#Custom Tanks and Metal Finishing System

Explore tagged Tumblr posts

Photo

Back in a former life, I had an addiction that I loved beyond sanity. Here’s the story of it. 2002 2003 2004 2005 2006 2007 2008 2009 pt1 2009 pt2 2009 Redux

This is the final spec list for my glorious, insane Brutal Truth.

Nissan Skyline BCNR33 GT-R (Type 2) manufactured in April 1996. JDM non V-Spec vehicle retailed through Osaka Nissan Prince in May/June 1996. Imported to the UK in June 1997. Remained in original JDM spec without speedometer conversion until August 2002. Only the steering wheel & white dial sets were fitted in Japan.

Nismo RB26N1 bare engine: [N1 water pump (improved flow & less cavitation)/Reinforced cylinder block head bolt boss/Increased sump capacity (6L 20w60)/1.2mm oil restrictor]

N1 head with 0.5mm overbore (2598cc)

Cryogenically hardened N1 crankshaft

Wossner forged & cryogenically hardened pistons

Abbey Motorsport reinforced & cryogenically hardened con-rods

ACL Race Series conrod & crankshaft bearings

Tomei sump baffle kit

Tomei high flow (larger drive gears) oil pump

HKS 1.2mm metal head gasket

Tomei Procam Spec 2 cam kit (270 degree inlet & outlet with 10.25mm lift)

HKS V-Cam System Step 1 Type B (variable 248-278 degree inlet; replaces Procam inlet camshaft)

HKS vernier cam pulleys

HKS kevlar reinforced timing belt

Trust metal intake & throttle gaskets

HKS front pipe & decat gaskets

GReddy Iridium 08 Racing sparkplugs

Mocal 19-row oil cooler & Abbey Motorsport remote oil filter assembly

Abbey Motorsport catch tank & washer reservoir with SFS breather hoses

Abbey Motorsport Pro Alloy large radiator

Tomei fuel pump, fuel regulator & 600cc injectors

A’PEXi Power Intake induction kit

A’PEXi GT Spec intercooler (237x610x136mm) & hard pipe kit

HKS GT-SS turbos

HKS twin AFM delete kit

Tomei turbo elbows

HKS downpipes

HKS Silent Hi-Power exhaust

Abbey Motorsport 80mm decat pipe

Mine’s VX-ROM

HKS F-Con V Pro

HKS EVC 6 boost controller (1.6 bar)

AEM wideband lambda sensor

Splitfire DI Super Direct Ignition System

HKS Circle Earth kit

HKS GD Max twin-plate clutch (with lightened flywheel)

Abbey Motorsport rebuilt transfer box

Abbey Motorsport rebuilt gearbox with cryogenically hardened gear set, modified Nissan synchromesh upgrade and OS Giken strengthening plate

Abbey Motorsport rebuilt rear diff

Nismo gearbox mounts

Nismo Solid Shift gear stick (10% short shift)

Omex Shift Light Sequential

Sunsei SE-135 solar panel trickle charger mounted on a custom aluminium riser between the rear parcel shelf speaker enclosures.

Team Dynamics Equinox alloys 19x9.5, ET+15 in silver with polished stainless steel rim.

Falken FK452 265/30/19 Y-rated tyres

Cusco brake master cylinder brace

Cusco rear steering delete kit

Cusco front & rear upper suspension links

AST Sport Line 1 full suspension kit with UK spring setup

Nismo stainless steel braided brake hoses

StopTech 355mm rotor 4 pot caliper front brake kit

StopTech 355mm rotor 2 pot caliper rear brake kit with Abbey Motorsport modified pad retainers

Ferodo DS2500 brake pads front & rear

Bomex AD-390 front splitter

Nismo R34 smoked front indicators in custom aluminium mounting plates finished in crackle black

Nissan Xenon headlamp units

Border Racing Aero Fenders (vented front wings) with silver GT emblems from a R32 Skyline

Nismo smoked side repeaters

Top Mix one-off FRP twin blade rear spoiler on custom aluminium mounting plates

Entire exterior resprayed in BMW black (code 086) base and lacquer

Nissan Motorsport International carbon fibre B-pillar plates

PIAA carbon effect silicon wipers, front pair with spoilers, rear without

Nismo white face dial sets (dashboard & centre console) in carbon fibre panels

AEM AFR gauge mount replaces the lighter socket

HKS EVC display mounted on custom carbon fibre plate replacing the ashtray

Lighter socket relocated to the fog light switch panel

Nissan Momo steering wheel (with airbag)

Dressycar Nismo harness pads

Redline Automotive leather gearstick & handbrake gaiters

Abbey Motorsport carbon fibre door sill trims

Carbon fibre boot sill trim

Inlet plenum and sundry induction pipework finished in powder grey

Trust clear cam pulley cover

HKS Kansai Service carbon fibre spark plug cover

Right hand cam cover finished in crackle black

Nismo radiator & washer reservoir caps

HKS Kansai Service front strut brace finished in high gloss black

GReddy aluminium slam panel finished in crackle black

Tein bonnet dampers with black sleeves

Custom made one-off Cobra Misano Lux front seats: [Alcantara (colour code 9189) outers/Alcantara (colour code 9182) centre panels/One-piece carbon fibre backs/Sidewinder bases on custom subframes adapted by Abbey Motorsport/Cobra logo in silver thread on the headpads/GT-R logo beneath the grommets on seat backs]

JVC KD-AVX2 multi-media DVD/CD receiver with built-in 3.5” widescreen monitor

2x JL Audio Evolution VR600-CXi 6” speakers (front)

2x JL Audio Evolution TR650-CXi 6.5” speakers (rear)

Multiple and interlaced Thatcham rated security systems.

500 bhp. 520 ft/lb.

Ludicrously, hilariously, unbelievably fast.

Hope you enjoyed this little trip down memory lane with me. Cheers! JM.

(Photo by N. Liassides.)

#r33#bcnr33#skyline#gt-r#nissan skyline#Abbey Motorsport#HKS#Bomex#Tomei#A'PEXi#GReddy#Nismo#RB26N1#Mocal#Team Dynamics

13 notes

·

View notes

Text

Essential Machines for Making Jewelry: A Simple Guide

In the detailed craft of jewelry making, precision and quality are essential. Achieving excellence requires the integration of advanced machinery designed to enhance efficiency and craftsmanship. Here, we explore five essential machines that are instrumental in modern jewelry manufacturing: the Melting Furnace, Ultrasonic Cleaner, Sand Blasting (Dull) Machine, Buffing Machine, and Steam Generator.

1. Melting Furnace

A melting furnace is fundamental in transforming raw metals into workable materials. Capable of reaching temperatures up to 1100 °C, these furnaces are suitable for melting gold, silver, copper, brass, and aluminum. With material loading capacities ranging from 1 kg to 10 kg, they cater to various production scales. Features such as compact size, rapid melting times, user-friendly interfaces, and durable thermocouples enhance their functionality, ensuring jewelers can efficiently prepare metals for crafting.

2. Ultrasonic Cleaner

Precision cleaning is crucial in jewelry making to maintain the luster and quality of pieces. Ultrasonic cleaners utilize high-frequency sound waves to remove contaminants from intricate jewelry parts without causing damage. Models like the Double Tank Ultrasonic Cleaner offer efficient cleaning and rinsing processes simultaneously. Equipped with digital controls and heating elements, they ensure comprehensive cleaning cycles with precise temperature and timing adjustments, making them indispensable in maintaining the brilliance of jewelry items.

3. Sand Blasting (Dull) Machine

To achieve a matte or satin finish on jewelry pieces, sand blasting machines are employed. These machines use compressed air to propel fine abrasive materials onto the surface, effectively removing imperfections and creating a uniform dull texture. Features such as heavy-duty stainless steel bodies, recirculating systems for abrasive materials, and foot pedal-controlled air valves enhance their efficiency and user comfort. Adjustable settings allow jewelers to customize textures, catering to diverse design preferences.

