#Control valve

Explore tagged Tumblr posts

Text

The TopWorx TXP N20GNPM00000N003 Discrete Valve Control is a high-performance solution for monitoring and controlling industrial valve operations. Designed for reliability, it ensures precise valve position feedback in demanding environments. This unit supports various process automation systems, enhancing efficiency and safety. With its rugged construction, it withstands extreme conditions, making it ideal for oil & gas, chemical, and manufacturing industries. The TXP N20GNPM00000N003 offers easy installation, low maintenance, and high durability, ensuring long-term performance. Get this trusted valve control solution at Auto2mation for smooth and efficient operation in industrial applications.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Control Valve#Topworx

0 notes

Text

Why Partnering with a Control Valve Wholesaler is Crucial for Fuel Injection Head Rotor Quality

Maintaining the efficiency and reliability of diesel engines heavily depends on the quality of components like the fuel injection head rotor and control valves. These components play critical roles in regulating fuel flow and ensuring precise injection timing, directly impacting engine performance and longevity. Partnering with a reputable control valve wholesaler is essential to achieving consistent quality and performance.

A control valve wholesaler supplies high-quality valves that ensure smooth fuel delivery and accurate pressure control. These valves are integral to the operation of fuel injection head rotors, which are responsible for distributing fuel evenly to the engine’s cylinders. Poor-quality control valves can lead to uneven fuel flow, reduced engine efficiency, and increased emissions, highlighting the importance of sourcing from a trusted supplier.

Additionally, a reliable control valve wholesaler often works with manufacturers to ensure that their products meet industry standards and specific customer requirements. By choosing the right wholesaler, businesses can gain access to components designed for optimal compatibility with fuel injection head rotors, reducing the risk of mechanical failures and costly downtime.

Another advantage of partnering with a trustworthy wholesaler is their ability to provide technical expertise and after-sales support. From offering insights into product advancements to ensuring timely delivery, a good control valve wholesaler can significantly streamline the supply chain for automotive and diesel engine manufacturers.

In conclusion, the synergy between a control valve wholesaler and high-quality fuel injection head rotors is crucial for maintaining engine efficiency and reliability. For those seeking a trusted partner in this space, Wunfagroup stands out as a reliable supplier offering premium control valves and head rotors, ensuring excellent performance and customer satisfaction.

#pizo valve#denso valve#engine parts#diesel engine parts#diesel engine parts manufacturer#test bench#common rail test bench#delivery valve#remanufacture injector#bosch injector#Fuel Injection Head Rotor#Head Rotor#Control valve wholesaler#Control valve

0 notes

Text

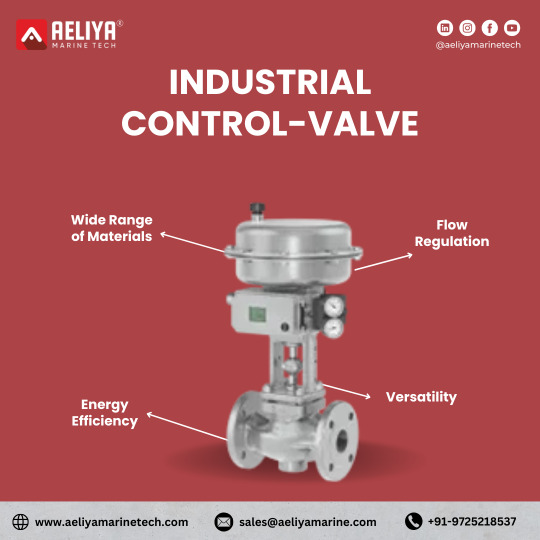

Enhance Efficiency and Precision with Aeliya Marine’s Control Valves

When it comes to managing fluid flow, pressure, and temperature in any system—whether industrial, marine, or even residential—control valves are indispensable. These essential components help regulate the flow of liquids, gases, and steam, ensuring that operations run smoothly and safely. If you’re looking for high-quality control valves that deliver exceptional performance in demanding conditions, Aeliya Marine offers a comprehensive range of options designed to meet your specific needs.

Why Choose Aeliya Marine’s Control Valves?

Aeliya Marine’s control valves are engineered for precision, durability, and reliability in a variety of applications. Here’s why they should be your go-to choice for controlling flow and pressure in your systems:

1. Superior Performance At Aeliya Marine, performance is a priority. Their control valves are built to provide accurate regulation of pressure, temperature, and flow. Whether used in complex industrial systems or marine equipment, Aeliya Marine's control valves offer high reliability in even the most critical applications. These valves are designed to operate seamlessly under fluctuating pressures and flow rates, ensuring consistent performance.

