#DC Electromagnetic Brakes

Explore tagged Tumblr posts

Text

Benefits of Using DC Electromagnetic Brakes

DC electromagnetic brakes are widely used in industrial applications due to their reliability, energy efficiency, and precision. They provide smooth stopping, reduce wear and tear on machinery, and enhance safety by offering quick braking action. These brakes are ideal for heavy-duty operations, ensuring consistent performance and durability.

0 notes

Text

Get the Best DC Electromagnetic Brakes for Your Industrial Equipment

Ensure reliable performance and safety with DC Electromagnetic Brakes from Industries Syndicate—India’s leading manufacturer with over 65 years of experience. Our DC electromagnetic brakes are engineered for precision, durability, and smooth operation, making them ideal for various industrial applications, including material handling, automotive, and heavy machinery.

At Industries Syndicate, we understand the importance of high-quality, dependable braking systems in maintaining the efficiency and safety of your equipment. Our DC electromagnetic brakes are designed to deliver consistent braking power, reduce wear and tear, and enhance the overall performance of your machinery.

Why Choose Industries Syndicate’s DC Electromagnetic Brakes?

Precision Performance: Smooth, reliable braking action for your equipment.

Durability: Built to endure even the most demanding industrial environments.

Customization: Customized solutions to meet your specific operational requirements.

Competitive Pricing: High-quality brakes at affordable prices.

Upgrade your equipment with Industries Syndicate DC Electromagnetic Brakes. Contact us for more information and a customized quote to improve your operational efficiency and safety today!

Contact us:

Phone: +91-33-2237-5540/ +91-33-2237-6295

Email: [email protected]/ [email protected]

Website: https://indusynd.com/

0 notes

Text

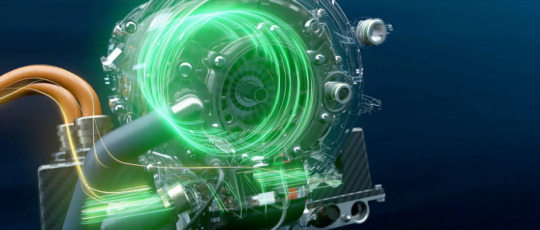

Brushless motor controller can provide steady speed and sensitive control of braking and direction changes. It regulates the speed and torque of the motor; it can also start, stop, and reverse its rotation. Visit us now for more.

0 notes

Text

What Is Hollow Cup Motor? Hollow Cup Motor Technology And Application

Hollow cup motor (Micro coreless motor) is a special DC motor. Traditional DC motor is widely used in industrial production, household appliances, transportation and other fields, composed of two core parts of the stator and rotor, the stationary part of the DC motor is called the stator, the main role of the stator is to generate a magnetic field, composed of the frame, main magnetic pole, reversing pole, end cap, bearing and brush device. Commonly used stator magnet materials include Ndfeb, Samarium cobalt, aluminum nickel cobalt and ferrite. The part that rotates during operation is called the rotor, and its main role is to produce electromagnetic torque and induced electromotive force, which is the hub of DC motor for energy conversion, so it is usually called the armature, which is composed of rotating shaft, armature core, armature winding, commutator and fan.

The hollow cup motor breaks through the structural form of the traditional DC motor in structure, using a no-core rotor, and its armature winding is a hollow cup coil, similar in shape to a water cup, so it is called "hollow cup motor". Hollow cup motor belongs to DC, permanent magnet, servo micro motor. This novel rotor structure makes the hollow cup motor have the following excellent characteristics: ① Energy-saving characteristics: core-free design completely eliminates the power loss caused by the formation of eddy currents in the iron core, and the energy conversion efficiency is very high, the maximum efficiency is generally more than 70%, and some products can reach more than 90% (iron core motors are generally 70%); (2) Control characteristics: fast starting and braking, fast response, mechanical time constant less than 28 milliseconds, some products can reach less than 10 milliseconds (core motors are generally more than 100 milliseconds); The speed can be easily adjusted sensitively under the high speed running state in the recommended operating area; (3) Drag characteristics: The operation stability is very reliable, the fluctuation of speed is very small, as a micro motor, its speed fluctuation can be easily controlled within 2%; ④ Lightweight characteristics: compared with the same power core motor, its weight and volume are reduced by 1/3-1/2, and the energy density is greatly improved. The core indicator of the hollow cup motor is the power density, that is, the ratio of the output power to the weight or volume. The rotor without iron core eliminates eddy current and hysteresis loss at the molecular end and improves the energy conversion efficiency. Reduced weight and volume at the denominator end.

The brush is an important component of the brushed motor, responsible for conducting the current between the rotating parts and the stationary parts. Because it is more made of graphite, it is also called carbon brush. In the ordinary DC motor, in order to keep the rotor rotating, the rotor current direction needs to be changed in real time, so the commutator and carbon brush need to be used. The brushless motor cancels the mechanical brush commutation mode, so the rotor position needs to be detected to complete the electronic commutation. There are two common ways to obtain rotor position information: (1) sensorless control mode, when the motor is running, the rotor position is determined by the measurable variable fed back by the motor; The position sensor control mode, the motor rotor position is directly detected by the position sensor inside the motor. Commonly used position sensors are Hall sensors, photoelectric encoders, rotary transformers and so on. Hall sensor detection accuracy is not high, but the price is low; The photoelectric encoder and rotary transformer position detection is accurate and the error is small, and they are generally used for high-performance control systems, such as magnetic field orientation control and direct torque control.

