#Deck Machinery Market Size

Explore tagged Tumblr posts

Text

How Do Cage Trailers for Sale in Newcastle Improve Flexibility for Businesses?

A top-quality flat top tipper trailer is an essential tool for many businesses that need to transport heavy machinery effortlessly including for construction businesses to complete projects on time. Flat-top trailers come with a spacious flat deck that provides ample space for transporting large and heavy equipment while being stable and safe.

At the same time, these businesses often search for large galvanised cage trailers for sale, exclusively from reputable suppliers to get trusted material and top-quality products with a warranty on their durability, versatility, and dependability.

In addition, galvanisation increases rust and corrosion resistance, improving the trailer's durability even in hostile conditions.

Why Large-sized Trailers are High-Demand for Some Businesses?

Well-known trailer vendors provide huge trailers measuring 10x6 feet with spacious designs suitable for hauling bulky things, tools, or equipment.

Whether for commercial or personal usage, trusted suppliers provide easy and effective transportation, making it an advantageous resource for both large-scale corporations to medium and small-scale businesses.

The spacious dimensions and flat surface safeguard both the equipment and the trailer itself from potential damage during transit.

Furthermore, they source from reputable manufacturers for durable equipment that can withstand the weight and pressure of huge machines, ensuring dependable performance even under the most demanding conditions.

Its strong chassis and strengthened frame, which boost stability and endurance, allow it to transport valuable assets securely. Furthermore, the flat top design allows for easy transportation and setup of a variety of machinery types, saving interruption and boosting productivity.

Businesses can transfer manufacturing tools, building machinery, or machinery for agriculture with convenience and economy by using huge trailers, which are a practical and cost-effective option for carrying heavy equipment.

Buy Trailers from a Certified Dealer Nearby:

Find suppliers with a strong reputation for dependability and quality, as well as positive ratings and comments.

Evaluate their range of products for diverse needs from different businesses and provide a facility for personalised trailers and post-purchase assistance.

Examine whether they have any certifications or links with reputable trade bodies and adhere to local regulations on safety and product quality.

Get referrals from professionals in the sector, and read market reviews of service providers.

Finally, contact a reliable trailer supplier near you who provides excellent customer service, clear communication, and reasonable prices.

Source

0 notes

Text

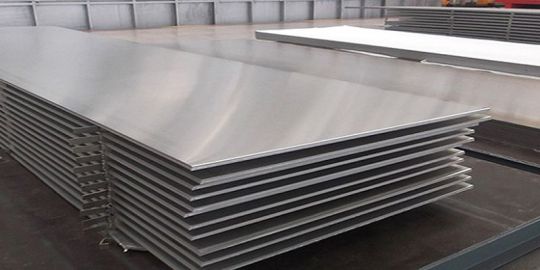

The Importance and Applications of Hot Rolled Plates in Tamil Nadu

With strength, durability, and cost-effectiveness, Hot Rolled Plates have become a cornerstone for most of the industries in Tamil Nadu. The manufacture of these plates through the rolling process at high temperatures makes them very important in applications requiring toughness, together with versatility. In this blog, we glance at the importance, use, and market demand of hot-rolled plates in Tamil Nadu, one of the premier states in India when it comes to industries and manufacturing units.

What is a hot-rolled plate?

Hot-rolled plates are sheets of steel produced through the rolling of steel at higher temperatures above the recrystallization point. It gives them a more flexible structure, hence making shaping or working with the plates quite easier. The resultant plates are strong, uniform, and suitable for heavy-duty applications. Most growing industries in Tamil Nadu depend a lot on hot-rolled plates because of their adaptability and performance.

Applications of Hot Rolled Plates in Tamil Nadu

1. Construction Industry:

This means there is an emerging requirement for durable materials within construction in rapidly burgeoning Chennai, Coimbatore, and Madurai cities of Tamil Nadu. The applications of hot-rolled plates consist of building frames, bridges, and other infrastructures, as their strength and load-carrying capacities make them one of the favorite choices for the erection of long-lasting structures.

2. Automotive Industry:

Tamil Nadu is the "Detroit of India," boasting quite a few key automotive players. The hot-rolled plates find their applications while manufacturing vehicle parts such as chassis, wheels, and body frames. Their toughness will enable them to bear a lot of stress and wear for the auto components.

3. Shipbuilding and Marine Applications:

With a long coastline area hosting some major cities, Tamil Nadu promises huge potential for the shipbuilding and marine industry. Hot-rolled plates are essential in making ship hulls, decks, and other marine facilities due to their resistance to deformation under pressure.

4. Industrial Machinery:

Industrial cities like Coimbatore and Salem in Tamil Nadu rely heavily on hot rolled plates for heavy machinery and equipment fabrication. In fact, those are highly demanded plates that would be used to manufacture storage tanks, boilers, and pressure vessels, which are produced using materials capable of withstanding extreme conditions.

5. Farm Tools and Equipment:

Hot-rolled plates can be considered one of the most usable items for Tamil Nadu in agriculture because their usage is in making strong and long-lasting tools, irrigation, and storage containers. These are flexible and strong, hence assured for reliable performance even under challenging rural conditions.

Why Hot Rolled Plates are more in Demand in Tamil Nadu

The reason why Tamil Nadu uses hot rolling plates is due to the several key advantages it provides:

• Durability: Hot-rolled plates have a lot of strength and bear heavy loads; hence, they are ideal for both industrial and structural purposes.

•Cost-Effective: They offer excellent value for money, making them an economical choice for large-scale projects.

• Easy Customization: Hot-rolled plates are easy to cut, weld, and shape. It gives an opportunity for the manufacturers to make it according to the application.

• Local Availability: A number of suppliers and manufacturers of hot-rolled plates have links in Tamil Nadu. Therefore, since these are locally available, one can access quality lots faster and economically.

How to Select the Best Hot Rolled Plates Supplier in Tamil Nadu

During the sourcing process for hot-rolled plates in Tamil Nadu, the need to identify an appropriate supplier arises. The suppliers that offer certified products to meet the standards of the industry will also provide options related to different thicknesses and sizes to present just what one's project requires.

Conclusion

Hot-rolled plates in Tamil Nadu are also inseparable in industries like construction, automotive, shipbuilding, and in agriculture sectors. Really durable, versatile, and inexpensive, it is one of the trusted materials for diversified applications.With Tamil Nadu continuing to occupy the first position in the industrial growth of the country, the demand for hot rolled plates is bound to increase. A good deal of profit is assured to businesses and contractors investing in quality hot rolled plates, which ensures the longevity and success of their ventures.

0 notes

Text

Marine Vinyl Market Size To Reach USD 488.0 Million By 2030

Marine Vinyl Market Growth & Trends

The global marine vinyl market size is expected to reach USD 488.0 million by 2030, growing at a CAGR of 5.3 from 2024 to 2030, according to a new report by Grand View Research, Inc. The market growth can be attributed to the surging demand for recreational boating, water sports, and yachting in North America and Europe. Furthermore, the expansion of maritime tourism in the Middle East & Africa, the Caribbean, and the Mediterranean is boosting the demand for marinas and waterfronts, thereby driving the product demand.

