#Cryogenic Valves Market Price

Explore tagged Tumblr posts

Text

Understanding the Benefits of EIGA-Certified Nitrogen and Oxygen Generators

In today’s industrial landscape, reliable and efficient gas supply is crucial for various applications. Nitrogen and oxygen, two of the most commonly used industrial gases, play a vital role in numerous sectors, including:

Traditionally, these gases were sourced from bulk suppliers and delivered in high-pressure cylinders or cryogenic tanks. However, this method comes with several limitations, such as:

Logistical challenges: Dependence on external suppliers can lead to delivery delays and disruptions, impacting production schedules.

Safety concerns: Handling high-pressure gas cylinders requires specialized training and poses inherent safety risks.

Storage limitations: Storing large quantities of gas cylinders or cryogenic tanks can be challenging and requires dedicated space.

Cost fluctuations: The price of bulk gas can fluctuate based on market dynamics, impacting production costs.

EIGA E941-Certified Nitrogen and E948-Certified Oxygen Generators: Reliable and Cost-Effective Solutions

EIGA (European Industrial Gases Association) is a safety and technically oriented organisation representing the vast majority of European and a number of non-European companies producing and distributing industrial, medical and food gases. EIGA sets safety and quality standards for the manufacturing, distribution, and use of compressed gases. EIGA E941- Certified Nitrogen & EIGA E948- Certified Oxygen generators offer a compelling alternative to traditional bulk gas supply, providing several significant benefits:

On-site Gas Generation: EIGA-certified generators produce nitrogen or oxygen directly at your facility, eliminating dependence on external suppliers and ensuring a consistent and reliable gas supply. This reduces the risk of disruptions and delays, improving production efficiency and overall operational control.

Enhanced Safety: EIGA certification guarantees that the generators meet stringent safety standards for design, manufacturing, and operation. These generators incorporate various safety features, such as pressure relief valves, alarms, and automatic shut-off mechanisms, minimizing safety risks associated with handling high-pressure gas cylinders.

Reduced Storage Footprint: EIGA-certified generators eliminate the need for storing bulky gas cylinders or cryogenic tanks, freeing up valuable space in your facility. This can be particularly beneficial for facilities with limited space constraints.

Cost Savings: EIGA-certified generators can offer significant cost savings compared to traditional bulk gas supply. The elimination of transportation and delivery costs, coupled with potential bulk gas price fluctuations, can lead to long-term cost reductions.

Environmental Benefits: On-site generation of nitrogen or oxygen reduces reliance on transportation, minimizing the environmental impact associated with gas delivery trucks. Additionally, some generators utilize energy-efficient technologies, further contributing to environmental sustainability.

Customization and Flexibility: EIGA-certified generators offer a high degree of customization to meet your specific gas purity and flow rate requirements. This flexibility ensures you have the exact gas supply needed for your application, eliminating potential overspending on unnecessary gas volumes.

Ease of Use: EIGA-certified generators are designed for user-friendly operation, often featuring intuitive control panels and automated processes. This minimizes the need for specialized operator training, making them suitable for various industrial settings.

Scalability: EIGA-certified generators come in various sizes and capacities, allowing you to choose a system that aligns with your current and future gas requirements. As your production needs evolve, you can easily scale up your gas generation capacity by adding additional generators.

Also Read – Nitrogen Generator: A Game-Changer in Food Packaging

Types of oxygen generators used in the ceramic industry:

There are two main types of oxygen generators used in the ceramic industry:

Pressure Swing Adsorption (PSA) generators: These generators use a zeolite material to separate oxygen from air in compressed air. PSA generators are a popular choice for the ceramic industry due to their relatively low cost and ease of operation.

Vacuum Swing Adsorption (VSA) generators: These generators work on a similar principle to PSA generators, but they use a vacuum pump to create the pressure differential needed to separate oxygen from nitrogen. VSA generators are typically more energy-efficient than PSA generators, but they are also more expensive.

Choosing the Right EIGA E941-Certified Nitrogen or E948 -Certified Oxygen Generator

Selecting the right EIGA E941-certified nitrogen or EIGA E948-certified oxygen generator for

your facility requires careful consideration of several factors, including:

Gas purity requirements: Different applications have varying gas purity needs. Ensure the generator can deliver the required purity level for your specific use case.

Flow rate requirements: The generators capacity to produce gas should meet your peak and average flow rate demands.

Facility space constraints: Choose a generator with a footprint that fits comfortably within your designated space.

Budgetary considerations: Compare the initial investment cost of the generator with the potential long-term operational cost savings.

Conclusion

EIGA E941 -certified nitrogen and E948 -certified oxygen generators offer a safe, reliable, and cost-effective solution for various industrial gas requirements. By providing on-site gas generation, these generators eliminate dependence on external suppliers, enhance safety, reduce storage needs, and offer long-term cost savings. When choosing an EIGA-certified generator, carefully consider your specific gas purity, flow rate, space, and budget requirements to ensure you select the most suitable system for your application.

0 notes

Text

Cryogenic Equipment Market Is Booming Worldwide

The global cryogenic equipment market size stood at USD 17.24 billion in 2021. The market is estimated to rise from USD 18.06 billion in 2021 to USD 32.86 billion by 2028 at 8.9% CAGR during the forecast period. Fortune Business Insights™ has delved into these insights in its latest research report, titled, “Cryogenic equipment Market, 2021-2028.”

According to the analysis increasing investments in LNG power plants and rising focus on processing and manufacturing industries to foster market development. The rising demand for clean energy power is anticipated to boost the market in the near future. The transportation, storage, and regasification applications for generating clean energy hold substantial potential for the growth of the market.

List of Key Companies Profiled in the Market Report:

Chart Industries, Inc. (U.S.)

Cryofab, Inc. (U.S.)

Linde (Germany)

Nikkisso Cryoquip (U.S.)

Nikkiso Co. Ltd (Japan)

SHI Cryogenics Group (Japan)

HEROSE GMBH (Germany)

Wessington Cryogenics (U.K.)

Cryo Pur (France)

INOXCVA (INOX India Pvt Ltd) (India)

Sulzer (Switzerland)

Schlumberger (U.S.)

Flowserve Corporation (U.S.)

Fives (France)

Phpk Technologies (U.S.)

Marshall Excelsior Company (U.S.)

ACME Cryogenics (U.S.)

RegO (U.S.)

Habonim Industrial Valves & Actuators LTD (U.S.)

Impact of COVID-19:

Restrictions on Manufacturing and Transport to Hinder Market Progress

This market is expected to be negatively affected during the COVID-19 pandemic because of the restrictions imposed on manufacturing and transport activities. The sudden spike in COVID-19 infections led to the adoption of stringent norms. This has led to the closure of industries and the lack of raw materials for cryogenic equipment production. However, the adoption of production machinery, advanced sanitization methods, reduced capacities, and half capacities have enabled manufacturers to recover their losses. This factor is expected to boost market growth during the pandemic.

Report Coverage:

The report has been prepared meticulously through quantitative and qualitative assessments to offer a comprehensive market view. Notably, many primary interviews have been conducted with major stakeholders and suppliers. Primary data has been collected through questionnaires, telephonic conversations and emails. Moreover, the report also includes secondary sources, such as government websites, SEC filings and press releases. The report also gives an in-depth view of market size, share, revenue, volume and delves into SWOT analysis.

Drivers and Restraints:

Rising Demand for Clean Energy Source to Bolster Market Expansion

The rising demand for regasification, storage, and transportation of clean energy is expected to boost cryogenic equipment’s demand. The rising demand for LNG fuels for automotive use is expected to increase the equipment’s sales. Further, significant investments in the petrochemical and chemical sectors are likely to boost market growth. Rising usage of refrigerators, pumps, vaporizers, valves, and oil tankers is likely to increase the demand for the equipment. The equipment increases the safety of the fuel and maintains safety.