Hollow cup motor according to its structure can be divided into brush and brushless two kinds. ① Brushed hollow cup motor (also known as DC brushed coreless motor, rotor without iron core) : The use of mechanical brush commutator, generally by the shell, soft magnetic material inner stator, permanent magnet stator, hollow cup rotor armature composition. When the hollow cup brush motor is energized, the winding has current through, generating torque, the rotor begins to rotate, if the rotor turns to a specific Angle, the brush uses the mechanical commutator to change the direction of the current, so that the output torque direction is unchanged, the rotor continues to rotate. Because the hollow cup brush motor uses the brush commutation, there is a certain relative friction during the operation of the motor, which will produce noise, electric spark, and reduce the service life of the motor. Generally domestic "hollow cup motor" generally refers to brush motor; ② brushless hollow cup motor (also known as DC brushless slotless motor, stator without iron core) : The use of electronic commutation, generally by the shell, soft magnetic materials, insulating materials and hollow cup armature composed of the stator and permanent magnetic steel rotor. The hollow cup brushless motor connects different windings to the circuit by controlling the on-off of electronic components to achieve the effect of reversing. This commutation mode makes the hollow cup brushless motor have the characteristics of high efficiency, small torque fluctuation, high service life, compact structure, easy maintenance and so on.

1.2. Core barrier: winding process

The process flow of hollow cup motor is complex, and the processing difficulty is far more than that of ordinary DC slotted motor. Taking the DC slotless motor of Dingzhi Technology (that is, its hollow cup motor products) as an example, from the front coil winding, middle bearing, mandrel, support ring and other core parts installation, to the rear cover installation and circuit board welding line, etc., involving nearly 30 processes, the complexity is far more than ordinary DC slotted motors. Coil production needs to go through the process of enameled wire - winding - heating shaping - wire stripping, connecting the common wire - coil installation and so on.

Among them, coil manufacturing is one of the core processes of hollow cup motor. Coreless self-supporting windings are made of so-called enameled wire, which is an insulated copper wire with a coat of paint on the outside. In the manufacturing process, the paint of adjacent wires is fused together by applying pressure and temperature. Proper bonding (tape or fiberglass) can further improve the strength and shape stability of the winding, which is especially important under high current loads.

The production technology of hollow cup motor coil is mainly divided into three categories according to the forming method of coil: 1) manual winding. Through a series of complex processes, including pin insertion, manual winding, manual wiring and other steps to produce. 2) Winding production technology. The winding production technology is semi-automatic production, the enameled wire is first sequentially wound to the main shaft with a diamond-shaped cross-section, and it is removed after reaching the required length, and then flattened into a wire plate, and finally the wire plate is wound into a cup-shaped coil. Taking a winding hollow cup as an example, the manufacturing process can be roughly divided into the following steps: (1) Winding of hexagonal wire billet coil: it is carried out on the inclined winding group winding machine; ② The wire blank coil is pasted with two pieces of shaped pressure sensitive tape, demoulding to be flattened; ③ Flattening: the shape plate is inserted into the wire blank coil, and the coil is flattened, and then sent to the flattening machine to flatten and become a flat wire blank. Shape with a bamboo scraper. Cut off the excess tape, leaving only one hitch, the hitch should be left on the slightly raised side of the flat strand, so that the reel can form a row; ④ Coil: the flat wire blank is fed into the coil of the hollow cup coil machine, so that the wire blank is connected to the end, and the tape is pasted on the surface of the wire blank head to become the hollow cup coil; ⑤ Coating epoxy shaping: After coating epoxy adhesive, put it in the oven for curing and shaping. 3) One molding production technology. The winding machine winds a enameled wire to a spindle according to the law through the automation equipment, and takes off the coil after winding into a cup, forming at a time, and does not require multiple processes such as rolling and flattening, with a high degree of automation.

Overseas winding process developed early, the degree of automation is higher than domestic. The domestic mainly adopts winding production, the process is more complicated, the labor intensity of workers is large, can not complete the coil with thicker wire diameter, and the scrap rate is high. Foreign countries mainly use one-time wound production technology, high degree of automation, high production efficiency, coil diameter range, good coil quality, tight arrangement, motor types, good performance. The hollow cup motor can be divided into straight wound, saddle shape and inclined wound according to the winding method. In 1958, Dr.F. F. aulhaber (von Haber) of Germany developed the inclined winding coil winding technology, and obtained the patent technology of the inclined winding of the rotor coil of the hollow cup motor in 1965. Germany, Switzerland, Japan and other hollow cup motor development earlier, in the winding process has accumulated rich experience. Among the three leading hollow cup motors in the world, Swiss Maxon mostly uses straight wound shape and saddle shape, and German Faulhaber and Swiss Portescap mostly use inclined wound shape. The process of straight-wound winding is more complicated, and it is mostly used for long winding structures, often made of multiple winding. Saddle shape can reduce coil thickness, reduce magnetic air gap effectively on high power density motor, increase the length of cutting magnetic field, and make better use of stator magnetism; Oblique winding developed earlier, relatively simple winding, tight wiring, suitable for large batch production.