Marine vinyl is one of the ideal materials designed to withstand the harsh conditions of marine environments as it is highly resistant to tear, punctures, and abrasions. This makes it an ideal material for boat interiors and exteriors wherein constant exposure to physical stress is common. Moreover, marine vinyl is also waterproof. It prevents issues such as rotting, warping, and degrading of the components of the watercraft owing to no water absorption.

Innovations in marine vinyl, such as improved UV resistance, better textures, and enhanced durability, attract more consumers who are looking to renovate or refurbish their recreational boats, cruise ships, and yachts. Trivantage introduced pleated marine vinyl as part of its Nassimi Seaquest, Causeway Roll-N-Pleat, Nautolex Capitano, and Sunbrella Horizon brands. The pleated marine vinyl is durable, easy to clean, does not require specialized machinery for installation, and is available in multiple colors and patterns.

Moreover, the maintenance of marine vinyl is relatively simpler than other materials. It can be easily cleaned with soap and water and hence, has no requirement for special treatment methods or coatings to maintain its appearance and functionality. This ease of maintenance is appealing for outdoor applications wherein frequent cleaning might be necessary. Such factors contribute to the rising product demand for conventional fabrics in marine applications across the world.

Rising concerns among the masses across the world over the environmental impact of using vinyl affect the market growth. PVC contributes more to global warming compared to other types of plastic owing to its high energy consumption and discharges a significant amount of carbon dioxide (CO2) during its manufacturing process. Hence, with the growing awareness regarding climate change, the inclination of consumers toward sustainable alternatives is hampering the market demand.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/marine-vinyl-market-report

Marine Vinyl Market Report Highlights

Based on end use, cruise ships dominated the market in 2023, accounting for a revenue share of 36.86%. This growth is attributed to the extensive use of marine vinyl in seating, upholstery, wall covering, cabin interiors, and outdoor furniture applications due to its versatility, durability, low maintenance, and aesthetic appeal

Marine vinyl is also a preferred material for seating and upholstery on cruise ships, including lounges, dining areas, and outdoor deck furniture. It is resistant to UV rays, saltwater, and mildew, making it ideal for both indoor and outdoor applications. It can also endure heavy use while maintaining its aesthetic appeal, which is crucial for high-traffic areas on cruise ships

North America is projected to be the largest market in terms of revenue, with USD 230.2 million by 2030. The U.S. and Canada have a strong culture of recreational boating. Furthermore, the presence of coastal areas, Great Lakes, and numerous inland waterways has led to a higher demand for boating as well as marine vinyl in the region

The market is characterized as moderately competitive owing to the presence of both regional and multinational players. The key players in this industry are focusing on improving the quality of their products and enhancing their production capabilities. They are also increasingly focused on enhancing the quality of their products and providing customization options for them in terms of color, texture, and size for use in specific applications

Established brands with higher goodwill and a reputation for producing reliable and high-quality marine vinyl products tend to attract more consumers. Brand loyalty is an important factor affecting the buying decisions in the market, where consumers rely on trusted brands to ensure the safety and longevity of their marine upholstery

Marine vinyl can have higher upfront costs than conventional fabrics and materials. This may deter budget-conscious consumers and small businesses from using marine vinyl, especially due to a lack of awareness about its long-term benefits over conventional materials

Marine Vinyl Market Segmentation

Grand View Research has segmented the marine vinyl market based on end use, and region:

Marine Vinyl End Use Outlook (Volume, Thousand Square Meters; Revenue, USD Million; 2018 - 2030)

Yachts

Cruise Ships

Sport Boats

Others

Marine Vinyl Regional Outlook (Volume, Thousand Square Meters; Revenue, USD Million; 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

Germany

UK

France

Spain

Asia Pacific

China

Singapore

Japan

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

UAE

List of Key Players in the Marine Vinyl Market

Sunbrella

The Swavelle Group

Charlotte Fabrics

Richloom

Morbern Europe BV

OMNOVA North America Inc.

Herculite

Reliatex Inc.

Uniroyal Engineered Products, LLC.

BZ Leather

SPRADLING GROUP

Nassimi LLC

Ultra Fabrics

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/marine-vinyl-market-report

0 notes

Text

Plant Trailers For Sale: Highlighting Unique Advantages And Distinctions

Introduction:

These days, plant trailers are valuable assets in many industries, particularly when it comes to moving big machinery and equipment. Those looking for dependable plant trailers for sale may need to understand the distinctive benefits and defining features in order to make an informed decision. Plant trailers, whether utilised for construction sites or agricultural operations, have unique advantages that set them apart in the market.

1. Specific Load Capacity:

The specific load capacity of them is one of their main advantages. Heavy machinery and equipment frequently used in landscaping, agriculture, and construction are designed to be carried by these trailers. They are a dependable option for easily transferring large and heavy cargo because of their sturdy construction and reinforced structure, which ensures that they can support a significant amount of weight.

2. Adjustable Loading Ramps:

Heavy equipment may be loaded and unloaded more easily and safely with the help of them, which come with adjustable loading ramps. Ensuring a safe passage onto and off the trailer, the ramps can be adjusted to suit various kinds and sizes of machinery. Plant trailers are more adaptable and fit a variety of equipment thanks to this flexible feature.

3. Improved Stability and Maneuvrability with Tandem Axles:

Tandem axles are a common feature on plant trailers, and they improve stability and manoeuvrability. Tandem axles uniformly distribute the weight, lessening the strain on the towing car and enhancing handling in general while being transported. When crossing difficult terrain or cramped areas on building sites, this ability is invaluable.

4. Integrated Hydraulic Systems:

These systems are frequently included which makes loading and unloading them more convenient. Ramp adjustment is made simple by hydraulic mechanisms, which eliminate the need for manual labour. This function reduces the possibility of mishaps and injuries related to operating heavy machines while also saving time.

5. Adjustable Deck Lengths:

To suit a range of equipment sizes, they provide adjustable deck lengths. This adaptability maximises productivity and minimises the need for multiple journeys by enabling customers to transport various combinations of apparatus on a single trailer. The ability to alter deck lengths increases plant trailers' adaptability for a range of uses.

6. Robust Suspension Systems:

To handle the rigours of hauling large loads, they are built with heavy-duty suspension systems. Strong suspension reduces vibrations and shocks that can possibly harm the machinery being transported, making for a smoother ride. Robust suspension systems guarantee the longevity of the trailer and lower the possibility of equipment damage.

For the special needs of carrying large machinery and equipment, plant trailers for sale provide a number of advantages and distinctive features. With features like movable loading ramps and customised load capacities, these trailers are the epitome of effectiveness, security, and adaptability. The unique benefits of these trailers position them as essential assets in the realm of transportation and logistics, particularly as businesses continue to rely on heavy gear for a variety of purposes.

0 notes

Text

Top Quality Paver Block Making Machine in India

In the rapidly evolving construction industry, efficiency and quality are paramount. BTM Product has emerged as a leading manufacturer of top-tier machinery, including the renowned paver block making machine in India. Our commitment to innovation and excellence has positioned us at the forefront of the market, providing solutions that cater to the diverse needs of construction professionals across the country.

