#DIN 2.4819

Text

Trustworthy Manufacturer and Supplier of Hastelloy C276/DIN 2.4819/UNS N10276 in India.

As the first Manufacturer and Supplier of Hastelloy C276/DIN 2.4819/UNS N10276 in India, Piyush Steel holds a leading position. Our company is renowned for its dependability and dedication to excellence, offering premium Hastelloy C276 goods that adhere to the most exacting industry requirements. Our dedication to quality guarantees that every product satisfies the rigorous requirements of industrial applications, guaranteeing performance and lifetime.

Contact Us

0 notes

Text

#Hastelloy UNS N10276 Plates#Hastelloy DIN 2.4819 Coils#Hastelloy UNS N10276 Sheets#Hastelloy Werkstoff Nr. 2.4819 Plates#Hastelloy Alloy C276 Sheets#Hastelloy C276 Plates#Hastelloy C276 Coils#Hastelloy DIN 2.4819 Sheets#Hastelloy UNS N10276 Coils#Hastelloy C276 Plates Supplier in Mumbai#India.

1 note

·

View note

Text

Hastelloy has four properties

The alloy, Hastelloy C-276, is a special alloy material with excellent properties, its characteristics are as follows:

Chemical stability

In oxidizing and reducing environments, Hastelloy C-276 alloy can resist the erosion of various corrosive media, showing excellent corrosion resistance.

It has excellent resistance to pitting, crevices and stress corrosion, thanks to its high molybdenum (Mo) and chromium (Cr) content, which make the alloy resistant to chloride ions.

The addition of tungsten (W) further enhances the corrosion resistance of the alloy.

Hastelloy C-276 is one of the few materials that can withstand the corrosion of humid chlorine, hypochlorite and chlorine dioxide solutions, and it also exhibits significant corrosion resistance to high concentrations of chloride salt solutions, such as ferric chloride and copper chloride.

In addition, it is suitable for sulfuric acid solutions of various concentrations and is one of the few materials that can be applied to hot concentrated sulfuric acid solutions.

Physical properties

The material composition of Hastelloy C-276 consists of 57% nickel (Ni), 16% chromium (Cr), 16% molybdenum (Mo), 5% iron (Fe), 4% tungsten (W), a maximum allowance of 2.5% cobalt (Co), 1% manganese (Mn), 0.35% vanadium (V), 0.08% silicon (Si), and 0.01% carbon (C).

It complies with several international and regional standards, including UNS N10276, ASTM B575, ASME SB575, DIN/EN 2.4819 and others.

The alloy has a density of 8.90g/cm³.

Mechanical properties

The tensile strength of Hastelloy C-276 alloy reaches or exceeds 730Mpa, and the elongation is not less than 40%.

When hot forming, the alloy should be immediately annealed at 1150 ° C and water quenched.

Cold deformation processing can increase the strength of the alloy, but it should be noted that due to its high strength, compared with ordinary austenitic stainless steel, greater stress will be generated during the cold forming process.

Because the work hardening rate of Hastelloy C-276 alloy is faster than that of ordinary stainless steel, it is necessary to take intermediate annealing treatment in the extensive cold forming process to avoid excessive hardening.

Welding and heat treatment

The welding performance of Hastelloy C-276 alloy is similar to that of ordinary austenitic stainless steel. Before any welding method is adopted, measures must be taken to ensure that the corrosion resistance of the weld and the heat affected zone is minimized.

Suitable welding methods include tungsten gas shielded welding (GTAW), metal gas shielded welding (GMAW), submerged arc welding, etc. These methods help maintain the corrosion resistance of the weld and the heat affected zone.

Not suitable welding methods include oxy-acetylene welding and other methods that may increase the carbon or silicon content of the weld and heat affected zone of the material, as this will reduce the corrosion resistance of the material.

