

Competition from Alternative Materials: ABS faces competition from other engineering thermoplastics, such as polycarbonate (PC) and polypropylene (PP), which offer similar or enhanced properties in certain applications.

Conclusion:

Acrylonitrile Butadiene Styrene (ABS) is a versatile polymer with numerous useful applications. It is an essential in automotives and Electrical & Electronics industries owing to its unique set of properties. The surging demand for Acrylonitrile Butadiene Styrene (ABS) from Automotive, Home Appliances, Electrical & Electronics, and Building & Construction end-use industries, is anticipated to play a role in the demand-supply dynamics of the Acrylonitrile Butadiene Styrene (ABS) market.

0 notes

Text

The Role of Emulsion Polymers in the Textile Industry

In the ever-evolving textile industry, innovation drives progress, and one of the most significant advancements in recent years has been the utilization of emulsion polymers. These versatile materials have revolutionized fabric treatments, enhancing functionality, durability, and sustainability. As the demand for high-performance and environmentally friendly textiles continues to grow, emulsion polymers play a pivotal role in meeting these industry challenges.

Understanding Emulsion Polymers

Emulsion polymers are produced by the polymerization of monomers dispersed in water, forming a colloidal suspension. This method is environmentally favorable as it typically requires fewer organic solvents than other polymerization techniques. The resulting polymers are versatile and can be engineered with specific properties to suit various applications within the textile sector, ranging from fabric finishing to fiber manufacturing.

Enhancing Fabric Finishes

One of the primary applications of emulsion polymers in textiles is in the finishing process, where they are used to impart desirable characteristics to fabrics such as softness, wrinkle resistance, and water repellency. For instance, acrylic emulsion polymers are extensively used to create soft yet durable finishes on fabrics. These polymers form films on the fabric surface, providing a protective layer that enhances wear resistance and longevity.

Water repellency is another critical feature highly sought in textiles, especially in outdoor and sportswear. Emulsion polymers such as fluoropolymers offer exceptional water and stain-resistant properties without significantly affecting the fabric's breathability. This technology not only improves the consumer's wearing experience but also extends the garment's life by protecting it from the elements.

Improving Flame Retardancy and Strength

Safety is paramount in the textile industry, particularly in applications requiring fire-resistant clothing, such as in the military, firefighting, and certain industrial environments. Emulsion polymers are integral in the production of flame-retardant fabrics. These polymers can be formulated to form a char barrier on the fabric when exposed to heat, thus slowing down the spread of fire and providing crucial extra seconds for the wearer to escape danger.

Additionally, emulsion polymers are employed to enhance the mechanical strength of fibers. In the manufacturing of synthetic fibers, such as nylon and polyester, emulsion polymers are added to improve tensile strength and elasticity. This is particularly important in the production of high-performance textiles used in sportswear and automotive industries, where durability and performance under stress are essential.

Sustainability and Environmental Impact

The textile industry is increasingly under scrutiny for its environmental impact, particularly concerning water pollution and the use of toxic chemicals. Emulsion polymers offer a more sustainable alternative to traditional treatments that rely heavily on solvents. Water-based emulsions significantly reduce the need for volatile organic compounds (VOCs), which are harmful to both the environment and human health.

Furthermore, the development of biodegradable emulsion polymers is on the rise, which represents a significant step forward in reducing the ecological footprint of textile production. These innovative materials degrade more quickly and safely in the environment, helping to address the issue of textile waste and pollution.

Future Prospects

Looking ahead, the role of emulsion polymers in the textile industry is set to expand further. Advances in polymer chemistry are expected to produce even more specialized emulsions that could unlock new functionalities in textiles. For instance, there is ongoing research into emulsion polymers that can enable textiles to conduct electricity or change color in response to environmental stimuli, opening up possibilities for smart and interactive garments.