The Rise of Paver Blocks in Modern Construction

Paver blocks have revolutionized the way we approach outdoor flooring and landscaping. Their versatility, durability, and aesthetic appeal have made them a popular choice for various applications, from residential driveways to commercial parking lots. As demand grows, so does the need for efficient and reliable production methods.

Introducing BTM Product's Paver Block Making Machine

Our state-of-the-art paver block making machine in India is designed to meet the increasing demand for high-quality interlocking tiles and paver blocks. Engineered with precision and built to last, this machine offers unparalleled performance and consistency in production.

Key Features of Our Paver Block Making Machine

1. Advanced Hydraulic System

Our machines utilize cutting-edge hydraulic technology, ensuring smooth operation and precise control throughout the manufacturing process.

2. Customizable Molds

We offer a wide range of mold options, allowing you to produce various shapes and sizes of paver blocks to suit different project requirements.

3. High Production Capacity

With the ability to produce thousands of blocks per day, our machines are ideal for both small-scale and large-scale operations.

4. User-Friendly Interface

The intuitive control panel makes it easy for operators to adjust settings and monitor production, maximizing efficiency and minimizing downtime.

5. Durability and Low Maintenance

Built with high-quality materials, our paver block making machine in India is designed for longevity and requires minimal maintenance, ensuring a high return on investment.

The Versatility of Interlocking Tiles Making Machine in India

In addition to traditional paver blocks, our interlocking tiles making machine in India offers the flexibility to produce a wide array of interlocking tiles. These tiles are increasingly popular for their ease of installation and ability to create stunning patterns in outdoor spaces.

Applications of Interlocking Tiles

1. Residential Landscaping 2. Commercial Walkways 3. Public Parks and Gardens 4. Parking Areas 5. Pool Decks

The interlocking tiles making machine in India from BTM Product allows manufacturers to tap into this growing market segment, offering products that meet the diverse needs of architects, landscapers, and property owners.

Fly Ash Brick Making Machine: A Sustainable Solution

As the construction industry moves towards more sustainable practices, BTM Product proudly offers a cutting-edge fly ash brick making machine in India. This innovative equipment allows for the production of eco-friendly bricks using fly ash, a byproduct of coal combustion.

Benefits of Fly Ash Bricks

1. Environmental Sustainability

By utilizing fly ash, a waste product, these bricks help reduce the carbon footprint of construction projects.

2. Cost-Effective

The production process for fly ash bricks is often more economical than traditional clay bricks.

3. Strength and Durability

Fly ash bricks exhibit excellent compressive strength and resistance to weathering.

4. Uniform Size and Shape

Our fly ash brick making machine in India ensures consistent dimensions, facilitating easier and faster construction.

5. Fire Resistance

The properties of fly ash contribute to improved fire resistance in buildings.

Quality Assurance and Technical Support

At BTM Product, we understand that the success of our clients depends on the reliability and performance of our machines. That's why we place a strong emphasis on quality assurance throughout the manufacturing process of our paver block making machine in India, interlocking tiles making machine in India, and fly ash brick making machine in India.

Our commitment to excellence extends beyond the point of sale. We offer comprehensive technical support and after-sales service to ensure that our clients can maximize the potential of their investment. Our team of experienced technicians is always ready to assist with installation, maintenance, and troubleshooting.

Training and Capacity Building

To help our clients get the most out of their paver block making machine or interlocking tiles making machine in India, we offer extensive training programs. These sessions cover all aspects of machine operation, maintenance, and troubleshooting, empowering your team to operate the equipment efficiently and safely.

Customization Options

We recognize that every business has unique requirements. That's why we offer customization options for our paver block making machine in India and other equipment. Whether you need a specific production capacity, specialized molds, or integration with existing systems, our engineering team can tailor solutions to meet your precise needs.

Industry Applications

Our machines cater to a wide range of industries and applications:

1. Construction Companies 2. Landscaping Firms 3. Municipal Corporations 4. Real Estate Developers 5. Brick and Tile Manufacturers

Regardless of the scale of your operations, BTM Product has a solution that can enhance your productivity and product quality.

The BTM Product Advantage

Choosing a BTM Product machine means partnering with a company that values innovation, quality, and customer satisfaction. Here's why we stand out in the market:

1. Years of Industry Experience

Our team brings decades of combined experience in the construction equipment industry.

2. Cutting-Edge Technology

We continuously invest in research and development to incorporate the latest technologies into our machines.

3. Comprehensive Product Range

From paver block making machines to fly ash brick making machine in India, we offer a complete range of solutions.

4. Nationwide Service Network

Our extensive service network ensures prompt support wherever you are in India.

5. Competitive Pricing

We offer high-quality machines at competitive prices, ensuring excellent value for your investment.

Future-Ready Solutions

As the construction industry evolves, so do the demands placed on equipment manufacturers. At BTM Product, we're always looking ahead, developing machines that not only meet current needs but are also adaptable to future requirements. Our paver block making machine in India and interlocking tiles making machine in India are designed with flexibility in mind, allowing for easy upgrades and modifications as technology advances.

Conclusion

In the competitive landscape of construction equipment manufacturing, BTM Product stands out as a reliable partner for businesses seeking top-quality paver block making machines in India and fly ash brick making machine in India. Our commitment to excellence, combined with our comprehensive range of products including interlocking tiles making machines and fly ash brick making machine in India, positions us as a one-stop solution for all your construction material production needs.

By choosing BTM Product, you're not just investing in a machine; you're investing in a partnership that supports your growth and success. Our dedication to quality, innovation, and customer satisfaction ensures that you have the tools and support needed to thrive in the dynamic construction industry.

Whether you're looking to start a new production line or upgrade your existing equipment, BTM Product has the expertise and solutions to help you achieve your goals. Contact us today to learn more about how our paver block making machine in India and other innovative products can transform your business.

#paver block making machine in India#interlocking tiles making machine in India#fly ash brick making machine in India

0 notes

Text

Discover the Best WPC Machines at Machinemg.com

In today's world, the demand for sustainable and durable materials is higher than ever. Wood Plastic Composite (WPC) is one such material that has gained significant popularity due to its versatile applications and eco-friendly properties. Whether you're in construction, furniture manufacturing, or any industry requiring robust and sustainable materials, WPC is a fantastic choice. At Machinemg.com, we offer a comprehensive range of top-notch WPC machines designed to meet your manufacturing needs efficiently and effectively.

Why Choose WPC?

Wood Plastic Composite is a revolutionary material made from a unique blend of wood fibers and plastic. This combination offers numerous advantages:

Durability: WPC is highly resistant to moisture, rot, and decay, making it an excellent choice for outdoor applications.

Eco-friendly: By utilizing recycled wood and plastic, WPC helps reduce waste and promote sustainability.

Low Maintenance: Unlike traditional wood, WPC requires minimal maintenance, saving both time and money.

Versatility: WPC can be molded into various shapes and sizes, making it ideal for a wide range of applications from decking and fencing to furniture and automotive components.

