#Defence parts manufacturers in india

Explore tagged Tumblr posts

Text

India's Defence Parts Manufacturing Policy: A Comprehensive Guide

Imagine a nation that can independently produce its defense equipment, from fighter jets to submarines. This is the vision behind India's military manufacturing policy. Historically reliant on imports for its military requirements, India is rapidly progressing toward defense manufacturing self-sufficiency, with an increasing number of defence parts manufacturers in India playing a crucial role in this shift.

These manufacturers, which range from large-scale public-sector endeavors to innovative private-sector businesses, play an essential role in developing a wide range of defense components and systems. This change is about more than just national security; it's about strengthening the economy, creating employment, and establishing India as a worldwide military manufacturing powerhouse. The participation of local manufacturers in this attempt is a big step forward.

Policy Objectives:

Self-reliance is the cornerstone of India's defense production policy. This entails less reliance on foreign suppliers and the development of home capacities to design, develop, and manufacture a wide range of defense equipment. The policy intends to do this through many major strategies:

Promoting Public-Private Partnerships (PPP): Bringing together business and public sector entities to encourage innovation and efficiency.

Foreign Direct Investment (FDI): Encourage foreign direct investment (FDI) in the defense sector to attract capital, technology, and best practices.

Research and Development (R&D): Improving R&D infrastructure and capabilities, emphasizing indigenous innovations.

Export Promotion: Assisting domestic manufacturers in approaching global markets, thus expanding the economic benefits of defense production.

This defense policy is a boon for aerospace parts manufacturers in India, offering them a platform for growth, innovation, and global outreach. It is consistent with the larger goal of making India self-reliant in the defense and aerospace industries, reinforcing national security and economic vitality.

Achievements and Milestones:

In recent years, the policy has resulted in remarkable accomplishments. Indigenously built military equipment such as airplanes, battleships, and missile systems has increased in India. The Tejas Light Combat Aircraft and the Arihant-class nuclear submarines are notable examples. The policy has also attracted global defense companies to establish manufacturing units in India independently or through joint ventures.

Challenges and Solutions:

Despite these advances, the path has challenges. These include technological gaps, bureaucratic hurdles, and the need for a skilled workforce. Addressing these issues needs a multifaceted approach:

Streamlining Regulatory Frameworks: Making it easier for enterprises to participate in defense manufacturing by simplifying procedures and regulations.

Enhancing Skill Development: Investing in education and training to create a trained workforce capable of addressing the needs of this high-tech sector.

Fostering Innovation: Establishing innovation centers and funding research to overcome technology gaps are two ways to foster innovation.

Impact on the Economy and Security:

The policy on defense production has significant economic and national security ramifications. It stimulates industrial growth, produces jobs, and can earn foreign currency through exports. From a security standpoint, it increases India's strategic autonomy while decreasing susceptibility to supply chain disruptions. The initiative has also increased the importance of defense parts manufacturers in India. These firms are more important than ever. Their success and expansion under this strategy indicate India's determination to develop a robust and self-sufficient military sector.

Final Thoughts:

The defense production policy in India is critical to the country's overall defense and economic strategy. While issues must be addressed, the policy's emphasis on self-sufficiency, creativity, and teamwork points to a hopeful future. As India develops its military manufacturing capabilities, it improves its defense preparedness and adds to its aim of becoming an economic powerhouse. This strategy is about imagining a future in which India remains at the forefront of defense technology and innovation, delivering security and prosperity for its people.

Sujan Industries is well-known in India as a significant maker of military parts, particularly control links, O-rings, gaskets, diaphragms, rubber pistons, boots and bellows, radar seals, mounts, and bushes. Sujan Industries is the preferred choice for top-tier defense parts manufacturers because of their high-quality and trustworthy goods—our dedication to quality guarantees that every component they manufacture meets the highest reliability and performance criteria.

0 notes

Text

HOW NEHRU CAN TRULY BE CALLED 'THE ARCHITECT OF INDIA'S BIMARU ECONOMIC STRUCTURE'. ................................................................................. - HOW NEHRU INCOMPETENTLY, & PER MANY HISTORIANS, MALICIOUSLY, RUINED EASTERN INDIAN ECONOMIES, LIKE BENGAL, BIHAR, JHARKHAND, MADHYA PRADESH, CHHATTISGARH, & ORISSA, BY HIS ONE SIDED (SUBSIDIZED/EQUALIZED FREIGHT COST OF RAW MATERIAL ONLY & NOT FOR FINISHED GOODS) FREIGHT EQUALIZATION POLICY. - HOW NEHRU IN THE GARB OF A SOCIALIST INDIA, MANAGED TO CREATED A REGRESSIVELY CAPITALISTIC INDIA INSTEAD.

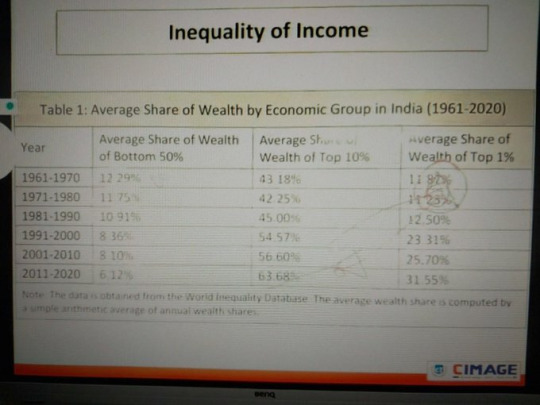

Here are India's 60 yr Share of Wealth stats, from 1961-2020, taken from the 'World Inequality Database'.

Looking at which, most would be forced to ask, why is it that in a wholly socialized state like India (& heavily publicized so at that for 60 yrs)....that our Top 1% 's share in wealth goes up 3 times, Top 10%'s share goes up 1.5 times, BUT SHARE OF THE BOTTOM 50% IS LITERALLY HALVED?

The answer to this lies largely in one man, Nehru, & his policies, either incompetently unintentional or maliciously intentional, policies directly responsible for creating a deeply disparate & heavily lopsided yet overall non-flourishing economic structure, for the entire first half century of the 'Dominion (of Britain) India'.

And the biggest mishap-causing misadventure, being 1951's infamous FREIGHT EQUALIZATION POLICY.

👇

https://en.wikipedia.org/wiki/Freight_equalisation_policy#:~:text=Freight%20equalisation%20policy%20was%20adopted,subsidised%20by%20the%20central%20government.

☝

Above is the Russian Govt+military reaction, to Indian 'independence' in mid 1947. This article was published in the Russian central military newspaper 'Red Star' on July 31, 1947, just 2 weeks before the official date of India's so-called Independence.

"Chief economic positions still remain in British hands–railways,marine transport,port economy,irrigation systems,finance,basic part of jute,industry,almost whole mining industry etc"

“The defence of economic positions and interests is not possible without political power. That power will be secured in the person of the capitalists, landowners and businessmen who are dependent upon British capital.”

“The partition, does not affect the feudal power of the Princes who have always supported British domination.”

"The British Govt plans to artificially separate industrial from agricultural areas,turning it to a agrarian & raw material appendage of Britain."

Exactly what Nehru's Freight Equalization Policy achieved 4 yrs later!