4. Buffing Machine

Achieving a mirror-like polish is essential for many jewelry designs. Buffing machines are designed to restore brilliance by polishing metal surfaces to a high shine. Features such as heavy-duty suction motors, vibration-free bench polishers, aerodynamic hoods for better dust suction, and availability in both stainless steel and powder-coated bodies enhance their functionality. Options for single or double hoods and various motor configurations provide flexibility to suit different workshop needs, making them vital for producing flawless jewelry pieces.

5. Steam Generator

Steam generators play a pivotal role in cleaning and preparing jewelry pieces during manufacturing. They produce high-pressure steam to remove residues and contaminants without the use of harsh chemicals. Features such as stainless steel bodies and cylinders, simple operation with foot switch controls, energy-saving auto on/off functions, and safety components like release valves and low-level sensors ensure reliable and efficient performance. Capacities ranging from 6 liters to 30 liters accommodate various production requirements, making them essential for maintaining the cleanliness and quality of jewelry items.

Integrating these advanced machines into a jewelry workshop not only enhances productivity but also ensures that each piece meets the highest standards of quality. By leveraging modern technology, jewelers can refine their craftsmanship, reduce production times, and consistently deliver exquisite creations that resonate with elegance and precision.

#jewellery making#jewellery making machines#melting#melting furnace#ultrasonic cleaners#buffing machine#steam generator

0 notes

Text

Stainless Steel Plates Supplier in Andhra Pradesh

Company Overview: Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading provider of Pipeline Project Services in Andhra Pradesh, India.

Our manufacturer unit is in Ahmedabad, Gujarat, India.

Stainless steel plates, often referred to as SS plates, are flat, durable pieces of stainless steel with various thicknesses, lengths, and widths.

Made from an alloy of steel that contains at least 10.5% chromium, SS plates are resistant to rust, oxidation, and corrosion.

These plates are primarily used in manufacturing, construction, and other sectors where strength and durability are paramount.

Types of SS Plates Austenitic Stainless Steel Ferritic Stainless Steel Martensitic Stainless Steel Duplex Stainless Steel

Specifications of SS Plates Thickness: SS plates can be manufactured in a wide range of thicknesses to meet specific requirements. Size: Plates are available in standard and custom sizes to accommodate diverse applications. Grade: The grade of stainless steel determines its chemical composition and mechanical properties. Surface Finish: SS plates can be supplied with various surface finishes, such as 2B, 2D, No. 4, and mirror finish.

Applications of SS Plates Stainless steel plates are used across a wide range of applications, including:

Architectural Applications: Building facades, roofing, and interior design. Industrial Equipment: Tanks, heat exchangers, and machinery parts. Automotive Industry: Body panels, exhaust systems, and structural components. Food Processing: Cooking equipment, storage tanks, and countertops. Marine Industry: Boat hulls, ship components, and marine hardware.

What is the difference between 304 and 316 stainless steel plates? 304 Stainless Steel: Offers excellent corrosion resistance and is suitable for general purposes. 316 Stainless Steel: Contains molybdenum for enhanced corrosion resistance, especially in marine or chemical environments.

Can SS plates be welded easily? Yes, stainless steel plates are highly weldable, especially austenitic grades like 304 and 316. Proper techniques and filler materials ensure strong welds.

Keshar Bhawani Metal & Tubes Pvt. Ltd is Stainless Steel Plates Supplier in Andhra Pradesh, India Including Anantapur, Chittoor, East Godavari, Guntur, Krishna, Kurnool, Prakasam, Srikakulam, Sri Potti Sriramulu Nellore, Visakhapatnam, Vizianagaram, West Godavari, Kadapa, Visakhapatnam, Vijayawada, Nellore, Kurnool, Rajamahendravaram, Tirupati, Kakinada, Srikakulam, Yemmiganur, Nagarjunakoṇḍa, Rajahmundry, Adoni, Amaravati, Chandragiri, Dowlaiswaram, Eluru, Guntur, Kadapa, Kakinada.

For detailed information or inquiries, please feel free to contact us.

0 notes

Text

Bates Machine & Mfg. Texas Machine Shop

Bates Machine & Mfg. Texas Machine Shop

Machine shops perform a variety of tasks related to controlled material removal. They often use hand tools, power tools, and measuring instruments. They also use workholding devices and deburring tools. The quality of a shop can depend on many factors. Its organization and the level of compliance over safety practices may differ from one establishment to another.

Bates Oil Field Machine Shop

Texas machine shops can manufacture cost-effective oil field parts and BOP components according to blueprints. They offer a full range of

services including machining, cutting, milling, welding, and more. They also provide quality monitoring and traceability. The oil and gas industry operates in harsh environments. It needs specialized equipment to explore, drill, extract, refine, and transport natural resources. These machines must withstand extreme temperatures and corrosive chemicals. Black Diamond Oilfield Services provides pressure control equipment and drilling tools for the oil & gas industry. Their products include a patented In-Line Filtration Technology, Detritus Defender, and Thru-Tubing tools. Their rotary subs can be made to order for double-pin or double-box crossovers, lift subs, bitsubs, and top drive subs. Located in Farmersville, Texas, Bates Machine and Mfg. is your best source for oil field machine shop and cnc work. This company has excellent reviews from previous customers. Visit their website today to see what they have to offer!

CNC Work at Bates Machine & Mfg.

Whether working on complex machinery, precision parts for medical devices, or fabricated metal structures in the oil field, machine shops must meet strict standards of quality and accuracy. They use advanced technology like CNC (Computer Numerical Control) machines to automate the machining process, which saves time and reduces human error. These advances in technology make machining an efficient and cost-effective solution for bulk production orders. In addition to these specialized tools, a machine shop also utilizes cooling systems and sawing machines to cut raw materials into manageable sizes for the machining process. Additionally, the machine shop may have a warehouse or storage space for finished products. The methodology a machine shop uses to store its tools, equipment, and materials, as well as how stringently it adheres to safety protocols, can vary from one establishment to the next. For example, some machine shops keep their workspaces swept and cleaned regularly while others do not. Also, some shops require workers to wear personal protective equipment and adhere to established safety protocols while handling machinery.

Precision Machining

Precision machining is an essential part of manufacturing many products, especially ones where even the slightest error could be disastrous. Precision machining utilizes highly-trained machinists and advanced machinery to create a product with extremely tight tolerances. The machinists follow very specific blueprints made by CAD or CAM programs. The machinists then feed these exact instructions into the CNC machine, allowing the machine to cut and shape the metal or plastic as needed. The process is very quick, and the machines can work up to 24 hours a day. Using this process can save a company a lot of time and money. It can also help them meet the dimensional specifications they need for their products. This is an important factor in reducing waste and improving production efficiency. It can also reduce the amount of defective or unusable parts that get sent back to a company for scrap. Lastly, it can help improve the overall quality of the final product.

Metal Fabrication

A metal fabrication company is a great choice for creating parts for industrial projects, such as tanks and silos. The company’s skilled team will use a variety of methods, including welding, to create the desired products. They’ll also ensure that the materials are safe for the environment. Structural metal is a critical component of modern buildings, from fire escapes to catwalks and metal staircases. Without the processes of metal fabrication, these structures wouldn’t be as sturdy or safe for emergency use. The best metal fabricators have a wide range of technical capabilities and equipment, such as CNC machines. They’ll use these tools to cut, etch, grind, sand, and polish metals into different shapes. They’ll also have the expertise to provide insight and solutions for complex machining tasks. In addition, they’ll offer customer service that’s responsive to your needs. They’ll work with you to achieve the right results within your budget and timeline. Read the full article

0 notes

Text

The Anchor: A Tribute to Precision on Two Wheels

When the spirit of craftsmanship meets the world of motorcycle customization, the result is bound to be extraordinary. "The Anchor" is precisely that—a powerful, old-school hardtail chopper built on a Royal Enfield Himalayan frame. Designed for an Indian Naval officer, this unique build brings to life the aesthetics of a war submarine, creating a bike that is as bold as it is meticulously crafted.

At the heart of "The Anchor" is its distinctive setup, starting with an impressive 12021" front tire paired with a robust 20018" rear tire. This aggressive stance gives the bike a solid road presence, which is complemented by the fatter front suspension. Notably, there is no brake setup on the front end—a rare choice that puts all the focus on its stunning 80-spoke wheel assembly. With this bold decision, the bike achieves a minimalist look while still retaining a vintage, raw appeal.

