#Cotton Bags wholesale

Explore tagged Tumblr posts

Text

Unveiling the Future of Sustainable Fashion with Wholesale Canvas Bags

Elevate your brand and champion sustainability with GX Bags' canvas bags at wholesale prices. We blend rugged durability with refined aesthetics to craft the ultimate canvas bags that speak volumes of our commitment to a greener planet. Perfect for businesses, our bulk ordering system simplifies your operations while showcasing your brand on a global canvas. Choose us for a fusion of quality, versatility, and sustainability, making every bag a testament to your eco-friendly pledge. For more information, visit us at: https://www.gxbags.com/custom-canvas-bags.

0 notes

Text

Top Cotton Tote Wholesalers in German Market for Quality Bags

The German market is leading the way in sustainable solutions, and cotton tote bags are fast becoming a must-have for environmentally conscious businesses and consumers. Choosing the right wholesaler can make all the difference to your business's success and sustainability efforts. If you're looking for trusted Cotton Tote Wholesalers in German markets, then Ronak Industries is a name you should know.

Why cotton tote bags are an all-around business winner

These are so useful and yet make a statement. German businesses opt for cotton tote bags because they are ecologically friendly, durable, and bring huge branding value. Here's why they're good:

Eco-Conscious Appeal: As plastic pollution is an ever-growing concern, cotton tote bags are an environmentally friendly alternative with consumers.

Long-Lasting Durability: These bags are made from strong, high-quality cotton and are built to last through daily use.

Customizable for Branding: Ideal for displaying logos or unique designs, cotton totes serve as a mobile billboard for your business.

Things to look for in a Cotton Tote Bag

A smooth and successful partnership, then, is ensured through some essential factors in choosing a wholesaler.

Quality of Products

Your customers deserve the best, so work with wholesalers who use high-grade, organic cotton. Ronak Industries ensures that every tote bag meets top-quality standards.

Commitment to Sustainability

A trustworthy wholesaler will prioritize eco-friendly practices, from sourcing materials to manufacturing processes. Ronak Industries exemplifies this with its commitment to sustainable solutions.

Customization possibilities

Brand identity is important. Choose wholesalers that can offer extensive customization options to create personalized tote bags that resonate with your audience.

Price and quantity discount

It should be competitive, yet not, by any stretch of the imagination, sacrifice its quality at all. Ronak Industries aptly maintains a perfect balance between the quality and affordability requirements.

Reliability and Logistics

There is no debate over timely delivery and efficient logistics in wholesale partnerships. Ronak Industries always offers reliable service and, what is more, in time and smooth.

Ronak Industries - leading cotton tote wholesalers in German markets

Ronak Industries is one of the biggest cotton tote wholesalers in German markets. Good quality, environment-friendly practices, and customer-oriented have fetched them this reputation. Let's discover why-

Cotton tote bags Ronak Industries produces high-quality organic cotton tote bags that are both tough and useful yet fashionable. They create the bags for business needs as well as for consumer demand.

2. Green Manufacture The mission of Ronak Industries is pretty sustainable because they help businesses cut down their carbon footprint through the use of ethically sourced materials as well as reducing waste.

3. All custom options Ronak Industries understands that branding is one area that is worth investing in. The corporation allows businesses to come up with various designs that would make them market unique in the competitive German environment by their brand.

4. Competitive price for volume orders Ronak Industries can offer competitive prices for bulk orders without compromising on quality. They have a transparent pricing policy that ensures no surprise on the bill.

5. Quality of service and timely delivery

It comes with Ronak Industries as a team that values your time and business goals. Their effective logistics ensure that orders are going to reach their desired destinations on time.

Choosing the Right Cotton Tote Wholesalers in German: The Significance

It would make or break the reputation of your business by which wholesaler you choose. Quality cotton tote bags reflect the commitment you hold towards sustainability and customer satisfaction. Ronak Industries is outclassed in all respects, which makes them a reliable Cotton Tote Wholesaler choice among German markets.

Steps to Partner with Ronak Industries

Browse their catalogue: Browse through their collection of tote bags to find the styles that would suit your business needs.

Discuss Personalization: Work with their team to make bags that show the identity of your brand.

Quote Request: Obtain clear pricing for your bulk orders customized according to your needs.

Order your papers and enjoy smooth communication with guaranteed delivery services.

How Cotton Tote Bags can benefit your brand

Build customer loyalty Eco-friendly products such as cotton totes show that your business cares about the environment, which will create stronger connections with customers.

Increased Brand Awareness Custom designs will ensure that your brand is seen every time the bags are in use. It is like free advertising!

Meets market demand As people's awareness regarding the increasing demand for eco-friendly products grows, selling environmentally friendly cotton bags makes your business seem innovative.

Conclusion

All this can only be accomplished when one looks out for a good wholesaler. With unmatched quality, sustainability, and customer satisfaction, Ronak Industries are the Cotton Tote Wholesalers in German that top the list of German markets. Partnering with Ronak Industries can raise your brand and help make the world greener.

#Cotton Tote Wholesalers in German#Cotton tote wholesaler in german#cotton tote bag#cotton tote bags#cotton tote bags in german#cotton tote#tote bags in german

1 note

·

View note

Text

Guides for Eco-Friendly Gift Bags

DIY eco-friendly bags: Learn how to design the simplest and prettiest eco-friendly Christmas gift bags. Follow these tips for a thoughtful, sustainable approach to holiday gifting.

#gift bag wholesalers#gift bags with logo wholesale#goodie bags in bulk#bulk goodie bags#organic cotton bags supplier

0 notes

Text

Paramount Corporation is a renowned jute and cotton bag manufacturer and supplier in mumbai, india.Paramount Corporation’s vertical integration, state-of-the-art infrastructure, customization expertise, sustainability commitment, and quality assurance set them apart as an excellent choice for jute bag manufacturing. Their competitive pricing, timely delivery, customer-centric approach, and track record of excellence further solidify their position as a reliable and trusted partner for your jute bag manufacturing needs.

0 notes

Text

New sewing pattern <Kikyo> 3-in-1 Jacket

A new item is just released from Waffle Patterns. Meet the 3-in-1 Jacket <Kikyo> sewing pattern. This is a set of 3 items; an outdoor style jacket + zip-in/zip-out removable hood + zip-in/zip-out removable liner. Convenient and fun utility item for your trip, outdoor activity or daily use for all seasons!

You can make only an unlined utility jacket or a full set of items.

<design options>

-Jacket The jacket is unlined with a zipper+button opening. There are a lot of functional pockets. Please mix and combine the pocket designs as your usage.

The waist pockets have 2 kinds of hand-warmer layer designs. One is easy to sew patch type, and one is a welt type. The chest pocket designs are 2 types, too; flap+patch or zipper type.

My personal favourite is the zipper pocket on the chest and the sleeve pocket. I find they are very handy. I always put important things here like keyholders.

There are other functional details like a back belt, sleeve pleats, or shoulder tabs. You can skip some details.

The fit is loose-regular for room of the removable liner.

-Removable Liner The liner is zip-in / zip-out type. You can attach it to the shell at the front facing with zippers supported by small buttons and elastic loops.

It has a pocket and you can use as an inside pocket.

Of course, you can skip the liner. But it is very fun to add! And pretty easy to sew compared to the shell.

Btw, it is not really impossible to wear this liner as a jacket, especially if you make both inside and out clean. But the front area of the fitting goes off, so I do not recommend it officially.

-Removable Hood The zip-in / zip-out removable hood is lined and has a front button opening. You can attach it to the shell at the neckline on the collar by a zipper. The zipper is attached to the inside of the hood, so the hood layer comes outside of the garment. I found it is functional because when it rains, the rainwater should not sit between the layer of the Collar and hood. It has a string, but you can skip this.

Please make your creative style by mixing your favourite details!

<fabric recommendation>

<Shell> The pattern is drafted for woven fabrics. Light to medium weight durable but not too stiff woven jacket fabrics are recommended. like denim, gabardine, twill, canvas, etc.

Please consider the fabric with some body because it has to support the removable liner.