And to add to what y'all I assume would already have read from above, as to it's evil designs & effects, it created a reverse-reward scenario, whereby all the resource-rich states were essentially penalized for their natural advantages, by taking away all incentive for processing-industries & final transportation industries, that are a logical next step from the extraction industries, to germinate & set base in these places. Thereby creating a scenario where the South-western & western coastal states like Maharashtra, Gujarat & Tamil Nadu, & parts of Punjab in North India, were able to find logical easy base for all the processing & transportation industries in their states, for industries like steel, cement, heavy manufacturing, & power, all enabled via raw materials from the other far-off states, like iron ore, coal, limestone, bauxite, copper etc, even w/o any personal natural resources to rely on themselves, merely by virtue of being easy locations to set up ports in for exports, & w/o industries having to compromise on higher transportation & value-added processing costs, that cost aspect equalized & protected for all distances from the resource point. All this, with resource states not finding even some respite in terms of return benefits from any possibly subsidized finished product costs, finished goods not covered by this policy!

These 4-5 states effectively thus became the parasites, for atleast 7 of the traditionally god-gifted states of today like Bihar, Jharkhand, Madhya Pradesh, Chhattisgarh, Orissa, Bengal & Uttar Pradesh, killing all their hope at industrial development & economic progress, & where there is economic (or lotsa times attached) spiritual hopelessness, springs leftism in all it's devious forms, giving birth to intense communism & it's shameful offsprings of caste-divide & gang-culture, literally turning these states HOUSING HALF OF INDIA'S POPULATION, into the pot-holes of the Indian Union -the BIMARU (for Bihar, Madhya Pradesh, Rajasthan, Uttar Pradesh) states of India.

Now in all of this, it's not as if the above-mentioned coastal states were turning themselves into heavens of prosperity either, merely relatively well-off & with a hopeful disposition of the future, that in itself enough to attract large-scale migration from the above BIMARU states, particularly Maharashtra with a more traditionally Hindi-friendly ambience, but also in TN, creating a new urban housing problem, giving birth anew to Mumbai's infamously gargantuan chawl (dingy hutment) lifestyle.

And the reasons for these states, given all these special privileges, not able to take off well enough, aren't directly visible, yet that we can now, on basis of our analysis of Nehru & his so-called Independent India, over innumerable blogs prior, safely interpret, to be an India yet functioning in 1950s & till mid-1960s as some sort of a vassal state of Britain. Only natural then for a supreme state in such a relationship, to not be assumed to desire nations other than itself any sorta economic or strategic base in it's territory, thus curtailing more robust foreign economic to-and-fro.

A utterly class-subservient bent, not seen just for the British race, but per historians, eg Kanchan Gupta, in his hateful sense of complex & hatred of dark-skinned & skinny Bengali community, even worse passionate Hindu Durga-lovers, & per many, all largely borne of his hatred for Bose.

And thus ends yet another inglorious chapter from the life of the self-confessed Last British Ruler of India.

The Tale of the Internal Destruction of India, & it's Premier at it.

2 notes

·

View notes

Text

Satellite Manufacturing Market By Geography — Opportunity Analysis & Industry Forecast, 2024–2030

Satellite Manufacturing Market Overview:

Request sample:

Satellite manufacturing market is being reshaped by the Proliferation of Satellite Constellations and Miniaturisation of Satellite Technology. Next up is SpaceX’s Starlink project, which represents the rise of satellite constellations, with nearly 70 % of its 115 Falcon 9 launches in 2024 aimed at expanding its network. SpaceX launched 23 Starlink satellites on November 2024, 12 of which will have direct to smartphone connectivity and is pushing the boundaries of global connectivity to close the digital divide. On the other hand, the trend of miniaturisation is picking up, with Bengaluru based Pixxel achieving the milestone in July 2023. To develop compact satellites up to 150 kg in weight, with advanced technologies such as synthetic aperture radar and hyperspectral imaging, the company secured a multi-crore grant under the Ministry of Defence’s iDEX programme. These satellites, designed for the Indian Air Force, meet important defence and surveillance requirements and are part of the industry’s move toward smaller, cost-effective solutions with high impact capabilities.

Satellite Manufacturing Market- Report Coverage:

The “Satellite Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Satellite Manufacturing Market.

AttributeSegment

By Solution

Hardware

Software

By Size

Small Satellites (up to 500kg)

Medium Satellites (500–1000kg)

Large Satellites (Above 1000kg)

By Range

Low Earth Orbit (LEO)

Medium Earth Orbit (MEO)

Sun Synchronous Orbit (SSO)

Geosynchronous Orbit (GEO)

By Application

Communication

Earth Observation & Remote Sensing

Research & Experiment

Reconnaissance

Mapping & Navigation

Others

By End User

Government

Defense

Commercial

Research Institutions

Maritime & Transportation

Academic

Others

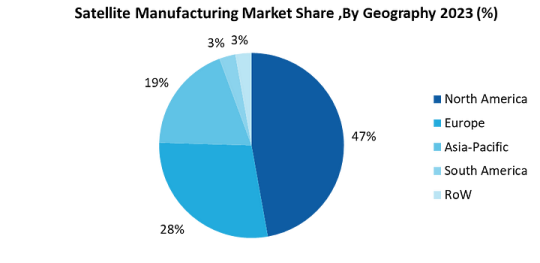

By Geography

North America (U.S., Canada and Mexico)

Europe (Germany, UK, France, Italy, Spain, Netherlands and Rest of Europe)

Asia-Pacific (China, India, Japan, South Korea, Australia, New Zealand, and Rest of Asia-Pacific)

South America (Brazil, Argentina, Colombia, Chile and Rest of South America)

Rest of World (Middle East and Africa

Inquiry Before Buying:

COVID-19 / Ukraine Crisis — Impact Analysis:

The satellite manufacturing market was disrupted by the COVID-19 pandemic which led to delays in production and breaks in the supply chain. Labour shortages, delayed component deliveries, and deferred satellite launches were the result of lockdowns and restrictions. The pandemic saw communication and Earth observation satellite demand spike as remote connectivity and monitoring were relied on more, but manufacturers struggled to meet the demand in time.

The Russia Ukraine war had a significant impact on the satellite manufacturing market especially in terms of supply chain and geopolitical tensions. Russia is a major supplier of launch services and materials like titanium, propulsion systems, etc. At the outset of the war that disrupted access to the critical resources. sanctions on Russia added to difficulties, forcing manufacturers to look to alternative sources of supply. At the same time, the conflict drove up demand for military and reconnaissance satellites to track the situation in Ukraine and to maintain strategic communication.

Key Takeaways:

North America Dominates the Market

North America is the dominant region in the Satellite Manufacturing market largely due to the presence of players and substantial investments in the space sector. The United States, in particular, leads with companies such as SpaceX, RTX, Lockheed Martin and more which drive innovation in satellite manufacturing. Additionally, North America’s extensive launch infrastructure and high frequency of successful space missions support the demand for satellites. Additionally, the U.S government invests in satellites for surveillance, reconnaissance, and strategic defense applications which is driving the need for satellite manufacturing. In In November 2024, the Biden-Harris Administration announced CHIPS incentives awards to BAE Systems and Rocket Lab, underscoring North America’s leadership in the satellite manufacturing market. BAE Systems received $35.5 million to modernize its New Hampshire Microelectronics Center, significantly increasing production of critical MMIC chips for satellites and defense systems. Rocket Lab secured $23.9 million to expand its Albuquerque facility, boosting the production of space-grade solar cells essential for satellites and space programs like NASA’s Artemis. As the space economy continues to grow, including the need for satellite communications, Earth observation, and defense applications, North America’s robust framework positions it to retain its leading role in the global satellite manufacturing market.