1 note

·

View note

Text

Hastelloy C276 Round Bars Suppliers in Chennai

Divine Metal & Alloys This Hastelloy C276 Bars are being manufactured, supplied and traded by us to our esteemed clienteles in best possible rates. Hastelloy C276 Rods (UNS N10276) can be used in the as-welded condition in most chemical and petrochemical process equipment. Although these Alloy C276 Round Bars tends to work-harden, you can have it successfully spun, deep-drawn, press formed or punched. Alloy C276 Rods can be used as-welded for most chemical process environments. Alloy C276 Bars can be successfully fabricated by many methods. Inconel C276 Round Bars also has extra ordinary corrosion resistance and the ability to with stand extreme temperature. These offered Inconel C276 Rods are available in various specifications to meet the application requirements of the clients'. Divine Metal & Alloys also offers these products in custom-made shapes and sizes with respect to highest international standard quality.

Hastelloy UNS N10276 Round Bars are used in many industries because of their superior properties. These bars are composed of a combination of Nickel, Molybdenum, and Chromium, allowing them to resist corrosion when exposed to extreme temperatures and harsh chemicals. As a result, they are excellent for use in highly corrosive environments such as aerospace parts, pharmaceutical products, and nuclear power plants. In addition, their remarkable physical properties make them ideal for construction in high-stress and high-temperature applications where metal needs to be durable and robust.

Alloy c-276 bars have quickly become popular among industrial manufacturers due to their incredible advantages. Its high level of resistance to corrosion makes it an early choice for those looking for long-term use of the material. Additionally, it shows impressive mechanical strength, giving it a greater career span than many other materials. Furthermore, even in extreme hot and cold temperatures, c-276 can hold its own against severe conditions as if unaffected by them. Furthermore, its versatility and ease of welding make it an ideal option for industrial engineers.

Hastelloy C276 Round Bars Specification

Specification

ASTM B574, ASTM B574 UNS N10276 , NACE MR-01-75, ASME SB574 Bar Products, AMS 5750 (Hastelloy C, UNS N10002), Inconel C276 (trademark), Werkstoff Nr. 2.4819, ASTM B751, DIN 17744, DIN 17751, DIN 17750 and DIN 17752,VRC276GradeHastelloy C276 – UNS N10276UNS N10276 Hex Bar size2-100mm A/FASTM B574 Hastelloy C276 Round bar sizeDiameter: 3-~C276mmASTM B574 Hastelloy C276 Square bar size4 to 100mmN10276 Flat bar sizeThickness: 2 -100mmWidth: 10 to 500mmHastelloy C276 Rectangles Size33 x 30mm to 295 x 1066mmASTM B574 N10276 Angle bar size3mm*20mm*20mm~12mm*100mm*100mmUNS N10276 Section3.0 to 12.0mm thicknessHastelloy C276 AMS 5666 Channel Bar80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thicknessN10276 Hollow Bar32mm OD x 16mm ID to 250mm OD x 200mm ID)ASTM B574 N10276 Billet Size1/2" to 495mm DiameterFinishCold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & BlackToleranceH8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirementsSurfaceHot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline, PolishedConditionHardened & tempered, annealedTechniqueHastelloy C276 Cold Drawn, Hot Rolled, Forged Round Bar,Cold Rolled, RodProcessingBar cutting to 650mmFormHastelloy C276 Round, Welding Rod, T-Bar, Rod, Precision Ground Bar, Channel Bar, Square, Flat Bar, Blocks, Round Rod, Hollow, Rings, Rectangle, Hex (A/F), Triangle, Threaded, Profiles, Billet, Ingot, I/H Bar, Half Round Bar, Forging etc.Our stockyad location for fast delivery across IndiaHyderabad, Noida, Shivamogga, Pimpri-Chinchwad, Agra, Coimbatore, Chennai, Tiruchirappalli, Tirunelveli, Bhubaneswar, Chennai, Pune, Bengaluru, Ahmedabad, Thiruvananthapuram, Dhanbad, Navi Chennai

0 notes

Text

Hastelloy C276 Pipes & Tubes Suppliers in India

Hastelloy C276 Line is a titanium-settled chromium nickel molybdenum compound. This mix offers a wide assortment of mechanical properties and has a few advantages. Hastelloy Compound C276 Lines items offer great consumption obstruction. These lines’ protection from pitting and fissure consumption makes them interesting.

