#Cone Crushers Sales

Text

Maximizing Power Generation Efficiency with Cone Crusher Spare Parts and Small Jaw Crushers

Power generation is a critical component of modern society, providing us with the energy we need to power our homes, businesses, and industries.

In order to maintain a steady and reliable source of power, it is essential that power generation equipment is well-maintained and functioning optimally.

One key aspect is the crushing of large rocks into smaller pieces, and this is where cone crushers and small jaw crushers play a vital role.

Cone Crusher Spare Parts

Cone crushers are an integral part of power generation processes, as they are responsible for crushing large rocks into smaller, more manageable pieces.

The wear and tear of cone crusher parts over time can lead to the need for replacement, and this is where cone crusher spare parts come into play.

Cone crusher spare parts provide quick and easy replacement of worn-out parts, ensuring the continued optimal functioning of power generation equipment.

The foundry shop is a reliable and trustworthy provider of cone crusher spare parts, offering a wide range of high-quality products to suit all of your needs.

Whether you are looking for bearings, bushings, wear plates, or liners, the foundry shop has the expertise and resources to provide you with the cone crusher spare parts you need.

With a focus on providing durable and long-lasting products, the foundry shop is committed to maximizing the efficiency and reliability of your equipment.

Small Jaw Crushers for Sale in Australia

Small jaw crushers for sale in Australia are another crucial component of power generation processes.

These machines are designed to crush small rocks into smaller pieces which can then be processed and used in the production of power.

The compact and easy-to-operate design of small jaw crushers makes them ideal for use in remote and challenging locations, where larger, more complex power generation equipment may not be practical.

Additionally, small jaw crushers are cost-effective, making them an ideal choice for facilities with limited budgets.

Small jaw crushers for sale in Australia are available in a range of sizes and capacities, so you can choose the model that best suits your power generation needs.

Whether you are looking to crush small rocks for use in power generation or you need a machine that is capable of processing larger rocks, small jaw crushers are up to the task.

With their simple design, small jaw crushers are easy to operate and maintain, so you can be sure that they will continue to perform at their best for many years to come.

Benefits of Using Cone Crusher Spare Parts and Small Jaw Crushers

The use of cone crusher spare parts and small jaw crushers in power generation processes offers numerous benefits.

Firstly, they are reliable and efficient, ensuring that power generation equipment continues to function optimally.

This is essential for maintaining a steady and reliable source of power.

Secondly, they are cost-effective, helping facilities save money on replacement parts and maintenance costs.

This can be a critical factor for facilities with limited budgets.

Finally, they are easy to use and maintain, making them ideal for use in remote and challenging locations.

Environmental Benefits

The use of cone crusher spare parts and small jaw crushers in power generation processes also offers environmental benefits.

The smaller rock pieces produced by these machines can be used to produce renewable energy, reducing our reliance on non-renewable sources of energy and helping to reduce greenhouse gas emissions.

Additionally, small jaw crushers are designed to be energy-efficient, helping to reduce the carbon footprint of power generation facilities.

By choosing to invest in cone crusher spare parts and small jaw crushers, power generation facilities can play an active role in protecting our environment.

Customization and Support

Finally, the foundry shop also provides customization and support services to ensure that you get the best possible results from your cone crusher spare parts and small jaw crushers.

Our team of experts will work with you to understand your unique requirements and develop a customized solution that meets your specific needs.

Whether you need help with installation, maintenance, or troubleshooting, our team is here to support you every step of the way.

With our extensive experience and expertise in power generation, you can trust that we will provide you with the guidance and support you need to achieve maximum efficiency and reliability.

Conclusion

In conclusion, cone crusher spare parts and small jaw crushers for sale in Australia are an integral part of power generation processes.

These machines are designed to operate under extreme conditions and are subject to constant wear and tear.

With the right spare parts and maintenance, however, they can continue to function optimally for many years to come.

If you are looking for high-quality, reliable, and cost-effective power generation equipment, look no further than cone crusher spare parts and small jaw crushers.

The foundry shop

is your one-stop shop for all of your power generation needs, providing a wide range of durable and long-lasting products to suit all of your requirements.

So why wait? Invest in cone crusher spare parts and small jaw crushers today and experience the benefits of maximum power generation efficiency for yourself.

0 notes

Text

Rock Crusher Machine: A Key Asset for Quarrying and Mining Construction

The rock crusher machine stands as an indispensable tool within the realms of quarrying and mining construction. This dynamic apparatus is not merely a piece of equipment; it embodies the very backbone of the aggregate production process. As the demand for construction materials surges, the efficiency and efficacy of rock crushing equipment for sale have become paramount. Without these machines, the industry would face insurmountable challenges in meeting the escalating needs of infrastructure development. This article delves into the significance of rock crushers, exploring their types, functionalities, and the profound impact they have on the mining sector.