Small Satellites Represent the Largest Segmen

In the Satellite Manufacturing market, small satellites are the dominant segment. Small satellites have revolutionized the satellite manufacturing landscape driven by their affordability, versatility and rapid development cycles. These satellites including nanosatellites and microsatellites are significantly cheaper to design, build and launch compared to traditional large satellites. Their compact size allows multiple small satellites to be launched on a single rocket reducing per-unit launch costs. Moreover, advances in miniaturized electronics and high-performance materials have enabled small satellites to perform complex tasks, from Earth observation and scientific research to navigation and defense. The rise of commercial constellations heavily relies on small satellite technology due to its scalability and ease of replacement. In May 2024, Revolv Space secured $27.33 million to enhance small satellite capabilities, highlighting growing demand in the segment.

Schedule A Call :

The funding will support the launch of its autonomous Solar Array Drive Assembly (SARA), designed to boost small satellite performance and meet the increasing needs of constellation operators. Additionally, research institutions leverage small satellites for educational purposes and low-cost experimentation further driving demand. All these factors combined with shorter production timelines and increasing innovation in modular designs position small satellites as a major segment in the satellite manufacturing industry.

LEO is the Largest Segment

In the Satellite Manufacturing market, Low Earth Orbit (LEO) has become the dominant segment due to its unique advantages and expanding applications. Satellites in LEO operate at altitudes between 500 and 2,000 km, allowing for lower latency in communications and higher-resolution imaging compared to higher orbits. This makes LEO ideal for Earth observation, remote sensing and real-time data transfer. Additionally, the reduced launch energy required to reach LEO contributes to lower overall mission costs makes it more viable for commercial ventures and smaller organizations. The growing trend of mega-constellations such as SpaceX’s Starlink and Amazon’s Kuiper relies on LEO for its ability to support large networks of interconnected satellites that provide global coverage. Furthermore, advancements in satellite design and propulsion systems enable efficient orbital deployment and maintenance within LEO. The World Economic Forum reckons that Earth observation data could add up to $700 billion in value by 2030, contributing $3.8 trillion to global GDP over that period. In addition, Earth observation can help to support policies and practices that could reduce over 2 billion tons of CO₂ emissions per year, making it an invaluable resource in the global sustainability field. With such a large economic and environmental influence, Low Earth Orbit observation is the largest application segment in the Satellite Manufacturing market. Additionally, the increasing private sector investments and evolving market demands ensure LEO’s continued dominance in satellite manufacturing.

Expansion of Satellite Constellations Boosts the Market

Expansion of satellite constellations is one of the major factors driving the Satellite Manufacturing Market, as can be seen from the recent growth of the European Galileo navigation system. Two more satellites were launched in September 2024, bringing the number of operational satellites to 32 in total. The placement of these satellites in medium Earth orbit at 23,222 km improves the constellation’s robustness and reliability. This expansion is crucial to guarantee the uninterrupted provision of high precision global navigation services, which Galileo intends to provide to more than two billion users around the globe. The demand for satellite manufacturing is still growing as more satellites are set to be deployed by 2026, and second-generation satellites are being developed. With countries and private companies investing in expanding their satellite networks for enhanced communication, navigation and data services, the opportunities to innovate and manufacture satellites more efficiently have never been higher. The growing need for satellite constellations is fueling the growth of the satellite manufacturing industry, which is accelerating advancements.

Buy Now:

High Cost of Materials to Hamper the Market

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Satellite Manufacturing Market. The top 10 companies in this industry are listed below:

L3Harris Technologies Inc.

SpaceX

Lockheed Martin Corporation

RTX

Airbus

Boeing

Thales

AAC Clyde Space, Inc.

Ariane Group

Sierra Nevada Corporation

#SatelliteManufacturing#AerospaceIndustry#SatelliteTechnology#SpaceInnovation#NewSpaceEconomy#SatelliteDevelopment#AerospaceEngineering#SpaceTech

0 notes

Text

[ad_1] Prime Minister Narendra Modi met with US President Donald Trump at the White House for crucial discussions on defence, trade, technology, energy, and multilateral cooperation. The meeting, which followed PM Modi’s visit to France, occurred shortly after President Trump introduced a new reciprocal tariff policy affecting all US trading partners, including India. During the meeting, the two leaders launched the COMPACT initiative (Catalyzing Opportunities for Military Partnership, Accelerated Commerce & Technology for the 21st Century), which aims to enhance cooperation in defence, trade, technology, energy, and multilateral partnerships. Here are the major outcomes of the meeting: Defence: A new 10-year framework for the US-India Major Defence Partnership will be signed later this year, with new deals for Javelin anti-tank missiles, Stryker armoured vehicles, and six additional P8I maritime surveillance aircraft. The International Traffic in Arms Regulations (ITAR) will be reviewed to streamline technology transfers and spare parts supplies. Negotiations for a Reciprocal Defence Procurement agreement will begin to facilitate mutual defence purchases. The US and India will accelerate defence technology collaboration, with a focus on space, air defence, missile systems, maritime, and undersea warfare, including a review of releasing fifth-generation fighter jets to India. The two nations launched the Autonomous Systems Industry Alliance (ASIA) to co-develop underwater domain awareness (UDA) technologies, with India being the first country to collaborate with the US on sensitive UDA technologies. Ongoing talks about joint development of various autonomous surveillance systems and undersea vehicles. Trade: The leaders set a new trade goal, “Mission 500,” aiming to increase bilateral trade to $500 billion by 2030. A bilateral trade agreement is expected by autumn 2025, which will address multiple sectors and trade barriers, including reciprocal tariffs. Indian investments of $7.355 billion in the US, supporting 3,000 high-quality jobs, were acknowledged. Trade talks occurred against the backdrop of Trump’s 25% tariffs on global steel and aluminium imports, which could affect Indian exports. Technology: India and the US announced the TRUST (“Transforming the Relationship Utilizing Strategic Technology”) Initiative to promote partnerships in emerging technologies. A US-India AI Roadmap will be finalized by the end of the year, and next-generation data centres and AI partnerships were also highlighted. The launch of INDUS Innovation, based on INDUS-X, to enhance collaboration in space, energy, and biotechnology. Expansion of Indian pharmaceutical manufacturing in the US, focusing on critical medicines. A Strategic Mineral Recovery initiative to process rare earth minerals, lithium, and cobalt for high-tech industries. A new MoU was signed between the US National Science Foundation and India’s Anusandhan National Research Foundation to boost research collaboration in emerging technologies. Energy: Both leaders reaffirmed their commitment to the India-US Energy Security Partnership, with plans to support India’s full membership in the International Energy Agency (IEA). Progress was made on the India-US 123 Civil Nuclear Agreement, which will enable US-designed nuclear reactors in India. There will be cooperation on advanced small modular reactors to scale up nuclear energy production. People-to-People Ties: The leaders pledged to expand joint degrees, offshore campuses, and Centres of Excellence, with India’s 300,000-strong student community in the US contributing over $8 billion annually to the US economy. They discussed streamlining student and professional mobility while addressing issues such as illegal immigration and human trafficking. Strengthening law enforcement cooperation to combat organized crime, drug trafficking, and terrorism was also a priority. Multilateral Cooperation: Both leaders condemned