2. Robust and Durable Construction Aeliya Marine understands that control valves are often exposed to harsh environments, especially in marine applications. That’s why their valves are made from high-quality materials that resist corrosion, erosion, and wear. Whether you need valves for a marine engine, an offshore platform, or a processing plant, you can trust that Aeliya Marine’s control valves will stand the test of time.

3. Precise Flow Control Control valves regulate the flow of fluids and gases within a system to maintain optimum performance. Aeliya Marine’s valves are engineered for precision control, which helps enhance system efficiency, reduce energy consumption, and improve overall performance. Their control valves help to fine-tune the system’s response to dynamic changes, ensuring smoother operation and minimizing wear on the components.

4. Wide Variety of Valves No matter the application, Aeliya Marine offers a wide selection of control valves to suit various operational needs. Some popular types include:

Pressure Control Valves : These valves maintain pressure within a desired range, protecting your system from pressure spikes or drops that could cause damage to components or lead to inefficiencies. They are essential in marine applications, industrial machinery, and process systems.

Flow Control Valves : These valves regulate the flow of fluids within pipelines, controlling the speed or volume of liquids or gases moving through a system. They help ensure that systems operate with optimal flow, preventing overflows or blockages.

Temperature Control Valves : Ideal for systems that involve temperature-sensitive processes, these valves regulate the flow of fluids based on temperature measurements, ensuring the system maintains the required temperature for optimal operation.

Throttle Valves : Throttle valves are designed to control the speed and pressure of fluids or gases in a system. These are often used in engines, hydraulic systems, and other applications that require fine-tuned control of movement.

5. Marine-Specific Solutions For those in the marine industry, Aeliya Marine offers specialized control valves that are built to withstand the extreme conditions of the sea. These valves are constructed from corrosion-resistant materials to ensure longevity and reliable performance even when exposed to saltwater, high humidity, and varying temperatures.

6. Cost-Effective Solutions At Aeliya Marine, you don’t have to sacrifice quality for affordability. Their control valves are priced competitively, allowing you to get high-performance products that fit your budget. This makes it easier for both small businesses and large corporations to access top-tier control valves without breaking the bank.

Key Applications of Control Valves

Control valves are used across various industries, each requiring different specifications based on the type of fluid or gas being controlled and the operational demands. Here are just a few examples:

Marine Industry : Control valves in the marine industry regulate fuel systems, water systems, and engine cooling systems. Aeliya Marine’s control valves are designed to resist saltwater corrosion and provide precise control even under extreme conditions.

Industrial Systems : Whether in manufacturing, processing, or energy generation, control valves help regulate steam, air, and water flow to ensure that production lines run efficiently and safely.

HVAC Systems : In heating, ventilation, and air conditioning (HVAC) systems, control valves help manage the temperature and air quality by regulating the flow of gases and liquids throughout the system.

Oil and Gas : Control valves are critical in oil and gas operations for regulating pressure, temperature, and flow in pipelines, refineries, and drilling equipment.

Water Treatment : Control valves are often used in water treatment plants to manage the flow of water and chemicals, ensuring that treatment processes maintain the desired flow rates and pressures.

Why Aeliya Marine Is Your Trusted Supplier for Control Valves

Industry Expertise : Aeliya Marine has years of experience serving customers in both the marine and industrial sectors. They understand the unique challenges faced by their clients and offer products designed to perform under the toughest conditions.

High-Quality Materials : Whether you need a valve for a harsh marine environment or an industrial setting, Aeliya Marine ensures that all their control valves are made from high-quality, durable materials that resist corrosion, wear, and stress.

Excellent Customer Support : Aeliya Marine’s customer service team is always ready to assist you with any questions or concerns you may have about their control valves. They offer personalized support to ensure you choose the right valve for your application.

Global Shipping : No matter where you are in the world, Aeliya Marine ships their products globally, ensuring you get the control valves you need, when you need them.

Conclusion

Whether you're working on a marine vessel, an industrial plant, or an HVAC system, Aeliya Marine’s control valves are the perfect solution for precise flow control, pressure regulation, and temperature management. With their high-quality construction, durability, and wide range of options, you can trust Aeliya Marine to provide the best control valves for your specific needs.