In conclusion, emulsion polymers are crucial in pushing the boundaries of what's possible in textile production. Their ability to enhance fabric properties, coupled with their environmental benefits, positions them as key components in the future of textile manufacturing. As the industry continues to innovate and move towards more sustainable practices, emulsion polymers will undoubtedly play a central role in its evolution, offering solutions that meet the needs of modern consumers and the planet alike.

0 notes

Text

Bio-Polybutadiene Market to Reach US$ 99.4 Mn by 2031; Owing to Increase in Demand for sustainable polymers and Rise in adoption of electric vehicles

In the realm of polymer chemistry, bio-polybutadiene has emerged as a frontrunner in the quest for sustainable materials. As we navigate through the period from 2023 to 2031, the bio-polybutadiene market is poised for substantial growth, driven by environmental concerns, technological advancements, and increasing demand for eco-friendly alternatives. Let's delve into the dynamics shaping this market, its segmentation, regional landscape, key drivers, challenges, trends, and future outlook.

In 2022, the global industry was valued at US$ 46.1 Mn. It is forecasted to grow at a CAGR of 8.9% from 2023 to 2031, reaching US$ 99.4 Mn by the end of 2031.

The bio-polybutadiene market is witnessing a surge in demand as industries seek sustainable alternatives to traditional petroleum-based polymers. Bio-polybutadiene, derived from renewable sources such as biomass, offers comparable properties to its synthetic counterpart while reducing the environmental footprint associated with polymer production.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85580

Market Segmentation:

By service type:

Solution Polymerization

Emulsion Polymerization

By sourcing type:

Renewable Sources

Non-renewable Sources

By application:

Tires

Industrial Rubber

Polymer Modification

Others

By industry vertical:

Automotive

Construction

Chemical

Others

By region:

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

Regional Analysis:

North America and Europe are anticipated to lead the bio-polybutadiene market, driven by stringent environmental regulations and the increasing adoption of sustainable materials in manufacturing processes.

The Asia Pacific region is poised for significant growth, fueled by rapid industrialization, expanding automotive sectors, and government initiatives promoting bio-based industries.

Latin America and the Middle East & Africa are expected to witness steady growth, supported by growing awareness regarding environmental sustainability and resource conservation.

Market Drivers and Challenges:

Drivers:

Growing environmental concerns and emphasis on sustainable materials.

Favorable government policies and regulations promoting bio-based industries.

Increasing consumer awareness and demand for eco-friendly products.

Challenges:

High production costs compared to conventional petroleum-based polymers.

Limited availability of raw materials and infrastructure for large-scale bio-polybutadiene production.

Technical challenges in achieving desired performance characteristics and consistency.

Market Trends:

Adoption of advanced biotechnological processes for bio-polybutadiene production, enhancing efficiency and yield.

Collaborative research and development initiatives to overcome technical barriers and optimize polymer properties.

Integration of bio-polybutadiene in tire manufacturing, leveraging its superior performance and environmental benefits.

Future Outlook:

The future of the bio-polybutadiene market appears promising, driven by increasing environmental awareness, regulatory pressures, and technological innovations. As industries strive to reduce their carbon footprint and embrace sustainable practices, bio-based polymers like polybutadiene are expected to play a pivotal role in achieving these objectives.

Key Market Study Points:

Analysis of market dynamics, including drivers, challenges, and opportunities.

Assessment of regional market trends and growth prospects.

Evaluation of key players, their strategies, and competitive landscape.

Exploration of technological advancements and their impact on market dynamics.

Competitive Landscape:

The bio-polybutadiene market is characterized by a competitive landscape with key players including:

Kuraray Co., Ltd.

Kraton Corporation

Zeon Corporation

JSR Corporation

Lanxess AG

Recent Developments:

Investments in research and development to enhance bio-polybutadiene production processes and properties.

Strategic partnerships and collaborations to expand product portfolios and market reach.

Integration of sustainable practices and bio-based materials in manufacturing operations.

About Transparency Market Research

Transparency Market Research, a global market research company registered in Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision-makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyse information.

Our data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll-Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Emulsion Polymer Market Demand By Type, Application, End-Use, Region And Forecast To 2030: Grand View Research Inc.

