#Corrosion-resistant tanks

Explore tagged Tumblr posts

Text

Zincalume Silo Solutions – Durable, Corrosion-Resistant Storage by Royal Water Project

At Royal Water Project, we offer a premium range of Zincalume Silos designed to deliver long-lasting, efficient, and cost-effective storage solutions for various industrial and agricultural applications. Our Zincalume Corrugated Storage Tanks combine strength with advanced corrosion resistance, making them an ideal choice for bulk storage.

🔩 Advanced Zincalume Corrugated Steel Tanks

Our Zincalume Tanks are constructed using high-quality Zincalume corrugated steel, known for its superior durability and resistance to harsh environmental conditions. These Corrugated Steel Tanks are ideal for storing water, chemicals, grains, and other industrial materials safely and efficiently.

🛢️ Custom Zincalume Silos for Diverse Needs

As a trusted manufacturer of Zincalume Silos in India, we provide Custom Zincalume Silos tailored to meet specific industry requirements. Whether you need vertical or horizontal designs, small or large capacities, our engineering team ensures every silo meets performance, quality, and safety benchmarks.

✅ Corrosion-Resistant & Long-Lasting

Our Corrosion-Resistant Tanks are built for longevity, ensuring minimal maintenance and extended service life. These Industrial Storage Tanks are perfect for industries looking for robust and weather-resistant storage options.

🌍 Serving Pan-India with Reliable Installations

Backed by professional installation services and unmatched after-sales support, Royal Water Project is your trusted partner for Durable Storage Solutions in India. From design to deployment, we deliver excellence at every stage.

Why Choose Our Zincalume Silos?

High-strength corrugated Zincalume material

Excellent corrosion resistance

Customizable size and capacity

Quick and professional installation

Trusted by industries across India

📞 Contact Royal Water Project today to learn more about our Zincalume Silos and how we can provide the perfect storage solution for your industrial or agricultural needs.

#Zincalume Silo#Zincalume Corrugated Storage Tanks#Zincalume Tank#Royal Water Project#Zincalume Silos in India#Corrugated Steel Tanks#Custom Zincalume Silos#Corrosion-Resistant Tanks#Industrial Storage Tanks#Durable Storage Solutions in India

0 notes

Text

UK Enviro Systems manufactures premium Industrial Storage Tanks, offering high-strength, corrosion-resistant FRP tanks for chemicals, water, and waste storage. Our durable, leak-proof tanks meet industry standards, ensuring long service life and safety in harsh environments. Get customized solutions for your needs!

#Industrial Storage Tanks#FRP Storage Tanks#Corrosion-Resistant Tanks#Chemical Storage Solutions#Leak-Proof Storage Tanks#Durable Industrial Tanks#Water & Waste Storage Tanks#High-Quality FRP Tanks#Industrial Liquid Storage

0 notes

Text

UK FRP TANK specializes in premium Waste Water Storage Tanks, designed for durability and efficiency. Our FRP tanks provide a corrosion-resistant, leak-proof, and long-lasting solution for industrial and municipal wastewater management. Engineered for superior chemical resistance, they ensure safe and sustainable storage, helping industries comply with environmental standards.

#Waste Water Storage Tanks#FRP Waste Water Tanks#Industrial Wastewater Storage#Corrosion-Resistant Tanks#Leak-Proof Storage Tanks#Wastewater Treatment Tanks#Durable Water Storage Tanks#High-Performance FRP Tanks#UK FRP TANK#Industrial Water Management

0 notes

Text

High-Quality Industrial manufacturer and supplier Storage Tanks | gfstank

When it comes to commercial water storage tanks and industrial water storage solutions, GFS Tank stands as a trusted name in the industry. We specialize in providing high-quality industrial storage tanks that are durable, corrosion-resistant, and designed to meet the demands of various industries. Whether you need commercial water storage tanks in Pune or are looking for FM-approved fire tanks anywhere in India, GFS Tank has the right solution for you. Our extensive range includes UASB, GFL, and FM Approved tanks, making us a leading storage tank supplier in India. For businesses seeking the best storage tank manufacturer in India, GFS Tank offers unmatched quality and service. Explore our products and services at GFS Tank.

#Commercial water storage tanks#Commercial water storage tanks in Pune#Commercial water storage tanks in India#Gfstank#commercial & industrial water storage tank#Gfs Tank in India#Gfl#UASB#FM-approved fire tanks#FM Approved#High-quality industrial storage tanks#Corrosion-resistant tanks#Storage tank supplier in India#Storage tank manufacturer in India

0 notes

Text

Chemical Plastic Tanks: Durable, Corrosion-Resistant Storage Solutions for Industries

Chemical storage is a crucial aspect of various industries, requiring safe and durable containers to prevent leaks, contamination, and environmental hazards. Chemical plastic tanks have emerged as a reliable alternative to traditional metal storage options, offering superior corrosion resistance, cost-effectiveness, and versatility. In this guide, we’ll explore the benefits, types, applications,…

#Best plastic tanks for chemicals#Chemical Plastic Tanks#Chemical storage solutions#Corrosion-resistant plastic tanks#Industrial chemical storage tanks#Polyethylene chemical storage tanks

0 notes

Text

Unraveling the Mystery of Corrosion Control Treatments

Corrosion – the silent enemy of metal structures and equipment. It sneaks in unnoticed, gradually eating away at surfaces, compromising structural integrity, and causing costly damage. But fear not! With the right Corrosion Control Treatments, you can wage war against this formidable foe and protect your assets from its destructive grasp. Let's delve into the world of corrosion control treatments, exploring their importance, strategies, and the transformative impact they have on industries across the United States.

Understanding the Significance of Corrosion Control Treatments

Why are corrosion control treatments crucial for industrial assets? Imagine your metal equipment as knights in shining armor, vulnerable to the relentless assault of rust – corrosion control treatments act as their protective shield, preserving their strength and resilience against the ravages of time and the elements.

Preventing Structural Deterioration

Corrosion control treatments are not just about aesthetics; they're about preserving the structural integrity of metal assets. How do these treatments prevent deterioration? By forming a barrier that shields surfaces from moisture, oxygen, and corrosive agents, corrosion control treatments prevent the electrochemical reactions that lead to corrosion, ensuring that structures remain sound and functional for years to come.

Extending Service Life

Just as a well-maintained suit of armor can withstand the test of time, corrosion control treatments extend the service life of metal assets. How do they achieve this? By proactively addressing corrosion and preventing its spread, these treatments reduce the need for costly repairs and replacements, saving both time and money in the long run.

Strategies for Corrosion Control Treatments

Protective Coatings

Protective coatings are the frontline defense against corrosion, forming a durable barrier that shields metal surfaces from environmental exposure. What types of coatings are commonly used?

Epoxy Coatings: Known for their excellent adhesion and chemical resistance, epoxy coatings are ideal for protecting metal structures in harsh industrial environments.

Zinc-rich Primers: Zinc-rich primers provide sacrificial protection by corroding in place of the underlying metal, delaying the onset of corrosion and extending the lifespan of the coating system.

Polyurethane Coatings: Polyurethane coatings offer superior UV resistance and weatherability, making them suitable for outdoor applications where exposure to sunlight and moisture is a concern.

Cathodic Protection

Cathodic protection is another effective strategy for combating corrosion, particularly in buried or submerged metal structures. How does cathodic protection work? By introducing a sacrificial anode or impressed current system, cathodic protection creates a cathodic environment that inhibits corrosion, preserving the integrity of underground pipelines, storage tanks, and marine structures.

Benefits of Corrosion Control Treatments

Cost Savings

One of the primary benefits of corrosion control treatments is cost savings. How do these treatments save money? By preventing corrosion-related damage and the need for extensive repairs or replacements, corrosion control treatments help organizations minimize downtime, reduce maintenance costs, and prolong the lifespan of their assets.

Safety and Reliability

In addition to cost savings, corrosion control treatments enhance safety and reliability. How do they achieve this? By ensuring that metal structures and equipment remain structurally sound and free from corrosion-induced failures, these treatments minimize the risk of accidents, environmental contamination, and costly shutdowns, promoting a safer and more reliable operating environment.

youtube

Conclusion: Embracing the Power of Corrosion Control Treatments

Corrosion may be a formidable adversary, but with the right corrosion control treatments in place, you can protect your metal assets and ensure their longevity and performance. Whether it's applying protective coatings, implementing cathodic protection systems, or adopting other corrosion mitigation strategies, investing in corrosion control is an investment in the future resilience and reliability of your industrial infrastructure. So, don't wait for corrosion to strike – take proactive steps to safeguard your assets and keep them shining bright for years to come.

#Corrosion Resistant Industrial Paints#Professional Warehouse Painting Services#Advanced Surface Preparation Techniques#Durable Industrial Painting Solutions#Bespoke Industrial Coating Applications#Safety Line Marking Services#Industrial Tank Coating Specialists#Environmentally Friendly Painting Options#Heavy-Duty Industrial Paint Systems#Youtube

1 note

·

View note

Text

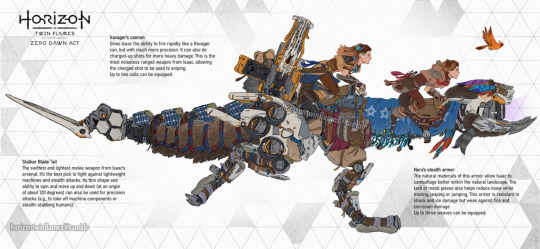

Horizon AU: Twin Flames - Isaac's final armor and weapons variations (Zero Dawn Act). Text transcription under the cut after the images!

REPOST, EDIT/USE OR FEED MY ART TO AI ISN'T ALLOWED

Edit: Updated some text on the Oseram and Banuk arts.

You can read Isaac's lore here: [LINK]

Will he use those variations in the story? Yes! :D hehe. Also, in this AU only Aloy wears Oseran armor while only Beta wears Carja armor, because Oseran's armor is too heavy and noisy for Beta's stealth strategies, while Carja's armor is too weak for Aloy's melee fighting style.

This AU has an ongoing fanfic! You can read on Ao3: [LINK]

Text transcription:

Ravager's cannon: It gives Isaac the ability to fire rapidly like a Ravager can, but with much more precision. It can also do charged-up shots for more heavy damage. This is the most noiseless ranged weapon from Isaac, allowing the charged shot to be used for sniping. Up to two coils can be equipped.

Stalker Blade Tail: The swiftest and lightest melee weapon from Isaac's arsenal. It's the best pick to fight against lightweight machines and stealth attacks. Its thin shape and ability to spin and move up and down (at an angle of about 120 degrees) can also be used for precision attacks (e.g., to take off machine components or stealth-stabbing humans).

Nora's stealth armor: The natural materials of this armor allow Isaac to camouflage better within the natural landscape. The lack of metal pieces also helps reduce noise while moving. This armor is resistant to shock and ice damage but weak against fire and corrosion damage. Up to three weaves can be equipped.

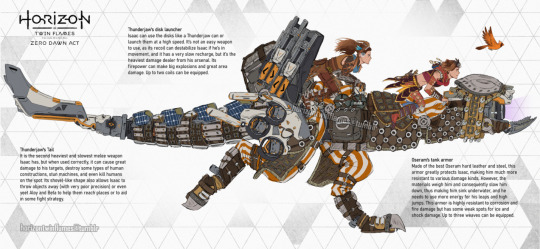

Thunderjaw’s Disk Launcher: Isaac can use the disks like a Thunderjaw can or launch them at a high speed. It’s not an easy weapon to use, as its recoil can destabilize Isaac if he’s in movement, and it has a very slow recharge, but it’s the heaviest damage dealer from the arsenal. Its firepower can make big explosions and great area damage. Up to two coils can be equipped.

Thunderjaw’s Tail: It is the second heaviest and slowest melee weapon Isaac has, but when used correctly, it can cause great damage to his targets, destroy some types of human constructions, stun machines, and even kill humans on the spot. Its shovel-like shape also allows Isaac to throw objects away (with very poor precision) or even yeet Aloy and Beta to help them reach places or to aid in some fight strategy.

Oseram's tank armor: Made of the best Oseram hard leather and steel, this armor greatly protects Isaac, making him much more resistant to various damage kinds. However, the materials weigh him and consequently slow him down, thus making him sink underwater, and he needs to use more energy for his leaps and high jumps. This armor is highly resistant to corrosion and fire damage but has some weak spots for ice and shock damage. Up to three weaves can be equipped.

Bellowback’ Snout: This weapon is an adapted version of the Bellowback’s ranged elemental weapon for Isaac. It gives him the ability to shoot fire or acid projectiles. It can also be used as a close-range defense weapon; hence, it can be used as a flamethrower or acid jet-like gun as well. Up to two coils can be equipped.

Stormbird’s Tail: Isaac can use this weapon like a Stormbird: an electric whip-like melee weapon, still keeping the shocking damage but in a much smaller range and potency. However, if not used cautiously, the whip can get stuck in places or be grabbed by bigger machines. This tail is also useful for Isaac to balance himself while climbing or walking in places such as metal columns in ruins. Isaac must have this tail equipped to be able to swim underwater correctly.

Carja’s speed armor: The sisters arranged the traditional Carja clothing adornments in a way that makes Isaac more aerodynamic, and the lightness of the materials also helps Isaac run faster, leap further, and jump higher than he normally could. Although pretty, the materials of this armor aren’t made for battle, leaving Isaac vulnerable to all kinds of damage - especially physical damage. Up to three weaves can be equipped.

Scorcher’s Mine Launcher: Aside from the normal mines a scorcher can use, this version of its weapon also has the option to use stick mines. Either version of ammos can be used on battle strategies of timed controlled explosions, as the mines won’t explode until they get hit. These mines have two versions: fire and electric explosions. Up to two coils can be equipped.

Frostclaw’s Front Paw: The closest Isaac will get to “grabby hands” so far. It’s the biggest physical damage dealer but the slowest melee weapon due to its heavy weight. Isaac can not just inflict heavy damage but also use the big hand to grab huge objects and machines way bigger than him. This weapon is so heavy that it may destabilize him during curves at high speed, compromise his balance while climbing, and increase the needed energy to sprint, jump, and leap.

Banuk Power Armor: The Sobecks learned with the Banuk crafting how to improve the energy flow and distribution on a machine. This armor increases Isaac's total stamina energy and reduces the needed charge to sprint, jump, or leap. The improved energy flow also helps increase the damage from Isaac’s melee and ranged weapons. However, the increase in the energy flow makes Isaac heat up way faster if not used correctly. Up to three weaves can be equipped.

#horizon au twin flames#alternative universe#horizon forbidden west#horizon zero dawn#sobeck sisters#beta sobeck#aloy sobeck#aloy#hfw beta#aloy horizon#aloy hfw#aloy fanart#aloy despite the nora#horizon fanart#hzd#hfw#hfw aloy#beta hfw#beta horizon#elisabeth hzd#hfw elisabeth#hzd elisabeth#elisabeth sobeck#elisabet sobeck#sobeck twins#isaac the watcher#horizon original character#horizon oc#horizon au#horizon fanfic

3K notes

·

View notes

Note

Quirk: Cape

This mutant quirk spawns a cape-like hide (which is a lighter shade of the user's skin color) from the user's shoulders, which covers their back and reach down near the user's feet. The cape acts as a resistant yet tearable shield and a makeshift glider, which gives the user situational defense and mobility. The user can manipulate the cape like an extra limb if attached and change its width, reaching down towards the user's wrists and its length up to 6 ft extra, similar to Ojiro's tail and Shoji's Dupli-arms. They can also manipulate its durability by making it flexible or stiff, making it easy to tear off the cape for strategic purposes while also doubling as a shield strong enough to tank high-speed projectiles, which it will suffer dents and scars from. Its capabilities allow the user to fend off opponents with defensive strategy while using it as a makeshift weapon if need be. However, it also has weaknesses, such as being only limited to defense and mobility, not having the capability to nullify explosive forces and corrosive elements when hit as a shield, and causing painful reactions to the user when torn off since it is attached to their skin, similar to pulling out hair or scabs. Overall, it is a basic quirk that allows its user to defend themselves and become better at wielding cape through training.

I think that a lot of this could work, but it could use some changes. I may just make it a regular cloak they create from their back. I'm certain that running around in a skin cloak would be bad for optics. That aside, the biggest issue is with the balance. All the applications of the Quirk are fine and make sense, but the downsides are too much relative to the power that the Quirk offers. The user can feel pain through it, it's limited in application and range, and it's weak to certain kinds of attacks, and the numerous tactical issues with having a cape. These all work for this kind of power, but they don't all work together. I think it'd work better if you expanded on the applications some more or if you removed some of the downsides. Preferably a bit of both. I would remove the pain downsides, as that kind of defeats the purpose of using it as a shield. Having it be a more minor issue, like the cape getting caught or grabbed by people, would fit a lot better with everything else. Maybe you could expand the range of it, either through removing it or giving the user the ability to grow it out, or they have such fine control over it they can use it on reaction, improving on the traits you already mentioned. Maybe try taking ques from characters like Doctor Strange and Spawn with their own cloaks.

7 notes

·

View notes

Text

Subject Classification: M-08-035

Damage Type: Null ⚪️

Danger Level: HELFER 🔵

Anomaly Type: Mineral

Discovery Classification: Expedition (08)

Department: MOTHRA Storage Facilities

Lead Researcher: Dr. Ironclad

Identification: Titanic Metal

Containment: ANM-035 bars are stored in different warehouses of the MOTHRA Institution. The "containment" must have a temperature regulator where the ambient temperature must remain at 22°C, never exceeding 120°C. If this happens, the emergency alarm should be activated immediately.

Titanic metal bars can be used to build secure cells for complex anomalies, materials or weapons, protective gear, and other related uses advantageous to MOTHRA.

Description: As of the writing of this file, ANM-035 is a set of 800 bars of a type of metal nicknamed "Titanic Metal." While its original color was white, it was observed that the metal bars could change to blue over time, a process similar to copper, which also makes the ore even more resistant.

The ANM-035 bars are extremely durable, being 60 times stronger than common metal, 49 times more resistant than tungsten, and 20 times more resistant than graphene. Upon further analysis, a significant mix of graphene atoms and hexagonal boron nitride was detected in the metal.

Regarding its durability, some tests were conducted:

Over 100 strikes with a machete were made against the bar, resulting in no scratches.

Some shots were fired at the bar, but the test was quickly canceled when it was noticed that the bullets ricocheted back.

ANM-014 attempted to break the bar but, after several strikes, complained that his "hand hurt." (ANM-014 typically manages to break titanium bars in half.)

ANM-035 was dropped from an airplane at an altitude of 12,000 meters, and the bar suffered no damage, though the surrounding environment did sustain significant damage.

ANM-032 was set to try piercing the bar with its beak. The instance failed to do so.

Multiple RPG shots followed by explosions were tested, but the bar remained unaffected.

A tank rolled over the bar several times, but nothing happened to it.

Finally, it was discovered that if ANM-035 is exposed to a temperature above 70°C, the ore tends to melt into an extremely corrosive and radioactive liquid.

ANM-035 can be used to create more powerful tools, utensils, and weapons (only melee weapons). A shield made from ANM-035 was built and is completely bulletproof and resistant to various other blows or attacks. Additionally, armor was constructed, and together with the shield, they are capable of repelling numerous attacks, including pecks from ANM-032 or attacks from humanoid ANMs.

The bars typically measure 55cm in length and 25cm in height, weighing approximately 500kg. All were found in a military bunker dating back to World War II in the USA.

5 notes

·

View notes

Text

Metal Welding Services in Miami: What to Know

Metal Welding Services in Miami: What to Know

If you’re searching for top-notch metal welding services near me in Miami, finding a professional and reliable service provider is key. Miami’s booming construction, automotive, and marine industries demand high-quality welding solutions for various projects. Let’s explore what makes metal welding services in Miami stand out and what you should look for when selecting a provider.

What Are Metal Welding Services?

Metal welding involves joining two or more metal parts through heat, pressure, or both. Welding is an essential process in industries like construction, automotive, manufacturing, and shipbuilding. Miami is home to a range of experienced welding professionals who cater to diverse project needs, including:

Structural welding: For buildings and bridges.

Automotive welding: For vehicle repairs and customization.

Marine welding: Specializing in ships and boats.

Custom metal fabrication: Tailored designs for unique projects.

Why Choose Professional Metal Welding Services in Miami?

Miami is a hub for skilled welders offering precision, durability, and expertise. Here are some key benefits of choosing local welding services:

Expertise in Various Techniques: Certified professionals in Miami use advanced techniques such as TIG, MIG, and stick welding for high-quality results.

Access to High-Quality Materials: Miami welding shops have access to durable metals like aluminum, stainless steel, and carbon steel.

Compliance with Local Regulations: Professionals ensure projects adhere to Miami’s building and safety codes.

Fast Turnaround Times: Local services minimize delays, ensuring your project is completed on time.

Types of Metal Welding Services Offered in Miami

Whether you’re working on a large-scale construction project or need small repairs, Miami’s welding professionals provide a range of services:

Residential Welding: Gates, fences, and railings.

Commercial Welding: Storefronts, signs, and structural supports.

Industrial Welding: Heavy machinery, pipelines, and tanks.

Repair Services: Fixing broken metal parts for boats, vehicles, or equipment.

How to Find the Best Metal Welding Services Near You

Finding the right welding service in Miami can be overwhelming. Here are some tips to help you choose the best provider:

Check for Certifications: Look for welders certified by organizations like the American Welding Society (AWS).

Read Reviews and Testimonials: Online reviews on platforms like Google and Yelp can give insights into the quality of service.

Compare Pricing: Request quotes from multiple providers to ensure competitive pricing without compromising quality.

Ask About Experience: Providers with extensive experience in your specific project type are likely to deliver better results.

Inspect Their Equipment: Modern, well-maintained equipment indicates a commitment to quality.

Top-Rated Welding Companies in Miami

Here are some highly recommended welding services in Miami to consider:

Miami Welding & Fabrication: Specializing in custom designs and structural welding.

South Florida Marine Welding: Experts in marine welding and aluminum fabrication.

Elite Welding Services: Known for precision welding and on-site services.

Benefits of Choosing Local Welding Services

Opting for a local welding service in Miami comes with several advantages:

Quick Response Times: Local businesses can provide on-site services faster.

Knowledge of Miami’s Environment: Welders understand the impact of Miami’s humid climate on metal structures.

Supporting Local Economy: Working with local providers strengthens the community.

Common Metals Used in Welding Projects

Miami welding services work with a variety of metals depending on the project requirements. Common metals include:

Aluminum: Lightweight and corrosion-resistant, ideal for marine and automotive projects.

Stainless Steel: Strong and resistant to rust, perfect for construction and decorative purposes.

Carbon Steel: Durable and cost-effective, suitable for heavy-duty industrial applications.

Copper: Used for electrical and plumbing applications.

How Much Do Metal Welding Services Cost in Miami?

The cost of metal welding services in Miami varies based on factors like:

Type of Project: Custom designs or large-scale industrial jobs may cost more.

Materials Used: Exotic metals like titanium are more expensive.

Complexity of Work: Intricate designs or repairs require more time and expertise.

On average, welding services in Miami range from $75 to $150 per hour, but it’s best to request a detailed quote for accurate pricing.

Tips for Maintaining Welded Metal Structures

To ensure the longevity of your welded metal structures, follow these maintenance tips:

Regular Inspections: Check for signs of wear, rust, or cracks.

Cleaning: Use appropriate cleaners to remove dirt and prevent corrosion.

Apply Protective Coatings: Paint or galvanize metal surfaces to enhance durability.

Avoid Overloading: Prevent excessive stress on welded joints.

Why Miami’s Climate Matters for Welding Projects

Miami’s coastal location and humid climate can affect metal structures over time. Professional welders in Miami understand these challenges and take necessary precautions, such as:

Using corrosion-resistant materials.

Applying protective coatings to combat rust.

Ensuring proper welding techniques to withstand environmental stressors.

Conclusion

When searching for metal welding services near me in Miami, it’s important to choose a provider with expertise, modern equipment, and a proven track record. Whether you need custom fabrication, industrial repairs, or marine welding, Miami’s professionals offer reliable solutions to meet your needs. By selecting a trusted local welding service, you can ensure your project is completed efficiently and to the highest standard.

2 notes

·

View notes

Text

We UK Enviro Systems is one of the top Polypropylene Tank manufacturers in India, offering high-quality, durable tanks for a wide range of industrial applications. Our polypropylene tanks are corrosion-resistant, lightweight, and designed for maximum efficiency. Whether you need tanks for chemical storage or water treatment, we provide reliable, long-lasting solutions tailored to your specific requirements.

#Polypropylene tanks#corrosion-resistant tanks#industrial storage tanks#durable tanks#water treatment tanks

0 notes

Text

UK FRP TANK specializes in high-quality Industrial Storage Tanks, designed for durability and efficiency. Our tanks ensure safe storage of chemicals, water, and other industrial liquids. With corrosion-resistant FRP material, they provide a long-lasting solution for diverse industries.

#Industrial Storage Tank#FRP Storage Tank#Chemical Storage Tank#Water Storage Tank#Corrosion-Resistant Tanks#Industrial Liquid Storage#High-Durability Tanks#Long-Lasting Storage Solutions#UK FRP TANK#Leak-Proof Industrial Tanks

0 notes

Text

I made fanart for one of my favorite kids' books, "The Great Undersea Search" by Kate Needham. It was published back in 95 and it is just terrific.

(the shark, dive cage, and part of the background are clipped from the book)

☆-----☆-----☆

I love the retro late-20th century ocean exploration aesthetic.

Fishing nets and sample jars full of noxious preservatives and well-used knives and improvised tools

Cargo pants and swimtrunks and work shirts and stretched tank tops and flip flops and blown-out sneakers and sweaty, salt-encrusted trucker and bucket hats and the worst tanlines you've ever seen. The kind of stuff "Wandering Island" characters can be seen wearing.

Bathyscaphes and DSVs and bubble windows and ROV arms

yellow and white and blue and red and green and black and exposed corrosion-resistant metals and the rust that gathers on them anyways

Stuff like this book and the old Lego diver sets from the 90s and the little VHS clips of Jacques Costeau they showed in your classroom, too.

I can see myself on a scientific expedition in the open ocean, eating simple shipboard meals of rice and fish and whatever fruit and vegetables we can scrounge. A worn P38 can opener and a dogeared copy of "Log from the Sea of Cortez" are my constant companions. My cargo pants become increasingly bedraggled and cuffed, and my t-shirts are covered in odd stains. We bring up lanternsharks and daggertooths in the nets. This one has only been recorded once by a Russian scientist almost 25 years ago, but he was wrong about certain elements of its anatomy. Eat your heart out, Dolganov. The non-scientific crew do not understand our hesitancy to trawl the seafloor.

#internalmelon#meloncore i guess#the great undersea search#digital composite#collage#trans art#glitch art#shark

10 notes

·

View notes

Text

Innovative Applications of Stainless Steel Plates in Various Industries

Stainless steel plates have become a cornerstone material in various industries, thanks to their remarkable properties such as corrosion resistance, strength, and versatility. These plates are used in a wide range of applications, from construction and manufacturing to food processing and energy production. Their ability to withstand extreme environments, coupled with low maintenance costs, makes them a go-to choice for engineers, designers, and manufacturers across the globe.

In this blog, we will explore the innovative applications of stainless steel plates in different industries, highlighting how they contribute to improved efficiency and durability. As a trusted stainless steel plates dealer in Vadodara and Gujarat, Tube Trading takes pride in offering top-quality materials to meet the diverse needs of businesses across sectors.

Properties That Make Stainless Steel Plates Stand Out

Before diving into the various applications, it is essential to understand the key properties that make stainless steel plates such a valuable asset in industrial applications:

Corrosion Resistance: One of the most significant advantages of stainless steel is its ability to resist corrosion, even in harsh environments. This property is essential for industries such as marine, chemical processing, and food production, where materials are constantly exposed to moisture, chemicals, or salts.

Strength and Durability: Stainless steel plates offer exceptional strength, allowing them to withstand high-pressure environments and heavy loads. This makes them ideal for construction, infrastructure, and manufacturing industries.

Heat Resistance: Stainless steel can maintain its properties even at high temperatures, making it a preferred choice for applications in energy, aerospace, and automotive industries.

Aesthetic Appeal: The smooth, shiny surface of stainless steel plates gives them a modern, sleek look, which is often used in architectural applications and interior design.

Hygiene and Easy Maintenance: Stainless steel is easy to clean and maintain, making it a popular choice in the food, beverage, and pharmaceutical industries where hygiene is of utmost importance.

With these properties in mind, let us delve into the innovative applications of stainless steel plates in various industries.

1. Construction and Architecture

Stainless steel plates are a vital component in the construction industry due to their structural integrity and aesthetic appeal. In architectural design, stainless steel is often used in building facades, roofing, cladding, and interior décor. Its corrosion resistance ensures long-lasting durability in outdoor environments, while its sleek appearance adds a modern touch to buildings.

Additionally, stainless steel plates are used in the construction of bridges, tunnels, and other infrastructure projects. Their strength makes them ideal for load-bearing structures, while their resistance to rust ensures that they can withstand environmental exposure without degradation over time.

As a leading stainless steel plates dealer in Vadodara, Tube Trading has supplied high-quality stainless steel plates for numerous construction projects, ensuring the safety and longevity of these structures.

2. Food and Beverage Industry

The food and beverage industry requires materials that meet stringent hygiene standards. Stainless steel plates are widely used in this sector for the construction of food processing equipment, storage tanks, and countertops. Their non-porous surface prevents the buildup of bacteria, ensuring that food and beverages are processed in a clean and safe environment.

In addition to hygiene, stainless steel’s corrosion resistance is crucial when handling acidic or salty foods. For instance, in dairy processing or brewing, stainless steel ensures that equipment does not corrode or affect the taste and quality of the final product.

As a stainless steel plates supplier in Vadodara, Tube Trading works closely with food manufacturers to provide plates that meet industry standards for cleanliness, durability, and efficiency.

3. Chemical and Petrochemical Industries

In chemical and petrochemical industries, equipment is exposed to harsh chemicals, high temperatures, and corrosive environments. Stainless steel plates are used to construct reactors, storage tanks, pipelines, and other processing equipment. Their ability to resist chemical corrosion and withstand extreme temperatures makes them an ideal material for these applications.

Moreover, stainless steel's non-reactive properties ensure that it does not contaminate the chemicals being processed, maintaining the purity of the products.

In Gujarat, a hub for the chemical and petrochemical industries, Tube Trading stands as a reliable stainless steel plates supplier. Our stainless steel products are specifically designed to handle the rigorous demands of these industries, ensuring safety and operational efficiency.

4. Automotive and Transportation Industry

Stainless steel plates play a crucial role in the automotive and transportation industries due to their strength, durability, and ability to withstand impact. They are used in the construction of vehicle frames, exhaust systems, and various components that require resistance to heat and corrosion.

In addition to cars, stainless steel plates are essential in the railway and aerospace sectors, where safety and performance are critical. For example, stainless steel is used in the construction of airplane fuselages, train carriages, and ship hulls to ensure that these vehicles can handle extreme conditions without compromising safety.

As a stainless steel plates dealer in Gujarat, Tube Trading has a longstanding reputation for supplying top-quality materials to automotive and transportation manufacturers, helping them build safe, reliable, and efficient vehicles.

5. Energy and Power Generation

The energy sector, including oil and gas, nuclear, and renewable energy, requires materials that can withstand high temperatures, pressure, and corrosive environments. Stainless steel plates are used in the construction of pipelines, turbines, heat exchangers, and reactors.

In nuclear power plants, stainless steel is used to build containment vessels and other critical infrastructure that must remain operational under extreme conditions. In renewable energy projects, such as solar or wind power, stainless steel is employed in equipment that needs to be durable and weather-resistant.

In oil and gas refineries, stainless steel plates are essential for constructing equipment that handles corrosive materials and extreme temperatures, ensuring that operations run smoothly without frequent repairs or replacements.

Tube Trading supplies the stainless steel plates in Vadodara and Gujarat needed by power generation and energy companies to maintain efficient and safe operations.

6. Marine Industry

The marine industry is particularly challenging due to constant exposure to saltwater, which can rapidly corrode many metals. Stainless steel’s corrosion resistance makes it a preferred material for building ships, offshore platforms, and marine equipment.

In addition to corrosion resistance, stainless steel plates offer high strength, ensuring that marine structures can withstand the harsh conditions of the open sea. From ship hulls to underwater pipelines, stainless steel is a trusted material that guarantees long-lasting performance.

As a stainless steel plates supplier in Gujarat, Tube Trading caters to the unique needs of the marine industry, providing materials that perform reliably in saltwater environments.

7. Medical and Pharmaceutical Industry

In the medical and pharmaceutical industries, maintaining a sterile and clean environment is crucial. Stainless steel plates are widely used in the manufacture of surgical instruments, medical devices, and hospital equipment due to their easy-to-clean and non-reactive surfaces.

Moreover, stainless steel is essential in the construction of pharmaceutical processing equipment where contamination must be avoided. Its non-porous surface ensures that bacteria and other contaminants do not accumulate, ensuring the safety and efficacy of pharmaceutical products.

Tube Trading, a leading stainless steel plates dealer in Vadodara, supplies high-grade stainless steel to meet the strict hygiene and safety standards of the medical and pharmaceutical sectors.

Conclusion

Stainless steel plates have proven their versatility and durability across a wide array of industries. From construction and food processing to energy production and healthcare, the innovative applications of stainless steel plates continue to grow, driven by their corrosion resistance, strength, and ease of maintenance.

As a trusted stainless steel plates dealer in Gujarat and Vadodara, Tube Trading is proud to supply high-quality materials that meet the diverse needs of these industries. Our commitment to quality and customer satisfaction ensures that our clients receive the best possible products to enhance their operations, improve safety, and boost efficiency.

For businesses in need of durable and reliable stainless steel plates, Tube Trading is your go-to supplier in Gujarat. Whether you are in construction, automotive, or food processing, we provide solutions that cater to your specific requirements, ensuring long-term success and operational excellence.

#Stainless steel plates dealer in Vadodara#Stainless steel plates dealer in Gujarat#Stainless steel plates supplier in Vadodara#Stainless steel plates supplier in Gujarat

4 notes

·

View notes

Text

Solar Water Heaters vs. Electric Water Heaters: A Comprehensive Cost Savings Analysis

When considering options for heating water in your home, solar water heaters and traditional electric water heaters present distinct advantages and disadvantages, particularly in terms of cost savings. This detailed comparison will explore various aspects of both systems, helping you make an informed decision.

Initial Investment

The initial investment for a solar water heater is generally higher than that of an electric water heater. Solar systems typically range from ₹18,000 to ₹60,000 or more, depending on factors such as capacity, type, and additional features. While this upfront cost may seem daunting, it’s essential to consider the long-term benefits and savings.

In contrast, electric water heaters usually have a lower initial price point, with basic models starting around ₹6,000. This affordability makes them an attractive option for many homeowners looking for immediate solutions without a significant financial commitment.

Overview of Jupiter Solar Water Heaters

Jupiter Solar is a prominent brand in the solar water heater market, particularly known for its efficient and sustainable solutions. Their products harness solar energy to provide hot water, making them an environmentally friendly alternative to traditional electric water heaters. Below is a detailed overview of the features, benefits, and types of solar water heaters offered by Jupiter Solar.

Call +91 9364896193, +91 9364896194 to order solar heaters

Solar Water Heaters vs. Electric Water Heaters

Key Features of Jupiter Solar Water Heaters

Energy Efficiency: Jupiter Solar water heaters utilize advanced technology to maximize solar energy absorption, ensuring high efficiency and reduced energy costs.

Durable Construction: These heaters are designed with robust materials, including corrosion-resistant tanks and high-quality solar collectors, which enhance their longevity and performance.

Variety of Models: Jupiter Solar offers a range of models to cater to different household needs, including options suitable for hard water areas and varying capacities.

Energy Expenses

One of the most significant advantages of solar water heaters is their reliance on renewable solar energy. This means that once installed, the cost of heating water can be drastically reduced, as sunlight is free and abundant. Homeowners can expect to save anywhere from 50% to 80% on their monthly water heating bills. This substantial reduction in energy costs can lead to significant savings over time.

On the other hand, electric water heaters depend on grid electricity, which can fluctuate in price due to various factors, including demand and fuel costs. As electricity prices rise, the operating expenses associated with electric water heaters can become a considerable burden on household budgets.

Return on Investment

The payback period for solar water heaters is often favorable, typically ranging from three to five years. After this period, homeowners can enjoy nearly free hot water for the lifespan of the system, which can last for 15 years or more with proper maintenance. This long-term financial benefit makes solar water heaters an appealing investment for those looking to reduce their overall energy costs.

In contrast, electric water heaters do not provide the same level of long-term savings. While they may be cheaper to install initially, the ongoing energy costs can accumulate quickly, leading to higher overall expenses over time.

Environmental Considerations

Solar water heaters are an environmentally friendly choice, harnessing the power of the sun to heat water without emitting greenhouse gases. This renewable energy source contributes to a reduction in your carbon footprint, making it an excellent option for eco-conscious consumers.

Electric water heaters, however, often rely on electricity generated from fossil fuels, which can contribute to pollution and climate change. By choosing a solar water heater, homeowners can play a part in promoting sustainability and reducing reliance on non-renewable energy sources.

Maintenance Requirements

In terms of maintenance, solar water heaters generally have lower upkeep costs. With fewer moving parts and a simple design, these systems require minimal maintenance to operate efficiently. Regular checks and occasional cleaning of the solar panels are typically sufficient to ensure optimal performance.

Electric water heaters, however, may require more frequent maintenance and repairs, particularly as they age. This can lead to additional costs that can diminish the overall savings associated with using electric systems.

Conclusion

In summary, while solar water heaters necessitate a higher initial investment, they offer substantial long-term cost savings, environmental benefits, and lower maintenance requirements compared to traditional electric water heaters. The decision between these two options ultimately depends on your financial situation, energy needs, and commitment to sustainability. By carefully weighing these factors, you can select the water heating solution that best aligns with your values and goals.

#solar water heater#solar energy#bangalore#india#solar#solar water heaters#bengaluru#solar water heating#solar heater#water#electric heater#SolarWaterHeaters#ElectricWaterHeaters#CostSavings#RenewableEnergy#EnergyEfficiency#SustainableLiving#EcoFriendly#GreenEnergy#WaterHeating#SolarEnergy#ElectricitySavings#HomeImprovement#EnergyConservation#CarbonFootprint#GovernmentIncentives#LongTermSavings#ElectricGeysers#HotWaterSolutions#SustainableHomes

2 notes

·

View notes

Text

Combating Marine Corrosion

Combating Marine Corrosion

A distinguishing feature of the marine environment is the universally present high salt content in the air and seawater which acts as a catalyst for the corrosion of offshore structures, such as offshore oil rigs, Intake Pump Houses in Thermal Power Plants Handling Sea Water. Corrosion damage in these environments is also influenced by the presence of other chemicals and various pollutants in the seawater, air and ports and many other areas. The corrosive forces inherent in marine environments pose significant threats to the integrity and longevity of metal structures. In this technical blog, we explore the complexities of corrosion, its detrimental effects, and the imperative role of corrosion protection strategies using Kirloskar Corrocoat in safeguarding marine assets.

Understanding Corrosion:

corrosion refers to the natural process of deterioration that occurs when metallic structures, components, or equipment are exposed to the harsh conditions prevalent in marine environments. This deterioration is primarily driven by electrochemical reactions between the metal and its surroundings, which typically consist of high levels of salt, moisture, and other corrosive agents present in seawater and marine atmospheres.

The Significance of Corrosion Protection in the Marine Industry:

The harsh conditions prevalent in marine environments make ships and metallic infrastructure susceptible to corrosion. Left unchecked, corrosion can compromise the structural integrity of vessels and structures, posing safety hazards and necessitating costly repairs. Mild steel, commonly used in marine construction for its affordability and strength, is particularly prone to corrosion, making corrosion protection imperative for the longevity of marine assets.

Protective Measures:

Manufacturers and operators within the industry take various precautions to protect their assets such as vessels and offshore structures from corroding. We will explore some of the standard methods utilised to protect metallic structures in the marine environment.

1) Design

Ship and infrastructure designers and operators make an effort to reduce corrosion and keep them secure, which aids in extending the lifespan of the structure or vessel. A few design features can assist in reducing the rate of corrosion and in turn reducing the required maintenance costs, including:

The placement of drains aids in the draining of water from decks, wells and low-lying areas. This eliminates a direct cause of corrosive activity.

In an effort to reduce galvanic corrosion, insulation is set up in areas where different metals are placed close to one another. Impressed current systems that monitor corrosive cell activity and apply currents to protective anodes can be installed to detect and manage corrosion.

Insulation is required in locations where temperature shifts, stopping thermal fatigue.

However, Design changes alone are often unreliable in fully protecting marine equipment from corrosion. While they may address specific vulnerabilities, they may not comprehensively account for the dynamic and multifaceted nature of marine environments. Maintenance challenges, cost considerations, and long-term effectiveness further contribute to their limitations. A holistic approach, combining design improvements with other corrosion mitigation strategies such as Glass flake Coatings and rigorous Maintenance, is essential for effective corrosion management in the marine industry.

2) Glass flake Coatings

Glass flake coating is widely regarded as the optimal solution for corrosion prevention in the marine industry due to its following outstanding properties.

Exceptional Barrier Protection:

Glass flake coatings are highly regarded for their ability to create a dense barrier, effectively shielding metal surfaces from corrosive elements such as saltwater and moisture.

Mechanical Strength:

These coatings exhibit exceptional mechanical strength, providing robust protection against abrasion, impact, and wear in the harsh marine environment.

Chemical Resistance:

Glass flake coatings demonstrate high resistance to a wide range of chemicals commonly found in marine environments, ensuring long-term durability. They effectively cover a wide pH range, from 1 to 14, making them suitable for various applications.

Strong Adhesion Properties:

With strong adhesion to metal substrates, glass flake coatings ensure the longevity and integrity of the coating system, even in challenging conditions.

Cost-effective Solution:

Glass flake coatings offer long-lasting corrosion protection with minimal maintenance requirements, providing a cost-effective solution for preserving marine assets.

Flexibility and Versatility:

Their flexibility allows for seamless coverage of complex marine equipment and structures, making them suitable for various applications.

A specially designed non-toxic, anti-fouling coating, called “Corrocoat Biofoul” forms a durable barrier that inhibits the attachment and growth of algae, barnacles, and other fouling organisms. By minimizing biofouling, this innovative coating helps maintain the efficiency and performance of marine equipment and structures, extending the service life of assets.

Kirloskar Corrocoat and Corrosion Management:

Kirloskar Corrocoat has developed product lines that ensure they offer superior corrosion resistance for equipment and infrastructure surfaces exposed to harsh marine environments. With the right protective coating, seawater is not aggressive – our coatings withstand long-term exposure to high levels of salt for extended periods.

#tube sheet coating#tank internal coating#corrosion resistance coating#impeller coating#glass flake coating#water box coating#epoxy glass flake coating

0 notes