Explore Aeliya Marine’s Control Valve Collection today to find the right solution for your project and experience the precision and performance that top industries rely on.

#industrial equipment#automation#industrialautomation#industrial and marine automation#industrial spare parts#marine automation#Control Valve

0 notes

Text

0 notes

Text

Bellow Sealed Globe Control Valve

Industrial systems depend on reliable valve technologies to ensure optimal performance and safety. The bellow sealed globe control valve has emerged as a trusted solution, particularly in applications requiring leak-proof sealing and precise control. This article delves into the features, benefits, and applications of this versatile valve and its contribution to industry operations.

What Makes Bellow Sealed Globe Control Valves Unique?

Unlike traditional globe valves, these control valves incorporate a metallic bellow that provides an airtight seal between the valve stem and the bonnet. This design eliminates the risk of leakage, even under extreme conditions, offering a distinct advantage over conventional sealing mechanisms like gland packing.

These valves are particularly valued for their ability to regulate flow with precision while maintaining environmental safety by preventing fugitive emissions.

Features

Advanced Sealing Technology The bellows ensure zero leakage, supporting compliance with emission control regulations.

Corrosion-Resistant Construction High-quality materials like stainless steel are used to handle corrosive and high-temperature fluids effectively.

Compact and Sturdy Design These valves are designed for space-saving installations while withstanding harsh operational conditions.

Wide Range of Sizes and Configurations Customization options are available to meet diverse industrial requirements, including varying pressure and flow rates.

Ease of Automation Compatible with pneumatic and electric actuators, enabling integration into automated systems for improved efficiency.

Advantages

Leak Prevention The robust seal prevents hazardous fluids from escaping, ensuring workplace safety and environmental compliance.

Long-Term Durability The non-wearing bellow mechanism reduces maintenance frequency and operational downtime.

Energy Efficiency Accurate flow control minimizes energy losses, lowering operational costs.

Versatile Applications Suitable for a wide array of industries, including pharmaceuticals, oil and gas, chemical processing, and power plants.

Regulatory Compliance Meets global standards for safety, emissions, and performance, making it a preferred choice for critical systems.

Applications

1. Pharmaceutical Industry

In sterile environments, these valves maintain strict hygiene standards by preventing leaks and ensuring uncontaminated fluid transfer.

2. Chemical Processing

Their corrosion-resistant materials and leak-proof design are essential for handling aggressive chemicals and volatile fluids.

3. Oil and Gas

Used in pipelines and processing units, they ensure safe operation under high pressure and temperature.

4. Power Generation

Commonly employed in steam and condensate systems for efficient energy utilization and operational safety.

How to Select the Right Bellow Sealed Globe Control Valve

When selecting a bellow sealed globe control valve, consider the following factors:

Fluid Properties: Assess the fluid's chemical composition, temperature, and pressure.

Material Compatibility: Choose a valve constructed from materials resistant to the fluid's corrosive or abrasive nature.

Operational Needs: Evaluate the required flow rate, valve size, and end connections.

Automation Requirements: Determine if the system requires manual or automated control mechanisms.

Maintenance and Performance

Routine maintenance ensures the longevity and efficiency of these valves. Inspections should focus on the bellow’s integrity, the valve body, and the actuating components. By addressing minor issues proactively, operational disruptions can be minimized.

Conclusion

The bellow sealed globe control valve is an essential component for industries prioritizing leak-proof performance and precise flow control. Its advanced sealing technology, combined with robust construction, makes it suitable for the most demanding applications. These valves not only enhance operational efficiency but also support environmental and safety compliance.

Buy bellow sealed globe control valves from Freture Techno Pvt. Ltd., a trusted manufacturer delivering innovative and high-quality industrial valve solutions in Mumbai, India.

#control valve#bellow sealed globe control valve#manufacturers#suppliers#Mumbai#India#freture techno

0 notes

Text

Understanding the Importance of Control Valves in Industrial Applications

Control valves are made up of a valve body, actuator, and control mechanism, which work together to adjust flow conditions by opening or closing the valve partially or completely. The key purpose is to maintain the desired setpoint in a process by either throttling the flow or diverting it entirely.