Hastelloy Amalgam C276 Lines which are appropriate for seawater applications. These Hastelloy C276 Consistent Lines can work in destructive circumstances, for example, those in squander the board and contamination control. Hastelloy C276 Welded Lines have been demonstrated over an extensive stretch to deal with these conditions. These Hastelloy C276 EFW Lines can be effectively turned, profound drawn, press shaped, or punched with their capability to work solidify. Hastelloy C276 ERW Lines require more energy during cold framing since they are stiffer than most of austenitic treated steels. Various cold and hot working strategies can be utilized to make these Hastelloy C276 tubes. Numerous strategies can effectively manufacture Hastelloy C276 Consistent Cylinders.

Nicrofer® 5621 Funneling and Tubing, Hastelloy C-276 Empty Area, C276 Hastelloy® Amalgam Water driven Tubing Exporters, Hastelloy C-276 Instrumentation Lines, Hastelloy C-276 Empty Line and Cylinders Dealers, Hastelloy Combination C-276 Hairlike Funneling, Hastelloy C276 Loop Cylinder Providers in Mumbai, Grade C276 Hastelloy® Amalgam Intensity Exchanger and Condenser Tubing, Nickel Amalgam C276 Cold Drawn Consistent Lines, Noise 2.4819 Hastelloy® Hexagonal Line Stockyards.

These Hastelloy C276 Welded Cylinders are utilized for Latches, Forgings, Sulfuric corrosive reactors, and that's just the beginning. Hastelloy C276 EFW Cylinders are frequently utilized for Mash and paper creation, Squander treatment, etc. These Hastelloy C276 ERW Cylinders are likewise utilized for Parts around sharp gas, Fade plants, and digesters for assembling paper and mash, and so on. Fashioned types of Hastelloy UNS N10276 Lines are outfitted in the arrangement heat-treated condition except if generally determined. Brushing with a hardened steel wire brush in the wake of welding these Hastelloy Clamor 2.4819 Cylinders will eliminate the intensity color and produce a surface region that doesn't need extra pickling.

Hastelloy C276 Pipes & Tubes Specification

Specifications : ASTM B622, B619, B626 / ASME SB622, SB619, SB626

Standard : ASTM, ASME and API

Size Range : 15"NB – 150"NB

Outer Diameter : 1.250″ – 6.000″ (30-150mm)

Wall Range : 0.095″ – 1.000″ (.2.5-25mm)

Schedule : SCH 10, SCH20, SCH30, SCH40, STD, SCH60, XS, SCH80, SCH120, SCH140, SCH160, XXS

Type : Seamless / ERW / Welded / Fabricated / LSAW Pipes

Length : Single Random, Double Random & Cut Length

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, "U" Shape, Pan Cake Coils, Hydraulic Tube

Grade Hastelloy C276 Pipes & Tubes UNS (N10276), DIN (2.4819)

For More Information :

Visit Our Website: https://sankalpalloys.com

Contact No: 91-8828369483

E-Mail ID: [email protected]

0 notes

Text

Spiral Wound Gasket

This gasket is wound altermatively by V or W shaped metal hoop and non-metal filler of various kinds of materials selected based on specific working condition.

Depend on its excellent compression resilient, high-temperature and corrosion resistance. It is suitable for sealing alteration of temperature and pressure are frequent, such as pipe, valve, pump etc. They are available in all standard flanges of sizes, such as ASME, JIS, DIN, EN. etc.