The Importance of Rock Crushers in Quarrying

In the quarrying sector, rock crushers play a pivotal role in transforming raw materials into usable aggregates. These machines are designed to pulverize large rocks into smaller fragments, making it feasible to extract and process minerals.

Types of Rock Crushers

There are several types of rock crushers, each tailored for specific applications. The most prevalent include jaw crushers, cone crushers, and impact crushers. Jaw crushers are renowned for their ability to handle large, abrasive materials, crushing them through a series of compressive forces. Cone crushers, on the other hand, are adept at producing finely crushed materials, ideal for secondary and tertiary applications. Lastly, impact crushers excel in delivering high-speed reductions, perfect for softer materials. Understanding these distinctions is crucial for operators aiming to optimize their processes and output.

Operational Efficiency and Cost-Effectiveness

Utilizing rock crushers enhances operational efficiency significantly. By streamlining the material reduction process, these machines minimize manual labor and reduce the time required for material preparation. This leads to a notable decrease in operational costs, making it economically viable to undertake larger projects. Moreover, the precision with which rock crushers operate ensures minimal waste, allowing quarry operators to maximize their yield while adhering to environmental regulations.

Rock Crushers and Their Impact on Mining Construction

The influence of rock crushers extends beyond mere production; they are integral to the sustainability of mining operations. As construction demands evolve, so too must the methods employed to meet them.

Environmental Considerations

Modern rock crushers are designed with environmental considerations in mind. Many now feature advanced technologies that reduce noise, dust, and emissions, aligning with global sustainability initiatives. By employing these machines, mining companies not only enhance their operational capabilities but also contribute positively to the environment, ensuring that they remain compliant with increasingly stringent regulations.

The Future of Rock Crushing Technology

As technology continues to advance, the future of rock crushing looks promising. Innovations such as automated systems, artificial intelligence, and enhanced material handling processes are on the horizon. These developments are expected to further improve the efficiency and effectiveness of rock crushers, solidifying their position as vital assets in quarrying and mining construction.

In conclusion, rock crusher machines are more than just tools; they are essential components that drive the quarrying and mining industries forward. Their diverse functionalities, coupled with advancements in technology, ensure that they will remain pivotal for years to come.

0 notes

Text

BDI Wear Parts: Your Trusted Source for High-Quality Crusher Components

Amid the demanding and competitive world of heavy-duty crushing equipment, BDI Wear Parts shines as a symbol of quality and dependability. As a top supplier of crusher parts, we serve the mining, quarrying, construction, and recycling industries, providing a wide range of components designed to improve the efficiency and longevity of crushing machinery.

Our Key Solutions: Complete Range of Crusher Components

1. Jaw Crusher Parts: Durability Combined with Precision

At the heart of our product portfolio are jaw crusher parts, essential for primary crushing applications. Our jaw plates, available in various profiles and materials including high-manganese steel, are engineered to withstand extreme compressive forces and abrasive wear. Precision-machined to ensure a seamless fit, these parts minimize downtime and optimize crushing efficiency. Our commitment to durability ensures that you can rely on BDI Wear Parts to keep your jaw crushers running smoothly for longer.

2. Cone Crusher Parts: Power in Simplicity

Moving further down the crushing line, our cone crusher parts represent the epitome of engineering excellence. From bowl liners and mantles to concaves and adjusting rings, every component is crafted from premium materials such as high-chrome iron and manganese steel. These parts are designed to balance wear resistance with cost-effectiveness, ensuring maximum production with minimal downtime. With BDI Wear Parts, you can count on precise fitment, enhanced performance, and a lower total cost of ownership.

3. Impact Crusher Parts: Versatility Meets Durability

For applications requiring high throughput and versatility, our impact crusher parts are the ultimate solution. Our blow bars, hammers, and impact plates are constructed from the toughest alloys available, withstanding the intense impacts and abrasive wear characteristic of impact crushing. By utilizing advanced heat treatment and surface finishing techniques, we enhance the durability of these crusher parts for sale, extending their service life and reducing the need for frequent replacements.

4. Cutting Edge Components: Leading the Way in Innovation

BDI Wear Parts is constantly pushing the boundaries of innovation with our cutting-edge components. Our cutting edges, designed for screen decks, conveyor belts, and other applications, incorporate advanced materials like tungsten carbide to improve wear resistance and performance. Whether you’re looking to increase the throughput of your screening system or prolong the life of your conveyor components, our cutting-edge products offer the perfect solution.