0 notes

Text

White-Rodgers 36H32-423 Universal Gas Control Valve 3/4 Inch | HnKParts

#Manufacturer Name:WHITE RODGERS#Product Number:36H32-423#OEM Part Number:36H32-423#Order White-Rodgers 36H32-423 Universal Gas Control Valve 3/4 Inch today! Shop home & kitchen appliance parts at HnK Parts with same-day sh#available at the best prices.#36H32-423#WhiteRodgers#Gas#Control Valve#HnKParts#HomeAppliance#KitchenAppliance#700 Nicholas BLVD Suite 105 Elk Grove Village IL 60007#https://www.hnkparts.com/36h32-423-white-rodgers-universal-gas-valve-34

0 notes

Text

Essential Pump Spares for Optimized Marine Automation

In marine automation, having reliable pump spares is crucial for maintaining system efficiency and preventing costly downtime. Key pump spares, such as seals, bearings, impellers, and motors, ensure smooth operation of marine systems like ballast, cooling, and fuel pumps. These components are designed to withstand harsh marine conditions, offering long-lasting performance. Regular maintenance and timely replacement of pump spares enhance the overall reliability of marine automation systems, improving vessel operations and reducing maintenance costs. Investing in quality pump spares is essential for optimizing marine automation, ensuring safety, and maintaining peak performance at sea.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#control valve#Marine equipment#pump spares

0 notes

Text

Control valve wholesaler

Fine-tune your engine's fuel delivery with our Control Valves. We are the leading Control valve wholesaler offers control valves for a wide range of industries, including oil and gas, manufacturing, and HVAC systems. Offering durable and efficient flow control solutions, we provide competitive pricing and expert support to meet diverse industrial needs.

#common rail test bench#diesel engine parts manufacturer#pizo valve#delivery valve#test bench#remanufacture injector#diesel engine parts#denso valve#engine parts#bosch injector#Control valve wholesaler#Control valve

0 notes

Text

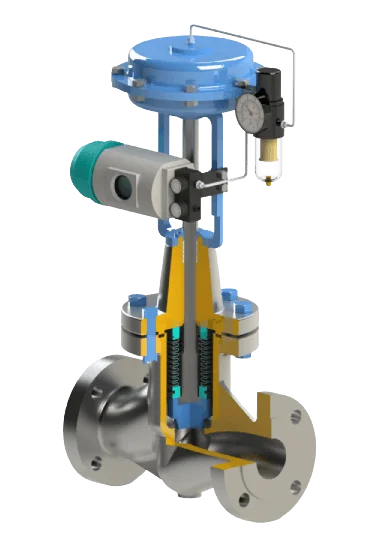

Applications and Working process of Control Valve

A valve is a device that regulates the fluid flow as well as the pressure within a system or process. Unlike on-off valves, a control valve is used to regulate the fluid flow by stopping and starting the fluid flow as per the direction is given by the controller.

Control Valve

Control valves consist of three main parts: the valve, the actuator, and the controller. Various components of the Actuator include rain cap, eye bolt, diaphragm, spring, actuator stem, diaphragm case, scale plate, stem connector, and yoke.

The components of body part include packing flange, packing follower, yoke claim nut, gland packing, valve stem, bonnet, stud bolt and nut, gasket, guide ring, guide bushing, valve plug, seat ring, valve body, trim set, and positioner.

Though the primary purpose of a control valve is to regulate the fluid flow, there are two main forms of action i.e. the sliding stem and the rotary action. The most common type of control valves in the sliding stem include globe valve, angle body valve, and angle seat piston valve while the rotary action includes a butterfly valve and ball valve.

Why Control Valves are Used?

Control valves are used for various purposes in the industrial, engineering, manufacturing, and scientific communities. The primary purpose of a control valve is to regulate the rate of the fluid flow by varying the size of the flow passage. Control valves are most commonly used for consequential control of process quantities including pressure, temperature, and the liquid level.

How do Control Valves work?

With the help of opening and closing internal passages, control valves regulate the fluid flow. Control valves form a control loop which is then used by a controller to send signals. Control valves respond to these signals and adjust the internal openings accordingly.

Control valves use the actuator to move the valve stem. Usually, it is either air (pneumatically) or electrically driven. The pressure between the inlet and outlet decides the rate of flow through the valve.

In order to reduce the fluid flow, the valve is closed, which results in more back-pressure and increases the difference between the inlet and outlet pressures.

Control valves help in controlling the fluid flow and are used in various industries including pipeline, oil & gas, food & beverage, the biopharma industry, and marine industry.