San Francisco, 13 March 2024: The Report Emulsion Polymer Market Size, Share & Trends Analysis Report By Type, By Application (Paints & Coatings, Adhesives & Sealants, Paper & Paperboard), By End-use, By Region, And Segment Forecasts, 2024 – 2030

The global emulsion polymer market size is anticipated to reach USD 49.35 billion by 2030 and it is projected to grow at a CAGR of 6.5% from 2024 to…

View On WordPress

0 notes

Text

Polymer Emulsion Market Size, Analysis with Covid-19 Impact, Trends, Key Players Analysis, Top Vendors by 2030

The polymer emulsion market refers to the global industry involved in the production and distribution of polymer emulsions, which are colloidal suspensions of polymers in water. Polymer emulsions are widely used in various applications such as paints and coatings, adhesives, textiles, paper and paperboard coatings, and construction materials.

Here is some comprehensive information about the polymer emulsion market:

Market Overview:

• The polymer emulsion market has experienced significant growth in recent years, driven by increasing demand from end-use industries and the shift towards water-based formulations.

• The market is characterized by a wide range of polymer types, including acrylics, styrene-butadiene rubber (SBR), vinyl acetate polymers, and others.

• The market is segmented based on application, polymer type, end-use industry, and region.

Key Drivers and Trends:

• Environmental regulations and the need for sustainable solutions have led to a shift from solvent-based to water-based formulations, boosting the demand for polymer emulsions.

• Growing construction activities, particularly in emerging economies, have increased the demand for polymer emulsions in applications such as architectural coatings, sealants, and adhesives.

• The automotive industry's emphasis on lightweight materials and increased focus on water-based coatings in the automotive refinish segment have further contributed to market growth.

• Rising disposable incomes, urbanization, and changing consumer preferences for aesthetically appealing products have driven the demand for paints and coatings, thereby augmenting the polymer emulsion market.

• Technological advancements, such as the development of bio-based and eco-friendly polymer emulsions, are expected to create new opportunities for market expansion.

Market Segmentation:

• Based on polymer type, the market is segmented into acrylics, SBR, vinyl acetate polymers, polyurethane dispersions, and others.

• Application-wise, the market is divided into paints and coatings, adhesives and sealants, paper and paperboard coatings, textiles and nonwovens, and others.

• End-use industries for polymer emulsions include construction, automotive, textiles, packaging, and others.

• Geographically, the market is analyzed across regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Competitive Landscape:

• The polymer emulsion market is highly competitive, with several key players operating on a global scale. Some of the prominent companies in the market include BASF SE, Dow Chemical Company, Arkema Group, Synthomer PLC, Celanese Corporation, and Wacker Chemie AG, among others.

• Companies are focusing on research and development activities to develop new and innovative polymer emulsions to cater to evolving customer needs.

• Mergers and acquisitions, collaborations, and strategic partnerships are common strategies adopted by market players to strengthen their market presence and expand their product portfolios.

Challenges:

• Fluctuating raw material prices, particularly for monomers used in polymer emulsion production, can impact the profitability of market players.

• Stringent environmental regulations and compliance requirements pose challenges in terms of formulating eco-friendly and low-VOC (volatile organic compound) products.

• Intense competition from alternative technologies such as powder coatings and solvent-based systems can hinder market growth.

Future Outlook:

• The polymer emulsion market is expected to witness steady growth in the coming years, driven by the increasing adoption of water-based coatings and adhesives across industries.

• The demand for bio-based polymer emulsions is likely to rise, owing to the growing emphasis on sustainability and environmental consciousness.

• Emerging economies, particularly in the Asia Pacific region, are anticipated to offer lucrative opportunities for market expansion due to rapid industrialization and infrastructure development.