The rising demand for fuel storage and the rising adoption of renewable energy resources is likely to increase the equipment’s adoption. Moreover, it is also used in the healthcare sector to store blood, package medicines, and purge equipment. These factors are likely to drive the cryogenic equipment market growth.

However, the fluctuating stainless steel prices and stringent green-house emission norms may hinder the market progress.

Competitive Landscape:

Major Players Set Up Facilities to Expand Market Reach Globally

Prominent companies operating in the company set up manufacturing facilities to expand their market reach worldwide. For example, Lide declared that it had set up a novel on-site manufacturing plant in Qinzhou, China, in July 2021. The company shall supply industrial gases and oxygen to Shanghai Huayi's new chemical complex by opening up the plant. The manufacturing plant comprises three air separation units designed to supply 5,000 tons of nitrogen and 7,500 tons per day of oxygen. This strategy may enable the company to expand its market reach. In addition, the adoption of research and development may enable companies to improve their product quality and boost their brand image.

Segmentation:

By product, the market is segmented into bayonet connection, actuator, vaporizer, pump, valve, tank, and others. As per cryogen, it is categorized into helium, hydrogen, liquefied natural gas (LNG), argon, oxygen, nitrogen, and others.

Based on end-user, it is classified into marine, chemical & petrochemical, power generation, metallurgy, oil & gas, and others.

Regionally, it is grouped into Asia-Pacific, Europe, North America, Latin America, and the Middle East & Africa.

0 notes

Text

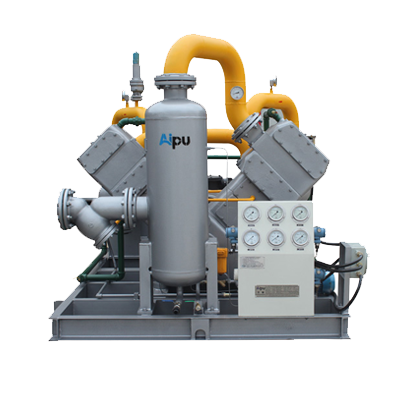

AIPU COMPRESSOR

Gas Compressor Manufacturer - Your professional supplier and reliable partner!

Bengbu Aipu Compressor Manufacturing Co., Ltd. is a professional manufacturer of gas compressors from China. Our main products include BOG compressors, LPG compressors, CNG compressors, and other gas compressors for CNG/LNG tank trucks, CNG filling station, LNG filling station, LNG gasification station, L-CNG filling station, LNG storage station, LNG peak regulation station, LNG receiving station, LPG filling station, chemical plant, oil and gas plant, etc. Each of Aipu piston reciprocating compressor is designed and manufactured professionally on the basis of the technical data and requirements from the end-users. We have different types of gas compressors such as industrial reciprocating compressor, natural gas booster compressor, reciprocating compressor, etc. We keep developing new technology and manufacturing processes to improve our different types of gas compressors and gas compression systems so that they could meet the market demand and the users' expectations.

BOG Compressor

BOG Compressor

BOG compressors also called boil-off gas compressors, are widely used to recover natural gas and boil-off gas left after the unloading of LNG cryogenic tanks and CNG tankers. The boil-off gas recovery system would be recovered and pressurized to CNG refilling station or pipeline network to achieve the dual purpose of maximum economic efficiency and environmental protection.

Z-type BOG Compressor

V-type BOG Recovery Compressor

More details

LPG Compressor

LPG Compressor

LPG compressors, one type of gas compressors for sale, are widely applied in liquefied petroleum gas stations, LPG car filling stations and mixed gas stations, and they are also an ideal equipment for chemical plants to pressurize the gases and benefit themselves from it, and popular in the areas of loading and unloading of LPG tank truck and vessel and bottle filling and tank decanting of LPG and similar media.

Z-type LPG Compressor

More details

CNG Compressor

CNG compressor is often used for medium size CNG filling stations, especially for CNG standard and daughter stations. It is a reciprocating (piston) gas compressor, which uses reciprocating compressor oil to operate and is mainly composed of the main compression,anti-explosive electric motor, cooling unit, lubrication unit, internal connection pipeline, safety valve, and the blow-down valve, the PLC control cabinet, etc. Currently, we have many natural gas compressors with reasonable prices for sale and they are widely used in the domestic and overseas markets.

D-type CNG Compressor

M-type CNG Compressor

More details

Other Compressors

There are different types of gas compressors, such as hydrogen gas compressor, ammonia gas compressor, electric gas compressor, gas booster compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

V-type Hydrogen Gas Compressor

Z-type Ammonia Gas Compressor

More details

Compressor Solutions

Aipu, one of the oil and gas compressor manufacturers in oil and gas industry can be widely seen in the field of gas recovery and storage, oil and gas plants, liquefied petroleum gas (LPG) filling stations, CNG filling stations, chemical areas, etc., its professional design and manufacture of oil and gas compressors with great prices meet the national standards and industrial requirements as well as the needs of users.

Compressor For LPG

Compressor For CNG

Recycle Compressor For BOG

https://www.aipucompressor.com/products/

1 note

·

View note

Text

A Leading Provider of Valves with Custom Design

Is it difficult to find valves that look great, work smoothly and fit in your industry, medium? Well, this is not a problem at all if you deal with Valves Only Europe. This is a leading brand in the world of valves and is considered as the top brand in Germany that offers top-notch quality valves available in the market. They have valves which look great and work smoothly for years but the best part is that they offer you these fantastic features at very cheap prices. The company is always willing to give you a service that is worth your money. The company makes all types of valves like cryogenic valves, control valve, butterfly and electric butterfly actuated valves and many more of them.

If we talk about cryogenic valves then Valves Only Europe is the best cryogenic valve manufacturer in Germany. These specialists offer a wide range of valves for cryogenic system. Cryogenic valves can easily work through the cold and lower temperature surroundings. They are tested properly according to the API and BS standards before being exposed to extreme industrial situations in the gas production plants and transportation. As a result, the easy flow of gas and liquids is at your disposal. Cryogenic valves are perfect performers in cold surroundings than any other valves available. They are known for their advantages like energy saving, high-flow ability, high durability, and tight shut-off. There is a wide range of cryogenic valves to choose from including cryogenic globe valve, cryogenic ball valve, cryogenic gate valve, cryogenic long stem globe valve, steam jacket globe valve, and cryogenic check valve. Whenever you buy cryogenic valves from Valves Only Europe, you can place your order as per your demands and they can come either with Lever operated, Gear operated, Pneumatic or electric operated. So look no further and trust this cryogenic valve manufacturer in Germany.

Valves Only Europe is also a reliable Control Valve Manufacturer in Germany. Control valve is used for control of Steam, Air, Water and Gas. Valves Only Europe provides control valves which are used for directing the flow, temperature, pressure, and the fluid level, and are heavily being used in the industrial sectors. All valves provide by this team are properly and specially designed to fit the needs of various refinery, petrochemical and chemical industries. Being an experienced Control Valve Manufacturer in Germany, this company can meet your requirements and manufacture these valves in any structure like 2way Globe control valve, 3way Globe control valve, and cage control.

Being a trustworthy Electric Actuated Butterfly Valve Manufacturer in Germany, Valves Only Europe also offers high performance electric actuated valves. Rest assured that you are dealing with a reputable and credible manufacturer of water flow control valves in Germany and Italy. Once you buy electric actuated valves, they can be produced with materials like SS316, stainless steel, WCB, CF8, CF8M and CF3M. They will be customized to suit your demands and bring the best value for your budget. So hurry up to contact this Electric Actuated Butterfly Valve Manufacturer in Germany and enjoy the unmatched quality.