If your fabric is very thick/stiff, please consider using other lighter fabrics partly to avoid the thick layers, like pocket flaps or layered pocket parts.

Please choose a suitable one for your design intention and how you want to wear it. I strongly recommend checking with actual samples.

<Lining for shell> The hood and the pocket bags use lining fabric. Normal lining fabrics like plain cotton or acetate will work, but functional ones like quilted or faux fur will be fun, too.

<Removable liner> The liner constructed from; -Lining fabric(outside) -Thermal lining fabric (inside when you wear)

-Lining fabric(outside) Light weight lining fabric with a smooth texture will work like plain cotton or acetate etc.

-Thermal lining fabric (inside when you wear) Consider fabric like thin quilt, light weight fleece, flannel, or light faux fur, etc.

I recommend avoiding too heavy fabrics which cannot be supported by the shell. I made one with boiled wool. It is very warm but a bit heavy. A thick quilt may be too much volume. If you want to go with a volumy liner, maybe going 1-2 size up is a better idea.

For flannel and fleece versions, I used slippery fabric for the sleeve parts of the inside liner for comfort, but maybe no need to do that depending on your intention. If you use thick or fluffy fabric and worry about comfort about this part, please remember slippery fabrics are a safer choice.

<Sample fabrics in the photos> Here is a fabric list I used for the samples. I could not get all the shops which I bought from because some are too old or from wholesalers.

- Brick orange x plaid Shell ; cotton mixed twill Liner (thermal inside) ; wool mixed flannel Liner (outside) ; plain cotton lining

- Yellow sample Shell ; light weight water repellent outdoor fabric (from kniphal.nl) I think it is not for garments originally, but not very thick so it still worked. Liner (thermal inside) ; thin pre-quilted (thin insulation like under 80g backed with satin) Liner (outside) ; plain cotton lining

- khaki sample Shell ; cotton mixed twill (from nnstoffen.nl) Liner (thermal inside) ; light fleece (from nnstoffen.nl) Liner (outside) ; plain cotton lining

The fabric choice all depends on your design intention and how you want to wear it. I strongly recommend checking with actual samples as much as possible. Also researching store bought jackets will help your ideas.

<Size>

The fitting is loose-regular. I made just size for the yellow and khaki, but the orange one is one size smaller because the liner is thinner. I strongly recommend making a muslin for perfect fit. Some of my testers made 1 size larger with a mid-weight liner. If you use very fluffy volumy liner or want to wear thick sweater underneath, maybe considering 1-2 size larger is a good idea.

<Other materials>

-Zipper for attaching the liner I used general width (about 28mm) plastic teeth zippers. Because 2 zipper tapes come on the R-side facing(see the 1st photo), wide type zippers are not suitable.

-Zipper for attaching the hood This part is curved, so should be flexible. I used plastic teeth type and have no problem. Maybe some coil types are more flexible. But, I avoided coil type because I broke them often for some reason (maybe only me?)

Also, this jacket comes with many zipper tapes, I prefer plastic type because of the light weight.

-Other I attached the tabs on the pocket flaps. Those are pieces of folded twill tape(keperband).

<Other>

-Because the jacket is unlined, I finished the most seams with flat fell seam. If you do this, maybe it is better to add extra 2-3mm to the seam allowance. Some parts are not suitable for flat fell finish like bulky parts or armholes. I used bias tapes for armholes, and serger for bulky parts(like front yoke with flap).

-If you do not like visible zipper tapes, you can add twill tape or folded strips of shell fabric over the zipper tape.

-Some store bought jackets with a zip-on hood use a placket over the zipper. I think it is suitable if your fabric is thin. (I tried one and find too bulky)

********************* The sewing pattern includes 18 pages of instructions and all the sewing processes are described with detailed illustrations. The pattern files are available for both home printers (A4 or US letter) and copyshop(A0 format).

You can check other photos of this model on my Flickr page.

The 3-in-1 Jacket -Kikyo- (size 32 - 54) PDF sewing pattern is available here. Also in the Etsy shop.

Special discount price until 14th Oct. 2024 (CEST) with other popular patterns. No discount code is needed! The sale page is here.

***** Special offer for Paper pattern and free shipping Paper pattern + PDF option is available limited time. *The paper includes only the pattern, please print out the instruction by yourself or read it with your tablet or PC. The PDF + Paper listing page is here.

Enjoy your sewing!

(Japanese post here 日本語ポストはこちら).

**********************

follow me! Instagram /// Facebook /// Shop /// Pinterest /// Newsletter

83 notes

·

View notes

Text

Wholesale Lot Of Indian Block Printed Tote Bag, Cotton Handmade Marketing Bag, Grocery Carry Bag, Eco friendly Reversible Bag, Shoulder bags

#cotton tote bag#Quilted bag#reversible bag#marking bag#shoulder bag#grocery carry bag#tote bag#cotton shopping bga#handmade#womenclothing#shopping bag

2 notes

·

View notes

Text

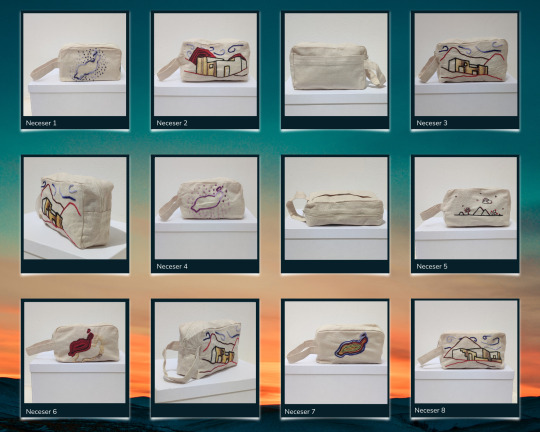

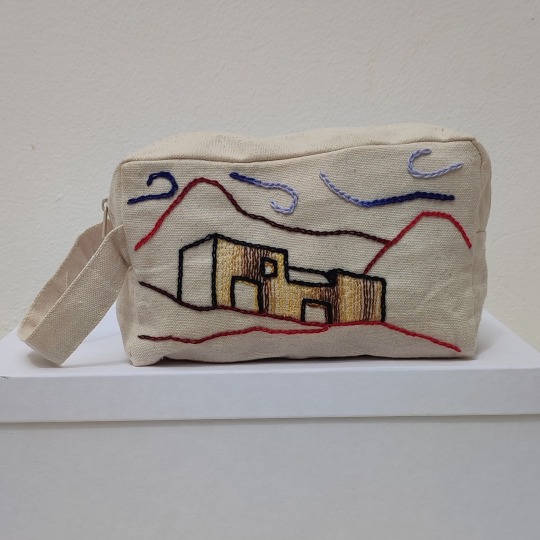

Neceser bordado a mano; Colección Lanzarote.

Siento a Lanzarote como una isla áspera.

Cuando llegué aquí, hace más de 20 años, sentía la isla suficientemente alejada para calmar un ruido que me angustiaba.

Horas de sol y sal templaron mi alma.

Ahora escucho al mar como balsa de aceite, cuando viene de fondo, cuando hay ventolera o hay calima. Se ve y se escucha diferente.

La silueta de la isla y su arquitectura de otro tiempo, son trazos fáciles de reconocer para residentes y visitantes que decidan regalar un producto funcional como recuerdo de Lanzarote.

Algunos de los bordados están inspirados en los dibujos de Santiago Alemán; Catedrático, ilustrador y profesor de la Escuela de Arte de Lanzarote, del cual fui alumna.

-Some of the embroideries are inspired by the drawings of Santiago Alemán; Professor, illustrator and teacher of the School of Art of Lanzarote, of which I was a student.-

Los neceser son de algodón 100% ecológico y elaborados en la India. Los compro a un mayorista español que importa productos naturales desde Asia. El estuche tiene una cremallera en la parte superior y un bolsillo en la parte posterior.

Sus medidas aproximadas son de 21 cm. de ancho, 7.50 cm. de largo y 11.50 cm. de alto.

-The toiletry bags are 100% organic cotton and made in India. I buy them from a Spanish wholesaler who imports natural products from Asia. The case has a zipper on the top and a pocket on the back.