Machinemg.com: Your One-Stop Shop for WPC Machines

At Machinemg.com, we understand the importance of quality and efficiency in WPC production. That's why we offer a diverse selection of cutting-edge WPC machines designed to cater to different production needs. Here’s a glimpse of what we offer:

WPC Extrusion Machines: Our state-of-the-art extrusion machines are designed to produce high-quality WPC profiles. These machines ensure precise mixing and uniform output, resulting in consistent and superior quality WPC products.

WPC Pelletizing Machines: For those looking to produce WPC pellets, our pelletizing machines are the perfect solution. These machines are engineered for high efficiency and reliability, ensuring smooth and continuous pellet production.

WPC Board Production Lines: If you're in the market for WPC boards, our production lines are equipped with advanced technology to produce boards of various sizes and thicknesses. These lines offer excellent performance and flexibility to meet diverse manufacturing requirements.

WPC Recycling Machines: Sustainability is at the heart of our mission. Our WPC recycling machines are designed to process waste WPC materials, converting them back into usable raw materials. This not only helps reduce waste but also lowers production costs.

Auxiliary Equipment: In addition to our primary machines, we offer a range of auxiliary equipment to complement your WPC production line. From mixers and crushers to cooling systems and conveyors, we have everything you need to streamline your manufacturing process.

Why Machinemg.com?

Choosing the right machinery is crucial for the success of your WPC production. Here’s why Machinemg.com stands out:

Expertise and Experience: With years of experience in the industry, we have the knowledge and expertise to provide the best solutions for your WPC manufacturing needs.

Quality and Reliability: Our machines are built with high-quality materials and advanced technology, ensuring durability and reliability.

Customer Support: We offer comprehensive support, from installation and training to maintenance and troubleshooting. Our team is always ready to assist you in maximizing the efficiency of your production line.

Competitive Pricing: We believe in providing high-quality machines at competitive prices, ensuring excellent value for your investment.

Conclusion

Wood Plastic Composite is paving the way for a more sustainable and durable future. At Machinemg.com, we are committed to providing the best WPC machines to help you achieve your production goals. Explore our range of WPC machines today and discover how we can help you enhance your manufacturing process with innovative and efficient solutions.

For more information, visit Machinemg.com and take the first step towards revolutionizing your WPC production.

#wpc machine#wood plastic composite machine#wpc extrusion line#plastic crusher machine#waste shredder machine#pet bottle washing line#plastic recycling washing machines#wpc production line

0 notes

Text

A Guide to Selecting Flat Deck Trailers for Your Needs

Are you considering investing in a flat-deck trailer but feeling overwhelmed by the choices? Fear not!

This guide will walk you through everything you need to know to select the perfect flat-deck trailer for your needs, especially if you're in the Christchurch area. Let's dive in and find the best trailers Christchurch has to offer!

Flat deck trailers are versatile and sturdy, making them popular for transporting various loads. Whether you're moving heavy machinery, construction materials, or even large vehicles, these trailers provide a flat, open surface that can accommodate almost anything.

Key Factors to Consider

Load Capacity

One of the most critical factors is the trailer's load capacity. You'll need to ensure that the trailer can handle the weight of your cargo.

Overloading a trailer can lead to serious safety issues and damage to the trailer and your vehicle.

Check the manufacturer's specifications and choose a trailer that exceeds your maximum load requirements to be safe.

Trailer Size

Another important consideration is the size of the trailer. Flat deck trailers come in various lengths and widths, so you'll want to choose a size that suits your needs.

A more extensive trailer will be necessary if you're transporting oversized loads. However, a more compact trailer may be more practical and easily maneuverable for smaller loads.

Material and Build Quality

The material and build quality of the trailer are crucial for durability and longevity. Look for trailers made from high-quality steel or aluminium.

Steel trailers are robust and can handle heavy loads, while aluminium trailers are lighter and more rust-resistant. Consider the type of cargo you'll be transporting and the conditions in which the trailer will be used.

Hitch Compatibility

Ensure that the trailer you choose is compatible with your vehicle's hitch. Different hitches, such as gooseneck and bumper pull, require a specific trailer coupling. Correctly matching your truck and trailer hitch is essential for safe and efficient towing.

Finding the Best Trailers in Christchurch

When finding the best trailers Christchurch offers, shopping around and comparing different options is essential. Visit local dealerships, read reviews, and ask for recommendations. Feel free to ask questions and test the trailers to ensure they meet your requirements.

Local Dealerships

Start by visiting local trailer dealerships in Christchurch. They often have a wide range of flat deck trailers and knowledgeable staff who can help you make an informed decision. Take the time to inspect the trailers in person and discuss your needs with the experts.

Online Resources

Numerous online resources exist where you can compare different trailer models and prices. Websites like Trade Me or specialised trailer retailers' sites can provide valuable information and customer reviews, which can help you understand what's available in the Christchurch market trailers.

Word of Mouth

Ask friends, family, or colleagues who purchased trailers for recommendations. Personal experiences can provide insights you won't find in brochures or online reviews.

Conclusion

Selecting the right flat deck trailer for your needs can be manageable. Consider factors like load capacity, size, material, and special features to make an informed choice.

Whether you're buying your first trailer or upgrading your current one, take the time to explore the options and find the best trailers Christchurch has to offer.

Source: https://safaritrailers.blogspot.com/2024/06/a-guide-to-selecting-flat-deck-trailers.html

0 notes

Text

Steel Plate Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

In 2023, the global Steel Plate market reached around 33 million tonnes and is projected to grow at a CAGR of 2.5% through 2034.

Introduction:

Steel plates are fundamental to numerous industrial applications, prized for their strength, durability, and versatility. In South Africa, the Steel Plate Market is experiencing robust growth as the country advances its industrial and infrastructural capabilities. This article explores the dynamics of the Steel Plate Market in South Africa, focusing on its applications, market trends, and impact on industrial development.

Click Here: https://www.chemanalyst.com/industry-report/steel-plate-market-4170

Industrial Applications and Demand:

Steel plates are integral to various sectors, including construction, automotive, shipbuilding, and heavy machinery. Their ability to withstand high stress and environmental factors makes them indispensable in projects requiring structural integrity and longevity. As South Africa continues to develop its infrastructure and industrial base, the demand for steel plates is on the rise.

Construction Industry:

In the construction industry, steel plates are used in building structures, bridges, and highways. They provide the necessary strength and stability for large-scale projects. South Africa's focus on urbanization and infrastructure development drives the demand for high-quality steel plates, essential for creating resilient and durable structures.

Automotive Sector:

The automotive industry uses steel plates in the manufacturing of chassis, body panels, and other structural components. The strength and malleability of steel plates enable the production of safer and more efficient vehicles. As South Africa's automotive sector aims to enhance production capabilities and meet international standards, the demand for steel plates is expected to grow.

Shipbuilding and Marine Applications:

Steel plates are crucial in shipbuilding for constructing hulls, decks, and other critical components. Their corrosion resistance and strength are vital for maritime applications. With South Africa's strategic location and investment in maritime infrastructure, the shipbuilding industry sees increasing demand for robust steel plates to ensure the longevity and safety of vessels.