1 note

·

View note

Text

Cryogenic Valves Market Gets Significant Impetus During Covid-19 Outbreak; Demand to Sustain Post Pandemic

Cryogenic Valves Market Gets Significant Impetus During Covid-19 Outbreak; Demand to Sustain Post Pandemic

“Cryogenic Valves Market Research: Global Status & Forecast by Geography, Type & Application (2016-2026)” the new research report adds in kandjmarketresearch.com research reports database. This Research Report spread across 60 Pages, with summarizing Top companies and supports with tables and figures.

The market study also includes the key drivers expected to boost the market growth and…

View On WordPress

#Cryogenic Valves#Cryogenic Valves Market Analysis#Cryogenic Valves Market CAGR#Cryogenic Valves Market Demand#Cryogenic Valves Market Forecast#Cryogenic Valves Market Growth#Cryogenic Valves Market Industry#Cryogenic Valves Market Price#Cryogenic Valves Market Share#Cryogenic Valves Market Size#Cryogenic Valves Market Trends

0 notes

Link

The Global Cryogenic Valve Market Outlook 2018-2023 offers detailed coverage of cryogenic valve industry and presents main market trends. The market research gives historical and forecast market size, demand, end-use details, price trends, and company shares of the leading cryogenic valve producers to provide exhaustive coverage of the market for cryogenic valve. The report segments the market and forecasts its size, by volume and value, on the basis of application, by products, and by geography.

#Industry Analysis#Market Research Reports#Company Profiles#Market Statistics#SWOT analysis#Flair Insights

1 note

·

View note

Text

Global Cryogenic Valve Market To Be Driven By The Rising LNG Trade In The Forecast Period Of 2022-2027

The new report by Expert Market Research titled, ‘Global Cryogenic Valve Market Report and Forecast 2022-2027’, gives an in-depth analysis of the global cryogenic valve market report, assessing the market based on its segments like types, gases, end user industries, applications, and major regions. The report tracks the latest trends in the industry and studies their impact on the overall market. It also assesses the market dynamics, covering the key demand and price indicators, along with analysing the market based on the SWOT and Porter’s Five Forces models.

Get a Free Sample Report with Table of Contents: https://www.expertmarketresearch.com/reports/cryogenic-valve-market/requestsample

Cryogenic Valve Market Report, Size, Trends, Key Player, Major Segments, and Forecast

The key highlights of the report include:

Market Overview 2017-2027

• Forecast CAGR (2022-2027): 4.7%

The global market is expected to be driven by the use of cryogenic valves in industrial applications, such as those in industrial gases and LNG. The rising LNG trade has led to the growing demand for storage and transportation of cryogenic gases, which in turn, is propelling the demand for cryogenic valves. A significant increase in the use of cryogenic valves in the oil and gas industry is one of the major reasons driving the market growth. The need for petrochemical products is increasing over time; thus, the demand for equipment such as cryogenic valves in transfer line applications is likely to increase rapidly. This is seen by rising orders for valves, notably cryogenic valves, from emerging economies.

Cryogenic Valve Market Industry Definition and Major Segments

Cryogenic valves are utilised in extremely cold applications (temperatures below -400°C), mostly for gas liquefaction. They are commonly used in businesses that work with compressed natural gas (CNG) and liquefied natural gas (LNG) (LNG). The valves are extensively employed in the oil and gas industry, where cryogenic temperatures can reach -1500°C. (-2380F).

Read Full Report with Table of Contents: https://www.expertmarketresearch.com/reports/cryogenic-valve-market

By type, the market is segmented into:

• Globe Valve • Gate Valve • Check valve • Ball Valve • Others

Based on gas, the market is divided into:

• Nitrogen • Oxygen • LNG • Others

The end- user industries of the market are:

• Energy and Power • Chemicals • Food and Beverage • Healthcare • Others

The major applications of the market are:

• Tanks and Cold Boxes • Liquefiers • Transfer Lines • Manifolds and Gas Trains • Others

On the basis of region, the market is segmented into:

• North America • Europe • Asia Pacific • Latin America • Middle East and Africa

Cryogenic Valve Market Trends

Cryogenic valves are effective and inexpensive, and they have no effect on the colour, taste, or flavour of the food. As a result, they are becoming more common in the food and beverage industry. This, coupled with the burgeoning food and beverage sector, is supporting the market growth. Also, cryogenic gases are extensively utilised for cryosurgery in the healthcare industry, positively influencing the sales of cryogenic valves worldwide. Aside from that, product applications in rock events and theatre stages throughout the world are also driving the market growth. Cryogenic valves are being widely used in the oil and gas industries, and the downstream manufacturing in China has expanded. This, along with government support in these nations, is likely to contribute to the rising demand for cryogenic valves in the region over the forecast period.

Key Market Players

The major players in the market:

• Flowserve Corporation • HEROSE GMBH • Emerson Electric Co • Samson Controls Inc. • Cryofab Inc • Actuators Ltd. • Powell Valves • others

The report covers the market shares, capacities, plant turnarounds, expansions, investments and mergers and acquisitions, among other latest developments of these market players.

About Us:

Expert Market Research (EMR) is a leading market research and business intelligence company, ensuring its clients remain at the vanguard of their industries by providing them with exhaustive and actionable market data through its syndicated and custom market reports, covering over 15 major industry domains. The company’s expansive and ever-growing database of reports, which are constantly updated, includes reports from industry verticals like chemicals and materials, food and beverages, energy and mining, technology and media, consumer goods, pharmaceuticals, agriculture, and packaging.

EMR leverages its state-of-the-art technological and analytical tools, along with the expertise of its highly skilled team of over 100 analysts and more than 3000 consultants, to help its clients, ranging from Fortune 1000 companies to small and medium sized enterprises, easily grasp the expansive industry data and help them in formulating market and business strategies, which ensure that they remain ahead of the curve.

Media Contact:

Company Name: Claight Corporation Contact Person:- James Rowan, Business Consultant Email: [email protected] Toll Free Number: US +1-415-325-5166 | UK +44-702-402-5790 Address: 30 North Gould Street, Sheridan, WY 82801, USA Website: www.expertmarketresearch.com LinkedIn: https://www.linkedin.com/company/expert-market-research

0 notes

Text

Polychlorotrifluorethylene Market Research Methodology, Structure, Forecast to 2027

Polychlorotrifluoroethylene is a thermoplastic polymer of chlorofluoropolymer. It offers excellent properties like high tensile strength, creep resistance, better moisture protection, and others. There was a price hike in last few years owing to increasing raw material prices which obligated end-use industries to increase their product prices. However, the prices stabilized in 2016, and this trend is expected to continue during the assessment period on account of steady prices of polymer. Owing to its water resistant and chemical stability, it has wide applications in blister packaging, seals and gaskets, eyeglasses, tubes, and others.

Based on form, the global polychlorotrifluoroethylene market has been segmented into powder, pellet, and granule. The powdered or pellet form of PCTFE can be prepared by treating an aqueous suspension of chlorotrifluoroethylene with polymerization catalysts. Whereas, the granular form is produced by suspension polymerization in an aqueous medium with no dispersing agent. The powdered form of PCTFE has the largest market share owing to its superior chemical and thermal characteristics. NEOFLON PCTFE molding powder, a DAIKIN INDUSTRIES Ltd. product, has various applications in the production of seals and gaskets, laboratory ware, coatings for pipes, fittings, and valves. Additionally, recent advances in the aerospace and pharmaceutical industries are expected to drive the global PCTFE market.