Its approximate measurements are 21 cm. wide, 7.50 cm. long and 11.50 cm. high.-

Escribe y dime el número del neceser que quieres, tiene una oferta de 24,00 €. con envío incluido.

-Write and tell me the number of the vanity case you want, you have an offer of 24,00 €. with shipping included.-

www.piedadmaker.com

Catalogo https://wa.me/p/6864434433579645/34744402294

#Neceser#toiletry bag#natural fabrics#algodón natural#coottonnatural#bordadoamano#Lanzarote#hand embroidery#Piedad Maker

3 notes

·

View notes

Photo

Searching for large quantities of environmentally friendly bags? Your search ends here! @PuspaJute Bags provides sustainable packaging options. Take action now and become part of the eco-friendly movement! Don't pass up the opportunity to place a bulk order today! Grow your business with our products get your Logo Printed Bags nowMOQ- 500 Pieces.Our products are exported to the overseas markets of USA, UK, UAE, Germany, United Kingdom, Canada, Spain, France, Netherlands, Thailand, Ireland, Australia, New Zealand, Denmark, Singapore, Russia, South Africa, Italy & Japan and many other countries across the Globe.

Contact Us: [email protected]:

https://wa.me/09874061535

...#singapore#jutebag #jute #juterug #cotton #cottonbags #shopping #shoppingbag #ladiesbag #bulkorder #export #import #bagsforsale #ecofriendly #wholesalers #bulkorders #MarketPrice #onlineshoppingstore #pushpa #sustainable #canada #france #southafrica #newzealand #unitedkingdom #australia #markets #singapore

2 notes

·

View notes

Text

Looking for an eco-friendly and affordable way to promote your brand or reduce plastic waste? Look no further than GX Bags for custom canvas bags wholesale. Our bags are made from durable cotton material that is both biodegradable and recyclable. Order in bulk and add your company logo or tagline to create walking billboards for your business. Invest in quality and sustainability with us. For more information, please visit our website: https://www.gxbags.com/ or call us on 0433 121 179.

0 notes

Text

Tote, Rayon Fabric, Handmade, Handbag, Stitch Bag, Soft Bag, Shooping Bag, Market Bag, Jhola Bag, Colorful Bag, Large Tote, Gifts

We take Wholesale and Custom Order also.

The Indian Rayon Printed Women's Handbags from Rajasthan India. This Handbag is completely Indian Printed on good quality Rayon.

At the top of this bag we have attached a triangular leaf which makes it look even better. If you go shopping with this bag or go to buy any small item then it will suit you very well. Especially this bag will be very nice and comfortable for teenagers, its print and design have been kept according to the choice of teenagers.

Rayon Jhola Bag made by Indian Artisans, this cotton quilted shopping bag is totally unique and multi purpose. Use this for your grocery or as a travel bag. Perfect to suit all. Read more

#TotesAdorable#ToteBagLove#ToteLife#ToteBagStyle#ToteGoals#ToteObsessed#ToteBagAddict#ToteFashion#ToteBagSwag#TotesChic#sales#swimwear#welcome home#beachvibes#etsy#house coat robe#handmade