The color combination of black and copper mirrors the style of a submarine, paying homage to the military inspiration behind the build. The bike’s fuel tank and wiring box are attached to the chassis with a unique fastening system, featuring Indian Air Force Helicopter Mil Mi-4 fastening cables—a confidential component that truly elevates the bike’s authenticity and gives it an air of exclusivity. Copper studs are crimped into place, adding a level of finesse that speaks to the skill and creativity poured into every inch of this build.

The hand-crafted touches extend to the foot controls and hand grips, both turned from copper, tying the theme together and lending a warm metallic contrast against the sleek black body. Meanwhile, the front and rear hubs have been turned out of aluminum and painted black, aligning with the bike's no-nonsense, military-grade look. The visible bolts, cables, and fittings reinforce the “super mechanical” vibe, much like the intricate, exposed workings found in a submarine’s engine room.

One standout feature is the ape handlebars, installed under the T-plate to achieve a clean, old-school finish. This attention to detail enhances "The Anchor’s" vintage chopper appeal while maintaining a polished, cohesive look from end to end.

"The Anchor" isn’t just a bike—it’s a story of military-inspired craftsmanship, a showcase of dedication, and an embodiment of raw power. Each detail, from the submarine-inspired color scheme to the specially sourced copper and aluminum components, tells a story of precision, discipline, and artistry that’s sure to captivate motorcycle enthusiasts and military aficionados alike.

#automotive innovation#automobile#automotive#automotive design#custom motorcycle#motorcycle#cafe racer#moto love#harley davidson#royal enfield

1 note

·

View note

Text

What Is Heavy Fabrications and It’s Uses

Heavy fabrication is a specialized sector within the manufacturing industry that involves creating large and complex structures, primarily using metal materials. This process encompasses various activities, including cutting, welding, machining, and assembling metal components to form finished products. Heavy fabrication is crucial for several industries, including construction, energy, transport, and manufacturing, as it contributes to infrastructure development and the production of essential machinery and equipment.

Understanding Heavy Fabrication

At its core, heavy fabrication is about transforming raw materials into valuable products that meet specific functional requirements. The materials commonly used in heavy fabrication include steel, aluminum, and other alloys, which are selected for their strength, durability, and resistance to environmental conditions. The processes involved in heavy fabrication are often carried out in large manufacturing facilities equipped with specialized tools and machinery designed to handle heavy loads.

Heavy fabrication is characterized by the scale and complexity of the projects undertaken. Unlike light fabrication, which may focus on smaller components, heavy fabrication deals with significant structures, such as bridges, large tanks, and industrial machinery. This necessitates a high level of expertise and precision, as the components produced must meet stringent quality and safety standards.

Key Uses of Heavy Fabrication

Infrastructure Development: One of the most visible applications of heavy fabrication is in infrastructure development. This includes constructing bridges, tunnels, and high-rise buildings. Heavy fabricated components provide the necessary strength and stability to support these structures, ensuring they can withstand heavy loads and adverse weather conditions.

Energy Sector: The energy industry heavily relies on heavy fabrication for the production of components used in power generation. This includes heat exchangers, pressure vessels, and piping systems, which are essential for power plants and oil refineries. The fabrication of these components requires specialized techniques to ensure they can handle high pressures and temperatures safely.

Transport Industry: Heavy fabrication plays a critical role in the transport sector, particularly in the production of railway components, locomotive parts, and heavy machinery. These fabricated products are essential for ensuring the safe and efficient operation of transport systems, from trains to construction equipment.

Manufacturing: In the manufacturing sector, heavy fabrication is vital for producing customized machine parts that enhance operational efficiency. Businesses often require specific components tailored to their processes, and heavy fabrication allows for the creation of these specialized parts, ensuring optimal performance and productivity.

Shrao Engineering: A Leader in Heavy Fabrication

At Shrao Engineering, we pride ourselves on being a leading heavy fabrication company in India. With over 40 years of experience, our ISO-certified facility in Bhopal is equipped to handle a wide range of fabrication projects. We specialize in manufacturing high-quality products, including transformer tanks, industrial components, and customized solutions for various industries.

Our commitment to innovation, quality, and customer satisfaction sets us apart in the heavy fabrication industry. We understand the unique requirements of our clients and work closely with them to deliver tailored solutions that meet their specific needs.

If you're seeking a dependable partner for your heavy fabrication needs, look no further than Shrao Engineering. With our extensive expertise and unwavering commitment to quality, we are well-equipped to support your projects. Visit our website to discover how our comprehensive heavy fabrication services can help turn your vision into reality. Let us collaborate with you to achieve your goals efficiently and effectively.

Source: https://www.shraoengg.com/what-is-heavy-fabrications-and-its-uses/

0 notes

Text

Is Hayati Pro Ultra Worth the Hype? A Complete User Review

Vape enthusiasts are constantly searching for devices that offer the perfect balance of performance, style, and innovation. One device that's been generating a lot of buzz recently is the Hayati Pro Ultra. But with so many options in the market, is this vape really worth all the hype it’s getting? In this review, we'll dive deep into the features, user experiences, and why or why not the Hayati Pro Ultra should be your next vape purchase. 1. First Impressions: Sleek Design and Build Quality When it comes to vape devices, design matters just as much as functionality. The Hayati Pro Ultra immediately stands out for its sleek, modern design. The build quality feels premium, with a sturdy metal finish that gives it an air of sophistication. Whether you’re new to vaping or a seasoned pro, the moment you pick it up, you’ll notice the attention to detail. The buttons and ports are strategically placed for ease of use. It’s a comfortable size, fitting perfectly in the palm, and its lightweight nature makes it convenient for everyday use. If aesthetics are important to you, this device certainly delivers. The variety of color options allows users to choose a model that fits their style. But does the beauty match the beast within? Let’s explore further. 2. Vapor Production: Does It Live Up to the Claims? At the heart of any vape device is its ability to produce thick, satisfying vapor clouds. The Hayati Pro Ultra has been promoted as one of the top-tier devices in terms of vapor production, but how does it actually perform? After multiple user tests and real-world usage, it’s clear that the Hayati Pro Ultra delivers consistent and dense vapor with every puff. Its adjustable airflow feature is a big plus, allowing users to customize their vape experience, whether they prefer tight, controlled hits or more open, airy drags. The coils are designed to enhance flavor without compromising vapor production, which is especially beneficial for those who enjoy a smooth and flavorful hit. For cloud chasers, the Hayati Pro Ultra won’t disappoint. On the highest settings, it produces impressive, billowing clouds. For flavor aficionados, its temperature control ensures that every puff is rich in flavor without burning the liquid. But, what about ease of use? 3. Ease of Use: Perfect for Beginners and Pros Alike? Let’s be honest nobody wants a vape device that’s complicated to use, especially when you’re out and about. The Hayati Pro Ultra keeps things simple with an intuitive interface. Whether you're a first-time vaper or someone with years of experience, navigating the device is a breeze. One of the standout features is its clear OLED screen, displaying all the essential information battery life, wattage, and temperature settings. The menu system is straightforward, with no unnecessary complexity. Charging the device is quick thanks to its USB-C port, which is a much-needed upgrade from older micro-USB models. The cartridge system is easy to refill, and the magnetic snap-on feature for the tank ensures you won’t be fumbling around. This convenience makes it an attractive option for those who want a hassle-free vaping experience. However, like any device, there are a few learning curves, especially when it comes to advanced settings for experienced users. - Battery Life: Does It Last All Day? Battery life is one of the key considerations when choosing a vape device. Nobody wants to be constantly searching for a charger. The Hayati Pro Ultra boasts a powerful 2500mAh battery, which should, in theory, last all day with moderate use. In practice, users have reported being pleasantly surprised by the longevity of the battery. On a full charge, the device easily lasts for a full day of regular use. For those who prefer vaping at higher wattages or longer sessions, you might need to charge it once in the evening, but even then, the USB-C quick charge option ensures you’re back up and running in no time. For those who vape occasionally or at lower wattages, the device can go for a couple of days without needing a charge This long battery life makes it perfect for those on the go. But what really takes it to the next level is the pass-through charging feature, allowing you to vape while charging no downtime needed! 5. Flavor Quality: A Game-Changer for Flavor Lovers Let’s talk about flavor—a critical aspect for any vaping device. The Hayati Pro Ultra doesn’t just focus on producing large vapor clouds; it also excels in delivering a rich and flavorful experience. The advanced coil technology used in the device ensures that the flavor of your e-liquid isn’t diluted or compromised, even after extended use. From fruity flavors to more complex dessert profiles, the Hayati Pro Ultra consistently delivers a punch of flavor. This is largely due to its temperature control settings, which allow users to find the sweet spot for each type of e-liquid. Whether you like a warmer, richer vape or a cooler, crisp flavor, the device adjusts accordingly. Even after multiple refills, users report that the taste remains fresh and consistent. This is a huge advantage for those who prioritize flavor in their vaping experience. The device’s ability to maintain flavor quality over time makes it stand out from many other devices in the market. 6. Durability and Maintenance: Built to Last? Durability is something that many vape users overlook until it's too late. The Hayati Pro Ultra is designed with long-term use in mind. The metal body and high-quality components make it resistant to everyday wear and tear. Drops and scratches are less of a concern compared to some other models in the same price range. Maintenance is another area where the Hayati Pro Ultra shines. Its parts are easy to clean, and replacing the coils or tank is a quick process. The device is also leak-proof, a feature many users will appreciate, especially those who carry their vape in bags or pockets. Proper maintenance, of course, is key to making the device last even longer, but Hayati Pro Ultra certainly makes it easy. 7. The Price Tag: Is It Worth the Investment? Let’s get to the part many are curious about—the price. The Hayati Pro Ultra sits in the mid-to-high range for vape devices, but considering all the features and the overall experience it offers, many users believe it’s worth every penny. While there are cheaper options available, they often compromise on durability, battery life, or vapor quality. On the other hand, more expensive devices may offer a few extra bells and whistles, but the Hayati Pro Ultra strikes a nice balance between performance and price. Plus, with its long-lasting battery and durable build, you’re likely saving in the long run by not needing to replace it anytime soon. 8. User Feedback: What Are Real Users Saying? So, what’s the general consensus from actual users? Many users rave about the Hayati Pro Ultra’s combination of design, ease of use, and vapor production. The consistent feedback is that it’s a great all-rounder, perfect for both beginners and experienced vapers. Some users mentioned that while it offers fantastic flavor and vapor, they wish it had more customizable features like some high-end devices. However, for most, the simplicity paired with solid performance outweighs any advanced customization limitations. The customer support from the brand also gets high marks, which is always a plus when investing in a vape device. 9. Final Verdict: Is Hayati Pro Ultra Worth the Hype? In a crowded market of vape devices, the Hayati Pro Ultra manages to carve out its own space. With its sleek design, excellent vapor production, long battery life, and fantastic flavor quality, it certainly lives up to the hype. For those looking for a reliable, stylish, and user-friendly device, the Hayati Pro Ultra is a strong contender. Of course, no device is perfect, but the Hayati Pro Ultra’s combination of features and performance make it a great choice for vapers at any level. If you're on the fence, it’s worth giving it a try you might just find your next favorite vape. Read the full article