Pakistan’s failure to take action against terrorist networks, calling for accountability for the 26/11 Mumbai and Pathankot attacks. Trump announced the approval of the extradition of 26/11 convict Tahawwur Rana to India. PM Modi is set to host President Trump for the next Quad Leaders’ Summit, which includes India, the US, Japan, and Australia. New initiatives will be introduced in 2025 under the India-Middle East-Europe Corridor (IMEC) and I2U2 Group. The Indian Ocean Strategic Venture will foster economic and security cooperation. Meta also announced a 50,000 km undersea cable project. [ad_2] Source link

0 notes

Text

How Can I Control Contaminants in My Industrial Air Compressor System?

Maintaining a clean and contaminant free industrial air compressor system is essential for ensuring efficiency, extending equipment lifespan, and maintaining product quality. Contaminants in compressed air can harm your business in more ways than one. They reduce product quality, damage manufacturing equipment, and even pose health risks to customers and end users. The good news? You can control these harmful particles before they impact safety or your bottom line. But first, let’s explore what these contaminants are, where they come from, and the problems they cause—so you can tackle them effectively.

Common contaminants in industrial air compressors

Several contaminants can enter an industrial air compressor system, affecting its performance. The most common include:

Moisture (Water vapour and condensation)

Moisture is the number one enemy of compressed air systems. Condensed water and aerosols can rust pipes, reduce efficiency, and increase maintenance costs. Without proper drying and filtration, your system’s performance takes a hit. If not removed, this moisture can lead to:

Corrosion of pipes and system components

Growth of bacteria and mold

Reduced efficiency of pneumatic tools

Particulates (Dust, dirt, and debris)

Rust, pipe scale, dust, and microorganisms slink into your system despite filtration. These tiny particles wear down components, damage equipment, and shorten the lifespan of an industrial air compressor. These contaminants can:

Block filters and valves

Damage moving parts inside the industrial air compressor

Contaminate end products in sensitive industries (e.g., food and pharmaceuticals)

Oil contamination

Many India compressor use oil for lubrication, cooling, or sealing. But when oil enters the system as a vapour, aerosol, or liquid, it mixes with moisture, turning acidic. This leads to rust, potential system failures, and even product contamination., leading to:

Damage to air-operated tools and machinery

Health hazards when used in breathing air applications

Reduced efficiency of pneumatic processes

Microorganisms and bacteria

Warm and humid environments inside air compressors create a breeding ground for bacteria, fungi, and mould. These can:

Contaminate production processes

Cause foul odors in compressed air output

Lead to product spoilage in food and beverage industries

Effective strategies to control contaminants in industrial air compressor

Use High-quality air filters:

Air filters are the first line of defence against airborne contaminants. Air compressor manufacturers can use different types of filters to remove specific pollutants:

Particulate filters: Catch dust, dirt, and solid debris.

Coalescing filters: Remove oil aerosols and fine particles.

Activated carbon filters: Absorb oil vapours and odors for higher air purity.

Best methods for air filters:

Inspect and replace filters regularly.

Use multiple filters in sequence for enhanced protection.

Ensure filters match the required air purity standards for your industry.

Execute air dryers to remove moisture:

Moisture is one of the most damaging contaminants in a compressed air system. Installing air dryers can help control excess water.

Types of air dryers:

Refrigerated dryers: Cool the air to condense and remove moisture.

Desiccant dryers: Absorb moisture using chemical desiccants.

Membrane dryers: Use selective permeable membranes to dry compressed air.

Install automatic drain valves:

Even with air dryers, condensation can collect in the system. Automatic drain valves help remove this moisture from an industrial air compressor, tanks, and filters.

Drain valve guidance:

Use electronic or timer-based drain valves for automatic moisture removal.

Install drains at multiple points, including air tanks and low-lying sections.

Maintain oil-free compressed air where necessary:

In industries such as food processing and medical applications, oil-free air is necessary. Using oil-free compressors or advanced filtration can ensure minimal oil contamination.

Oil-free solutions:

Use oil-free air compressors if the application requires pure air.

Install oil removal filters and coalescing filters in oil-lubricated systems.

Monitor and maintain system components regularly:

Routine maintenance plays an essential role in controlling contaminants. Regular inspections and servicing prevent buildup and maintain system efficiency.

Key maintenance tips:

Check and replace filters, dryers, and drain valves regularly.

Inspect air lines for leaks and corrosion.

Conduct regular audits to monitor air quality and performance.

Ensure proper air intake placement:

Where the air compressor removes air from affects contamination levels. Placing the intake in a clean, dry area away from dust, fumes, and pollutants minimizes contamination.

Air intake placement tips:

Keep air intake away from exhaust fumes and chemical storage areas.

Install pre-filters if the air source contains excessive dust.

Summary:

Controlling contaminants in industrial air compressor systems is essential for optimizing efficiency, ensuring product quality, and extending equipment life. By executing proper filtration, drying techniques, regular maintenance, and following industry standards, you can significantly reduce the risk of contamination. Choosing high-quality air compressor manufacturers and reliable filtration solutions will also enhance system performance and safety. With the right strategies in place, you can maintain clean, high-quality compressed air that meets the demands of your industry.

#compressed air#air compressor manufacturers#industrial air compressor#air compressors#air compressor manufacturers in india

0 notes

Text

Apollo Micro Systems: Strengthening Defence Systems Through Indigenisation

Apollo Micro Systems Limited (AMS), a key player in the defence, aerospace, and homeland security sectors, continues to reinforce its commitment to indigenisation and technological advancements. The company has released its investor presentation for the quarter ending December 31, 2024, showcasing its growth trajectory, manufacturing capabilities, and strategic direction.

Founded in 1985 and headquartered in Hyderabad, AMS has carved a niche for itself in designing, developing, and manufacturing mission-critical electronic and electromechanical systems. Over the years, the company has built a strong reputation as a trusted partner of the Defence Research and Development Organisation (DRDO), Bharat Electronics Limited (BEL), and other key stakeholders in the defence and space sectors. With a broad portfolio that includes weapons handling systems, secure communication solutions, electronic warfare systems, and air defence technologies, AMS is poised to drive innovation and self-reliance in India's defence ecosystem.

The company’s journey has been marked by significant milestones, from early contributions in electronic CAD design to the development of indigenous defence systems. AMS has played a crucial role in supporting India's missile programs, aerospace applications, and naval systems, gradually transitioning from being a buyer to a builder. In recent years, AMS has expanded its manufacturing infrastructure to cater to the growing demand for indigenous defence solutions. The establishment of its new Integrated Plant for Ingenious Defence Systems (IPiDS) in Hyderabad underscores its commitment to backward integration, enhancing in-house capabilities and production efficiency. This state-of-the-art facility, expected to be operational by the end of FY25, will position AMS as a premier Tier-1 OEM manufacturer.