Spiral Wound Gasket Application

It is suitable for sealing flange joints, manhole and handhold covers, tube covers, boilers, heat exchangers, press vessels, pumps, compressors and valves; industries such as petrochemical, pharmaceutical, shipbuilding, and food processing, in power industries and nuclear power station. They are ideal for steam, oil, liquids, gases, acids, alkalines, various organic mediums and solvents.

Spiral Wound Gasket Standards

ASME,JIS,DIN,EN,GB,Size as requirements.

Spiral Wound Gasket Structure

1.Metal strip:the processed metal strip has good elasticity and recovery.It provides the fller enough tensile strength.

2.Filler:this part is the main body of the gasket and different material is used in different conditions

3.Centering ring:the centering ring does not come into direct contact with contained fluid.It is normally made of carbon steel and electro plate or painted to avoid corrosion.Other materials are available on request.

4.Inner ring:inner ring is used to avoid excessive compression due to high seating stress in high pressure service and it is also used to reduce turbulence in the flange area.It is normally made of the same material as the gasket metallic strip.

If you interest in our products, please click our website https://www.sealing-china.com/ or contact us [email protected]

具体信息

Filler NormalThickness(mm)

Material Code Temperature(℃) V Shape/Ring

Asbestos ASB 500

Graphite FG 650 4.8/3.0

PTFE PTFE 250 3.2/2.0 5.5/4.0

Mica MICA 950 4.5/3.0 7.5/5.0

Ceramic CER 1000

Non-asbestos NAF 300

Metal of Material:

Hoop Material GB/T 20878 DIN ASTM Temperature(℃) Guide Ring

Color Code

SS304 06Cr 19 Ni 10 1.4301 304 -195~700 Yellow

SS316L 022Cr 17Ni12Mo2 1.4435 316L -195~700 Green

SS321 06 Cr 18Ni11Ti 1.4541 321 -195~700 Turquoise

SS347 06Cr 18Ni 11Nb 1.4550 347 -195~925 Blue

SS317 06 Cr 19Ni 13Mo3 1.4449 317 -195~760 Maroon

2205 X2 CrNi Mo N2253 1.4462 S31803 -40~300 Orange

2507 X2 CrNi MoN2563 1.4410 S32750 -40~300 Orange

MONEL 400 NiCu30Fe 2.4360 N04400 -150~820 Orange

INC600 Ni Cu 15 Fe 2.4816 N06600 -100~1090 Gold

INC625 NiCr 22 Mo9Mb 2.4856 N06625 -100~1090 Gold

INC800 X10NiCr A1Ti 3220 1.4876 N08800 -100~870 White

INC825 Ni Cr21Mo 2.4858 N08825 -100~870 White

HAST-B2 Ni Mo 28 2.4617 N10665 -185~1090 Brown

HAST-C276 Ni Mo16 Cr15W 2.4819 N10276 -185~1090 Beige

TITANIUM Ti998 3.7025 R50400 -195~1090 Purple

0 notes

Link

Buy Online Hastelloy c276 Round bar, Rod and Hex/Flat bar at dealer price in India. We are supplier of ASTM B574 UNS N10276 hot rolled & cold rolled bar in custom sizes. See DIN 2.4819 bar Price List.

0 notes

Link

We are Hastelloy C276 Sheets manufacturer in India, buy Hastelloy Alloy C276 Plate, ASTM B575 UNS N10276 sheet at best price, view Hastelloy DIN 2.4819 Sheets specification, C276 Hastelloy Cold Rolled Plates suppliers.

0 notes

Text

Inconel Steel Plate | Chhajed Steel & Alloys

Chhajed Steel and Alloys supplies Inconel® blends Inconel 600 , Inconel 601 , Inconel 617 , Inconel 622 , Inconel 625 , Inconel 690 ,Inconel 718 , Inconel 800 , Inconel 825 as Plate.