Heavy Machinery and Equipment:

Heavy machinery and industrial equipment rely on steel plates for manufacturing components that endure significant stress and wear. The mining and agricultural sectors, vital to South Africa's economy, require durable machinery built with high-quality steel plates. This need propels the demand for steel plates in the production of equipment that supports these industries.

Click Here: https://www.chemanalyst.com/industry-report/steel-plate-market-4170

Market Trends and Growth Drivers:

Several trends and growth drivers influence the Steel Plate Market in South Africa. These include the increasing focus on infrastructure development, technological advancements in steel production, and the push for sustainable and eco-friendly materials. The growth of renewable energy projects, such as wind and solar farms, also boosts the demand for steel plates used in constructing support structures.

Significant players in the Global Steel Plate market are ArcelorMittal S.A., Thyssenkrupp AG, POSCO, TATA Iron & Steel Co. Ltd., Baosteel Iron & Steel Co. Ltd., Outokumpu Oyj, JFE Holdings Co. Ltd., Nippon Steel Engineering Co. Ltd., Sumitomo Metal Industry Ltd., Novolipetsk Steel Group, and Essar Steel India Ltd., and Others.

Challenges and Strategies:

The Steel Plate Market in South Africa faces challenges such as fluctuating raw material prices, competition from alternative materials, and environmental regulations. Addressing these challenges requires strategic initiatives like investing in advanced manufacturing technologies, enhancing local production capacities, and adopting sustainable practices. These strategies can help mitigate costs, improve efficiency, and ensure compliance with environmental standards.

Conclusion:

The Steel Plate Market in South Africa is a critical component of the country's industrial and infrastructural development. With its wide-ranging applications and exceptional properties, steel plates support key sectors like construction, automotive, shipbuilding, and heavy machinery. By leveraging market opportunities, addressing challenges, and fostering innovation, South Africa can maximize the potential of the Steel Plate Market, driving industrial growth, technological advancement, and economic development in the region.

0 notes

Text

Game Accuracy: Advances in Playing Card Manufacturing Machinery

China Sale Flying Playing Cards Manufacturing Machine Supplier

In the intricate world of playing card manufacturing, precision reigns supreme. Advancements in Playing Card Manufacturing Machinery have propelled the industry forward, ushering in an era of unparalleled accuracy and efficiency. From the initial design phase to the final product, these cutting-edge machines play a pivotal role in ensuring that every card meets high standards of quality.

Precision in Play: Advancements in Playing Card Manufacturing Machinery have revolutionized the way playing cards are produced. These machines utilize high technology to precisely cut, print, and package playing cards with meticulous attention to detail. With high precision, manufacturers can produce cards that are consistent in size, shape, and print quality, resulting in a predominant gaming experience for players worldwide.

At the heart of Precision in Play: Advancements in Playing Card Manufacturing Machinery are advanced printing techniques. High-speed printing presses equipped with precision registration systems ensure that each card is printed with pinpoint accuracy. Whether it's intricate designs, vibrant colors, or fine details, these machines can reproduce every aspect of the artwork with stunning clarity and precision.

But precision doesn't stop at printing. Playing Card Manufacturing Machinery also incorporates cutting-edge cutting and sorting mechanisms. Precision die-cutting technology ensures that each card is cut to exact specifications, with clean edges and uniform dimensions. Meanwhile, automated sorting systems meticulously organize the cards into decks, ensuring that every pack is complete and ready for play.

The role of Precision in Play: Advancements in Playing Card Manufacturing Machinery extends beyond production to quality control. Advanced inspection systems meticulously examine each card for defects, ensuring that only flawless cards make it into the final product. From checking print alignment to verifying card thickness, these systems leave no stone unturned in their quest for perfection.

In addition to precision, Playing Card Manufacturing Machinery also focuses on efficiency. Automated workflows and streamlined processes lessen downtime and less productivity, allowing manufacturers to meet the demands of a rapidly growing market. With shorter production cycles and faster turnaround times, manufacturers can keep pace with consumer demand and stay ahead of the competition.

Looking ahead, the future of Precision in Play: Advancements in Playing Card Manufacturing Machinery is bright. As technology continues to evolve, we can expect even greater levels of precision, efficiency, and innovation in playing card production. From advancements in materials to breakthroughs in automation, the possibilities are endless. One thing is certain: Precision will always be at the high of playing card manufacturing, ensuring that every deck is a masterpiece of quality and craftsmanship.

These advancements not only enhance the gaming experience but also drive the growth of the playing card industry. With Precision in Play: Advancements in Playing Card Manufacturing Machinery shaping the future, players can expect nothing but the high-quality cards for years to come.

Manufacturers continue to invest in research and development, pushing the boundaries of what's achievable in playing card production. With a relentless focus on precision and innovation, the playing card industry is poised for continued success and expansion.

As technology progresses, the integration of artificial intelligence and machine learning promises to further enhance the capabilities of playing card manufacturing machinery. These advancements will not only improve efficiency but also enable predictive maintenance, ensuring uninterrupted production and less downtime. With precision and innovation driving every aspect of production, the future of playing card manufacturing is set to reach unprecedented heights, delivering unmatched quality and reliability to players worldwide.

0 notes

Text

Steel Plate: A Guide to Its Uses and Benefits

Piping Projects is one of the Best Quality Steel Plate Manufacturers in USA. A steel plate is a thin metal sheet. In comparison to stainless steel plates, the steel plates are thinner, but they are thicker than foils, Strong corrosion resistance and good performance in a variety of scenarios define steel plates. They have a better capacity for hardening and impressive corrosion resistance.

We are a market-leading provider of carbon steel, alloy steel, and stainless steel plate solutions on a global scale, having obtained ASME Quality and ISO 9001:2015 Certifications. In addition to producing the best-quality Steel Plate, we are an official Jindal and ISMT dealer for the provision of carbon and alloy steel plates.We are a high-quality Steel Plate Manufacturers USA in the metal market.

Benefits of the Steel Plates

The Steel plate manufacturing process consists of many essential processes, Steel plates are integral components in the realm of construction and manufacturing, known for their exceptional strength and versatility.

Material Consistency:

The production method makes sure that the steel's composition is consistent, which produces plates with reliable mechanical qualities. For applications where exact strength and durability are required, this uniformity is essential.

Customization and Versatility:

Size, thickness, and form may all be customized throughout the steel plate production process. This flexibility guarantees that the generated plates may be customized to meet particular project needs, increasing their suitability for a wide range of applications.

Strength and Durability:

Because of their extraordinary strength, Steel Plate Manufacturers are appropriate for heavy-duty applications and buildings requiring a high load-bearing capacity.

Their long-term endurance is ensured by their capacity to tolerate extreme weather conditions and resistance to flexing.

Versatility:

Steel plates are available in a range of sizes and forms, providing flexibility in both use and design.

They are an adaptable option for many different sectors as they may be tailored to match certain project requirements.

Recyclability:

Steel is one of the products that is recycled the most worldwide, supporting environmentally friendly manufacturing and building methods.

Steel plates' capacity to be recycled reduces its negative effects on the environment and protects natural resources.