As part of its strategic expansion, AMS has also acquired 2.5 acres of land to further bolster its manufacturing footprint. The company’s Unit-II facility, spanning 40,000 square feet, and its upcoming Unit-III facility at Hardware Park-II, Hyderabad, will add another 3,50,000 square feet of operational space. This significant growth in manufacturing capacity will enable AMS to scale up production and cater to the increasing demand for indigenous defence products.

Innovation and research remain at the core of AMS’s growth strategy. The company has been actively involved in more than 60 defence programs as a sub-system partner and has developed over 150 indigenous programs. With a robust Research & Development (R&D) team of 165+ professionals, AMS continues to drive technological excellence and strategic collaborations. Notably, AMS has entered the radio frequency (RF) and microwave domain through a strategic acquisition, reinforcing its capabilities in advanced defence electronics.

The investor presentation also highlights AMS’s corporate structure, which includes subsidiaries such as Ananya SIP RF Technologies Private Limited and Apollo Defence Industries Private Limited (ADIPL). In December 2024, AMS incorporated a new step-down subsidiary, Apollo Strategic Technologies Private Limited, with a 51% stake, further strengthening its presence in the defence manufacturing sector.

Certified under ISO 9001:2015 and CEMILAC, AMS adheres to stringent quality standards, ensuring reliability and precision in its offerings. The company’s dedication to excellence is reflected in its collaborations with leading defence institutions and its commitment to delivering cutting-edge solutions tailored to India’s defence and aerospace requirements.

As AMS charts its course for sustained growth, it remains steadfast in its mission to “Convert Your Concepts into Reality.” With a vision to emerge as a world-class solution provider offering “Total Solutions Under One Roof,” the company is well-positioned to play a pivotal role in India's journey towards defence self-reliance.

With its solid foundation, continuous innovation, and unwavering commitment to indigenisation, Apollo Micro Systems Limited is set to drive the future of defence technology, ensuring that India remains at the forefront of strategic and technological advancements.

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] "Saluting the Indomitable Spirit of Indian Armed Forces Veterans - Exclusive T-Shirts for the True Heroes!" At RedClub, we take immense pride in presenting our heartfelt collection of T-Shirts specially curated for the Veterans of the Indian Armed Forces. These brave souls have fearlessly shed sweat and blood, standing tall with unyielding determination, even in the face of uncertainty. Today, they bask in the well-deserved recognition as Veterans, having served our beloved Mother India with unwavering devotion. Participating in esteemed ceremonies like flag hoisting, inaugurations, and Republic and Independence Day celebrations, Veterans are revered with special honors, as they remain a symbol of unparalleled sacrifice and service. Adorned in attire that sets them apart, Veterans catch everyone's eye and command respect without boasting of their extraordinary achievements. In this era of trending selfies, people eagerly seek to capture moments with these true heroes during such special occasions. To make these cherished days even more memorable and prestigious, we proudly present selective accessories, memoirs, apparels, and gift articles, adding a touch of military flair to the years dedicated to serving the nation. Our T-Shirts, carefully designed with Dry Fit fabric, ensure comfort and style, while the Regular Fit and Unisex appeal cater to every esteemed Veteran. These T-Shirts serve as a perfect gift for Special Occasions, Veteran Day, Armed Forces Day, Air Force Day, Navy Day, Army Day, Independence Day, and Republic Day, celebrating the valor and dedication of our nation's defenders. Join us in honoring our Indian Defence Services Veterans by proudly wearing these exclusive T-Shirts and carrying their legacy forward. Show your gratitude and admiration by getting yours today! Limited stock available. Embrace the spirit of patriotism and order now to be part of this noble tribute!" Date First Available : 23 December 2023 Manufacturer : RedClub ASIN : B0CQVNYVWX Item part number : Army-Polo Country of Origin : India Department : Unisex Manufacturer : RedClub, RedClub Packer : RedClub [ad_2]

0 notes

Text

[ad_1] Cycle Pure Agarbathi, India’s leading agarbathi manufacturer, is extending their support as the title sponsors of the Ability Sports League T20 (previously known as Karnataka Wheelchair Premier League). The tournament will be held from 10th December 2024 to 17th December 2024 at Alur KSCA Ground. The 3rd edition of the league will provide wheelchair athletes with the opportunities to showcase their unique talents and abilities, while competing in an inclusive arena. The brand equipped all the 90 players with professional-grade cricket kits, including helmets, gloves, pads, and bats The T20 tournament is the first South Asian wheelchair cricket league, offering athletes a unique platform to represent the future of India’s wheelchair cricket team. Launched in 2018, the league offers over 600 players in wheelchairs with the chance to showcase their talents and play for an international league. Cycle Pure Agarbathi has further extended their support by supplying the 90 players from six teams with helmets, gloves, pads, bats and kits. The brand's support aims to level the playing field by providing each player with their own individual kit. This includes helmets, gloves, pads, and bats, ensuring that every athlete has the necessary equipment to perform at their best. Mr. Arjun Ranga, Managing Director, Cycle Pure Agarbathi said, “At Cycle Pure Agarbathi, we believe in the power of sports to inspire and unite communities. Supporting the Karnataka Wheelchair Premier League is our way of supporting the incredible athletes who demonstrate strength, resilience, and determination. We are proud to contribute to this platform that celebrates inclusivity and empowers individuals to achieve greatness, regardless of the challenges they face.” Cycle Pure Agarbathi has showcased their support on numerous occasions to athletes by providing a platform to display their skills. The organisation is renowned for their contributions towards the Tiger Cup and Mysore Warriors, where the team was awarded the winners of the 2024 Maharaja Trophy. About NRRS The Mysuru-based NRRS was founded by Shri N. Ranga Rao in 1948. A true visionary and philanthropist, Shri Ranga Rao created the ubiquitous Cycle Pure Agarbathi which has, today, become the largest selling incense stick brand in the world. From a home-grown enterprise, NR Group has evolved into a successfully run business conglomerate with an established presence in India and abroad. The Group has diversified into various business categories like functional air care products (Lia brand of room fresheners and car fresheners), wellness home fragrance products (IRIS) under Ripple Fragrances, floral extracts (NESSO), and Rangsons Technologies. Today, it is truly an Agarbathi to Aerospace conglomerate as it is also involved in making parts for defence helicopters. The organization has largely committed towards social responsibilities and fulfils them, through its charity arm ‘NR Foundation’. NR Group today is managed by the third generation of the Ranga family. For more information on NR Group, please visit www.nrgroup.co.in. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

Transforming Precision Engineering With Advanced Machining Solutions

In the realm of manufacturing, precision and efficiency are paramount. Modern machining technologies like Vertical Turning Lathes, 5-axis Turnmills and Special-Purpose Machines have revolutionised the way industries operate, offering unparalleled accuracy and productivity. Leading the charge in this transformation is WIDMA, a division of Kennametal India Limited, known for its cutting-edge machining solutions tailored to diverse industrial needs.