0 notes

Text

The report "Polymer Emulsion Market by Type (Acrylic Polymer Emulsion, Vinyl Acetate Polymer Emulsion, SB Latex), Application (Paints & Coatings, Adhesives & Sealants, Paper & Paperboard), End-Use Industry, Region - Global Forecast To 2025", The global polymer emulsion market size is projected to grow from an estimated value of USD 25.2 billion in 2020 to USD 38.1 billion by 2025, at a CAGR of 8.6% during the forecast period. The growth of the market is driven mainly by the increasing demand from growing end-use industries in emerging markets and stringent regulations regarding VOC emission.

The paints & coatings segment is the largest consumer of polymer emulsion. The growth of the market is attributed to the high demand in industries, such as construction and automotive. Polymer emulsion is used widely in paints & coatings as its manufacturing process has a lower carbon footprint. The high VOC content of solvent-based products and the implementation of government regulations regarding air pollution control has stimulated the development of low VOC paints & coatings. This increased the demand for water-based paints & coatings, which in turn, drive the growth of polymer emulsions in the paints & coatings segment.

The building & construction end-use industry is the largest consumer of polymer emulsion. The growth of the market in this segment is attributed to the high demand for polymer emulsion in architectural paints, deck & trim paints, and elastomeric wall coatings, among others. Excellent durability and high water resistance drive its demand in the end-use industries.

APAC is the largest and fastest-growing market for polymer emulsion. The region is witnessing growth in the polymer emulsion market because of the rapid expansion of building & construction, consumer durables, and transportation sectors. The manufacturers are attracted to the region as skilled labor required for the operation of manufacturing units is available at lower wages. The presence of major polymer emulsion manufacturers and stringent government regulation related to VOC emission are major factors supporting the growth of polymer emulsion in the region.

DIC Corporation (Japan), Dow Chemical Company (US), BASF SE (Germany), Arkema Group (France), Celanese Corporation (US), Trinseo (US), The Lubrizol Corporation (US), Wacker Chemie AG (Germany), Synthomer Plc (UK), and Asahi Kasei Corporation (Japan) are the major players in the polymer emulsion market.

#Polymer Emulsion Market#COVID-19 impact on Global polymer emulsion market#Polymer Emulsion Industry#Demand for Polymer Emulsion#Polymer Emulsion Sales#Polymer Emulsion Market Size#Polymer Emulsion Market share#Polymer Emulsion Market Forecast#Polymer Emulsion Market Research Report#Polymer Emulsion Market Opportunity

0 notes

Text

Chemical Evolution: Pioneering Innovation and Precision in Petrochemical Engineering

In the heart of the Middle East, Saudi Arabia's oil and gas industry remains a cornerstone of its economy, with production chemicals playing a pivotal role in enhancing efficiency, safety, and productivity in hydrocarbon extraction and processing operations. As we approach 2024, the Saudi Arabia Production Chemicals Market is poised for significant growth, driven by factors such as increasing oil and gas exploration activities, advancements in chemical formulations, and the emphasis on maximizing production from existing assets. This article delves into the key trends, market dynamics, and factors shaping the Saudi Arabia Production Chemicals Market in the coming years.

Market Overview:

The Saudi Arabia Production Chemicals Market is experiencing steady growth, with a projected Compound Annual Growth Rate (CAGR) exceeding 4% from 2022 to 2024. This growth is propelled by factors such as the expansion of oil and gas production activities, the need for specialized chemicals to address reservoir challenges, and the adoption of enhanced oil recovery (EOR) techniques.

Key Factors Driving Growth:

Expanding Oil and Gas Exploration Activities: Saudi Arabia continues to invest in oil and gas exploration and development projects to maintain its position as a leading global energy producer. The exploration of new reservoirs and the development of unconventional resources drive demand for production chemicals tailored to address specific reservoir challenges and enhance hydrocarbon recovery rates.

Advancements in Chemical Formulations: The development of advanced chemical formulations, including demulsifiers, corrosion inhibitors, scale inhibitors, and biocides, enhances the efficiency and effectiveness of oil and gas production operations. These chemicals are designed to mitigate production challenges such as emulsions, corrosion, scaling, and microbial contamination, optimizing production rates and prolonging asset life.