1 note

·

View note

Photo

I get a lot of startup founders wanting to make custom t-shirts. And when I suggest they go the organic cotton t-shirt wholesale route, so they can buy t-shirt blanks for a fraction of the price it would cost to develop them from scratch… their answer is usually, “Absolutely not.” “My brand is special,” they say. “My brand needs a custom fit and will have only premium fabrics. No one will take my brand seriously if I use pre-made shirts.” But as someone who has been in this industry for well over a decade, I can tell you that this mindset is so, so wrong. Learning how to understand the world of t-shirt blanks could be the difference between a brand that launches and is successful for years to come, and a brand that fizzles out before they get their first sale. So, if you have been thinking about starting a sustainable t-shirt brand, this post will cover everything you are going to need to know. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. What You’ll Learn: My inspiration for this post (because I know some of you like hearing the tea before I get into the fashion details) What are blanks, and how are they used in the industry The pros of using blanks The cons of using blanks Looking for blanks? – here is who I recommend NO TIME TO READ? CHECK OUT THIS 60 SECOND RECAP... I DIDN’T REALIZE I WAS ON THIS T-SHIRT SUPPLIER’S RADAR . . . Oh, little old me? Even though I should kind of be used to it by now, I still get surprised when people know who I am. A little bit ago, I even got stopped on my run because someone recognized me. Anyway. I get so many spammy emails from brands asking me to feature them on the blog. And I rarely respond. I just delete them. Because, honestly, they are a bunch of buzzwords and greenwashing. You know the type – we invented the most sustainable hoodie ever, and our clothes empower women . . . buzzword, buzzword, buzzword. But the other day, I got excited when I recognized the brand on the other end of the email for once – Original Favorites. Because, for years, I have recommended that my clients and students check out Original Favorites for organic cotton blanks. SO, WHAT ARE T-SHIRT BLANKS? Blanks are pretty much what they sound like. Blank garments that are ready for customizations like screen printing and or dying - they are literally a blank canvas. It’s kind of like buying a 5-pack of Hanes Deep V-necks (literally my uniform in college, along with some Hard Tail leggings and Ugg boots). Except it’s on a bigger scale, A LOT cheaper, and blanks are intended for brands to purchase and customize. How it all works is that a company, like Original Favorites, puts in a huge order for a few styles of t-shirt blanks. Because their order is so big, they get really good prices on the shirts throughout the entire supply chain. From fabric to sewing to shipping – the bigger the order, the better the prices. So, they take advantage of that. They then pass on those giant bulk order savings to you and take a small cut. So instead of you having to order tens or hundreds of thousands of the same shirt to get a good price, you can order just a few – like 10, and still get a much lower price than you would ever be able to get trying to produce 10 t-shirts on your own (I’ll break down the math in just a minute). Blanks are made to be customized. So, you can add your own designs and even labels. And the cool thing is, blanks aren’t just for t-shirts. You can buy blanks in almost any type of garment. Scarves, dresses, skirts, sweatpants, hoodies, polo shirts, tote bags – the options are limitless. 4 PROS OF USING T-SHIRT BLANKS 1. NO DEVELOPMENT COSTS A lot goes into developing a single t-shirt. And if everything is custom, there isn’t much you can do to cut development corners. You need to source everything, have patterns made and graded, and have various samples made to check the fit. Then, you need to make sure there are no issues for your customer. This gets pretty expensive, especially when you are making garments domestically. In the United States or Europe, this will all cost anywhere from about $400 - $1,000 just for a t-shirt. And developing more technical items could cost up to $3,000, depending on who you work with and how complex the garment is. The other thing worth mentioning is that development costs are fixed. So it costs the same whether you develop 100 shirts or 10,000 shirts. Here is how the development costs of a shirt break down... For example, say it costs you $500 to do all the development work and perfect your t-shirt and you only want to make 50 pieces. And in production, each piece is $10. Well, on top of the $10 production price, you would need to add in your development cost. So, $500 divided by 50 is $10. That means the real cost of each production piece is $10 plus $10 for development = $20 total. Now, if you are making 1,000 pieces, we would take the $500 divided by 1,000 pieces, and the development cost per piece would be just 50 cents. So, your total unit cost would be $10 plus $0.50, which is a total of $10.50 per piece. To be clear, I would never recommend a new startup brand buy 1,000 units on their first order. But hopefully, you get the point I am trying to make . . . development costs are costs that effect your bottom line, and they are expensive! So, by using blanks, new brands can completely cut out that development cost, lower the overall cost of their product, and still get low MOQs (minimum order quantities). 2. NO SURPRISES Even if you work with the best factories, I can promise you that things will not be perfect. In your sample and development process, there will always be small things you need to tweak or reevaluate. And that is exactly why you must have a development and sampling stage and can’t skip it. One of the most disheartening things for new brands is when they finally open their box of samples after months of work and feel like everything is wrong. Us industry pros know that it’s all part of the garment game – alterations need to be made and new samples need to be submitted for approval. But for newbies, it is sometimes so disheartening (and expensive) that they give up completely. The other scary thing that sometimes happens is brands will think they have a perfect sample, place their production order, and then realize something is wrong after they receive their bulk order. Now, they have hundreds of defective t-shirts to deal with. When you are buying t-shirt blanks, you know exactly what you are getting. You can buy a few (like 1 or 2), make sure you absolutely love them, and then buy larger quantities. And the best part? Every time you reorder, you have the assurance that you are getting the exact same item because someone else is taking care of all the quality assurance for you. 3. THE BEST PRICING ON SMALL ORDERS I already told you about how much money you can save in the development process by using t-shirt blanks. Now, let’s talk about how much more money you can save on production. Here is the reality of fashion and the secret behind why fast fashion and other big brands can offer such low prices. The more you buy, the more you save. That is for a few reasons. Let’s start with the fabric. When you give a fabric mill a huge fabric order, they can program the machines once and let them run day and night (new fabric orders require cleaning the machine, re-programming the machine, and in general, a lot of downtime). It is extremely efficient to run just one fabric for a long time for big orders. And the more efficient you can be, the faster things can get made, and the more money you can save. People become more efficient too Garment sewing at a factory becomes more efficient with larger orders as well. Factories like big orders because it gives their workers time to get good at making your product. If you only want 50 pieces, by the time the workers find their groove, the order is done. But with an order of 10,000 pieces, every day, the workers get better and better at making the product from all of the repetition. They also get quicker, so you get a lower price. Factory workers can go from making 15 pieces daily to 30 just by repetition and getting to know the product inside and out. On large orders, when workers become masters at making your product, the work becomes almost mindless for them. They can laugh, joke, and listen to podcasts while working. So, when you order blanks, you get a product that’s been replicated many times and produced more cheaply, thereby cutting production costs for you and your customer. Versus placing a small custom order with a factory, which means garment sewing will take longer and production costs will be higher. 4. GREAT FOR RE-ORDERS Worried about selling out fast and running out of product? When you have a custom order and want to order more, it can take quite a bit of time. You first need to re-order the fabric, which can take anywhere from a month to 3 months. Then, the shirts need to be sewn, which could take another month or two. With blanks, they are usually always in stock. So as soon as you need more, you can order them and get them immediately. This can be great for customer retention because, the longer customers have to wait for a product on backorder, the less likely they are to place their order. It’s also great for your cash flow because it allows you to get product out quickly and not tie it up while waiting for new items to be made. 2 MISCONCEPTIONS ABOUT USING T-SHIRT BLANKS 1. “NO CUSTOM FITS OR FABRICS MEANS MY CUSTOMER WON’T GET WHAT THEY NEED” “But Melanie, I have done all the research, and know that the exact shirt I want to develop isn’t out there right now. There is a need for my custom design.” Here is a hard dose of reality. I need you to check your ego and listen up. I get that you want to make the same shirt you have in your closet, but you want the sleeves 1 inch longer, the body 2 inches shorter, and the fabric just slightly heavier. Because, then, it will fit you perfectly. But here’s the thing. Most people who are buying your shirt do not have your exact measurements. When you make those sleeves 1 inch shorter, even though they’ll fit YOU perfectly, they might be way too short for someone else (read, a paying customer). The truth is, blank companies have done all the research. They are so confident in their research that they’re ordering probably millions of units of the same style. They know what sells. Lean into that expertise. “From operating their clothing brand, our founders realized the perennial items that sold-out every season were t-shirts and hoodies. They're the most accessible styles for any demographic and often the most-worn and loved by customers. We expanded our fleece styles from there but never ventured too far away from the classics and never changed our silhouette.” Rachel, Original Favorties What that means is that based on tons of sales data from their past and current businesses Orignal Favorites was able to assess what customer really want and make that. 2. “PEOPLE WILL THINK I'M NOT A ‘REAL’ BRAND” Yes, you will. Period. Full stop. If you are making printed t-shirts, all people really care about is the print or the logo. That is what they are buying. I have one student in LMCL who started her business using a print-on-demand service (basically, a company that will print your designs on blanks). And, IMO, it was the smart thing to do. While others were struggling with their first patterns, she was already testing product. And when her cohorts were finally just launching, she was already scaling and hiring her first employee. The bottom line. Using this method allowed this student to launch and scale quickly, and her customers didn’t even know she was cutting design corners. Think about it. The last time you bought a shirt with a cute design on it, did you email the brand to confirm they paid for the development and design of the shirt? No. Because that would be bananas. So, if you don’t shop that way, why do you think your customers would? I’m telling you, top brands do this to make their lives easier - and you should be considering it too! The other cool thing with blanks is that with a lot of them, their labels are meant to be ripped out, so you can sew in your own brand label. If you sew in your own label, this gives the final product a more branded and polished look. MY FAVORITE T-SHIRT BLANK SUPPLIERS Okay, now that you know all of the pros and cons of using shirt blanks and why I love them, here are a few of my favorites (move over Gildan and Bella Canvas) for women, men, unisex,and even kids! But one last tip before I go. With blanks fiber content is important for the type of printing you plan to use. If you want sublimation printing for vivid colors and detailed photoreal designs, you will probably need to use 100% polyester. So, if an eco product is what you’re after, screen prints, and some types of digital prints can be done on blends and pure cotton. ORIGINAL FAVORITES Organic cotton and Supima blank options at competitive prices. And, with this brand, you don't have to stress about your supply chain practices because you know you are getting sustainable t-shirt blanks! Bonus, they have pre-vetted resources to help you customize your blank apparel, like printers, dyers, and more! PS - Did you like the blanks in the pictures on this post? They are all from Orginal Favorties! HEA NOW Because they work with Chetna farms (which I love), these blanks are made using Indian Chetna 100% cotton, which is not just organic but also biodynamic! And, they even come in different colors to choose from, so you can skip the garment dying and print right on top CREATE FASHION BRAND For my European readers. These are some of the best quality blanks you can get in Portugal. They are known for their heavy cotton jersey fabric options. And as an added bonus, they even do low MOQ custom orders! DHARMA TRADING For everything blanks and wholesale clothing, not just short sleeve t-shirts – I’m talking dresses, scarves, tank tops, etc. So much blank variety on this site! WHAT DO YOU THINK? Are you going to give blanks a try for your startup clothing brand? Let me know in the comments! Source link