The Role of Vertical Turning Lathes

A Vertical Turning Lathe (VTL) is a highly efficient machine tool designed for machining large, heavy and complex components. Industries like automotive, aerospace and energy rely on VTLs for their ability to handle high material removal rates and deliver precise surface finishes. WIDMA specialises in manufacturing robust VTLs that are equipped with advanced features to meet the demanding requirements of these industries. Their machines ensure minimal downtime, optimal productivity and long-term reliability, making them a preferred choice for manufacturers worldwide.

Unleashing the Power of 5-axis Turnmills

When it comes to versatility in machining, 5-axis Turnmills are unmatched. These machines combine milling and turning functionalities, allowing manufacturers to produce complex parts in a single setup. The result is reduced cycle times, improved precision and minimised handling errors. WIDMA’s 5-axis Turnmill solutions are designed to meet the challenges of modern manufacturing, offering high-speed operation and seamless integration with Industry 4.0 technologies. These machines are ideal for creating intricate geometries needed in industries like aerospace, defence and precision engineering.

Special-Purpose Machines for Tailored Solutions

Every industry has unique manufacturing needs that cannot always be met with standard equipment. This is where Special-Purpose Machines (SPMs) come into play. SPMs are designed for specific tasks, providing higher productivity and efficiency compared to conventional machines. WIDMA excels in creating customised SPMs for a wide range of applications, from deep-hole drilling to high-precision machining. Their expertise in turnkey solutions ensures that businesses receive machines tailored to their exact requirements, reducing costs and enhancing operational efficiency.

Why Choose WIDMA?

Innovative Technology: WIDMA leverages cutting-edge technologies to deliver machines that meet the highest standards of performance and precision.

Custom Solutions: From Vertical Turning Lathes to Special-Purpose Machines, WIDMA’s portfolio caters to diverse industrial requirements.

Comprehensive Support: With an integrated facility for design, manufacturing and after-sales support, WIDMA ensures seamless execution and long-term reliability.

Global Presence: WIDMA’s machines are trusted by industries across the globe, reflecting their commitment to quality and innovation.

The Future of Machining

As industries evolve, the demand for advanced and efficient machining solutions will continue to grow. Machines like 5-axis Turnmills, Vertical Turning Lathes and Special-Purpose Machines will remain at the forefront of this evolution, driving innovation and productivity. With companies like WIDMA leading the way, manufacturers can expect solutions that are not only reliable but also future-ready.

Conclusion

Precision engineering is the backbone of modern manufacturing and technologies like Vertical Turning Lathes, 5-axis Turnmills and Special-Purpose Machines are key to achieving excellence. With a legacy of innovation and expertise, WIDMA is empowering industries to meet their challenges head-on, ensuring success in an ever-competitive market. Choose WIDMA for cutting-edge solutions that redefine machining efficiency and precision.

0 notes

Text

Best Customer Feedback Research Companies in India

BDB India Private Limited is a leading global business strategy consulting and market research company in India. Since 1989, BDB has been providing clients with solutions to expand their businesses in the Indian and international marketplace. We are an ISO certified company. BDB India is the leading global business strategy consulting and market research firm for automotive industry. BDB is a Best Customer Feedback Research Companies in India .Read more at… https://bdbipl.com/.

Aerospace & Defense

The Aerospace and Defense (A&D) business in India is predicted to grow to a value of about $70 billion by 2030 as a result of government initiatives and improved infrastructure. The India defense budget is worth $74 billion in 2023 and is expected to achieve a CAGR of more than 4% during 2024-2028.

Component Manufacturing – This provides a compelling argument for Indian suppliers and global OEMs to consider India as a location for a key position in the global supply chain for aerospace components and parts. The combination of low costs in India and the availability of technical and engineering skills producing high-precision and high-quality components may result in a number of benefits. It is extremely likely that the aircraft business, as well as the services and components associated with it, will experience the same trends as the automotive (small car) industry.

In the past century, government-owned companies like HAL, NAL, ISRO, and others have largely been responsible for the advancement of domestic aerospace manufacturing of aircraft, helicopters, and other aerospace products. However, since the turn of the century, the private sector has aggressively expanded its participation, supported by major corporate houses have successfully entered the aircraft industry.[/vc_column_text]

Manufacturing Industry structure can be broadly classified into

MOD and other government entities: For purchasing aircraft and other equipment for defence and other requirements.

Aircraft/airplane, helicopter, space equipment manufacturers: OEMs largely restricted to PSUs like HAL, NAL, ISRO and other government entities.

Ancillary Manufacturers of aerospace components and assemblies: Various types of metallic, non-metallic and composite parts for engines, aero structures, airplane interiors, space programs etc. for both domestic supply and exports to international manufacturers.

MRO and other service operators: For maintenance and repair services for airplanes and other aircrafts.

Read More at… https://bdbipl.com/index.php/aerospace-defence/

0 notes

Text

Four Essential Factors for Defense Part Manufacturers in India

Did you know that India's defense exports have grown six times in the previous 5-6 years?

Made in India defense equipment and services are now being provided to more than 75 countries. This surge in demand highlights the increasing prominence of defense part manufacturers in India.

But what are the key factors shaping defense part manufacturers in India? Let’s explore the driving forces behind the success of the Indian defense manufacturing industry.

Growing Demand

One of the primary factors shaping defense part manufacturers in India is the growing demand for defense equipment and services. As countries around the world prioritize strengthening their defense capabilities, the need for reliable and technologically advanced defense parts has increased. Indian manufacturers have seized this opportunity and are catering to both domestic and international markets, fueling the growth of the defense manufacturing sector.

Competitive Advantage

Indian defense part manufacturers enjoy a competitive advantage due to several factors. First and foremost, India has a vast pool of skilled labor and engineering talent, enabling the production of high-quality defense parts. Additionally, the cost of production in India is relatively lower compared to many developed nations, making Indian manufacturers more cost-competitive. This advantage has attracted foreign companies to collaborate with Indian counterparts, leading to technology transfers and further boosting the capabilities of Indian defense part manufacturers as well as the aerospace components manufacturers in India.

Government Support

The Indian government has played a crucial role in shaping the defense manufacturing landscape. Various Government initiatives in India have significantly reduced the expenditure on defence procurement from foreign sources. Over the past four years, it has dropped from 46% to 36%.

This positive trend aligns with the Atmanirbhar Bharat Initiative, which promotes domestic manufacturing of 411 defence products instead of relying on imports. To further boost indigenization, the SRIJAN portal has been launched, showcasing 19,509 defence items for local production.

Opportunities

The Indian defense manufacturing sector offers immense opportunities for both established players and emerging companies. Initiatives have encouraged innovation and entrepreneurship in the sector, attracting new entrants with novel ideas and technologies. These opportunities have led to the establishment of a vibrant ecosystem, fostering the growth of defense part manufacturers in India.

Did you know?

The establishment of Defence Industrial Corridors in Uttar Pradesh and Tamil Nadu creates opportunities for the country's 194 defence tech startups, which are driving innovation and supporting India's defence efforts. These measures demonstrate India's commitment to self-reliance in the defence manufacturing sector, paving the way for a robust and innovative indigenous defence indu

Parting Thoughts

The defense manufacturing sector in India has witnessed a remarkable transformation, and they are making their mark on the global stage. As the industry continues to evolve and adapt to changing global dynamics, Indian defense part manufacturers like Sujan Industries are poised to thrive and contribute significantly to the nation's defense sector. Right from control links to ballast broom, you will find everything you need at Sujan Industries. Check our website for more information regarding our products and services.