Winding is the core technical barrier of hollow cup motor. ① Design link: overseas three main technology originated in the 1960s, the domestic hollow cup motor started late, less research, lack of combination of material subdivision grade, rotor cup type to optimize the motor, lack of systematic forward design, lack of customized requirements of system drive scheme configuration and product design capabilities; ② Processing link: Compared with the traditional brushless motor, brush motor, servo motor, the structure of the hollow cup motor belongs to the toothless groove structure, there is no fixed groove, all enameled wire is suspended winding, there is no internal support, it is very difficult in the process, and the early yield is low. In terms of winding accuracy, the precision requirements of hollow cup motors are higher than those of traditional motors. The hollow cup motor itself is small in size, and the tolerance for error is lower than that of ordinary permanent magnet motors and stepper motors, and the processing accuracy directly affects the stability of the magnetic field. The difference of wire thickness and winding turns makes the winding resistance value, starting current, speed constant and other motor parameters have great differences. Because of this, domestic manufacturers need to improve the precision, yield and automation in the production and processing links. Compared with overseas, China is also relatively weak in terms of winding equipment. Winding equipment can be divided into automatic and manual non-automatic equipment. Compared with overseas, the degree of automation of winding equipment in China is relatively low. The world's leading manufacturers of winding equipment include Meteor of Switzerland, Tanaka Seiki Co., Ltd. of Japan, and Hitote Mechanical Engineering Co., LTD. Domestic enterprises are still in a relatively vacant state in terms of equipment, and they purchase more Japanese winding equipment, with prices ranging from hundreds of thousands to millions. The relatively representative companies in China include Zhongspecial Technology, Dongguan Taili Electronic Machinery Co., LTD., Qinlian Technology, Kunshan Cook and so on.

1.3 Downstream applications: The characteristics of the hollow cup motor determine the downstream application scenario

The hollow cup motor belongs to the micro motor, and the upstream raw materials are similar to the raw materials of the micro motor, including copper, steel, magnetic steel, bearings, plastics, etc. Hollow cup motor was originally used in aviation, aerospace, military and other cutting-edge industries, in recent years, its application gradually expanded to civilian industries, such as medical devices, consumer electronics, power tools, industrial automation and other scenarios.

The different performance of the hollow cup motor corresponds to its application in different fields: 1) the characteristics of small size, light weight, and large power to volume ratio make it suitable for areas with high weight requirements, such as various types of aircraft, etc., which can minimize the weight of the aircraft; It is also widely used in various consumer electronic products, such as electric toothbrushes and portable electric fans. 2) The characteristics of rapid starting and braking and extremely fast response make it suitable for areas that need to achieve fast automatic control, such as missile direction adjustment with high control performance requirements, high-rate optical drive follow-up, highly sensitive equipment, industrial robots, etc. 3) The characteristics of high energy conversion efficiency and long running time make it suitable for all kinds of fields requiring energy saving and battery life, such as portable instruments and field work equipment.

Humanoid robot opens a new blue ocean of hollow cup motor applications. According to the latest development of Optimus, a humanoid robot released by Tesla, each hand includes six drives and 11 degrees of freedom, two drives for the thumb and one drive for each of the other four fingers, and the hand can carry up to 20 pounds. The hand joint module is mainly composed of hollow cup motor, precision planetary reducer, ball screw and sensor. The hollow cup motor enables the finger to have the ability to move, the precision planetary gearbox enables the manipulator to position more accurately and use more flexible, the encoder provides high-precision position feedback and speed feedback of the hand, and the sensor enables the robot to have human-like perceptual function and reaction ability. According to Musk, the number of humanoid robots in the future will exceed the number of humans, and it is expected to reach the level of 100 billion units in the long term. Hollow cup motor is the mainstream technical solution of robot hand with high certainty. Humanoid robots use 6 hollow cup motors per hand, considering the end situation, humanoid robots are expected to reach the level of one billion units, if the mass production of humanoid robots landing, will pull hollow cup motor related enterprises revenue growth.

0 notes

Text

YEJ Electromagnetic Brake Three Phase Asynchronous Motor

YEJ Series brake motors are fully enclosed three-phase asynchronous motors with additional disc-type DC brakes. It has the advantages of rapid braking, simple structure, high reliability and strong versatility. In addition, the brake has a manual release structure, which is widely used in a variety of mechanical equipment that needs speed regulation and rapid stop, accurate positioning, reciprocating start, frequent start, and prevent sliding. For example, in the start of transport machinery for lifting and walking machinery drag, all kinds of metal cutting machine tools, printing presses, forging presses, cement mixers, woodworking machinery, paper machinery, rubber and plastic machinery and textile machinery drag.