0 notes

Photo

I get a lot of startup founders wanting to make custom t-shirts. And when I suggest they go the organic cotton t-shirt wholesale route, so they can buy t-shirt blanks for a fraction of the price it would cost to develop them from scratch… their answer is usually, “Absolutely not.” “My brand is special,” they say. “My brand needs a custom fit and will have only premium fabrics. No one will take my brand seriously if I use pre-made shirts.” But as someone who has been in this industry for well over a decade, I can tell you that this mindset is so, so wrong. Learning how to understand the world of t-shirt blanks could be the difference between a brand that launches and is successful for years to come, and a brand that fizzles out before they get their first sale. So, if you have been thinking about starting a sustainable t-shirt brand, this post will cover everything you are going to need to know. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. What You’ll Learn: My inspiration for this post (because I know some of you like hearing the tea before I get into the fashion details) What are blanks, and how are they used in the industry The pros of using blanks The cons of using blanks Looking for blanks? – here is who I recommend NO TIME TO READ? CHECK OUT THIS 60 SECOND RECAP... I DIDN’T REALIZE I WAS ON THIS T-SHIRT SUPPLIER’S RADAR . . . Oh, little old me? Even though I should kind of be used to it by now, I still get surprised when people know who I am. A little bit ago, I even got stopped on my run because someone recognized me. Anyway. I get so many spammy emails from brands asking me to feature them on the blog. And I rarely respond. I just delete them. Because, honestly, they are a bunch of buzzwords and greenwashing. You know the type – we invented the most sustainable hoodie ever, and our clothes empower women . . . buzzword, buzzword, buzzword. But the other day, I got excited when I recognized the brand on the other end of the email for once – Original Favorites. Because, for years, I have recommended that my clients and students check out Original Favorites for organic cotton blanks. SO, WHAT ARE T-SHIRT BLANKS? Blanks are pretty much what they sound like. Blank garments that are ready for customizations like screen printing and or dying - they are literally a blank canvas. It’s kind of like buying a 5-pack of Hanes Deep V-necks (literally my uniform in college, along with some Hard Tail leggings and Ugg boots). Except it’s on a bigger scale, A LOT cheaper, and blanks are intended for brands to purchase and customize. How it all works is that a company, like Original Favorites, puts in a huge order for a few styles of t-shirt blanks. Because their order is so big, they get really good prices on the shirts throughout the entire supply chain. From fabric to sewing to shipping – the bigger the order, the better the prices. So, they take advantage of that. They then pass on those giant bulk order savings to you and take a small cut. So instead of you having to order tens or hundreds of thousands of the same shirt to get a good price, you can order just a few – like 10, and still get a much lower price than you would ever be able to get trying to produce 10 t-shirts on your own (I’ll break down the math in just a minute). Blanks are made to be customized. So, you can add your own designs and even labels. And the cool thing is, blanks aren’t just for t-shirts. You can buy blanks in almost any type of garment. Scarves, dresses, skirts, sweatpants, hoodies, polo shirts, tote bags – the options are limitless. 4 PROS OF USING T-SHIRT BLANKS 1. NO DEVELOPMENT COSTS A lot goes into developing a single t-shirt. And if everything is custom, there isn’t much you can do to cut development corners. You need to source everything, have patterns made and graded, and have various samples made to check the fit. Then, you need to make sure there are no issues for your customer. This gets pretty expensive, especially when you are making garments domestically. In the United States or Europe, this will all cost anywhere from about $400 - $1,000 just for a t-shirt. And developing more technical items could cost up to $3,000, depending on who you work with and how complex the garment is. The other thing worth mentioning is that development costs are fixed. So it costs the same whether you develop 100 shirts or 10,000 shirts. Here is how the development costs of a shirt break down... For example, say it costs you $500 to do all the development work and perfect your t-shirt and you only want to make 50 pieces. And in production, each piece is $10. Well, on top of the $10 production price, you would need to add in your development cost. So, $500 divided by 50 is $10. That means the real cost of each production piece is $10 plus $10 for development = $20 total. Now, if you are making 1,000 pieces, we would take the $500 divided by 1,000 pieces, and the development cost per piece would be just 50 cents. So, your total unit cost would be $10 plus $0.50, which is a total of $10.50 per piece. To be clear, I would never recommend a new startup brand buy 1,000 units on their first order. But hopefully, you get the point I am trying to make . . . development costs are costs that effect your bottom line, and they are expensive! So, by using blanks, new brands can completely cut out that development cost, lower the overall cost of their product, and still get low MOQs (minimum order quantities). 2. NO SURPRISES Even if you work with the best factories, I can promise you that things will not be perfect. In your sample and development process, there will always be small things you need to tweak or reevaluate. And that is exactly why you must have a development and sampling stage and can’t skip it. One of the most disheartening things for new brands is when they finally open their box of samples after months of work and feel like everything is wrong. Us industry pros know that it’s all part of the garment game – alterations need to be made and new samples need to be submitted for approval. But for newbies, it is sometimes so disheartening (and expensive) that they give up completely. The other scary thing that sometimes happens is brands will think they have a perfect sample, place their production order, and then realize something is wrong after they receive their bulk order. Now, they have hundreds of defective t-shirts to deal with. When you are buying t-shirt blanks, you know exactly what you are getting. You can buy a few (like 1 or 2), make sure you absolutely love them, and then buy larger quantities. And the best part? Every time you reorder, you have the assurance that you are getting the exact same item because someone else is taking care of all the quality assurance for you. 3. THE BEST PRICING ON SMALL ORDERS I already told you about how much money you can save in the development process by using t-shirt blanks. Now, let’s talk about how much more money you can save on production. Here is the reality of fashion and the secret behind why fast fashion and other big brands can offer such low prices. The more you buy, the more you save. That is for a few reasons. Let’s start with the fabric. When you give a fabric mill a huge fabric order, they can program the machines once and let them run day and night (new fabric orders require cleaning the machine, re-programming the machine, and in general, a lot of downtime). It is extremely efficient to run just one fabric for a long time for big orders. And the more efficient you can be, the faster things can get made, and the more money you can save. People become more efficient too Garment sewing at a factory becomes more efficient with larger orders as well. Factories like big orders because it gives their workers time to get good at making your product. If you only want 50 pieces, by the time the workers find their groove, the order is done. But with an order of 10,000 pieces, every day, the workers get better and better at making the product from all of the repetition. They also get quicker, so you get a lower price. Factory workers can go from making 15 pieces daily to 30 just by repetition and getting to know the product inside and out. On large orders, when workers become masters at making your product, the work becomes almost mindless for them. They can laugh, joke, and listen to podcasts while working. So, when you order blanks, you get a product that’s been replicated many times and produced more cheaply, thereby cutting production costs for you and your customer. Versus placing a small custom order with a factory, which means garment sewing will take longer and production costs will be higher. 4. GREAT FOR RE-ORDERS Worried about selling out fast and running out of product? When you have a custom order and want to order more, it can take quite a bit of time. You first need to re-order the fabric, which can take anywhere from a month to 3 months. Then, the shirts need to be sewn, which could take another month or two. With blanks, they are usually always in stock. So as soon as you need more, you can order them and get them immediately. This can be great for customer retention because, the longer customers have to wait for a product on backorder, the less likely they are to place their order. It’s also great for your cash flow because it allows you to get product out quickly and not tie it up while waiting for new items to be made. 2 MISCONCEPTIONS ABOUT USING T-SHIRT BLANKS 1. “NO CUSTOM FITS OR FABRICS MEANS MY CUSTOMER WON’T GET WHAT THEY NEED” “But Melanie, I have done all the research, and know that the exact shirt I want to develop isn’t out there right now. There is a need for my custom design.” Here is a hard dose of reality. I need you to check your ego and listen up. I get that you want to make the same shirt you have in your closet, but you want the sleeves 1 inch longer, the body 2 inches shorter, and the fabric just slightly heavier. Because, then, it will fit you perfectly. But here’s the thing. Most people who are buying your shirt do not have your exact measurements. When you make those sleeves 1 inch shorter, even though they’ll fit YOU perfectly, they might be way too short for someone else (read, a paying customer). The truth is, blank companies have done all the research. They are so confident in their research that they’re ordering probably millions of units of the same style. They know what sells. Lean into that expertise. “From operating their clothing brand, our founders realized the perennial items that sold-out every season were t-shirts and hoodies. They're the most accessible styles for any demographic and often the most-worn and loved by customers. We expanded our fleece styles from there but never ventured too far away from the classics and never changed our silhouette.” Rachel, Original Favorties What that means is that based on tons of sales data from their past and current businesses Orignal Favorites was able to assess what customer really want and make that. 2. “PEOPLE WILL THINK I'M NOT A ‘REAL’ BRAND” Yes, you will. Period. Full stop. If you are making printed t-shirts, all people really care about is the print or the logo. That is what they are buying. I have one student in LMCL who started her business using a print-on-demand service (basically, a company that will print your designs on blanks). And, IMO, it was the smart thing to do. While others were struggling with their first patterns, she was already testing product. And when her cohorts were finally just launching, she was already scaling and hiring her first employee. The bottom line. Using this method allowed this student to launch and scale quickly, and her customers didn’t even know she was cutting design corners. Think about it. The last time you bought a shirt with a cute design on it, did you email the brand to confirm they paid for the development and design of the shirt? No. Because that would be bananas. So, if you don’t shop that way, why do you think your customers would? I’m telling you, top brands do this to make their lives easier - and you should be considering it too! The other cool thing with blanks is that with a lot of them, their labels are meant to be ripped out, so you can sew in your own brand label. If you sew in your own label, this gives the final product a more branded and polished look. MY FAVORITE T-SHIRT BLANK SUPPLIERS Okay, now that you know all of the pros and cons of using shirt blanks and why I love them, here are a few of my favorites (move over Gildan and Bella Canvas) for women, men, unisex,and even kids! But one last tip before I go. With blanks fiber content is important for the type of printing you plan to use. If you want sublimation printing for vivid colors and detailed photoreal designs, you will probably need to use 100% polyester. So, if an eco product is what you’re after, screen prints, and some types of digital prints can be done on blends and pure cotton. ORIGINAL FAVORITES Organic cotton and Supima blank options at competitive prices. And, with this brand, you don't have to stress about your supply chain practices because you know you are getting sustainable t-shirt blanks! Bonus, they have pre-vetted resources to help you customize your blank apparel, like printers, dyers, and more! PS - Did you like the blanks in the pictures on this post? They are all from Orginal Favorties! HEA NOW Because they work with Chetna farms (which I love), these blanks are made using Indian Chetna 100% cotton, which is not just organic but also biodynamic! And, they even come in different colors to choose from, so you can skip the garment dying and print right on top CREATE FASHION BRAND For my European readers. These are some of the best quality blanks you can get in Portugal. They are known for their heavy cotton jersey fabric options. And as an added bonus, they even do low MOQ custom orders! DHARMA TRADING For everything blanks and wholesale clothing, not just short sleeve t-shirts – I’m talking dresses, scarves, tank tops, etc. So much blank variety on this site! WHAT DO YOU THINK? Are you going to give blanks a try for your startup clothing brand? Let me know in the comments! Source link