In-House Manufacturing & Streamlined Logistics: Your Edge in the Market

What sets BDI Wear Parts apart is our advanced in-house manufacturing and efficient logistics network. Equipped with state-of-the-art machinery and skilled technicians, our facilities ensure that every component meets the highest standards of quality and precision. Coupled with our optimized logistics system, we deliver parts swiftly to customers around the globe, reducing downtime and boosting operational efficiency.

Conclusion

In summary, BDI Wear Parts is the go-to source for premium crusher components that enhance the performance and longevity of your crushing equipment. From jaw crusher parts to cone crusher parts for sale Canada, impact parts, and cutting-edge components, our extensive product range caters to the diverse needs of the mining, quarrying, construction, and recycling industries. With our in-house manufacturing and streamlined logistics, we are dedicated to delivering the best solutions for your crushing needs. Choose BDI Wear Parts today and discover the impact that quality and reliability can have on your operations.

0 notes

Text

Top 5 Cone crusher manufacturer in India

Craftsmen Industry, one of the Top 5 Cone crusher manufacturer in India, is a leading cone crusher manufacturer in India, known for its high-quality machinery designed to crush and process large chunks of rocks and minerals. Cone crushers are vital in the construction and mining industries, where they help break down materials into smaller, more manageable pieces. The cone crushers made by Craftsmen Industry are highly efficient and durable, ensuring that they can handle even the toughest materials with ease. These machines are engineered with precision, using advanced technology to provide consistent performance and long-lasting service. One of the standout features of Craftsmen's cone crushers is their robust build, which ensures minimal downtime and low maintenance costs. The company prides itself on offering excellent customer support and comprehensive after-sales service, ensuring that clients can rely on their equipment for years to come. Craftsmen Industry's cone crushers are also designed to be environmentally friendly, with energy-efficient motors that reduce power consumption and lower operational costs. Additionally, their crushers come with user-friendly controls, making them easy to operate and adjust according to specific needs. Whether for large-scale mining operations or smaller construction projects, Craftsmen Industry's cone crushers are a dependable choice for any crushing requirements. With a strong commitment to quality and customer satisfaction, Craftsmen Industry has established itself as a trusted name in the Indian manufacturing sector, providing top-notch equipment that meets the highest standards of safety and efficiency.

0 notes

Text

Stone Crusher Manufacturer –Picson International

In the field of building and infrastructure development, Stone Crusher Manufacturer is important for the development of building foundations and environments. Leading this industry at the top is Picson International, a manufacturer dedicated to creating innovative designs that raise standards for stone crushing equipment.

A dedication to innovation and quality of Stone Crusher Manufacturer:-

Picson International is committed to provide its clients durable, high-performing equipment. Their constant dedication to excellence shows by their:

Use of premium materials: To guarantee that their crushers can handle even the most difficult jobs, they place a high priority on sturdy and dependable components.

Dedicated engineering: Their group of skilled engineers creates their crushers with maximum production and efficiency in mind.

Extensive testing: Every crusher is subjected to extensive testing to ensure it truly satisfies their exacting performance requirements.

Reliability and Quality of Stone Crusher Manufacturer in India:

Picson International is committed to providing excellent products. They make sure that their stone crushers are powerful, durable, and dependable by using premium-grade parts and advanced manufacturing methods. Even under the most critical conditions, the durable build and careful engineering of their devices provide durability.

Stone Crusher: - Technology and Innovation:

Picson International understands the need of being current of technical developments. They consistently allocate resources towards research and development in order improve their stone crushers and integrate modern facilities features. They make sure that their machines are effective, productive, and tailored to the specific needs of their clients by accepting technology.

Customer support:

Picson values client satisfaction, and they stand out for their commitment to provide outstanding client service. They have a group of skilled professionals on hand to help users with any questions or issues pertaining to their cone crushers. Picson places its clients' needs first, from installation assistance to after-sales support, promising an error-free and enjoyable experience every step of the way.

Why choose to Picson International?

Picson International divides out as a dependable and creative manufacturer of stone crusher equipment. Here are some strong arguments supporting the idea of choosing them:-

Unmatched experience: Having worked in the field for more than 30 years, they have a wealth of knowledge and experience.

Put reliability first: Their dedication to use high-quality components and thorough testing provides sustained performance.

Extensive product point: They provide a range of crushers to meet the needs of different applications.

Excellent customer service: Their commitment to follow-up support guarantees an easy client journey.

Look little more than Picson International if you're searching for a stone crusher manufacturer that puts a premium on quality, innovation, and client happiness. Visit their website at https://www.picsinternational.com/ for more about their equipment and how it can improve your crushing operations.