+86-15861132046

E-mail: [email protected]

0 notes

Text

The Evolution of Electric Motors: How They're Powering the Future of Transportation

Electric motors have undergone remarkable advancements since their inception, transforming the landscape of transportation and driving the future of mobility. The evolution of electric motors has not only revolutionized how we travel but also influenced various industries, including motor insurance. As electric vehicles (EVs) become more prevalent, understanding the progression of electric motor technology provides insight into its impact on transportation and related fields.

1. Early Beginnings and Technological Milestones

The journey of electric motors began in the 19th century with pioneers like Michael Faraday and Joseph Henry laying the groundwork for electromagnetic principles. The first practical electric motor was developed by Hungarian engineer Ányos Jedlik in the 1820s, but it was not until the late 19th and early 20th centuries that electric motors began to gain traction in transportation.

Early electric vehicles (EVs) were simple and relatively low-powered compared to today’s standards. They were mainly used for short-distance travel and were soon overshadowed by gasoline-powered vehicles due to their limited range and performance. However, the basic principles of electric motor technology continued to evolve, setting the stage for future advancements.

2. The Rise of Modern Electric Motors

The late 20th and early 21st centuries marked a significant turning point in the evolution of electric motors. Advances in battery technology, particularly lithium-ion batteries, played a crucial role in revitalizing interest in electric vehicles. These batteries offered higher energy density, longer life, and faster charging times compared to their predecessors.

Modern electric motors are characterized by their efficiency and power. Innovations such as brushless DC (BLDC) motors and induction motors have enhanced performance and reliability. BLDC motors, for instance, offer high efficiency and require less maintenance due to the absence of brushes that wear out over time. Induction motors, on the other hand, are known for their robustness and simplicity.

3. Integration with Advanced Technologies

The integration of electric motors with advanced technologies has further propelled the evolution of transportation. The advent of regenerative braking systems, which capture and store energy during braking, has improved energy efficiency and extended the range of electric vehicles. Additionally, advancements in power electronics and control systems have optimized the performance and responsiveness of electric motors.

Electric motors are now being used in a variety of transportation modes, including cars, buses, bikes, and even airplanes. The development of high-performance electric motors has enabled the production of electric vehicles with impressive acceleration, long ranges, and enhanced driving experiences. This diversification and innovation in electric motor technology are shaping the future of transportation.

4. Impact on Motor Insurance

The rise of electric vehicles has also impacted the motor insurance industry. As electric vehicles become more common, insurance companies are adapting their policies to address the unique characteristics and risks associated with EVs. Electric vehicles typically have fewer moving parts compared to traditional internal combustion engine vehicles, which can lead to lower maintenance costs and potentially lower insurance premiums.

However, electric vehicles also introduce new considerations for motor insurance, such as the cost of battery replacement and the availability of specialized repair services. Insurance companies are developing tailored policies that address these factors, ensuring that EV owners are adequately covered. Additionally, the growing emphasis on sustainability and environmental responsibility is influencing insurance companies to offer incentives for electric vehicle owners, further driving the adoption of green transportation.

5. The Future of Electric Motors

Looking ahead, the evolution of electric motors is expected to continue advancing with innovations in materials, design, and integration with renewable energy sources. The development of solid-state batteries, which promise higher energy densities and faster charging times, is on the horizon. Furthermore, advancements in autonomous driving technologies are likely to enhance the capabilities of electric vehicles, paving the way for a new era of transportation.

The evolution of electric motors has significantly transformed the transportation industry, driving the development of more efficient, powerful, and sustainable vehicles. As electric motors continue to advance, they are not only shaping the future of transportation but also influencing related fields such as motor insurance. The ongoing progress in electric motor technology promises to bring further innovations and improvements, heralding a new chapter in the future of mobility.

0 notes

Text

The key components of electric vehicle

EV Motor

EV motor is a very important in EV Components. The motor is the power source of electric vehicles, and its performance directly affects the power performance and driving efficiency of electric vehicles. There are two main types of motors basically: DC motors and AC motors. DC motors have fast starting speed and a wide speed range, but they require frequent maintenance; AC motors are highly efficient, quiet, and have a long life.

Motor Controller

MCU plays a vital role in EV components. It is responsible for receiving instructions from VCU and accurately controlling the torque and speed output of the motor to drive the vehicle. The MCU’s efficient conversion function converts the DC power of the power battery into the high-voltage AC power required to drive the motor. It also has fault diagnosis and storage capabilities to ensure the stable operation of the motor system.

Electric Battery

As an energy storage device for electric vehicles, the capacity and performance of batteries directly determine the range and safety of electric vehicles. Currently, there are two main types of batteries : lead-acid batteries and lithium batteries. Lead-acid batteries are cheap and stable, but they are heavy and have low energy density. Lithium batteries have the advantages of high energy density, light weight, and long life, but they are more expensive and less stable than lead-acid batteries.