0 notes

Text

JSW Defence to invest $90 million to bring American Shield AI's fixed-wing drone to India

By N. C. Bipindra Mumbai: Indian firm JSW Defence Private Limited, part of the US$24-billion JSW Group, today announced a “strategic partnership” with Shield AI Inc., a leading American defence technology company, to indigenise and manufacture Shield AI’s ‘V-BAT‘ fixed-wing Unmanned Aerial System (UAS) in India. “This collaboration marks a significant step in boosting India’s defence…

#Aircraft#American#Armed Forces#Brandon Tseng#Defence#Defense#Group 3 UAS#Group 5 UAS#India#Indian#Indian Armed Forces#Industry#JSW Defence#JSW Defence Private Limited#JSW Group#Major Defence Partner#Major Defense Partner#Manufacturing#Marine Expeditionary Units#MEUs#Military#Parth Jindal#Partnership#Plane#Production#Shield AI#Stategic Authorization Tier 1#Technology#UAE#UAS

0 notes

Text

Every Indian can be proud of India’s journey in defence production: PM Modi

New Delhi: Prime Minister Narendra Modi Wednesday hailed the country’s rise in defence production and export, saying every Indian can be proud of this journey, as he gave a passionate call to startups, manufacturers and innovators to be a part of the sector. In a post on LinkedIn, he told the youth, startups, manufacturers and innovators that India’s defence sector is calling them. This is their…

0 notes

Text

3D Printing Plastic Market,Industry Forecast, 2024–2030.

3D Printing Plastic Market size is forecast to reach $3,004.71 million by 2030, after growing at a CAGR of 17.1% during 2024–2030. Globally, the demand for 3D printing plastic is rising from various application sectors such as aerospace and defense, electrical and electronics, and healthcare, by reducing the efforts, time, and costs incurred in the project. The increasing demand for 3D printing plastic from various industries, such as aerospace, automotive, healthcare, and electronics, for applications such as prototyping, tooling, and functional parts. The cost-effectiveness, strength, durability, and versatility of 3D printing plastic compared to other materials. The development of new types and grades of 3D printing plastic, such as biodegradable, conductive, and flexible plastics. The increasing use of photopolymers and polyamide (nylon) materials in 3D printing owing to its alluring properties is estimated to drive the 3D printing plastics market growth. Furthermore, the development of innovative, stronger, lighter, and safer components and parts with lower lead times and costs is anticipated to create new opportunities for the growth of the global 3D printing plastic industry in the forecast period.

Request Sample :

Covid-19 Impact

The rise in positive COVID-19 cases worldwide generated a huge demand for the 3D printing plastics market from the healthcare sector. The market for medical components such as face shields, masks, ventilator vales, and others has seen an upsurge since the outbreak of COVID-19. Owing to the COVID-19 palindrome the increasing demand of medical components from across the globe, has also increased the demand for 3D printing adoption in various regions.

Market Snapshot :-

3D Printing Plastic Market Report Coverage

The: “3D Printing Plastic Market Report — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the 3D Printing Plastic Market. By Form: Filament, Ink, and Powder.

By Type: Polycarbonates, Photopolymers, Acrylonitrile Butadiene Styrene (ABS), Polyamide/Nylon, Polylactic Acid, Polyethylene Terephthalate (PET), Glycolized polyester (PETG), High Performance Polymers, and Others.

By Application: Prototyping, Automotive, Healthcare, Consumer Goods, Aerospace & Defence, Electrical & Electronics, and Others.

By Geography: North America (U.S, Canada, and Mexico), Europe (U.K., Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), APAC (China, Japan India, South Korea, Australia & New Zealand, and Rest of Asia Pacific), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle east and Africa).

Inquiry Before Buying:

Key Takeaways

The rising demand for laser sintering technology by engineers and manufacturers in various commercial sectors will increase the demand for polyamide (nylon), which is further expected to drive the 3D printing plastic industry growth.

Owing to the ability of the plastic being shaped easily, they are used in the initial stages of the onset of 3D printers. Very recently, NASA has been using space-based 3D printers with plastic as the key material for space-based objects.

Also, the rise of the automobile industry is set to hold the market for 3D printing plastics at its height in the years to come. Quick advances in diverse materials and technology are allowing the industry to gain momentum.

For more details on this report — Request for Sample

3D Printing Plastic Market Segment Analysis — By Form

Filament form is widely used in the 3D Printing Plastic Market. They are only manufactured and consumed in two diameters, namely 1.75 mm and 3 mm. By using the process of heating, extruding and cooling plastic, filament form is produced to turn nurdles into finished product. Thus, it is possible to dye these filaments in various colours. Also, due to their flexible properties there is an increase in demand from several application industries such as food packaging, tableware, upholstery, and disposable clothing.

3D Printing Plastic Market Segment Analysis — By Type

Polyamide/Nylon segment held the largest share in the 3D Printing Plastic Market in 2023. Nylon (known as polyamide) is a synthetic linear polyamide thermoplastic and is a well-known 3D printing filament owing to its stability, toughness, low friction and corrosion resistance. Nylon is also a common substance used in the manufacture of clothing and accessories. Due to its improved strength and elasticity over PLA and ABS, Nylon is ideal for manufacturing uses, such as machine parts or equipment, or the replacement of automotive parts. As compared to ABS and PLA Nylon is tougher and more resistant to chemicals, but its poor strength and hardness prohibits it from being commonly used in the manufacturing industry. With the increasing demand for nylon the market for 3D printing plastic is also estimated to rise in the forecast period.

3D Printing Plastic Market Segment Analysis — By Application

Prototyping segment held the largest share in the 3D Printing Plastic Market in 2023 and is projected to grow at a CAGR of 17.1% during the forecast period 2024–2030. Creating a concept can be a costly and slow process. Fortunately, certain methods are available to help you enhance the product creation process, helping to make high-quality prototypes at a cheaper cost. From office to the factory floor, 3D printers produce plastic concept models, precision and practical prototypes, master patterns and actual end-use components for refining every project, streamlining the workflows and getting creative products to the market quicker. Besides, 3D printing plastic is the best solution for designing the prototypes. By beginning to create the 3D printing project, one will have access to a wide variety of efficient 3D printing supplies, saving time and resources. Thus, rising usage of 3D printing plastic for prototyping applications is set to drive the market growth over the forecast period.

Schedule a Call :

3D Printing Plastic Market Segment Analysis — By Geography

North America held the largest share with 51% in 3D Printing Plastic Market in 2023 Due to the increasing demand for 3D printing plastics in medical devices and equipment, and the increasing adoption of 3D printing technology in U.S., Canada, Mexico and various other countries in the region is set to drive the market growth in the upcoming future. According to the U.S. Department of Health and Human Services, the Fiscal Year (FY) 2023 budget represents the responsibilities of the U.S. government to advance a patient-centered healthcare system. The budget proposes a discretionary budget authority of $96.1 billion and mandatory support for Health and Human Services of $1.86 trillion.Thus, the rising investments by the government in the healthcare sector are estimated to boost the 3D Printing Plastic Market growth in the forecast period.