#Stone Crusher Manufacturer#Stone Crusher Manufacturer in India#Stone Crusher#Stone Crusher in India

0 notes

Text

Exploring the Benefits of Buying Gravel Crushers

Gravel crushers are essential equipment in various industries, including construction, mining, and landscaping. They play a crucial role in processing gravel, aggregates, and other materials used in infrastructure projects, road construction, and landscaping initiatives. Investing in gravel crushers offers numerous benefits that contribute to operational efficiency, cost savings, and overall productivity. This article explores the advantages of buying gravel crushers and their significance in diverse applications.

Increased Efficiency in Material Processing

One of the primary benefits of buying gravel crusher for sale is the increased efficiency in material processing. Gravel crushers are designed to efficiently crush and screen gravel, aggregates, and other materials, reducing them to the desired size and shape for use in construction and landscaping projects. With their robust construction and powerful crushing mechanisms, gravel crushers streamline the material processing workflow, saving time and labor while maximizing productivity.

Customized Crushing Solutions

Gravel crushers offer customized crushing solutions tailored to the specific requirements of each project. Whether crushing large rocks, gravel, or recycled materials, gravel crushers come in various sizes and configurations to accommodate different applications and production needs. From jaw crushers to impact crushers and cone crushers, there are options available to suit various material types, sizes, and end product specifications.

Versatility Across Applications

Another significant benefit of gravel crushers is their versatility across a wide range of applications. Gravel crushers can process diverse materials, including gravel, aggregates, sand, limestone, and recycled concrete, making them indispensable equipment in construction, mining, and landscaping projects. Whether used for road construction, building foundations, or landscaping enhancements, gravel crushers offer the flexibility to adapt to different project requirements.

Cost Savings and Resource Efficiency

Investing in gravel crushers can result in significant cost savings and resource efficiency over time. By processing materials on-site, gravel crushers eliminate the need for transporting materials to and from processing facilities, reducing transportation costs and carbon emissions. Additionally, gravel crushers enable the efficient use of resources by recycling and reusing materials, minimizing waste and conserving natural resources.

Improved Product Quality and Consistency

Gravel crushers play a crucial role in ensuring the quality and consistency of the final product. By crushing and screening materials to the desired size and specifications, gravel crushers produce high-quality aggregates and gravel products that meet industry standards and project requirements. Consistent product quality enhances the durability, performance, and aesthetic appeal of construction and landscaping projects.

Enhanced Operational Control and Flexibility

Gravel crushers provide operators with enhanced control and flexibility over material processing operations. With advanced features such as adjustable settings, variable speed drives, and automated control systems, gravel crushers empower operators to optimize crushing parameters, adjust production rates, and respond to changing project demands quickly. This operational control enhances efficiency, productivity, and responsiveness in material processing operations.

Conclusion

Investing in gravel crushers offers a multitude of benefits for construction, mining, and landscaping professionals. From increased efficiency and customized crushing solutions to versatility across applications and cost savings, gravel crushers play a pivotal role in modern material processing operations. By prioritizing efficiency, quality, and sustainability, businesses can leverage the advantages of gravel crushers to streamline operations, maximize productivity, and achieve success in their projects. As essential equipment in the construction and mining industries, gravel crushers continue to drive innovation, efficiency, and progress in material processing and infrastructure development.

0 notes

Text

Enhancing Efficiency and Performance: Shell Lubricants for Machinery and Industries | Caravan Oil Suppliers

Enhancing Efficiency and Performance: Shell Lubricants for Machinery and Industries:

Transmission Oils

The Shell Spirax range of oils

The Shell Spirax range of oils is designed to keep your axles and gearboxes going. Those in the Construction segment, as well as Crusher, Quarry, and Fleet Owners have been very satisfied by using Spirax in their machines. Our oils can be used for

Gearboxes and manual transmissions

Axles

Automatic transmissions

Cone Lubrication (for Crushers)

Slideway Oils

The Shell Tonna range of Slideway oils

The Shell Tonna range of Slideway oils is very useful for CNC Machines and in Steel Industries. The oils are designed to prevent stick-slip and thus reduce the number of rejections. They also have a faster rate of separation from water which allows for reuse.

Contact Details:

Address: 106 Road number 4 2nd phase, Jigani Industrial Area Anekal Taluk Bangalore, Karnataka 562106

Phone Number: 9980005255

Email: [email protected]

0 notes

Text

Chinalco Shanxi New Materials Limestone Mine Division achieved the time task of "double over half"

In the first half of the year, Chinalco Shanxi New Materials Limestone Mine Business Department carefully organized production, cadres and employees worked together in the same direction, and carried out in-depth work such as all-factor benchmarking, quality improvement and efficiency enhancement. As of the end of June, the mine supply completed 52% of the annual plan; 58.8% of the annual plan target was achieved in terms of income and efficiency, and the production and operation task target of "positive year-on-year growth and more than half of the tasks" was successfully achieved.