Cities We Supply Steel Plate

Steel Plate Supplier in Texas

Steel Plate Supplier in California

Steel Plate Supplier in Florida

Steel Plate Supplier in New York

Steel Plate Supplier in Los Angeles

Uses Of Steel Plate

Steel plates find diverse applications across various industries due to their strength, durability, and versatility. Steel plate is a metal plate which manufacture using steel, that can be cut and fabricated into a more complex product. Steel plates offer a variety of thicknesses and can be produced to whatever length or width you desire.

Construction Industry:

Structural Components: Steel plate Suppliers are widely used in the construction of buildings, bridges, and other structures as primary load-bearing elements, ensuring stability and durability.

Flooring and Decking: They serve as flooring and decking materials, providing a robust and sturdy surface for various applications.

Manufacturing and Machinery:

Industrial Equipment: Steel plates are employed in the manufacturing of heavy-duty machinery, equipment, and tools due to their high strength and resistance to wear and tear.

Automotive Industry: In the automotive sector, steel plates are used for the production of vehicle bodies and structural components, enhancing safety and performance.

Energy and Infrastructure:

Oil and Gas: Steel plates are crucial in the oil and gas industry for the fabrication of pipelines, storage tanks, and other infrastructure, providing a reliable and long-lasting solution for transporting and storing resources.

Power Plants: They are used in the construction of power plants, supporting the heavy machinery and providing a robust foundation for the generation of electricity.

Common Uses For SS Plate

Architecture includes the design and construction of building exteriors, such as facades, roofs, railings, doors, and windows.

Foodservice includes tables and countertops, sinks and appliances, and food preparation equipment.

Industrial: Chemical processing equipment, pharmaceutical equipment, marine equipment, oil and gas equipment.

Other: Manufacturing Automation, Energy Management, and Application.

STEEL PLATE MANUFACTURERS - SPECIFICATIONS

Standard: DIN, BS, EN, IS, ASTM, AMS, JIS & Other International Standards.

Thickness: 0.3mm to 100mm

Width: 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length: 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Website: pipingprojects.us

0 notes

Text

How Can Flat Top Tipper Trailer Cut Costs for Your Construction Projects?

A top-quality flat top tipper trailer is an essential tool for many businesses that need to transport heavy machinery effortlessly including for construction businesses to complete projects on time. Flat-top trailers come with a spacious flat deck that provides ample space for transporting large and heavy equipment while being stable and safe.

At the same time, these businesses often search for large galvanised cage trailers for sale, exclusively from reputable suppliers to get trusted material and top-quality products with a warranty on their durability, versatility, and dependability.

In addition, galvanisation increases rust and corrosion resistance, improving the trailer's durability even in hostile conditions.

Why Large-sized Trailers are High-Demand for Some Businesses?

Well-known trailer vendors provide huge trailers measuring 10x6 feet with spacious designs suitable for hauling bulky things, tools, or equipment.

Whether for commercial or personal usage, trusted suppliers provide easy and effective transportation, making it an advantageous resource for both large-scale corporations to medium and small-scale businesses.

The spacious dimensions and flat surface safeguard both the equipment and the trailer itself from potential damage during transit.

Furthermore, they source from reputable manufacturers for durable equipment that can withstand the weight and pressure of huge machines, ensuring dependable performance even under the most demanding conditions.

Its strong chassis and strengthened frame, which boost stability and endurance, allow it to transport valuable assets securely. Furthermore, the flat top design allows for easy transportation and setup of a variety of machinery types, saving interruption and boosting productivity.

Businesses can transfer manufacturing tools, building machinery, or machinery for agriculture with convenience and economy by using huge trailers, which are a practical and cost-effective option for carrying heavy equipment.

Buy Trailers from a Certified Dealer Nearby:

Find suppliers with a strong reputation for dependability and quality, as well as positive ratings and comments.

Evaluate their range of products for diverse needs from different businesses and provide a facility for personalised trailers and post-purchase assistance.

Examine whether they have any certifications or links with reputable trade bodies and adhere to local regulations on safety and product quality.

Get referrals from professionals in the sector, and read market reviews of service providers.

Finally, contact a reliable trailer supplier near you who provides excellent customer service, clear communication, and reasonable prices.

Source

0 notes

Text

Exploring The Diverse Range Of Plant Trailers In Melbourne

Plant trailers play a pivotal role in the construction, landscaping, and agriculture industries in Melbourne, serving as reliable carriers for transporting heavy machinery, equipment, and plant materials. These trailers come in various types, each designed to cater to specific hauling needs. In this blog, we'll delve into the diverse range of plant trailers available in Melbourne.

1. Flatbed Plant Trailers:

Flatbed trailers are versatile and commonly used for transporting various types of machinery, equipment, or materials. These trailers offer a flat loading surface without sidewalls, providing ample space to accommodate different sizes and shapes of loads. They're ideal for carrying excavators, skid steers, or bulk materials like pallets, timber, and landscaping supplies.

2. Tilt Plant Trailers:

Tilt trailers feature a hydraulic tilting mechanism, allowing easy loading and unloading of machinery or equipment. With the press of a button, the trailer bed tilts, facilitating safe and efficient loading without the need for ramps. These trailers are particularly useful for transporting vehicles, small tractors, or machinery that require easy maneuverability.

3. Low Loader Plant Trailers:

Low loader trailers are specifically designed with a low deck height to accommodate taller equipment or machinery. They offer easy access and loading for oversized or taller items like forklifts, scissor lifts, or other heavy machinery. The lowered deck height ensures stability and safer transportation of taller loads.

4. Multi-axle Plant Trailers:

Multi-axle trailers are equipped with multiple axles to distribute weight more evenly across the trailer, enhancing stability and load-bearing capacity. These trailers are suitable for transporting heavier machinery or equipment, such as excavators, bulldozers, or larger agricultural machinery. They offer better weight distribution and balance while on the road.

5. Caged Plant Trailers:

Caged trailers feature high sides or removable mesh panels, providing additional security and containment for transported materials. These trailers are commonly used for hauling landscaping materials, green waste, or smaller machinery like lawnmowers or small tractors. The caged design prevents items from shifting during transit.

6. Customized Plant Trailers:

Manufacturers often offer customized trailers tailored to specific needs. These trailers can be modified with additional features like toolboxes, winches, ramps, or special tie-down points to accommodate unique hauling requirements. Customizations ensure the trailer meets individual preferences and industry-specific demands.

7. Enclosed Plant Trailers:

Enclosed trailers offer protection from weather elements and theft, making them suitable for transporting sensitive equipment, tools, or smaller machinery. These trailers come with a roof and enclosed sides, providing security and weatherproofing for items being transported, making them ideal for tradespeople or contractors needing secure storage on-site.

8. Specialized Plant Trailers:

Some trailers are designed for specific purposes, such as hydraulic trailers for transporting specialized machinery requiring controlled tilting or tipping mechanisms. Additionally, trailers equipped with hydraulic brakes, LED lighting, or other advanced features cater to specialized needs and safety requirements.

Melbourne boasts a diverse market of plant trailers catering to various industries and transportation needs. Understanding the different types available allows buyers to select the most suitable trailer for their specific requirements, ensuring safe and efficient transportation of machinery, equipment, or materials across the bustling city and its surrounding areas.