Sonu Hose is the top Control Valve suppliers and they are also the leading control valve suppliers in India. All their products are tested for resilient durability to provide the best industrial valve to their customers.

Contact Us

Call now: +91-9311288288

G-mail: [email protected]

Visit our Site: https://sonuhose.com

0 notes

Text

A control valve is a crucial device used in industrial processes to regulate the flow of fluids, including gases, liquids, and steam. By adjusting the size of the flow passage, it controls variables like pressure, temperature, and fluid levels to ensure optimal system performance. Control valves are typically integrated into automated systems, receiving signals from controllers to open or close in response to real-time conditions.

0 notes

Text

Selecting the Right Control Valve for Fluid Handling in the Oil and Gas Industry

Control valves are critical components in the oil and gas sector, playing a vital role in regulating the flow, pressure, and temperature of fluids. These valves are essential for ensuring operational efficiency, safety, and environmental compliance. Selecting the right control valve requires a thorough understanding of the application requirements and the challenges specific to the oil and gas industry.

Challenges in Fluid Handling in the Oil and Gas Sector

The oil and gas industry presents unique challenges due to the demanding conditions under which equipment must operate. From handling high-pressure crude oil and gas to managing corrosive fluids, control valves must be robust and reliable. Some key challenges include:

High Pressure and Temperature Many oil and gas processes involve extreme pressure and temperature conditions. Equipment must be capable of withstanding these stresses without compromising performance or safety.

Corrosive and Abrasive Fluids The fluids in oil and gas operations can be highly corrosive and abrasive. Valves must resist corrosion and wear caused by contaminants, chemicals, and sand particles present in crude oil and gas streams.

Strict Regulatory Standards The industry operates under stringent safety and environmental regulations. Control valves must adhere to standards like API, ISO, and ASME to ensure compliance and prevent environmental damage.

Flow Variability Fluctuating flow rates in pipelines and processing systems demand valves that can adapt to varying conditions without impacting efficiency or safety.

Key Features of Control Valves for Oil and Gas Applications

When selecting control valves for the oil and gas industry, the following features should be considered:

Material Compatibility Valves should be constructed from materials that can withstand exposure to corrosive and abrasive substances. Common materials include stainless steel, Hastelloy, and other high-strength alloys. Coatings and linings may also be used to enhance resistance to corrosion and erosion.

Pressure and Temperature Ratings Valves must be rated for the maximum pressure and temperature conditions they will encounter. Failing to meet these specifications can result in leaks, equipment failure, or safety hazards.

Seal Integrity Leak-tight sealing is crucial to preventing fluid loss and ensuring safety. Valves with advanced sealing technologies, such as metal-to-metal seals or polymer-based seals, provide enhanced reliability under high-pressure conditions.

Flow Control Precision Valves must deliver precise control to maintain stable flow rates and pressure levels. Actuation options, such as pneumatic or electric actuators, can improve accuracy and responsiveness in critical applications.

Ease of Maintenance Given the remote and hazardous locations of many oil and gas facilities, control valves should be easy to maintain and repair. Modular designs and readily available spare parts simplify servicing and reduce downtime.

Applications of Control Valves in Oil and Gas

Control valves are used across various stages of oil and gas production, processing, and distribution. Common applications include:

Upstream Operations In drilling and extraction, control valves regulate the flow of crude oil and gas from wells. They manage pressures to prevent blowouts and ensure steady production.

Midstream Processes During transportation and storage, valves maintain pressure and flow within pipelines, preventing leaks and ensuring safe delivery of hydrocarbons.

Downstream Applications In refining and petrochemical processes, control valves regulate temperature, pressure, and chemical reactions to produce refined products like gasoline, diesel, and plastics.

Ensuring Optimal Performance Through Proper Maintenance

The harsh environments of oil and gas facilities make regular maintenance essential to extend the life of control valves and prevent unplanned downtime. Key maintenance practices include:

Routine Inspections Inspect valves regularly for signs of wear, corrosion, or damage. Seals and actuators should be checked for proper functioning.

Cleaning and Lubrication Remove debris and contaminants to maintain smooth valve operation. Lubricate moving parts to reduce friction and wear.

Testing and Calibration Periodically test valve performance, including pressure containment and flow control accuracy. Calibration ensures the valve continues to meet operational requirements.

Replacement of Worn Components Replace seals, seats, and other worn components promptly to prevent leaks or operational failures.