0 notes

Text

Thanksgiving Goodie Bag Inspiration

Create stunning Thanksgiving goodie bags that showcase your feelings! Use warm colors, thoughtful messages, and festive goodies to delight your loved ones this holiday season.

#turkey-designed goodie bags supplier#wholesale white cotton drawstring bag#wholesale goodie bags vendor#wholesale goodie bags manufacturer#wholesale goodie bags supplier

0 notes

Photo

I get a lot of startup founders wanting to make custom t-shirts. And when I suggest they go the organic cotton t-shirt wholesale route, so they can buy t-shirt blanks for a fraction of the price it would cost to develop them from scratch… their answer is usually, “Absolutely not.” “My brand is special,” they say. “My brand needs a custom fit and will have only premium fabrics. No one will take my brand seriously if I use pre-made shirts.” But as someone who has been in this industry for well over a decade, I can tell you that this mindset is so, so wrong. Learning how to understand the world of t-shirt blanks could be the difference between a brand that launches and is successful for years to come, and a brand that fizzles out before they get their first sale. So, if you have been thinking about starting a sustainable t-shirt brand, this post will cover everything you are going to need to know. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. What You’ll Learn: My inspiration for this post (because I know some of you like hearing the tea before I get into the fashion details) What are blanks, and how are they used in the industry The pros of using blanks The cons of using blanks Looking for blanks? – here is who I recommend NO TIME TO READ? CHECK OUT THIS 60 SECOND RECAP... I DIDN’T REALIZE I WAS ON THIS T-SHIRT SUPPLIER’S RADAR . . . Oh, little old me? Even though I should kind of be used to it by now, I still get surprised when people know who I am. A little bit ago, I even got stopped on my run because someone recognized me. Anyway. I get so many spammy emails from brands asking me to feature them on the blog. And I rarely respond. I just delete them. Because, honestly, they are a bunch of buzzwords and greenwashing. You know the type – we invented the most sustainable hoodie ever, and our clothes empower women . . . buzzword, buzzword, buzzword. But the other day, I got excited when I recognized the brand on the other end of the email for once – Original Favorites. Because, for years, I have recommended that my clients and students check out Original Favorites for organic cotton blanks. SO, WHAT ARE T-SHIRT BLANKS? Blanks are pretty much what they sound like. Blank garments that are ready for customizations like screen printing and or dying - they are literally a blank canvas. It’s kind of like buying a 5-pack of Hanes Deep V-necks (literally my uniform in college, along with some Hard Tail leggings and Ugg boots). Except it’s on a bigger scale, A LOT cheaper, and blanks are intended for brands to purchase and customize. How it all works is that a company, like Original Favorites, puts in a huge order for a few styles of t-shirt blanks. Because their order is so big, they get really good prices on the shirts throughout the entire supply chain. From fabric to sewing to shipping – the bigger the order, the better the prices. So, they take advantage of that. They then pass on those giant bulk order savings to you and take a small cut. So instead of you having to order tens or hundreds of thousands of the same shirt to get a good price, you can order just a few – like 10, and still get a much lower price than you would ever be able to get trying to produce 10 t-shirts on your own (I’ll break down the math in just a minute). Blanks are made to be customized. So, you can add your own designs and even labels. And the cool thing is, blanks aren’t just for t-shirts. You can buy blanks in almost any type of garment. Scarves, dresses, skirts, sweatpants, hoodies, polo shirts, tote bags – the options are limitless. 4 PROS OF USING T-SHIRT BLANKS 1. NO DEVELOPMENT COSTS A lot goes into developing a single t-shirt. And if everything is custom, there isn’t much you can do to cut development corners. You need to source everything, have patterns made and graded, and have various samples made to check the fit. Then, you need to make sure there are no issues for your customer. This gets pretty expensive, especially when you are making garments domestically. In the United States or Europe, this will all cost anywhere from about $400 - $1,000 just for a t-shirt. And developing more technical items could cost up to $3,000, depending on who you work with and how complex the garment is. The other thing worth mentioning is that development costs are fixed. So it costs the same whether you develop 100 shirts or 10,000 shirts. Here is how the development costs of a shirt break down... For example, say it costs you $500 to do all the development work and perfect your t-shirt and you only want to make 50 pieces. And in production, each piece is $10. Well, on top of the $10 production price, you would need to add in your development cost. So, $500 divided by 50 is $10. That means the real cost of each production piece is $10 plus $10 for development = $20 total. Now, if you are making 1,000 pieces, we would take the $500 divided by 1,000 pieces, and the development cost per piece would be just 50 cents. So, your total unit cost would be $10 plus $0.50, which is a total of $10.50 per piece. To be clear, I would never recommend a new startup brand buy 1,000 units on their first order. But hopefully, you get the point I am trying to make . . . development costs are costs that effect your bottom line, and they are expensive! So, by using blanks, new brands can completely cut out that development cost, lower the overall cost of their product, and still get low MOQs (minimum order quantities). 2. NO SURPRISES Even if you work with the best factories, I can promise you that things will not be perfect. In your sample and development process, there will always be small things you need to tweak or reevaluate. And that is exactly why you must have a development and sampling stage and can’t skip it. One of the most disheartening things for new brands is when they finally open their box of samples after months of work and feel like everything is wrong. Us industry pros know that it’s all part of the garment game – alterations need to be made and new samples need to be submitted for approval. But for newbies, it is sometimes so disheartening (and expensive) that they give up completely. The other scary thing that sometimes happens is brands will think they have a perfect sample, place their production order, and then realize something is wrong after they receive their bulk order. Now, they have hundreds of defective t-shirts to deal with. When you are buying t-shirt blanks, you know exactly what you are getting. You can buy a few (like 1 or 2), make sure you absolutely love them, and then buy larger quantities. And the best part? Every time you reorder, you have the assurance that you are getting the exact same item because someone else is taking care of all the quality assurance for you. 3. THE BEST PRICING ON SMALL ORDERS I already told you about how much money you can save in the development process by