VCU

As the “brain” of electric vehicles, VCU is responsible for the core control tasks of the entire vehicle. It accurately calculates the torque and other parameters required by the motor based on the driver’s operations, such as the accelerator pedal position, gear shift instructions and brake pedal force, combined with the battery status, to ensure that the electric vehicle runs smoothly. At the same time, VCU also has energy management functions, which achieves efficient energy utilization by optimizing driving charging and braking energy recovery, and works in conjunction with the intelligent body system to ensure instant response and safety of driving.

Power Inverter

It converts the DC power from the battery into AC power. It also converts the AC current generated during regenerative braking into DC current. This is further used to charge the battery. The inverter can change the speed.

EV Charging system

It includes charging interface, charging controller, charger and other equipment, supporting slow and fast charging. AEAUTO EV chargers consist of DC ev charger and AC ev charger together.

Braking system

It includes brake pads, brake discs, etc., responsible for deceleration or stopping. It adopts electric braking to ensure safety performance.

High-voltage system

It includes high-voltage cables, connectors and protective devices to ensure the safety of power transmission. High-voltage wiring harnesses are very critical and must meet the requirements of electromagnetic compatibility regulations. Therefore, methods such as glue injection and shielding wire wrapping are used on the surface of high-voltage wiring harnesses to reduce electromagnetic interference. Fuses are divided into two types: AC and DC. The fuses used in electric vehicles are related to the current type. DC systems use DC fuses, and AC systems use AC fuses.

Thermal management system

The thermal management system of electric vehicles can be divided into battery system thermal management, air-conditioning system thermal management and motor and electronic control system thermal management; the battery system thermal management and air-conditioning system thermal management have two major functions: cooling and heating, while the motor and electronic control system thermal management is mainly cooling. It controls environmental parameters such as temperature and humidity of the vehicle to ensure the normal operation and service life of components.

These AEAUTO EV components work together to enable electric vehicles to operate efficiently and safely while also meeting environmental protection and energy-saving requirements.

1 note

·

View note

Text

Understanding the Different Types of Elevator Motor Technology

Elevators are an essential part of modern buildings, enabling efficient vertical transportation for people and goods. The heart of any elevator system is its motor, which drives the movement of the elevator car. Over the years, elevator motor technology has evolved significantly, enhancing performance, efficiency, and reliability. Understanding the different types of elevator motors is crucial for selecting the right system for a building’s specific needs. This article delves into the primary types of elevator motors, their applications, advantages, and impact on elevator systems.

AC Motors: Alternating Current Efficiency

AC motors are widely used in modern elevator systems due to their efficiency and reliability. There are two main types of AC motors used in elevators: induction motors and synchronous motors.

Induction Motors: These motors are the most common type of AC motor. They operate on the principle of electromagnetic induction, where the rotor is induced to move by the magnetic field of the stator. Induction motors are robust, cost-effective, and require minimal maintenance, making them ideal for a wide range of elevator applications, especially in residential and low to mid-rise commercial buildings.

Synchronous Motors: Unlike induction motors, synchronous motors operate at a constant speed, regardless of the load. This is achieved by maintaining a constant frequency of the AC power supply. Synchronous motors offer high efficiency and precise speed control, making them suitable for high-rise buildings where smooth and consistent elevator operation is critical.

DC Motors: Direct Current Precision

DC motors were among the first types of motors used in elevator systems and are still in use today, particularly in older installations and specific applications that require precise speed control.

Series Wound DC Motors: These motors provide high starting torque and are capable of handling varying loads effectively. They are well-suited for elevators that experience frequent stops and starts, such as those in busy commercial buildings. However, series-wound DC motors require more maintenance than their AC counterparts due to brush and commutator wear.

Permanent Magnet DC Motors: These motors use permanent magnets to create the magnetic field instead of relying on windings. This design reduces maintenance needs and increases efficiency. Permanent magnet DC motors are often used in smaller, low-capacity elevators where precise control and efficiency are desired.

Gearless Traction Motors: The Modern Standard

Gearless traction motors represent a significant advancement in elevator motor technology. These motors are typically AC synchronous motors that drive the elevator directly without the need for a gearbox. This direct drive mechanism offers several benefits:

Smooth Operation: Gearless traction motors provide exceptionally smooth and quiet operation, making them ideal for high-end residential and commercial buildings where noise reduction is important.

Energy Efficiency: By eliminating the gearbox, gearless traction motors reduce energy losses and improve overall efficiency. This makes them a sustainable choice for modern buildings focused on energy conservation.

Low Maintenance: The simplified design of gearless traction motors, with fewer moving parts, translates to lower maintenance requirements and longer service life compared to traditional geared systems.

Regenerative Drives: Harnessing Energy Efficiency

Regenerative drive technology is a recent innovation that enhances the efficiency of elevator motors, particularly in high-rise buildings. Regenerative drives capture the energy generated during the braking process of the elevator and convert it back into usable electricity, which can be fed back into the building’s power grid. This not only reduces energy consumption but also lowers operating costs.