Based on end-use industry, the global polychlorotrifluoroethylene market has been segmented into pharmaceuticals, electrical and electronics, aerospace, and others. Aerospace sector accounted for the largest market share in global PCTFE market in 2017 due to its use in various end-use applications due to low outgassing value, low inflammability, and light weight. PCTFE can retain its mechanical properties under a wide temperature range and is chemically resistant to aggressive chemicals which make it ideal for manufacturing valves, impellers, diaphragms and plugs which propels the global polychlorotrifluoroethylene market.

Get Free Sample PDF@ https://www.marketresearchfuture.com/sample_request/6417

Market Segmentation

The global polychlorotrifluoroethylene market has been segmented based on form, application, end-use industry, and region.

On the basis of form, the global polychlorotrifluoroethylene market has been segmented as powder, pellet, and granule.

By application, the global polychlorotrifluoroethylene market has been distributed into films and sheets, tubes, wires and cables, coating, seals and gaskets, medical equipment, cryogenics, and others.

Based on end-use industry, the global polychlorotrifluoroethylene market has been categorized into pharmaceuticals, electrical and electronics, aerospace, oil and gas, and others.

The global polychlorotrifluoroethylene market has been studied across five regions, namely, Asia-Pacific, North America, Latin America, Europe, and the Middle East & Africa.

Regional Analysis

The global market for polychlorotrifluoroethylene is studied for five key regions namely, Asia-Pacific, North America, Latin America, Europe, and the Middle East & Africa. Asia-Pacific is estimated to dominate the PCTFE market owing to increasing demand from pharmaceutical, aerospace and electronics end-use industries. In 2017, China was the leading manufacturer of pharmaceutical ingredients and ranked second in the production of medicines worldwide. North America is another prominent region contributing mainly due to the growth in demand from the aerospace sector. The US and Canada are the key countries aiding to the growth of PCTFE market in this region. Europe is also expected to witness growth due to the rapidly expanding semiconductor industry. Major contributors from this region are Germany, the UK, France, Italy, and Spain. In Latin America, Brazil and Mexico are the leading markets where growth can be attributable to the recent advances in the aerospace and chemical industries. Due to relatively less demand of application based end-use industry, the Middle East & Africa region is likely to witness slack growth.

Competitive Analysis

The key players in the global polychlorotrifluoroethylene market are DAIKIN INDUSTRIES Ltd. (Japan), Arkema Group (France), Honeywell International Inc. (US), HaloPolymer (Russia), Saint-Gobain (France), Allied Chemical Corporation (US), Qingdao Hongfeng Si-F Science Ltd (China), Welch Fluorocarbon Inc (US), and GAPI Group (Italy).

Access Report @ https://www.marketresearchfuture.com/reports/polychlorotrifluoroethylene-market-6417

0 notes

Text

China Cryogenic Valve Market Report & Forecast 2021-2027

This report contains market size and forecasts of Cryogenic Valve in China, including the following market information:

China Cryogenic Valve Market Revenue, 2016-2021, 2022-2027, ($ millions)

China Cryogenic Valve Market Sales, 2016-2021, 2022-2027, (K Units)

Download FREE Sample of this Report @ https://www.grandresearchstore.com/report-sample/china-cryogenic-valve-2021-2027-362

China top five Cryogenic Valve companies in 2020 (%)

The global Cryogenic Valve market size is expected to growth from US$ 872.3 million in 2020 to US$ 1095 million by 2027; it is expected to grow at a CAGR of 3.3% during 2021-2027.

The China Cryogenic Valve market was valued at US$ XX million in 2020 and is projected to reach US$ XX million by 2027, at a CAGR of XX% during the forecast period.

QYResearch has surveyed the Cryogenic Valve manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price change, product type, recent development and plan, industry trends, drivers, challenges, obstacles, and potential risks.

Total Market by Segment:

China Cryogenic Valve Market, By Type, 2016-2021, 2022-2027 ($ Millions) & (K Units)

China Cryogenic Valve Market Segment Percentages, By Type, 2020 (%)

LNG

Oxygen

Nitrogen

Hydrogen

Helium

Other

China Cryogenic Valve Market, By Application, 2016-2021, 2022-2027 ($ Millions) & (K Units)

China Cryogenic Valve Market Segment Percentages, By Application, 2020 (%)

Energy & Power

Chemicals

Food & Beverage

Healthcare

Other

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Cryogenic Valve revenues in China market, 2016-2021 (Estimated), ($ millions)

Key companies Cryogenic Valve revenues share in China market, 2020 (%)

Key companies Cryogenic Valve sales in China market, 2016-2021 (Estimated), (K Units)

Key companies Cryogenic Valve sales share in China market, 2020 (%)

Further, the report presents profiles of competitors in the market, key players include:

Emerson

Flowserve

Schlumberger(Cameron)

Kitz

Velan

KSB

Herose

Parker Bestobell

Samson

Powell Valves

L&T Valves

Bray

Zhejiang Petrochemical Valve

Bac Valves

Habonim Industrial Valves & Actuators

Valco Group

Meca-Inox

Get the Complete Report & TOC @ https://www.grandresearchstore.com/manufacturing-and-construction/china-cryogenic-valve-2021-2027-362

Table of content

1 Introduction to Research & Analysis Reports 1.1 Cryogenic Valve Market Definition 1.2 Market Segments 1.2.1 Segment by Type 1.2.2 Segment by Application 1.3 China Cryogenic Valve Market Overview 1.4 Methodology & Sources of Information 1.4.1 Research Methodology 1.4.2 Research Process 1.4.3 Base Year 2 China Cryogenic Valve Overall Market Size 2.1 China Cryogenic Valve Market Size: 2021 VS 2027 2.2 China Cryogenic Valve Revenue, Prospects & Forecasts: 2016-2027 2.3 China Cryogenic Valve Sales: 2016-2027 3 Company Landscape 3.1 Top Cryogenic Valve Players in China Market 3.2 Top China Cryogenic Valve Companies Ranked by Revenue 3.3 China Cryogenic Valve Revenue by Companies 3.4 China Cryogenic Valve Sales by Companies 3.5 China Cryogenic Valve Price by Manufacturer (2016-2021) 3.6 Top 3 and Top 5 Cryogenic Valve Companies in China Market, by Revenue in 2020 3.7 Manufacturers Cryogenic Valve Product Type 3.8 Tier 1, Tier 2 and Tier 3 Cryogenic Valve Players in China Market 3.8.1 List of Tier 1 Cryogenic Valve Companies in China 3.8.2 List of Tier 2 and Tier 3 Cryogenic Valve Companies in China 4 Sights by Type 4.1 Overview 4.1.1 By Type - China Cryogenic Valve Market Size Markets, 2021 & 2027 4.1.2 LNG 4.1.3 Oxygen 4.1.4 Nitrogen 4.1.5 Hydrogen 4.1.6 Helium 4.1.7 O

CONTACT US: 276 5th Avenue, New York , NY 10001,United States International: (+1) 646 781 7170 / +91 8087042414 Follow Us On linkedin :- https://www.linkedin.com/company/grand-research-store/

0 notes

Text

Cryogenic Valve Market Size, Share, Trends And Opportunity

Cryogenic Valve Market research report discusses the key drivers influencing global growth, opportunities, current challenges and the risks faced by key players and the market as a whole. The Research study also analyses key emerging trends and their impact of Covid-19 on present and future development.

Cryogenic Valve market share is expected to offer several growth opportunities to the stakeholders of the market during the forecast period. However, there are several environmental and governmental regulations on the use or discharge of primarily to reduce casualties and minimize its adverse effects on the environment.