0 notes

Text

Leading Process Design & Automation | Quintessential Systems

Quintessential Systems, formerly known as Process Design Group, has been at the forefront of delivering innovative process systems for over two decades. Their expertise spans various specialized areas, from metal finishing systems to wastewater treatment solutions. Here’s an exploration of the critical technologies and systems they offer, which are essential in modern industrial settings.

Process Systems Engineering

Process Systems Engineering (PSE) is the backbone of efficient industrial operations, and it plays a crucial role in optimizing manufacturing systems. At Quintessential Systems, PSE involves designing, analyzing, and implementing integrated systems to enhance productivity and sustainability. By developing customized systems tailored to specific industrial needs, they help streamline processes across various sectors, such as aerospace, defense, and manufacturing.

Metal Finishing Systems

Metal finishing systems are integral to industries that require durable and aesthetically pleasing surface finishes on metal products. Quintessential Systems excels in providing advanced metal finishing systems, including automated cleaning, degreasing, and paint stripping processes. Their custom-designed systems ensure that each product receives a high-quality finish, which enhances durability and corrosion resistance. For example, the metal finishing lines they implemented for the Corpus Christi Army Depot demonstrate their capability in large-scale automated systems.

Aluminum Anodizing Systems

Aluminum anodizing systems are critical for industries that rely on corrosion-resistant aluminum parts. Anodizing not only enhances the metal’s durability but also improves its aesthetic properties. Quintessential Systems specializes in providing both manual and automated anodizing lines. A notable project includes the installation of a manual anodizing line at Precision Machine of Savannah, which included semi-automatic tank covers and enhanced operator control. Their anodizing solutions help businesses like PMS maintain in-house control of surface treatment, improving operational efficiency.

Wastewater Treatment Systems

As industries continue to prioritize environmental responsibility, wastewater treatment systems are crucial. Quintessential Systems offers closed-loop wastewater treatment solutions, which are designed to minimize environmental impact by recycling and treating wastewater efficiently. These systems reduce waste and operational costs while ensuring compliance with environmental regulations. Quintessential Systems’ expertise in closed-loop treatment, as seen in their work with Precision Machine, helps companies manage water resources effectively and sustainably.

Custom Hoist Systems

To enhance automation and safety in industrial processes, custom hoist systems are a vital solution. Quintessential Systems designs and installs hoists tailored to specific requirements. For instance, the overhead hoist systems they provided for aerospace and defense projects automate the handling of heavy parts, reducing manual labor and increasing safety. Their hoist systems are often integrated into larger process systems, providing seamless operational efficiency.

Chemical Etching Systems

Chemical etching is another surface treatment process used to engrave or create patterns on metals. Quintessential Systems specializes in chemical etching systems, which are designed to handle a wide range of materials and part sizes. Their systems allow manufacturers to achieve highly detailed surface finishes with minimal waste. The precision offered by these systems is especially beneficial in industries such as electronics and aerospace, where intricate designs are required.

Exhaust Systems Design

Energy efficiency and air quality are key considerations in industrial environments. Quintessential Systems has developed advanced exhaust systems to manage hazardous emissions and reduce energy consumption. Their exhaust systems are integrated with automated tank covers that open and close based on operational needs, reducing unnecessary ventilation and conserving energy, as seen in their work for the Corpus Christi Army Depot.

Surface Finishing Equipment

Quintessential Systems provides a wide range of surface finishing equipment, from degreasing tanks to anodizing systems, tailored to meet the specific needs of industries. This equipment ensures that metal products receive the right surface treatment, improving their longevity, appearance, and performance. Their surface finishing solutions are designed for durability and ease of operation, allowing businesses to maintain high standards in product quality.

Automated Cleaning Systems

In high-demand industries, automated cleaning is essential for maintaining equipment and product quality. Quintessential Systems has implemented automated cleaning systems that streamline processes, reduce manual labor, and ensure consistent cleanliness. For example, the automated cleaning lines they installed in Corpus Christi Army Depot involved extensive stainless steel tanks and automated hoists, reducing operational time and increasing efficiency.

Closed-Loop Systems

Finally, closed-loop systems are essential for reducing waste and improving the environmental impact of industrial processes. By recycling and reusing water and chemicals within the manufacturing line, closed-loop systems can drastically cut down on waste and resource consumption. Quintessential Systems has integrated closed-loop solutions into many of its designs, providing both cost savings and environmental benefits to clients.

Conclusion

Quintessential Systems has established itself as a leader in process systems engineering, driving innovation in metal finishing systems, aluminum anodizing systems, wastewater treatment systems, and more. By integrating custom hoist systems, closed-loop wastewater treatment, and advanced surface finishing equipment, they continue to set the standard for efficiency, sustainability, and precision in industrial process design. Their commitment to cutting-edge solutions ensures that they remain at the forefront of their industry, providing clients with tailored, state-of-the-art systems that deliver long-term value.

For more information, visit 7-Qs.com.