Documentation Maintain detailed records of valve maintenance, repairs, and testing. This information helps track performance trends and plan future maintenance activities.

Conclusion

The oil and gas industry relies heavily on control valves to ensure the efficient, safe, and environmentally responsible handling of fluids. Choosing the right valve with appropriate materials, precise control capabilities, and robust construction is crucial for overcoming the sector's challenges. Regular maintenance further ensures reliability and prolongs the lifespan of the valves.

By prioritizing the selection and upkeep of high-quality control valves, oil and gas operators can enhance safety, improve operational efficiency, and meet regulatory standards. As technology advances, modern control valves equipped with smart features will continue to play a pivotal role in optimizing oil and gas processes.

0 notes

Text

A Comprehensive Guide to Selecting the Right Control Valve for Your Application

Fluid flow, pressure, and temperature are regulated by control valves in a variety of industries. Selecting the right control valve for your application is crucial to ensuring smooth operation, efficiency, and safety. Making an informed choice can be difficult with so many options available. This guide provides insights into key factors you should consider when choosing the ideal control valve for your needs.

Understand Your Process Requirements

The first step in selecting the right control valve is understanding the specific requirements of your process. Determine the type of fluid you’re dealing with, whether it’s gas, liquid, or steam. Additionally, consider the operating conditions, such as pressure, temperature, and flow rate. For example, high-temperature or corrosive fluids may require valves made from special materials that resist wear and tear.

Choose the Right Valve Type

There are several types of control valves, each suited for different applications. The most common types include:

Globe Valves: Known for precise control, especially in throttling applications.

Ball Valves: Suitable for quick shut-off applications, offering low-pressure drops.

Butterfly Valves: Ideal for large pipes and lower-pressure applications, offering cost-effective solutions.

Diaphragm Valves: Great for handling corrosive or viscous fluids.

The choice of valve type will depend on your specific application needs, such as the level of control, response speed, and space constraints.

Material Selection

The materials used in control valve construction play a critical role in determining their durability and compatibility with the medium being handled. Common materials include stainless steel, carbon steel, and various alloys. When dealing with harsh chemicals or high-temperature environments, opt for materials that are resistant to corrosion and can withstand extreme conditions.

Consider the Actuation Method

It is possible to operate control valves manually, pneumatically, electrically, or hydraulically. Depending on the application, each method has its advantages. Pneumatic actuators are widely used due to their reliability and ability to handle extreme conditions, while electric actuators offer more precise control. Hydraulic actuators are suitable for high-force applications, and manual actuators are best for simpler, low-maintenance systems.

Check Flow Characteristics

Every control valve has specific flow characteristics that describe how the valve’s position affects the flow rate. The three main types are:

Linear: The flow rate changes linearly with the valve position.

Equal Percentage: The flow rate changes more at the end of the valve travel than at the beginning.

Quick Opening: Provides a rapid increase in flow at the beginning of valve travel.

Understanding these flow characteristics is essential for selecting a valve that will perform optimally in your system.

Look for Industry Standards and Certifications

Control valves must meet industry standards to ensure they are safe and efficient for use in various applications. When choosing a valve, check for certifications such as ISO, API, or ASME, depending on your industry requirements. These certifications help guarantee the quality and reliability of the valve.

Maintenance and Service Life

Another important consideration is the maintenance requirements and the expected service life of the control valve. A high-quality valve will require less frequent maintenance, reducing downtime and increasing productivity. Choose a valve that offers easy access for repairs and replacements to minimize disruptions in your process.

Supplier Reliability

Selecting a reliable control valve manufacturer in Ahmedabad or your region ensures that you receive quality products and after-sales support. A good manufacturer will offer technical expertise, guidance during the selection process, and comprehensive customer service. Be sure to research reviews, certifications, and the manufacturer’s experience in the industry before making a purchase.

Conclusion

Choosing the right control valve for your application is a critical decision that impacts the overall performance and safety of your system. By considering factors such as process requirements, valve type, material, actuation method, flow characteristics, and supplier reliability, you can ensure that your system operates efficiently and effectively. For industries looking for a reliable control valve manufacturer in Ahmedabad, a thorough evaluation of their offerings will help you make an informed decision.

0 notes

Text

BENZ DIRECTION CONTROL VALVE

UDA No.: JD13017 REF No.: 0012602057 PORT 1,2,4: 1/8”NPT PORT 41: 1/8”NPT APPLICATION: BENZ

0 notes