Environmental Impact: By reducing the overall energy demand, regenerative drives contribute to a building’s sustainability and help reduce its carbon footprint.

Cost Savings: The energy savings achieved through regenerative drives can be substantial, leading to lower utility bills and a quicker return on investment for building owners.

Conclusion

Choosing the right elevator motor technology is critical for ensuring efficient, reliable, and cost-effective elevator operation. AC motors, including induction and synchronous types, offer reliability and efficiency for various applications. DC motors, particularly in older systems, provide precise control and high starting torque. Gearless traction motors represent the pinnacle of modern elevator technology, offering smooth operation, energy efficiency, and low maintenance. Additionally, regenerative drive technology further enhances energy efficiency by capturing and reusing energy.

Understanding these different types of elevator motors and their respective benefits allows building designers, engineers, and owners to make informed decisions that align with their specific requirements and sustainability goals. As elevator technology continues to evolve, these advancements promise even greater efficiency, reliability, and environmental benefits for the future of vertical transportation.

0 notes

Text

Reasons to Buy 2000 lb Electric Powered Tugger Online

Material handling is the absolute requirement in various industrial and commercial operations. However, this activity should be done with utmost safety and efficiency. Whether it is a warehouse, manufacturing complex or other industrial sphere where efficient material handling is required, it is quite important to transport heavy loads safely, and in such a context, buying a 2000 lb electric-powered tugger online would be the best way to ensure smoothness and effective material handling. With robust features and ergonomic design, this outstanding material handling equipment can revolutionize the workflow while prioritizing the worker’s safety.

Here are the best features of these tuggers that ensure smooth material handling to meet your requirements.

Drive Motor

The motor is considered the heart of these tuggers. The 24V DC/800W drive motors ensure optimal efficiency to tug any weight up to 2,000 lbs. This efficient motor is designed to tackle even the most demanding tasks easily. Whether you want to navigate through narrow spaces or transport heavy and bulky items, rest assured that this motor can smoothly carry out the tasks.

Handle

These tuggers function well because of the beautiful combination of the ergonomic handle and comfort. Designed with user-friendly features, it offers a firm grip and intuitive control. Due to the easy-to-operate throttle, it can smoothly accelerate and decelerate within the facility. Due to this control system, it becomes easy for precise manoeuvring in any kind of environment.

Outstanding Speed Control

Versatility is key, and the 2000 lb electric-powered tugger delivers the forward and reverse speeds according to the operational requirement. Whether you are zipping through the aisles or navigating through the narrow corridors, the operator can control the speeds.

Efficient Breaking System

Breaking the system of these tuggers plays a crucial role in ensuring that there is no safety breach in the working area. To ensure workplace safety, these tuggers are equipped with electromagnetic disc brakes. Due to this reliable braking system, the tugger can be stopped at any condition and gives peace of mind knowing that your cargo and personnel are secure.

Dead-Man Feature

Accidents happen in this fast-paced material-handling world within seconds. To tackle these issues and to avoid such unwanted accidents, these tuggers are equipped with a dead-man feature. It gets activated when the user releases the handle, and this safety mechanism brings the tugger to an immediate halt while preventing mishaps and ensuring the well-being of everyone associated with the operation.

Efficient Battery

The efficient battery of two 12V batteries offers maximum power to this electric tugger. If there is any extended application required, these batteries are ready to provide ample energy. Since it comes with an integral battery charger and a battery level gauge, it is quite easy for the operators to monitor and maintain the power levels, which significantly minimizes downtime and boosts productivity.

Added Features

The 2000 lb electric-powered tugger comes with several other features that add to its core functionalities. These include horns to alert pedestrians. Pin hatch for towing is also available for the additional equipment. Since these electric tuggers come with optional attachments, it is easy to customize them to suit the specific material handling needs.

When you buy a 2000 lb electric-powered tugger online, it will work more than just a piece of equipment. This is a game-changer for businesses that are looking to streamline material handling operations while minimizing workplace accidents and boosting productivity.

Resource: https://superliftca.wordpress.com/2024/02/29/reasons-to-buy-2000-lb-electric-powered-tugger-online/

#superlift#electric powered tugger#electric tuggers#best stainless steel tuggers for sale#buy industrial tuggers florida#stainless steel tuggers#electric pushers for sale#industrial pushers#column lift#electric powered tugger online

0 notes

Text

Navigating the Automotive Electric Motors Market: An In-Depth Analysis

In the era of electrification and sustainable transportation, the Automotive Electric Motors Market emerges as a pivotal force driving innovation, efficiency, and environmental stewardship within the automotive industry. With the relentless pursuit of electrified mobility solutions and the transition towards zero-emission vehicles, automotive electric motors play a central role in reshaping the future of transportation. In this comprehensive analysis, we delve into the intricacies and market dynamics shaping the landscape of automotive electric motors.