1 note

·

View note

Text

Stainless Steel Plates in Bihar

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Plates in Bihar, India. We established our company in 2011 in Ahmedabad, Gujarat, India. Stainless Steel (SS) Plates are renowned for their exceptional strength, durability, and corrosion resistance, making them indispensable in various industries. These plates, made from high-quality stainless steel alloys, offer a broad range of applications due to their robust nature and the ability to withstand extreme conditions. Technical Specifications: Material: Stainless Steel (SS) 304, 316, 410, etc. Thickness: 0.5mm to 50mm. Size: 4' x 8', 5' x 10', custom sizes. Finish: Polished, brushed, mirror, and more. Standard: ASTM A240, ASME SA240. Features of SS Plates: Corrosion Resistance: Withstands harsh environments and chemicals. High Strength: Excellent tensile strength and load-bearing capacity. Low Maintenance: Easy to clean and maintain. Hygienic: Ideal for food processing and pharmaceutical applications. Aesthetically Pleasing: Polished or brushed finishes available. Applications and Industries: Food Processing: Equipment, containers, and storage. Pharmaceutical: Machinery, equipment, and packaging. Chemical: Reactors, tanks, and piping. Construction: Handrails, decorative features, and cladding. Automotive: Exhaust systems, engine components, and trim. Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Plates in Bihar, India Including Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhi-sarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran. Feel free to contact us for more information and inquiries. View Product: Click Here Read the full article

0 notes

Text

The Benefits of PP Glass Lined Sheets: Enhanced Chemical Resistance and Longevity

Polypropylene (PP) glass lined sheets represent a cutting-edge advancement in material science, combining the strengths of polypropylene and glass fibers to deliver exceptional performance in a wide range of applications. These sheets are engineered to provide superior durability, resistance to environmental factors, and versatility, making them ideal for industries that demand high performance and reliability.

In this comprehensive guide, we will explore the features, benefits, applications, and PP Glass-Lined Sheet Installation, along with answering some frequently asked questions to provide a thorough understanding of this innovative material.

What Are PP Glass Lined Sheets?

PP glass lined sheets are composite materials made from a combination of polypropylene (PP) and glass fibers. The base material, polypropylene, is a thermoplastic polymer known for its flexibility, chemical resistance, and lightweight nature. When reinforced with glass fibers, the material gains enhanced rigidity, strength, and dimensional stability.

These sheets are produced through a process where glass fibers are incorporated into the polypropylene matrix, resulting in a product that offers the best of both worlds: the durability of glass and the lightweight, cost-effective nature of polypropylene. The end product is a sheet that can withstand harsh environments while maintaining its structural integrity.

Key Features of PP Glass Lined Sheets

High Strength and Durability The incorporation of glass fibers into polypropylene significantly increases the strength and durability of the sheets. This makes them suitable for applications where high impact resistance and long-term performance are required.

Chemical Resistance PP glass lined sheets exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them ideal for use in industries such as chemical processing, pharmaceuticals, and agriculture.

Temperature Tolerance These sheets can withstand a broad temperature range, making them suitable for both high and low-temperature environments. They maintain their structural integrity and performance under varying thermal conditions.

Lightweight and Easy to Handle Despite their strength and durability, PP glass lined sheets remain lightweight compared to traditional materials like metal or concrete. This makes them easier to handle, transport, and install.

Corrosion Resistance The glass lining provides excellent protection against corrosion, making PP glass lined sheets ideal for use in environments prone to moisture and chemical exposure.

Versatility PP glass lined sheets can be customized in terms of thickness, size, and surface finish, making them suitable for a variety of applications, from industrial processes to construction and beyond.

Common Applications of PP Glass Lined Sheets

The PP Glass-Lined Sheet Suppliers are used in numerous industries due to their unique combination of properties. Here are some common applications:

Chemical Processing In the chemical processing industry, PP glass lined sheets are used to line tanks, reactors, and pipelines. Their resistance to chemicals and high strength makes them ideal for handling corrosive substances and maintaining the integrity of processing equipment.

Pharmaceutical Industry The pharmaceutical industry utilizes PP glass lined sheets for their resistance to contamination and ease of cleaning. They are often used in areas where hygiene and chemical resistance are critical, such as in the production of medicines and other healthcare products.

Agriculture In agriculture, these sheets are used for constructing storage tanks, irrigation systems, and protective barriers. Their durability and resistance to environmental factors make them suitable for outdoor and agricultural applications.

Construction PP glass lined sheets are used in construction for applications such as wall cladding, flooring, and protective panels. Their lightweight nature and durability make them an excellent choice for both structural and decorative purposes.

Marine Applications The corrosion resistance and durability of PP glass lined sheets make them suitable for marine environments. They are used in the construction of marine vessels, docks, and other structures exposed to saltwater.

Electronics In the electronics industry, PP glass lined sheets are used for protective casings and insulation due to their excellent electrical properties and resistance to environmental stressors.

Benefits of PP Glass Lined Sheets

Enhanced Strength and Longevity The combination of polypropylene and glass fibers results in a material that offers superior strength and longevity compared to traditional materials. This translates to reduced maintenance and longer service life.

Superior Chemical and Corrosion Resistance PP glass lined sheets can withstand exposure to a wide range of chemicals and corrosive substances, making them ideal for demanding industrial environments.

Lightweight and Cost-Effective The lightweight nature of PP glass lined sheets simplifies handling and installation, while their cost-effectiveness makes them a budget-friendly option for various applications.

Customizability These sheets can be customized to meet specific requirements, including different thicknesses, sizes, and finishes. This flexibility allows for tailored solutions that fit a wide range of needs.

Low Maintenance Requirements The durability and resistance properties of PP glass lined sheets reduce the need for frequent maintenance, saving time and resources in the long run.

Environmental Impact By choosing PP glass lined sheets, industries can contribute to sustainability efforts. The materials used are often recyclable, and their long-lasting properties reduce the need for replacements and repairs.

Installation of PP Glass Lined Sheets

Installing PP glass lined sheets involves several steps to ensure proper placement and performance. Here’s a general overview of the installation process:

Preparation Ensure that the surface where the sheets will be installed is clean, dry, and free of any debris. Any irregularities or damages should be repaired before proceeding with the installation.

Cutting and Shaping Measure and cut the PP glass lined sheets to the required dimensions using appropriate cutting tools. The sheets can be easily cut to size, but care should be taken to avoid damaging the edges.

Positioning Position the sheets on the surface where they will be installed. Ensure proper alignment and fit before securing them in place.

Securing Depending on the application, PP glass lined sheets can be secured using screws, adhesives, or mechanical fasteners. Follow the manufacturer’s guidelines for the recommended fastening method.

Sealing Seal any joints or seams between the sheets to ensure a watertight and secure installation. Use appropriate sealants or gaskets as specified by the manufacturer.

Inspection After installation, inspect the sheets to ensure they are properly secured and sealed. Check for any potential issues and address them promptly.

Conclusion

The PP Glass-Lined Sheet Price represent a remarkable advancement in material technology, offering a blend of polypropylene’s flexibility and glass fibers’ strength. Their exceptional durability, chemical resistance, and versatility make them a valuable solution for a wide range of industrial, agricultural, and construction applications. By understanding the features, benefits, and proper installation of PP glass lined sheets, industries can make informed decisions and leverage this innovative material to enhance their operations and achieve long-term performance and reliability.

Frequently Asked Questions (FAQs)

1. What are PP glass lined sheets made of? PP glass lined sheets are composed of polypropylene (PP) combined with glass fibers. The glass fibers reinforce the polypropylene, enhancing its strength and durability.

2. What industries use PP glass lined sheets? PP glass lined sheets are used in various industries, including chemical processing, pharmaceuticals, agriculture, construction, marine applications, and electronics.

3. How do PP glass lined sheets compare to traditional materials? PP glass lined sheets offer a combination of lightweight properties, high strength, chemical resistance, and durability that may surpass traditional materials like metal or concrete in certain applications.

4. Are PP glass lined sheets resistant to environmental factors? Yes, PP glass lined sheets are resistant to environmental factors such as moisture, UV radiation, and temperature fluctuations, making them suitable for both indoor and outdoor applications.