Competitive Landscape and Global Market Share Analysis

The major players covered in Cryogenic Valve are: Emerson, Flowserve, Schlumberger(Cameron), Kitz, Velan, KSB, Herose, Parker Bestobell, Samson, Powell Valves, L&T Valves, Bray, Zhejiang Petrochemical Valve, Bac Valves, Habonim Industrial Valves & Actuators, Valco Group, Meca-Inox market competitive landscape provides details by vendors, including company overview, company total revenue (financials), market potential, global presence, sales and revenue generated, market share, price, production sites and facilities, SWOT analysis, product launch.

Market segmentation

Cryogenic Valve market is split by Type and by Application. For the period 2021-2026, the growth among segments provides accurate calculations and forecasts for sales by Type and by Application in terms of volume and value.

Cryogenic Valve Breakdown Data by Type

· Energy & Power

· Chemicals

· Food & Beverage

· Healthcare

· Other

Cryogenic Valve Breakdown Data by Application

· LNG

· Oxygen

· Nitrogen

· Hydrogen

· Helium

· Other

Regions and Countries Level Analysis

Regional analysis is another highly comprehensive part of the research and analysis study of the global Cryogenic Valve market presented in the report. For the historical and forecast period 2021 to 2026, it provides detailed and accurate country-wise volume analysis and region-wise market size analysis of the global market.

The report offers in-depth assessment of the growth and other aspects of the Global Cryogenic Valve Market – Growth, Trends And Forecast (2021 – 2026) By Types, By Application, By Regions and By Key Players – Emerson,Flowserve,Schlumberger(Cameron),Kitz, Cryogenic Valve market in important countries (regions), including: North America (United States, Canada and Mexico), Europe (Germany, France, UK, Russia and Italy), Asia-Pacific (China, Japan, Korea, India and Southeast Asia), South America (Brazil, Argentina, etc.), Middle East & Africa (Saudi Arabia, Egypt, Nigeria and South Africa) and ROW.

INDUSTRY DATA ANALYTICS

About - IndustryDataAnalytics is your single point market research source for all industries including pharmaceutical, chemicals and materials, energy resources, automobile, IT, technology and media, food and beverages, and consumer goods, among others.

Head of Sales: Mr. Hon Irfan Tamboli

+1 (704) 266-3234 | [email protected]

0 notes

Text

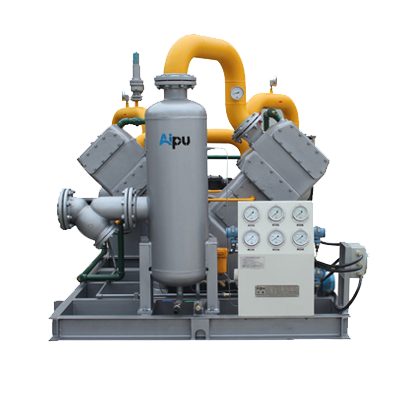

AIPU COMPRESSOR

https://www.aipucompressor.com/products/

Bengbu Aipu Compressor Manufacturing Co., Ltd. is a professional manufacturer of gas compressors from China. Our main products include BOG compressors, LPG compressors, CNG compressors, and other gas compressors for CNG/LNG tank trucks, CNG filling station, LNG filling station, LNG gasification station, L-CNG filling station, LNG storage station, LNG peak regulation station, LNG receiving station, LPG filling station, chemical plant, oil and gas plant, etc. Each of Aipu piston reciprocating compressors is designed and manufactured professionally on the basis of the technical data and requirements from the end-users. As one of the leading reciprocating natural gas compressor manufacturers, we have different types of gas compressors for sale such as industrial reciprocating compressors, natural gas booster compressors, reciprocating compressors, etc., which are offered at a reasonable price. We keep developing new technology and manufacturing processes to improve our different types of gas compressors and gas compression systems so that they could meet the market demand and the users' expectations. Here you can find our natural gas compressor for sale.

BOG Compressor

BOG compressors also called boil-off gas compressors, are widely used to recover natural gas and boil-off gas left after the unloading of LNG cryogenic tanks and CNG tankers. The boil-off gas recovery system would be recovered and pressurized to CNG refilling station or pipeline network to achieve the dual purpose of maximum economic efficiency and environmental protection.

Z-type BOG Compressor

V-type BOG Recovery Compressor

LPG Compressor

LPG compressors, one type of gas compressors for sale, are widely applied in liquefied petroleum gas stations, LPG car filling stations and mixed gas stations, and they are also an ideal equipment for chemical plants to pressurize the gases and benefit themselves from it, and popular in the areas of loading and unloading of LPG tank truck and vessel and bottle filling and tank decanting of LPG and similar media.

Z-type LPG Compressor

CNG Compressor

CNG compressor is often used for medium size CNG filling stations, especially for CNG standard and daughter stations. It is a reciprocating (piston) gas compressor, which uses reciprocating compressor oil to operate and is mainly composed of the main compression,anti-explosive electric motor, cooling unit, lubrication unit, internal connection pipeline, safety valve, and the blow-down valve, the PLC control cabinet, etc. Currently, we have many natural gas compressors with reasonable prices for sale and they are widely used in the domestic and overseas markets.

D-type CNG Compressor

M-type CNG Compressor

Other Compressors

There are different types of gas compressors, such as hydrogen gas compressor, ammonia gas compressor, electric gas compressor, gas booster compressor, etc. Generally, they pressurize the gas to some desired pressure to meet people's demands although the compressing mediums are different.

V-type Hydrogen Gas Compressor

Z-type Ammonia Gas Compressor

Compressor Solutions

Aipu, one of the oil and gas compressor manufacturers in oil and gas industry can be widely seen in the field of gas recovery and storage, oil and gas plants, liquefied petroleum gas (LPG) filling stations, CNG filling stations, chemical areas, etc., its professional design and manufacture of oil and gas compressors with great prices meet the national standards and industrial requirements as well as the needs of users.

Compressor For LPG

Compressor For CNG

Recycle Compressor For BOG

0 notes

Text

Cryogenic Insulation Market Statistics, Overview, Analysis, Region & Country Revenue Share, & Forecast Till 2027

Market size- USD 2.52 billion in 2018, Market Growth- CAGR of 7.3%, Market Trends- Launch of improved insulations and research and development.

According to the current analysis of Reports and Data, the global Cryogenic Insulation Market was valued at USD 2.52 billion in 2018 and is expected to reach USD 4.41 billion by year 2026, at a CAGR of 7.3 %. Cryogenics are materials that reach very low temperatures. The temperatures scales for cryogenics are not very well defined. However, it is believed that a gas is cryogenic if it can be liquefied at a temperature as low as -150°. In simple terms, cryogenic is fundamentally about energy and insulation is about energy conservation. With the rising focus on thermal isolation, the use of cryogenics and low temperature refrigeration is taking more and more significant role. In the recent times, it has become prominent due to the increasing awareness and its versatility in application. It has become a major requirement throughout industries, from food industry, transportation, energy and medical application to Space Shuttles. No matter where its application lies, cryogenic liquids must be stored, handled and transferred from one point to another. The growing demand for LNG and LPG across several sectors such as automotive, power and energy, domestic and commercial fuel. This is boosting the natural gas exploration initiatives, thus requiring cryogenic insulation.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1537

Major Companies Operating in the industry and profiled in the report are:

· Lydall Inc.,

· Armacell International Holding GmbH,

· BASF,

· Dunmore,

· Kaefer,

· Aspen Aerogel,

· Rochling Group and Vita Group.