The utilization safe superalloys are everything viewed as used as slightly of uncommon conditions where huge warmth and separating restriction is manager to the uprightness of the last outcome. are staying behind our thing which we've given and additionally we issued a high quality assistance on the brink of our thing which we make supplies and areas

we are apart from makers, suppliers, exporters and stockists of stainless steel plate, Quenched and Tempered plate , Pressure Vessel plate , High Strength plate , High nickel alloy plate, HIC plate, Corten Steel, Clad plate, plate

Name of product Inconel alloy plate

A type Plate

Thickness 0.3-150 mm

Length 3000mm, 5800mm, 6000mm, 9000mm, 12000mm, etc.

Standard ASTM , JIS, AISI, GB, DIN, EN

Surface BA, 2B, # 1, # 4, 4K, HL, 8K

Certification ISO, SGS

Equipment Cold rolled, hot rolled

Edge Milling edge Slot edge

Heat-resistant alloys

UNS N06601, 2.4851 like Inconel 601

It exhibits particularly good resistance to descaling in cyclic oxidation with heat variation and is therefore utilized in various parts of heat treatment furnaces, diesel vehicle glow plugs and thus the likes of .

Provide from,

applicability

Hot work is relatively easy with the N06601. for decent working, the temperature should be between 1050 and 1200 ℃, although light work are often done at temperatures as low as 850 ℃. After hot working, we also recommend cooling within the temperature range of 500 to 800 ℃ as quickly as possible to avoid carbide precipitation. N06601 has excellent cold workability almost like Type 310S and Alloy 800.

weldability. Mechanical cutting is desirable for edge preparation. Wide angles of the U- and V-groove should be used. Care must be taken to remain the welding part clean, as N06601 is sensitive to surface contamination.

Heat treatment

After cold working, softening occurs at a temperature of about 900 ℃. If high heat resistance is required, we recommend processing the mortar from 1100 to 1200 ℃. Cooling is completed with water, air cooling are often used for thinner materials also . We recommend refrigerating, although the temperature range is 500 to 800 ℃, as quickly as possible to avoid carbide deposition.

Machinability

As a high-nickel alloy, N06601 isn't as machinable as austenitic stainless steel . A high speed steel cutter are often used, although a carbide tool is usually recommended . additionally , the feed rate must be slightly reduced so on chop deep. The recommended feed rates of the lathe are as follows:

• High speed steel tool: 1050 ~ 1350mm / min

• Sintered carbide tool: 3000 ~ 5250mm / min

After operating the machine, the grease must be completely removed before welding or heat treatment.

Application

Muffle furnaces, baskets and other parts for furnaces, parts for industrial heat treatment furnaces, parts for special glass furnaces, parts for automobile glow plugs, covers for automobile exhaust gas sensors.

Ratings:

N06600 N06600 Inconel 6001 , alloy INCOLOY 625,

N07718, Inconel 718, INCOLOY Alloy 718, N07750, Inconel X750, N04400, MONEL400,

N08926 , INCOLOY Alloy 25-6Mo , etc.

2.4060、1.4980、1.4529、2.4460.41.46 、 1.4876、1.4876、2.4858、2.4816 、

2.4851、2.4856、2.4856、2.4668、2.4669、2.4360、2.4375、2.4819、2.4610、2.4602 、

2.4617、2.4660 、 etc.

Equivalent Inconel Grades

STANDARD WERKSTOFF NR. UNS JIS BS GOST AFNOR RU

Inconel 600 2.4816 N06600 NCF 600 NA 13 MNZhMts 28-2.5-1.5 NC15FE11M NiCr15Fe

Inconel 625 2.4856 N06625 NCF 625 NA 21 KhN75MBTYu NC22DNB4M NiCr22Mo9Nb

Incoloy 800 1.4876 N08800 NCF 800 NA 15 EI670 Z8NC32-21 X10NiCrAlTi32-20

Incoloy 825 2.4858 N08825 NCF 825 NA 16 EP703 NFE30C20DUM NiCr21Mo

Applications

Components for the aerospace industry - bellows and expansion joints, air passage systems, jet exhaust systems, engine thrust reversers, turbine shroud rings.