Understanding the Evolution of Automotive Electric Motors

The evolution of automotive electric motors represents a paradigm shift in vehicle propulsion technology, offering enhanced performance, efficiency, and sustainability compared to traditional internal combustion engines. From the pioneering days of electric vehicles to the current wave of electrification sweeping across the automotive sector, electric motors have evolved into sophisticated powertrains capable of powering a diverse range of vehicles.

Types of Automotive Electric Motors

Permanent Magnet Motors: Characterized by high efficiency and compact design, permanent magnet motors leverage rare-earth magnets to generate magnetic fields, enabling efficient power conversion and torque delivery.

Induction Motors: Renowned for their robustness and reliability, induction motors utilize electromagnetic induction to produce rotational motion, making them well-suited for various automotive applications.

Brushless DC Motors: With their brushless design and electronic commutation, brushless DC motors offer improved efficiency, reduced maintenance, and precise control, making them ideal for electric vehicles (EVs) and hybrid electric vehicles (HEVs).

Market Trends and Growth Drivers

Amidst the rapid electrification of the automotive industry, the Automotive Electric Motors Market experiences dynamic shifts driven by technological advancements, regulatory mandates, and shifting consumer preferences.

Electrification Initiatives and Regulatory Imperatives

In response to mounting concerns over air quality and greenhouse gas emissions, governments worldwide are implementing stringent emissions regulations and incentivizing the adoption of electric vehicles. Mandates such as zero-emission vehicle (ZEV) mandates and emission targets propel automakers towards electrification, catalyzing demand for automotive electric motors and electrified powertrains.

Technological Innovation and Performance Enhancement

Advancements in motor design, materials science, and power electronics unlock new frontiers in motor efficiency, power density, and thermal management. Innovations such as silicon carbide (SiC) power semiconductors, advanced cooling systems, and integrated motor-inverter solutions elevate the performance and reliability of automotive electric motors, paving the way for next-generation electric vehicles with extended range and enhanced driving dynamics.

Market Segmentation and Application Landscape

The Automotive Electric Motors Market encompasses a diverse array of applications spanning passenger vehicles, commercial vehicles, and electric mobility solutions.

Buy the Full Report for Additional Automotive Electric Motors Market Forecast Insights or Download the Free Sample Report

Passenger Electric Vehicles (EVs) and Plug-in Hybrid Electric Vehicles (PHEVs)

With the proliferation of EV platforms and the emergence of long-range electric vehicles, passenger EVs and PHEVs represent the vanguard of electrified mobility. High-performance electric motors, coupled with advanced battery technology and regenerative braking systems, enable EVs to deliver exhilarating acceleration, extended range, and seamless driving experiences.

Commercial Vehicles and Urban Mobility Solutions

In the realm of commercial transportation and urban mobility, electric motors power a myriad of applications, including electric buses, delivery vans, and last-mile logistics solutions. The electrification of commercial fleets promises reduced operating costs, lower emissions, and enhanced urban air quality, driving adoption and investment in electric propulsion technologies.

Conclusion

In conclusion, the Automotive Electric Motors Market epitomizes the convergence of innovation, sustainability, and transformative change within the automotive industry. As automakers embrace electrification and transition towards sustainable mobility solutions, automotive electric motors emerge as indispensable enablers of this paradigm shift. By fostering collaboration, innovation, and strategic partnerships, industry stakeholders can accelerate the transition to electrified transportation and forge a greener, more sustainable future for mobility.

0 notes

Text

8 Types of Electric Motors that Power EVs

In the dynamic landscape of the automotive industry, electric vehicles (EVs) have emerged as a beacon of sustainability and environmental responsibility. At the heart of these cutting-edge vehicles lies a crucial component: the electric motor. These motors are the driving force, quite literally, behind the push for a cleaner, greener transportation future. Let's take a closer look at five prominent types of electric motors that propel electric vehicles into the future.

Brushed DC Motor: The brushed DC motor, a pioneer in the realm of electric propulsion, employs a coil of wire and brushes to conduct electricity, propelling the rotor into motion. Despite its simplicity and cost-effectiveness, the brushed DC motor faces challenges such as friction-related efficiency limitations and higher maintenance demands.

Brushless DC Motor (BLDC): Addressing the limitations of its brushed counterpart, the BLDC motor boasts electronic commutation, eliminating brushes and ushering in increased efficiency, reduced maintenance, and an extended lifespan. The higher manufacturing costs and complex control algorithms are a trade-off for the enhanced performance and power density that BLDC motors offer.

Induction Motor: Widely adopted in the electric vehicle industry for its simplicity and reliability, the induction motor operates by inducing a current in the rotor through electromagnetic fields. While it excels in ruggedness and reliability, challenges include lower efficiency at low speeds and light loads, requiring additional control electronics for optimal performance.

Permanent Magnet Synchronous Motor (PMSM): The PMSM, a stalwart in the electric vehicle domain, leverages permanent magnets on the rotor to synchronize with the stator's rotating magnetic field. This design choice results in high efficiency, superior power density, and efficient regenerative braking. However, challenges such as costs associated with permanent magnets and the need for complex control algorithms persist.