In order to ensure the full completion of the target task of turning losses into profits for the whole year, the Limestone Mine Division has strengthened the production command centered on scheduling, focusing on the balance of mining and stripping, and reasonably equipped truck shovels by confirming the transportation distance and shovel loading conditions. At the same time, solidly carry out labor competitions in terms of output, cost, equipment, safety, etc., implement heavy rewards and punishments, and fully stimulate employees' enthusiasm for work. In the mining and stripping work area, through measures such as strengthening quality control, the subjective initiative of the repairing, posting, and point-checking employees was fully mobilized, and the comprehensive inspection of the gyratory crusher was completed in only 2 days. The overall efficiency of the equipment has been steadily improved, and the average daily raw ore production is 5,000 More than tons, creating favorable conditions for high production. Combined with activities such as "two belts and two innovations" and "creation of party members' value", we will report and comment on the work of party members' waste identification and rectification every month, establish a tracking account, grasp the work progress, pass on the pressure layer by layer, and strive to be a "reduced budget" This expert". As of the end of June, the 19 "waste identification and rectification" projects of the business unit had created a total of 210,000 yuan, effectively improving the ability and level of the party organization to integrate into the work of the center.

Adtech Metallurgical Materials Co., Ltd is a Sino-foreign joint venture integrating R&D, production, operation and service of metallurgical materials. With strong technical force and perfect production and operation system, it has passed ISO 9001 quality system certification and ISO14001 environmental assessment certification. It has established long-term cooperative partnerships with more than a dozen countries and regions. The main products of Adtech :

,ceramic foam filter, ceramic filter plate, alumina ceramic foam filter,

degassing machine, degassing system.

boron nitride coatings , refining flux , aluminum casting Flux.

launder system . electric launder system . flow control unit,

tap out cone,caster tip, etc.

To learn more, please follow website: http://www.adtechamm.com/

Contact: [email protected]

1 note

·

View note

Link

ASTEC has more than 100 years' experience in aggregate processing and state-of-the-art machineries. ASTEC innovative line of jaw crushers, cone crushers, impactors and offers customers a line of reliable products for their operational needs.

0 notes

Text

Why BDI is the Perfect Partner for All Your Supply and Logistics Needs

Selecting the Right Crusher Wear Parts

When choosing crusher wear parts, it's important to consider several key factors. First and foremost, ensure that the wear parts are compatible with the specific type and model of your crusher. Different crusher parts have unique designs and requirements, so using the wrong crusher parts can lead to premature wear, decreased efficiency, and even damage to the crusher.

Secondly, the material of the wear parts is crucial. High-quality materials, such as manganese steel or chrome alloy steel, offer superior wear resistance and durability, ensuring longer service life and reduced downtime.

Finally, it's crucial to consider the supplier's reputation and experience in the industry. A reliable supplier like BDI can provide crusher parts for sale that meet or exceed industry standards, backed by years of expertise and a commitment to quality.

When to Replace Crusher Parts

Crusher wear parts Canada need to be replaced periodically to maintain the crusher’s optimal performance. Some of the indicators that suggest the need for replacement include:

Visible wear or damage to the wear parts, such as cracks, breaks, or excessive thinning.

Decreased production efficiency or increased power consumption, which can be caused by worn-out wear parts.

Inconsistent material output or particle size, indicating that the wear parts may no longer be performing as intended.

Regular inspections and maintenance can help identify these signs early on, allowing for timely replacements and minimizing the impact on operations.

Best Material for Wear Parts

The best material for crusher wear parts depends on the specific application and operating conditions. However, manganese steel is a commonly preferred material due to its excellent wear resistance and toughness. It can withstand high impact forces and abrasion, making it suitable for crushers that handle hard and abrasive materials.

Chrome alloy steel is another excellent choice, offering high strength and corrosion resistance. This material is often used in crushers that operate in wet or corrosive environments.

BDI: Your Reliable Supplier with Logistical Support

BDI is a trusted supplier of high-quality crusher wear parts, offering a wide range of products to suit various crusher parts types and applications. We source our wear parts from the most reliable manufacturers, ensuring they meet or exceed industry standards in terms of durability, wear resistance, and performance.