0 notes

Text

Why MIG Welders Are Essential for Home Workshops

Have you ever considered diving into the world of welding but felt overwhelmed by the sheer amount of equipment and knowledge required? Or maybe you’ve heard about MIG welding and wondered, “Is this really the right choice for my home workshop?” MIG welding, or metal-inert gas welding, has become a popular method for both amateur and professional welders alike. In this article, we will explore why a MIG welder is a must-have for any home workshop, discussing its benefits, essential equipment, and practical applications.

What Makes MIG Welding Stand Out?

MIG welding is favored for its simplicity and efficiency. Unlike other welding methods that can be complex and time-consuming, MIG welding uses a continuous feed of filler material through a nozzle, making it straightforward and user-friendly. This process is perfect for those who want to get high-quality results without extensive training.

Essential Equipment for MIG Welding

MIG Welder MachineThe cornerstone of MIG welding is, of course, the MIG welder machine. This device controls the welding process, feeding the filler wire, and adjusting the voltage and wire speed. A reliable MIG welder is crucial for achieving consistent, high-quality welds.

Welding Gas Bottles and Argon TanksMIG welding requires an inert gas, typically argon or a mix of argon and carbon dioxide, to shield the weld pool from contaminants. Investing in good-quality welding gas bottles and an argon tank is essential to ensuring clean, strong welds.

ESAB welding helmetSafety is paramount in welding. An ESAB welding helmet provides necessary protection for your eyes and face from the intense light and heat generated during welding. It also helps you maintain a clear view of your work area.

Welding TableA sturdy welding table is not just a convenience but a necessity for precise and safe welding. It provides a stable surface for your workpieces and can be equipped with clamps and fixtures to hold materials in place.

Benefits of MIG Welding in a Home Workshop

Ease of UseMIG welding is known for its user-friendly nature. It’s often recommended for beginners due to its ease of setup and operation. The machine’s automatic wire feed reduces the need for advanced skills, making it accessible for hobbyists.

VersatilityMIG welders are versatile tools that can handle a variety of materials, including steel, aluminum, and stainless steel. This adaptability makes them suitable for a wide range of projects, from automotive repairs to home improvement tasks.

Speed and EfficiencyOne of the standout features of MIG welding is its speed. The continuous wire feed allows for faster welding compared to other methods, which means you can complete projects more quickly and efficiently.

Clean WeldsMIG welding produces clean, strong welds with minimal spatter. The use of shielding gas helps prevent contamination, resulting in a smooth finish that often requires less post-weld cleanup.

Common Projects for MIG Welders

DIY Repairs and FabricationsFrom fixing garden tools to creating custom metal brackets, a MIG welder can handle a variety of DIY repair and fabrication tasks. Its versatility allows you to tackle projects that range from simple fixes to more complex creations.

Automotive WorkMIG welders are ideal for automotive repairs, such as patching up rusted panels or fabricating custom exhaust systems. Their ability to weld different types of metal makes them a valuable tool in any car enthusiast’s workshop.

Home ImprovementIf you’re into home improvement, a MIG welder can be used to build and repair metal structures, such as gates, railings, or custom furniture. The clean welds and efficient operation make it a great asset for enhancing your living space.

Conclusion: Why You Need a MIG Welder in Your Workshop

So, why is a MIG welder essential for your home workshop? The answer lies in its combination of ease of use, versatility, speed, and clean results. Whether you’re a seasoned DIYer or just starting out, having a MIG welder can greatly expand your capabilities and streamline your projects. Investing in a MIG welder, along with the right accessories like a quality ESAB welding helmet, reliable gas bottles, and a solid welding table, will enhance your welding experience and open up a world of possibilities for your home workshop.

In summary, MIG welding provides a practical solution for many welding needs, making it an indispensable tool for any workshop. So, if you’re ready to elevate your DIY projects and professional tasks alike, a MIG welder is a worthy addition to your toolkit.

0 notes

Text

Fiberglass Tank Manufacturers

Benefits of Fiberglass Tanks

Fiberglass tanks are known for their durability, corrosion resistance, and versatility. These tanks are ideal for a wide range of applications, from water storage to chemical processing.

Durability and Longevity

Corrosion Resistance: Unlike metal tanks, fiberglass tanks do not rust and can withstand harsh chemicals and environmental conditions.

Strength and Lightweight: Combining strength with a lightweight structure, these tanks are easier to handle and install.

Versatility

Customizable: Fiberglass tanks can be tailored to specific needs, including size, shape, and features.

Wide Range of Applications: Suitable for numerous industries, from water storage and chemical processing to wastewater treatment and agriculture.

Cost-Effectiveness

Low Maintenance: These tanks require minimal maintenance, reducing long-term costs.

Longevity: Their extended service life leads to fewer replacements and cost savings.

Manufacturing Process of Fiberglass Tanks

Design and Engineering

Initial Design: Specifications such as size, capacity, and features are determined.

Engineering Analysis: Structural analysis ensures the tank can withstand intended loads and conditions.

Material Selection

Resins and Reinforcements: FRP materials, with different resins chosen based on the application.

Fiberglass Reinforcement: Materials like fiberglass mats or woven roving provide additional strength.

Molding Process

Filament Winding: Continuous fiberglass filaments are wound around a rotating mandrel.

Hand Lay-Up: Layers of fiberglass mat are manually applied and saturated with resin.

Curing: The tank is cured to harden the resin and achieve desired properties.

Quality Control

Inspection and Testing: Tanks undergo rigorous inspections and tests.

Final Finishing: Includes adding fittings, nozzles, and other accessories.

Applications of Fiberglass Tanks

Water Storage

Potable Water: Suitable for storing drinking water, meeting safety standards.

Rainwater Harvesting: Used in rainwater harvesting systems for water conservation.

Chemical Processing

Chemical Storage: Ideal for storing acids, alkalis, and solvents.

Process Tanks: Used in various stages of chemical processing.

Wastewater Treatment

Sewage and Industrial Effluent: Used in treatment plants for sewage and industrial effluent.

Agriculture

Irrigation Storage: Used for storing water, fertilizers, and pesticides in agriculture.

Key Considerations When Choosing a Fiberglass Tank Manufacturer

Experience and Reputation

Industry Experience: Opt for manufacturers with extensive experience in the industry.

Customer Feedback: Review testimonials and case studies to gauge reputation.

Quality Standards

Certifications: Ensure the manufacturer holds relevant certifications like ISO 9001, NSF/ANSI 61, and ASME RTP-1.

Quality Control Procedures: Check for stringent quality control procedures.

Customization Capabilities

Custom Design Options: The ability to customize tanks to specific needs is crucial.

Technical Support: Reliable manufacturers offer support throughout the process.

After-Sales Service

Warranty and Maintenance: Look for manufacturers that provide warranties and maintenance services.

Installation Assistance: Some manufacturers offer installation services or guidance.

Why Choose Pipeco?

Pipeco is a leading name in the fiberglass tank manufacturing industry, known for its high-quality products and exceptional customer service. Here’s why Pipeco stands out:

Expertise and Innovation: With years of experience and a focus on innovation, Pipeco continuously improves its products and processes.

Stringent Quality Control: Adhering to the highest quality standards, every tank undergoes rigorous testing and inspection.

Custom Solutions: Offering a wide range of customizable options, Pipeco ensures each tank meets specific requirements.

Comprehensive Support: From initial consultation to after-sales service, Pipeco provides comprehensive support, ensuring customer satisfaction at every stage.

Conclusion

Fiberglass tanks offer numerous advantages, making them a preferred choice across various industries. When selecting a fiberglass tank manufacturer, it is essential to consider factors such as experience, quality standards, customization capabilities, and after-sales service. Pipeco, with its commitment to excellence and customer satisfaction, stands out as a trusted partner for all your fiberglass tank needs. By choosing Pipeco, you can be assured of receiving high-quality, durable, and cost-effective solutions tailored to your specific requirements.