Air pollution control - chimney liners, dampers, components for flue gas desulfurization (FGD)

Chemical treatment - equipment working with both oxidizing and reducing acids, superphosphoric acid production.

Marine service - steam line bellows, exhaust systems of naval ships, auxiliary propulsion systems for submarines.

Nuclear industry - core and rod components, waste treatment equipment.

Offshore oil and gas production - waste gas incineration pipes, piping systems, riser shells, piping and tubing for sour gas

Refining - flare gas stacks

Waste treatment - waste incineration components

Why Choose Emily Metal?

EN 10204 / 3.1B,

Raw material certificate

100% X-ray test

report Third party inspection report, etc.

High special strength, high freezing point

Excellent corrosion resistance, good thermal resistance

Customer service after-sales service

Huge stock, on-time delivery

Strict inspection from staple to finished inconel late

0 notes

Link

Raaj Sagar Steels is the Supplier of Hastelloy C276 Round Bar, Hastelloy c276 hot rolled bar, Hastelloy c276 forged bar, ASTM b574 rod, din 2.4819 bar, Hastelloy c276 hex bar, Hastelloy c276 flat bar, and many more at an affordable price. For more price-related information visit the website!

0 notes

Text

TUBOS HASTELLOY C276

la mayoría de los fabricantes de tubos sólidos hastelloy c276, proveedor de tubos sin costura ASTM B622 Hastelloy C276, productores de tubos soldados ASTM B619 Hastelloy C276 en España

Los mejores proveedores de tubería sin costura de aleación C276, consulte el precio de tubería soldada UNS N10276 en España, productores de tubería de aleación C276 en España, España

Hastelloy DIN NR. 2.4819 Bush Hex Pipe es una superaleación a base de níquel. Además de su componente de aleación de base esencial, el compuesto para Hastelloy C276 Hexagonal Pipe también contiene componentes de molibdeno y cromo, lo que hace que la amalgama aumente ciertas propiedades.

Recurso todo incluido para todos Hastelloy WERKSTOFF NR. 2.4819 Pipe, proveedores de tubería hueca C276 Hastelloy en España, comerciante de tubería de amalgama c276 en España, fabricantes de tubería Hastelloy C276, consultar la lista de precios de tubería EFW de aleación C276

Hastelloy WERKSTOFF NR. 2.4819 La tubería se produce con una expansión de tungsteno en la combinación. La tubería sin costura ASTM B622 Hastelloy C276 ha sido diseñada para tener una protección asombrosa contra el consumo en una amplia gama de situaciones extremas. La tubería C276 Hastelloy ERW es una adaptación mejorada creada del compuesto C. Lo que implica que la tubería sin costura Alloy C276 normalmente no debe tratarse térmicamente después de soldarse. Otra distinción entre la combinación C y la tubería EFW de aleación C276 es que la última tiene una fabricación tremendamente mejorada.

El bajo contenido de carbono en la línea consistente hastelloy c276 es lo que limita la disposición de la precipitación de carburo durante la actividad de soldadura, que es necesaria para mantener la obstrucción del consumo en las estructuras soldadas. Esta tubería soldada Hastelloy C276 es impermeable al desarrollo del límite de grano se acelera en el territorio influenciado por el calor de la soldadura. De esta manera, la tubería hueca Hastelloy C276 es apropiada para la mayoría de las aplicaciones de ciclo compuesto en condiciones de soldadura.