3D Printing Plastic Market Drivers

Rising Demand for 3D Printing Plastic from the Healthcare Industry

Rising usage of 3D printing plastic in the healthcare sector is driving the market growth. Key factors driving demand in the medical industry for 3D printing plastics include cost-effectiveness, ease of customization, as well as the rising occurrence of vascular and osteoarthritis diseases. Polyamide or nylon is often used for injection molding in medical device owing to its inflexible nature, strength, chemical compatibility, and temperature resilience. Increasing use of photopolymers for high-resolution, ultra-fine parts in medical devices will also drive the market growth. Moreover, the market demand in medical applications is expected to be fueled by advanced 3D technology, favorable government funding, and rapid product growth. According to the India Brand Equity Foundation, the government of India aims to increase the healthcare spending to 3% of the GDP by 2022, which means the healthcare sector will rise three-fold to Rs. 8.6 trillion (US$ 133.44 billion). Hence, the growing demand for 3D printing plastic from the healthcare sector will raise the growth for 3D Printing Plastic Market in the forecast period.

Increasing Demand for Biodegradable Materials for 3D printing

The growing need for the “green” alternative to traditional polymers has propelled the demand for polylactic acid in the 3D printing plastic industry. Since, polylactic acid is very inexpensive, easy to print, and produces components that can be used for a wide variety of applications, it is the ideal first material to be used in 3D printing. It is also one of the most environmental friendly products made from crops such as corn and cane that are used today. This material is thermoplastic aliphatic polyester and is the predominant natural raw material that consists of recycled raw materials used in 3D printing plastics. For most extrusion-based 3D printing, polylactic acid is also the default filament of choice, since it can be printed at low temperatures and does not require a heated bed. Thus, with the rising demand for biodegradable materials the growth for 3D printing plastics market is estimated to rise in the forecast period.

Buy Now :

3D Printing Plastic Market Challenges

Environmental Issues Regarding 3D Printing Plastic Materials will Hamper the Market Growth

Over the last few years, one environmental issue has gradually stolen the spotlight that is plastic pollution. The reliance on plastics-especially single-use plastics-is now one of the world’s leading environmental concerns. 3D printing uses the flexible, durable design of plastics in a wide variety of applications, from aerospace to healthcare. Polyethylene terephthalate (PET) is one of the most common filaments used in plastics such as bottles of disposable beverages and food packaging. Other filaments include polycarbonate and ABS: both are relatively inexpensive, flexible and easy to manufacture. Unfortunately, these materials are not commonly recyclable and so any waste generated in the printing process would find its way to the landfill or to the natural environment. Thus, rising environmental concerns due to the use of various 3D printing plastics is estimated to hinder the 3D printing plastics market growth.

3D Printing Plastic Market Outlook

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the 3D Printing Plastic Market. Major players in the 3D Printing Plastic Market are:

3D Systems Corporation

Arkema SA

Stratasys, Ltd.

Evonik Industries AG

HP Inc.

SABIC

DowDuPont Inc.

EOS GmbH Electro Optical Systems

Solvay

Royal DSM N.V., among others.

Acquisitions/Technology Launches

In March 2023, BASF SE acquired Sculpteo, a French online 3D printing service provider, to expand its 3D printing solutions portfolio and customer base.

In February 2023, Arkema acquired Lambson, a UK-based company that specializes in photo initiators for 3D printing, to strengthen its position in the 3D printing market and offer innovative solutions for UV-curable resins.

In January 2023, Stratasys Ltd. acquired Origin, a US-based company that develops 3D printers and materials for mass production, to enhance its capabilities in the fast-growing segment of end-use parts.

In December 2022, Evonik Industries AG acquired 3D Printing Materials, a US-based company that produces high-performance thermoplastics for 3D printing, to broaden its product portfolio and customer base in the additive manufacturing market.

For more Chemicals and Materials Market reports, please click here

0 notes

Text

[ad_1] Cycle Pure Agarbathi, India’s leading agarbathi manufacturer, is extending their support as the title sponsors of the Ability Sports League T20 (previously known as Karnataka Wheelchair Premier League). The tournament will be held from 10th December 2024 to 17th December 2024 at Alur KSCA Ground. The 3rd edition of the league will provide wheelchair athletes with the opportunities to showcase their unique talents and abilities, while competing in an inclusive arena. The brand equipped all the 90 players with professional-grade cricket kits, including helmets, gloves, pads, and bats The T20 tournament is the first South Asian wheelchair cricket league, offering athletes a unique platform to represent the future of India’s wheelchair cricket team. Launched in 2018, the league offers over 600 players in wheelchairs with the chance to showcase their talents and play for an international league. Cycle Pure Agarbathi has further extended their support by supplying the 90 players from six teams with helmets, gloves, pads, bats and kits. The brand's support aims to level the playing field by providing each player with their own individual kit. This includes helmets, gloves, pads, and bats, ensuring that every athlete has the necessary equipment to perform at their best. Mr. Arjun Ranga, Managing Director, Cycle Pure Agarbathi said, “At Cycle Pure Agarbathi, we believe in the power of sports to inspire and unite communities. Supporting the Karnataka Wheelchair Premier League is our way of supporting the incredible athletes who demonstrate strength, resilience, and determination. We are proud to contribute to this platform that celebrates inclusivity and empowers individuals to achieve greatness, regardless of the challenges they face.” Cycle Pure Agarbathi has showcased their support on numerous occasions to athletes by providing a platform to display their skills. The organisation is renowned for their contributions towards the Tiger Cup and Mysore Warriors, where the team was awarded the winners of the 2024 Maharaja Trophy. About NRRS The Mysuru-based NRRS was founded by Shri N. Ranga Rao in 1948. A true visionary and philanthropist, Shri Ranga Rao created the ubiquitous Cycle Pure Agarbathi which has, today, become the largest selling incense stick brand in the world. From a home-grown enterprise, NR Group has evolved into a successfully run business conglomerate with an established presence in India and abroad. The Group has diversified into various business categories like functional air care products (Lia brand of room fresheners and car fresheners), wellness home fragrance products (IRIS) under Ripple Fragrances, floral extracts (NESSO), and Rangsons Technologies. Today, it is truly an Agarbathi to Aerospace conglomerate as it is also involved in making parts for defence helicopters. The organization has largely committed towards social responsibilities and fulfils them, through its charity arm ‘NR Foundation’. NR Group today is managed by the third generation of the Ranga family. For more information on NR Group, please visit www.nrgroup.co.in. !function(f,b,e,v,n,t,s) if(f.fbq)return;n=f.fbq=function()n.callMethod? n.callMethod.apply(n,arguments):n.queue.push(arguments); if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0'; n.queue=[];t=b.createElement(e);t.async=!0; t.src=v;s=b.getElementsByTagName(e)[0]; s.parentNode.insertBefore(t,s)(window,document,'script', 'https://connect.facebook.net/en_US/fbevents.js'); fbq('init', '311356416665414'); fbq('track', 'PageView'); [ad_2] Source link

0 notes

Text

Aerospace Parts Manufacturer & Supplier in India | Machine Maze

Discover top-quality aerospace parts with Machine Maze, a leading aerospace parts manufacturer & supplier in India. Trusted for precision engineering with unmatched expertise. Visit -

1 note

·

View note