Maximizing Production from Existing Assets: With maturing oil fields and aging infrastructure, maximizing production from existing assets becomes imperative for Saudi Arabia's oil and gas industry. Production chemicals play a crucial role in optimizing well performance, maintaining flow assurance, and extending the productive life of reservoirs through techniques such as water flooding, gas injection, and chemical treatments.

Adoption of Enhanced Oil Recovery (EOR) Techniques: The adoption of enhanced oil recovery techniques, including polymer flooding, surfactant flooding, and steam injection, drives demand for specialized production chemicals tailored to EOR applications. These chemicals enhance oil recovery rates by altering the reservoir's fluid properties, improving sweep efficiency, and displacing residual oil trapped in pore spaces.

Challenges and Opportunities:

While the Saudi Arabia Production Chemicals Market presents significant growth opportunities, challenges such as regulatory compliance, environmental concerns, and fluctuations in oil prices remain. However, these challenges also create opportunities for industry players to innovate, develop environmentally friendly formulations, and collaborate with stakeholders to address the evolving needs and challenges of the oil and gas industry.

For More Info@ https://www.gmiresearch.com/report/saudi-arabia-production-chemicals-market/

Conclusion:

In 2024, the Saudi Arabia Production Chemicals Market stands as a cornerstone of the kingdom's oil and gas industry, enabling efficient and sustainable hydrocarbon extraction and processing operations. As Saudi Arabia continues to invest in its energy sector and optimize production from existing assets, the market's growth is not just about production chemicals; it is about driving efficiency, sustainability, and competitiveness in the global energy market. The Saudi Arabia Production Chemicals Market is not merely a segment of the chemical industry; it is a catalyst for innovation, enabling the kingdom to unlock the full potential of its vast hydrocarbon reserves and maintain its leadership position in the global energy landscape. In embracing the opportunities presented by advancements in chemical formulations, digitalization, and enhanced oil recovery techniques, the Saudi Arabia Production Chemicals Market is not just fueling production; it is powering progress, prosperity, and resilience for generations to come.

0 notes

Text

Building the Future: Exploring the Versatility of Bitumen in Construction

Bitumen, also known as asphalt, is a viscous and black hydrocarbon material that is derived from crude oil through a process called fractional distillation. It is a complex mixture of organic liquids with various properties, including waterproofing, adhesion, and elasticity. Bitumen has a wide range of applications due to its versatile nature and is commonly used in the construction industry.

Applications of Bitumen:

Road Construction and Paving:

Bitumen is a key component in the construction of roads and highways. Asphalt, a mixture of bitumen and aggregates, provides a durable and flexible surface suitable for vehicular traffic.

Waterproofing:

Bitumen, especially oxidized bitumen and bitumen emulsion, is widely used for waterproofing applications. It is applied to roofs, foundations, and other structures to prevent water penetration.

Adhesives:

Bitumen's adhesive properties make it suitable for various adhesive applications, including in the manufacturing of roofing materials, flooring, and in some industrial processes.

Insulation:

Bitumen can be used for thermal insulation in buildings and pipelines. It provides a protective layer that helps regulate temperature and prevents heat loss or gain.

Industrial Coatings:

Bitumen is utilized as a coating material for corrosion protection in pipelines, tanks, and other industrial equipment.

Pavement Preservation:

Bitumen-based products are used for pavement preservation, extending the lifespan of roads and reducing the need for extensive repairs.

Polymer Modified Bitumen (PMB):

Modified with polymers, PMB offers enhanced performance and is used in specialized applications where increased strength and durability are required, such as high-traffic roads and airports.

Demand for Bitumen:

The demand for bitumen is influenced by several factors:

Infrastructure Development:

The construction of roads, highways, and other infrastructure projects is a primary driver of bitumen demand.

Urbanization:

As urban areas expand, there is an increased need for durable road surfaces, leading to higher demand for bitumen.