In addition to quality products, BDI also provides comprehensive logistical support. We understand that timely delivery is crucial for maintaining operations, and our efficient logistics system ensures that your wear parts arrive on schedule, ready to be installed and put to use.Whether you need wear parts for your jaw crusher, cone crusher, or impact crusher, BDI has the right solution for you. Contact us today to learn more about our products and services, and let us help you optimize your crushing operations.

0 notes

Text

Top 10 Crusher Manufacturers in India

India's crusher manufacturing industry has seen significant growth over the past few decades, with numerous companies emerging as leaders in the market. Among the top 10 crusher manufacturers in India, Craftsmencrusher has established itself as a prominent player. Known for its innovative engineering and robust machinery, Craftsmencrusher specialises in producing high-performance crushers designed for various industrial applications, including mining, construction, and recycling. The company's product range includes jaw crushers, cone crushers, impact crushers, and mobile crushing units, all of which are engineered to deliver optimal efficiency and reliability under the most demanding conditions.

Craftsmencrusher's commitment to both customer satisfaction and quality is evident in its state-of-the-art manufacturing facilities, which employ advanced technologies and stringent quality control measures to ensure each crusher meets international standards. Additionally, the company invests heavily in research and development to continually enhance the performance and durability of its equipment. This focus on innovation has allowed Craftsmencrusher to introduce several industry-first features, such as automated control systems and energy-efficient designs, setting new benchmarks for performance and sustainability.

The company’s vast distribution system ensures timely delivery and exceptional after-sales support across India and beyond. Craftsmencrusher also offers customized solutions to meet the specific needs of its clients, providing comprehensive consulting services, from site evaluation to equipment selection and maintenance planning. This customer-centric approach has earned the company a loyal clientele and a strong reputation in the market.

Overall, Craftsmencrusher stands out among the top 10 crusher manufacturers in India due to its unwavering focus on quality, innovation, and customer service. With a proven track record and a forward-looking approach, the company is well-positioned to continue leading the industry and contributing to the growth of India's infrastructure and industrial sectors.

0 notes

Text

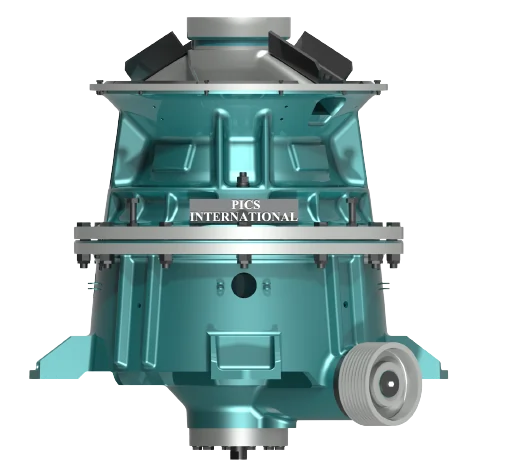

Cone Crusher Manufacturer -Picson

PICS INTERNATIONAL introduces the latest technology Hydro Cone Crusher Manufacturer. PICS INTERNATIONAL cone crushers are suitable for a wide range of applications to get excellently shaped product in polyhydric shape.

GC Series:-

The high crushing ratio of the PICS INTERNATIONAL Hydro Cone Crusher Manufacturer In India makes it ideal for secondary and tertiary stage crushing of hard rocks, perlite, corundum, bauxite, basalt, iron ores, etc. With the PICS INTERNATIONAL Hydro-cone series, you can run your crusher at its peak efficiency under varying feed conditions without worrying about overloading the cone crusher. Its design promotes maximum productivity and performance with high outputs, dependability, and low operating costs.

HP Series:-

A standard jaw crusher combined with an HP Series Cone crusher from PICS International is a great secondary crusher option. They reduce your investment cost and save energy by producing finer goods through fewer crushing processes. Greater product form, a high reduction ratio, and a high capacity are the outcomes of improved inter-particle crushing action in the crushing chamber, which is caused by increased density and pressure.

Maximizing Efficiency and Productivity: The Benefits of Choosing a Cone Crusher Manufacture

1. Quality Assurance: Selecting an experienced cone crusher manufacturer is like making an investment in quality control. Through the production process, reputable manufacturers maintain strict quality control procedures to guarantee that every component satisfies or exceeds industry requirements.

2. Customization and Innovation: cone crusher manufacturer that welcomes innovation and provides customizing choices. Prominent producers allocate resources towards research and development in order to continually improve their product's quality and modify it to suit changing market demands.

3. Comprehensive Support and Service: Choosing to buy a cone crusher is more than just the money spent on it initially. Maintaining uninterrupted operations and reducing downtime requires constant support and maintenance.