A pesar del hecho de que existen algunas variedades de la combinación de níquel Hastelloy, los proveedores de tuberías Hastelloy C276 señalan que esta evaluación, por ejemplo, la tubería Hastelloy C276 es, por un amplio margen, la más utilizada en todo el mundo. La tubería Hastelloy C276 se utiliza ampliamente en las situaciones más graves. Los clientes de los proveedores de tuberías hastelloy c276 en Chennai incorporan algunas empresas, por ejemplo, control de contaminación, creación de puré y papel, preparación sintética, tratamiento mecánico y de desechos civiles, así como recuperación de gas regular afilado. fabricantes, mayoristas, exportadores y proveedores de tuberías hastelloy c276 en España

0 notes

Photo

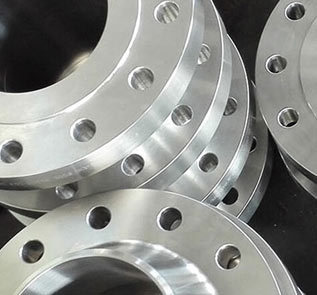

Dinesh Industries is a worldwide supplier of Alloy 20 Flange for over few decades now to countries like Iran, France, Oman, Thailand, USA, Italy, Turkey, Egypt, UK, Indonesia, Germany, Sweden, Canada, Russia, Malaysia, Qatar, Israel, Bahrain, Kuwait, UAE, Australia, Sri Lanka, Singapore, & Saudi Arabia. We export various equipments and products like UNS N08020 Blind Ring Type Joint Flange and Alloy 20 DIN 2.4819 Lap Joint Flange. You can find the flanges for the best price and with excellent quality all over India. We are ISO certified suppliers and manufacturers with other accreditations. Dinesh Industries is one of the biggest Alloy 20 Flange manufacturers in India.

0 notes

Link

Tarang Steeel is Manufacturer of Hastelloy C276 Round Bar.We offer a wide range of product like Alloy C276 Rod, Hastelloy C276 Flat Bar, Hastelloy DIN 2.4819 Threaded Bar, ASTM B574 UNS N10276 Square Bar, ASTM B574 UNS N10276 Bright Bar and more at an affordable price.Contact us for Price List.

0 notes

Text

Hastelloy flanges manufacturer in india

http://www.hiteshsteel.com/

We are Supplier & Exporter of Hastelloy Pipe Flanges, Hastelloy C276 Slip on Flanges, Hastelloy B2 DIN Blind Flanges, Alloy C22 UNS N10276 Plates Flanges Manufacturer in India.

ASTM A564 Hastelloy Flanges, Hastelloy C276 Orifice Flanges, Hastelloy WNR 2.4819 Forged Flanges, Alloy C22 Socket weld Flanges, Hastelloy ANSI/ASME B16.5 Reducing Flanges Supplier in India.

Hastelloy Flanges

US $0.2-25 / Piece (FOB Price)

Hastelloy Alloy Pipe Flanges

US $15-100 / Piece (FOB Price)

Hastelloy Weld Neck Flanges

US $10-500 / Piece (FOB Price)

ASTM B564 Hastelloy Alloy plate flanges

US $10-118 / Piece (FOB Price)

Hastelloy Alloy Pipe Flanges

US $0.1-10 / Piece (FOB Price)

Email : [email protected]

28, Sindhi Lane, Shop No. - 4,

Near Alankar Cinema,

Mumbai - 400 004, Maharashtra

http://www.hiteshsteel.com/

0 notes

Link

Largest exporter, manufacturer & supplier of Hastelloy B2 Round Bar & Hastelloy B2 Rods, ASTM B335 Hastelloy B2 Round Bars, Hastelloy B2 ASTM B335 Bar, ASME SB 335 Hastelloy B2 Rods, Hastelloy DIN 2.4819 Round Bars, Rods Products in India.

0 notes

Link

Raaj Sagar Steels is the Supplier of Hastelloy C276 Round Bar, Hastelloy c276 hot rolled bar, Hastelloy c276 forged bar, ASTM b574 rod, din 2.4819 bar, Hastelloy c276 hex bar, Hastelloy c276 flat bar, and many more at an affordable price. For more price-related information visit the website!

0 notes