0 notes

Text

The Ultimate Guide to Choosing the Perfect Trailer for Your Business

Are you in the market for a trailer to level up your business operations? Whether you're in the construction, landscaping, or delivery industry, finding the best trailers Auckland is crucial to meeting your unique business needs.

With a plethora of options available, it's essential to make an informed decision. This comprehensive guide will help you navigate through the process of selecting the perfect trailer for your business.

Understanding Your Business Needs

Before diving into the world of trailers, take a moment to assess your business requirements. What will you be transporting? How frequently will you be using the trailer? Do you need specific features such as ramps, refrigeration, or security locks? Understanding these key aspects will guide you towards the best trailers for your business.

Types of Trailers

Enclosed Trailers

Enclosed trailers provide protection from the elements and security for your cargo. If your business involves transporting valuable goods or materials that require shelter from weather conditions, an enclosed trailer might be the best trailer for you. Consider factors such as interior space, loading options, and durability when choosing an enclosed trailer.

Flatbed Trailers

These versatile trailers are suitable for carrying heavy equipment, machinery, or oversized items. The open design allows for easy loading and unloading, making them a popular choice for businesses in construction, agriculture, and landscaping. When selecting a flatbed trailer, focus on weight capacity, deck size, and manoeuvrability to ensure you're getting the best trailer for your specific needs.

Utility Trailers

Utility trailers are designed for general-purpose use and can be customised to accommodate various loads. If your business involves hauling different types of cargo, a utility trailer might be the best trailer for you. Consider the trailer's construction, towing capacity, and potential for modifications when exploring utility trailer options.

Legal and Safety Considerations

When choosing a trailer for your business, it's crucial to comply with legal regulations and prioritise safety. Ensure that the trailer meets the necessary standards for road usage, including proper lighting, braking systems, and weight restrictions.

Safety features such as trailer brakes, reflective tape, and sway control should also be taken into account when selecting the best trailer for your business.

Quality and Durability

Investing in a high-quality, durable trailer is essential for long-term use and reliability. Consider materials, construction techniques, and reputable brands when evaluating potential trailers.

Prioritising quality over cost can lead to fewer maintenance issues and higher overall satisfaction with the perfect trailer for your business.

Assessing Budget and Financing Options

Finally, consider your budget and explore financing options when purchasing a trailer for your business.

While it's important to find the best trailers Auckland for your needs, striking a balance between quality and affordability is key. Research financing plans, grants, or leasing options that can help make the investment in a trailer more manageable for your business.

Conclusion

Choosing the perfect trailer for your business involves a careful assessment of your needs, thorough research into available options, and mindful consideration of legal, safety, and financial factors.

By understanding your business requirements and exploring the diverse range of trailer types, you can confidently select the best trailers Auckland to enhance your operations and propel your business forward.

0 notes

Text

The Importance of Exterior Cleaning Services

Whether guests are coming to your business or home, they want to see a clean exterior. Dirty buildings give a bad impression and can even negatively impact resale value.

Over time, dirt, moss, mildew, bugs and bird droppings accumulate on the outside of your building. This can lead to expensive construction work if left unattended.

Commercial Buildings

Commercial buildings are the first thing potential customers and clients see and the exterior of these facilities can often make or break a company’s reputation. Dirty and unkempt exteriors make businesses look unprofessional, while clean and wellmaintained buildings convey professionalism and trustworthiness.

Moreover, regularly cleaning a building’s exterior cleaning can help to extend the life of its surfaces and prevent expensive repair or replacement costs. This is because commercial buildings are usually made from materials that are vulnerable to damage if exposed to moisture. Pressure washing can remove stains and dirt from the surface of these buildings without damaging them, helping to prolong their life.

The key to successful commercial cleaning is finding a team with the right skills and experience to complete the task. They should have the necessary knowledge and equipment to work safely with high-powered machinery that can cause serious injury if not used properly. In addition, they should be able to find the best products and techniques to clean different types of surfaces.

Residential Homes

Wood can also collect dust and debris. It is usually cleaned with a soft washing technique or a pressure washer on the low setting to avoid damaging the surface. This process can remove fungus, mildew and bacteria, preventing damage to the surface.

A professional cleaning service can also clear the gutters of a home, reducing water damage and improving drainage. They can even help identify leaks in the roof or walls of a house, and they can recommend repairs. They can also make a property more appealing to prospective buyers by adding curb appeal.

Landscaping

Offering exterior cleaning services is a lucrative option for your cleaning business. With a market size of $8 billion, tapping into this industry segment can increase your earnings and attract new customers.

Keeping the walls, entryways and patio of your clients’ homes clean is a crucial element of maintaining a clean home exterior. Mold, mildew and discoloration can ruin the exterior of your clients’ properties and cause health problems for their families. Power washing is the most effective way of keeping these surfaces free of contaminants.

The exterior of a home is the first impression guests, neighbors and potential buyers get. A clean, well-maintained house can increase the value of a property. However, if left unchecked, dirt, mildew, mold, bugs and moss can erode or stain siding, windows, decks and awnings. Regular Exterior Cleaning Services with a soft washing or pressure washing method can help prevent damage to these surfaces and prolong their life.

However, some hearty plants and trees can’t withstand high-pressure sprays of water. In such cases, you need to employ soft washing methods with a bristle brush and a gentle detergent or cleaning agent. Incorporating these techniques can safely clean surfaces such as flagstone, pavers and tile flooring. It can also prevent the spread of bacteria and germs. Lastly, it helps keep the greenery around your client’s home healthy. Your clients will appreciate your thoughtfulness and diligence in maintaining their outdoor spaces.

Driveways

Your driveway is a critical path to your home and often the first impression guests have. If your driveway is stained or contaminated with oil, grease, mildew, dirt, rust, bio-growth and other unsightly substances it can be hard to make your house a welcoming place for family and friends.

Concrete and asphalt are a challenge to clean, but you can boost your curb appeal by hiring a professional with the right equipment and cleaning solutions. Our experts use a soft washing technique that is gentle enough to clean your surfaces but powerful enough to blast away oil and other stubborn stains without damaging your landscaping, gutters, windows or siding.

Mold or mildew growth on your concrete can be removed by scrubbing with a mold killing detergent such as 30 Seconds Outdoor Cleaner (available at Amazon) or a bleach solution (1 cup of bleach per gallon of water). If the stain is caused by a latex paint spill, try using a household scouring powder or spraying it with a commercial rust killer like Iron OUT before scrubbing.

0 notes

Text

Cargo Handling Equipment Market Outlook, Trends, Report 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global cargo handling equipment market size at USD 24.63 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global cargo handling equipment market size to grow at a steady CAGR of 3.5% reaching a value of USD 30.28 billion by 2029. Major growth drivers for the global cargo handling equipment market include globalization, rapid industrialization, and increasing cargo activities. Cargo handling equipment has garnered significant attention due to its multifaceted benefits, which encompass the mitigation of revenue losses stemming from protracted cargo loading and unloading procedures. Moreover, this equipment augments the efficiency of cargo handling operations, reinforces safety protocols, and diminishes the probability of accidents. Significantly, it expedites cargo processing by streamlining cargo movement within docks and warehouses, thereby enhancing precision and reducing handling durations. Also, the equipment curtails the risk of worker injuries and the occurrence of accidents, thereby elevating safety benchmarks within the industry. However, high initial cost is anticipated to restrain the growth of the overall market during the period in analysis.