4. Access to Expertise: When you work with a respectable cone crusher manufacturer, you may benefit from their extensive experience and industry understanding. Technicians educated by the manufacturer are highly acquainted with their equipment, which allows them to offer insightful advice, help with investigating, and proactive maintenance suggestions.

In conclusion, the benefits of choosing a reputable cone crusher manufacturer extend far beyond the equipment itself. From quality assurance and customization to comprehensive support and long-term value, the advantages are clear. When selecting a cone crusher manufacturer, prioritize reliability, innovation, and expertise to unlock the full potential of your crushing operations. By making an informed decision today, you're laying the groundwork for success tomorrow and beyond.

Contact: - +919081777945 , [email protected]

Address: - 986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat

Visit for More Information: - https://www.picsinternational.com/cone-crusher

0 notes

Text

Mesin Stone Crusher

Mesin Stone Crusher adalah sebuah mesin yang digunakan untuk menghancurkan batu menjadi ukuran yang lebih kecil sesuai dengan kebutuhan pengguna. Mesin ini biasanya digunakan untuk menghancurkan batu-batu besar yang akan digunakan dalam konstruksi bangunan, jalan raya, jembatan, dan sebagainya.

Mesin Stone Crusher terdiri dari beberapa bagian, antara lain hopper, feeder, jaw crusher, impact crusher atau cone crusher, conveyor, dan vibrating screen. Batu-batu besar dimasukkan ke dalam hopper, kemudian diumpankan ke dalam mesin melalui feeder. Di dalam mesin, batu-batu tersebut dihancurkan oleh jaw crusher, impact crusher atau cone crusher hingga menjadi ukuran yang lebih kecil. Kemudian, batu-batu tersebut akan dipisahkan dengan menggunakan vibrating screen, dan hasilnya akan dibawa keluar oleh conveyor.

Mesin Stone Crusher memiliki berbagai jenis dan ukuran yang berbeda, tergantung pada jenis batu yang akan dihancurkan dan kapasitas produksi yang dibutuhkan. Beberapa jenis mesin Stone Crusher yang umum digunakan antara lain jaw crusher, impact crusher, cone crusher, dan hammer crusher. Penting untuk memilih jenis mesin yang sesuai dengan kebutuhan produksi dan jenis batu yang akan dihancurkan untuk mengoptimalkan hasil produksi dan kualitasnya.

Spesifikasi :

Kapasitas produksi : 25 - 30 kubik/hari

Operator : 5 - 6 orang

Rangka jaw : Plate 16mm, plate 20mm, plate 25mm

Ayakan 4 output 3.5 / 2.3 / 1.1 / abu batu. dengan sistem ayun

Penggerak : Mesin diesel 24pk doble stater

Berat : 2.5 ton

Jaw plate : Mangan steel import

Jaw plate : 150 x 250

Kelebihan produk kami :

Bearing berkualitas sehingga umur mesin lama

Jaw plate dari bahan mangan steel pilihan

Body lebih kokoh dan kuat

kawat ayakan dari bahan baja pilihan

After sales terjamin

Kompenen Mesin Stone Crusher

Mesin Crusher Pemecah Batu terdiri dari beberapa komponen utama, di antaranya:

Hopper : Komponen yang berfungsi menampung batu sebelum masuk ke mesin clusher

Feeder: Komponen yang berfungsi untuk memasukkan batu ke dalam mesin crusher.

Jaw Crusher: Komponen yang berfungsi untuk menghancurkan batu dengan cara menekan batu ke dalam rongga yang ada di dalamnya. Jaw crusher terdiri dari dua plat baja yang dapat bergerak, yaitu fixed jaw (rahang tetap) dan movable jaw (rahang bergerak).

Cone Crusher: Komponen yang berfungsi untuk menghancurkan batu dengan cara menghancurkan batu dengan menggunakan gaya tekanan antara mantle (lapisan luar) dan concave (lapisan dalam).

Impact Crusher: Komponen yang berfungsi untuk menghancurkan batu dengan cara memukul batu dengan rotor yang berputar pada kecepatan tinggi.

Vibrating Screen: Komponen yang berfungsi untuk menyaring batu yang sudah dihancurkan menjadi beberapa ukuran yang berbeda.

Conveyor: Komponen yang berfungsi untuk mengangkut batu yang sudah dihancurkan ke tempat yang ditentukan.

Control Panel: Komponen yang berfungsi untuk mengendalikan dan memonitor seluruh proses kerja mesin crusher, mulai dari feeder hingga conveyor.