The report provides a comprehensive analysis of current market dynamics and the factors that might influence the growth of the market or hamper it. The report provides insight into revenue growth, global and regional analysis, and market segmentation based on types and applications.

Cryogenic Insulation Market Segmentation based on Product Types:

· Fibreglass

· Cellular glass

· Perlite insulation

· Polyurethane (PU)

· Polyisocyanurate (PIR)

Cryogenic Insulation Market Segmentation based on Applications:

· Transportation

· Energy and Power

· Electronics

· Medical

· Chemical

The report additionally discusses in-depth the strategic initiatives taken by the major market players for expanding their consumer base and to gain market size. This includes a list of mergers, acquisitions, joint ventures, product launches, collaborations, partnerships, and agreements. The report includes an extensive profiling of the key companies including their product catalogues, pricing analysis, and business expansion strategies.

Request a discount on the report @ https://www.reportsanddata.com/discount-enquiry-form/1537

The regional analysis of the Cryogenic Insulation market provides an insight into the regions expected to hold the largest share in the market. According to the research report, North America is expected to dominate the market holding the largest share. Asia Pacific is expected to show a significant growth in the coming years owing to adoption of advanced technologies and growing consumer base. Europe is expected to follow closely behind North America & APAC countries. Latin America and Middle East & Africa are expected to hold a significant share in the market.

The regional analysis covers:

· North America (U.S., Canada, Mexico)

· Europe (U.K., Italy, Germany, France, Rest of EU)

· Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

· Latin America (Chile, Brazil, Argentina, Rest of Latin America)

· Middle East & Africa (Saudi Arabia, U.A.E., South Africa, Rest of MEA)

To know more about the report, visit @ https://www.reportsanddata.com/report-detail/cryogenic-insulation-market

Further key findings of the report suggested that:

· The cryogenic insulation market has been categorised into various tools and equipment such as tanks, pumps, valves etc. Essentially, it comes in three forms namely, foam, bulk-fill and multi-layer. Multi-layer form of insulation is further categorised into two namely, films and foils. Each type of cryogenic insulation comes under any one of the forms

· Continuous developments in this field have too played a role in encouraging the consumers and driving them towards the market. The varied applicability of cryogenic insulation throughout several industries has also been identified as an important driving factor.

· Due to an increase in LNG terminals, storage tanks and ships carrying LNG, a substantial amount of insulating materials are required. Also a rise in environmental regulations regarding carbon dioxide emission is seen to be propelling the market.

· Rising demand for LNG as fuel and environmental awareness acts as one of the key factors driving the market.

About Us: We are a boutique market intelligence and strategic consulting firm dedicated to make an meaningful impact on businesses across the globe. Our stellar estimation and forecasting models have earned recognition across majority of the business forum across the globe. Our services are arrayed over diverse sectors and industries looking to expand in alternative regions and products.

Request a customization of the report @ https://www.reportsanddata.com/request-customization-form/1537

Contact Us:

John W

Head of Business Development

Reports And Data | Web: www.reportsanddata.com

Direct Line: +1-212-710-1370

E-mail: [email protected]

0 notes

Text

Medical Gases And Equipment Market Set For Rapid Growth And Trend By 2027

The global Medical Gases And Equipment market was valued at US$ xx million in the year 2019. The market is estimated to be valued at US$ xx million in the year 2020, and is expected to reach US$ xx million by the year 2027, with an estimated CAGR of xx% during the forecast period (2021-2027). The research study also includes exhaustive information about market dynamics such as drivers, restraints, opportunities, technological advancements, future trends, supply chain analysis, patent landscape, pricing analysis, regulatory and reimbursement framework for precise market estimations and forecasts.

Additionally, the business intelligence study encompasses the COVID-19 scenario as follows:

· Long-Term, Mid-Term, and Short-Term Impact of COVID-19

· Pre- and Post-COVID-19 Scenario

· Disruptions in the Supply Chain

Get Free PDF Brochure Of This Report @ https://www.fostermarketresearch.com/product/industry/7/446/Pdf%20Brochure/

Competitive Insights

Leading and emerging companies of the global Medical Gases And Equipment market were identified based on their current offerings. Further, the Medical Gases And Equipment industry is one of the most competitive industries, with the leading players actively competing against each other to gain a greater share in the industry. Some of the major companies in the Medical Gases And Equipment market are: Matheson Tri-Gas, Inc, Air Liquide, Air Products and Chemicals, Inc, Linde, Praxair Technology, Inc., Taiyo Nippon Sanso Corporation, Atlas Copco (India) Ltd, Messer Group, Gas Control Equipment Ltd, Amico Group of Companies, SOL Spa, Rotarex, Medical Gas Solutions Inc., Flogas, and BeaconMedaes, among other domestic players.

The competitive landscape of the Medical Gases And Equipment industryexhibits an inclination towards emerging strategies including product launches, partnerships, collaborations and contracts, acquisitions, funding, and other developments to achieve the objectives faster.

Our reports fill up the gaps and provide you with all the detailed analysis of competitive companies involving:

· Analyzing competitive strategies and techniques

· Competitive positioning of key players

· PORTER’s and SWOT analysis for competitive risk analysis

· Competitive Share Analysis

· Financial analysis of players to determine their withstand capacity

· Analyzing their sales path and product study

For More Information Of This Report @ https://www.fostermarketresearch.com/product/industry/7/446/

Key Segments Covered in the global Medical Gases And Equipment market report are:

· By Type (Medical Gas (Pure Medical Gases by Type (Oxygen, Carbon Dioxide, Nitrous Oxide, Nitrogen, Medical Air, and Helium), Pure Medical Gases by form of delivery (High Pressure Cylinders, Liquid Tanks, and Bulk Delivery), Medical Gas Mixtures (Blood-gas Mixtures, Lung Diffusion Mixtures, Nitrous oxide-oxygen Mixtures, Carbon dioxide-oxygen Mixtures, Laser-gas Mixtures, Aerobic Mixtures, Anaerobic Mixtures, Ethylene Oxide, and Helium-oxygen Mixtures))

· By Medical gas equipment (Equipment Accessories (Hoses, Manifolds, Regulators, Flowmeters, Suction Regulators, Vacuum Systems, Outlets, Monitoring Systems, Valve with Integrated Pressure Regulator, and Medical Air Compressors), Cryogenic Products, and Gas Delivery Systems)

· By Application (Diagnostic Applications (Medical Imaging and General laboratory Use), Therapeutic Applications (Respiratory Diseases, Cardiovascular Diseases, Anesthesia, Cryosurgery, and Others), Pharmaceutical manufacturing and research (Drug Discovery, Process Development, Pharmaceutical Manufacturing, and Quality Control), Other Therapeutic Applications (Tissue and Platelet Preservation)

Market Dynamics:

Increased adoption of factors like rising prevalence of chronic diseases, growing occurrence of respiratory ailments as a result of the massive consumption of tobacco and increasing pollution extent, the surge in the geriatric population is predicted to drive market growth in the forecast period.

With the dynamic nature of lifestyle and eating patterns of citizens, the aggregate of people agonizing from obesity and associated ailments worldwide has expanded significantly in recent years. In 2016, as per the WHO reports, approximately 1.9 billion adults (18 years and above) were evidently overweight worldwide. Out of these, around 650 million were reported to be obese. Moreover, in 2016, approximately ~340 million toddlers and teenagers aged 5–19 were counted to be overweight/stout globally.