Global Cargo Handling Equipment Market – Overview

Cargo handling equipment encompasses specialized off-road, self-propelled vehicles and machinery used in intermodal rail yards and ports to handle containers, bulk goods, and liquid cargo transported by sea, air, or rail routes, with additional functions including scheduled maintenance and repairs. This equipment includes a range of machines such as mobile cranes, yard trucks, rubber-tired gantry cranes, side handlers, reach stackers, top handlers, loaders, forklifts, sweepers, dozers, excavators, and aerial lifts. The choice of equipment depends on the specific cargo type. Tankers are equipped with pumping systems, hose-handling cranes, and tank cleaning machinery. Dry-bulk carriers often rely on shoreside facilities, but some feature self-unloading mechanisms like conveyors or deck-mounted cranes. Reefer vessels are designed with refrigerated cargo holds and extensive refrigeration systems. Given the global dominance of containerized cargo transportation across land, air, and sea, precise handling of containers is vital, particularly at sea, where challenging weather conditions and strong winds prevail.

Sample Request @ https://www.blueweaveconsulting.com/report/cargo-handling-equipment-market/report-sample

Impact of COVID-19 on Global Cargo Handling Equipment Market

COVID-19 pandemic adversely affected the global cargo handling equipment market. Lockdown restrictions during the outbreak led to the closure of manufacturing units in this market. Despite the initial challenges caused by a lack of skilled professionals, there is a projected resurgence in the supply sector post-lockdown, as restrictions are gradually lifted. Also, the heightened demand for cargo handling and transportation services has created growth opportunities for the market in the aftermath of the pandemic, underscoring the profound impact of COVID-19 on the global cargo handling equipment market.

Global Cargo Handling Equipment Market – By Equipment

Based on equipment, the global cargo handling equipment market is divided into Industrial Trucks Tow Tractors, Conveying Equipment, Stackers, and Port Cranes segments. The industrial trucks tow tractors segment holds the highest share in the global cargo handling equipment market by equipment. The segment's prominence is attributed to the vital role tow tractors play in the efficient movement of materials and cargo within industrial settings, such as warehouses, factories, and distribution centers. Tow tractors are prized for their versatility and ability to tow heavy loads, making them indispensable for various logistics and materials handling operations. Their reliability, ease of use, and adaptability to diverse applications have contributed to their widespread adoption, solidifying their position as a key driver of the cargo handling equipment market.

Competitive Landscape

Major players operating in the global cargo handling equipment market include Hangcha Forklift, Siemens Logistics GmbH, TOYOTA INDUSTRIES CORPORATION, Terex Corporation, Anhui Heli, Textron Ground Support Equipment Inc., Liebherr-International Deutschland GmbH, TLD, KION GROUP AG, ABB, Hoist Material Handling, Inc., Hyster-Yale Group, Inc., and Konecranes. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

Navigating Jindal MS Plate Prices: A Comprehensive Guide

In construction, manufacturing, and infrastructure development, the cost of materials plays a pivotal role in shaping projects, budgets, and overall success. When it comes to Jindal MS plate prices, understanding the factors that influence pricing, market dynamics, and the wide range of applications for MS plates is crucial for informed decision-making. In this comprehensive guide, we delve deep into the intricacies of Jindal MS plate pricing, providing valuable insights into pricing determinants, the versatility of MS plates, and strategies for optimizing your investments.

Unveiling Jindal MS Plate Prices

The Jindal ms plate price list is influenced by a multitude of factors that collectively contribute to the final cost:

Raw Material, CostsThe cost of raw materials, particularly steel, is a primary driver of Jindal MS plate prices. Fluctuations in global steel prices, influenced by supply and demand dynamics, trade policies, and economic conditions, can lead to variations in plate costs over time.

Plate Dimensions and Thickness

The size, dimensions, and thickness of Jindal MS plates significantly impact their pricing. Larger and thicker plates require more raw material and manufacturing effort, contributing to higher costs.

Manufacturing Techniques

The manufacturing process employed for producing Jindal MS plates can influence pricing. Techniques such as hot and cold rolling may have distinct cost implications due to differences in energy consumption, equipment, and labour requirements.

Market Demand and Supply

The balance between market demand and supply is a key determinant of Jindal MS plate prices. Infrastructure projects, industrial growth, and global economic trends influence demand, impacting pricing.

Quality and Specification

Jindal MS plates are available in various grades and specifications to meet industry requirements. Plates with specific qualities like high tensile strength or corrosion resistance may command different price points.

The Versatility of Jindal MS Plates

Jindal MS plates find applications in an array of industries and sectors owing to their strength, versatility, and durability:

Construction and Infrastructure

Jindal MS plates are used for fabricating beams, columns, trusses, and structural components in the construction and infrastructure sectors. Their load-bearing capacity and reliability contribute to the integrity of buildings and projects.

Manufacturing and Machinery

Jindal MS plates are pivotal in manufacturing processes, serving as essential components in machinery, equipment, and industrial applications. Their malleability and ability to withstand heavy loads make them a preferred choice.

Automotive and Transportation

The automotive industry relies on Jindal MS plates for manufacturing chassis, frames, and body parts of vehicles. The plates' combination of strength and formability ensures the safety and performance of automobiles.

Energy and Power

Jindal MS plates are used in power plants, including thermal and renewable energy installations in the energy sector. They contribute to constructing boilers, pressure vessels, and other critical components.

Shipbuilding and Marine Applications

Jindal MS plates are vital for constructing hulls, decks, and superstructures in shipbuilding. Their durability and resistance to harsh marine environments are essential for ensuring the longevity of vessels.

Strategies for Informed Decision-Making

Supplier Evaluation

Research and evaluate reputable suppliers of Jindal MS plates to ensure quality and reliability. Consider product consistency, delivery times, and customer reviews when choosing suppliers.

Material Optimization

Work closely with engineers and designers to optimize the use of Jindal MS plates within your projects. Efficient material usage and design can save costs without compromising structural integrity.

Long-Term Durability

Balancing upfront costs with long-term benefits is key. Investing in high-quality Jindal MS plates may result in extended service life, reduced maintenance, and overall cost savings over the lifespan of projects.

Market Awareness

Stay informed about steel market trends and global economic factors that influence pricing. Timely procurement during favourable market conditions can positively impact your bottom line.

Collaboration and Expertise

Collaborate with experts in the field, including structural engineers and material consultants. Their insights can guide you toward optimal plate choices and design considerations.

Conclusion

You're empowered to make well-informed decisions as you navigate the realm of Jindal MS plate prices, armed with a comprehensive understanding of pricing determinants and applications. By considering raw material costs, plate dimensions, manufacturing techniques, market dynamics, and the diverse applications of Jindal MS plates, you can strategically optimize your investments and contribute to the success of your projects.

0 notes