0 notes

Text

Unlocking Innovation: Plate Bending Machines Lead the Way in Metal Forming

In the bustling world of metal manufacturing, innovation is the key to staying ahead. One company that epitomizes this ethos is Himalaya Machinery, a heavy engineering powerhouse based in India. Among their arsenal of cutting-edge equipment, plate bending machines stand out as game-changers in the realm of metal forming.

Introduction

Innovation is the cornerstone of progress, especially in industries like metal manufacturing. Himalaya Machinery, a renowned heavy engineering company in India, has been at the forefront of this innovation, particularly with their groundbreaking advancements in plate bending machines. Let's delve into the world of plate bending machines and explore how they're reshaping metal forming processes.

The Evolution of Plate Bending Machines

Plate bending machines have come a long way since their inception. Initially simple in design, these machines have evolved into sophisticated pieces of equipment capable of handling a variety of metal bending tasks with precision and efficiency. From manual operation to fully automated systems, the evolution of plate bending machines mirrors the advancements in technology and engineering prowess.

Understanding 4 Roller Bending Machines

Among the various types of plate bending machines, the 4 Roller Bending Machine stands out for its versatility and superior performance. Unlike traditional 3 roller machines, the addition of an extra roller enables more precise bending, especially for complex shapes and thicker materials. This makes it a preferred choice for demanding metal forming applications.

The Power of Hydraulic Plate Bending Machines

Hydraulic plate bending machines leverage the force of hydraulic cylinders to exert immense pressure, facilitating seamless bending of metal plates. This hydraulic power not only enhances the efficiency of the bending process but also allows for greater control and accuracy, resulting in high-quality finished products.

Mastering Cone Rolling with Precision

Cone rolling, a specialized form of metal forming, requires meticulous precision and expertise. Plate bending machines equipped with advanced features excel in this domain, enabling manufacturers to produce flawless conical shapes with ease. Whether it's for architectural elements or industrial components, the cone rolling machine becomes an indispensable tool, offering precision and versatility in shaping metal into intricate conical forms.

Applications Across Industries

Plate bending machines find applications across a wide range of industries, from automotive and aerospace to shipbuilding and construction. Their versatility makes them indispensable for tasks such as manufacturing cylinders, pipes, tanks, and various structural components. The ability to adapt to diverse requirements makes plate bending machines invaluable assets in modern manufacturing facilities.

Advantages Over Traditional Methods

Compared to traditional methods of metal bending, plate bending machines offer several distinct advantages. They significantly reduce manual labor, minimize material wastage, and ensure consistent quality throughout the production process. Additionally, the speed and precision of plate bending machines translate to shorter lead times and increased overall productivity.

Enhancing Efficiency and Productivity

In today's competitive landscape, efficiency and productivity are paramount. Plate bending machines play a pivotal role in enhancing both aspects of metal forming operations. By streamlining the bending process and minimizing downtime, these machines enable manufacturers to meet tight deadlines and fulfill customer demands with ease.

Key Considerations When Choosing a Plate Bending Machine

When selecting a plate bending machine for your manufacturing needs, several factors come into play. Considerations such as the desired bending capacity, material thickness, and level of automation should be carefully evaluated. Additionally, factors like maintenance requirements and after-sales support can influence the long-term performance and reliability of the machine.

Maintenance Tips for Longevity

Proper maintenance is essential to ensure the longevity and optimal performance of plate bending machines. Regular inspection of hydraulic systems, lubrication of moving parts, and calibration of machine settings are key maintenance tasks. Additionally, providing adequate training to operators on safe and efficient operation can prevent premature wear and tear, prolonging the lifespan of the equipment.

Conclusion

Innovation is the driving force behind progress in the metal manufacturing industry, and plate bending machines exemplify this ethos. From their humble origins to their current state-of-the-art capabilities, these machines continue to lead the way in metal forming processes. With companies like Himalaya Machinery pushing the boundaries of engineering excellence, the future of metal fabrication looks brighter than ever.

FAQs

1. What are the primary advantages of using a plate bending machine?

Plate bending machines offer several advantages, including increased efficiency, precision bending, and versatility in handling various metal forming tasks.

2. How do hydraulic plate bending machines differ from other types?

Hydraulic plate bending machines utilize hydraulic power to exert pressure, providing greater control and accuracy in the bending process compared to mechanical or manual methods.

3. Can plate bending machines handle thick materials?

Yes, plate bending machines, particularly 4 Roller Bending Machines with hydraulic capabilities, are capable of bending thick materials with ease, thanks to their superior strength and precision.

4. What industries benefit most from the use of plate bending machines?

Industries such as automotive, aerospace, shipbuilding, and construction benefit significantly from the versatility and efficiency of plate bending machines in manufacturing various components and structures.

5. How important is regular maintenance for plate bending machines?

Regular maintenance is crucial for ensuring the longevity and optimal performance of plate bending machines. It helps prevent breakdowns, prolongs the lifespan of the equipment, and ensures consistent quality in the finished products.

0 notes

Text

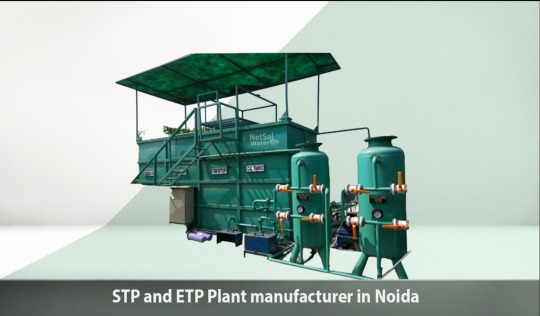

Find The Top STP & ETP Plant Manufacturer In Noida

The Netsol Water-managed sewage treatment plant & effluent treatment plant are excellent facilities designed to effectively treat & cleanse the wastewater. These treatment facilities can remove a wide range of contaminants & toxins out of sewage, including chemicals, bacteria, viruses, & biological waste, thanks to their cutting-edge technology & sturdy structural construction.

Netsol Water has achieved great success in the market by providing its clients with an economical wastewater treatment plant facility along with all the guarantees both before & after the machine is produced. Getting this plant would be easy if you got in touch with a Noida-based STP & ETP plant manufacturer, like Netsol Water. Netsol Water has sites around the country & is always here to help our customers.

Among the treatment procedures incorporated in this kind of treatment plant system are filtration, sedimentation, biological component treatment, disinfection, & screening out. Modern sensors & control systems have been added to ensure optimal & efficient operation. As the most reasonably priced manufacturer of STP-ETP treatment plant systems in Noida, Netsol Water is ascending to the top rapidly.

An overview of STPs & ETPs

The technology applied to STPs is easy to maintain & set up. Generally speaking, you may get it from the STP Manufacturer in Noida. It may be useful in a wide range of instances, notably residential, commercial, as well as industrial ones.

Manufacturer of stp & etp plants in Noida

Yet, either sewage or industrial effluent wastewater must be treated & cleaned before being discharged into the environment-ecosystem. An ETP, which can be purchased from Noida ETP Plant Suppliers, cleans & disposes of waste material generated by industrial activity. The job of an ETP is to purge or purify wastewater of dangerous contaminants & toxins so that it satisfies legal & environmental requirements. Netsol Water is the best stp and etp plant manufacturer in noida at best affordable price.

Throughout the treatment process, physical, chemical, & biological methods are frequently implemented to eliminate pollutants & poisons from wastewater. Physical techniques including screening, sedimentation, & filtration are employed to get rid of solid & suspended pollutants from wastewater.

Various retarders as well as other Chemical compounds categorized as flocculants or coagulants are applied in the tanks to get rid of dispersed, dissolved materials or particles from the raw wastewater. Microorganisms play a significant part in biological processes by breaking down organic compounds found in wastewater.

Numerous applications of STP-ETP treatment plants

Factories related to clothing: The textile industry requires a lot of operations related to ETPs & STPs to treat wastewater that is produced during the printing, dying, & finishing operations. because hazardous substances including dyes, solvents, & even heavy metals can be found in wastewater that may deteriorates the current condition of the environment-ecosystem if released hysterically untreated.

The production of wastewater, often known as effluent or sewage, by the pharmaceutical industry, have constituents such as active pharmaceuticals & is hazardous to both the environment & human health. ETPs serve to eliminate contaminants & make sure wastewater satisfies regulatory requirements before it is released into the environment. They are readily available from ETP treatment plant manufacturers.