using t-shirt blanks. Now, let’s talk about how much more money you can save on production. Here is the reality of fashion and the secret behind why fast fashion and other big brands can offer such low prices. The more you buy, the more you save. That is for a few reasons. Let’s start with the fabric. When you give a fabric mill a huge fabric order, they can program the machines once and let them run day and night (new fabric orders require cleaning the machine, re-programming the machine, and in general, a lot of downtime). It is extremely efficient to run just one fabric for a long time for big orders. And the more efficient you can be, the faster things can get made, and the more money you can save. People become more efficient too Garment sewing at a factory becomes more efficient with larger orders as well. Factories like big orders because it gives their workers time to get good at making your product. If you only want 50 pieces, by the time the workers find their groove, the order is done. But with an order of 10,000 pieces, every day, the workers get better and better at making the product from all of the repetition. They also get quicker, so you get a lower price. Factory workers can go from making 15 pieces daily to 30 just by repetition and getting to know the product inside and out. On large orders, when workers become masters at making your product, the work becomes almost mindless for them. They can laugh, joke, and listen to podcasts while working. So, when you order blanks, you get a product that’s been replicated many times and produced more cheaply, thereby cutting production costs for you and your customer. Versus placing a small custom order with a factory, which means garment sewing will take longer and production costs will be higher. 4. GREAT FOR RE-ORDERS Worried about selling out fast and running out of product? When you have a custom order and want to order more, it can take quite a bit of time. You first need to re-order the fabric, which can take anywhere from a month to 3 months. Then, the shirts need to be sewn, which could take another month or two. With blanks, they are usually always in stock. So as soon as you need more, you can order them and get them immediately. This can be great for customer retention because, the longer customers have to wait for a product on backorder, the less likely they are to place their order. It’s also great for your cash flow because it allows you to get product out quickly and not tie it up while waiting for new items to be made. 2 MISCONCEPTIONS ABOUT USING T-SHIRT BLANKS 1. “NO CUSTOM FITS OR FABRICS MEANS MY CUSTOMER WON’T GET WHAT THEY NEED” “But Melanie, I have done all the research, and know that the exact shirt I want to develop isn’t out there right now. There is a need for my custom design.” Here is a hard dose of reality. I need you to check your ego and listen up. I get that you want to make the same shirt you have in your closet, but you want the sleeves 1 inch longer, the body 2 inches shorter, and the fabric just slightly heavier. Because, then, it will fit you perfectly. But here’s the thing. Most people who are buying your shirt do not have your exact measurements. When you make those sleeves 1 inch shorter, even though they’ll fit YOU perfectly, they might be way too short for someone else (read, a paying customer). The truth is, blank companies have done all the research. They are so confident in their research that they’re ordering probably millions of units of the same style. They know what sells. Lean into that expertise. “From operating their clothing brand, our founders realized the perennial items that sold-out every season were t-shirts and hoodies. They're the most accessible styles for any demographic and often the most-worn and loved by customers. We expanded our fleece styles from there but never ventured too far away from the classics and never changed our silhouette.” Rachel, Original Favorties What that means is that based on tons of sales data from their past and current businesses Orignal Favorites was able to assess what customer really want and make that. 2. “PEOPLE WILL THINK I'M NOT A ‘REAL’ BRAND” Yes, you will. Period. Full stop. If you are making printed t-shirts, all people really care about is the print or the logo. That is what they are buying. I have one student in LMCL who started her business using a print-on-demand service (basically, a company that will print your designs on blanks). And, IMO, it was the smart thing to do. While others were struggling with their first patterns, she was already testing product. And when her cohorts were finally just launching, she was already scaling and hiring her first employee. The bottom line. Using this method allowed this student to launch and scale quickly, and her customers didn’t even know she was cutting design corners. Think about it. The last time you bought a shirt with a cute design on it, did you email the brand to confirm they paid for the development and design of the shirt? No. Because that would be bananas. So, if you don’t shop that way, why do you think your customers would? I’m telling you, top brands do this to make their lives easier - and you should be considering it too! The other cool thing with blanks is that with a lot of them, their labels are meant to be ripped out, so you can sew in your own brand label. If you sew in your own label, this gives the final product a more branded and polished look. MY FAVORITE T-SHIRT BLANK SUPPLIERS Okay, now that you know all of the pros and cons of using shirt blanks and why I love them, here are a few of my favorites (move over Gildan and Bella Canvas) for women, men, unisex,and even kids! But one last tip before I go. With blanks fiber content is important for the type of printing you plan to use. If you want sublimation printing for vivid colors and detailed photoreal designs, you will probably need to use 100% polyester. So, if an eco product is what you’re after, screen prints, and some types of digital prints can be done on blends and pure cotton. ORIGINAL FAVORITES Organic cotton and Supima blank options at competitive prices. And, with this brand, you don't have to stress about your supply chain practices because you know you are getting sustainable t-shirt blanks! Bonus, they have pre-vetted resources to help you customize your blank apparel, like printers, dyers, and more! PS - Did you like the blanks in the pictures on this post? They are all from Orginal Favorties! HEA NOW Because they work with Chetna farms (which I love), these blanks are made using Indian Chetna 100% cotton, which is not just organic but also biodynamic! And, they even come in different colors to choose from, so you can skip the garment dying and print right on top CREATE FASHION BRAND For my European readers. These are some of the best quality blanks you can get in Portugal. They are known for their heavy cotton jersey fabric options. And as an added bonus, they even do low MOQ custom orders! DHARMA TRADING For everything blanks and wholesale clothing, not just short sleeve t-shirts – I’m talking dresses, scarves, tank tops, etc. So much blank variety on this site! WHAT DO YOU THINK? Are you going to give blanks a try for your startup clothing brand? Let me know in the comments! Source link