Regional Coverage:

The global Medical Gases And Equipment market segregates into five regions including North America, Europe, Asia-Pacific, Latin America, and Middle East and Africa. North America followed by Europe held the major share of the global market (in terms of value) in 2020. However, Asia-Pacific region exhibit highest CAGR (%) during the forecast period (2021-2027). Our research study further sub-divides regions into countries as follows:

· North America - the U.S. and Canada

· Europe - Germany, the U.K., France, Spain, Italy, Russia, and Rest-of-Europe

· Asia-Pacific - China, India, Japan, South Korea, Australia, ASEAN, and Rest-of-Asia-Pacific

· Latin America - Mexico, Brazil, and Rest-of-Latin America

· Middle East and Africa - Gulf Cooperation Council (GCC) Countries, South Africa, Israel, and Rest-of-Middle East and Africa

Buy Now This Business Strategic Report To Improve Your Profits @ https://www.fostermarketresearch.com/product/buy/7/446/

About Foster Market Research:

Foster Market Research is a global market intelligence and advisory firm engaged in providing data-driven research extract from rigorous analysis, to the clients to make critical business decisions and execute them successfully. Foster connects over various distribution channels and numerous markets for great understanding of the trends and market to deliver our clients with accurate data.

Our focus is on providing market research that delivers a positive impact on your business. We work continuously to provide our clients with the most accurate analytics data and research reports without any delay so as to improve their business strategies and provide them with rich customer experience.

Contact Us:

1701 Royal Lane,

#1306, Dallas

Tx-75229

Phone: +1 469 4981929

Email: [email protected]

0 notes

Text

Global Industrial Nitrogen Market Forecast and Trends

According to BlueWeave Consulting, the global Industrial Nitrogen market has reached USD 16.59 Billion in 2019 and estimated to reach USD 23.759 Billion in 2026 and anticipated to grow by CAGR of 5.28% during the forecast period 2020-2026. The fast-growing food and beverage and steel industries are the most significant growth factor in the global industrial nitrogen market.

Rapid advances made in this end-use industry in different parts of the world are promoting business growth. Raising concerns about hygienic storage and food safety are some of the significant drivers of lucrative growth rate industrial nitrogen demand in the food & beverage industry. Nitrogen is commonly used for food aeration, packaging, and storage in the food and beverage industry to improve the food products ' shelf-life. It is used for winemaking to avoid oxidation at the time of fermentation, which preserves product quality.

Cylinders & packaged gas is the most dominating transportation method used to distribute nitrogen

The most widely used mode of transport for the delivery of nitrogen is cylinder & packed gas. The cylinders are produced and constructed in compliance with the relevant pressure and temperature requirements and practices involved. The compressed gas category is driven by the fact that nitrogen gas finds extensive use in a large number of industries since it is used to store explosive and flammable liquefied petroleum materials. As nitrogen is an inert gas, it is also used in stainless steel manufacturing. Cryogenic liquid cylinders are vacuum jacketed and sealed pressure containers that come with rupture disks and safety relief valves to protect the cryogenic cylinders against increased pressure.

Nevertheless, industrial nitrogen is likely to encounter regulatory and systemic structural challenges. Different emerging nations are still not conducive to the development of nitrogen.

Followed by the food & beverage segment pharmaceutical end-user sector contribute to the significant growth rate in the global industrial nitrogen market.

It is projected that the pharmaceutical & healthcare sector will grow in value at the fastest CAGR between 2019 and 2026. Following the food & beverage industry, the use of industrial nitrogen in the pharmaceutical field, with significant demand for industrial nitrogen as a cryogen for freezing and preserving cell tissue, blood, etc. in the healthcare sector, is expected to further fuel the projected market growth. The increased use of nitrogen in the healthcare industry and drug production in developing and developed regions is a notable phenomenon which can play a key role in the growth dynamics. Nonetheless, various factors may be hindering the global market's steady expansion. Besides, high production costs of nitrogen, along with strict regulations regulating nitrogen production, are likely to impede market growth during the forecast period.

Asia-Pacific expected to witness lucrative demand in the global industrial nitrogen market

The Asia Pacific represented the largest share of the global industrial nitrogen market and is projected to grow at the highest rate over the forecast period. The increase in demand for industrial nitrogen can be attributable primarily to the region's rising population with high disposable incomes and growing industrialization. Nitrogen supply and use have become standard across a wide range of manufacturing and processing sectors, thanks to which there are now several applications of nitrogen in each industry that can help improve quality, reinforce protection and avoid the adverse effects of oxygen exposure on end products. For example, according to the US statistics bureau. Nitrogen fertilizer demand exceeded the global 147.8 million tons in 2014.

Rising crop prices lead to increased demands for fertilizers and have been especially noted in South Asia in recent years. Favorable weather conditions in major agricultural regions often increase the need for fertilizers. Countries such as India, China, and Singapore lead the Asia-Pacific market with strong economic growth in the region, ever-increasing demands for the population, rapid industrialization, and significant investment by leading industry players considering potential growth opportunities in the region. The rising economic growth in the Asia Pacific would deliver lucrative market-size prospects in the forthcoming years. Besides, the increased use of ammonia-formulated fertilizers in agricultural countries such as India and China to improve soil fertility, which is likely to boost product market growth during the forecast timeframe.

0 notes

Text

Cryogenic Insulation Market Trend , End-Use Industry, Pricing Analysis, Regulatory Framework, Key Players and Estimated Value

Market Synopsis: According to the MRFR analysis, Cryogenic Insulation Market is expected to reach over USD 3.7 Billion by the end of 2025 at a CAGR of 7.2%.

Cryogenic insulation is used to reduce or eliminate the energy loss from the cold storage tanks and transfer lines. Cryogenic insulation effectively controls a system’s environment and helps in maintaining economic effectiveness. Cryogenic insulation are high-performance materials such as polyisocyanurate, polyurethane, expanded foams, fiberglass cellular glass, polystyrene, and aerogel. The growing demand for cryogenic equipment in the food & beverage and medical industries coupled with increasing demand for liquified natural gas (LNG) and various industrial gases is expected to drive the growth of the cryogenic insulation material market during the forecast period.

Global Cryogenic Insulation Market Trend is estimated to record a CAGR of 7.2% during the forecast period and is estimated to reach a value of USD 3.7 Billion by 2025.

By Material Type

PU/PIR: The segment accounted for the largest share of the global market and is projected to witness moderate growth during the forecast period. The high demand for PU/PIR insulation is attributed to low thermal conductivity, fire resistance, moisture resistance, and good workability. PU and PIR are widely used for insulating cold storage buildings, pipelines, storage tanks, and valves in various industries. Furthermore, the high vermin resistance enables its use in the food & beverage and medical industries.

Polystyrene: The polystyrene segment is expected to witness moderate growth during the forecast period. Polystyrene is mostly preferred for cryogenic insulation applications in the areas of high moisture exposure.

Cellular Glass: Cellular glass is widely used for insulating piping, fittings, tanks, and equipment operating in the temperature ranges of -268°C to 480°C. It is widely preferred in the chemical industry and ground chilled piping systems. The cellular glass segment is expected to witness healthy growth driven by its superior properties, chemical resistance, and corrosion resistance.

Others: The others segment includes perlite, fiberglass, aerogel, and elastomer foams. This segment is expected to witness fastest growth during the forecast period owing to the high demand for aerogel for pipeline insulation.

By End-Use Industry

Energy & Power: The segment dominated the global cryogenic insulation market in 2018 and is expected to witness significant growth during the forecast period. The growth is primarily attributed to the increasing demand for liquefied natural gas (LNG) as a fuel, favored by government policies encouraging a cleaner energy mix. The US and China accounted for over 60% of the global LNG consumption.

Food & Beverage: The segment is expected to witness healthy growth driven by increasing demand for cold storage and frozen food transportation. The long-term outlook of the food & beverage segment is expected to remain positive backed by socio-economic trends such as economic growth, urbanization, changing demographics, population growth, and increasing disposable income.