Switched Reluctance Motor (SRM): A less common but promising contender, the SRM operates on the principle of magnetic reluctance, offering a simple construction and robust design. However, efficient operation requires intricate control algorithms, and performance at high speeds may be limited, making SRMs less widespread in EV applications.

Each of these electric motor types brings a unique set of advantages and challenges to the table. The rising stars, such as BLDC and PMSM motors, are witnessing increased adoption in the electric vehicle sector, driven by their efficiency, precise control, and extended lifespan. Meanwhile, emerging contenders like axial flux and toroidal motors are captivating attention with their compact designs and unique capabilities.

In the ever-evolving landscape of electric mobility, the choice of electric motor becomes a pivotal decision for manufacturers. As technology advances, innovation in electric motor design will likely overcome current limitations, paving the way for even more efficient, powerful, and reliable electric vehicles cruising our roads. The journey towards a sustainable and electrifying future continues, driven by the relentless pursuit of cleaner and greener transportation solutions.

To read more, click here.

Discover the fascinating world of advanced electric vehicles and beyond with SearchEV, your ultimate gateway to awe-inspiring EV technology and much more!

0 notes

Text

Emco Brake - Reliable Industrial Brake Solutions for Enhanced Safety

Emco Precima is one of the best leading Supplier of superior quality mechanical transmission and engineering products, catering to diverse industrial needs. With a reputation for excellence, the company offers a wide range of products designed for efficiency, durability, and safety. Their portfolio includes Emco brakes, Precima brakes, hoist brakes, crane hoist brake systems, crane brakes, machine brakes, and Kateel brakes. Additionally, they specialize in AC electromagnetic brakes, brake linings, brake drum couplings, EOT crane parts, electromagnetic DC brakes, and thruster brakes. Their expertise extends to advanced systems like EHT brakes, hydraulic brakes, band brakes, storm brakes, and rail brakes, ensuring comprehensive solutions for industrial power transmission requirements.

With a commitment to customer satisfaction, they provide reliable solutions for cranes, hoists, and various mechanical systems, making them a trusted partner in the engineering and mechanical transmission industry.

1 note

·

View note

Text

Get the Best DC Electromagnetic Brakes for Your Industrial Equipment

Ensure reliable performance and safety with DC Electromagnetic Brakes from Industries Syndicate—India’s leading manufacturer with over 65 years of experience. Our DC electromagnetic brakes are engineered for precision, durability, and smooth operation, making them ideal for various industrial applications, including material handling, automotive, and heavy machinery.

At Industries Syndicate, we understand the importance of high-quality, dependable braking systems in maintaining the efficiency and safety of your equipment. Our DC electromagnetic brakes are designed to deliver consistent braking power, reduce wear and tear, and enhance the overall performance of your machinery.

Why Choose Industries Syndicate’s DC Electromagnetic Brakes?

Precision Performance: Smooth, reliable braking action for your equipment.

Durability: Built to endure even the most demanding industrial environments.

Customization: Customized solutions to meet your specific operational requirements.

Competitive Pricing: High-quality brakes at affordable prices.

Upgrade your equipment with Industries Syndicate DC Electromagnetic Brakes. Contact us for more information and a customized quote to improve your operational efficiency and safety today!

Contact us:

Phone: +91-33-2237-5540/ +91-33-2237-6295

Email: [email protected]/ [email protected]

Website: https://indusynd.com/

0 notes

Text

These Jib Cranes come with single as well as dual-disc electromagnetic DC brakes that features automatic braking when the power fails. This type of JIB cranes are generally used for light or medium duty jobs. These JIB cranes are made as per BIS numbers 3938, 807 & 3177.

0 notes

Text

Electromagnetic Brake Three-Phase Asynchronous Motor

YEJ Series brake motors are fully enclosed three-phase asynchronous motors with additional disc-type DC brakes. It has the advantages of rapid braking, simple structure, high reliability, and strong versatility. In addition, the brake has a manual release structure, which is widely used in a variety of mechanical equipment that needs speed regulation and rapid stop, accurate positioning, reciprocating start, frequent start, and prevent sliding. For example, in the start of transport machinery for lifting and walking machinery drag, all kinds of metal cutting machine tools, printing presses, forging presses, cement mixers, woodworking machinery, paper machinery, rubber and plastic machinery, and textile machinery drag.

+86-15861132046

E-mail: [email protected]

1 note

·

View note

Text

YVFEJ2 SERIES VARIABLE FREQUENCY SPEED REGULATIONELECTROMAGNETIC BRAKE MOTO

Web:https://www.zjpinyi.com/product/yvfej2-serise/yvfej2-series-frequency-conversion-speed-electromagnetic-brake-motor.html

Controller power supply:base center height≤100mm; AC 220V(DC 99v after rectification) Base center height:= 112mm; AC 380v (DC170V after rectification) Power range:0.55~45KW Rated voltage:380v (other voltages need tobe agreed separately) Rated frequency:50Hz(or 60Hz) Base center height:80 ~225mm Protection grade:lP54 Working system:S1

1 note

·

View note