0 notes

Photo

I get a lot of startup founders wanting to make custom t-shirts. And when I suggest they go the organic cotton t-shirt wholesale route, so they can buy t-shirt blanks for a fraction of the price it would cost to develop them from scratch… their answer is usually, “Absolutely not.” “My brand is special,” they say. “My brand needs a custom fit and will have only premium fabrics. No one will take my brand seriously if I use pre-made shirts.” But as someone who has been in this industry for well over a decade, I can tell you that this mindset is so, so wrong. Learning how to understand the world of t-shirt blanks could be the difference between a brand that launches and is successful for years to come, and a brand that fizzles out before they get their first sale. So, if you have been thinking about starting a sustainable t-shirt brand, this post will cover everything you are going to need to know. BUT BEFORE WE GET STARTED... I love helping startup brand founders succeed, so I created a bunch of free guides that will help you with your business. They won’t be free forever, so make sure to grab them while you can. What You’ll Learn: My inspiration for this post (because I know some of you like hearing the tea before I get into the fashion details) What are blanks, and how are they used in the industry The pros of using blanks The cons of using blanks Looking for blanks? – here is who I recommend NO TIME TO READ? CHECK OUT THIS 60 SECOND RECAP... I DIDN’T REALIZE I WAS ON THIS T-SHIRT SUPPLIER’S RADAR . . . Oh, little old me? Even though I should kind of be used to it by now, I still get surprised when people know who I am. A little bit ago, I even got stopped on my run because someone recognized me. Anyway. I get so many spammy emails from brands asking me to feature them on the blog. And I rarely respond. I just delete them. Because, honestly, they are a bunch of buzzwords and greenwashing. You know the type – we invented the most sustainable hoodie ever, and our clothes empower women . . . buzzword, buzzword, buzzword. But the other day, I got excited when I recognized the brand on the other end of the email for once – Original Favorites. Because, for years, I have recommended that my clients and students check out Original Favorites for organic cotton blanks. SO, WHAT ARE T-SHIRT BLANKS? Blanks are pretty much what they sound like. Blank garments that are ready for customizations like screen printing and or dying - they are literally a blank canvas. It’s kind of like buying a 5-pack of Hanes Deep V-necks (literally my uniform in college, along with some Hard Tail leggings and Ugg boots). Except it’s on a bigger scale, A LOT cheaper, and blanks are intended for brands to purchase and customize. How it all works is that a company, like Original Favorites, puts in a huge order for a few styles of t-shirt blanks. Because their order is so big, they get really good prices on the shirts throughout the entire supply chain. From fabric to sewing to shipping – the bigger the order, the better the prices. So, they take advantage of that. They then pass on those giant bulk order savings to you and take a small cut. So instead of you having to order tens or hundreds of thousands of the same shirt to get a good price, you can order just a few – like 10, and still get a much lower price than you would ever be able to get trying to produce 10 t-shirts on your own (I’ll break down the math in just a minute). Blanks are made to be customized. So, you can add your own designs and even labels. And the cool thing is, blanks aren’t just for t-shirts. You can buy blanks in almost any type of garment. Scarves, dresses, skirts, sweatpants, hoodies, polo shirts, tote bags – the options are limitless. 4 PROS OF USING T-SHIRT BLANKS 1. NO DEVELOPMENT COSTS A lot goes into developing a single t-shirt. And if everything is custom, there isn’t much you can do to cut development corners. You need to source everything, have patterns made and graded, and have various samples made to check the fit. Then, you need to make sure there are no issues for your customer. This gets pretty expensive, especially when you are making garments domestically. In the United States or Europe, this will all cost anywhere from about $400 - $1,000 just for a t-shirt. And developing more technical items could cost up to $3,000, depending on who you work with and how complex the garment is. The other thing worth mentioning is that development costs are fixed. So it costs the same whether you develop 100 shirts or 10,000 shirts. Here is how the development costs of a shirt break down... For example, say it costs you $500 to do all the development work and perfect your t-shirt and you only want to make 50 pieces. And in production, each piece is $10. Well, on top of the $10 production price, you would need to add in your development cost. So, $500 divided by 50 is $10. That means the real cost of each production piece is $10 plus $10 for development = $20 total. Now, if you are making 1,000 pieces, we would take the $500 divided by 1,000 pieces, and the development cost per piece would be just 50 cents. So, your total unit cost would be $10 plus $0.50, which is a total of $10.50 per piece. To be clear, I would never recommend a new startup brand buy 1,000 units on their first order. But hopefully, you get the point I am trying to make . . . development costs are costs that effect your bottom line, and they are expensive! So, by using blanks, new brands can completely cut out that development cost, lower the overall cost of their product, and still get low MOQs (minimum order quantities). 2. NO SURPRISES Even if you work with the best factories, I can promise you that things will not be perfect. In your sample and development process, there will always be small things you need to tweak or reevaluate. And that is exactly why you must have a development and sampling stage and can’t skip it. One of the most disheartening things for new brands is when they finally open their box of samples after months of work and feel like everything is wrong. Us industry pros know that it’s all part of the garment game – alterations need to be made and new samples need to be submitted for approval. But for newbies, it is sometimes so disheartening (and expensive) that they give up completely. The other scary thing that sometimes happens is brands will think they have a perfect sample, place their production order, and then realize something is wrong after they receive their bulk order. Now, they have hundreds of defective t-shirts to deal with. When you are buying t-shirt blanks, you know exactly what you are getting. You can buy a few (like 1 or 2), make sure you absolutely love them, and then buy larger quantities. And the best part? Every time you reorder, you have the assurance that you are getting the exact same item because someone else is taking care of all the quality assurance for you. 3. THE BEST PRICING ON SMALL ORDERS I already told you about how much money you can save in the development process by using t-shirt blanks. Now, let’s talk about how much more money you can save on production. Here is the reality of fashion and the secret behind why fast fashion and other big brands can offer such low prices. The more you buy, the more you save. That is for a few reasons. Let’s start with the fabric. When you give a fabric mill a huge fabric order, they can program the machines once and let them run day and night (new fabric orders require cleaning the machine, re-programming the machine, and in general, a lot of downtime). It is extremely efficient to run just one fabric for a long time for big orders. And the more efficient you can be, the faster things can get made, and the more money you can save. People become more efficient too Garment sewing at a factory becomes more efficient with larger orders as well. Factories like big orders because it gives their workers time to get good at making your product. If you only want 50 pieces, by the time the workers find their groove, the order is done. But with an order of 10,000 pieces, every day, the workers get better and better at making the product from all of the repetition. They also get quicker, so you get a lower price. Factory workers can go from making 15 pieces daily to 30 just by repetition and getting to know the product inside and out. On large orders, when workers become masters at making your product, the work becomes almost mindless for them. They can laugh, joke, and listen to podcasts while working. So, when you order blanks, you get a product that’s been replicated many times and produced more cheaply, thereby cutting production costs for you and your customer. Versus placing a small custom order with a factory, which means garment sewing will take longer and production costs will be higher. 4. GREAT FOR RE-ORDERS Worried about selling out fast and running out of product? When you have a custom order and want to order more, it can take quite a bit of time. You first need to re-order the fabric, which can take anywhere from a month to 3 months. Then, the shirts need to be sewn, which could take another month or two. With blanks, they are usually always in stock. So as soon as you need more, you can order them and get them immediately. This can be great for customer retention because, the longer customers have to wait for a product on backorder, the less likely they are to place their order. It’s also great for your cash flow because it allows you to get product out quickly and not tie it up while waiting for new items to be made. 2 MISCONCEPTIONS ABOUT USING T-SHIRT BLANKS 1. “NO CUSTOM FITS OR FABRICS MEANS MY CUSTOMER WON’T GET WHAT THEY NEED” “But Melanie, I have done all the research, and know that the exact shirt I want to develop isn’t out there right now. There is a need for my custom design.” Here is a hard dose of reality. I need you to check your ego and listen up. I get that you want to make the same shirt you have in your closet, but you want the sleeves 1 inch longer, the body 2 inches shorter, and the fabric just slightly heavier. Because, then, it will fit you perfectly. But here’s the thing. Most people who are buying your shirt do not have your exact measurements. When you make those sleeves 1 inch shorter, even though they’ll fit YOU perfectly, they might be way too short for someone else (read, a paying customer). The truth is, blank companies have done all the research. They are so confident in their research that they’re ordering probably millions of units of the same style. They know what sells. Lean into that expertise. “From operating their clothing brand, our founders realized the perennial items that sold-out every season were t-shirts and hoodies. They're the most accessible styles for any demographic and often the most-worn and loved by customers. We expanded our fleece styles from there but never ventured too far away from the classics and never changed our silhouette.” Rachel, Original Favorties What that means is that based on tons of sales data from their past and current businesses Orignal Favorites was able to assess what customer really want and make that. 2. “PEOPLE WILL THINK I'M NOT A ‘REAL’ BRAND” Yes, you will. Period. Full stop. If you are making printed t-shirts, all people really care about is the print or the logo. That is what they are buying. I have one student in LMCL who started her business using a print-on-demand service (basically, a company that will print your designs on blanks). And, IMO, it was the smart thing to do. While others were struggling with their first patterns, she was already testing product. And when her cohorts were finally just launching, she was already scaling and hiring her first employee. The bottom line. Using this method allowed this student to launch and scale quickly, and her customers didn’t even know she was cutting design corners. Think about it. The last time you bought a shirt with a cute design on it, did you email the brand to confirm they paid for the development and design of the shirt? No. Because that would be bananas. So, if you don’t shop that way, why do you think your customers would? I’m telling you, top brands do this to make their lives easier - and you should be considering it too! The other cool thing with blanks is that with a lot of them, their labels are meant to be ripped out, so you can sew in your own brand label. If you sew in your own label, this gives the final product a more branded and polished look. MY FAVORITE T-SHIRT BLANK SUPPLIERS Okay, now that you know all of the pros and cons of using shirt blanks and why I love them, here are a few of my favorites (move over Gildan and Bella Canvas) for women, men, unisex,and even kids! But one last tip before I go. With blanks fiber content is important for the type of printing you plan to use. If you want sublimation printing for vivid colors and detailed photoreal designs, you will probably need to use 100% polyester. So, if an eco product is what you’re after, screen prints, and some types of digital prints can be done on blends and pure cotton. ORIGINAL FAVORITES Organic cotton and Supima blank options at competitive prices. And, with this brand, you don't have to stress about your supply chain practices because you know you are getting sustainable t-shirt blanks! Bonus, they have pre-vetted resources to help you customize your blank apparel, like printers, dyers, and more! PS - Did you like the blanks in the pictures on this post? They are all from Orginal Favorties! HEA NOW Because they work with Chetna farms (which I love), these blanks are made using Indian Chetna 100% cotton, which is not just organic but also biodynamic! And, they even come in different colors to choose from, so you can skip the garment dying and print right on top CREATE FASHION BRAND For my European readers. These are some of the best quality blanks you can get in Portugal. They are known for their heavy cotton jersey fabric options. And as an added bonus, they even do low MOQ custom orders! DHARMA TRADING For everything blanks and wholesale clothing, not just short sleeve t-shirts – I’m talking dresses, scarves, tank tops, etc. So much blank variety on this site! WHAT DO YOU THINK? Are you going to give blanks a try for your startup clothing brand? Let me know in the comments! Source link

0 notes

Photo