Temukan dan cari kami di:

WEBSITE : https://jauramesin.com/

Youtube : https://www.youtube.com/@juaramesin/

IG : https://www.instagram.com/juaramesin/

Twitter : https://twitter.com/JuaraMesin/

FB : https://web.facebook.com/juaramesin

Call/Whatapp : 085 707 300 536 (admin Muhyi)

Terima kasih atas kunjungan anda di situs Juara Mesin produsen Mesin cetak batako dan paving, mesin bata ringan, mixer, conveyer dan mesin stone clusher pemecah batu serta mesin pelengkap lainnya

#mesinstonecrusher#mesinpemecahbatu#mesinpemecahbatumini#mesinpemecahbatumurah#mesinpemecahbatumobile#mesinpemecahbatusurabaya#stoneclusher#juaramesin

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more concrete crushers for sale efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful machines, their different varieties, and concrete recycling may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Various Designs of Concrete Crusher Machines

Concrete is the most responsible for developments in architectural design and construction out of all the construction materials known to man. Without concrete, there would be no urban expansion, highway construction, dam construction, military sites, or a plethora of other critical parts of modern society. Despite its value due to its high durability, any concrete structure has a limited life duration. As a result, the very characteristic that makes concrete valuable is also what makes it difficult to recycle or dispose of. We have become reliant on the concrete crusher as the demand for concrete has increased.

The purpose of a concrete crusher is to break down huge blocks of concrete waste into smaller bits that may be disposed of or recycled more efficiently. The following is a general explanation of the many types of concrete crushers in use today.

Concrete crushing is accomplished in steps. The first stage is where big concrete blocks are broken down into smaller, more manageable bits. At this point of the demolition, a jaw crusher is often used. These machines can accept concrete blocks of any size, with a reduction ratio ranging from 3/1 to 5/1. Because the process of breaking concrete appears to be quite similar to chewing, jaw crushers have a pretty simple design. micro crusher for sale Two strengthened metal plates form a tapering funnel. One of the plates is fixed in place, while the other moves back and forth. The concrete is crushed into smaller and smaller boulders as it passes along the chute, until the pieces are finally small enough to fall out.

Depending on the intended use of the concrete, the concrete will either be reused in this form or crushed further. Secondary concrete crushers, the most popular of which are cone crushers and impact crushers, are frequently used. Each one is named after the mechanical process that was employed to break down the concrete.

Cone crushers have a concave tapering region with a revolving spindle that gyrates as it turns. Concrete is dropped into the machine at the top and crushed into smaller and smaller pieces as it goes down into smaller gaps. Pieces eventually grow small enough to pass through the chute and into a hopper. Cone crushers, like jaw crushers, have a reduction ratio of 3/1 to 51/. Cone crushers can be enormous, but there are also smaller, portable models that can be moved between locations.

Impact crushers operate by using hitting force rather than pressure. Impact crushers are classified into two types: horizontal shaft impactors and vertical shaft impactors. The concrete is held in a metal container by a horizontal impact crusher. Hammers attached to a spinning rotor pound the concrete until it breaks down into manageable pieces that can be pushed out of slots in the machine's side. They feature a reduction ratio of 25/1 and are better suited to softer materials.

The velocity of a vertical shaft concrete crusher is used rather than surface force. A high-speed rotor smashes concrete blocks against a hard interior surface. The rotor speed and distance thrown influence the size of the ultimate product. The smaller the fragments, the harder the concrete hits the confining wall or anvil. Because of the quadratic shape of the end product, recycled concrete produced using this technology has a wide range of applications. A typical vertical shaft concrete crusher has an 8/1 reduction ratio.

We can reasonably expect that the concrete crusher will continue to be a helpful instrument for some time to come due to the constantly expanding use of concrete in the building industry. Although alternate development methods and materials are being utilised, concrete has yet to find a sustainable successor for large-scale constructions. As a result, the concrete crusher will most likely be around for a long time.

Are you interested in learning more about concrete crusher [http://concretecrusher.net] machines? Please go to [concretecrusher.net]. Further information on these powerful machines, their different varieties, and concrete recycling may be found here. Doug Henderson is a big fan of the economic and environmental savings these devices bring.

1 note

·

View note

Text

Mobile Stone Crusher for Sale

Mobile Stone Crusher for Sale

Available used and fully refurbished portable mobile stone crushing plant. We are supplier and exporters of mobile crushers from India. The crushers we supply are sourced from auctions and complete sevicing and reconditioning is done at our yard by qualified engineers.

We also supply spare parts for Mobile Stone Crushers. The Spare parts we supply are genuine OEM, Remake and used reconditioned,…

View On WordPress

#Business#crusher for sale#mobile cone crusher for sale#mobile crushers#mobile crushers for rock#mobile impact crusher for sale#mobile jaw crusher for sale#used mobile crusher for sale

1 note

·

View note