Maintenance and Rehabilitation:

Ongoing maintenance and rehabilitation activities in the existing infrastructure contribute to sustained demand for bitumen-based products.

Industrial Applications:

Bitumen's use in industrial coatings, adhesives, and insulation contributes to its demand in various industries.

Economic Growth:

The overall economic growth of a region is linked to increased construction and infrastructure development, impacting the demand for bitumen.

Innovation and Product Development:

Ongoing research and development in the industry, leading to the introduction of new and improved bitumen products, can influence demand.

The demand for bitumen is expected to continue growing as global infrastructure development persists and new technologies are adopted to enhance the performance of bitumen in various applications. However, environmental concerns and the development of alternative materials may also shape the future demand for bitumen.

Product Segmentation:

a. Paving Grade Bitumen: This is commonly used in the construction of roads and highways due to its ability to provide durability and flexibility.

b. Oxidized Bitumen: Produced by the air blowing process, it is used in waterproofing, electrical products, and some industrial applications.

c. Cutback Bitumen: Bitumen that has been liquefied by blending it with a solvent, often used in road construction and maintenance.

d. Bitumen Emulsion: A mixture of bitumen and water, stabilized with an emulsifying agent. It finds application in various sectors like road construction and maintenance.

e. Polymer Modified Bitumen (PMB): Bitumen modified with polymers to enhance its performance characteristics, often used in high-stress applications such as heavy traffic roads.

f. Others: This category may include specialty bitumen products designed for specific applications.

2. Application Segmentation:

a. Roadways: Paving grade bitumen and polymer modified bitumen are extensively used in the construction and maintenance of roads and highways.

b. Waterproofing (Roofing): Oxidized bitumen and bitumen emulsion are commonly used for waterproofing applications in roofing.

c. Adhesive: Bitumen can be used as an adhesive in various industries, providing a strong bonding agent.

d. Insulation: Bitumen may be utilized for insulation purposes, particularly in industries where thermal insulation is crucial.

e. Others: This category may include other miscellaneous applications where bitumen is used for specific purposes.

Market Dynamics: The demand for bitumen is closely tied to infrastructure development, construction activities, and the overall economic growth of a region. Factors such as government investments in road construction, urbanization, and the need for durable and sustainable materials influence the bitumen market.

0 notes

Text

Acrylic Acid Market Review: Trends and Future Prospects

Understanding Acrylic Acid:

Acrylic acid is an organic compound with the chemical formula CH2=CHCOOH. It is a colorless liquid with a sharp, pungent odor and is primarily used as a precursor in the production of acrylic esters, acrylic polymers, and other specialty chemicals. Acrylic acid finds applications in industries such as adhesives, coatings, textiles, and personal care products.

Market Dynamics:

Adhesives and Sealants Industry: Acrylic acid is a key raw material in the production of pressure-sensitive adhesives and sealants, contributing to its significant demand in the construction, automotive, and packaging sectors.

Coatings and Paints: Acrylic acid and its derivatives are widely used in the formulation of water-based paints, coatings, and emulsions, owing to their excellent adhesion, weatherability, and UV resistance properties.

Textile Industry: Acrylic acid polymers are utilized in the textile industry for manufacturing synthetic fibers, carpets, and non-woven fabrics, benefiting from their softness, durability, and dyeability.

Personal Care Products: Acrylic acid-based polymers are employed in personal care products such as hair styling gels, skin care formulations, and hygiene products due to their film-forming and thickening properties.

Applications Across Industries:

Adhesives and Sealants: Pressure-sensitive adhesives, sealants, tapes.

Coatings and Paints: Water-based paints, coatings, emulsions.

Textiles: Synthetic fibers, carpets, non-woven fabrics.

Personal Care Products: Hair styling gels, skin care formulations, hygiene products.

Market Trends:

Shift towards Sustainable Solutions: The acrylic acid market is witnessing a growing demand for bio-based and eco-friendly acrylic acid derivatives to address environmental concerns and meet regulatory requirements.