Medical: The medical segment is expected to witness moderate growth driven by increasing healthcare spending. According to the World Health Organization, in 2016, the global spending on health was USD 7.5 trillion and average per capita health expenditure was USD 1,000. The spending on healthcare in the low- and middle-income countries is expected to be 6%, and 4% in high-income countries during the forecast period.

Chemical: Increasing investment to increase the production capacities of various chemicals across the globe, particularly in Asian countries such as China and India, is expected to augment the growth of the global cryogenic insulation market.

Others: The others segment is expected to witness moderate growth during the forecast period.

Regional Analysis

Asia-Pacific accounted for the largest share of the global market. The regional market is expected to witness robust growth during the forecast period driven by the increasing investment in the energy & power and food & beverage industries. Furthermore, rapid industrialization and increasing demand for LNG are factors expected to drive the growth of the regional market. China, India, Japan, and Indonesia are expected to contribute significantly toward the growth of the market.

Europe is expected to be the second-largest market for cryogenic insulation during the forecast period. The growth of the market in the region is led by Germany, Russia, the UK, and France.

North America is expected to witness significant growth primarily driven by increasing demand for LNG in the US. Furthermore, the increasing spending on healthcare in the US is expected to support regional market growth.

Latin America: The growth of the Latin American market is driven by the healthy growth of the end-use industries in Brazil, Mexico, and Argentina.

Middle East & Africa: The growth of the market in the region is likely to be driven by the growth of the energy & power sector.

Key Players

KAEFER (Germany)

Cabot Corporation (US) – Nanogel

BASF SE (Germany)

Lydall, Inc (US)

Armacell Enterprise GmbH & Co. KG (Germany) – Armaflex

Owens Corning (US) – FOAMGLAS

Aspen Aerogels (US) – Pyrogel, Cryogel

Röchling (France) – Durolight

DUNMORE (US) – CRYO-SHIELD Multilayer

NICHIAS Corporation (Japan) – FOAMNERT Board-TN

Norplex Micarta (US) – NP500CR

Access Full Report Details and Order this Premium Report @

https://www.marketresearchfuture.com/reports/cryogenic-insulation-market-8494

NOTE: Our Team of Researchers are Studying Covid19 and its Impact on Various Industry Verticals and wherever required we will be considering Covid19 Footprints for Better Analysis of Market and Industries. Cordially get in Touch for More Details.

0 notes

Text

Cold Insulation Market Analysis on Top Key Vendors, Revenue Growth

Global Cold Insulation Market: Snapshot

Growing environmental awareness, changing climate conditions, increasing demand for cryogenic insulation materials, escalating need for refrigeration and air conditioning devices, prosperity of the construction industry, and growth of the oil and gas industry are some of the key factors driving the global cold insulation market. Cold insulation is one of the most convenient way of protecting the environment from harmful greenhouse gases.

In the near future, the oil and gas industry and the building and construction sector will primarily sustain the demand in the global cold insulation market. In the oil and gas industry, cold insulation is used for insulating storage tanks as well as to convert natural gas into liquid state.

Get Brochure of the Report @ https://www.tmrresearch.com/sample/sample?flag=B&rep_id=653

Based on material, the global cold insulation market can be segmented into phenolic foam, fiber glass, polystyrene foam, polyurethane foam, and others. Currently, polyurethane foam has the maximum demand, finding application in padded materials and mattresses as well as for refrigeration. Polyurethane form are versatile and offer several unique properties such as low thermal conductivity, lightness, good strength, high chemical resistance, and low water absorption.

This report on the global cold insulation market provides in-depth analysis of all the material, end-use, and geographical segments, and estimates their demand during the forecast period of 2017 to 2025. A number of leading companies operating in this market have also been profiled in the report in order to represent the competitive scenario, recent strategic developments, and the opportunities available for the entrance of new players. The report aspires to serve as a credible business document for the stakeholders connected to the value chain of the global cold insulation market.

Global Cold Insulation Market: Overview

Cold insulation involves low temperature application insulation methods. It is essentially a technology leveraged to lessen energy leakages from infrastructure to up energy efficiency. Cold insulation finds application in industries such as chemicals, refrigeration, oil and gas, and food and beverage. It is applied over processing lines such as tanks, pipes, valves, ducts, and fittings to bring down operational costs and improve process efficiency. The market for cold insulation can be segmented on the basis of the material into fiber glass, phenolic foam, polystyrene foam, and polyurethane foam. Of these, polyurethane foam holds maximum market share because of their versatility and unique properties such as lightness, low thermal conductivity, low water absorption, good strength, and high chemical resistance.

A report by TMR Research studies the global cold insulation market in details and offers key insights about it. For example, it furnishes a detailed qualitative analysis of factors driving and restraining the market and the promise it holds going forward. The report leverages popular analytical tools to gauge the competitive dynamics in the market. It lists leading players and examines their product offerings, market shares, and growth prospects.

Global Cold Insulation Market: Drivers and Trends

The increasing thrust on energy efficiency because of high energy costs is predicted to drive the global cold insulation market in the near future. Need to stem greenhouse gas emissions will also likely stoke the market along with policy support to enhance energy efficiency of public infrastructure. Besides, rising expenditure on research and development by savvy companies to develop insulation materials through sustainable raw material sources will also create opportunities for market participants in the near future.

To get Incredible Discounts on this Premium Report, Click Here @ https://www.tmrresearch.com/sample/sample?flag=D&rep_id=653

Further, rising fortunes of people leading to greater demand for air conditioning and refrigerating devices in developing economies is predicted to stoke demand for cold insulation materials. Rising demand for cryogenic equipment from oil and gas industry – the dominant end use industry – will possibly propel demand for cryogenic insulation materials. Additionally, food storage, LNG storage, chemicals storage, and some amount of cryogenic medical applications are also expected to generate demand in the near future.

Countering the growth in the market is the unstable prices of TDI, benzene, and MDI that are needed to produce polyurethane and polystyrene based insulation materials.

Global Cold Insulation Market: Regional Outlook

Geographically, Europe is a dominant region that holds maximum share in the global market for cold insulation because of stringent regulations framed by the authorities pertaining to sustainable materials and energy savings guidelines to bring down greenhouse gas emissions. Asia Pacific follows in the second position and is expected to outshine all other regions in terms of growth rate. Growth in the region will be primarily driven by high expenditure on construction in countries, namely India, China, and Japan and regulations in favor of improving energy efficiency of buildings. The market in China is also expected to be boosted by the emergence of domestic manufacturers. North America is another key market bolstered mainly by government efforts to up energy efficiency of public infrastructure. Presence of numerous thermal insulation companies in North America has also helped its growth.

Companies Mentioned in Report

To present a detailed assessment of the competition prevailing in the global cold insulation market, the report profiles important companies such as Evonik Industries, BASF SE, Dongsung Finetec Corporation, Bayer Material Science, the Dow Chemical Company, Fletcher Insulation Group, and Huntsman Corporation.

Request TOC of the Report @https://www.tmrresearch.com/sample/sample?flag=T&rep_id=653

About TMR Research:

TMR Research is a premier provider of customized market research and consulting services to business entities keen on succeeding in today’s supercharged economic climate. Armed with an experienced, dedicated, and dynamic team of analysts, we are redefining the way our clients’ conduct business by providing them with authoritative and trusted research studies in tune with the latest methodologies and market trends.

Contact:

TMR Research,

3739 Balboa St # 1097,

San Francisco, CA 94121

United States

Tel: +1-415-520-1050

0 notes