The beverage & food industries: ETPs are typically utilized for the control & treatment of wastewater from manufacturing processes including brewing, bottling, condensing, along with distilling, as well as wastewater sewage or effluent water from sanitation & processing equipment. Wastewater from effluent sources needs to be cleaned, refined, & treated in order to remove extraneous contaminants, organic debris, & other types of surplus organic nutrients.

Chemical Production Industry: ETPs play a critical role in wastewater treatment during manufacturing processes including purification & several types of chemical synthesis. Hazardous compounds, bases, & acids that are bad for the environment & people's health might be present in the effluent.

Conclusion

Remember that only a reliable & trustworthy STP-ETP manufacturer can handle all of the following challenges & procedures to provide their clients top-notch treatment plants in Noida. One of the top manufacturers, Netsol Water, has always been steadfast providing all resources to this industry & provides a wide range of these equipment & components.

One of the best choices among the several manufacturing companies in the Noida area is Netsol Water because of their reliability & efforts, which also determine how much technology they can provide & combine into their products.

#netsolwater#industrial ro plant manufacturers#commercial ro plant#industrial ro plant#sewage treatment plant manufacturer#effluent treatment plant#sewage treatment plant#effluent treatment plant manufacturer#watertreatment plant

0 notes

Text

What Does a Vape Look Like? The Ultimate Guide to Recognizing Modern Vaping Devices

Ever found yourself wondering, "What does a vape look like?" If you’ve ever been puzzled by the myriad of gadgets people are puffing on, you’re not alone. Vapes come in a dizzying array of shapes, sizes, and colors, making them as diverse as the people who use them. From sleek, futuristic devices that look like they belong in a sci-fi movie to colorful, quirky contraptions that scream personality, the world of vaping is as varied as it is fascinating. In this guide, we’ll take a lighthearted yet informative dive into the visual world of vaping, exploring the different styles and designs that make these devices so intriguing. The Sleek and Stealthy - Pod Systems Pod systems are the ninjas of the vaping world. These compact, sleek devices are designed to be discreet and easy to use. Picture a USB stick or a high-end pen – that’s the kind of low-profile look we’re talking about. Their minimalist design makes them perfect for vapers who prefer to keep their habit under wraps. Most pod systems come in matte or metallic finishes, with a subtle LED indicator that’s more James Bond than flashing disco light. If you’re all about vaping in stealth mode, pod systems are your best bet. But don’t let their modest appearance fool you – these little guys pack a punch. Despite their size, pod systems are known for delivering a satisfying hit that rivals much larger devices. They’re also super user-friendly, often featuring a simple draw-activated mechanism. Just inhale, and you’re good to go. No buttons, no fuss, just pure, unadulterated vaping pleasure. Whether you’re a newbie or a seasoned pro, pod systems offer a stylish, no-nonsense way to get your vape on. The Bold and the Beautiful - Box Mods If pod systems are the ninjas, box mods are the samurais of the vaping world. These devices are bold, powerful, and built to make a statement. Imagine a small, sturdy box with a digital display, often adorned with eye-catching graphics or sleek metallic finishes. Box mods are the heavyweight champions of vaping, offering advanced features like adjustable wattage, temperature control, and even customizable LED lights. They’re the perfect choice for vapers who love to tinker and fine-tune their experience. Box mods come in a variety of shapes and sizes, from compact, single-battery models to hefty dual-battery beasts. Their robust design means they can handle a lot of power, making them ideal for cloud chasers and flavor aficionados alike. And let’s not forget the customization options – with a box mod, you can swap out tanks, change coils, and personalize every aspect of your vaping setup. If you’re the type who likes to stand out from the crowd, a box mod is the way to go. The Quirky and Colorful - Vape Pens Vape pens are the fun, free-spirited cousins of the vaping family. These slender, pen-like devices come in a rainbow of colors and designs, making them the perfect accessory for vapers who love to express their individuality. From glittery finishes to intricate patterns, vape pens are all about making a statement. They’re also incredibly portable, fitting easily into a pocket or purse, which makes them a great choice for vapers on the go. Despite their playful appearance, vape pens are no slouches when it comes to performance. They offer a solid vaping experience with easy-to-use features, often including a single-button operation and straightforward refilling systems. Vape pens strike a perfect balance between style and substance, providing a satisfying vape in a package that’s as fun to look at as it is to use. If you’re all about having a good time and looking fabulous while doing it, a vape pen is your perfect match. The Futuristic and High-Tech - Pod Mods Pod mods are the cutting-edge innovators of the vaping world. These devices combine the best features of pod systems and box mods, creating a hybrid that’s both sleek and powerful. Picture a device with the compactness of a pod system but the advanced features of a box mod, all wrapped up in a high-tech design that looks like it came straight out of a sci-fi movie. Pod mods often feature digital displays, adjustable settings, and refillable pods, making them a versatile choice for tech-savvy vapers. One of the standout features of pod mods is their versatility. They’re designed to be user-friendly while offering a customizable experience, perfect for vapers who want the best of both worlds. Whether you prefer a tight, cigarette-like draw or a looser, cloud-chasing hit, pod mods can be adjusted to suit your preferences. And with their sleek, modern designs, they’re sure to turn heads wherever you go. If you’re all about staying ahead of the curve and love gadgets that offer both style and functionality, a pod mod is the device for you. Conclusion Whether you’re a stealthy ninja, a bold samurai, a free-spirited artist, or a futuristic tech enthusiast, there’s a vape out there that’s perfect for you. So next time you find yourself asking, "What does a vape look like?" remember that the answer is as diverse and exciting as the world of vaping itself. Happy vaping! FAQs 1. What Does a Vape Look Like? A vape can look like many different things, from sleek USB-like devices to large, boxy gadgets with digital displays. The appearance varies greatly depending on the type of vape, such as pod systems, vape pens, or box mods. Some vapes are minimalist and discreet, while others are bold and colorful, making a statement with their design. 2. How Do I Choose the Right Vape for Me? Choosing the right vape depends on your preferences and experience level. Beginners might prefer a simple, easy-to-use pod system or vape pen, which are usually more compact and user-friendly. Experienced vapers who want more control over their vaping experience might opt for a box mod or pod mod, which offer advanced features like adjustable wattage and temperature control. 3. Are Vapes Safe to Use? While vapes are generally considered safer than traditional cigarettes, they are not without risks. Vaping can still deliver nicotine, which is addictive, and there are potential health concerns related to inhaling vaporized substances. It's important to buy vapes from reputable sources and follow the manufacturer’s instructions to minimize risks. 4. What Are the Different Types of Vapes? The main types of vapes include pod systems, vape pens, box mods, and pod mods. Pod systems are compact and easy to use, vape pens are slender and portable, box mods are powerful and customizable, and pod mods combine features of both pod systems and box mods for a versatile vaping experience. 5. How Do I Maintain My Vape? Maintaining your vape involves regular cleaning and replacing parts as needed. This includes cleaning the tank or pod to prevent residue build-up, replacing coils to ensure optimal performance, and charging the battery. Proper maintenance helps extend the life of your device and ensures a better vaping experience. Always refer to the user manual for specific maintenance instructions. Read the full article

0 notes

Text

316TI Stainless Steel Coil | ASTM A240 316TI stainless steel coil | AISI 316ti

316TI Stainless Steel Coil

Introduction:

In the realm of stainless steel products, versatility, durability, and corrosion resistance are paramount. One such versatile variant is the 316TI Stainless Steel Coil, renowned for its exceptional properties. Jainex Steel & Metal, a pioneering name in the industry, offers insights into the features, applications, and advantages of this remarkable material.

Understanding 316TI Stainless Steel Coil:

316TI Stainless Steel Coil is an austenitic alloy containing a blend of chromium, nickel, and molybdenum, with the addition of titanium. This combination enhances its resistance to corrosion, particularly in environments containing chlorides such as seawater or acidic solutions. The 'TI' in its name denotes the presence of titanium, which stabilizes the structure against sensitization during welding, thereby preventing intergranular corrosion.

Features and Properties: