#Copper Round Bars Exporters in India

Explore tagged Tumblr posts

Text

Copper Hex Bars Suppliers in India

Copper Hex Bars highlight predominant constitution, including the nearness of 99.99% of copper substance that makes these hex bars ideal for use in an extensive variety of electrical applications. We are Manufacturers, Exporters & Stockist of Copper Hex Bars in India. Further, our skill additionally enables us to convey these according to International Standards including DIN, ASTM, JIS, BS, EN, and IS as requested by the clients. We additionally offer these with electroplated tin plating wrap up.

We are the pioneer fabricator, stockist, and distributor of unendingly copper alloy hex bars in and around world. It has great assurance from marine water disintegrating and is great for an application that needs certification from wet use. It has higher security from stress disintegrating and breaking and has impact strength. Acidic attacks and impingement separation are not issues for this copper alloy. The copper grade has a higher level of physical and mechanical strength when exposed to high temperatures.

It has extraordinary oxidation catch in different circumstances, especially in seawater applications. Molybdenum is one of the conflicting parts, and it ordinarily avoids what many would consider a conceivable precipitation zone. These capacities are extraordinarily important in conditions where splitting and pitting crumbling are an issue. Compound adjustment, vehicle applications, building applications, and other organizing locales are noticeable purposes for Copper Alloy Hex Bars. These hex bars have splendid processability and fabricability, allowing them to be obligingly shaped into various standards, tasks, requirements, and complex plans at particularly low costs. The width of these hex bars goes from 4 mm to 75 mm, with lengths up to 6 m. Copper hex bars are very simple to process, drill, and saw. They're also used in things like base plates, keepsakes, furtGeneral Properties:

Size - 3/16" up to 3 5/16

Thickness - 4 mm to 75mm

Weight - Weight per feet in kg

Standard & Material -BS, IS, AMS, DIN & All International Standards her making work, and kitchenware.

#copper flat bars suppliers in mumbai#copper round bars suppliers in india#copper round bars exporters in india

0 notes

Text

Monel K500 Round Bar Exporters

Are you searching for top-notch corrosion-resistant materials in India? Look no further than Monel K500 Round Bars, the ultimate solution for your demanding industrial needs. Monel K500 is a high-performance alloy renowned for its exceptional corrosion resistance, making it the ideal choice for critical applications in various industries.

Unmatched Corrosion Resistance: Monel K500 is primarily composed of nickel and copper, with small additions of aluminum and titanium. This unique alloy composition offers extraordinary resistance to a wide range of corrosive environments, including seawater, acids, alkalis, and more. In India's diverse climate and industrial landscape, Monel K500 Round Bars ensure your equipment and structures remain robust and reliable for years to come.

Excellent Mechanical Properties: Beyond its corrosion resistance, Monel K500 offers outstanding mechanical properties. Its high tensile strength and durability make it suitable for a multitude of applications, from marine components to chemical processing equipment. Whether you're operating in the bustling cities of Mumbai or Chennai or the rugged terrains of the Himalayas, Monel K500 Round Bars are engineered to withstand the toughest conditions.

Exceptional Thermal Stability: Monel K500 retains its mechanical integrity even at elevated temperatures, making it perfect for high-temperature applications. Whether you're in the steel industry of Jamshedpur or the textile industry of Coimbatore, you can trust Monel K500 Round Bars to perform reliably in your specific environment.

Cost-Effective Solution: While Monel K500 Round Bars offer premium performance, they also provide long-term cost savings. Their extended service life and reduced maintenance requirements ensure that your investment pays off over time, allowing your business to thrive in the competitive Indian market.

Customized Solutions: We understand that every project is unique, which is why we offer customizable Monel K500 Round Bars to suit your exact specifications. Whether you require specific sizes, shapes, or quantities, we can deliver tailor-made solutions to meet your needs.

Compliance and Quality: Our Monel K500 Round Bars adhere to international quality standards, ensuring you receive a product of unmatched quality and consistency. We prioritize safety and reliability, making us the trusted choice for businesses across India.

In conclusion, Monel K500 Round Bars are the ideal choice for industries across India, offering unparalleled corrosion resistance, exceptional mechanical properties, thermal stability, cost-effectiveness, and customized solutions. Elevate your projects, enhance your equipment's longevity, and ensure the success of your business with Monel K500 Round Bars. Contact us today and experience the excellence of Monel K500 for yourself.

4 notes

·

View notes

Text

ASTM B221 Round Bars

The aluminum alloy used to make aluminum 6061 T6 Round Bar is well-known for its high heat capabilities and resistance to oxidation. One of the top producers and suppliers of aluminum 6061 T6 round bars, among other kinds, is Siddhgiri Tubes. Aluminum, chromium, titanium, magnesium, manganese, zinc, copper, iron, and silicon make up the substance. There are other trace elements.

Siddhgiri Tubes is a well-established supplier and exporter of Aluminium Alloy 6061T6 round bars in India. Renowned for offering top-quality products, they are a trusted name in the metal industry, catering to diverse sectors such as aerospace, automotive, and manufacturing with exceptional precision and reliability.

Product Overview:

Aluminium Alloy 6061T6 round bars are made from a heat-treated and artificially aged alloy, offering a combination of strength, light weight, and resistance to corrosion. These bars are used in a variety of applications, including structural and architectural components, marine equipment, and high-stress parts in machinery. Available in multiple sizes and grades, 6061T6 round bars are widely sought after for their versatility.

Specification Chart of Aluminium Alloy 6061 T6 Round Bars

Dimensions :- ASTM, ASME, AMS

Specifications:- ASTM B211, AMS 4115, 4116, 4117, 4128, AMS-QQ-A-225/8 & ASTM B221, AMS4150, 4160, 4161, AMS-QQ-A-200/8

Alloy:- 6061 – T6

Size:- 1/4” Dia – 16” Dia

Form:- Square , Round , Hex , Flat, Wire In Black & Bright Finish

Length:- Random, Fix & Cut Length

Finish:- Bright, Polish & Black

Advantages:

High Strength-to-Weight Ratio: Lightweight but with excellent strength, ideal for structural applications.

Corrosion Resistance: Resistant to oxidation, ideal for use in marine and industrial environments.

Machinability: Easily machined and formed to meet specific engineering requirements.

Versatility: Suitable for a wide range of applications due to its balanced properties.

Conclusion:

Siddhgiri Tubes stands out as a reliable exporter of Aluminium Alloy 6061T6 round bars, offering products that meet the highest standards of quality and performance. With exceptional durability, flexibility, and corrosion resistance, these bars are a top choice for industries needing robust, long-lasting solutions.

0 notes

Text

Best Round Bar Exporters In India

With Indian round bar exporters well-known over the world for their outstanding products, Nippon Alloys Inc. has emerged as a prominent player in the steel industry. Round bars are critical structural and equipment components that are widely utilised in the industrial, automotive, and construction industries. To fulfil the diverse demands of clients worldwide, our exporters provide a wide choice of round bars manufacturer of alloy steel, carbon steel, and stainless steel. They have built a great name in markets throughout Europe, Asia, and the Middle East due to their commitment to low costs and stringent quality standards.

Round bars are long, cylindrical products utilised in many different industries, such as infrastructure development, heavy machinery, automotive manufacturing, and construction. These round bars are made from a variety of materials, such as copper, alloy steel, carbon steel, and stainless steel. Because of their strength, resilience, and versatility, round bars are essential in modern manufacturing and construction.

Another significant market for round bars is the automotive industry. India, one of the world's largest automakers, has experienced an exponential surge in demand for quality round bars for use in axles, chassis, and engine parts. A large quantity of round bars was also required for the construction of train stock, signalling equipment, and rails in the country's developing railway network.

For More Detail

Website: nipponalloys.com

Product: Round Bar Exporter in India

Other Product: Alloy Round Bar Supplier in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Text

Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh

Arisa Impex is a leading Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Arisa Impex is a Manufacturer, Exporter and Supplier of stainless steel products, including stainless steel round bars, wires, rods, sheets, coils, pipes, flat bars, square bars, hexagonal bars, angles, flanges, and alloy steel. We offer a diverse range of stainless steel (SS) pipes and tubes available in various forms, material grades, wall thicknesses, types, dimensions, and specifications. All of our pipes and seamless tubes are crafted in accordance with Indian and international standards, including ASME, ASTM, ANSI, and AISI. Stainless steel is one of the most widely used metal alloys across various industries. It primarily consists of nickel and chromium, with additional elements such as copper, carbon, molybdenum, titanium, and nitrogen. Features of SS Pipe and Tubes: High Strength: Stainless steel offers excellent tensile strength, making it suitable for high-pressure applications. Temperature Resistance: Stainless steel pipes and tubes withstand extreme temperatures, making them suitable for both high-heat and low-temperature environments. Versatile Finishes: Available in various finishes, including polished, matte, and brushed, enhancing their aesthetic appeal and suitability for different applications. Lightweight: Compared to other materials like carbon steel, stainless steel is lighter, making it easier to handle and install. Hygienic Properties: Non-porous and easy to clean, stainless steel is ideal for sanitary applications in food and pharmaceutical industries. Application: Construction Food and Beverage Industry Pharmaceutical Industry Oil and Gas Automotive Marine Applications Chemical Processing Arisa Impex is a Supplier of Stainless Steel Pipe and Tubes in Andhra Pradesh including locations like Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Rajahmundry, Tirupati, Kadapa, Kakinada, Anantapur, Vizianagaram, Eluru, Ongole, Nandyal, Machilipatnam, Adoni, Tenali, Proddatur, Chittoor, Hindupur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Monel 400 Round Bars Exporters In India

Monel 400, a nickel-copper alloy renowned for its exceptional resistance to corrosion in a wide range of environments, is highly sought after for various industrial applications. Round bars made from Monel 400 are particularly valued for their combination of high strength, excellent mechanical properties, and resistance to acids, alkalis, and seawater. Indian exporters of Monel 400 round bars have earned a strong reputation in the global market for supplying high-quality products manufactured to stringent standards.

Manufacturers in India employ advanced production techniques and quality control measures to ensure that Monel 400 round bars meet or exceed international standards such as ASTM B164. These standards govern the chemical composition, mechanical properties, and dimensional tolerances of the round bars, ensuring consistency and reliability in performance across different applications. Monel 400 round bars are available in various diameters and lengths, catering to diverse industrial requirements.

Leading exporters like Ritinox Overseas, Jainex Steel & Metal, and Virwadia Metal & Alloys are known for their expertise in supplying Monel 400 round bars to customers worldwide. These exporters maintain comprehensive inventories and are capable of fulfilling both small-scale and bulk orders with efficiency and reliability. Additionally, they offer value-added services such as custom cutting, machining, and surface finishing to meet specific customer specifications and requirements.

Customer satisfaction is paramount for Indian exporters, and they prioritize timely delivery, competitive pricing, and responsive customer support. By adhering to the highest standards of quality and professionalism, these exporters have established long-term relationships with clients across various industries globally. When sourcing Monel 400 round bars from India, buyers can expect premium-quality products backed by technical expertise and excellent service throughout the procurement process.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Monel K500 Sheets & Plates Exporters In India#Monel 400 Round Bars Exporters In India#Monel K500 Round Bars Exporters In India

0 notes

Text

Monel Fasteners: Strength and Durability in Industrial Construction

Fasteners are of paramount importance when it comes to industrial construction. These seemingly small components play a crucial role in holding structures together. Among the myriad choices available, Monel fasteners stand out for their exceptional strength and durability. Jay Steel Corporation, we take pride in being a leading Monel fasteners manufacturer and supplier, offering unparalleled strength and durability for a wide range of industrial applications. Our commitment to quality extends to our diverse range of Monel alloy products, including Monel 400 Products and Monel K500 Products, available in various forms such as Monel Wire Mesh, Monel Round Bar, Monel Strips Sheet & Plats, Monel Tube & Pipe, Monel Fittings, Monel Flanges, and welding rods so that our customers can choose the one that will perfectly suit their project requirements!

In this blog post, we will explore the remarkable qualities of Monel fasteners and why they are considered a preferred choice in industrial construction.

Understanding Monel:

Monel is a nickel-copper alloy known for its corrosion resistance, high strength, and durability. The alloy primarily consists of nickel (approximately 67-70%) and copper (about 28-34%), with small amounts of iron, manganese, carbon, and silicon. The unique combination of these elements results in a material with superior properties that make it ideal for challenging industrial environments.

Strength Beyond Compare:

Monel fasteners are renowned for their remarkable strength, making them a reliable choice for heavy-duty applications in industrial construction. The high nickel content in Monel contributes to its exceptional tensile strength and resistance to deformation under extreme loads. This characteristic ensures that structures secured with Monel fasteners maintain their integrity even in the face of intense pressure and stress.

Corrosion Resistance:

One of the primary challenges in industrial construction is the corrosive nature of various environments. Monel fasteners excel in this regard, as they exhibit outstanding resistance to corrosion, particularly in harsh conditions such as exposure to saltwater, acids, and alkalis. This corrosion resistance significantly extends the lifespan of structures and reduces maintenance costs over time.

Durability in Diverse Environments:

Monel fasteners are versatile and well-suited for use in diverse industrial environments. Whether in chemical processing plants, marine applications, or oil and gas facilities, Monel's durability remains unwavering. The alloy's resistance to pitting, crevice corrosion, and stress corrosion cracking further enhances its suitability for challenging construction scenarios.

Temperature Stability:

Industrial construction often involves exposure to extreme temperatures, and Monel fasteners are designed to withstand such conditions. The alloy maintains its strength and structural integrity across a wide temperature range, making it a reliable choice for projects that face temperature fluctuations, whether in cold or scorching heat.

Ease of Fabrication and Installation:

Despite its impressive strength, Monel is also known for its malleability, which makes it relatively easy to fabricate into various fastener shapes. This characteristic simplifies the manufacturing process and contributes to the ease of installation, saving both time and resources in construction projects.

Final Words!

With a strong focus on quality Monel fasteners and alloy products, Jay Steel Corporation emerges as a leader in industrial construction. With a comprehensive range of Monel offerings and a global presence, we continue to contribute to the success of diverse industrial projects. Recognizing the global demand for top-notch Monel alloy products, Jay Steel Corporation serves as a reliable exporter to various countries, including Thailand, Singapore, Malaysia, India, Germany, Russia, France, Nigeria, USA, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, Jordan, Bahrain, the United Kingdom, and Italy. Our commitment to quality and competitive pricing has established us as a trusted partner in international markets. Choose us for your Monel Alloys Solutions that go beyond expectations, ensuring the resilience and longevity of your constructions.

#Monel Wire Mesh#Monel fasteners 400#Monel fasteners K500#Monel fasteners 400 Supplier#Monel fasteners K500 Exporters

0 notes

Text

🌟 Exciting News from Ozair Trade Link! 🌟

🔗 We're thrilled to announce that Ozair Trade Link is your go-to stockist for premium copper products! 🚀✨

🌈 Dive into our extensive collection, featuring: ✅ Copper Sheets ✅ Copper Plates ✅ Copper Pipes ✅ Copper Rods ✅ Copper Pipe Fittings

🛍️ Quality you can trust, service you deserve! At Ozair Trade Link, we take pride in offering top-notch copper solutions to meet all your needs. Whether you're a DIY enthusiast, a professional craftsman, or an industrial powerhouse, we've got you covered! 💪🔩

💡 Why choose Ozair Trade Link? 👉 Unparalleled Quality: Our copper products meet the highest industry standards. 👉 Extensive Inventory: Find everything you need under one roof. 👉 Expert Guidance: Our team is here to assist you with any questions or requirements.

📍 Visit us today or connect online to explore the world of superior copper products! 🌐✨

#OzairTradeLink #CopperProducts #QualityFirst #CopperSheets #CopperPlates #CopperPipes #CopperRods #PipeFittings #TrustedSupplier #QualityCraftsmanship #IndustrialSolutions

0 notes

Text

Monel K500 Round Bars Suppliers in Chennai

Divine Metal & Alloy is one of the largest exporter, manufacturer and supplier of Monel Alloy K500 Round Bars in India. Monel K500 Round Bars is a nickel-copper alloy, precipitation hardenable in the course of additions of titanium and aluminum. Monel K500 Bars (Monel K500 Rods) retains the outstanding corrosion resistant characteristics of Monel 400 and has better strength and hardness after precipitation hardening when compared with Alloy 400. Monel Alloy K500 Rods is particularly well suited for centrifugal pumps in the marine industry because of its high strength and low corrosion rates in high-velocity seawater.

Monel K500 Sheets & Plates Specificaton

GradeMonel K500 - UNS N05500, Nickel Alloy K500SpecificationASTM B 865 / ASME SB 865 / AMS 4676 / QQ N 286, ASTM B865 UNS N05500 Monel K500StandardASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS Alloy K500 Round bar sizeDiameter: 3-~800mmK500 Monel Hex Bar size2-100mm A/FMonel Alloy K500 Flat bar sizeThickness: 2 -100mmWidth: 10 to 500mmK500 Monel Alloy Square bar size4 to 100mmMonel K500 Angle bar size (in mm)3*20*20~12*100*100ASTM B865 Monel K500 Section3.0 to 12.0mm thicknessMonel WERKSTOFF NR. 2.4375 Channel Bar (in mm)80 x 40 to 150 x 75 section; 5.0 to 6.0 thicknessNickel Alloy K500 Hollow Bar (in mm)32 OD x 16 ID to 250 OD x 200 ID)2.4375 Monel K500 Billet Size1/2" to 495mm DiameterASTM B865 K500 Monel Rectangles Size33 x 30mm to 295 x 1066mmK500 Monel Round Bar FinishCold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & BlackAlloy Monel K500 Round Bar SurfaceBright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, HairlineMonel K500 round bar ConditionHardened & tempered, annealedK500 Monel Bar TechniqueHot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, RodMonel K500 Din 2.4375 Round Bar ToleranceH8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirementsUNS N05500 Monel Bar ProcessingBar cutting to 650mmOur Monel K500 round bar stockyad in IndiaPune, Gujarat, Noida, Tirunelveli, Thiruvananthapuram, Shivamogga, Hyderabad, Bengaluru, Bhubaneswar, Tiruchirappalli, Ahmedabad, Coimbatore, Chennai, Dhanbad, Agra, Chennai, Navi Chennai, Pimpri-Chinchwad,

0 notes

Text

Copper Round Bars Exporters

Copper Round Bars find utilized as a part of electrical applications and are produced in order to meet the requests of worldwide norms which incorporates accompanying the copper substance of 99.99%. The unrivaled complete of copper additionally makes it flawless to be utilized for hot and also frosty framing applications and also for applications requiring broad machining. We are Manufacturers, Suppliers & Stockist of Copper Round Bars in India.

Chhajed Steel and Alloys Pvt. Ltd. are universally managing as a solid and reliable industry with exceptionally enormous quantities of customers. We as a client centered are offering the great nature of Copper Round Bars. We are offering the bars in different widths and wall thickness according to the client's specification requirements. Additionally, we are offering quick delivery by requesting transfer and in great shape according to your material requirements.

General Properties:

• Size - 12' Standard Lengths

• Thickness - 4 mm to 150mm

• Weight - Weight per feet in kg

• Standard & Material -ASTM B-187, ASTM B-133; Available in 102, 110 and 122 Alloys

Chhajed Steel & Alloys Pvt Ltd.

Contact Address Office No 7, 42/46, Mughbat Lane, Shantaram Chawl, Mumbai-400 004. Call: + 022-2386 1894 / 23893666 T:+91-982-151-3630 / 932-111-3630 Email: [email protected] Fax No: 091-022-2386 4049\

#copper round bars manufacturers in india#copper flat bars suppliers in mumbai#copper round bars exporters in india

0 notes

Text

Copper Nickel 90/10 Round Bars Suppliers in India

Sankalp Alloys Overseas is one of the most outstanding exporter, manufacturer and supplier Copper Nickel Cu-Ni 90/10 (C70600) Round Bars in India. It has stunning use resistance. At any rate, it shows astounding security from impingement attack. Copper Nickel 90/10 Round Bars has striking hot and cold convenience. Cu-Ni 90/10 Round Bars are being produced by delineating and reshaping, welding. They are being used for a few purposes, for instance, in condensers, condenser plates, distiller tubing, evaporator and heat exchanger tubing, ferrules, salt water redirecting.

ASTM B111 Copper Nickel 90 / 10 Bright Bar, Copper Nickel 90 / 10 Forged Round Bar, Cu-Ni DIN 2.0872 Hex Bars, Cupro Nickel 90 / 10 Forged Bar Stock, Cu-Ni 90/10 Cold Finished Bars Suppliers in India.

Our UNSC70600 Round Bars are comparably used for Condenser Plates, Condensers, Weld Light Tips, Power Exchanger Burdens, Valve Bodies, Evaporator Burdens, Strain Vessels, Distiller Burdens, Siphon Impellers for Oil Refining, Ferrules, Evaporators, and that is just a short glance at something greater. These are accessible to our basic clients in different level of distances across, wall thicknesses and sizes at a lot of sensible rates.

AISI Copper Nickel Cu-Ni 90/10 Round Bars Specification

Dimension : EN, DIN, JIS, ASTM, BS, ASME, AISI

Specification : ASTM B111 / ASME SB111

Range : 5 mm To 500 mm thick in 100 mm TO 6000 mm

Copper Nickel 90/10 Round Bars Range : 6 mm to 120 mm.

Copper Nickel 90/10 Square Bars Range : 10 mm to 200 mm.

Length : 100 mm to 3660 mm Long

Other Grade : 17-4PH, 15.5 PH,

Material Grade : AISI/SAE 4140, 4130, 4340, 8620, 8640

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc.

Our Copper Nickel Cu-Ni 90/10 Round Bars conforms to NACE MR0175/ISO 15156.

0 notes

Text

Aluminium Alloy 2024 Round Bars Manufacturers In India

Siddhgiri Tubes is a renowned Manufacturer, Supplier, Stockist, and Exporter of Aluminium Alloy 2024 Round Bars. We specialize in crafting and delivering a diverse range of Aluminium Alloy 2024 Round Bars to our valued clientele. Our round bars are meticulously manufactured using top-grade alloys and other alloying elements, ensuring superior quality and performance. These round bars exhibit a range of appearances, from a dull grey to a rough surface texture. Understanding Aluminum Alloy 2024 Aluminium Alloy 2024 is an aluminium-copper alloy, primarily composed of aluminium (90.7-94.7%), copper (3.8-4.9%), manganese (0.3-0.9%), and magnesium (1.2-1.8%). This specific composition lends the alloy its remarkable strength and machinability. It is often used in applications where high strength-to-weight ratios are crucial. Key Properties of 2024 Aluminium Alloy Round Bars

High Strength: One of the standout features of Aluminium Alloy 2024 is its high strength. This makes it ideal for structural components in the aerospace and automotive industries.

Excellent Fatigue Resistance: The alloy's ability to withstand repeated stress cycles without significant degradation makes it perfect for use in aircraft structures and other high-stress environments.

Good Machinability: Aluminium 2024 round bars are easy to machine, allowing for the creation of complex shapes and components with precision.

Corrosion Resistance: While not as corrosion-resistant as some other aluminium alloys, 2024 offers adequate protection in most environments, especially when treated with anodization or protective coatings.

Benefits of Choosing Aluminium Alloy 2024 Round Bars Siddhgiritubes are a trusted provider of Aluminium Alloy 2024 round bars, offering high-quality products that meet industry standards. Here are some benefits of choosing Siddhgiritubes:

Quality Assurance: Siddhgiritubes ensures that their products undergo rigorous quality checks to meet the required specifications and standards.

Wide Range of Sizes: They offer a variety of sizes to cater to different industrial needs, ensuring you find the right fit for your project.

Custom Solutions: Siddhgiritubes provides customized solutions to meet specific project requirements, ensuring optimal performance and efficiency.

Specification Chart of Aluminium Alloy 2024 Round Bars Hardness 8 HW Grade and Specification 6000 Series, ASTM B 211 ASME SB 211 / ASTM B 619 ASME SB 619 Temper T3 - T8 Size Ranges 15- 150" NB IN Al (Min) 98% ASME B36.10M Schedule Chart SCH5, SCH10, SCH40, STD, SCH80, SCH120, SCH160 Alloy Or Not is Alloy Surface Treatment Anodized, Powder Coated, Mill Finished Most popular types Seamless / ERW / Welded / Fabricated Forms / Shapes Square, Round Pipe End Forming Treaded Both Ends, Plain One End, Treaded One End, Bevel both ends, Bevel large end, Bevel one end, Beveled end, Plain Both Ends, Bevel small end, Beveled One end Technique Extruded or seamless

Conclusion These round bars find extensive applications across numerous industries. Our Aluminium Alloy 2024 Round Bars are available in various types, including AMS 4121 round bars, hexagonal bars, hot-rolled bars, bars and rods, cold-rolled round bars, cold-drawn bars, round rods, hot finish bars, half-round bars, cold finish round bars, and pump shaft quality bars.

0 notes

Text

Types Of Silver Steel Round Bars

We at Triroundbar.com are one of the top Silver Steel Round Bar Manufacturers in India. Triroundbar.com is considered to be one of the pioneer organizations that manufacture and export a wide range of Silver Steel Round Bars. Silver Steel Round Bars products are also available from us as suppliers, dealers, and stockholders. We are committed to producing products that are made from the highest quality raw materials using the latest technology available today. We also provide our customers with Silver Steel Round Bars that have the finest quality finishing and are durable for long life, high pressure, and zero defects.

In Mumbai, India, we provide our clients with a wide range of Silver Steel Round Bars Suppliers, Manufacturers, and Stockholders

As a manufacturing company, Triroundbar.com manufactures quality Silver Steel Round Bars, which are solid solution strengthened and commercially pure wrought materials with a wide range of mechanical properties over a wide range of temperatures as well as excellent resistance to many corrosives, particularly hydroxides. These materials are highly resistant to corrosion over a wide range of temperatures.

Triroundsbar.com is one of the leading Silver Steel Round Bar Manufacturers in India. Besides manufacturing, exporting & importing a large amount of Silver Steel Round Bars, we are also suppliers, dealers, and stockholders of them. With the help of the latest technology, ASTM Silver Steel Round Bars are manufactured using superior quality raw materials. In addition to having a good finish and durability for long life with high pressure and a zero defect rate, our Silver Steel Round Bars are of high quality.

The company TriroundsBar.com manufactures quality Silver Steel Round Bars. Our company has been providing quality industrial products to the domestic and international markets for a number of years now. The Silver Steel Round Bars are produced by our highly organized and experienced team of employees who are dedicated to providing high-quality products. Furthermore, we also offer the same products in a variety of different forms, such as Aluminium 2024, 7075 Round Bar, Invar 36 Round Bar, and Alloy A286 Round Bar.

Silver Steel Round Bars are available in a variety of sizes so that the user can select one that suits his needs and requirements. The high carbon content aids the hardenability of silver steel thereby giving it considerable wear resistance. The chromium content gives it strength and hardness characteristics. With the annealed hardness in the range of 270 Brinell (Rockwell C 27), Silver Steel Round Bar is a popular tool room material.

For More Information visit

#aluminum #copper #metalart #metalwork #iron #engineering #welding #fabrication #metal #steel

0 notes

Text

From Manufacturing To Application: The Complete Journey Of Round Bars

Round bars play a crucial role in a multitude of industries, from construction to automotive, owing to their strength, versatility, and wide range of material options. In this article, we will explore the complete journey of round bars from their manufacturing processes to their application in various sectors, focusing on how their design and material composition meet the diverse demands of modern industries.

1. Round Bars

Round bars are cylindrical metal rods typically used as a basic material in manufacturing, construction, and mechanical applications. Their simple, versatile form allows them to be shaped into various components, including shafts, fasteners, and structural supports. Historically, round bars have evolved in terms of material composition and manufacturing techniques, making them indispensable across different industrial applications.

2. Types of Round Bars

There are several types of round bars, each suited to specific uses and industries:

Stainless Steel Round Bars: Known for their corrosion resistance, these bars are ideal for applications in harsh environments such as chemical plants, food processing units, and marine installations.

Carbon Steel Round Bars: These bars offer excellent strength and are used in construction, heavy machinery, and other high-stress environments.

Alloy Steel Round Bars: Alloyed with other elements to enhance mechanical properties, these are often used in aerospace and automotive industries.

Aluminum, Copper, and Other Round Bars: These bars are lightweight and corrosion-resistant, making them ideal for specialised applications in electronics, marine, and architectural industries.

3. Materials Used in Round Bar Manufacturing

The choice of material for round bars depends on the specific requirements of the application. Common materials include:

Stainless Steel: Offers excellent corrosion resistance and strength, suitable for both high and low temperatures.

Carbon Steel: Provides high strength and durability, making it a popular choice for construction and manufacturing.

Aluminum: Lightweight and resistant to corrosion, widely used in aerospace and automotive industries.

Copper: Known for its electrical conductivity, copper round bars are used in electrical and thermal applications.

The material properties, such as tensile strength, corrosion resistance, and temperature tolerance, determine the suitability of round bars for specific tasks.

4. Manufacturing Process of Round Bars

The production of round bars involves several key steps to ensure the material’s quality and dimensional accuracy:

Raw Material Procurement: Raw metal is sourced in the form of billets or ingots.

Melting and Casting: The metal is melted and cast into a cylindrical shape.

Hot Rolling and Cold Rolling: Depending on the desired strength and surface finish, the bar is either hot-rolled (for general applications) or cold-rolled (for precision).

Precision Machining: The round bars are machined to specific dimensions, ensuring accuracy in length, diameter, and surface finish.

5. Heat Treatment and Finishing of Round Bars

To improve mechanical properties and durability, round bars undergo heat treatment:

Annealing: Softens the metal for easier machining.

Quenching and Tempering: Enhances strength and toughness for high-stress applications.

Polishing and Coating: Surface treatments improve corrosion resistance and appearance, making the bars suitable for exposed applications.

Round Bar Exporters In India: A Full Overview For Industry And Trade

With Indian round bar exporters being well-known worldwide for their superior goods, Nippon Alloys Inc. has emerged as a major force in the steel sector. Round bars are crucial structural and equipment elements that are used extensively in the industrial, automotive, and building sectors. To meet the varied needs of customers throughout the world, our exporters provide a broad range of round bars made of alloy steel, carbon steel, and stainless steel. They have established a strong reputation in markets across Europe, Asia, and the Middle East because of their dedication to affordable prices and strict quality standards.

Round bars are cylindrical, long goods used in a wide range of sectors, including construction, automobile manufacture, heavy machinery, and infrastructure development. These round bars manufactured from a number of materials, including stainless steel, carbon steel, alloy steel, and copper, among others. Round bars are vital in contemporary manufacturing and construction because to their strength, durability, and adaptability.

Another important market for round bars is the automobile sector. India, one of the biggest automakers in the world, had an exponential increase in demand for premium round bars for usage in axles, chassis, and engine parts. Large amounts of round bars were also needed for the building of train stock, signalling equipment, and tracks in the nation's expanding railway network.

For More Detail

Website: nipponalloys.com

Product: Round Bar Exporter in India

Other Product: Alloy Round Bar Supplier in India, Monel Round Bar Importer in India.

#Round bar Supplier in India#Round bar Supplier#Round bar#Alloy Round Bar Supplier in India#Monel Round Bar Importer in India

0 notes

Photo

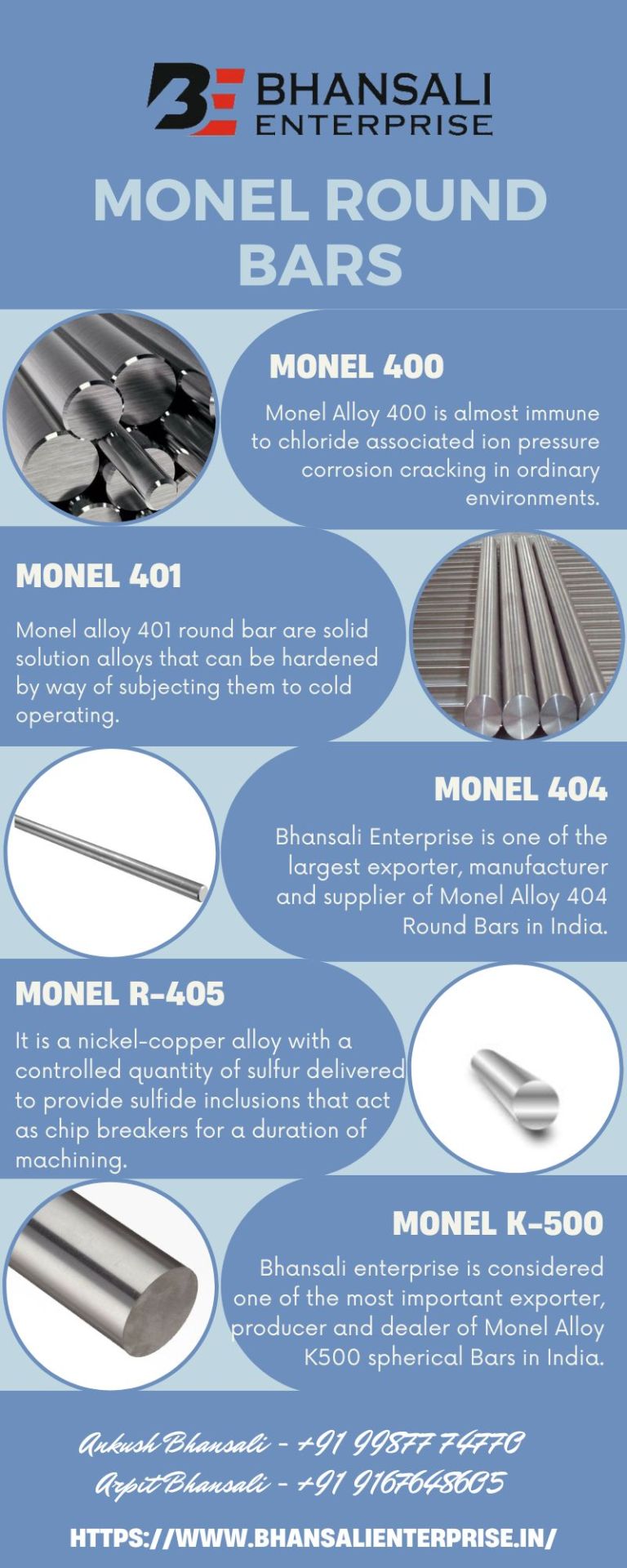

"Monel Round Bars."

Monel Alloy 400 Rod is known to have great mechanical properties at even at subzero temperatures. The alloy can be used in temperatures up that go to 1000° F. Monel 400 has a high melting point, it melts between the temperature range of 2370° F – 2460° F. Since alloy 400 has low strength in an annealed condition , a variety of tempering techniques may be used to increase the tensile strength. MONEL 401 is designed to be used in unique electric powered and digital applications. The common kinds of MONEL 401 alloy are strip and wire. This datasheet will look at the chemical composition, properties and applications of MONEL 401 alloy. Bhansali Enterprise is one of the largest exporter, manufacturer and supplier of Monel Alloy 404 Round Bars in India. Monel 404 Round Bars is more resistant to nickel under reducing environments and more resistant than copper under oxidizing environments, where it does exhibit however improved resistance to reducing media than oxidizing. Monel Alloy 404 Rods is a Nickel-Copper alloy, resistant to sea water and steam at elevated temperatures, in addition to caustic and salt solutions. Monel Alloy R-405 is the unfastened machining model of Monel 400. It is a nickel-copper alloy with a controlled quantity of sulfur delivered to provide sulfide inclusions that act as chip breakers for the duration of machining. Bhansali enterprise is considered one of the most important exporter, producer and dealer of Monel Alloy K500 spherical Bars in India.

#stainless steel round bar#manufacturer of stainless steel in india#stainless steel round bar manufacturer in india#ss round bar#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#monel metal composition#monel metal#stainless steel manufacturers in india#polished stainless steel

0 notes

Text

Copper Nickel 70/30 Round Bars Exporters In India

At Navneet Metal Corporation, is the best supplier of copper nickel 70/30 round bars and Rods. We are giving the wide degrees of the bars and Rods to the general clients in general. Anyway, we are giving the things in different particulars. Some of the decisions wherein the rods and bars are open are surface realisation, end finish, perspectives, shapes, sizes, and length. We overall have an enormous supply of our things, so the client doesn't need to experience the detestable effects of a shortfall of something essentially equivalent. We are also giving the bars and rods in the cut-made particulars of the clients. All the national and international quality standards are there in the supplied bars and rods.

#Copper Nickel 70/30 Round Bars#Copper Nickel 70/30 Round Bars Manufacturers#Copper Nickel 70/30 Round Bars Suppliers#Copper Nickel 70/30 Round Bars Stockists#Copper Nickel 70/30 Round Bars Exporters

0 notes